This year marked 10 years since we started The Brewers Journal. And in the early days of this publication I was living in Tunbridge Wells, Kent. That area and its surrounding environs had a lot of great pubs - it still does. And if you had access to a car (which I didn’t) then further afield you had places like East Sussex and all that had to offer, too.

But my go-to stop, like so many others, was Fuggles Beer Cafe on Grosvenor Road. Its commitment to both cask and keg meant you were guaranteed brilliant beer from local breweries such as Pig & Porter, Gun Brewery and Burning Sky as well as leading producers from elsewhere across the UK and Europe. In short, excellent beer (and cheese) was to be had - always.

What I always enjoyed about this establishment is that its founder, Alex Greig, and his team made the beers they sold, often of the weird and wonderful variety, accessible to all. Many of the bar’s patrons weren’t beer ‘enthusiasts’ but they appreciated the fantastic beers available - even if they didn’t particularly plan on trying a Barleywine that Thursday. This required a level of communication that demonstrated why a certain brewery isn’t one they may have heard of, or why the style might sound confusing initially, but it’s a beer they would probably enjoy.

I recall one St Patrick’s Day where a duo came in expressed their muted shock that Guinness wasn’t available. A minute later they were enjoying pints of Milkshake stout from Bristol’s Wiper and True. I’d have joined them had I not already been imbibing the same brilliant beer.

In addition to the wealth of beers you could get on a daily basis, Alex would

also ensure that Fuggles would help launch and showcase limited releases from producers across the UK and Europe such as the DIPA ‘V’ series from Manchester’s Cloudwater. These were special occasions with small pack stock selling out over the weekend and casks and kegs kicking in a matter of hours.

Speaking in the run-up to the judging for this year’s Brewers Choice Awards, Alex reminisced on how the market has changed over the last decade and also asked if breweries can work more closely with the trade to ensure this part of the industry isn’t lost forever.

“It might not be a very popular thing to say but things have changed. The market has changed in the way we sell beers to the consumer,” he says. “We would previously launch a beer to a huge fanfare but now the customer can order direct from the brewery and have it a week before the bar is able to.”

Greig adds: “Pubs, bars and bottleshops across the UK have done a good job in helping build the brand reputation of many breweries. We are an extension of their sales team. So you must ask if the industry will eat itself if we continue to undermine the frontline?

“I think we need more joined-up thinking between breweries and businesses such as ours. I feel that breweries should be cherishing the smaller spots because without them you are at risk. We need to give people a reason to go out at a time when they’re going out less. This industry needs to elevate each other and we need to support each other.”

Until next time,

Tim Sheahan Editor

Dear John

2025 has been one of loss and of change for John Keeling. And it’s helped him reflect on how work, and life, changes through the years.

Comment | SEIS

Just what is SEIS/EIS and what role do they play when it comes to raising brewery funding?

Comment | LPG

How Liquified Petroleum Gas and its reneweable counterpart offer a practical solution for breweries.

Brewers Intelligence | Autumn

The latest insights and expertise from across the field of ingredients and sales.

Inclusivity in Beer

Why Rachel Auty believes in collaboration and community to help make the world a better place.

Imposter Syndrome

Why imposter syndrome exists and advise from Inclusion In on how to overcome it.

Hops

The modern hop landscape is exciting and evolving. Here are some of the latest innovations and the leading companies on hand to help.

Green Energy

Why solar power is increasingly popular in beer.

Brewhouse Technology

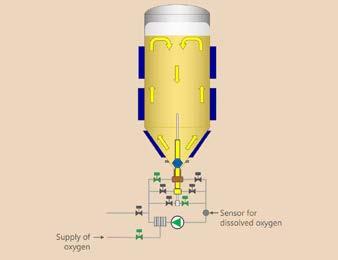

The role modern brewhouse technology has in the production of no and low alcohol beers.

Homebrewing

Alex (Alejandro) Troncoso shares his homebrewing journey. One that would lead him to Bristol, UK.

Closet Brewing of Edinburgh

How this Scottish brewery places an emphasis on quality vegan beers, queer community and a localminded, outgoing approach.

Hops | Spain

The history of hops and León in north-west Spain are intertwined. Here’s how brewers can benefit from utilising some of the diverse hop varieties grown in this of Europe.

2025 year’s event Autumn.

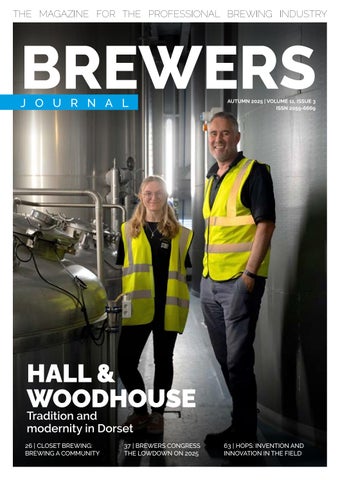

As the guardian of a brewing institution, Toby Heasman, the head brewer at Hall & Woodhouse is helping lead the Dorset brewery through its latest chapter as it approaches its 250th anniversary in 2027.

Tim Sheahan Editor tim.sheahan@reby.media

+44 (0)1442 780 592

Tim O’Rourke Technical Editor

John Keeling Contributor

Josh Henderson Head of sales josh.henderson@reby.media +44 (0)1442 780 594

Jon Young Publisher jon.young@reby.media

Reby Media 6 Grove Road, Hemel Hempstead, Herts, HP1 1NG

The Brewers Journal is a published four times a year and mailed every March, June, September & December. Subscriptions can be purchased for four issues. Prices for single issue subscriptions or back issues can be obtained by emailing: subscribe@ reby.media

UK & IRELAND £45 INTERNATIONAL £69

The content of The Brewers Journal is subject to copyright. However, if you would like to obtain copies of an article for marketing purposes high-quality reprints can be supplied to your specification. Please contact the advertising team for full details of this service. The Brewers Journal is printed at Manson Group, St Albans, UK.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or any information storage or retrieval system, without the express prior written consent of the publisher. The Brewers Journal ISSN 2059-6650 is published bimonthly by Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG. Subscription records are maintained at Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG.

The Brewers Journal accepts no responsibility for the accuracy of statements or opinion given within the Journal that is not the expressly designated opinion of the Journal or its publishers. Those opinions expressed in areas other than editorial comment may not be taken as being the opinion of the Journal or its staff, and the aforementioned accept no responsibility or liability for actions that arise therefrom.

As the sun sets on another summer, the popularity of no-and-low alcohol beers at pubs, bars, beer festivals and beyond showed no sign of abating. Quite the opposite, in fact, demonstrating that it remains a huge growth area for breweries.

The equivalent of 33 million pints of no and low alcohol beers were predicted to have sold in June and July, according to the British Beer and Pub Association.

In 2024, the equivalent of 27 million pints of no and low beer were sold, up from 23 million in the same period in 2023, and 20 million in 2022. This equates to a staggering 35% rise in just two years. This summer it was predicted to be a record, with June and July sales of no and low beer expected to have increased by 20% to that equivalent of 33 million pints.

The BBPA said the boom has been made possible by the sector adapting to trends and producing more no and low options than ever before, which also helps widely-reported public health goals.

Despite this, the BBPA also said that the current UK definition of low alcoholic beer is severely limited by the UK’s restrictive definition. Currently, an ‘alcohol free’ beer must be below 0.05% ABV, which limits what British brewers can

make. This is in contrast to many other countries, who define alcohol free as a marginally higher 0.5% ABV.

They said that if the government matches the thresholds, UK brewers will be able to invest in more no and low beers, which will give consumers extra options if they wish to moderate and boost economic growth.

Emma McClarkin, CEO of the British Beer and Pub Association, explained: “No and Low popularity is booming, and brewers and pubs have responded to this by creating and serving up great new options which help people choose moderation, if they wish. Government has heard our calls and taken a progressive approach by consulting on no-alcohol alcohol descriptions. Changing the no alcohol definition to 0.5% will open the door to greater investment, means we are on par with international markets, and more options for people who choose to moderate – everyone wins.”

No and low alcohol beer is the sector’s biggest growth category across the UK, with volume growth of 750% since 2013. While in Germany, the country’s Destatis federal statistics office reported last

month non-alcoholic sales have more than doubled in recent years - up 109% since 2013.

