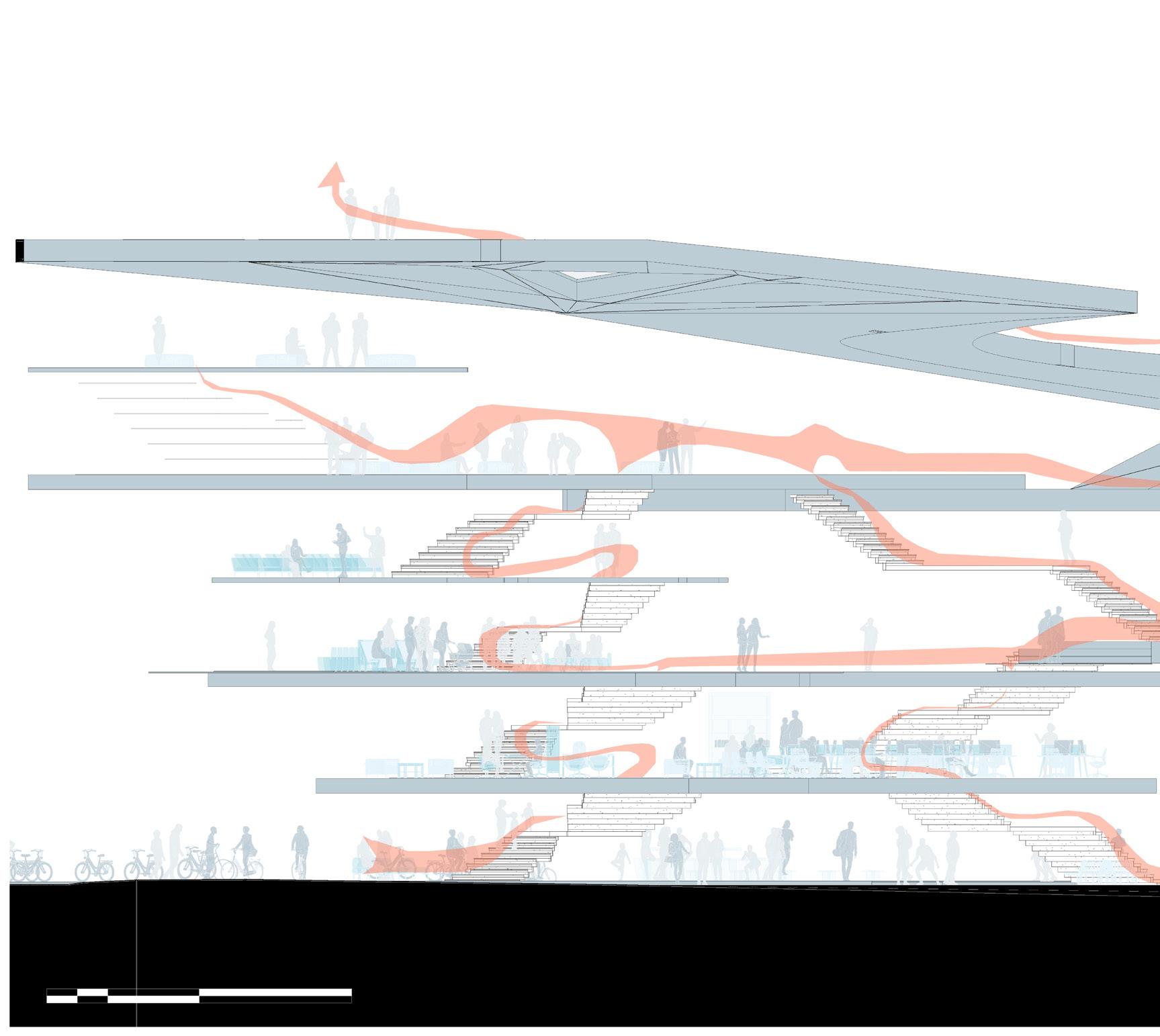

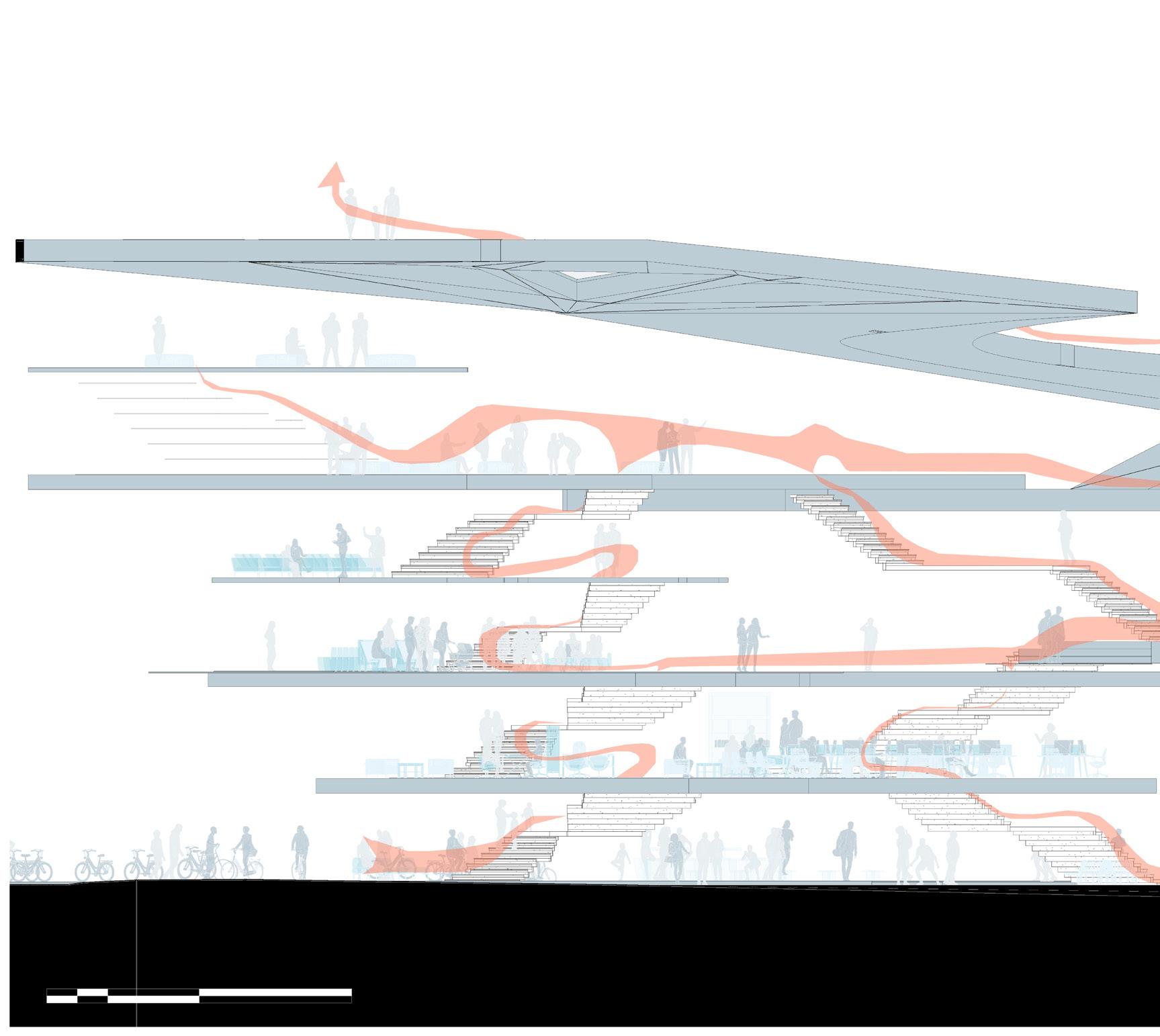

MOVEMENT

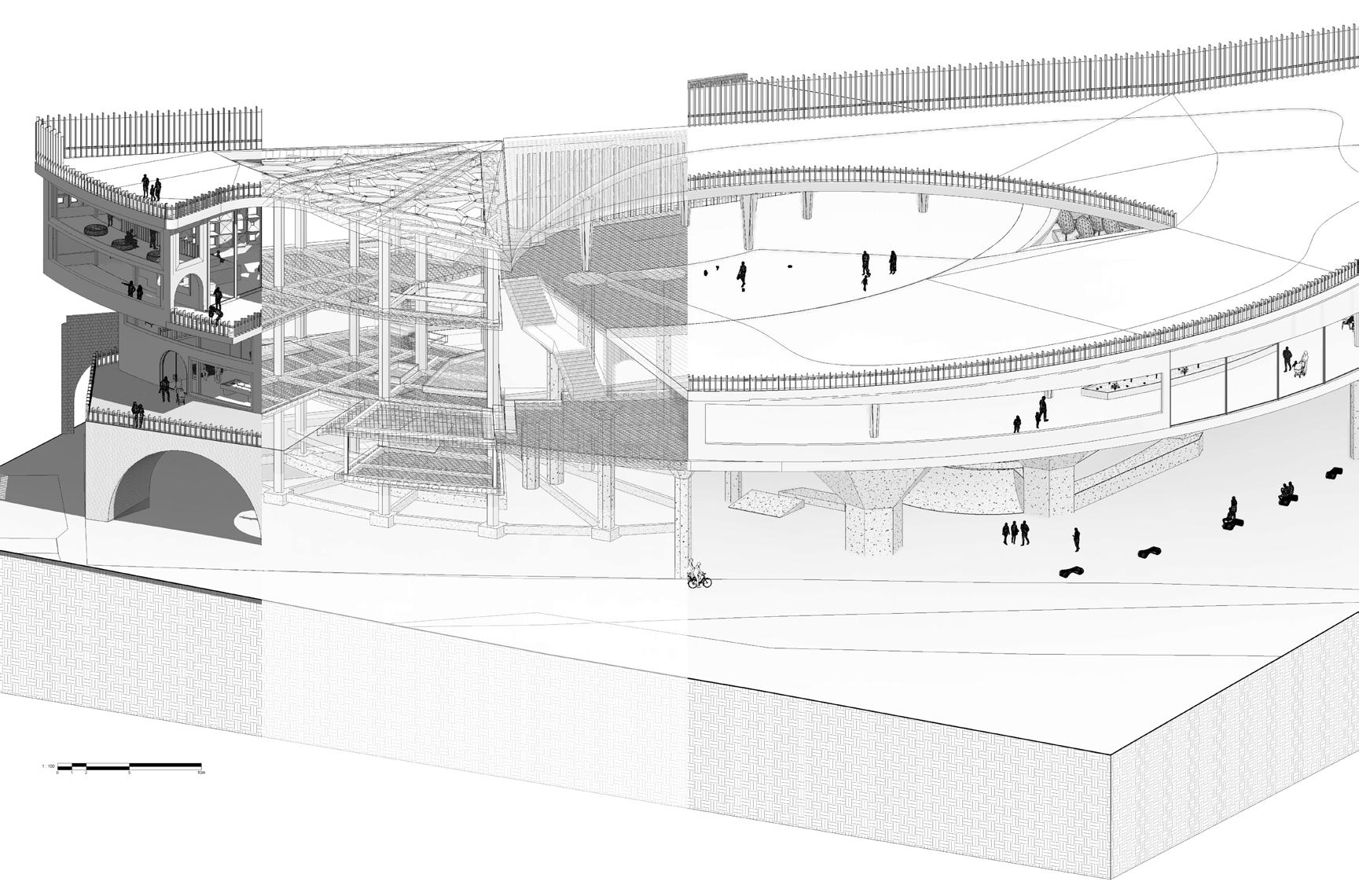

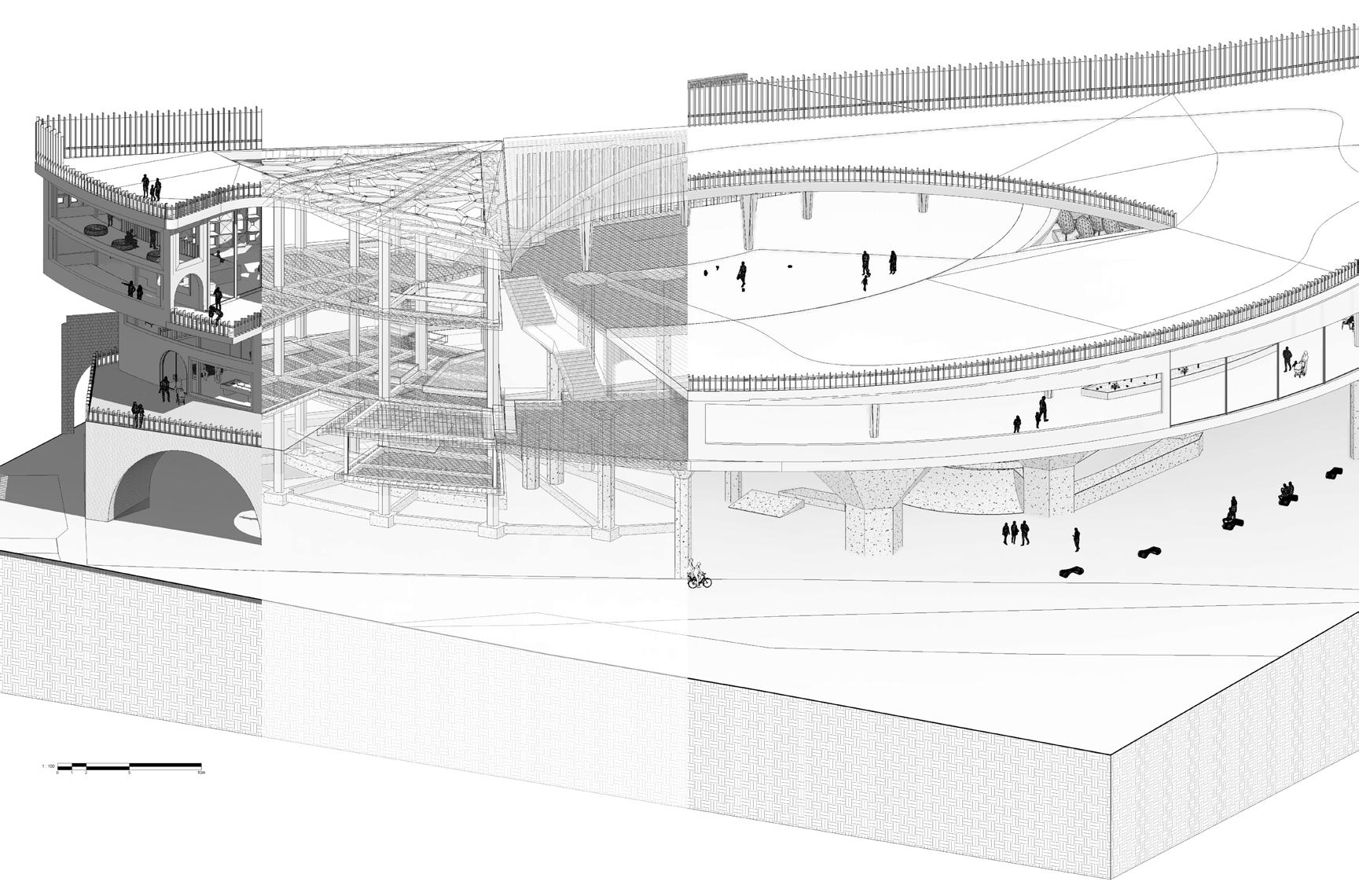

All parts of the site can be accessed by foot to ensure site cohesion with area. Care has been taken to allow ample fire exit routes in the case that a fire does break out, with stairs located both inside and outside running the height of the structure.

