The Oxford English Dictionary defines ‘Authentic’ as: ‘Genuine; not feigned or false’. Trationally these are qualities that people respect and admire. But in an age of the social media deluge, coupled with the seemingly weekly release of new Artificial Intelligence (AI) apps and software, it is becoming more difficult to realise what’s real and what’s not. And in turn, it is becoming difficult to ascertain what’s genuine and what isn’t.

In the world of beer, knowing the difference between a genuine beer brand or one that is masquerading as such remains a pertinent issue. Many consumers won’t know the difference. Some, if we’re being totally honest, won’t care either.

But recent research released shows that almost a third (31%) of young beer drinkers surveyed now recognise the Indie Beer campaign, which has set out to promote beer from genuinely independent breweries and help people make an informed choice when purchasing a beer in pubs, bars or retailers.

And for many, operating in the increasingly competitive and saturated world of brewing, means being genuine and authentic has become more than just a desirable trait—it’s a necessity.

Those goals of staying true to yourself, building a positive working culture, creating a business people admire and also producing beers that consumers and your peers enjoy are traits any brewery owner strives for. And in a recent episode of very our Brewers Journal podcast, Alex Troncoso, the co-founder of Bristol’s Lost and Grounded Brewers ended the episode by outlining his team’s approach to the world of beer through the lens their flying hippo mascot.

“I was watching this documentary recently and it panned to some floodplains. There was a drone shot of some water and through that there was a path some hippos had made by walking through it. Once that path has been forged, other animals often follow,” he told us. “The hippos aren’t the rockstars of the animal kingdom but they’re determined and just get on with things without much fanfare. I like to think that’s a bit like what we do with our beers. We do our own thing and see where we end up.”

Breweries like Lost and Grounded have stuck to their guns and thrived as a result. That honesty is evident in their business and the beers they produce. The same can be said for Anspach & Hobday, the London-based brewery that graces the cover of this issue. Founded by Paul Anspach and Jack Hobday, the business has grown year-on-year with its nitro porter London Black leading the pack. And like their Bristol peers, chasing trends has never been the duo’s raison d’être.

“I feel that London Black emerges very naturally from everything we were doing before,” says Hobday. “Look at New England IPAs, for example. I don’t want to speak for everyone that has worked here previously but we collectively just don’t like them very much. There are, of course, great examples, but they are just not the beers that we want to produce.

I just don’t think the market would find it particularly believable coming from a brewery that’s never ventured into that territory previously.”

In a market where you need a unique selling point, proving yourself as genuine, authentic and believing in what you do is a great place to begin.

Tim Sheahan Editor

Dear John

Beer changes but why, and how? There are numerous reasons with some positive and some much less so, explains John Keeling.

Comment | Solar

How Healey’s in Cornwall expect to cut some £3m off its energy bills thanks to a new solar install.

Brewers Intelligence | Summer Reports

The latest insights and expertise from across the field of ingredients and sales.

RedWillow Brewery

Starting out in 2010, RedWillow Brewery has long since established itself as a leading light in the UK brewing industry.

Europe | Ghent

Ghent has gone on to become one of Paul Davies’ favourite places in Belgium. A regular visitor to this fine city, he explains how it’s the perfect showcase of both storied brewing heritage and also modern, forward-thinking brewers.

Containers and Distribution

Ensuring your brilliant beers reach the consumer in the way you intended requires high-quality packaging and distribution to match.

CO2 and Nitrogen

More breweries are investing in CO2 recovery systems and nitrogen generators as CO2 alternatives. But why should you take the plunge?

Homebrewing

Mike Clayton-Jones, co-founder of DoubleBarrelled brewery, shares a wealth of his formative experiences that have helped shape the muchloved Reading, Berkshire-based business.

A week in my life

Miranda Hudson, co-founder of Duration Brewing, explains how she and the team help keep the revered Norfolkbusiness ticking.

17

Warminster Maltings

The team in south-west Wiltshire explain how they undertook a project of repair and restoration of Britain’s oldest working maltings.

31

Vital Voices

A more open, inclusive and welcoming brewing sector isn’t just fairer, it’s more sustainable, and it’s better for all of us. With ‘Vital Voices’ we showcase and celebrate those working towards a better brewing industry.

Tim Sheahan Editor tim.sheahan@reby.media

+44 (0)1442 780 592

Tim O’Rourke Technical Editor

John Keeling Contributor

Josh Henderson Head of sales josh.henderson@reby.media +44 (0)1442 780 594

Jon Young Publisher jon.young@reby.media

Reby Media 6 Grove Road, Hemel Hempstead, Herts, HP1 1NG

The Brewers Journal is a published four times a year and mailed every March, June, September & December. Subscriptions can be purchased for four issues. Prices for single issue subscriptions or back issues can be obtained by emailing: subscribe@ reby.media

UK & IRELAND £45 INTERNATIONAL £69

The content of The Brewers Journal is subject to copyright. However, if you would like to obtain copies of an article for marketing purposes high-quality reprints can be supplied to your specification. Please contact the advertising team for full details of this service. The Brewers Journal is printed at Manson Group, St Albans, UK.

56

Anspach & Hobday

Through a commitment to drinkability and consistency, Anspach & Hobday has become a byword for quality in the capital.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or any information storage or retrieval system, without the express prior written consent of the publisher. The Brewers Journal ISSN 2059-6650 is published bimonthly by Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG. Subscription records are maintained at Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG.

The Brewers Journal accepts no responsibility for the accuracy of statements or opinion given within the Journal that is not the expressly designated opinion of the Journal or its publishers. Those opinions expressed in areas other than editorial comment may not be taken as being the opinion of the Journal or its staff, and the aforementioned accept no responsibility or liability for actions that arise therefrom.

We work with brewers and distillers of all sizes to provide keg and cask rentals, container maintenance services and equipment finance solutions.

and others merging to survive, with pubs and hospitality venues continuing to hut for business and cease trading.

“Time and time again, the research shows that there is high demand for the innovative, interesting and tasty beers that indie brewers are best at making,” commented Andy Slee, SIBA CEO.

Demand for independent beer remains strong but UK brewers face “heavy headwinds” from increased taxation, market access restrictions and reduced alcohol consumption, according to a new report published earlier this month. While average production climbed 10% last year, nearly half (46%) of independent brewers say their main priority is survival and almost a third (29%) of these said they expect turnover to fall.

This is according to findings published by the Society of Independent Brewers and Associates (SIBA) which brings together industry insight and consumer polling to provide an authoritative report on the state of independent brewing in 2025. The SIBA Independent Beer Report 2025 shows that the average production of independent breweries last year climbed 10%, compared to an overall beer sector where national beer sales are down 1% since last year and now stand 6.6% below pre-pandemic levels.

For independent breweries the increasing popularity of porters, stouts, craft lagers and no and low alcohol beers helped drive growth.

But it’s not all good news for the indie beer sector, as at the same time the number of independent breweries fell by 5.5%, with around 100 closing their doors

“Our members are great at adapting to changing tastes and have increased the number of stouts, lagers and nolo beers on offer. Which has helped drive a double-digit growth in production amongst indie brewers. However, the current global trade anxiety and tax changes in the UK are making it a challenging market and indie brewers can’t get their foot in the door to get their beers to the customer.

“Our members currently have around 6% of the market and where they are allowed to compete against global breweries they could have 30% market share. This lack of access means beer drinkers are missing out, indie breweries are facing heavy headwinds to growth meaning fewer jobs are being created.” Slee added.

Andy Parker is the founder of Berkshirebased Elusive Brewing, which celebrates its ninth birthday this year. Commenting on the findings, he told us that it’s clear that the industry is still seeing some well established breweries fail in 2025 due to the hangovers of debt accrued during the Covid pandemic.

“Whilst they may be otherwise cash flow positive, the cost of servicing the debts is proving too much for some - especially those who are seeing aged debts called in without any room for further negotiation,” he explains. “Although the overall net number of breweries is down, we’re still seeing new openings and this must be seen as positive.

“Demand remains strong for local, independently produced beer and any new business would do well to focus on their local market as a priority, with a direct outlet such as a tap room being essential in today’s fluid and competitive market.”