And Diageo Ireland reported that ontrade sales of non-alcoholic Guinness 0.0 across its formats of can, draught and also micro-draught cans across Ireland had rocketed 35% earlier this year, following up from a 47% increase in sales of draught Guinness 0.0 in Ireland during 2024. The company added that such growth was set to continue into next year when Diageo Ireland’s previouslyannounced £25m investment into Guinness 0.0 production capacity comes online, too.

The popularity of brands like Guinness 0.0 were also felt by Stonegate Group, the UK’s biggest pub company. Earlier in the year they revealed an increase in demand for low and no alcohol beers and ciders with sales up by 32% in the first quarter of 2025, compared to the same period the previous year In total 271,000 low and alcohol-free beers and ciders had been sold across Stonegate’s pub and bar estate in the first few months in 2025 alone.

What we are seeing is a fundemental shift in drinking habits, which is here to stay,” David McDowall, Stonegate Group

David McDowall, CEO at Stonegate Group, said: “There has clearly been a growing demand for low and no alcohol options in recent years, but what we are seeing now is the evolution of the trend into a fundamental shift in drinking habits, which is here to stay.

“For some time, we’ve seen our guests going out earlier and demanding more from their experiences and nights out, but the depth of our data shows low and alcohol-free drinks are growing in popularity up and down the country. We recognise that our guests are increasingly looking for low and no alcohol beers that don’t compromise on taste, so its hugely important for us to have a quality range of beers available.”

Martin Dickie, the co-founder of Brewdog, has announced he is leaving the business. In a statement, he said that he was leaving the business and the wider alcohol sector for “personal reasons”.

He explained: “After over two decades in the brewing and distilling arena sadly for personal reasons it’s time for me to leave the industry that I love deeply and hopefully had a positive impact in.

“Leaving BrewDog isn’t easy but I’m ready to spend less time travelling and spend some more time at home with my young family. It has been an honour to have worked with incredible, likeminded, colleagues who live in a world of flavour and experimentation.

“Our hard work and passion is dedicated to bringing our customers a moment of beautiful escapism from the real world. In James Taylor and chief operating officer Lauren Carrol, BrewDog is in very strong hands and I will always remain a massive fan.”

Dickie leaves the company more than a year after his co-founder James Watt stepped down from his own role at BrewDog as CEO.

Watt was initially replaced by former Boots Opticians managing director James Arrow. Less than a year later, James Taylor would take on the position after being promoted from his role as CFO.

Commenting on the announcement, Taylor said: “Martin’s contributions to BrewDog have been immeasurable,” Taylor said. “His creativity, passion and relentless drive have shaped our company over the years and inspired countless others in the industry.

“We would like to thank him for his focus primarily on product quality, NPD, workplace safety and sustainable supplier relationships. Martin will always be part of the BrewDog family and we wish him every success in the future.”

Bristol Beer Factory has invested £1.2 million in a new, environmentally sustainable facility to expand its production capacity with an aim to achieve Net Zero emissions by 2040.

The company secured a seven-figure capital import finance and hire purchase funding package from Lloyds. It has operated in South Bristol for more than 20 years and owns four pubs across the city: BBF Tap Room & Studio, The Barley Mow, Arnolfini Harbourside Café-Bar and Junction.

Having outgrown its previous premises, the company has expanded into a new 12,000 sq ft facility- doubling its original footprint. This significant growth enables increased production capacity, including the launch of a new 4.1% Pilsner lager.

The new brewery features carbon capture and vapour heat recovery technology to boost its carbon efficiency. The carbon captured is recycled and reused to carbonate the beer, reducing emissions while also mitigating the cost of buying the gas in – which can be impacted by price volatilities. The technology will deliver estimated annual savings of £100,000.

With 80% of its volume sold through direct delivery to local venues, the business remains focused on serving Bristol’s hospitality sector – even as it partners with wholesalers nationwide.

Sam Burrows, managing director at Bristol Beer Factory, said: “This expansion is about more than just brewing more beer, we’ve also been able to make improvements across the board, benefitting our people, community and planet. We’re continuing towards our goal of being a leading brand in the city, that’s known for doing right by the community we operate in. This new brewery means we can better respond to a positive trend in customer demand while also increasing our ability to deliver social value-driven projects. We’re excited to see what the future holds.”

Langham Brewery is celebrating its 20th anniversary by handing the reins to the next generation of brewers.

Lesley Foulkes and James Berrow are retiring, transitioning ownership to experienced brewer Charlie Long (ex-Fuller’s and Wimbledon Brewery), who plans to build on the company’s commitment to quality, character, and community, whilst retaining the existing team and main brews.

”I have been a big fan of Langham’s brews and ethos for many years”, said Long. “Serendipity arose when my family and I were looking to relocate to the area, and raise our kids in this glorious countryside location. A chance conversation led to the opportunity to take the reins of the business, so the timing was perfect,” he explained.

“I’m excited for what the future holds for Langham Brewery and the brilliant team we have here.”

Exmoor Brewery has resumed start on the site of the former Cotleigh Brewery in Wiveliscombe

Exmoor Ales ceased brewing at its Golden Hill site in Wiveliscombe in May this year, at the same time starting a collaboration with Hogs Back Brewery which saw its award-winning ales replicated at the Surrey brewer’s site. Hogs Back will continue to brew Exmoor’s main beers for the time being including Exmoor Gold, while the New Exmoor Brewery will focus on NPD and specials.

Hogs Back chairman Rupert Thompson said: “In these very difficult times, one way to survive and, in time, prosper, is to collaborate with fellow like-minded businesses. We were pleased to be in a position to help Exmoor Ales and keep alive this popular local beer brand.”

THE YEAR HAS BEEN ONE OF LOSS AND OF CHANGE FOR JOHN KEELING. AND IT HAS CALLED HIM TO REFLECT ON HOW WORK, AND LIFE, CHANGES THROUGH THE YEARS.

In my time as a member of the brewing world I have had numerous discussions with fellow brewers about the ‘Golden Age of Brewing’. It’s important to note that this is distinct from the ‘Golden Age of Drinking’.

I believe there are two drinking golden ages. The first is when when you are young and have no responsibilities and also when you are old and have no responsibilities left. I am currently in the second of these.

Each brewing generation claims to be in

a golden age, or more accurately at the end of the golden age. The number of times a brewer has said to me that we have seen the best of it are too numerous to mention.

Why do they say this? Usually, they are near the end of their career and view the past through rose-tinted glasses. They don’t like the changes that have challenged them at the end of their career. At this moment in time, I am in a reflective mood. This is because in the last few months I have lost two friends from the industry who were great influences on my life.

I first met James Fawcett when I took over malt buying from Reg Drury, my predecessor as head brewer at Fuller’s. This would have been around 1997. James was then the sales director before he would eventually go on to become the chairman of Thomas Fawcett’s & Sons.

James was the type of salesman who loved to chat to the brewer using his malt and didn’t particularly enjoy talking to purchasing managers.

Old fashioned I think is the word. He

always gave me good advice about when to buy malt and he liked a drink with me, too. I probably saved Fuller’s thousands by listening to maltsters. I don’t think he ever gave advice to those purchasing managers. I would see him about three times a year and would try to visit the maltings once a year, usually at harvest. I would also take people from Fuller’s to see him, mainly the sales team, marketeers or accountants because I felt it was important for them to understand the business and not just their part in it.

James was a great host. He delighted in showing us around the maltings. Fawcett’s are a great place to visit because they have floor malting, street malting and combined kilning and germination vessels.

Ken Don, the former head brewer, of Young’s really taught me to put back into the industry as well as take out. I followed in his footsteps on the Heriot-Watt committee then the advisory board. We both looked forward to the Heriot-Watt

former brewers’ weekend in Edinburgh. Ken famously drank 50 pints at one of these events.

These were great weekends meeting old friends and having a good time. If you have heard any of the stories about these weekends, then I can confirm they are mostly true.

I also joined the guild committee for

London and the Southeast when Ken was chair, and eventually I followed him as chairman too. One of the reasons I remain involved in brewing through the London Brewing Alliance is because of Ken’s influence. Young’s and Fuller’s brewers were great friends. We would visit each other, play darts and bowls and of course have the occasional pint. I miss Young’s and I will certainly miss Ken.

We have certainly lost a golden age, an age when people and not just brewers had time to enjoy themselves. A time when you could take colleagues to visit other breweries, maltings, hop growers and farmers.

Is life too hectic? Sometimes it feels like it. Does anyone have a long lunch anymore? Do people have a pint at lunch anymore?