1:100 10m 5 2 1

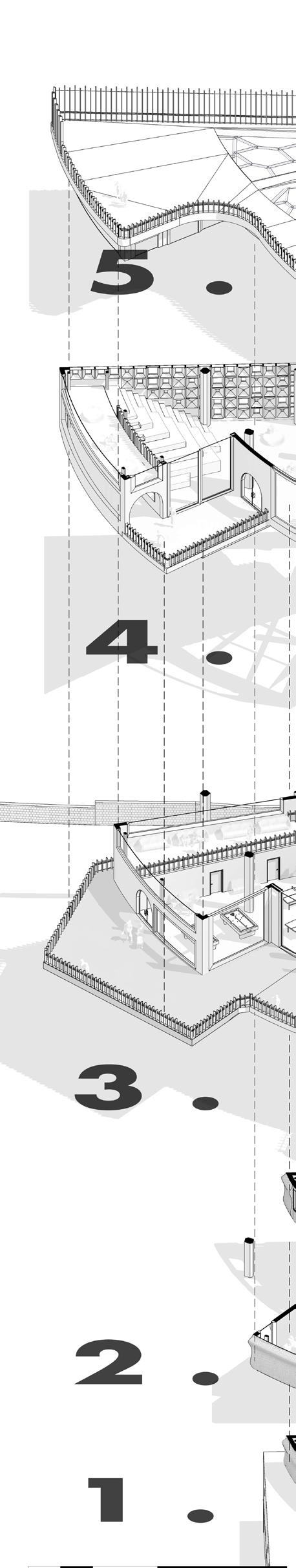

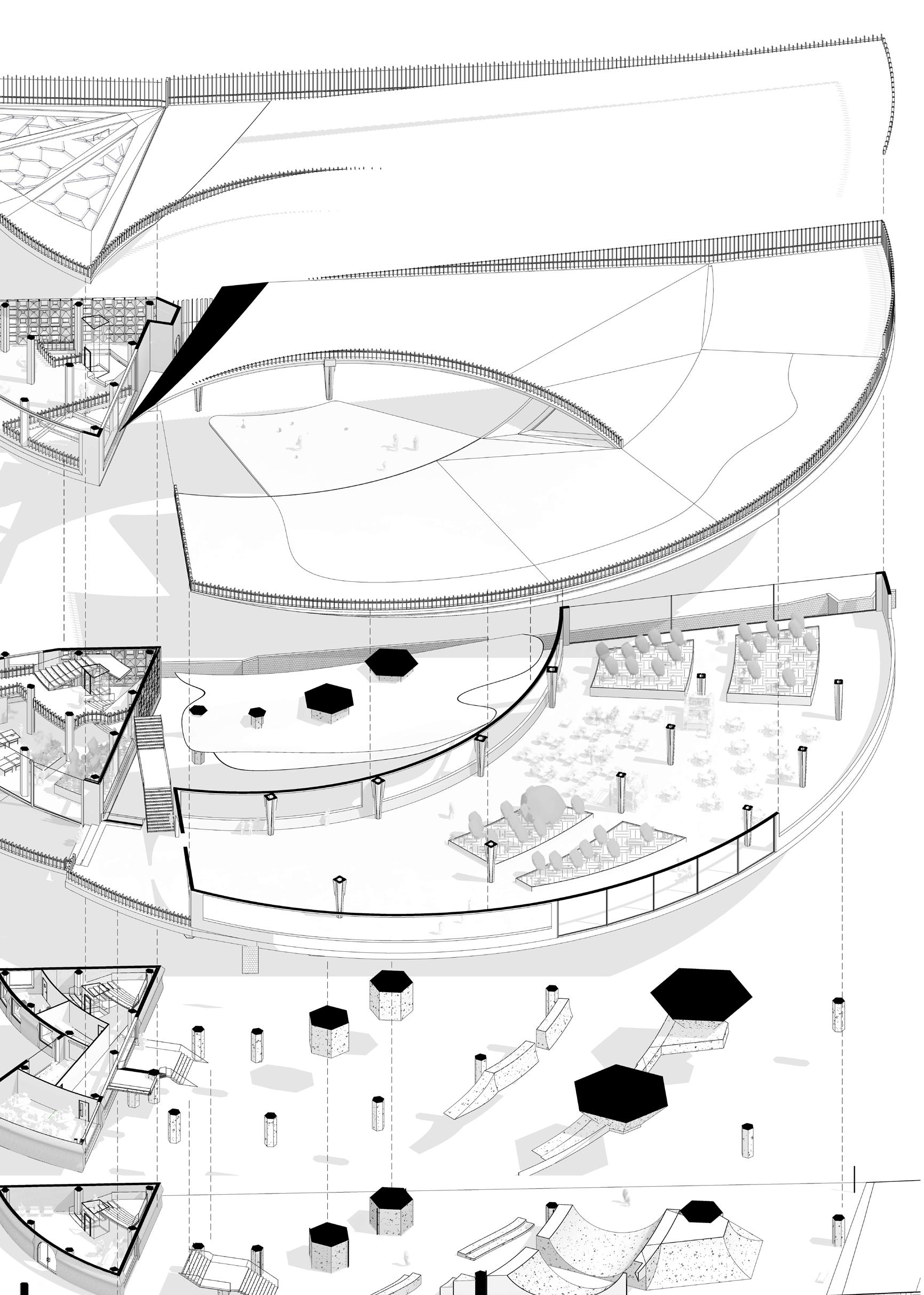

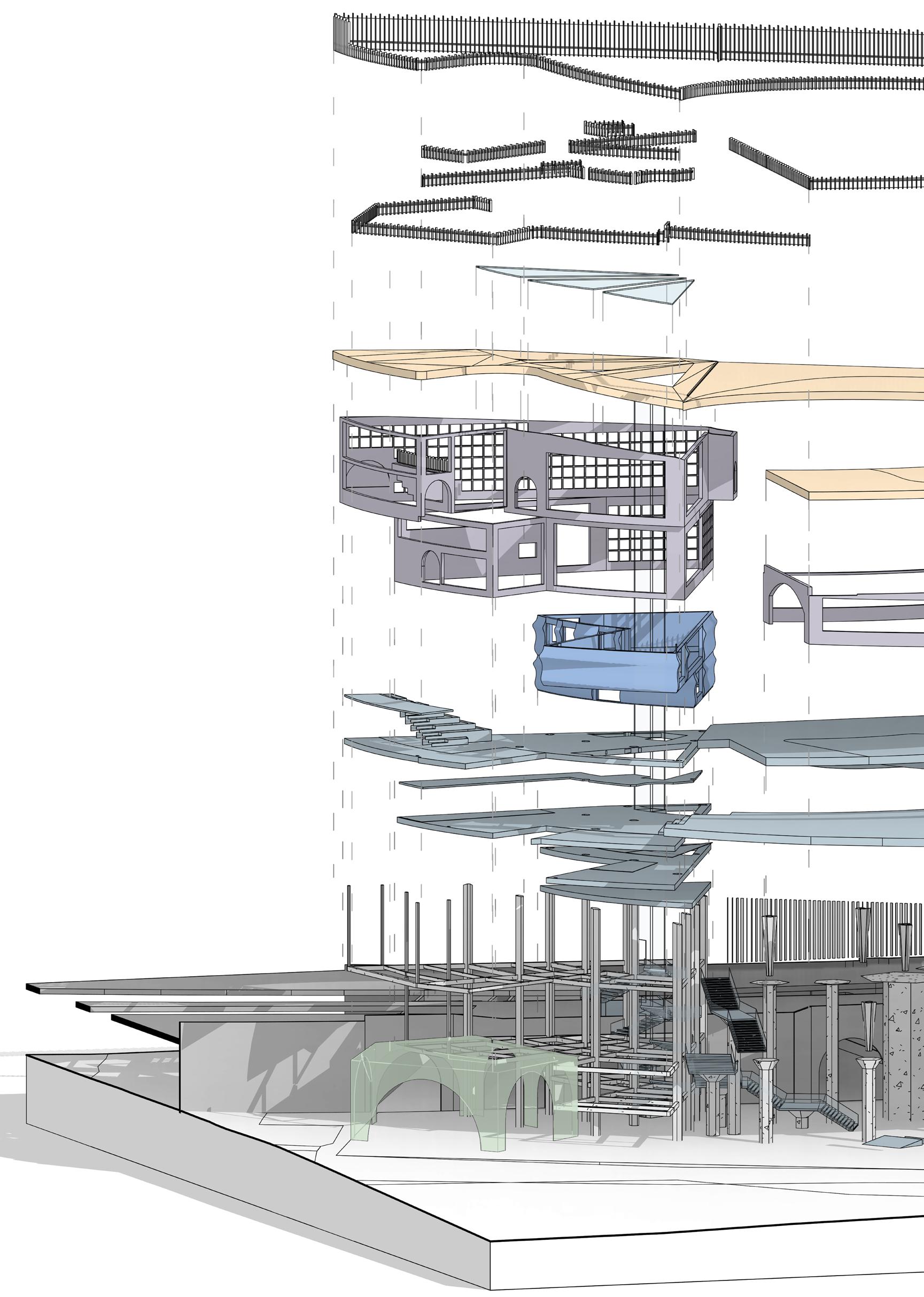

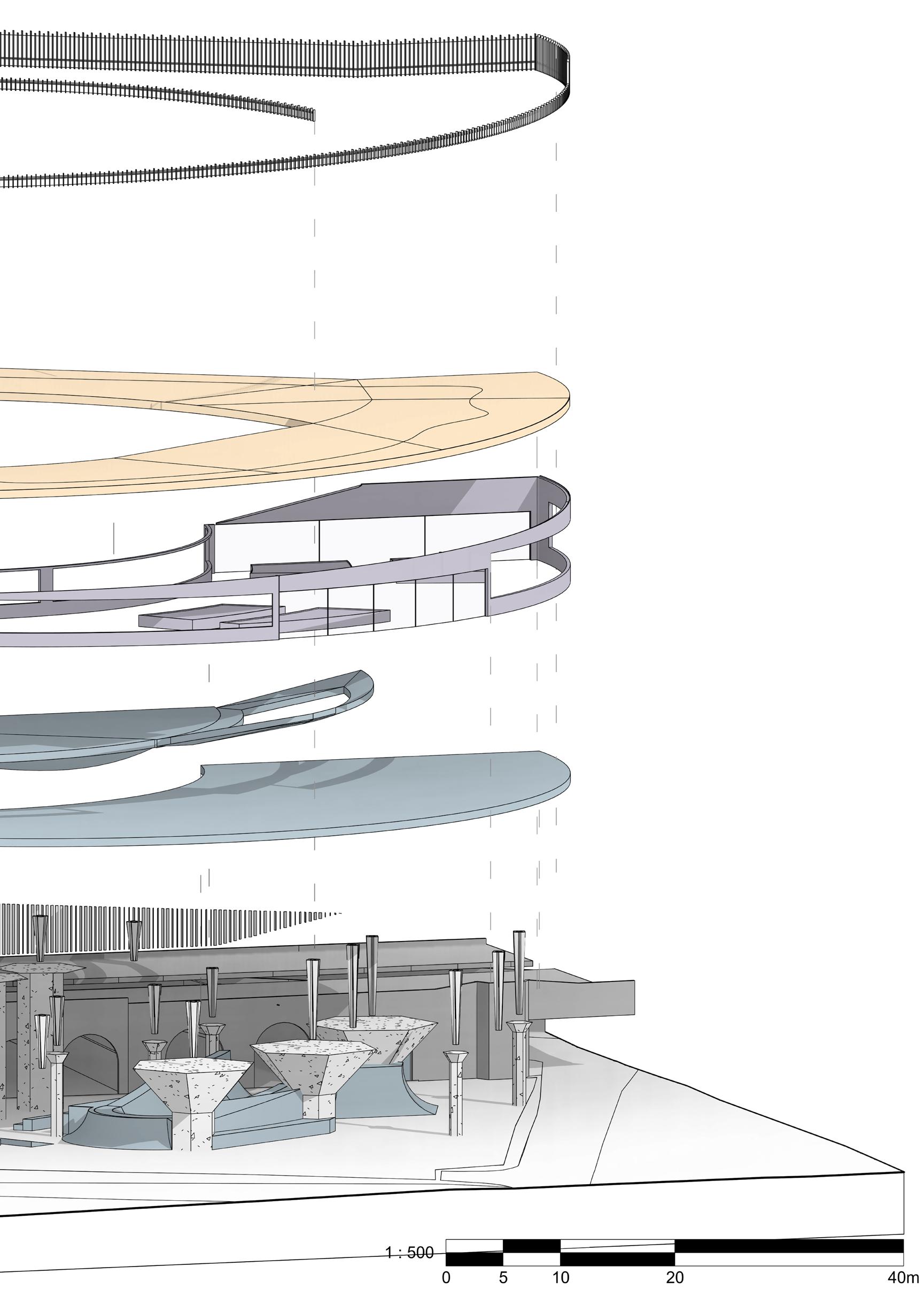

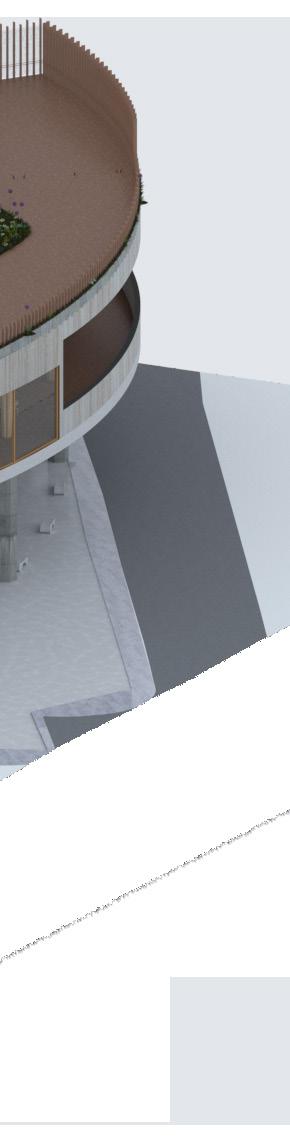

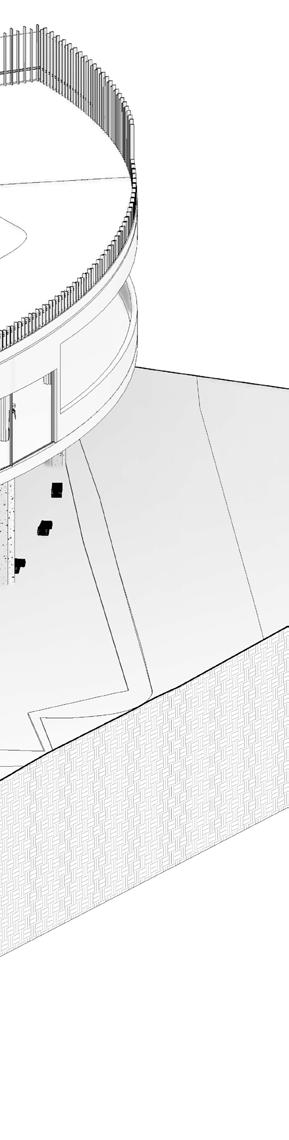

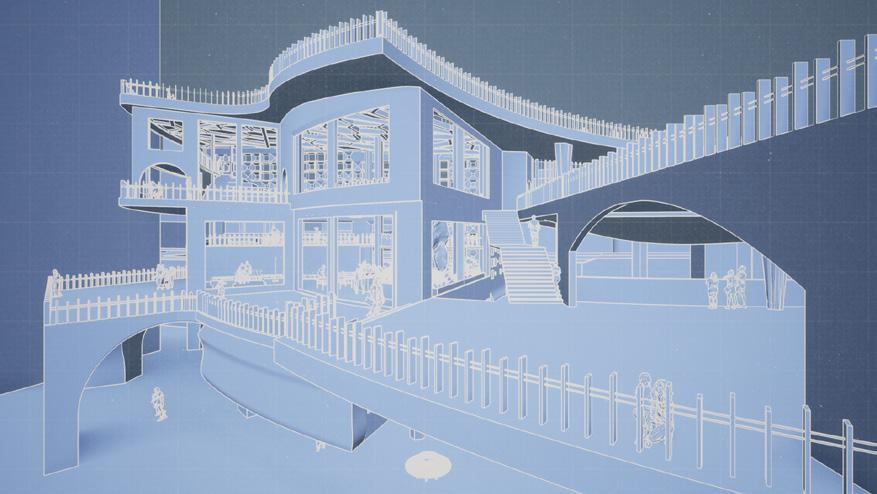

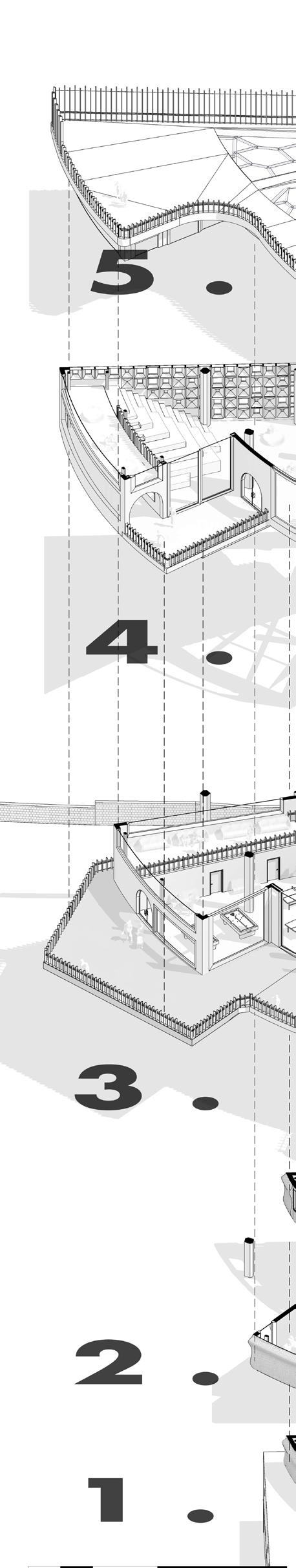

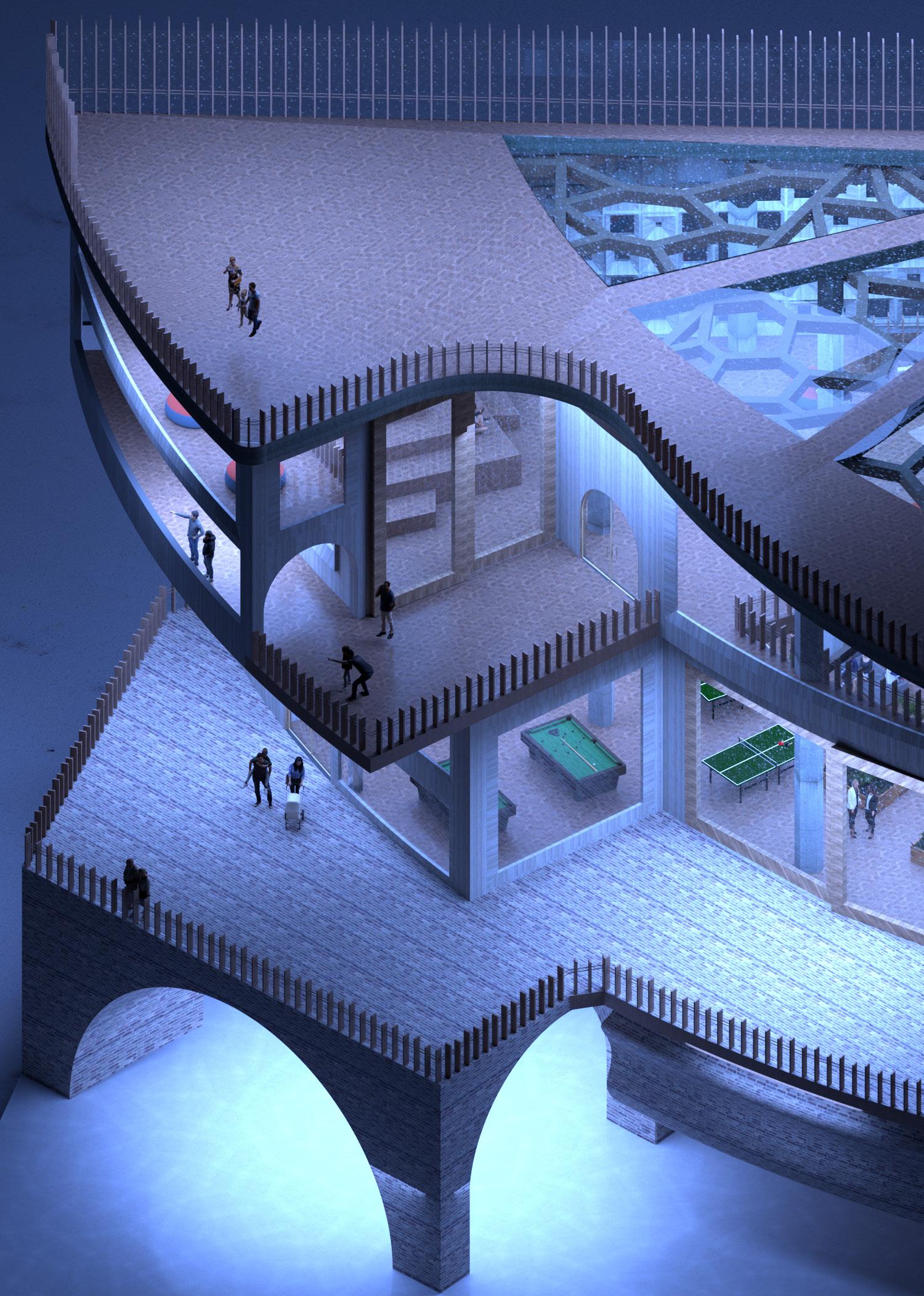