Elsewhere in the report YouGov polling, commissioned exclusively by SIBA, shows that less than half (47%) of all consumers ever drinking beer and only nearly a quarter (28%) of 18-24 years.

More and more people are choosing not to drink alcohol at all, with 21% of all consumers increasing to 36% for 18-24 year olds.

The volatile trading environment had a cooling impact on the sector with 80% of breweries surveyed making no major investments in their business last year.

While breweries still intend to create more than 500 jobs this year, this is a significant drop from last years nearly 800 jobs.

The YouGov/SIBA figures show that beer drinkers are demanding a local product, with more than three quarters (77%) THERE ARE

Time and time again, research shows that there is high demand for the innovative, interesting and tasty beers,” Andy Slee, SIBA

And access to market continues to be the biggest issue for independent brewers.

saying it is important for pubs to offer a range of beers from local breweries. And 56% of beer drinkers say they would be more likely to choose a beer if it was locally produced.

Yet independent brewers report being unable to sell to on average 60% of the pubs local to their brewery. Eight in ten brewers surveyed said that it was the lack of access to beer lines as the top barrier to sales and growth. With average production amongst independent brewers increasing, it is stouts, lagers and no/low alcohol that is leading the way, with 24% on average now going into keg beers.

Eighty percent of brewers are now producing a stout or a porter with CGA data showing a 121% increase in ‘craft stout’ value in the on-trade last year. Lager has jumped to second place amongst brewers this year, with 60% now producing them, suggesting that independent breweries are now making some inroads into a market usually

dominated by global lager brands. With 14% of drinkers now opting for no/low products, independent brewers are increasing adding them to their range, with 15% now making a non-alcoholic beer compared to 8% last year.

From a personal perspective, Andy Parker reports that Elusive managed to grow in 2024 by reconfiguring our tank farm and leaning more on cask ale production where local demand is especially strong.

He told us: “Our output increased 26% by volume with revenue growing 10% amid a backdrop of increased costs due to taking on a 3rd unit to build a dedicated tap room.

“Although brewery numbers are down, we are still seeing new brewery openings and this must be seen as a positive,” Andy Parker, Elusive Brewing

“We’re still seeing strong demand but remain cautious operationally heading into the peak period of 2025, with the focus being on cost management, delivering positive cashflow and reinvesting rather than borrowing.

“Staffing costs have increased with the recent changes brought in by the budget but on the plus side, energy and ingredient costs are coming down and we’ve just secured a new electricity deal which brings with it a 30% decrease over what we were paying previously.”

Timothy Taylor & Co has appointed Emma Gilleland as the company’s new operations director.

Gilleland, whose role is effective from 15th September, will join from Carlsberg Marston’s Brewing Company where she is currently director of production. In her career she was also brewing director and at Marston’s, she was the director of brewing, director of supply chain and head brewer. She was also the first woman to be awarded the All-Party Parliamentary ‘Brewer of the Year’ in 2014.

Emma Gilleland said: “I am very excited to be joining the executive leadership team at Timothy Taylor’s as Operations Director. I am looking forward to leading the operational team to further build on the success of Landlord and the beer portfolio that is underpinned by the passion for exceptional quality.”

Holden’s Bottling has acquired South East Bottling’s (SEB) small packaging operations, marking a strategic expansion of its small pack capabilities.

The agreement sees SEB’s entire smallpack packaging volume transferred to Holden’s, further strengthening our position as a leading provider of highquality bottling and canning solutions.

Under the terms of the deal, Holden’s will take over SEB’s existing packaging business, ensuring a seamless transition for SEB’s customers while maintaining the high standards of service they have come to expect. SEB, meanwhile, will focus on its core brewing operations, allowing both businesses to thrive in their respective areas of expertise.

“This is a significant step forward for Holden’s as we continue to expand our small pack packaging capabilities,” said Mark Hammond, managing director of Holden’s Bottling.

Craft brewers produced 23.1 million barrels of beer in 2024, a 4.0% decrease from 2023, while craft beer’s market share by volume remained flat, new figures from the Brewers Association show.

According to the latest figures from its annual production report, the modern US craft brewing industry is one characterised as a maturing market in a rapidly evolving environment.

Employment in the craft brewing sector grew to 197,112 in 2024, a 3.0% increase over the previous year. The rise was driven by the shift toward hospitalityfocused models such as taprooms and brewpubs, which create more jobs in local communities, they said.

Craft beer’s retail dollar value rose to an estimated $28.9 billion, a 3% increase over the previous year. This growth reflects pricing adjustments and steady performance in onsite sales, which outpaced distributed sales in many markets. Craft beer accounted for 24.7% of the total beer market in terms of retail dollar sales.

In 2024, the number of operating U.S. craft breweries was 9,612, including 1,934 microbreweries, 3,389 brewpubs, 3,695 taproom breweries, and 266 regional craft breweries. 2024 was the first year since 2005 that the overall number of operating craft breweries declined nationwide. The total number of breweries in the U.S. dropped to 9,680, down from 9,747 in 2023. Over the year, 434 new breweries opened while 501 closed. Although openings declined for the fourth consecutive year—reflecting a maturing and highly competitive industry—the closure rate remained relatively low at approximately 5%.

Malting capacity at the UK’s largest malting site has increased further following the commissioning of a new

germination and kilning vessel (GKV) located at Simpsons Malt Limited’s Tweed Valley Maltings.

The new GKV, which became fully operational in late 2024, has increased annual malt production capacity by up to 15,000 tonnes per year, bringing total production capacity at the Berwickupon- Tweed site up to 260,000 tonnes per year – around 90% of which is destined for the distilling industry.

Groundwork on the GKV, which is where the second and third stages of the active malting process – germination and kilning – take place, started in May 2023 as part of a £10 million investment. It is the tenth GKV to be built at the company’s Tweed Valley Maltings, with the total capacity of the vessel being 400 tonnes per batch.

Malt produced in the new GKV – as well as the other nine GKVs on-site – has a significantly lower carbon footprint than the industry average, with energy for the kilning stage supplied by the site’s neighbouring Energy Centre.

Lallemand Brewing has launched LalBrew Aurora, a Saccharomyces cerevisiae targeted at various IPA styles, particularly the new Northern IPA style.

The first yeast introduced in this series, LalBrew Aurora was carefully selected from Lallemand’s extensive yeast culture collection for robust fermentation performance and unique aroma expression. With inspiration from the northern lights, LalBrew Aurora ferments well at lower temperatures to produce floral and fruity aroma that is exceptionally crisp and clean, the company said.

The company added in a statement: “LalBrew Aurora brings IPA in new directions by defining the Northern IPA style, which combines the clean drinkability of traditional West Coast IPAs with the modern yeast character of East Coast styles.”

Does each generation rediscover beer and then in doing so, reinvent it? Certainly, beer has changed over time but why does this happen?

Obviously, consumer demand influences beer choice. But with the advent of marketing, are consumers now being influenced to drink beers they perhaps wouldn’t normally drink?

When I first started drinking, way back in the 1970s, you could argue that there were two types of young drinker. One type were those who were influenced by their dads and as a result, drank his drink of choice. And on the other hand you had those who rebelled, did the opposite and wouldn’t drink what the old man drank. Indeed, the term ‘Old man’s drink’ has often been something a of a derogatory criticism of beers like cask bitter.

I was definitely a member of the former category, however, and loved - almost from day one of my drinking career - to enjoy a pint of cask beer.

I remember one time in my early stages of that drinking career (i.e. underage). I was out with a bunch of friends and we bumped into one of my friends’ dads in the pub.

Instead of throwing us out he bought us a pint each and this reminds me of how civilised and inter-generational pubs were in those days.

All of my friends were cask beer drinkers and generally would not drink lager. British lager in those days was weak (often less than 3.4% ABV), cold (sometimes an advantage) and fizzy (making it harder to drink for me).

If you look at the history of beer in Britain a number of beers have been popular for a period and then replaced.

It did have the advantage of being propped up by massive marketing campaigns. It was served from a keg and also paid less duty.