Well, there you have it. That was my ‘Golden Age’ but don’t worry there will be another one just around the corner. There always has.

IF YOU’RE SCROLLING LINKEDIN WITH A FOCUS ON THE UK FOOD AND DRINK SCENE YOU’VE LIKELY SEEN FOUNDERS STATING THEY’RE “RAISING SEIS/EIS” BUT WHAT DOES THIS MEAN? DAN FINN, WHO HEADS UP THE BEVERAGES TEAM AT BRABNERS AND ACTS FOR A NUMBER OF BREWERIES AND DRINKS BUSINESSES ON THEIR FUNDING AND OTHER LEGAL REQUIREMENTS, EXPLAINS MORE.

The Seed Enterprise Investment Scheme (SEIS) and Enterprise Investment Scheme (EIS) are government initiatives designed to attract investment in early-stage businesses by offering tax incentives.

These schemes have become popular among craft breweries — Northern Monk, Mash Gang, Signature Brew, and Vaux Brewery to name a few all raising SEIS or EIS funds through direct investor engagement, crowdfunding platforms like SEEDRS and CrowdCube or a combination of the two.

The monies will usually be earmarked for a specific purpose with a view to growth, for instance purchasing brewing equipment to increase production, opening a new site or undertaking a rebrand and it is a key requirement of both schemes that the funds raised are used for a “qualifying business activity” which largely equates to being used as growth or working capital in the business.

SEIS supports fledgling businesses with fewer than 25 employees and £350,000 in assets at the time of investment. Investors can contribute up to £200,000 per tax year, receiving 50% income tax relief — meaning a £200,000 investment would yield £100,000 in income tax relief (of course, provided the investor is paying income tax for that relief to be applied towards). Additionally, investors pay zero capital gains tax (CGT) when selling

shares after three years, a significant saving compared to the standard 24% CGT rate. EIS targets more established ventures, allowing investments of up to £1 million per tax year, with 30% income tax relief and the same CGT exemption on a future sale of the shares after three years. To qualify, businesses must have fewer than 250 employees, be under seven years old, and hold less than £15 million in assets pre-investment.

For investors, the tax breaks are substantial. For founders, these schemes boost investment potential and improve company valuations — meaning they

might ultimately be able to give away less equity.

It is also a requirement under the schemes that the investor’s capital is “at risk” so there are limits on the type of rights that investors can demand as a precursor to putting money in.

Whilst they might require rights to regular financial information or veto rights for certain operational decisions, they can’t specify that they simply get their money returned if things don’t go to plan so will generally be on a fairly even footing to the founders and any pre-existing shareholders.

Investors pay zero capital gains tax (CGT) when selling shares after three years, a significant saving compared to the standard 24% CGT rate,” Daniel Finn, Brabners

A formal process, including an advance assurance application to HMRC, is required to secure SEIS or EIS investment and care should be taken when drafting the investment documents to ensure full compliance with the legislation. Therefore, professional legal advice is strongly recommended for businesses raising capital and likewise, investors expecting to receive the corresponding tax benefits to ensure all requirements are met.

Daniel Finn is a legal director in the Brabners corporate team. He also leads their breweries and beverages team, acting on complex and high value corporate acquisitions and disposals, shareholder agreements, governance arrangements and joint ventures. He also regularly advises on third-party capital investments — concerning venture capital, private equity, SEIS/EIS, angel investment and crowdfunding.

Tel : 01525 718288

E-mail : info@enterprisetondelli.co.uk

Website : www.enterprisetondelli.co.uk

• Want to take control?

• Want short production runs at your convenience?

• Want to reduce product losses at contract packers?

• Want to save transport costs and double handling?

• Want to reduce your carbon footprint?

• Want to control your own hygiene and QA procedures?

• Want improve your packaging?

• Want to save money on labour costs?

• Want to reduce your dissolved oxygen?

You can with an Enterprise Tondelli craft beer Canning, Bottling or Kegging line!

✓ 1,300 cans per hour upwards to 80,000 cph

✓ 1,200 bottles per hour upwards to 60,000 bph

✓ 16 kegs per hour upwards to 1,000 kegs per hour

The UK brewing industry is steeped in tradition, but its future is being shaped by sustainability. As breweries seek to reduce their environmental impact, many are investing in renewable technologies and rethinking their fuel choices. This shift is part of a broader transformation across the UK’s industrial landscape. The Government’s 2025 Clean Energy Industries Sector Plan and Modern Industrial Strategy both emphasise the need for scalable, low-carbon technologies to support decarbonisation in manufacturing and food production.

From independent craft producers to global brands, UK breweries are reevaluating their operations to align with environmental goals and consumer expectations. Globally, for example, Heineken – whose UK operations include breweries in Manchester and Tadcasteraims to be carbon neutral in production by 2030, while Carlsberg, operating sites in Wolverhampton and Northampton, is investing in natural carbon capture and renewable energy.

These efforts are setting a new standard, and the rest of the industry is under pressure to keep pace. While solar, wind and biogas are gaining traction, there’s growing recognition of the role transitional and sustainable fuels can play in accelerating decarbonisation – with liquified petroleum gas (LPG) and its renewable counterpart, BioLPG, offering practical solutions that support loweremissions progress.

Brewing is an energy-intensive process. From mashing and boiling to fermentation, cooling and packaging - every stage demands substantial heat and power. Traditionally, many breweries – especially those in rural or off-grid locations – have relied on fossil fuels such as oil or coal. These systems, while once standard, are increasingly incompatible with the sector’s sustainability ambitions and the UK’s net zero targets.

The food and drink sector is among the top five industrial energy consumers in the UK. Within this, breweries contribute significantly – not only due to their energy use, but also because of the emissions associated with thermal processes. While larger breweries may have the capital to invest in solar arrays or green hydrogen pilots, smaller operations often face financial and logistical barriers to adopting such technologies.

Although renewables are gaining traction, they come with limitations including high upfront costs, infrastructure requirements and intermittency. This creates a need for transitional solutions that can deliver immediate impact without requiring a complete overhaul of existing systems. Liquified petroleum gas (LPG) is emerging as a practical solution for breweries navigating the shift toward lower-carbon operations. It offers a reliable, flexible energy source that can be deployed quickly and efficiently, without extensive infrastructure changes.

For breweries seeking to reduce their carbon footprint, while maintaining operational continuity, LPG presents a pragmatic path forward as part of a phased approach to decarbonisation. LPG is already being used in UK breweries to power steam boilers, heat exchangers and even bottling lines. Its portability and scalability make it particularly valuable for rural or off-grid operations, where access to the electricity grid or renewable infrastructure may be limited.

Unlike some renewable systems that require long lead times and planning permissions, LPG systems can be installed and operational in a shorter window.

The fuels performance in highdemand industrial environments is well established. It enables rapid heat-up times, which is particularly valuable in brewing processes that require precise temperature control. Compared to oil or solid fuels, LPG systems can reach target temperatures faster, reducing production time and increasing throughput.

LPG is also compliant with the UK’s Medium Combustion Plant Directive (MCPD), which sets strict limits on emissions of sulphur dioxide, nitrogen oxides and particulates. It not only meets current standards but also provides a margin for future tightening of environmental regulations, offering breweries a reliable way to maintain compliance while progressing towards broader decarbonisation goals.

Importantly, LPG does not represent a step away from renewables – it complements them. For breweries that are not yet ready to fully electrify or adopt on-site renewables, LPG offers a practical and immediate emissions reduction strategy that can evolve over time. It supports internal sustainability goals and aligns with broader industry commitments, such as those outlined by the British Beer and Pub Association (BBPA), which has called for a sector-wide shift toward low-carbon technologies.

Hybrid systems that combine LPG with solar thermal or biomass are already being explored in the UK, offering a flexible path to full decarbonisation. This layered approach allows breweries to reduce their environmental impact today while building toward a more sustainable future. Another important consideration in this transition is BioLPG – a renewable alternative to conventional LPG. BioLPG can be used as a direct drop-in replacement, requiring no changes to

existing equipment or infrastructure. It is produced from sustainable feedstocks and can be supplied on different ‘blend’ tariffs. This allows breweries to control the pace and scale of their sustainability journey – starting with as little as 10% and increasing their use of renewable fuel in line with their evolving sustainability goals. This flexibility is particularly valuable for small and medium-sized breweries that may not have the resources to invest in largescale renewable systems but still want to make meaningful progress toward net zero.