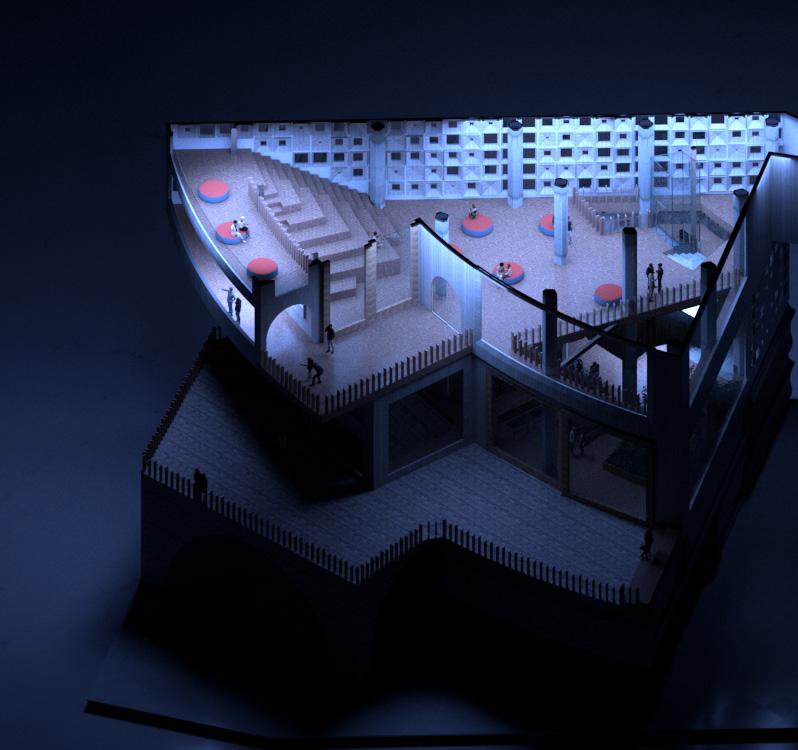

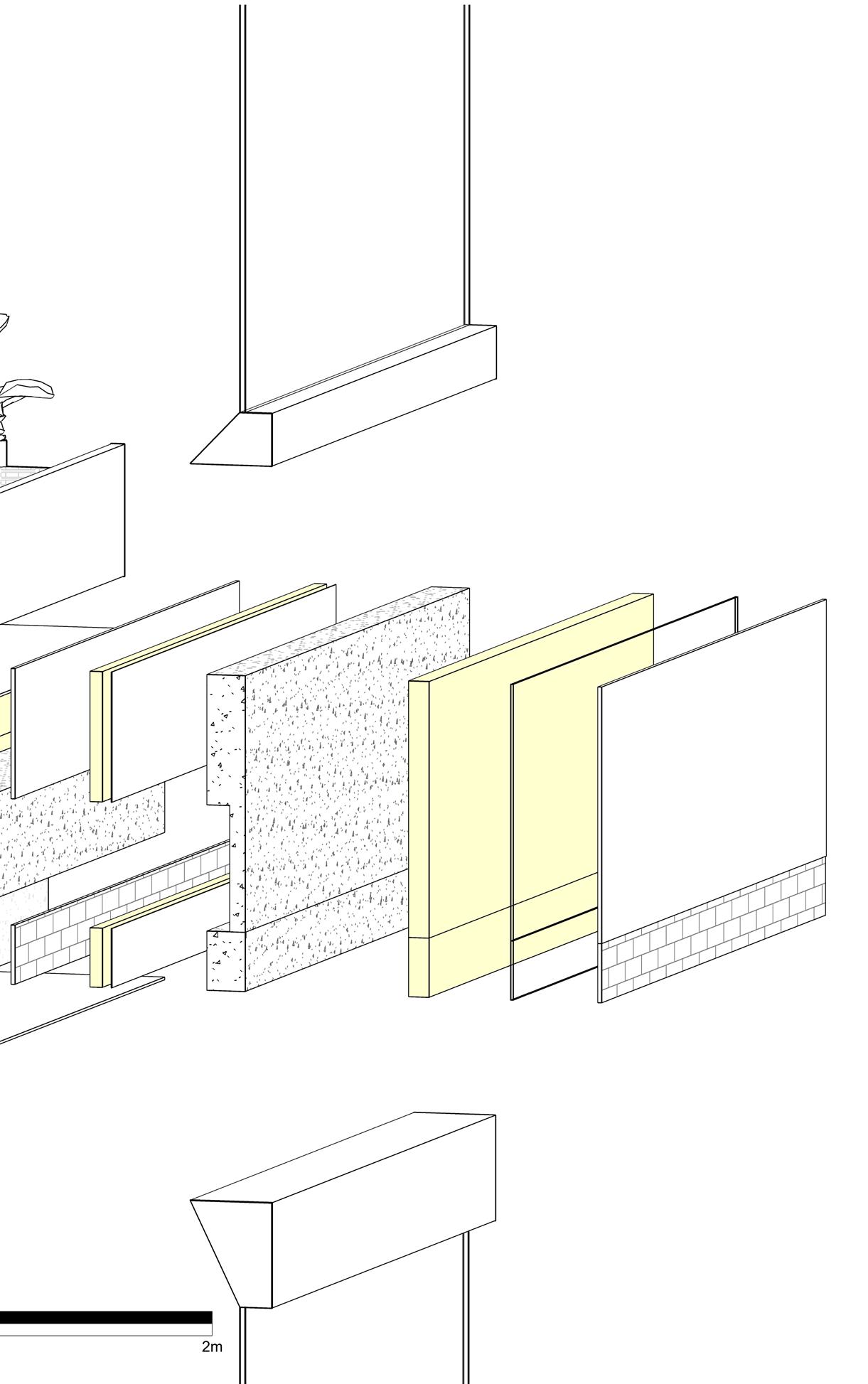

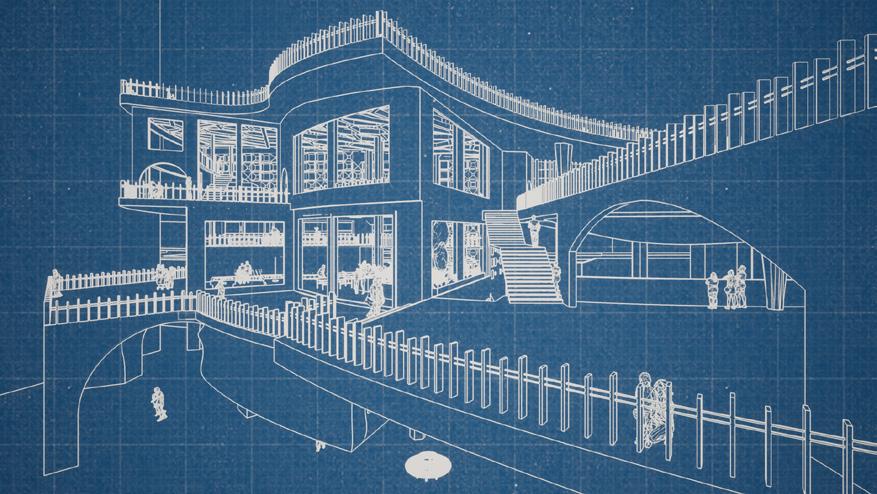

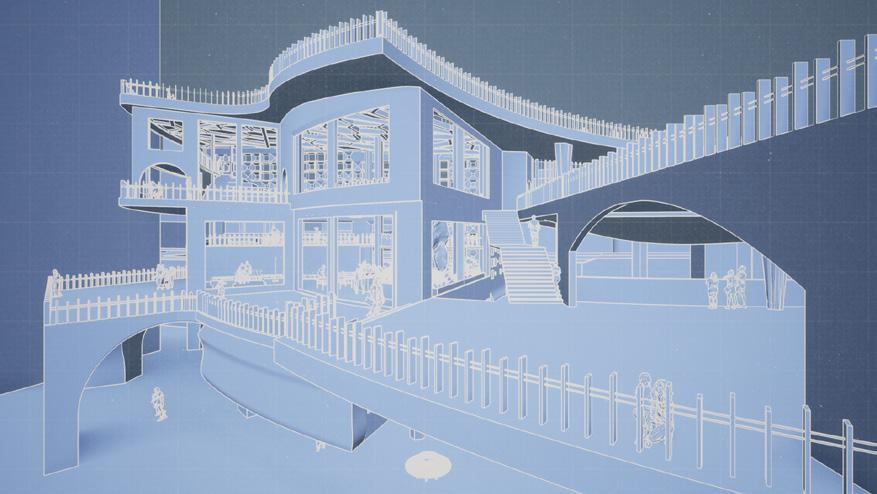

AXONOMETRIC

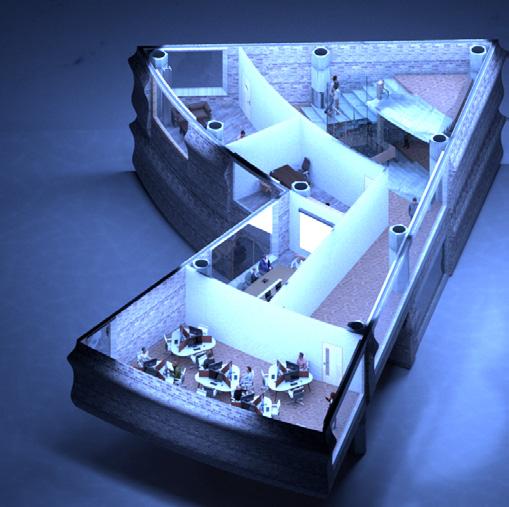

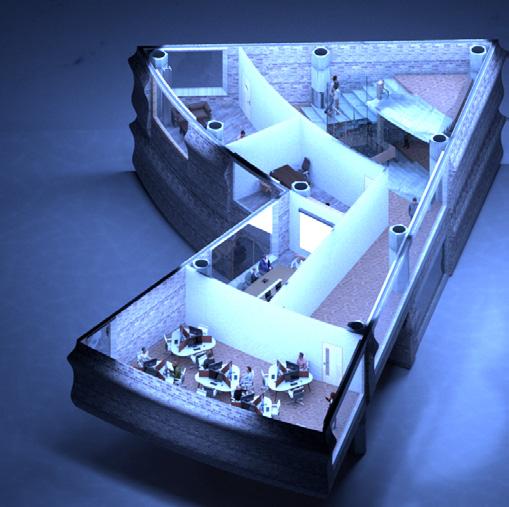

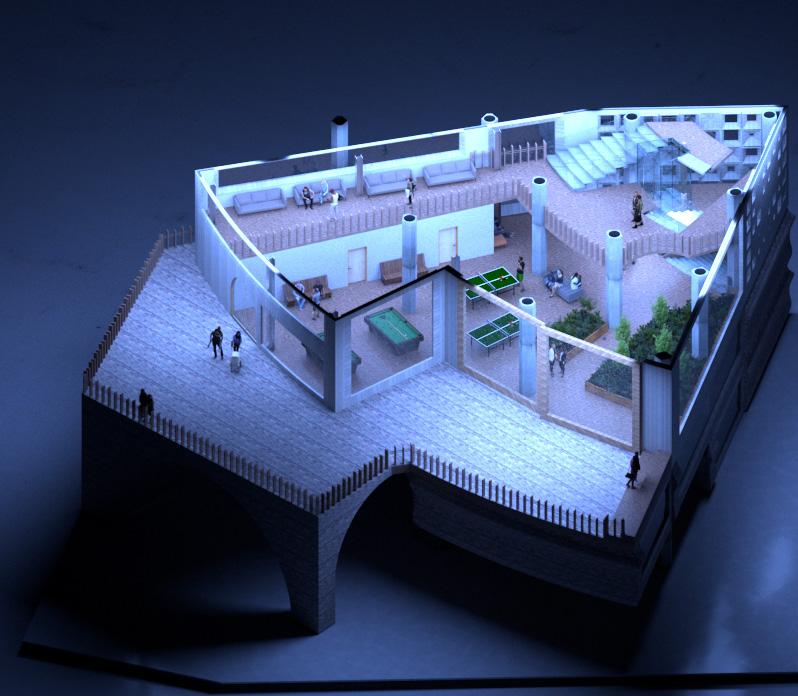

3D FLOOR PLANS

THIRD FLOOR

SECOND FLOOR

FIRST FLOOR

GROUND FLOOR

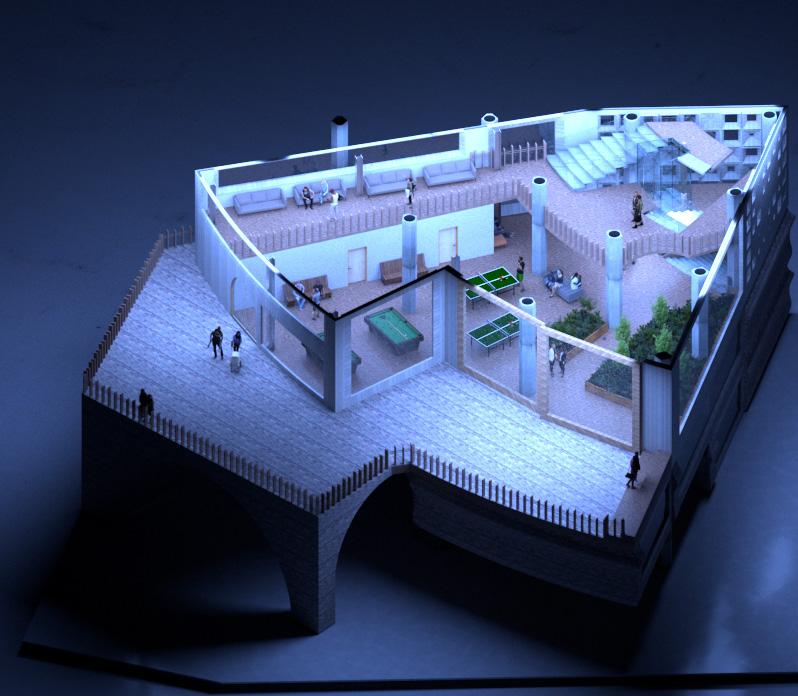

ROOF