This made it very attractive to brewery owners and not so attractive to certain consumers (CAMRA) who recognised that they were being duped.

If you look at the history of beer in Britain a number of beers have been popular for a period and then replaced.

Porter and stout was replaced by mild, mild was then replaced by bitter and bitter found itself replaced by lager.

All those were popular for a reason. In my opinion they were good beers and they were also easy to drink, which

helped make them ideal for the pub environment. Only in the 1970s, following the change to the lager of the day, did breweries end up having the tools to influence the consumer.

The changes before the shift to lager were probably due to the improved brewing and malting technology available as well as fashion. And what is fashion but generational.

The reason beer did not change with each generation was there no alternative till a new style was enabled, and invented by the new technology available.

So, what happened in the 1970s? I think it was different then because the big companies wanted to change from cask to keg (for profit reasons through centralisation), from ale to lager (lower duty) and to produce national beers (again, a case of more profit). They used the tools that were afforded to them by marketing and advertising to help

push their agenda. Unfortunately, they generally succeeded in this.

Unfortunately for them too, with rising duty and VAT costs, increased competition forcing greater and greater marketing spend and a slow down in drinking (Who wants to drink pish? Could have been a great CAMRA slogan). They had to exist on wafer-thin margins and were then prone themselves to takeover

So, these clever people at Watneys, Allied, Whitbread, Courage and Scottish and Newcastle ruined beer for the drinker and in doing so ruined themselves. You could say it was poetic justice of a sort.

All I can say is thank God for the next consumer-inspired change in the form the craft beer revolution and also the increased availability of fantastic lagers, too. But let’s leave that particular story for another day.

Cheers!

The big brewing companies used the tools that were afforded them by marketing and advertising to help push their agenda.

WITH THE ADOPTION OF AI ACCELERATING THE DRINKS INDUSTRY IS POISED TO BENEFIT SIGNIFICANTLY FROM ITS EVERGROWING NUMBER OF APPLICATIONS. MOHIB RAHMANI, MANAGING PRINCIPAL AND HEAD OF THE DATA AND AI TEAM (IRIS) AT GLOBAL OPERATIONS TRANSFORMATION CONSULTANCY ARGON & CO, OUTLINES HOW THE DRINKS INDUSTRY CAN HARNESS AI AS WELL AS AVOID SOME OF THE COSTLY PITFALLS WHEN INCORPORATING IT INTO THEIR PROCESSES.

Artificial intelligence is not a one-size-fits-all solution; it comes in many flavours – and beverage manufacturers are no exception. In this industry, as in many others, the focus is on narrow AI –designed to excel at specific tasks like demand forecasting or quality control. For instance, machine learning algorithms can analyse sales patterns to predict demand spikes. Similarly, computer vision systems inspect packaging for defects at high speeds, improving quality assurance.

The real value lies in understanding where AI adds value and where human judgement remains irreplaceable. Take supply chain management, for example. AI can flag a delayed shipment based on real-time data, but a procurement expert is needed to interpret the context – perhaps considering the supplier’s reliability during peak demand, or thinking about alternative options. AI needs to empower people, not replace them.

Choosing the right model can save beverage manufacturers from problems emerging later down the line.

The first step is understanding whether your operations need narrow AI or general AI, which is capable of more flexible problem-solving.

Most beverage operations typically benefit from using narrow AI, using tools like supervised learning models for predictive maintenance or natural language processing for automating order inquiries.

Before selecting the right AI model, manufacturers should ask themselves: what is the goal? How clean is our data?

Is it scalable? Can the model evolve as our operations grow? Whatever the answers to these questions, will shape which AI model is most suitable for your business needs.

For instance, if you’re focusing on forecasting, forecasting algorithms work well; but for production, computer vision or anomaly detection tools might be a better fit for you.

Predicting changes in consumer demand is where AI comes into its own. Shortterm forecasting often uses time-series analysis, a type of machine learning that identifies patterns in historical data. For example, AI can predict a 20% increase in soft drink demand on a hot weekend. By using demand forecasting with external data, such as weather forecasts, school holidays, social trends, and macroeconomic indicators, both manufacturers and retailers can radically improve their short-term and long-term demand planning.

The supply chain areas that benefit most are those where there is an element of human intervention or decision-making where AI can be used to augment humans and remove the repetitive tasks, enabling them to focus on the more value-added activities.

An alternative example of this would be AI’s role in order processing, where natural language processing can read customer emails and automatically process bulk orders. Paired with soft process automation, this ensures orders are checked, validated, and routed faster than manual methods.

One common pitfall is choosing the wrong type of AI for the job. For instance, using rule-based AI for

demand forecasting often falls short because it can’t account for external variables like weather – where machine learning models excel. To avoid this, manufacturers need to carefully match the AI approach to the specific problem they’re addressing.

Manufacturers that adopt AI should not underestimate the importance of communicating with staff about how their AI tools work.

Staff must understand how their AI tools work for them to have trust and confidence in the predictions that inform their decision-making.

This may also involve the change management aspect of taking the organisation on the journey and highlighting the need for change.

For example, in the context of quality control over ingredients, a supervised learning model might predict outputs based on standard wheat properties, but it could fail when there is a slight

change in moisture levels. Manufacturers can address this by incorporating unsupervised anomaly detection into their systems to flag deviations in their raw materials, for features like moisture content.

Manufacturers inexperienced with using AI should start small. A prudent first step might be piloting a simple anomaly detection model for defect detection on a single product line, before scaling it up across all lines or using more complicated models.

There is a real opportunity for success in the case of supplier document intelligence. Here, natural language processing can extract key information from supplier agreements, certifications, and specifications, meaning the entire review process can be automated.

For example, natural language processing can identify allergens or sustainability claims hidden in complex documents, meaning compliance

obligations can be fulfilled without the need for manual checks. Natural language processing tools can also be used to continuously scan regulatory updates globally and map them to the company’s product portfolio, meaning businesses can stay ahead of the curve when it comes to observing their compliance obligations.

Another exciting development is recipe optimisation and ingredient matching. Machine learning models can analyse historical recipe performance, ingredient costs, and nutritional data to suggest optimal formulations.

2025 is shaping up to be a big year for AI in the drinks industry, as we see faster adoption of machine learning models, the promise of reduced waste, and healthier, more cost-effective options will soon be realised.

Everyone goes home safely to their family, every single day...

Protect your most important asset, your team. Stay connected with real-time updates and get audible and visual alerts of any gas, panic or motionless alarms including the rescue location and hazard type.

Your test and calibration certificates are automatically generated, filed and searchable...

Say goodbye to manual paperwork and hello to seamless, automated compliance. Save time, reduce errors and ensure you are audit ready.

You never run out of test and calibration gas again...

When your cylinders reach your pre-defined re-order limit, our software will ensure a restocking report is sent direct to your purchasing team. No stockouts. No downtime. No lost revenue.

Personal, Area and Fixed gas detection systems are all connected...

Our software transmits data from your Dräger personal, area and fixed gas detection systems straight to the web-based platform, offering true visibility of your site safety and helping to identify high risk hotspots.

We are by your side, 24/7.

With the 24/7 support helpline, you can rest assured we have your back, day and night.

Imagine no longer, get Dräger’s Gas Detection Connect. Contact Dräger today.

WARMINSTER MALTINGS, BRITAIN’S OLDEST WORKING MALTINGS, IS 170 YEARS OLD THIS YEAR (BUILT IN 1855). AS THE ONLY STAND-ALONE ‘FLOOR MALTINGS’ REMAINING IN THE UK, ITS SURVIVAL IS QUITE REMARKABLE. BUT HAVING ACHIEVED THIS, THE BUSINESS, THE ONLY MALTING COMPANY IN THE WESTERN HALF OF THE COUNTRY, IS NOW SET FAIR TO CONTINUE MAKING MALT FOR A LONG TIME TO COME. HERE COMPANY MANAGING DIRECTOR ROBIN APPEL EXPLAINS HOW THEY UNDERTOOK A BRILLIANT PROJECT OF REPAIR AND RESTORATION.