By integrating LPG and BioLPG into their energy strategies, breweries can take measurable steps toward decarbonisation without compromising on performance or reliability. As the UK brewing industry continues its journey towards net zero, the focus must remain on solutions that are both effective and achievable. LPG offers a unique combination of environmental benefit, operational reliability and deployment speed. It enables breweries to reduce emissions, improve energy efficiency and

future-proof their operations, without compromising on performance. With the right support, transitional fuels like LPG and BioLPG can help bridge the gap between today’s infrastructure and tomorrow’s ambitions, offering substantial carbon savings without the need for system overhauls. For breweries navigating the complexities of decarbonisation, LPG is proving to be a quiet but powerful ally in the pursuit of a greener pint.

Brewing a Sustainable Future: A Holistic Approach to Eco-Friendly Beer Production - First Key Consulting

www.gov.uk/government/collections/theuks-modern-industrial-strategy-2025

www.weforum.org/stories/2021/06/ sustainable-beer-brewing-climatechange/

www.gov.uk/government/collections/theuks-modern-industrial-strategy-2025

WHETHER IT’S MILK, BARREL-AGED, IMPERIAL, NITRO OR PASTRY; LET ALIX BLEASE AT LALLEMAND GUIDE YOU THROUGH THE STOUT BREWING PROCESS AS WE HEAD INTO SHORTER DAYS.

No one will disagree that we have had a fantastic summer, the weather has been warm, the beer has been flowing and the outdoor taprooms have been bustling. But as the days get shorter, and the taproom benches get brought inside, signifying the end of summer, it’s time to consider your recipe for this year’s big stout.

Stouts with a high ABV and high adjunct content will push your equipment and yeast to its limits, so there are some considerations you need to make before diving head first into the brew day.

Stressed yeast leads to off-flavours and extended fermentation times. If a large proportion of the grain bill is made up of adjuncts, or you are considering adding lactose, then this can lead to the creation of a wort with a lower fermentability as well as lower level of FAN (Free Amino Nitrogen). Loading up your mash tun with a heavy dose of roasted malts can also make your beer harsh and unbalanced. Choosing a base malt which brings a nice, toasted flavour, but with plenty of fermentable extract such as Maris, Vienna or Munich is ideal. Layering some crystal malts to add sweetness and body, will help balance out any bitterness. Including some oats, wheat or dextrin will help enhance mouthfeel. If your mash tun is already creaking under the weight of a massive grain bill, then try adding 50-60g/hl of ISYEnhance into the whirlpool or at the end of the boil to achieve a similar effect of increasing the mouthfeel and body in the final beer without any additional kg of grain.

Water chemistry is always important in brewing and stouts are no different. A ratio of 1:3 sulphate:chloride is a good target to aim for in stouts and darker beers. These increased chloride levels enhance smoothness, malt flavour, and sweetness. If you are concerned about

the acidity of the roasted grains you have added, then you could consider using bicarbonate as a buffer.

Aiming to get into that higher duty bracket with over 8.5% ABV? Then your yeast choice can make or break it. There are three fermentable sugars in wort; glucose, maltose and maltotriose. Not all yeasts ferment all sugars. Windsor for example is maltotriose-negative, and LoNa only ferments glucose. Even between the maltotriose positive yeasts there is still variation in the affinity of the strain to metabolise maltotriose.

Opting for a strain with high maltotriose utilisation such as LalBrew Nottingham or LalBrew Verdant will mean that you can achieve the higher abv’s with less bother. Make sure that you are pitching plenty of yeast (maybe even more than the pitching rate on the TDS) to handle the higher gravity, there needs to be plenty of yeast cells to create all that alcohol!

In addition to selecting the correct yeast strain for the job you need to support it as well. Oxygen and nutrients are key here. For very high gravity worts oxygenating the wort on transfer and again on day 1 helps yeast replicate, meaning plenty of cells for fermentation. If there is not enough biomass then you could end up with your fermentation stalling or the production of off-flavours.

Stalling and off-flavours can also be avoided with the correct yeast nutrition. Adjunct heavy grain bills means that there is less FAN and zinc available to the yeast. Zinc is an essential trace element that is typically taken up rapidly by yeast early in fermentation. It contributes to protein synthesis and yeast growth, protects enzymes, stabilizes the protein and membrane systems, and

accelerates maltose and maltotriose uptake, which in turn can provide faster fermentations, and better flocculation and attenuation. YeastLife Extra provides all-around nutrition, including zinc and FAN, to ensure healthy yeast cells at each generation, minimising off-flavours and speeding up fermentation. For really imperial stouts, consider adding Servomyces alongside Yeastlife Extra. You could even add a smaller dose of nutrient mid-fermentation to help out the next generation of yeast.

As the yeast make their way through the sugars there is going to be a longer fermentation and more generations of yeast produced. This will lead to a higher proportion of dead yeast accumulating in the bottom of your fermentation vessel.

Knock off a small volume of yeast from the bottom of the fermenter every day to prevent autolysis flavours and keep yeast healthy.

To avoid higher alcohol flavours in the final beer it is recommended that you

ferment at a steady rate between 18-20 degrees. If you need to reduce tank residency time, then adding ALDC cuts maturation time by avoiding diacetyl production. As the yeast will have worked very hard during fermentation to create this beautiful stout, avoid reusing yeast from this batch as it’s probably pretty worn out already.

So as the nights draw in and roasted grains make the first runnings darker, remember: if you’re going to spend the season indoors, you might as well do it with a stout worth sipping.

Alix Blease is a Technical Sales Representative for Lallemand Brewing in the UK. She has a strong background in brewing and a flair for innovation. And throughout her career, she has crafted an extensive range of exceptional beers, showcasing her versatility and dedication to pushing boundaries.

Stouts with a high ABV and high adjunct content will push your equipment and yeast to its limits, so there are some considerations you need to make before diving into the brew day,” Alix Blease, Lallemand

Our class-leading range of fuel-fired, electrically-powered and hybrid steam boilers and portfolio of aftercare solutions can help with your decarbonisation strategies and put your brewery on the Road to Net Zero.

As a complete solutions provider, Fulton can provide your processing facility with:

· fuel-fired, electric and hybrid steam boilers

· off-grid and point-of-use solutions

· ancillary plant / engineered systems

· steam surveys

· project management

· water treatment contracts

· accredited / certified training

· installation / commissioning / upgrades

· repair / service / maintenance programmes

For further information scan the QR code, visit www.fulton.co.uk, email sales@fulton.co.uk or call the office on +44 (0)117 972 3322.

Natural stabilisation aids for a

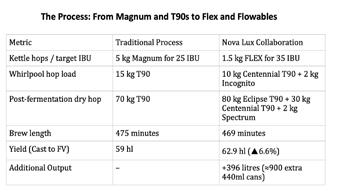

WHEN IT CAME TO BREWING A NEW WEST COAST IPA, ESTONIA’S PÕHJALA UTILISED A WEALTH OF HOP PRODUCTS INSTEAD OF TRADITIONAL T90 HOP PELLETS FROM BARTHHAAS. THE RESULTS INCLUDE A BOOST IN YIELD, REDUCED BREWHOUSE WASTE AS WELL AS THE MAXIMISATION OF BOTH TANK AND PROCESS CAPACITY.

Founded in 2011 in Tallinn, Põhjala Brewery is one of the most respected craft breweries in Northern Europe. Known for bold, experimental recipes and technical precision, Põhjala’s approach combines Baltic tradition with international flair. From decadent barrel-aged porters to highly aromatic IPAs, the brewery values innovation just as much as it does consistency.

The collaborative brew, named Nova Lux, was designed as a modern West Coast IPA, a style that calls for a clean, assertive bitterness and a bright, aromatic hop profile. But rather than simply increasing dry hop loads or sticking with conventional hop formats, the objective was to enhance aroma and bitterness while improving brewhouse efficiency.

To accomplish this, the Põhjala team replaced traditional T90 hop pellets

with a suite of BarthHaas advanced hop products including Flex for kettle bittering, Incognito in the whirlpool, Spectrum for post-fermentation dry hopping and HopAid Antifoam for increased tank utilization.

Despite a higher total hop load in Nova Lux, the use of Flex and other flowables drastically improved brewhouse performance. Martin Vahtra, Põhjala’s head brewer, explains: “The bitterness that Flex provided was incredibly clean, and the beer didn’t have the green bite one might usually associate with these dry-hopping levels.”