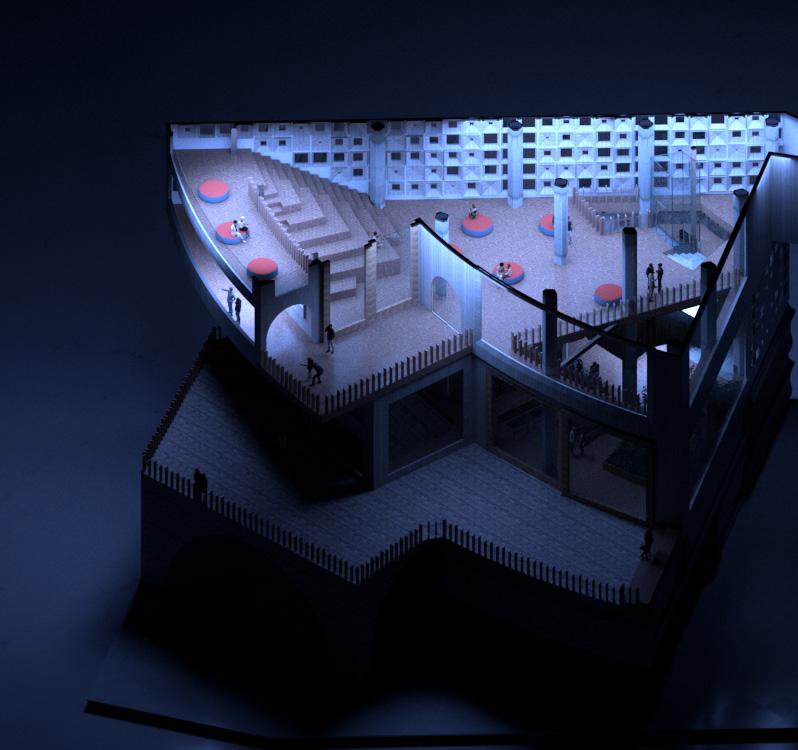

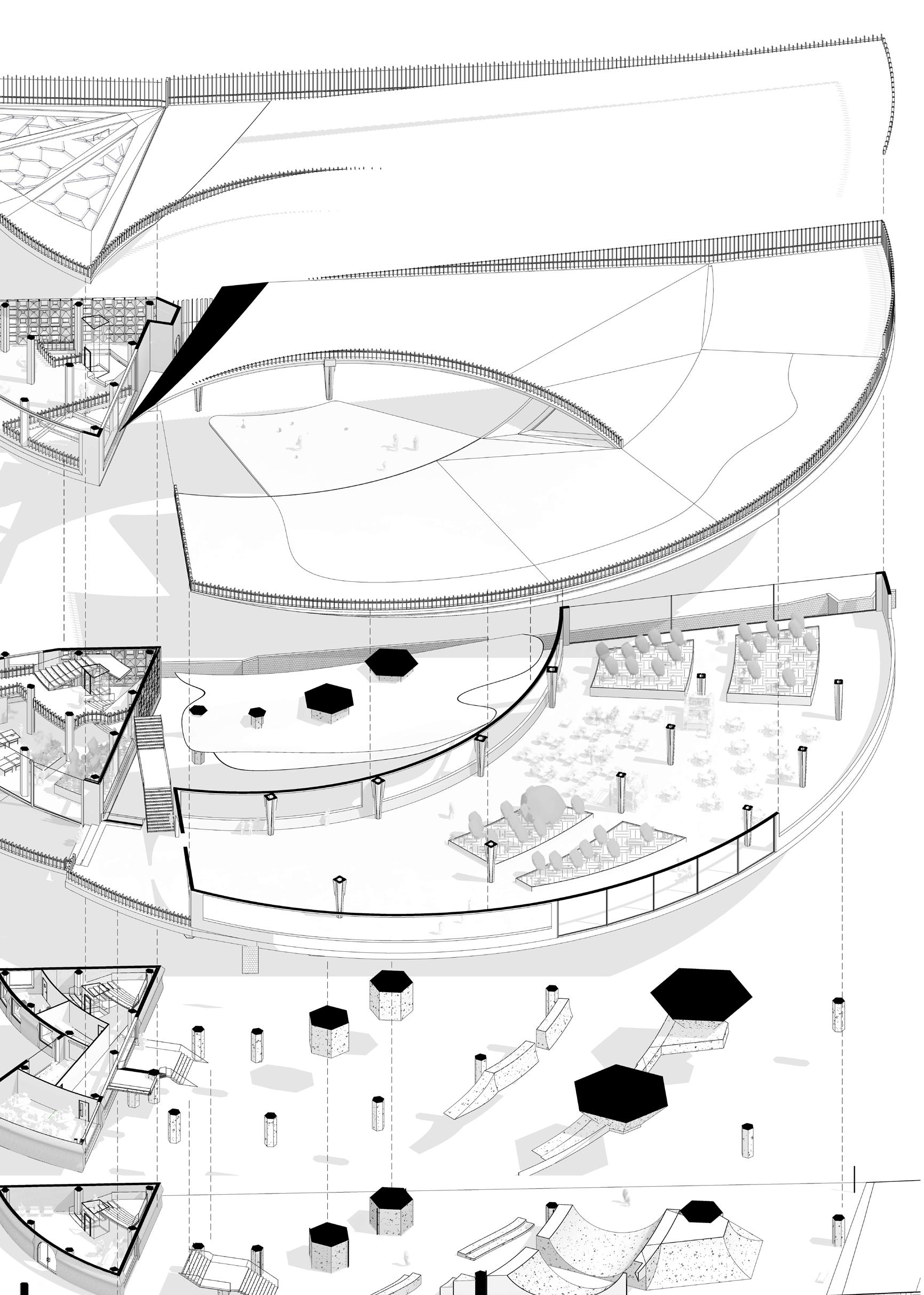

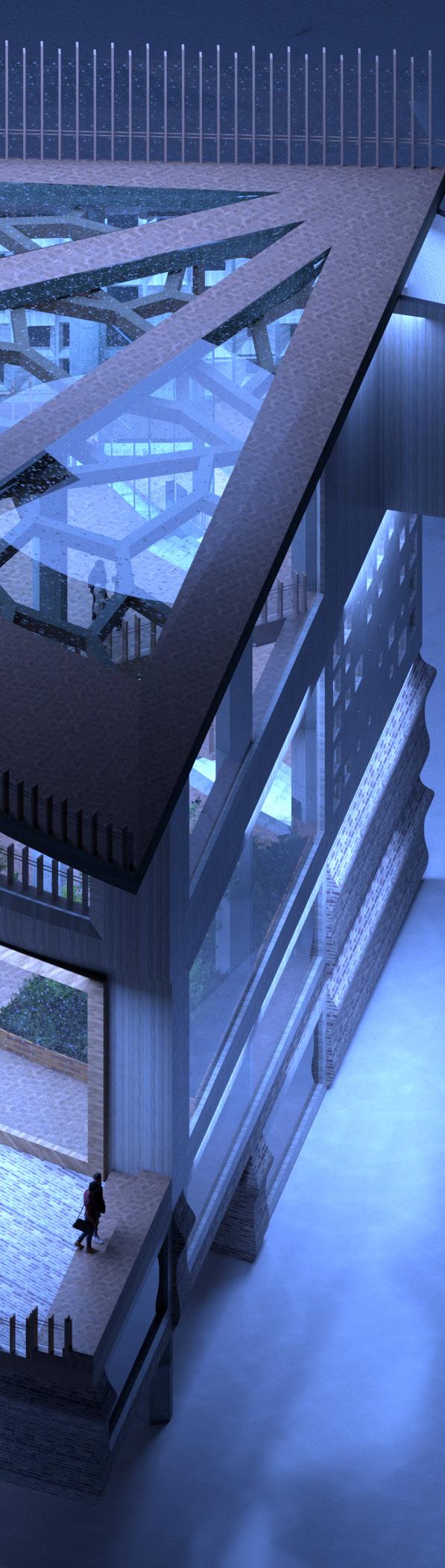

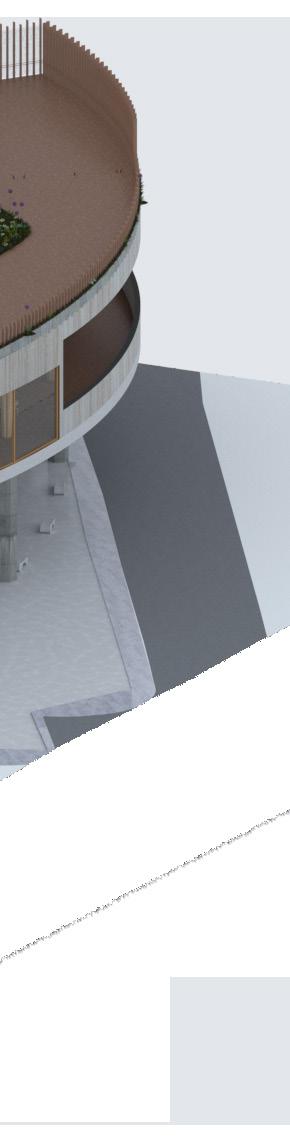

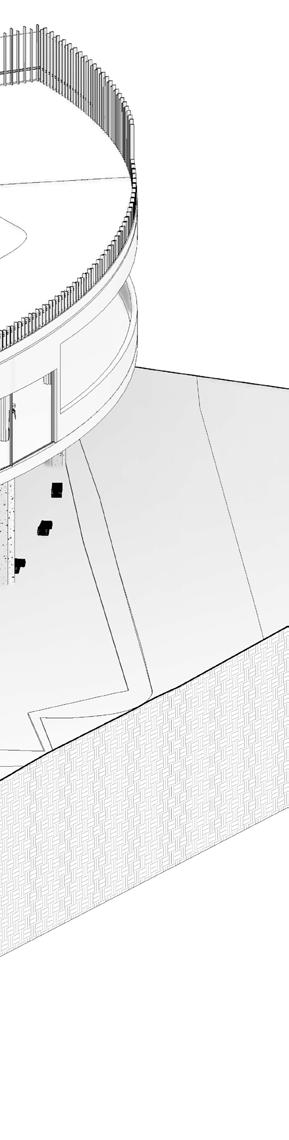

AXONOMETRIC SOUTH-EAST

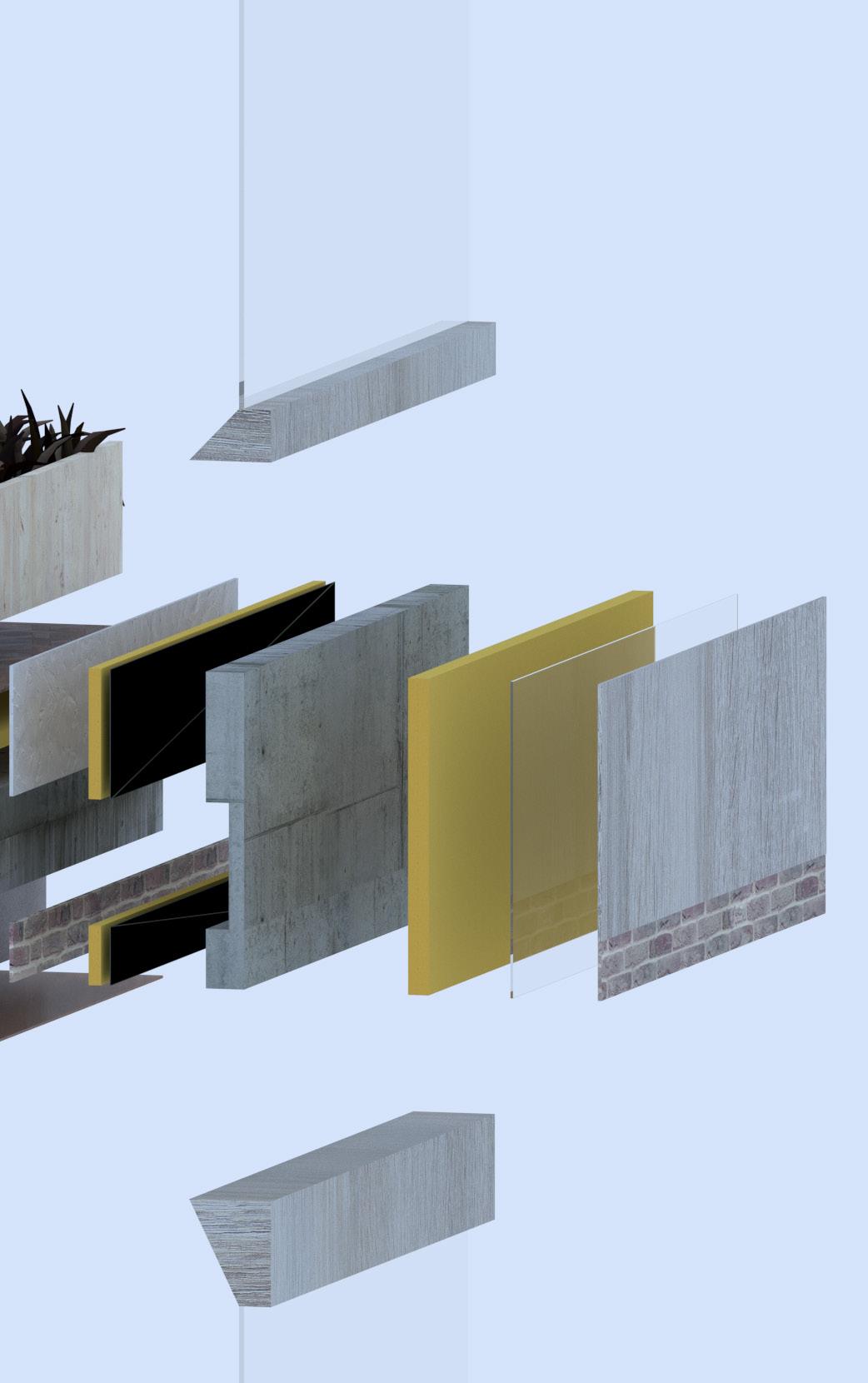

LARGE SKYLIGHTS

UPPER WOOD SECTION

LOWER BRICK SECTION

CONCRETE STRUCTURE

BRICK ARCH FEATURE

WALKABLE ROOF

CAFE WOOD FINISH