Following its acquisition by Robin Appel in 2001, repairs and restoration work began soon after. That the Grade 2 Listed malthouses were in such a poor state of repair could not be excused, but it could be explained. As a working maltings, the site had been on the condemned list for the previous 30 years but had always miraculously escaped. However, the introduction of Progressive Beer Duty in 2002 gave the business a whole new lease of life.

The arrival of a whole swathe of newbuild craft breweries brought with them a demand for malt products which exactly matched the Warminster business model. Individually, all orders were very modest – no more than 1 tonne per week, or per fortnight – but very precise: a range of different malts, malts that needed to be crushed, packed in 25kgs sacks, and delivered fresh ready for the mash tun. At the time, this was not a market that most of the UK malt capacity was geared up for.

This meant the Warminster business was quickly profitable, generating sufficient funds to start work on the buildings. This began at the front of the building, in the summer of 2003, creating new office space, and supporting facilities, along with space for visitors, mostly prospective customers, which had now become a frequent occurrence.

This first project turned out to be one of the most expensive, not least because the roof of kiln 1, immediately adjacent, but not part of the plan, chose to collapse at the same time. So that had to be rebuilt as well. You could say the 24 years long programme of works was punctuated by four major roofing projects, eleven separate roofs in all.

The second of these was in 2009, when all four roofs of the germination floors were stripped, enabling repairs to all the ‘A’ frames and rafters, which were all in a very poor state. Strict instructions from Historic England demanded that the original timbers, as much as possible, had to be retained. So, much bracing of new with old was required, in order to make the structures safe.

The third roofing project was what is termed as ‘The Old Store’, where the barley is stored above the steeping cisterns. This full width slate covered roof also included ‘The Sweater Kiln’ (for drying barley) immediately adjacent, a late Victorian ‘add on’ to the original complex. This project presented the opportunity to install 4×35 tonnes malt storage bins in the long redundant kiln, a hugely valuable addition to the somewhat cramped capacity.

At the same time as these major projects, involving outside contractors, much other work was also continually taking place, carried out by the Maltings’ own staff. This included all the windows which were fabricated on site, including restoring the wooden mullions, each exactly 4 inches apart, as laid down 200 years ago, by the strict regulations of The Malt Tax. Some of these windows also required replacement of the surrounding stoneware, and all those on the germination floors needed new hatches on the inside, courtesy of which the temperatures and humidity on the floors are controlled. And the list goes on.

However, the final roofing project has to be the most ambitious of them all. This is the restoration of the original pyramid style roofs to kilns 3 and 4, which were burnt down in a major fire in 1924. They were replaced then by ‘hipped’

roofs, with a flue running the full length of the apex. Planning permission from both Wiltshire County Council and Historic England was sought, and both agreed it was an exciting project, and permission was granted in 2018. But, unfortunately, Covid got in the way! So the work has only just been completed.

At the same time as all this structural work, all the engineering has been replaced or upgraded, and all the old electrics were stripped out and replaced with new. Then in 2017, a brand new ‘state of the art’ Weishapt gas fired kiln was installed. This has been a particularly

significant upgrade, both widening the spectrum of white malts produced, and combining the superiority of the ‘floor made’ modification with a very precise kilning capability.

Our maltings is our shop window, and it has always been our plan to present it in its best light. We do not want to be seen as a working museum, because we are quite definitely not that. We make malt the traditional way, and we want to show respect for that method.

We believe our malt is superior to “commercial malt” (a term the whisky

industry has conjured up for pneumatic malt), and our customers continually acknowledge that it is.

Not only that, we believe that the future of craft breweries does depend on maintaining the moral high ground through associations with desirable qualities such as local, artisanal, and sustainable. We are doing our best to deliver all this, and all the time we can, we are confident we have a robust and viable future. It is absolutely vital to maintaining everything that we have achieved so far, and to everything we look forward to achieving in the future.

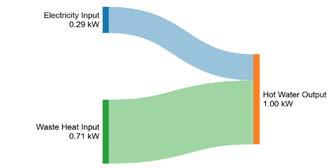

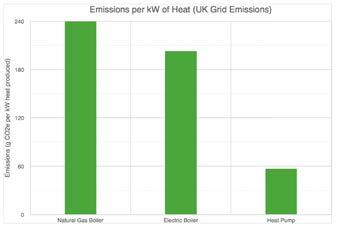

Healey’s Cyder Farm have been in operation since the 1980s when their first trees were planted.

As one of Cornwall’s very first independent brewers, they’re preparing their business for just as proud a future by working with CleanEarth Energy to install 1,224 solar PV panels at their site in Penhallow, Cornwall.

Healey’s have seen their energy bill triple in recent years, leading the business to reevaluate their energy mix.

Joe Healey, joint-managing explains: “The catalyst really was the energy spike. We wanted to maximise every square inch of every roof available.”

Their installation spans three rooftops and nine different roof aspects to get as much low-carbon low-cost electricity to their production line as possible –510,000kWh annually. This ambitious installation is going to take over £3m off their rising energy bill across the systems lifetime, savings that can be fed directly back into the business.

Price spikes in energy are unfortunately nothing new, and for breweries these kinds of growing costs can be difficult to navigate. Taxes, NIC contributions, tariffs, and the EPR fee are all pressures that will be felt by breweries wallets.

In light of the EPR regulation, recycling a glass bottle is now seven times more expensive than recycling a plastic bottle of the same size; making strategic decisions to mitigate overheads is increasingly crucial. But for Healey’s Cyder Farm and many other breweries, solar PV will have impacts even beyond these cost savings.

Recent reports have found that consumers are willing to spend more for sustainable beer options but are struggling to identify what these options even are. Though demand grows from consumers, brewers aren’t effectively communicating tangible sustainability efforts – a crucial gap between customer expectations and delivery from breweries. There’s also evidence to suggest that distributors and retailers are prioritising products with strong sustainability credentials.

Healey states: “It is very important to be demonstrating that we as a business take our environmental impact very seriously. It’s a fundamental part of our ability to sell our product to our customers”.

Renewable onsite generation is an easily evidenced step towards sustainability, that can not only power the energy intensive brewing process, but other innovations brewers may be putting in place for sustainability.

Last year, the UK’s independent brewing industry saw negative net closure rates every quarter, and by January 2025 the UK had seen a total loss of 100 independent breweries. The average closure rate was roughly 5.5%.

The industry is being squeezed, but despite the closures demand for independent breweries grew in 2024.

The potential is there, and breweries of any size or scale can incorporate cleaner electricity into their energy mix; grants open across the UK throughout the year that can offset varying amounts of the cost of solar.

At CleanEarth, a number of our clients in the brewing industry have benefited from this support, including Healey’s Cyder Farm, Lakedown Brewing Co, and Ludlow Brewing Co. The solar PV project at Healey’s Cyder Farm now means that roughly 40% of their onsite energy needs are met directly by their own renewable electricity.

Now in their second generation as a family-run business, Healey’s have reinforced their future resilience for the next generations. He concludes: “All of the decisions we make are with regards to the long-term future viability and sustainability of the business.”

And for many breweries in operation, this will mean embracing renewable onsite electricity generation.

All decisions we make are with regards to the long-term future,” Joe Healey. Healey’s Cyder Farm

BREWING HOPFORWARD NONALCOHOLIC BEERS DEMANDS NEW THINKING.

TRADITIONAL DRY HOPPING TECHNIQUES, DESIGNED FOR FULLSTRENGTH BREWING, FALL SHORT WHEN CONFRONTED WITH THE EXTRACTION, STABILITY, AND PROCESSING CHALLENGES OF <0.5% ABV PRODUCTION.

The non-alcoholic (NA) beer market (<0.5% ABV) is booming — but brewing truly hop-forward NA beers brings technical challenges that many brewers are only beginning to confront. Dry hopping, the cornerstone of modern aroma-driven beer styles, simply doesn’t behave the same way in lowalcohol environments. Without adapting their approach, brewers risk crafting beers that fall flat, lacking the vibrant hop character consumers expect.