By reducing vegetal matter, Põhjala’s centrifuge runs were faster and required less downtime. HopAid Antifoam also allowed the team to exceed tank volume by 15%, pushing 115 hl into tanks designed for 100 hl, a significant boost in production without extending brew days or labour hours.

A highlight of the recipe was the inclusion of Eclipse, a proprietary variety from Hop Products Australia (HPA), a member of the BarthHaas group. Eclipse is known for its bold sweet mandarin character, light pine, and bright citrus.

Used both as T90 and in Spectrum form, it contributed depth and complexity without haze instability or harshness.

“The hop character came off as very expressive… white grapefruit, pine, tangerine, pomelo, just an overall sweet citrus character,” adds Vahtra.

What started as a one-off experiment has now become part of Põhjala’s regular brewing practice. The results were clear enough to spark a permanent change.

“We’ve now started using Flex for all of our bittering additions across the board, for lagers, IPAs, barrel-aged beers… not just for yield gains, but also for the clean bitterness it brings,” he concludes.

For brewers facing rising raw material costs, tighter margins, and sustainability pressures, adopting liquid hop extracts and other advanced hop formats isn’t just an upgrade, it’s a necessity.

The Põhjala collaboration illustrates how brewers can use BarthHaas technology to boost yield and profitability, reduce brewhouse waste and labour, maintain clarity and quality while also maximising tank and process capacity.

Below: How traditional process compares with the recent Nova Lux collaboration

WITH THE YEAR DRAWING TO A CLOSE, HERE ARE SOME MALT VARIETIES LIKELY TO ENTER THE MARKET AS WE HEAD INTO 2026 AND BEYOND.

Earlier this summer the Malting Barley Committee completed the Spring 2025 round of meetings to evaluate the potential of new malting barley varieties. And in this guide, the MBC approved malting barley list for 2026 harvest gives brewers insight and also helps growers of malting barley identify varieties most likely to meet the needs of the market in the year ahead.

Here are some changes to the MBC approved list. Diviner stays at Provisional Approval 2 for malt distilling use. LG Aquarius and Bounty were moved to Provisional Approval 2 for brewing use. Belter and Olsen were moved to Provisional Approval 2 for Brewing and Malt Distilling use. Firecracker, Ptarmigan, KWS Enduris and SY Arrow were moved to Provisional Approval 1 for Brewing and Malt Distilling use.

Elsewhere in its update, SY Signet was removed from the Approved List for Brewing use – withdrawn by breeder while Electrum was removed from the Approved List for Brewing use. Flagon (Syngenta) continues to hold its’ market share, retaining 11% of the total UK winter malting barley market in 2024. It has high resistance to brown rust but is susceptible to net blotch. Craft (Syngenta) secured 48% of the UK winter malting barley purchased in 2024. This variety has given consistent treated

yields throughout the UK. It has high resistance to brown rust and is resistant to the common strains of barley mosaic viruses.

Buccaneer (Saaten Union) is a newly approved for 2025 crop, for brewing. Buccaneer has shown its best relative performance in the East region and on heavier soils. It shows no major weaknesses in disease resistance and has given high yields in untreated UK trials. It has high resistance to brown rust and is resistant to the common strains of barley mosaic viruses. SY Vessel (Syngenta) approved by the MBC as Special Use for malt distilling, for 2025 crop. Growers were advised to speak to their merchants about end markets.

Laureate (Syngenta) continues to dominate the UK spring barley market, with 63% market share in 2024. It has given high treated yields in the West region. It has high resistance to mildew, rhynchosporium and net blotch and has given high yields in untreated UK trials. Moderate resistance to brackling.

RGT Planet (RAGT Seeds) continues to hold its share of the spring barley market, at around 11% in 2024. Has high resistance to mildew but is susceptible to brown rust. A relatively stiffstrawed variety with moderate resistance to brackling. LG Diablo (Limagrain) continues to hold its share of the UK spring barley market at around 10% in 2024. Has given its best relative performance in the East and North regions. High resistance to mildew but is susceptible to brown rust. A late maturing and relatively stiff-strawed variety with moderate resistance to brackling.

Skyway (Agrii) is a newly-approved for brewing in 2024, Skway has given high treated yields in the West region.

Has high resistance to mildew and rhynchosporium but is susceptible to brown rust. A relatively stiff-strawed variety with moderate resistance to brackling.

SY Tennyson (Syngenta) is fully-approved by the MBC for brewing and malt distilling for 2025 crop, SY Tennyson has given high treated yields in the East region. High resistance to mildew but susceptible to brown rust. A late maturing and relatively stiff-strawed variety with moderate resistance to brackling.

Other profiles of note LG Aquarius (Limagrain) which is under test by the MBC for brewing, with completion due spring 2026. LG Aquarius has given high treated yields in the West region and has very high treated yield potential in the East region. High resistance to mildew but susceptible to brown rust. A stiffstrawed variety with moderate resistance to brackling.

Firecracker (Agrii) is under test by the MBC for brewing and malt distilling, earliest completion due spring 2026. Firecracker has given high treated yields in both the East & North regions and has very high treated yield potential in the West region. High resistance to mildew and net blotch and has given high yields in untreated UK trials. A relatively stiffstrawed variety with moderate resistance to brackling. While Ptarmigan (Agrii) is also under test by the MBC for brewing and malt distilling, earliest completion due spring 2026. Ptarmigan has a high yield potential in both the West & North regions. High resistance to mildew and net blotch.

The Maltsters’ Association of Great Britain formed in 1827. Its membership still represents more than 98% of the UK malting industry, buying around 2 million tonnes of choice UK malting barley, to make about 1.6 million tonnes of malt.

+44 (0) 1733 834264

+44 (0) 1733 834264

www.gravity-systems.co.uk

www.gravity-systems.co.uk

Trading Partners with PMG

Trading Partners with PMG

+44 (0) 1733 667052

+44 (0) 1733 667052

martin@premiummachinerygroup.co.uk

martin@premiummachinerygroup.co.uk

www.premiummachinerygroup.com/contact-pmg-uk

www.premiummachinerygroup.com/contact-pmg-uk

Over the next 10 years the beer market in the UK is expected to experience a Compound annual growth rate (CAGR) increase of 0.1% in volume to 4.1 billion litres and a 3.9% increase in value to $8bn (£5.9bn), according to a new report.

The figures, which form part of United Kingdom - Beer - Market Analysis, Forecast, Size, Trends And Insights from IndexBox, said that between 2024 and 2035, there will be an upward consumption trend in the UK over the next decade.

In 2024, approx. 4bn litres of beer were consumed in the UK; reducing by -4.7% compared with the year before. Overall, consumption showed a relatively flat trend pattern. Over the period under the report review, consumption hit record highs at 4.bn litres in 2016; however, from 2017 to 2024, consumption stood at a somewhat lower figure.

The revenue of the beer market in the UK reduced modestly to £3.9bn in 2024, falling by -4.6% against the previous year. This figure reflects the total revenues of producers and importers (excluding logistics costs, retail marketing costs, and retailers’ margins, which will be included in the final consumer price). According to the new report, over the period under review, consumption, however, showed

a relatively flat trend pattern. As a result, consumption attained the peak level of £4.9bn. From 2023 to 2024, the growth of the market remained at a lower figure.

In terms of production in 2024, approx 3.8bn litres of beer were produced in the UK; stabilizing at the previous year’s figure. Over the period under review, production saw a mild descent. The pace of growth was the most pronounced in 2021 with an increase of 19% against the previous year. Beer production peaked at 4.4bn litres in 2015; however, from 2016 to 2024, production remained at a lower figure.

In value terms, beer production fell modestly to £3.9bn in 2024 estimated in export price. The report adds that in general, production, however, showed a relatively flat trend pattern. The most prominent rate of growth was recorded in 2022 with an increase of 32% against the previous year. As a result, production reached the peak level of £4.9bn. From 2023 to 2024, production growth failed to regain momentum, they said.

On the import front, the UK recorded a decline in irs overseas purchases of beer, which decreased by -16% to 684m litres in 2024. In general, the report outlined, imports recorded a noticeable decrease. The pace of growth was the most pronounced in 2016 with an 18% increase. As a result, imports reached the peak of 1.1bn litres. From 2017 to 2024, the growth of imports failed to regain momentum. In value terms, beer imports declined slightly to £424m in 2024. Overall, imports showed a slight downturn. The most prominent rate of growth was recorded in 2016 with an increase of 18%. Over the period under review in the report, imports reached the maximum at £538m in 2018; however, from the period of 2019 to 2024, imports stood at a somewhat lower figure.