CONCRETE FLOOR WITH WOOD FINISH

CONCRETE SKATEPARK

RAILING

COMMUNITY CENTER

RECEPTION WORK SPACE CHILL SPACE STUDIO SPACE

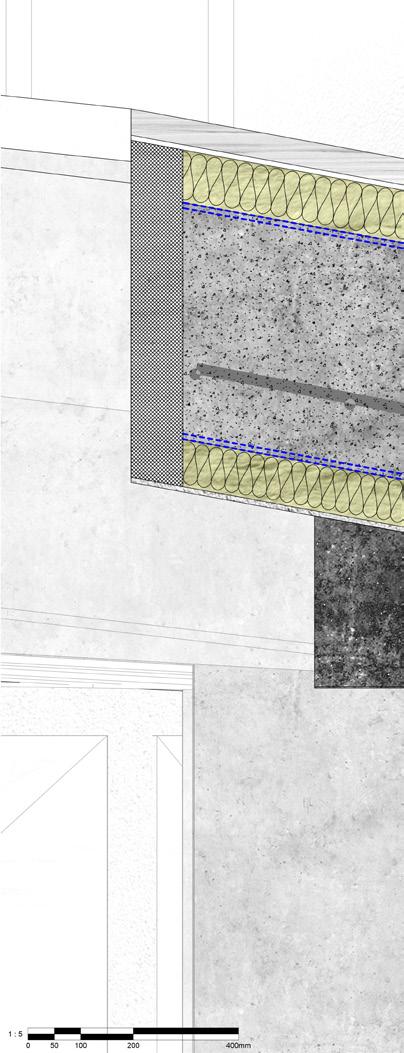

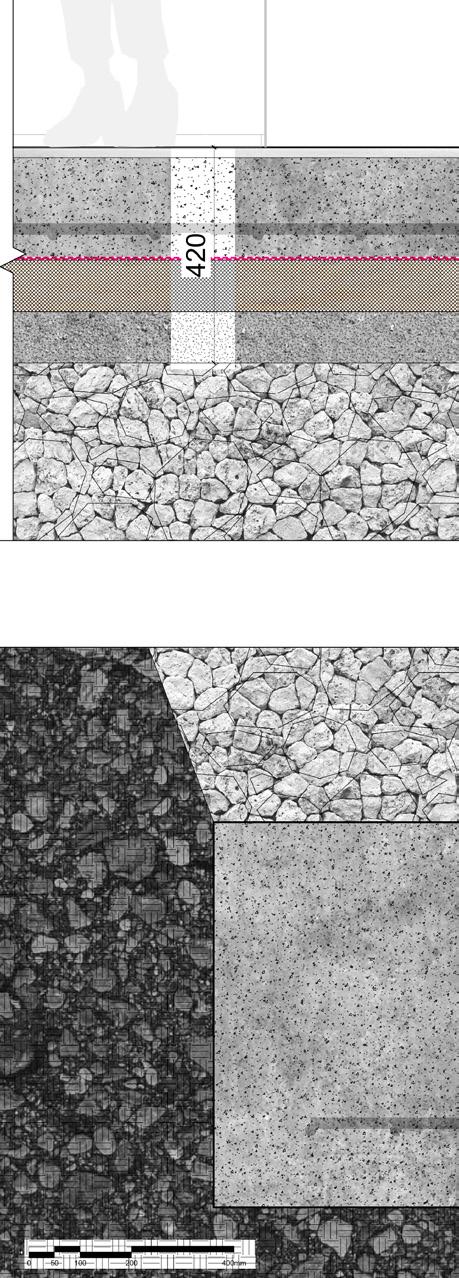

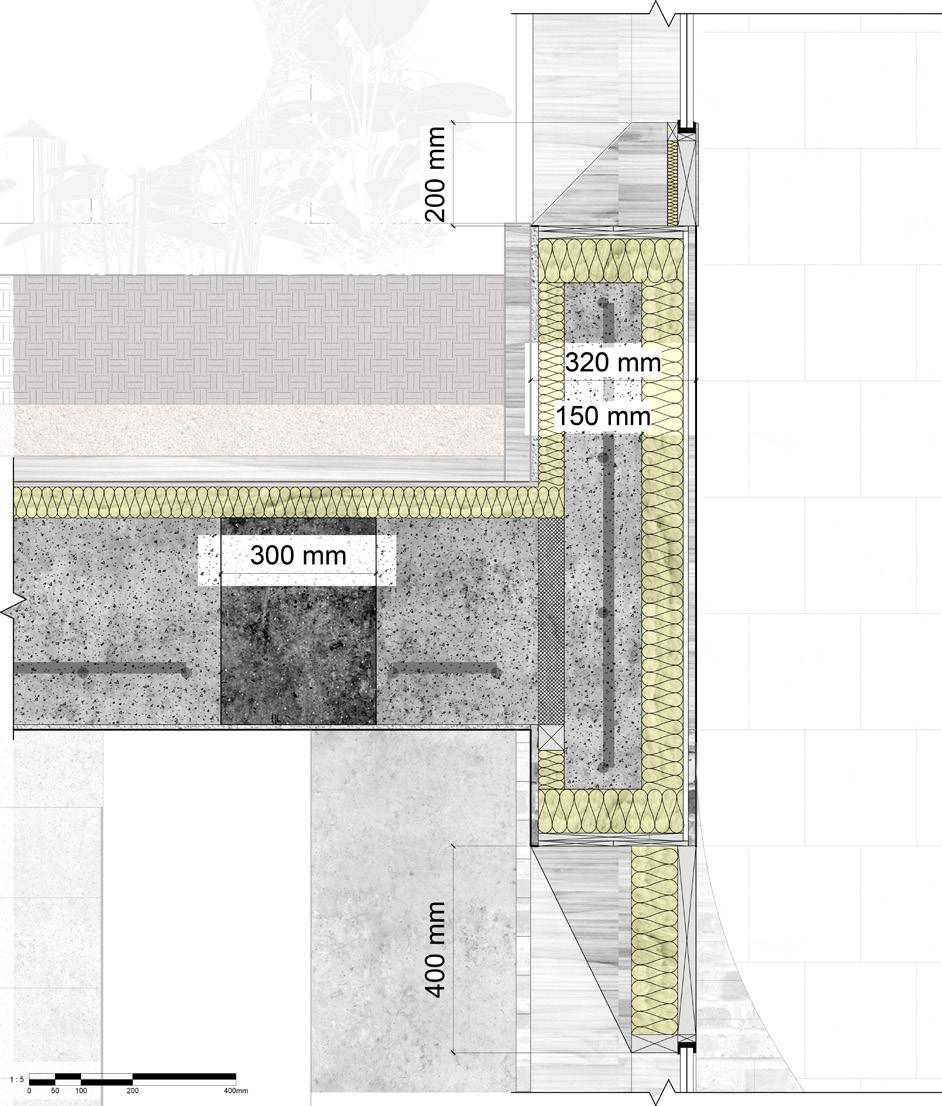

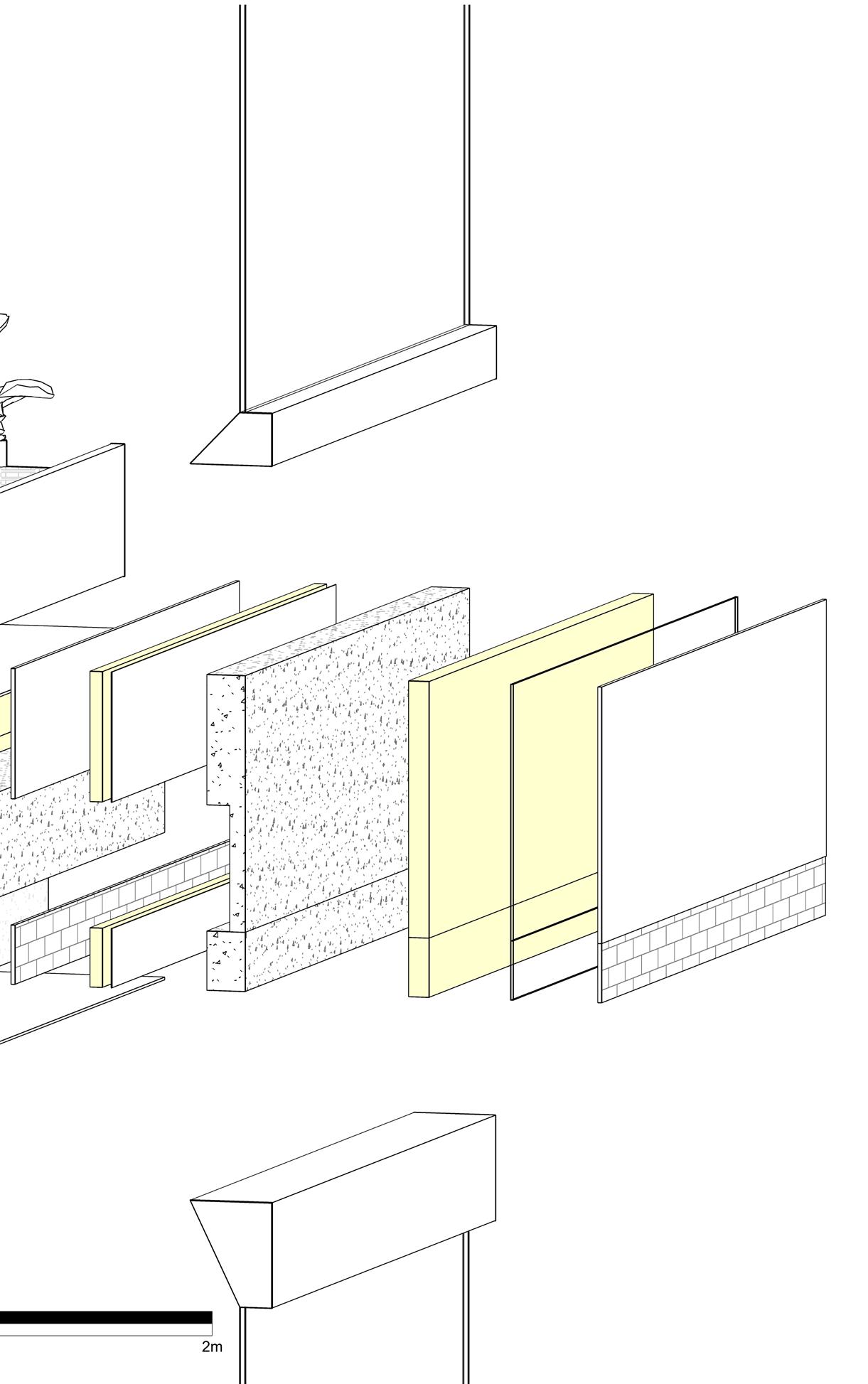

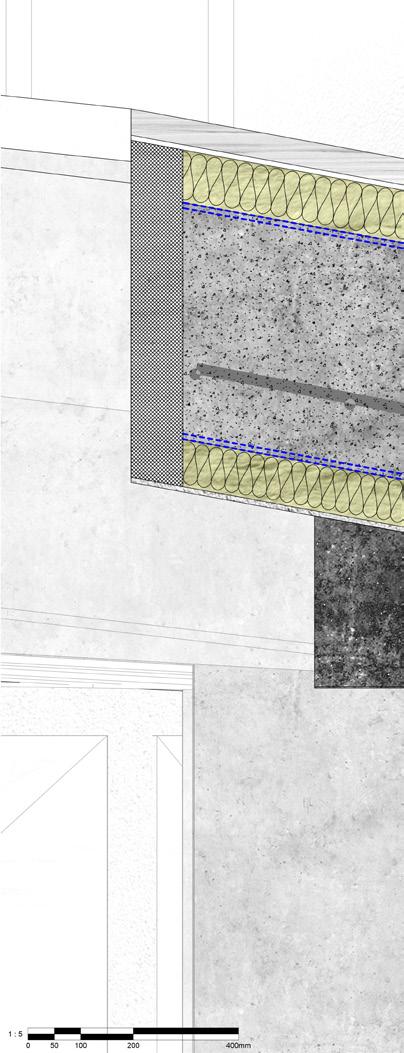

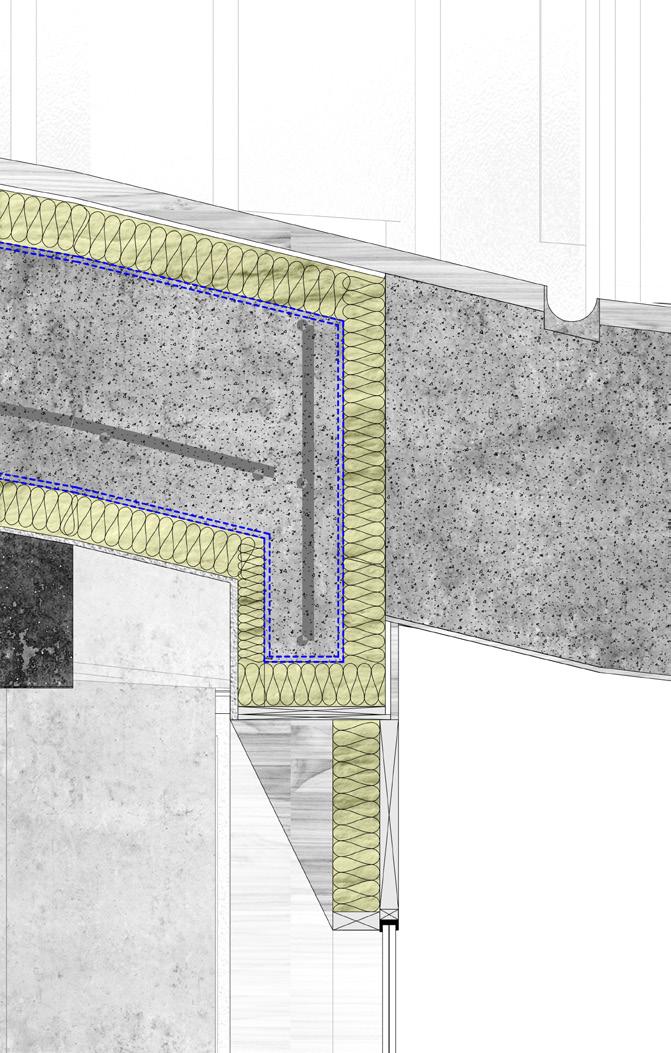

03. 300x400mm Concrete Beam.