Many hop oils, which contain the bulk of those aromatic compounds, rely on ethanol to dissolve and transfer into beer. Research shows that extraction of important hop volatiles dramatically decreases as alcohol levels drop. While terpene alcohols like linalool still extract relatively well even in NA beers, monoand sesquiterpenes — responsible for that “fresh hop” punch — struggle without alcohol’s solvent power.

Compounding this, fermentation in NA beer is often deliberately restricted. Less CO₂ evolution means less natural

convection inside the tank. Dry hops may not disperse fully, leading to poor contact and incomplete extraction. Brewers may attempt to compensate by increasing dry hopping rates, but beyond a certain point, adding more hops simply adds cost and raw material loss without delivering more aroma. Hop-derived enzymes introduce another layer of complication. Amylolytic enzymes can unlock residual fermentable sugars (hop creep), potentially triggering secondary fermentations and unwanted diacetyl formation — a defect that’s difficult to clean up with few active yeast cells left in suspension.

Meanwhile, esterases can erode the already limited yeast-derived fruity esters, dulling the overall flavor profile. Even when aroma molecules are liberated from hop vegetal matter, the majority of the hydrophobic terpene load binds to yeast cells and is therefore (unintentionally) removed during clarification steps. In short, traditional dry hopping — built for full-strength brewing — often fails to deliver the vibrant aroma brewers aim for in NA beer.

To evaluate real-world terpene loss at different production steps of the brewing process, Denmark-based EvodiaBio partnered up with Åben Brewery, analysing samples from a 20hL production trial of a 0.4% ABV hoppy IPA. The fate of key hop volatiles was tracked through the fermentation and clarification process using SPME-GC-MS (Solid Phase Microextraction coupled with Gas Chromatography–Mass Spectrometry).

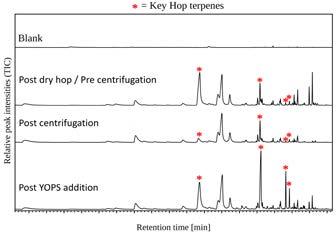

Figure 1: SPME-GC-MS volatile analysis of beer in process

Cold side production consisted of crash cooling at target attenuation, dry hopping, 1-day hop maceration with rousing, clarification by centrifugation, dosing of Yops flavors (details below), short storage in brite, packaging, and pasteurization. Samples from three separate stages were evaluated. The analysis revealed a significant loss: compared to before centrifugation, concentrations of four major hop terpenes dropped dramatically in the after-centrifugation sample, with losses ranging from 6% to as much as 89% of volatiles (Figure 1). While clarification is critical for shelf-life stability, it may come at the cost of sensory quality. The Senior Brewer summed up his frustration: “In an ideal world I would not add any T90s to the beer because it’s a waste — they are all stripped.”

EvodiaBio developed Yops — a curated collection of hop-inspired, yeast-derived natural flavors — to offer brewers a

practical solution. Yops is specifically designed to replicate the critical aroma compounds typically contributed by dry hopping, focusing on key terpenes that bring beer to life.

In the trial, two Yops blends (FruityFR1 and Citrus-C1) were dosed directly into the beer stream immediately after centrifugation, as the beer transferred to the brite tank. Adding hop flavors after clarification avoids the risk of terpene loss to yeast adsorption. The results were dramatic. As shown in the bottom panel of Figure 1 (bottom-left of this spread), the terpene profile was not only restored but, in several cases, significantly surpassed the original dry-hopped benchmarks. Concentrations of certain terpenes exceeded their pre-centrifuge levels by over 300%, restoring the juicy, vibrant character that dry hopping alone could not achieve.

Process-wise, Yops dosing required minimal time and workflow disruption. Preparation and dosing took less than

45 minutes — a minor operational investment compared to the complexity and waste of additional dry hopping cycles. With no risk of secondary fermentation, no added material losses, and a bright, shelf-stable hop character, Yops delivered both sensory and process advantages. By reducing losses and maximizing aroma recovery, it helped to unlock the full potential of this NA beer. As interest in NA beer continues to grow, these kinds of adaptable, efficient tools will play an important role in helping brewers meet evolving consumer expectations — with flavor, consistency, and process control at the forefront.

Yops offers brewers a practical tool to help bridge the sensory gap, enabling the addition of key hop aroma compounds that could otherwise be lost. Yops can support the creation of bright, expressive NA beers all without adding process complexity or compromising stability, too.

BREWERS SHOULDN’T BE AFRAID TO TRY SOMETHING NEW. THESE TOOLS AREN’T HERE TO REPLACE TRADITION— THEY’RE HERE TO HELP YOU EXPLORE IT IN NEW WAYS, EXPLAINS CHARLIE GORHAM FROM CHARLES FARAM

If you have been following our news you’ll know that we’re working with Abstrax, a Californiabased flavour and aroma company, equipping brewers with tools to do more with less—less hop matter, less variability, and less waste. All without compromising on flavour or authenticity. They’ve even unleashed some unexpected sensory profiles.

Founded during the wave of cannabis legalisation in California, Abstrax didn’t set out to simply make THC products. Instead, its founders were captivated by the untapped potential of the intricate web of compounds responsible for the plant’s scent and flavour.

With few resources or existing extraction technologies available, the company had to build its expertise from the ground up. Abstrax’s national sales manager Craig Thomas said that they became the authority in cannabis aromatics and that it had started to snowball. They looked at other applications, and wondered what other solutions were out there - what else smells really good? What can we do with these aromas? And to that end, they have now also become the supplier for a number of different industries, too.

He said: “With the brewing industry in particular, we’re talking about water soluble flavours that go into beer, and really the one stop shop for creative expression, for efficiencies, for new economies of scale, and for finding different ways of making beer that resonate with people - and frankly it just makes sense.”

From that unconventional origin story came a suite of high-impact products now making waves in brewing, including the Quantum series of hop-derived, varietal-specific solutions, Skyfarm fruit-forward flavour top notes, and the BrewGas line, derived from cannabis terpene profiles.

Abstrax’s Skyfarm line has gained traction, particularly among breweries developing fruit- forward IPAs, smoothie sours, or low-ABV offerings where fresh fruit additions may not be viable due to cost, perishability, or also due to regulatory issues.

For award-winning head brewer Julian Shrago of Beachwood Brewing, the spark came not from a sales pitch, but from a pint of beer. Shrago spent over a decade as an aerospace engineer before pivoting to brewing and approaches his craft with a scientist’s curiosity.

He said that it was when he had a beer from Russian River Brewing in Northern California that he saw the potential of the Quantum Brite product made from selected hop varietals.

The beer was made with Russian River’s batch selected Nectaron hops. “I was like, okay, this is it. I immediately called Abstrax, and I said, let’s get this queued up with our select varietals right now. Late last year, we started making some permanent changes in both of our flagship beers, and that also led to us using Abstrax, Quantum, BrewGas, and

Skyfarm products in other beers that we were doing.

It really helped to dial in new flavour profiles or achieve traditional flavour profiles with less hop matter in the beer. It’s been something that’s worked out great. It is absolutely better brewing through science.”

Shrago also said that he understands people’s apprehension. “I think anytime you take something like brewing, which is seen as a very traditional, old-fashioned process and you introduce something that is very scientifically driven, there are people who might be like, well, hold on a second.

This isn’t how people make beer. However, it is absolutely a way to make things more consistent, perhaps make things better. It’s also a way to create new flavour and aroma profiles, and variety of beer that it has never been imagined before. I see it only opening new doors.”

“The UK is steeped in many, many centuries of brewing tradition. I think American consumers are used to new and ever evolving products. The UK has a slightly different consumer base, but I don’t see any reason why these products can’t be used to create traditional beers.

The benchmark for us with our flagship beers was, are the consumers going to notice the difference?

Nobody said anything and we did this months ago. I think a lot of the breweries here in the UK could fold these products in seamlessly, and the consumer would not know. And I think that’s, the true test of how successful you are”.

Luckily for us Abstrax don’t aim to replace hops, but rather to amplify and stabilise the flavours that brewers already love. For breweries dealing with annual hop lot variability, Abstrax offers the ability to lock in a specific crop’s aromatic

fingerprint and also to replicate it across future batches.