When we focus on overseas shipments of beer, in 2024 these increased by 11% to 436M litres, rising for the second year in a row after three years of decline. Over the period under review in United Kingdom - Beer - Market Analysis, Forecast, Size, Trends And Insights exports, however, recorded a noticeable contraction. The pace of growth was the most pronounced in 2023 with an increase of 28%.

The exports peaked at 658M litres in 2013; however, from 2014 to 2024, the exports stood at a somewhat lower figure. In value terms, beer exports expanded notably to £455m in 2024. In general, exports, however, recorded a pronounced setback. The most prominent rate of growth was recorded in 2021 with an increase of 7.5% against the previous year. The exports peaked at £728m in 2013; however, from 2014 to 2024, the exports stood at a somewhat lower figure.

Looking at exports by country, Ireland (124M litres), the United States (93M litres) and France (32M litres) were the main destinations of beer leaving the UK, accounting for a combined 57% share of total exports.

The Netherlands, Spain, China, Canada, Italy, South Korea, Germany and Belgium lagged somewhat behind, together comprising a further 28%, the report demonstrated. From 2013 to 2024, the most notable rate of growth in terms of shipments, amongst the main countries of destination, was attained by China with a CAGR of +11.7%, while the other leaders experienced more modest paces of growth. When we look at value terms, the largest markets for beer exported from the UK were the United States (£118m), Ireland (£92m) and France (£44m), with a combined 54% share of total exports.

EDINBURGH-BASED CLOSET BREWING PLACES AN EMPHASIS ON QUALITY VEGAN BEERS, THE QUEER COMMUNITY AND KEEPING A LOCALMINDED, OUTGOING APPROACH AT THE CENTRE OF THEIR MISSION. THE BREWERY, FOUNDED BY LUCY STEVENS AND LIZZIE STEVENS USE UNIQUE FLAVOURS AND INNOVATIVE TECHNIQUES TO CREATE BEERS THAT ARE, AT THEIR HEART, A LOT OF FUN. HERE, COFOUNDER LUCY HELPS CHART THEIR JOURNEY TO-DATE.

Seven years ago, I was brewing my very first beers in a large plastic bucket in the cupboard of my first flat in Leith.

It was this cupboard that would later provide my wife and I with the name of our brewery; Closet Brewing.

Fast-forward to 2023, through Covid, countless batches of good (and less good) home-brewed beer, and my own ‘coming out’ journey, I would finally leave my cushy nine-to-five to embark on the reckless (and occasionally misguided) journey of making “Brewer” my full time job. The last two years have been a rollercoaster to say the least. Growing the fledgling brewery has often involved late nights and long weekends, and we’re not quite out of the woods yet, but we’re finally starting to carve out our space in the beer scene.

Closet Brewing started, literally, out of our house in July 2022. After a good four years of homebrewing and a lot of googling about the requirements for starting a brewery in your home, and then several forms, and a surprisingly straight-forward visit from the council we were brewing. Those first few batches were just 30L each, canned and labelled by hand, and sold to local independent bottle shops.

The learning curve was steep, and I will be eternally grateful to the bottle shops and pubs who supported us from the beginning, despite the various challenges we went through as such a small business. Almost to my amazement, the beer was good enough to generate far more demand than we could manage on this small kit and six months later we scaled up to a ‘massive’ 70L kit, taking up most of our kitchen, conservatory and spare bedroom.

It soon became clear that increasing production again within the confines of

our house was not feasible, lest we end up sleeping on sacks of malt. After a lot of debate about contract brewing, and visiting several facilities across the country, we brewed our first 16HL batch with our friends at Otherworld just outside Edinburgh. Though I wanted to avoid sounding overly sentimental when I wrote this, it is absolutely necessary to say that Closet Brewing wouldn’t have survived without their help getting our beer made and teaching me all the brewing tips and tricks I use today.

Contract brewing allowed us to build our fanbase without the overheads of capital and rent and test the waters for our growing brand, but it’s not without its disadvantages; the margins were much slimmer, we couldn’t build a significant range with the bigger batch sizes required, and we were heavily dependent on brewing in periods of lower demand. My wife and the other half of Closet Brewing, Lizzie, will tell anyone who listens about the day the first contract brews arrived and, having not yet secured warehouse space, we stacked them in our living room, entirely blocking out the windows. However, we didn’t have the funding available to lease and fit out a brewery, much less purchase a full brewhouse and tanks, so contract

Real change in the industry needs to come from more than just us,” Lucy Stevens Closet Brewing

brewing allowed us to start growing our audience at a scale we just couldn’t achieve on our own. Thus begins the latest chapter in the story, and our current set up; cuckoo brewing with our own permanent tanks at Stenroth Workers Cooperative.

We’re still tiny in the scale of things, and have kept our DIY mentality at the heart of what we do (although applying this to the brewery circuitry was perhaps not the best idea). Sharing the space with two other breweries allows us to make the most of cooperation, splitting costs, sharing equipment, and helping each other out to make really good beer.

This shift away from the traditional business model of prioritising profitability has been refreshing; our brewery has never been driven by financial gain.

As queer brewery owners, in what is still quite a straight, cisgender, male dominated industry, we wanted to create a place of our own to operate outside of the bounds normally enforced by capitalist enterprise.

To be able to create things just so they exist, because we want them to exist, regardless of profitability, is a freeing approach to running a business..

Our goals are simply to make good, interesting, and varied beer; I believe there is a beer out there for everyone, and we strive to create a space where everyone can enjoy a nice pint. Outside of the beer itself, we want to use our brewery as a platform to help other

queer individuals, and small businesses; through donating beer and profits to LGBT causes, collaborating with queer artists to design labels, and lending a hand at local community events.

Creating spaces that welcome queer people and women is at the core of our mission, but without our own taproom this isn’t always as straightforward as we’d like. We’ve had to find ways to foster this inclusive environment in pre-existing spaces; organising events where we are physically present and using our visibility to show people that they belong in these spaces.

We’re always looking for ways to connect in non-traditional spaces too; last year we held a pop-up ‘tiny taproom’ out of an old police box on Leith Walk, and used our digital platform to fundraise for the Good Law Project with an impromptu webstore. Having our own taproom and community space is still very much our end goal, but until then we’ll do everything we can to create places where anyone can feel safe and welcomed.

Real change in the industry needs to come from more than just us. While there are many people doing inspiring work to push beer into a better place, (Queer Brewing and Women in Beer just to name a couple) these are still small steps in a massive industry that is often resistant to change. Being an inclusive venue is about more than just putting

up a pride flag every June and calling it a day, queer businesses continue to exist all year round and allyship involves supporting them and standing up for members of the community even when it’s inconvenient to do so.

This includes being deliberate about who you do business with, and making sure that those breweries or bars are also safe for women and queer people. Our approach certainly isn’t all sunshine and rainbows though. It definitely comes with a healthy chunk of sacrifice.

Days off don’t exist - even when we aren’t physically brewing we are planning events, running social media, dropping off deliveries, fulfilling orders, discussing brews, troubleshooting issues together and realising we still haven’t ordered those damn business cards. Holidays are planned with military-like precision around the brewery calendar, and every room in our house has, at one point or another, housed equipment, cans, kegs, ingredients and labels.

But, in spite of this, our approach has allowed us to create an entity entirely our own, that reflects mine and Lizzie’s ideals, personalities and passions in every facet. By rejecting the idea that rapid growth and huge injections of capital are the only way to build a brewery, we’ve managed to carve out a little spot in this busy, fluctuating industry just for us.

Rembrandt Labels, part of the Belgian Graphius Group (also active in the UK with Park Communications and Geoff Neal), is now bringing its wet-glue label expertise to the UK market. With their graphic know-how and recent investments in label printing and die-cutting capacity, Rembrandt Labels is ready to meet all your label needs. Alu paper, uncoated, matt-coated, extended colour gamut, gloss and matt effects… Just ask Rembrandt Labels!