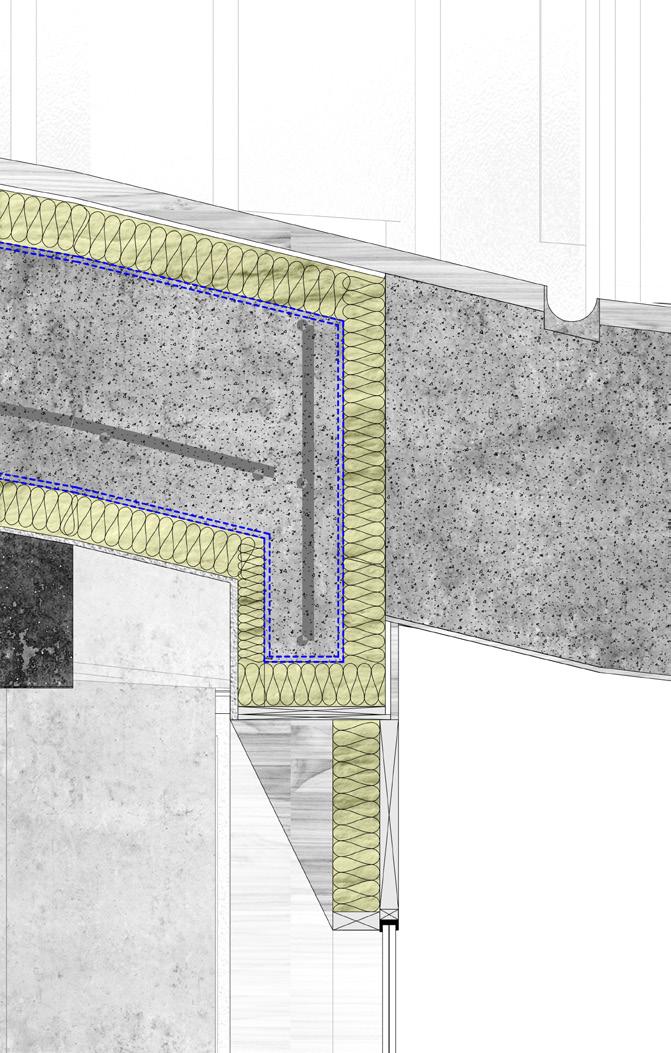

04. 100mm Hemp Insulation.

05. 50-80mm Hemp Insulation.

06. Rigid Hemp Insulation.

07. 22mm Rebar.

08. Wood Window Sill.

09. Glass Window Pane.

10. Interior Wood Laminated Floor.

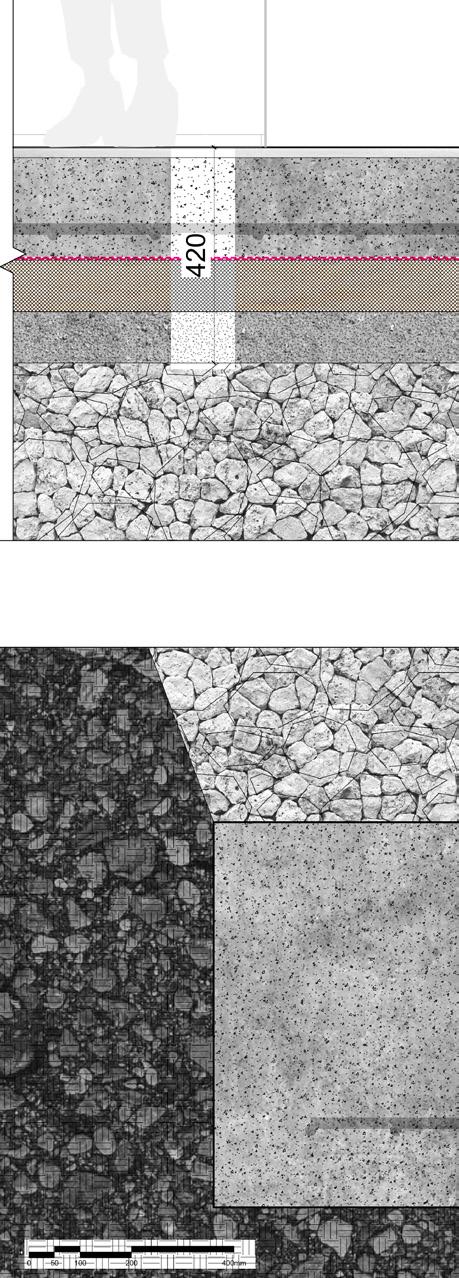

11. Concrete Foundation.

12. Foundation Layer.

13. Compacted Crushed Stone.

14. Angled stone to move water away.

15. Damp Proof Membrane.

16. Water Resistive Layer (WRB).

17. Thermal Break.

18. 15mm Thin Brick Finish.

19. 15mm Thin Wood Finish.

20. Air Gap.

21. Aluminium Window Frame.

22. Exterior Laminated Wood Floor.

23.Thick Glass Pane.

24. Gutter.

25. Exterior Concrete Structure.

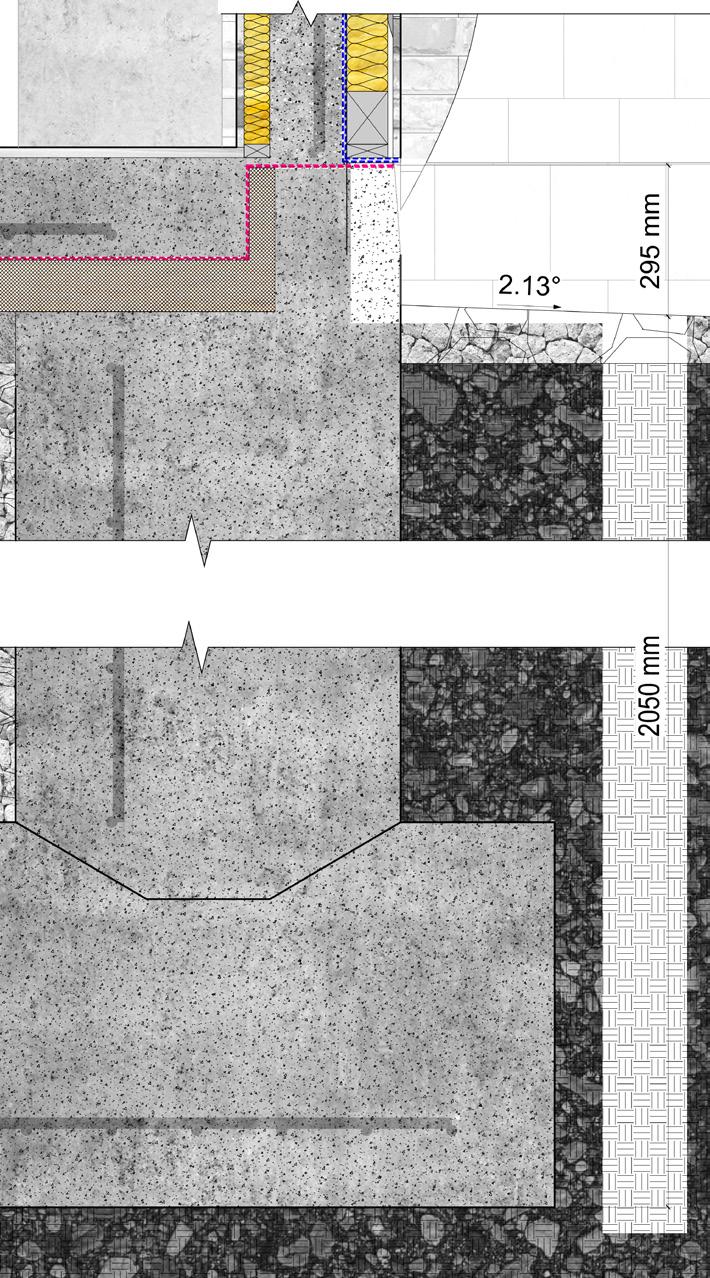

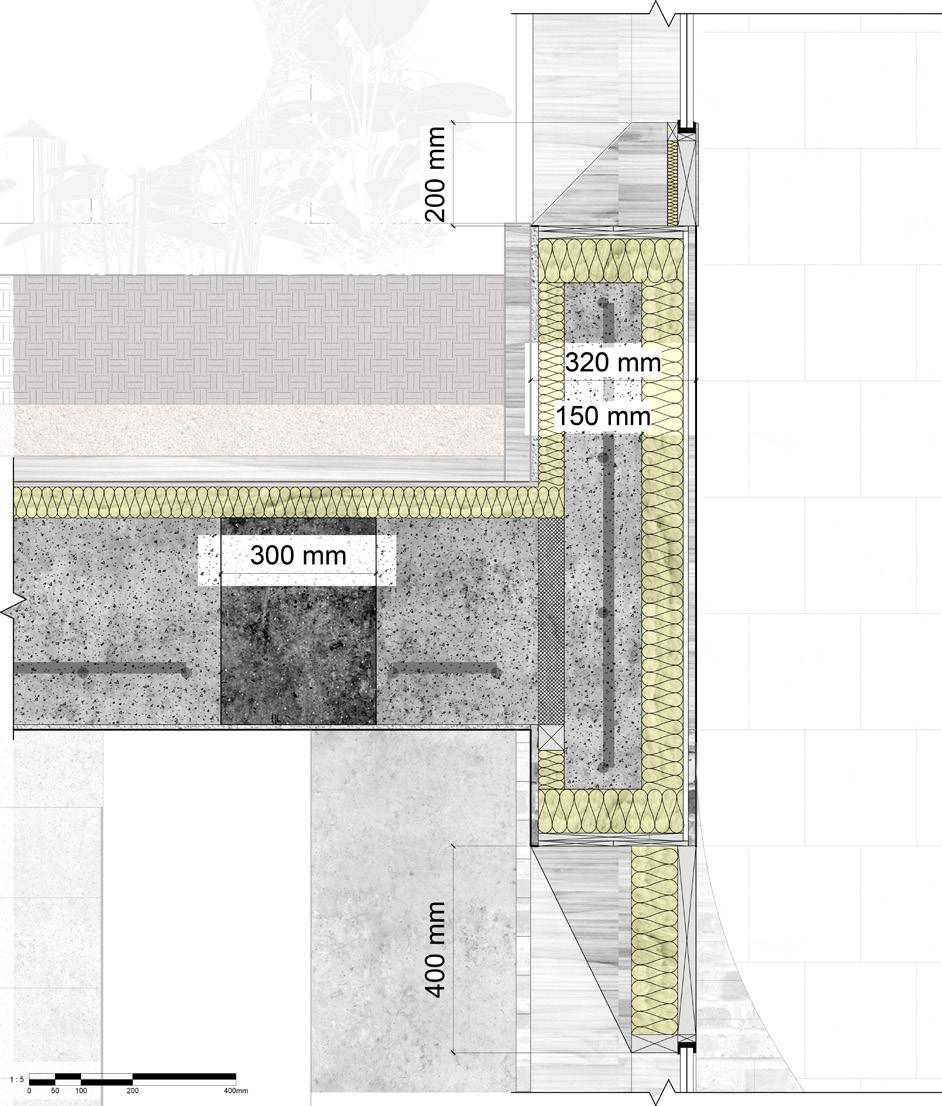

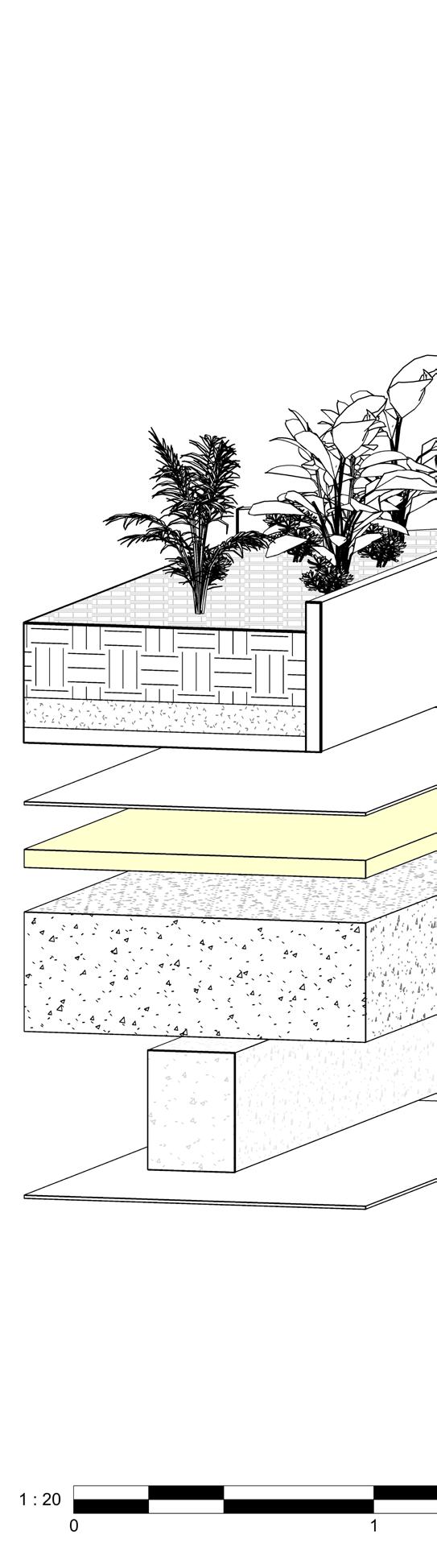

01. 400mm Concrete Floor.

02. 150mm Concrete Wall.