The claim is that if you get a standout lot of Mosaic or Nectaron, Abstrax can capture that exact profile through the Quantum technology and deliver it as a consistent input year-round, it’s like freeze-framing your best hops.

As hop prices fluctuate and consumer

you’re brewing on a one-barrel system or a fifty, Faram’s and Abstrax want to be part of that creative process for brewers of every size.

Beachwood Brewing is an independent, award-winning brewery crafting an innovative lineup of house beers, including distinctive West Coast-style IPAs, seasonal favorites, and limited releases. They started making beer at

“Margins are getting squeezed from every angle. If you can improve yield, reduce costs, and maintain quality, you have to do it,” Julian Shrago, Beachwood

SUPPLY

OUR RELATIONSHIP WITH THE FARMERS AND OUR OLD FRIENDUK WEATHER - ARE ALL POINTS THAT ROBIN APPEL, THE DIRECTOR OF WARMINSTER MALTINGS , ARGUES WE MUST PAY CAREFUL HEED TO IN 2025 AND BEYOND.

Spring has been “bustin’ out all over!” to quote those famous words of Oscar Hammerstein. The sun came out in the third week of February, and in the South of England, at least, it has almost been wall-to-wall sunshine ever since.

Farmers were very quickly out in their fields, comfortably sowing all their Spring barley within the critical window of 15th February to 15th March. With no frosts to speak of, barley seedlings were soon poking their heads out after 7-8 days, and have been romping away ever since. What a contrast to last year when incessant rain delayed sowing until the end of April. The point is that this year our barley crops just might enjoy a full and timely growing cycle, and the chance to really optimize both yield and quality.

Now, at the time of writing, we are into May, and still “the sun has got his hat on”, and farmers have begun to get concerned. Farmers always pray for rains in May, the last ‘top up’ of moisture before the high summer sets in. I am less concerned. Over my 50 years or so of crop walking alongside farmers, it is

my observation that there is absolutely no substitute for sunshine. Provided the root system has it’s toes in moisture, photosynthesis drives plant metabolism from dawn to dusk, and within our barley crops, peak performance in this department optimises ear formation and the number of grain sites per ear.

Not only this, when it comes to cereal growing, sunshine is natures disinfectant. Most of the foliar diseases of barley crops are wet weather induced, and our Spring barleys have already outpaced some of their early and worst potential pathogens. Net Blotch and Rhyncosporium spatter their damage at the seedling to early stem extension growth stage, and our barleys are already striding past that, a spectrum of lush and green. So what could possibly go wrong? If we get no rain to speak of until mid to late June, grain size will be impaired, and even some grain sites abhorted. But probably the worst scenario would be the arrival of heavy rains as harvest begins. So let’s not speculate on either of these outcomes at this stage.

However, a bumper crop of barley this harvest is not necessarily going to be any sort of bonanza for farmers, I’m afraid. The malt market has quite definitely slowed down, both for brewing and distilling. And not just in this country. My agent in North America reports a downturn of between 15 and 20%. That’s huge! That is not quite my experience at Warminster Maltings, but our brewing customers are definitely not taking quite as much malt as they have been. We all know why, of course. So no maltster is going to be chasing barley markets this summer, or perhaps want to pay the sort of premiums that some farmers have come to expect.

But herein lies a potential problem another day. If farmers cannot earn a reasonable premium for malting barley,

they will simply cease to plant it. They do not have to grow barley. Even within their “regenerative farming” policy, which depends on crop rotations (and preferably a livestock enterprise), there is still a wide choice of other crops they can select.

Most ominous amongst these are the particularly lucrative contracts for maize, for biomass production. Farmers do not have to grow food! This is precisely why, for most of my career in the grain trade, I have been a strong advocate of properly managed supply chains. I am talking about both farmers and first processors in constructive dialogue to ensure continuity of production, both weathering the storms of oversupply, and protecting against shortfalls another year. Over time, maltsters, and flour millers, have always been keen on these initiatives, but mostly to incentivise the production of preferred varieties of barley, or wheat. Latterly, some maltsters have recognised the virtue of these schemes to protect overall supply. But, for the most part, brewers themselves are less engaged. Time for change I suggest.

I am not advocating that brewers should start talking to farmers, we would need to bring back the Corn Exchanges to facilitate that.

But I do think that brewers should double check that their maltster has a sustainable barley supply chain, one that is on message to farmers to do their very best to maintain both quantity and quality of the right varieties. And it is time for brewers to underwrite these arrangements, even if it means paying up for them.

Farmers are feeling overlooked at present. Their banners, strung up on field gates proclaiming “No Farmers, No Food!”, expresses their frustration. If we end up with pubs with no beer, we will all be joining in with their protest!

STYLES ARE SELLING WELL AT SOME OF THE UK’S FINEST BOTTLESHOPS AND WHAT WOULD THESE BUSINESSES LIKE TO SEE BREWERIES IMPROVE UPON, TOO? BREWERY MARKET, INDIEBEER, AND STIRCHLEY WINES & SPIRITS TELL ALL.

The changing drinks landscape is one that both breweries and their customers have to navigate in order to cater of changing consumer demands. And the UK’s bottleshops play an integral role in help accommodate and shape drinking habits.

And in Holloway, London, you’ll find one such establishment at indiebeer, a craft beer shop and tasting room founded by Clare and Owen Daniel. And when it comes to the styles and ABVs that are selling well in the capital, Owen says that as both a bottleshop and a bar, they’ve found there are two quite different answers to that question...

“When it comes to draught beer, there’s been a clear shift towards lower-ABV options. Customers—especially on Arsenal match days—are often in for a session and are specifically after beers around 4%, or even as low as 3.5%. Those lower-strength options are really important to that audience,” he explains. “But in the fridges—whether customers are drinking in or taking away—it’s a very different picture and we have seen a

polarisation in preferences.

“There are our core customers who are increasingly looking for bigger, fuller-flavoured beers. For around a year now, we have had an entire fridge dedicated to double IPAs, and split our IPA section in two so there’s now one fridge just for DIPAs, and another for sessionable and standard IPAs.”

He adds that imperial stouts are also selling well—driven partly by increased access to exciting US releases and some excellent barrel-aged offerings from Eastern European breweries.

“Then there are customers are who are searching for classic European beers, in particular alternative lager styles, such as Schwarzbier and Rotbier, and know that we are always adding new and exciting options in the lager fridge,” he says.

“So, in summary: on draught, it’s all about lower ABV; in cans, it’s a polarisation between full-flavour, higher strength styles like DIPAs and those seeking cleaner classic styles.”

And with this, Daniel says there been a shift in what your consumers are purchasing. “It’s an interesting dynamic, because it sometimes puts us at odds with what breweries are focusing on. For a range of reasons—including changes in taxation—many breweries are pushing lower-strength beers and are keen to sell more draught overall.

“But the irony is that while our draught customers are increasingly looking for lower-ABV options, and some customers are cutting out alcohol completely, the majority of our can-buying core customers are moving in the opposite direction. So yes, there’s been a marked change—breweries leaning one way, consumers pulling in another.”

Krishan Rajput is the proprietor of Birmingham’s Stirchley Wines & Spirits. In terms of market trends in the last 12

months, he’s seen a noticeable surge in the availability and retail sales of standard strength stouts due to the supply issues of Guinness in the latter part of 2024, And a particular standout for him was Anspach & Hobday’s London Black.

“The Low & No category continues to be a growth area for sales, whilst gluten free has stalled slightly (despite increased availability of styles and wider adoption within the industry). As always, local beers are still a prime influence with our customers in terms of sales,” he explains.

“The continuing popularity of Low & No is a trend that is very much in line with previous years; the popularity is driven partially by shifting drinking trends as well as more visibility of these products in social media circles (Ben Gibbs/ Soberboozersclub on Instagram being a prime example). Whereas we would probably view the increased interest in alternatives to Guinness as probably more of an anomaly.”