Hemelstraat 2, 1651 Beersel - +32 (0)2 300 76 44 - labels@rembrandt.be www.rembrandt.be

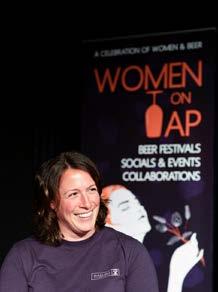

In his book Tribes, Seth Godin lays out his belief that everyone has the potential to start a movement - to bring together like-minded people and achieve something meaningful.

Of course, what that ‘something’ is will vary from tribe to tribe.

In this piece, I want to focus on building a better beer industry: specifically, by shaking off its historical misogynistic baggage and exclusionary male dominance, and moving toward a more inclusive future.

This is something I set out to drive back in 2017, when Women On Tap was born. After testing a few fun events that spotlighted and celebrated women in beer, we realised there was an opportunity - and a need - to do more. The concept quickly took on a life of its own, and people began turning to us for help, and with hope.

In 2018, I formally incorporated the business as a CIC - a Community Interest Company - and a Certified Social Enterprise. This move was a clear signal of our commitment to our socially driven mission to transform the brewing industry by dismantling gender barriers, offering education, and increasing meaningful opportunities for women. Since then, we’ve become known as pioneers of initiatives that spotlight brilliant women in the beer industry, through a programme of activism including events, campaigns, and arts commissions.

To date, we’ve delivered more than 100 events and seven festivals, alongside a range of campaigns and collaborations that celebrate women in beer, boost beer education, and push for progress in both the beer world and wider society. In other words, we’ve been busy building what you might call ‘our tribe’. In 2024, we formed an Advisory Board, bringing

together a team of experts from both within and beyond the beer industry.

Together, we explored how to build on our foundations, create meaningful impact, and drive real change.

From that process, we developed a strategic plan and a new Theory of Change model. We also took the lead on the iconic International Women’s Collaboration Brew Day (IWCBD) - the global campaign that brings together beer and International Women’s Day.

IWCBD, originally founded in 2014 by Sophie de Ronde, Burnt Mill Head Brewer, encourages women in the beer industry, homebrewers, and local communities to collaborate and create new beers in celebration of International Women’s Day (IWD). From its inception through 2023, the campaign provided a central platform to connect IWD brewing projects across the globe.

While many International Women’s Day brewing events took place in 2024, there was no unified IWCBD campaign.

Following a few conversations between myself and Sophie, Women On Tap CIC stepped in to coordinate and publicise the initiative for 2025, introducing a few small changes. I’d observed and participated in the campaign over the years, but stepping into a coordinator role gave me a whole new perspective. What struck me immediately was this: There was still a need for this campaign - its absence in 2024 was felt. And with an established profile and an engaged community, there was real potential to formalise the fundraising side and create meaningful, lasting impact.

We kept the campaign’s familiar icon but introduced a refreshed look. We commissioned a new design using Women On Tap’s signature purple and orange colour palette - a visual marker of our takeover.

Recognising the campaign’s potential to scale, we secured sponsorship that allowed us to invest in the project and bring in paid expertise in the form of freelance support from Kimberley Spivey. Huge thanks to the Society of Independent Brewers and Associates (SIBA) - our headline sponsors - as well as to Simpsons Malt. We also welcomed the Wine & Spirit Education Trust (WSET) as our Education Partner. Their supportincluding 18 free places on the globally recognised Level 1 Award in Beer for campaign participants - added a valuable formal education strand to our efforts.

I invited original founder Sophie to choose this year’s theme. She chose Unite Society, and with women’s rights being rolled back in real time across the world, this theme couldn’t feel more timely. Fast-forward to today, and what an incredible, humbling experience it’s been. This year, the campaign showcased 61 brew day projects across the EMEA and Americas regions, and more than 800 women and non binary people came together, brewed 66 beers and raised almost £27,000 for 44 women’s causes.

But beyond the numbers, the creativity and connection really stood out. Some of the beer artwork is outstanding, and the photographs from the brew days have been deeply moving - powerful images of communities coming together, sharing an experience, and boldly saying: “Here we are!”. The beer names themselves have been a masterclass in activism and storytelling, including Even If Your Voice Shakes, Wrong Sized Space Suits, Women Of A Certain Age, Shame Must Change Sides, That’s What She Said, Pirate Queen, and Here All Year.

This campaign sparks a level of innovation that’s a true credit to the brewing industry, and it’s been an honour to be part of it. The women driving this work are skilled, passionate, and relentless in their pursuit of change. I urge the wider industry to take a good look at what this rather special tribe has achieved over the last few weeks, and to ask what they can learn, take away, and action, so these efforts don’t go to waste. Naturally, we’re not done yet. We’re eager

to keep building: growing national and international engagement, raising more funds, expanding the tribe, and laying the foundations for a lasting legacy. We’re exploring exciting ideas like the introduction of IWCBD awards and a dedicated IWCBD Festival, where we can get as many of the beers brewed as part of the campaign as possible pouring on bars at a central celebration.

This could easily evolve into a yearround project. One thing is certain: the fusion of Women On Tap’s ambition with the energy of the IWCBD community is a force to be reckoned with. This goes beyond representation. Beyond networking. Beyond education. Beyond allyship. Beyond activism. We have a real chance to join forces and change the face of beer for good. I invite you to be part of that. Women On Tap CIC has launched Changemaker — a new supporter community helping to fund its continued operations and new projects.

: Claire McClean, Nicci Peet, Ryan Walsh, Turning Point Brew Co, Fern Dalton.

Thomas Fawcett & Sons Ltd is an independent, 8th generation family malting business, founded in 1809. The Company supplies high quality malt products to the brewing, distilling and food industries. It is looking to recruit a new Maltings Manager for its site in Castleford, West Yorkshire. The key responsibilities of the role are to manage and schedule all barley and raw material intake, process operations and maintain raw materials in optimum quality conditions for malting.

This is a diverse role with great opportunity for progression in a family-run, independent company. In addition to core responsibilities above, the Maltings Manager will be responsible for hiring personnel across key departments, SHEQ and engineering maintenance.

Applicants should have relevant industry experience, and apply by providing a CV/cover letter via post or email to Production Director, Brian Hickman: bhickman@fawcett-maltsters.co.uk

Thomas Fawcett & Sons Ltd, Eastfield Lane, Castleford, West Yorkshire, WF10 4LE.

The Company offers a competitive salary, options for a company car, and access to a defined contribution pension scheme.

LIKE AN IMPOSTER AND START TO DOUBT YOUR CAPABILITIES, IT CAN BE EASY TO THINK ABOUT GIVING UP ON SOMETHING BEFORE EVEN TRYING. THE ONLY TRUE FAILURE IN LIFE IS GIVING UP; AS LONG AS YOU KEEP PUSHING FORWARD, NO MATTER HOW SMALL THE STEPS

MAY BE, YOU WILL EVENTUALLY FIND

Imposter Syndrome is defined as an internal belief system of not being good enough – despite evidence to the contrary – which leads the sufferer to feel like an intellectual fraud.

Such is the influence that these selfdefined inadequacies hold over people’s confidence levels, that the result can have an adverse effect on a person’s career and overall feeling of wellbeing. An internal monologue determined to ignore intrinsic capability and proven achievement will repeatedly ask, “Who do you think you are?” or “When will they notice that I’m a fake?”

This invisible affliction manifests from a number of causes, the most common of which is self-doubt. Compared to others who appear to be higher achievers, having to ask for help from colleagues and receiving criticism are also contributing factors which, left unchecked, can lead to anxiety,

depression, and a negative impact on work life in terms of job performance and job satisfaction.

Identified by two American psychologists who were studying a group of highly successful women in the 1970s, the cognitive dissonance between indisputable achievement and perceived inadequacy has been labelled Imposter Syndrome. More recent studies have uncovered the scale of this form of anxiety within the workplace and, such is its prevalence, it can now almost be classified as ‘the norm’.

Reaching across a wide demographic, imposter syndrome affects a higher number of women than men.

Millennials appear to have greater susceptibility than other age groups due to societal pressures (including social media), and ethnic minority groups are also disproportionately more affected. This phenomenon also throws up the paradox of high achievers being some of the worst sufferers.

Particularly relevant in today’s work environment, remote workers lacking physical interaction with colleagues and therefore less likely to receive positive feedback and feel part of a team are among a growing section of society who are struggling to hold back the waves of isolation and professional insecurity. Thankfully, there are ways to fight back. The most important one being to talk about it honestly.