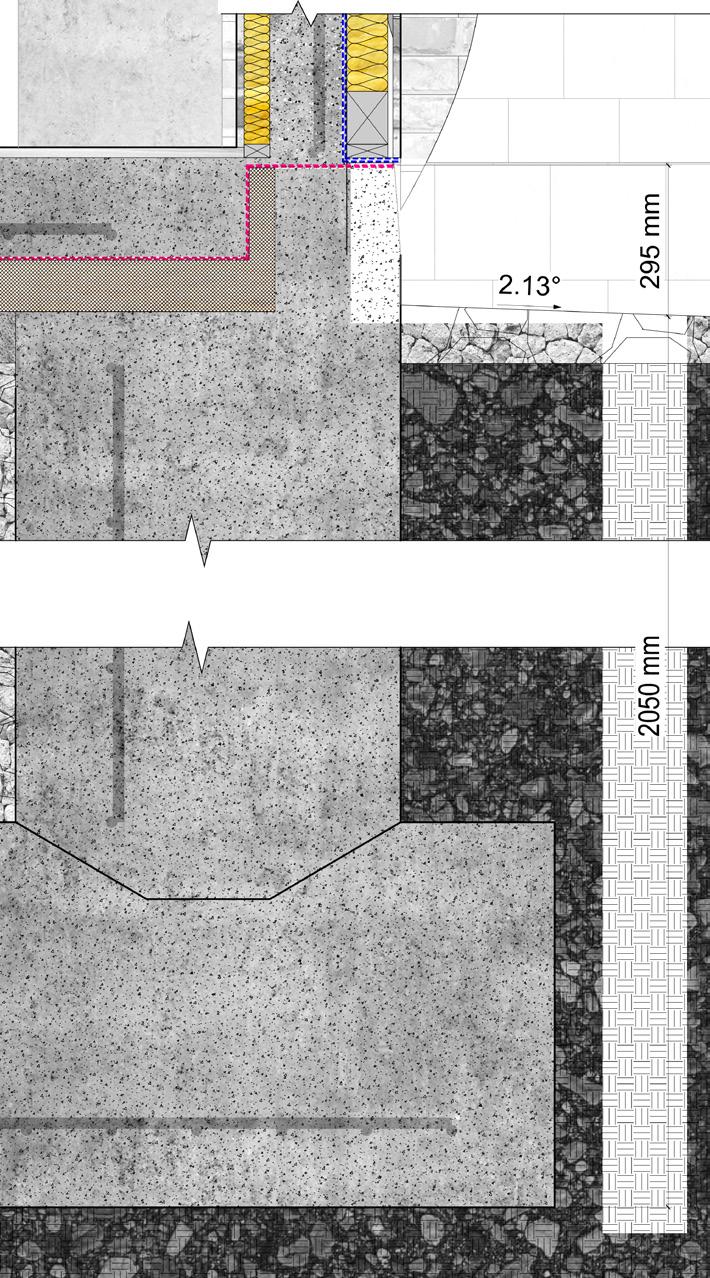

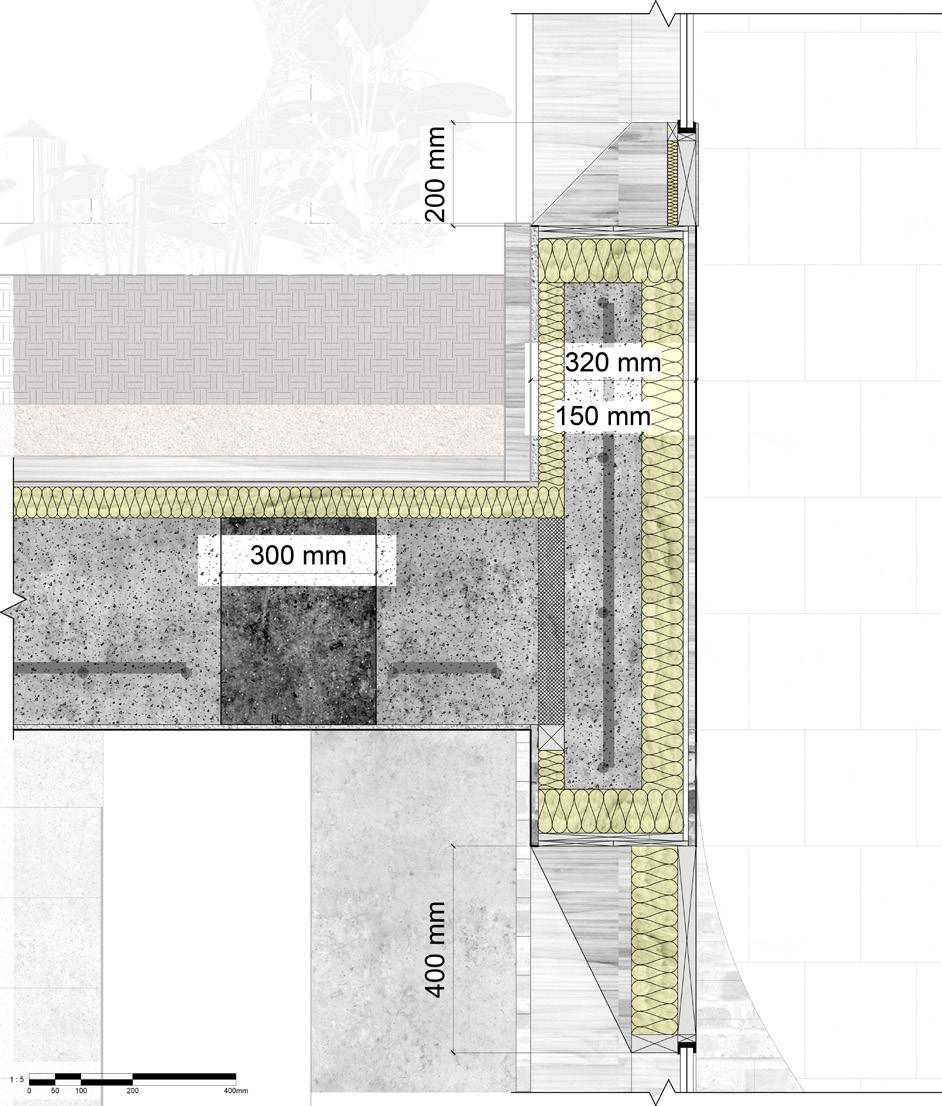

R O O F 1 : 5 F O U N D A T I O N S 1 : 5 295 mm 2.13° 2050 mm 420 320 mm 300 mm 200 mm 400 mm 150 mm

1. 2.

2.

2.

3. 4.

5.

4.

1. 2.

2.

2.

3. 4.

5.

4.

5. 6.

5.

4.

6. 7.

8.

7.

8.

9.

11. 12. 14. 15. 16. 17. 18. 19. 17. 18. 18. 17. 19. 20. 20. 21. 16. 17. 22. 19. 20. 24. 25. G R E E N R O O F L A N D I N G 1 : 5 ASSEMBLY DETAIL E A T

8.

9.