And in Twickenham, Linda Birch is the founder of Brewery Market. She echoes the views of Krishan Rajput adding that no and low-alcohol beers are continuing to gain traction. “We have increased the number of fridge spaces

“When it comes to draught beer, there has been a clear shift towards lowerABV options,” Owen Daniel, indiebeer

dedicated to this category, separated by style. Customers are seeking out flavourful options that suit a more mindful approach to drinking, and brewers have really stepped up their game here,” she tells us. “Also continuing from last year, one of the biggest sellers has been sparkling mead. It’s become a real talking point in the shop, it appeals to beer drinkers, wine drinkers, and the “not sure what I fancy” crowd alike. It’s that bridge beverage that invites curiosity.”

And what can breweries be doing more of and be doing better? “Packaging and delivery can still be a challenge— damaged cans from poor packaging or rushed couriers are all too common. Maybe there’s room for breweries in the same area to share a local driver?” asks Birch. “It could help cut waste, improve the cold chain, and even create jobs.

“We’d also really welcome more mixed packs and smaller MOQs tailored for independents. One thing that’s tough for small shops like ours is when breweries cancel events after we’ve placed a big order. We put a lot into sharing their stories—so a little more support for the little guys would go a long way.”

“Better transport packaging please,” adds Rajput. “And in terms of things that would be useful to us as a retailer, would be to see more breweries offer their beers in multiples of 12 rather than 24. That would give us more opportunity to take on beer with a reduced risk of getting “stuck” with stock, therefore more potential to restock with newer beers in a shorter time.”

At Indiebeer, Owen and Clare would love to see both breweries and consumers embrace a bit more style variety and experimentation. “It’s obviously a challenging time for everyone, with consumers wanting value for money and certainty when they make a purchase, and for breweries, and retailers, needing to be sure that the beer will be popular and sell quickly enough,” says Owen. “We’re currently stuck in a bit of a doomloop, which explains why we’re seeing so many customers gravitate towards DIPAs. It has become the ‘safe’ choice, and as a result, everyone’s sitting in that same hazy IPA space.

He adds: “We’ve seen a decline in classic European styles such as saisons, which is a shame, but we are also guilty of not pushing these enough. Those beers were a big part of what made craft beer exciting to begin with.

“And while I understand it’s risky, I really believe draft is still the best way to introduce people to new styles. But if you’re going to put something unusual— say a lemongrass or thyme saison—on draught, it shouldn’t be in a 30L keg. That’s a hard sell. Try and package it in a 10L keg instead.

“I know it costs more, and I know keg prices don’t scale with volume, but if we want variety on bars again, smaller formats might be the way forward.

“No venue wants a slower-selling beer to sit on the taps for weeks. It will look stale to the customers and also reflect badly on the brewery.”

And in working with a wealth of breweries Rajput highlights some names that have made an impression on him.

“The return to the industry of Burton Bridge/Heritage Brewing has been a very welcome sight this year. Burton Bridge was one of those breweries that we had stocked for a considerable amount of time up until the brewery was put up for sale,” he says.

“To see them return in such a vibrant way and with renewed vigour under the watchful eyes of Emma Cole and Al Wall is definitely something of note.

“It is one exampe that has shown us there is still a great deal of interest in traditional and heritage brewing.”

Rajput adds: We’ll also sing the praises for Elusive Brewing in Berkshire, who are fast-approaching their 9th year of operation and are still delivering excellent and approachable beers like Oregon Trail (their signature West Coast IPA) and their core red ale Level Up. As for newer breweries Rajput says that Scatterlings have caught the eye in the last 12-18 months.

The brewery is an offshoot mixed fermentation project from Brett Moore at Two Flints that focus primarily on saison style beers. Rajput says that one of their most recent releases ‘Green Hop, Green Bottle’ was “a genuine pleasure to drink”.

from poor packaging or rushed couriers are all too common,” Linda Birch, Brewery Market

At Brewery Market, Linda Birch says she wants to give a huge shout-out to Talking Tides Brew Co.

“I’ve been working with them for a little while and we’ve just secured a grant to scale up the kit and finally start canning ourselves. The brewery is fantastic— Steve McDonald is the brewer and the beers are consistently brilliant,” she says.

“Headland and Bark Side of the Moon really stand out for me. The new cans look great, the taproom’s got a brilliant vibe and top music, and they’re doing so much for the local area and community. They’ve worked incredibly hard to get to this point—they deserve more recognition. Their beers are currently available on Eebria, too!”

And for Clare and Owen at Indiebeer, both huge fans of West Coast IPAs, they’d understandably like to see more on the market. “We don’t think there are nearly enough of them these days, which is why we now have a dedicated West Coast section in both our IPA and pale ale fridges. It’s a style we’re keen to champion,” he says.

“Last year, we saw a wave of “modern” West Coasts, and slightly hazy versions, Bright IPAs and the like, that were all aiming to meet customers halfway. But I think there’s now a better understanding among drinkers of what a West Coast IPA is meant to be.”

Tel : 01525 718288

E-mail : info@enterprisetondelli.co.uk

Website : www.enterprisetondelli.co.uk

• Want to take control?

• Want short production runs at your convenience?

• Want to reduce product losses at contract packers?

• Want to save transport costs and double handling?

• Want to reduce your carbon footprint?

• Want to control your own hygiene and QA procedures?

• Want improve your packaging?

• Want to save money on labour costs?

• Want to reduce your dissolved oxygen?

You can with an Enterprise Tondelli craft beer Canning, Bottling or Kegging line!

✓ 1,300 cans per hour upwards to 80,000 cph

✓ 1,200 bottles per hour upwards to 60,000 bph

✓ 16 kegs per hour upwards to 1,000 kegs per hour

When we started this publication back in 2015, two words we would hear time and time again were community and camaraderie. These were qualities that the beer industry, especially in a time of rapid growth thanks to the popularity of independent craft beer, boasted that it had in abundance. Why? Because it had them in abundance.

Knowledge sharing between brewers and the actual sharing of the tangible such as ingredients, production and warehouse spaces fed into the aphorism of “A rising tide lifts all boats”. Many breweries and the people behind them all bought into the idea of us being in this together and everyone wanted their neighbours and peers to succeed also.

Craft beer was a movement that helped showcase and shine the spotlight on the little and the large. And while much has changed in the make-up of this industry during the last 10 years, I feel that those qualities of community and camaraderie still exist today.

Granted, the beer industry is far from perfect but it has an awful lot going for it, too. In many instances, it has shown that anyone can potentially try their hand at being part of a brewing business, the broader indusry or even consider starting a brewery that can call their very own.

But as the beer industry has evolved and changed during the last few years, the

cultural and political fabric it operates as part of has transformed, too. In the US, President Donald Trump had barely begun his second sting in The White House when he started rolling back orders from the Biden administration. These included a directive aimed at preventing discrimination based on gender identity or sexual orientation with officials saying at the time that Trump would be “ending DEI” inside federal government.

We could use all 100 pages of this publication and of each edition that follow, and not even begin to scratch the surface of such implications when you consider that Diversity, Equity and Inclusion (DEI) encompasses people of different ages, races, ethnicities, abilities, disabilities, genders, religions, cultures and sexual orientations, and also people with diverse backgrounds, experiences, skills and expertise.

But what is certain is publications such as The Brewers Journal through its printed magazine, website, podcast and live events that take place across the UK can do its own small part to help showcase and platform the breweries, businesses and individuals within the drinks sectors that are showing how we can collectively do better and do more to help make beer a more inclusive environment for all.

In each issue we continue to recognise the vital voices this industry posseses, the action that they are taking and also the important work that they are carrying out in their businesses and beyond.

And from this year we will also celebrate and recognise these difference makers with the inaugural 'Diversity and Inclusivity Champion' award at our 2025 Brewers Choice Awards, which are taking place in London at The Big Penny Social this September.

Closing one of our previous events, the Brewers Congress back in 2021, Garrett Oliver, the brewmaster at Brooklyn Brewery and the founder of the Michael James Jackson Foundation for Brewing and Distilling (MJF). shared some powerful advice on the importance of getting “everybody in the room”. He told us that you should never assume that you know more than the person sitting in front of you. That we all should be more inclusive, and to have the courage to put ourselves in front of people who don’t look like us and maybe haven’t heard about the beer we make.