Diffidence can encourage the desire to learn, to prepare better and to practise harder. Which, while it may not feel as such at the time, can only be a good thing. By acknowledging fear within the framework of a positive mindset, negative feelings can be transformed into motivation in order to stretch towards new goals and competencies. “When I feel self-doubt and lack of confidence creeping in, I pause and try to identify the root cause of that. 10 times out 10, I realise that I need to spend time

researching a topic, talking to somebody who is more experienced than me on the subject, and reading as much as I can about it. Inevitably, I feel better prepared and that in turn makes me feel more confident. It’s the internal change of perspective that matters,” says Tea Colaianni, founder of Inclusion in.

To counterbalance the unhelpful but hardwired human trait known as negativity bias (a tendency to focus on the bad stuff), reflecting on successes can help push back Imposter Syndrome by reframing thoughts into positive (rather than negative) achievements. This could be in the form of a list of accomplishments, remembering job progression or favourable testimonials about past work. A mental technique used by professional athletes is projecting future success. For example, visualising a positive response to a presentation prior to making it conditions the brain for a successful outcome and instils more confidence.

Focusing on achieving rather than failing and celebrating small wins at each step towards a goal prevent our motivation levels slipping. pace their understanding of inclusive leadership and their role as leaders in making an impact. One line of thought to tackle self-doubt is to conceal it in a layer of artificial bravado and pretend to be the confident person we want everyone to think we are. However, defining self-worth by our status within an organisation put being real into the “I’m going to get found out” danger zone.

Rita Clifton CBE, author of Love Your Imposter, discourages this approach preferring to advocate honesty and authenticity. Despite her own formidable career path, she assures that insecurities affect everyone and describes Imposter Syndrome as a normal part of the human condition. “Take on your imposter self and use it as a driver to come out stronger,” she explains.

Faking it for a short period might be manageable, but keeping up the pretence day in, day out uses up a great deal of energy, much in the same way that keeping up a lie needs a very good memory! The reality is that many, many people present themselves in this way. But does that make it right? appropriately and admit to sometimes not knowing or understanding. It is also important for male colleagues to cultivate self-awareness in relation to male privilege and unconscious biases while maintaining a growth mindset. To be more influential, male allies should make their stance clear and public from the start in order for others to follow, and finally, encourage male/ female colleague interaction within the workplace including gender equality initiatives. Positive professional encounters enable greater understanding and inclusion.

Adopting a growth mindset can be hugely beneficial. This is defined as the belief that intellect and natural talent are just a starting point in personal and professional development.

In order to grow, a love of learning and having a natural curiosity to advance authentic purpose, can encourage selfdoubters to add small, incremental steps to their climb up the corporate mountain. “I still have a little impostor syndrome… It doesn’t go away, that feeling that you shouldn’t take me that seriously. I share that with you because we all have doubts in our abilities, about our power and what that power is.” Michelle Obama – former First Lady.

Inner confidence can be developed through having clarity around personal strengths and talents and from there, fully defining goals – short, medium, and long term. Self-awareness is key. Applying brand thinking to our own personal brand – about us, ourselves and identifying our authentic purpose, understanding what drives us and what we are good at provokes mental solidity aka self-confidence. This added to a relevant skill set simplifies the process of creating a coherent (and desired) direction along a career path and speaking from such a place of authenticity will come across to others.

Evolving job needs are empowering women and levelling the playing field. The new service economy doesn’t rely on physical strength but skills that come easily to women, such as determination, attention to detail and measured thinking. The female brain is naturally wired for long-term strategic vision and community building. Strong leadership involves using the power of nurture, thereby creating space for employees to grow and shine.

To build long-term, sustainable relationships, CEOs need to lead by example. And women are naturally good at this through a willingness to share their vulnerabilities and to talk openly.

“Shame always shrivels when you share it out loud,” adds Marie Forleo – American entrepreneur.

When you feel like an imposter and start to doubt your capabilities, it can be easy to think about giving up on something before even trying. The only true failure in life is giving up; as long as you keep pushing forward, no matter how small the steps may be, you will eventually find success.

T

WELCOME TO THE 2025 BREWERS CONGRESS AND BREWERS CHOICE AWARDS. HERE YOU’LL GET THE FULL LOWDOWN ON THE WEALTH OF TALENT AND BEST-IN-CLASS BUSINESSES TAKING PART IN THIS YEAR’S EVENT AS WELL AS THE BRILLIANT BEERS, BREWERS AND BREWERIES SHORTLISTED FOR THE 2025 AWARDS.

LAST MONTH, JUDGES FROM ACROSS THE BREWING SPECTRUM CONVERGED LONDON, TO DEBATE AND DISCUSS THE WEALTH OF EXCELLENT ENTRIES SUBMITTED FOR THE 2025 ITERATION OF THE BREWERS CHOICE AWARDS. HERE’S HOW THEY GOT ON.

There was a real wealth of quality and talent demonstrated across each and every category in the 2025 Brewers Choice Awards, and judges from across the beer, brewing and the hospitality spectrum recently converged on the Mikkeller Brewpub in London, to debate and discuss the wealth of excellent entries submitted and nominated. The winners of which, will be crowned in London on the evening of 30th September.

The categories up for discussion were Young Brewer of The Year, Brewer of The Year, Packaging Powerhouse, New Brewery of The Year, Brewery of The Year, New Beer of The Year, Beer of The Year, Branding of The Year, Sustainability Champion, Diversity and Inclusivity Champion and the Roger Ryman Lifetime Achievement Award.

This year’s submissions were judged by a wealth of talent that included Lotte Peplow, the craft beer ambassador in Europe for the Brewers Association, Brew Resourceful founder Chris Lewington, Stuart Anderson the founder of London’s Ghost Whale and Alex Greig, the owner of Fuggles Beer Cafe in Tunbridge Wells and Tonbridge.

Also on the panel were Mikkeller location manager Jake Milne, Liquid Sky Drinks founder Stu McKinlay, freelance beverage and hospitality consultant Sean Robertson, the regarded pub landlord and champion of the on-trade Roger Molyneux and Paul Davies, founder of the award-winning AleHunters Brewery Tours. Tim Sheahan, editor of The Brewers Journal, chaired the judging session.

Tim Sheahan, global editor of The Brewers Journal, said: “It’s the sixth year of hosting our Brewers Choice Awards and I always consider it a genuine privilege that our publication can play

its own part in helping showcase and celebrate the brilliant beers, breweries and brewers that form the fabric of this fantastic industry. As expected, the calibre of the submissions was incredibly high and it was great to see the number of entries increase year-on-year.

“I would like to thank everyone that entered and a huge well done to everyone that has made the shortlist this year. We look forward to announcing the winners, alongside the recipients of the Roger Ryman Lifetime Achievement at our 2025 Brewers Choice Awards dinner in London this September.

“Special thanks to our sponsors, judges and also to Jake Milne and the team at the Mikkeller Brewpub in London for being the perfect hosts!”

There are some incredibly talented young brewers working in the UK brewing industry. Some young brewers are running their own operations, others are cutting their teeth working at established outfits. Regardless, these brewers are making their mark on the industry and are certain to have a long, successful career in the field.

Jake Astbury | Neighbourhood Brew Co

Sean Forde | Sureshot

Tilly Gonzalez | Turk’s Head, Exeter

Harry Gwilliam | Attic Brew Co

Reece Hugill | Donzoko

Ben Lucas | Mondo Brewing Company

Sam Martyn | Fable Brewery

Fiona Mullender | Northern Monk

Andy Potter | Queer Brewing

One of the finest qualities many brewers boast is humility. So this category it was always likely to need some convincing/ persuading/forcing when it comes to ensuring these excellent brewers are

considered. We wanted to acknowledge a brewer that is truly an industry tour de force. What sets them apart from the rest? Is it the beers they create, expansion they’ve overseen or a team they’ve built. Maybe it’s all of those….

Matt Dutton | Track Brewing Co

Daniel Gambino | Anspach and Hobday

Dan Gooderham | Adnams

Dan Hocking | Bundobust

Simon Perrett | King Street Brew House

Al Wall | Burton Bridge Brewing Company

New in 2025, this accolade is designed to recognise the brilliant talents and personalities that keep everything ticking. They might not always get the spotlight but their skillsets ensure the beers brewed across the UK leave the brewery in the condition the team intended and important, reach the consumer in that optimal condition, too.

Lee Branchett | Duration Brewing

Emily Mappin | Northern Monk

Matt Wickham | Lost and Grounded