“There are a lot of people everywhere who would really like to discover what it is that we do. So you’ve got to bring in new people and they are going to hopefully be diverse. They’re going to hopefully be of all genders, they’re going to hopefully be of all orientations,” he said. “They’re going to hopefully be of all colours, if you want to have a great business and more importantly, if you want to have a really good time, then get everybody in the room. Not just some of the people, not the same people that you already know, but everybody."

Tim Sheahan Editor

IN HELPING START LEITH-BASED MOONWAKE BEER CO, THE BREWERY’S CO-FOUNDER VINNY ROSARIO WANTED TO CREATE A WELCOMING SPACE FOR ALL TO ENJOY. AND TO DO THAT, HE DREW ON SOME LIFE EXPERIENCES TO HELP GUIDE HIM AND THE TEAM ALONG THE WAY.

Afew years back, a friend of mine, a fellow brewer, and I decided to take his Dad, an avid beer fan, out to a few taprooms around London. His Dad had just recovered from a stroke and was still unsure on his feet/couldn’t walk for long. We were both excited to take him out on his first outing since recovering, but it didn’t last long. Neither the excitement, nor the outing.

We soon realised almost every taproom we went to had little to no accessibility for people with disabilities, and the few that did had no adequate toilet facilities. I was shocked and saddened. I also felt bad for never noticing this before. I had not had a lot of interactions when it came to drinking with people

with disabilities until this point and had taken for granted my mobility.

When I got the chance to help start Moonwake Beer Co, having a taproom was a key part of the dream. Ideally a mezzanine taproom overlooking the brewery. We were lucky enough to achieve this but it also came with one major snag.

Remembering the time walking around frustrated with no accessibility, I didn’t want this pain repeated for anyone else. So we installed a (very expensive) lift for anyone unable to use the stairs, open to everyone. We didn’t want a situation where someone had to get a key to

use it, because that’s the thing with accessibility, you never know how much someone is struggling with just a glance. I love hearing how people who use the lift enjoy coming to the taproom because they feel part of the experience, and can enjoy the view overlooking the brewkit. After all who doesn’t love staring at stainless steel?

For me unfortunately it took a personal experience to open my eyes. For too long minorities have had to impact someone personally to see change. This goes for people from all walks of life, not just physical disabilities. Though once you open your eyes, it is amazing how much there is to see and change. Granted a lot of this comes with life experience, but we can all learn from each other and pass on what we know. I have always wanted for Moonwake to be a welcoming place, that you can not only easily access, but feel happy to be there when you do.

We have gathered an eclectic team at Moonwake, with a vast array of backgrounds and experiences. It has been a genuine joy working with so many different people and everyone is employed on merit. There are always challenges leading a diverse group of people. Though this adds to the fun. You can learn from their experiences and

help shape a team that cares for more than just their own ‘in group’. It also leads to more ideas when designing beers. For instance, we recently released a saffron rice lager to coincide with Persian New Year.

I have always wanted to brew a rice lager, and working with my colleague in sales of Persian decent, she came up with idea of adding saffron and Basmati rice, aiming to pair it with Persian style food. A local Persian restaurant launched it for us alongside a specially designed tasting menu which formed part of their Persian New Year celebrations.

I am happy to say it was a grand success. Importantly it also pushed me out of my comfort zone to brew a beer I wouldn’t normally have done. And most of importantly it is now one of my favourite beer to drink.

We want this collaboration, respect and openness throughout what we do at Moonwake. Not just during the working hours or between certain individuals. From collaborating with Women in Beer and Glasladies to create a beer for IWCBD, right through to how our taproom staff interact with every individual that comes through our door.

This attitude does come from the top however, from both the company and the people in charge. It takes patience and understanding, but mainly it takes just looking at the world from outside your own personal perspective.

We all know how great craft beer is, and we should all be working together to strip down any and all of the barriers that we find to it,” Vinny Rosario, Moonwake Beer Co

It is also worth reaching out to some of the local groups in your area who would love to help.

But it has to start with the people in charge, and be implemented throughout. We have the power to make a difference together. Moreover we all know how great craft beers is, and we should all be working together to strip down any and all barriers we find to it.

Remembering the time walking around frustrated with no accessibility, I didn’t want this pain repeated for anyone else,” Vinny Rosario, Moonwake Beer Co

Once you notice the array of different people around you, you need to engage with them, be it taproom visitors or brewery assistants. They all have stories to tell, and deserve our respect. It can be scary going into the unknown, and frustrating when your views on life are challenged. Though remember, often people face great challenges every day and that many of these go unnoticed.

There are many initiatives out there to help you make a start if you do not know where to begin. Like the ‘Everyone’s Welcome Initiative’ by Melissa Cole, which we implement in our taproom.

A few years back, I was completely unaware how a couple of steps and a tiny bathroom could curtail somebody’s day out. It made me awkward and it also made me uncomfortable. I have now learnt it is OK to feel that way, in fact it is even good. Through this discomfort you can grow as a person, and discover new things. Next time I aim to try see the barriers before the impact me personally.

Moonwake is a modern Scottish brewery, established in 2021 by a team with extensive craft beer and brewing careers. The Leith-based brewery believe there is a beer out there for everyone.

FOR PEOPLE WITH DISABILITIES, ACCESS TO A TOILET IS A MAKEOR-BREAK FACTOR WHEN DECIDING WHERE THEY GO; BE IT FOR WORK OR SOCIALISING, EVERYONE NEEDS TO PEE. JULIE SAWCHUK, AN ACCESSIBILITY STRATEGIST AND BEST-SELLING AUTHOR OF BUILDING BETTER BATHROOMS, EXPLAINS HOW WE CAN HELP ENSURE HOW BREWERIES AND TAPROOMS ARE MORE WELCOMING TO ALL.

If you can’t go pee you can’t drink beer. That’s a rather uncomfortable conversation starter, isn’t it? It’s biology — everyone (especially when drinking beer) has to empty their bladder. But what would you do, if after consuming a couple of pints, you realised that the WC was not available? You’d have a little panic and then you would seek out other options. BUT, what if there were no other options? No toilet that you could access. Cross your legs and have another beer? Not likely.

For people with disabilities, access to a toilet is a make-or-break factor when deciding where they go; be it for work or socialising, everyone needs to pee. For me, it’s the first thing I think about when planning an outing — where am I going that has a toilet that is accessible for me? What is special about me? I have a spinal cord injury that affects the way my body functions, including how I empty my bladder.

I literally arrange my day according to my need to pee; generally speaking, if I can’t use your toilet, you likely won’t ever meet me. What I eat and drink when I am away from home totally depends on the facilities that are available.

Have you ever considered that the toilets were the most important place in your establishment? If you don’t pay attention to how accessible they are, you are single-handedly excluding the world’s largest minority group, who (by the way) have money to spend.

The toilets? The most important place? Really? Look at it this way: what would you offer to do first? Would you help someone with a door to get into a

building or would you help someone within a toilet? You’d help with the door, right? Maybe it’s down a back alley and hard to find, or super heavy, or has an awkward handle that’s difficult to operate. Either way, you would help with the door. But the toilets?

You might go so far as to hold open a door for someone to get in, but that’s likely where your offer to help stops. The toilet is a personal space and society has taught us that no one is supposed to know or hear about what a person is doing behind that closed door.

Back in your establishment, you know you produce good beer. Your patrons enjoy themselves when they are drinking and eating at your establishment, right? guests are comfortable with nice stools at a bar, booths or chairs and tables, cozy lighting and great music. Everyone is welcome, right?

People with disabilities are the world’s largest minority community — are you considering the needs of all people?” Julie Sawchuck

Most people don’t even think about the toilets often; it’s just assumed that there is a toilet. But there are some things that you should make sure about that all-soimportant feature of your establishment. Is it: Easy to get to (i.e., no steps, steep ramps or sharp thresholds)?

Well signed (i.e., inclusive symbols, use of an arrow, easy to see from a distance)? Or is it equipped with a door that is easy to open (i.e., lightweight, free-swinging hinge or power operated)? Large enough for a person with a mobility device to get in with their device AND shut the door?