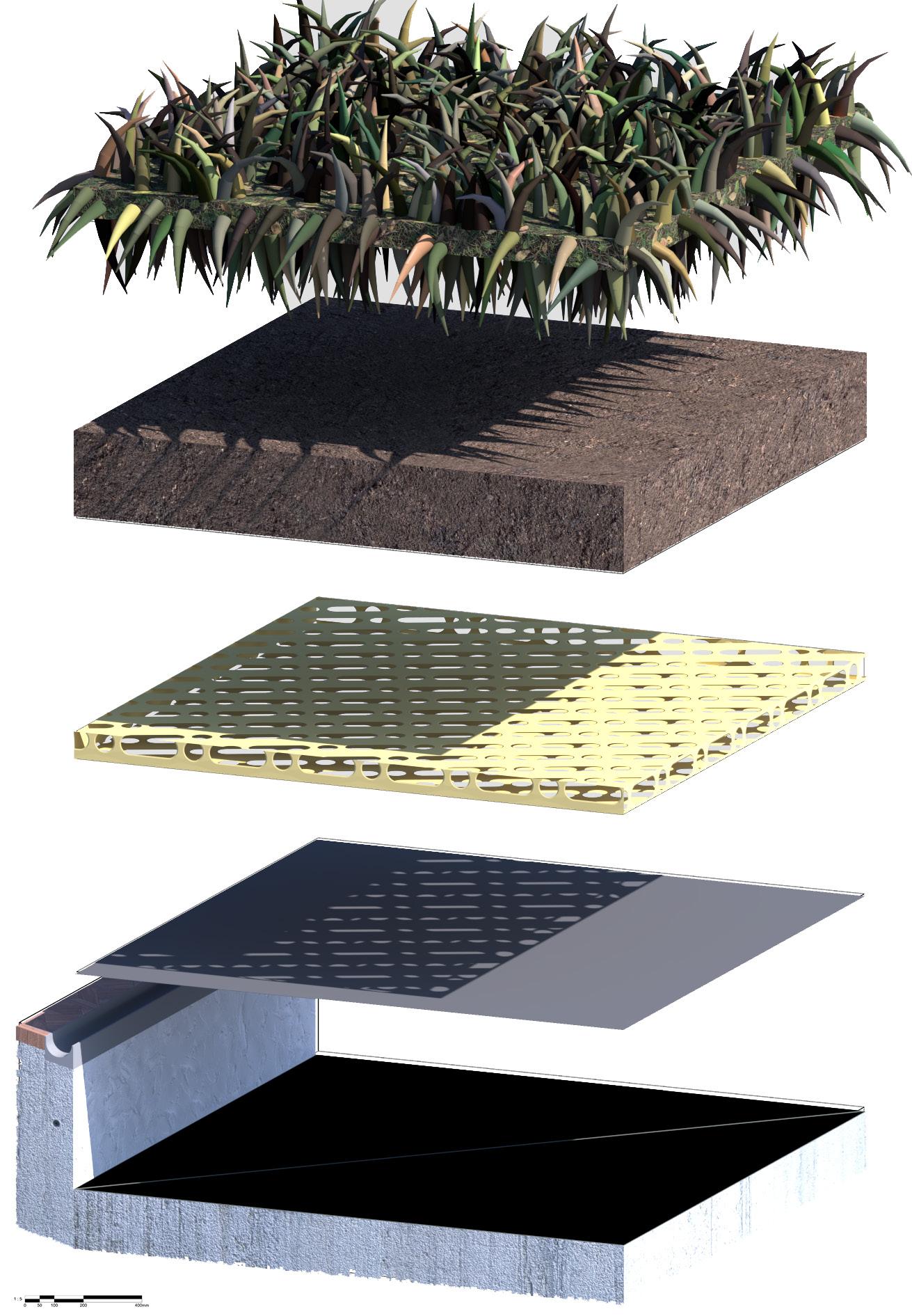

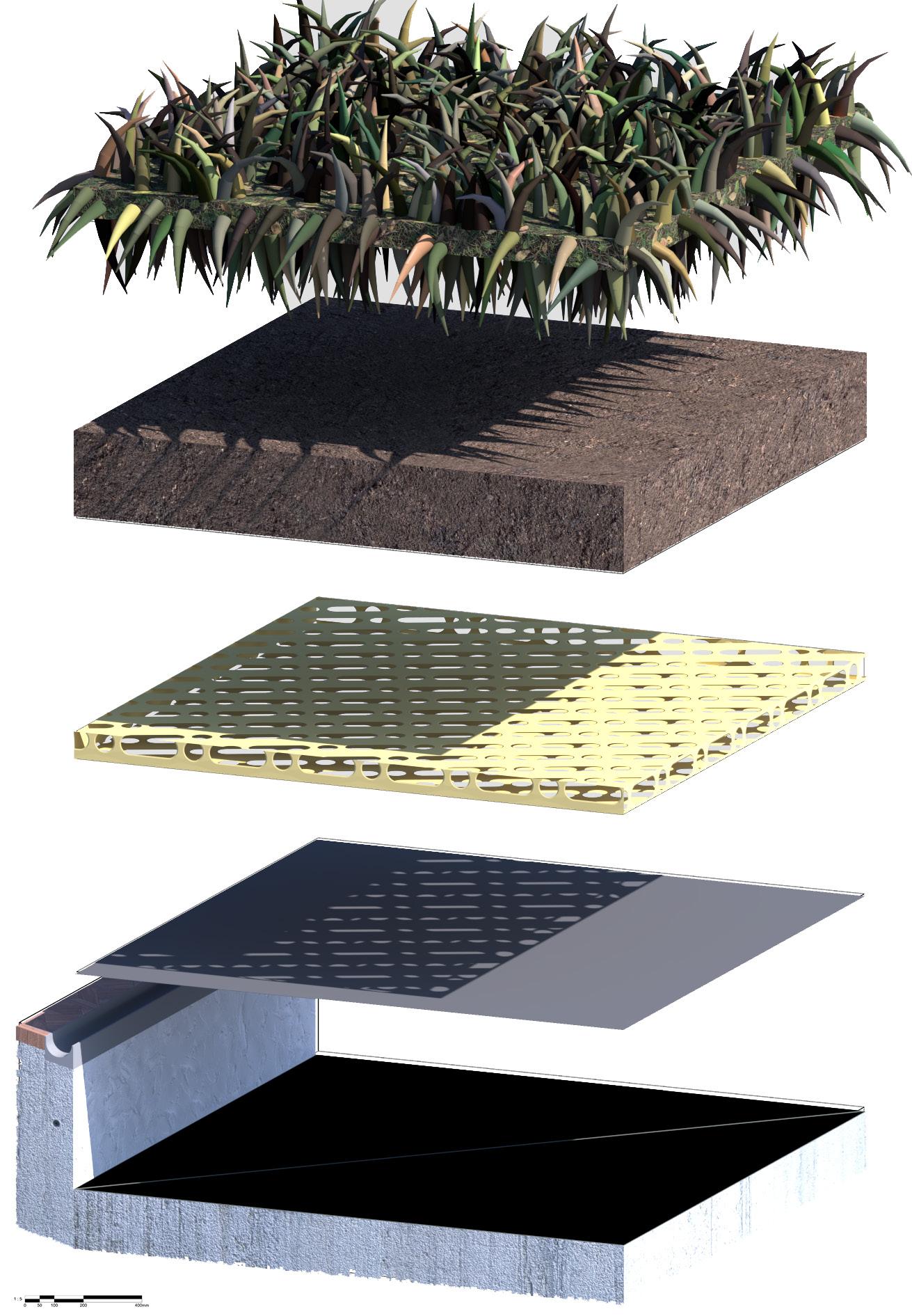

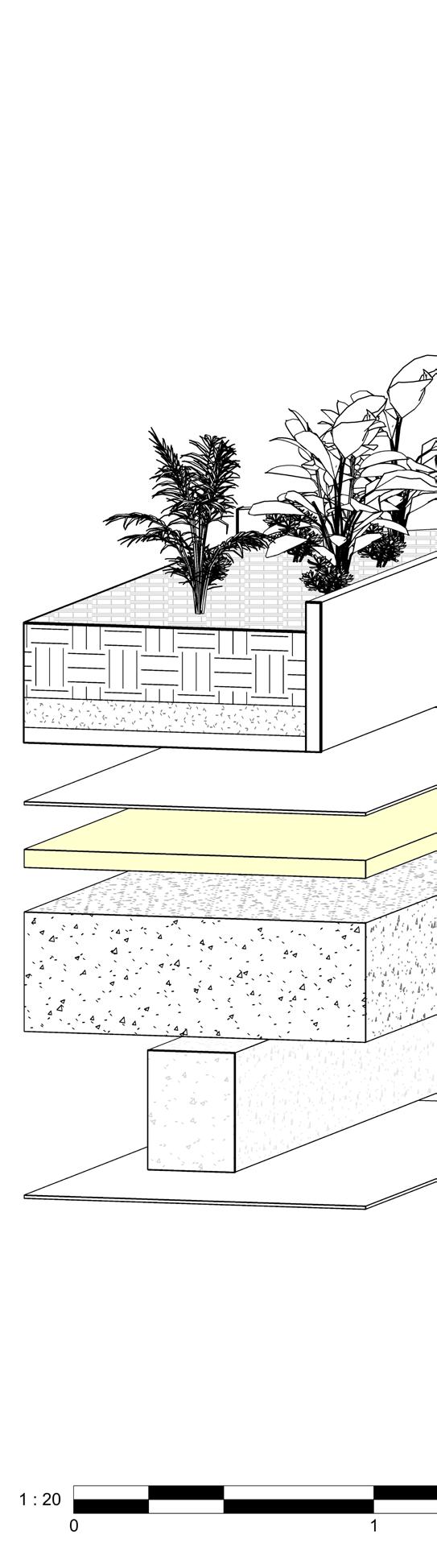

MATERIAL STUDY GREEN ROOF 1 : 5

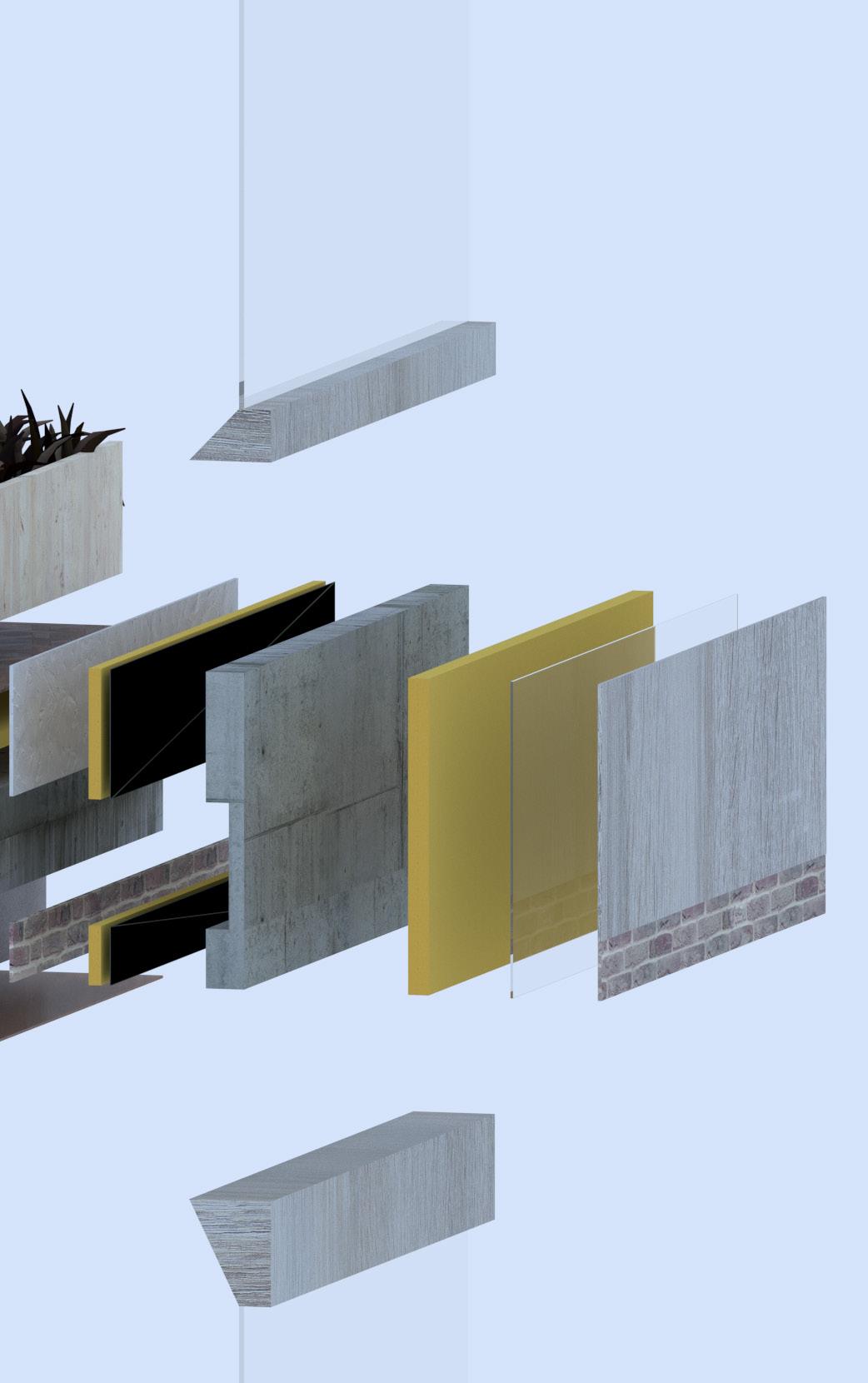

The two structures will sit on concrete strip foundations as this will allow for the load of the buildings to be absorbed and distributed evenly in columns ranging the length of the building. The reception floor will be placed 295mm off the ground to reduce the spread of moisture and the walls will be protected by a Water Resistive properties, this will allow for the main structure to stay dry and no mould to build up as the necessary ventilation will be available. In terms of insulation the building will employ hemp insulation, this is due to the benefits found with the material, for the project specifically and of insulating a building. It further has many environmental benefits and comes from purely renewable resources while also having solid thermal This will create a wall assembly which will benefit from numerous sought after properties which will be felt inside the building once constructed The roof detail replicates much of the same practise used for the rest of the building. It will have however, a larger concrete structure in order to heavy weight associated with planting vegetation. But also, depth enough in the floor itself to place the necessary aspects to create a successful and long-term use. This is why the green roof employs a mix of drainage systems, filter layers and waterproofing. Protecting the structure of the the elements as a result of the incline of the structure and the drainage layer of the green roof. The project aims to deliver a community centre of high quality for the residents and visitors of Salford alike, it is therefore important that the building out of the space and structure while considering specific needs of the area and locally available materials. This can be seen with the extra precautions terproofing/membrane layers or the choice of materials due to their thermal abilities and methods of self-regulating temperature.

A. Vegetation.

B. Substrate.

C. Draniage Layer.

D. Filter Layer.

E. Waterproofing Membrane.

F. Concrete.

G. Gutter.

H. Wood Floor with Waterproof coating.

A.

B.

C.

D.

E.

F.

A. Vegetation.

B. Substrate.

C. Draniage Layer.

D. Filter Layer.

E. Waterproofing Membrane.

F. Concrete.

G. Gutter.

H. Wood Floor with Waterproof coating.

A.

B.

C.

D.

E.

F.

G. H.

9.

10.

11.

7.

12.

13.

14.

15.

13.

01. 15mm Wood Finish.

02. 15mm Thin Brick Finish.

03. Air Gap.

04. 100mm Hemp Insulation.

05. Concrete Wall Structure.

06. Water Resistive Barrier (WRB).

07. 50-80mm Hemp Insulation.

07. Plaster.

08. Concrete Floor Structure.

09. Concrete Floor Structure.

10. Concrete Beam.

11. Wood Cieling.

12. Wood Floor.

13. Wood Casing.

14. Gravel.

15. Earth and Vegetation.

16. Window Frame.

17. Window Pane.

MATERIAL STUDY LANDING 1 : 20

TE Aorder to give sturdy buildings which can withstand the elements. Embedded 2m deep into the ground the foundations will connect to concrete Layer while a damp proof membrane is used for the floors. The walls further consist of a 10mm air gap which provides ventilation and drainage and wider the perspective. Hemp insulation is particularly good at resisting against mould and erosions making a durable and easy to instal way characteristics. Enabling the creation of an environment which requires low heating and cooling costs. due to its effective temperature control and the low running costs. to accommodate people and the green roof. The green roof requires not only a strong foundation which the thick concrete can provide due to the successful green roof, which not only adds a high level of biodiversity to the site successfully, but also meets technical requirements in terms of drainage the building from any moisture, pest or erosion as they will never be in direct contact with the building and there will be a constant movements of

building is soundly constructed from the big picture aesthetic to the smallest detail. Consequently, the details have been designed to bring the most precautions taken towards reducing dampness and keeping the walls and main structure ventilated through the implementations of air gaps and wa -

1.

3.

4.

5.

2.

6.

8.

2.

7.

13.

16.

16.

17.

17.

320 mm 300 mm 200 mm 400 mm 150 mm

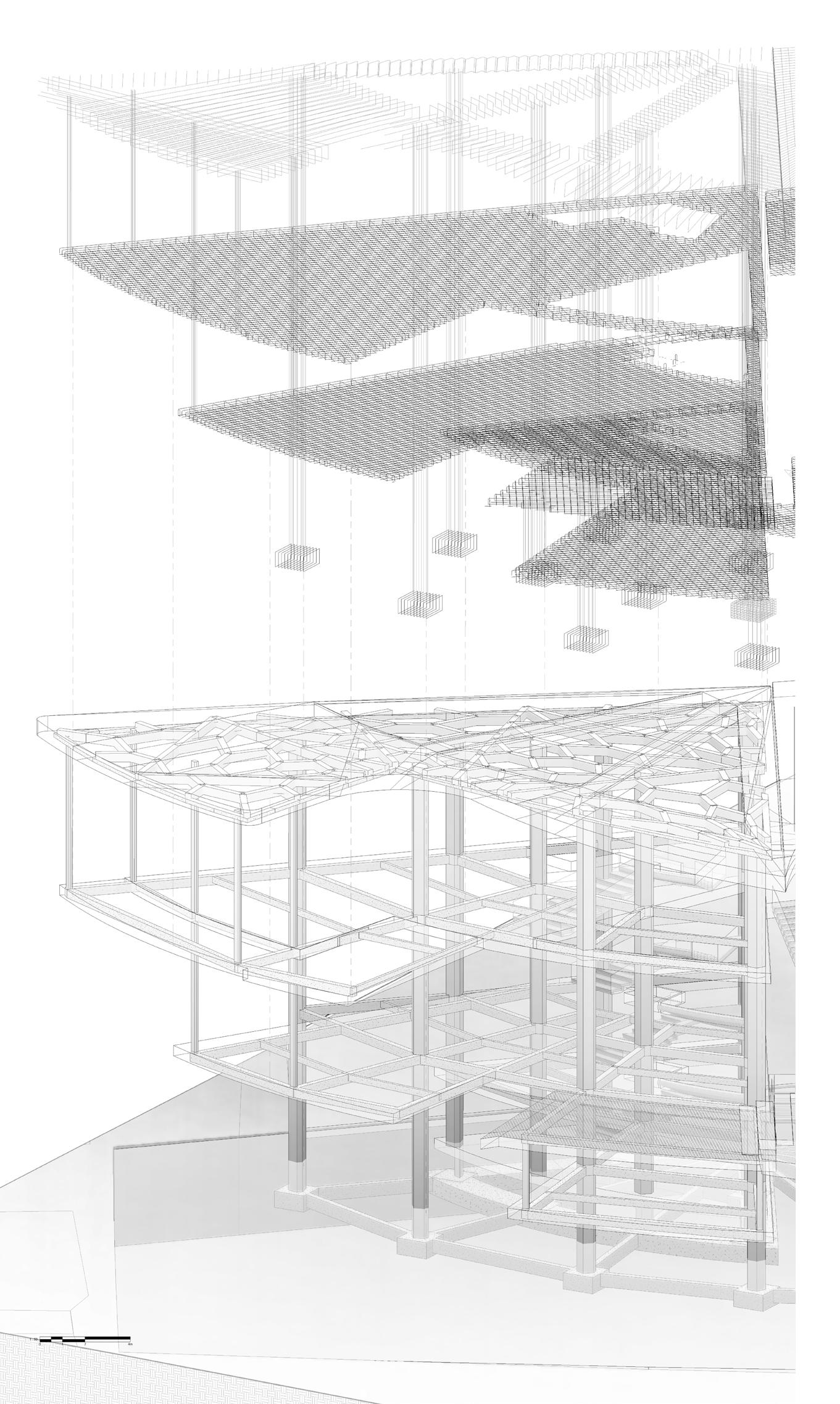

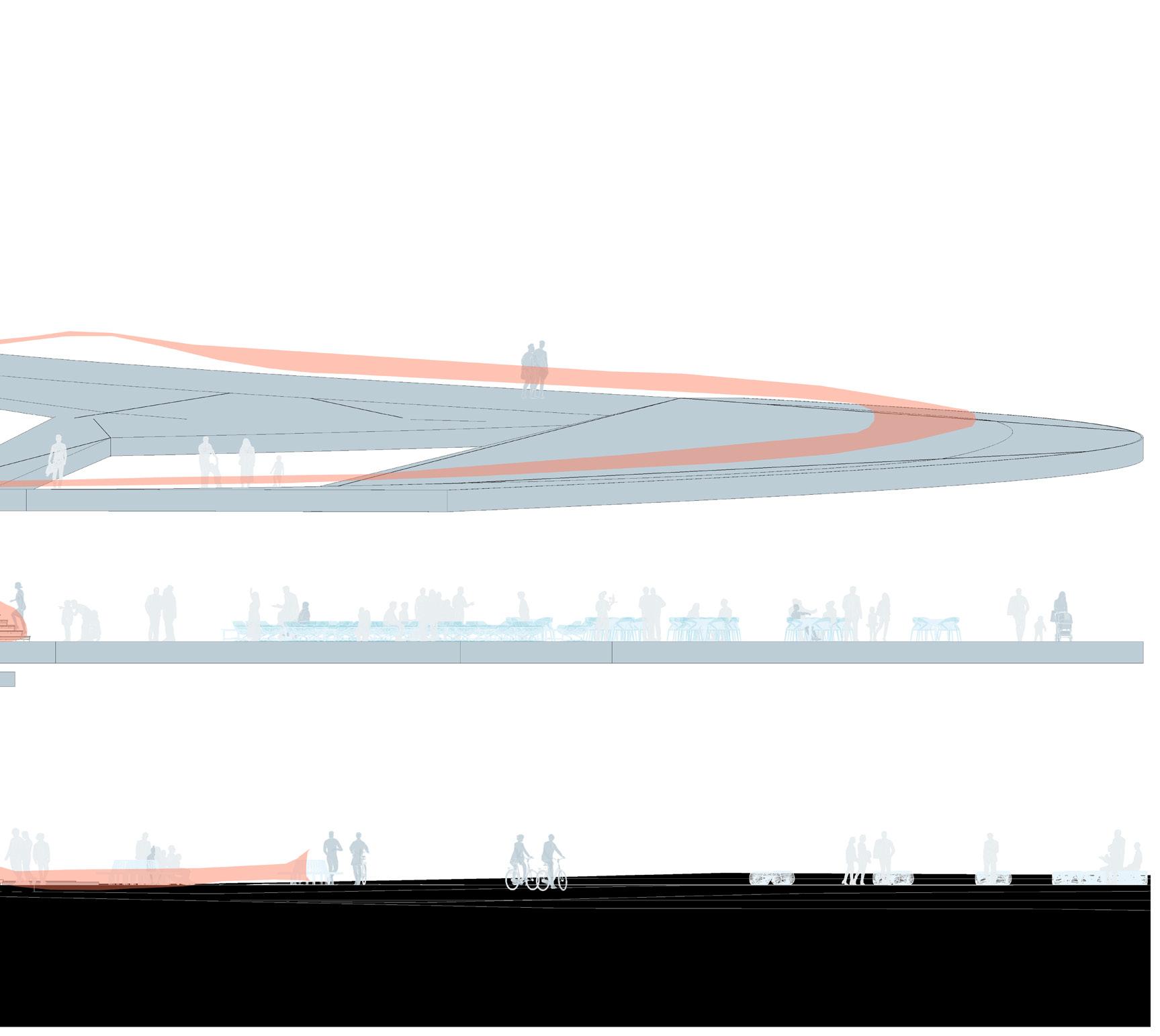

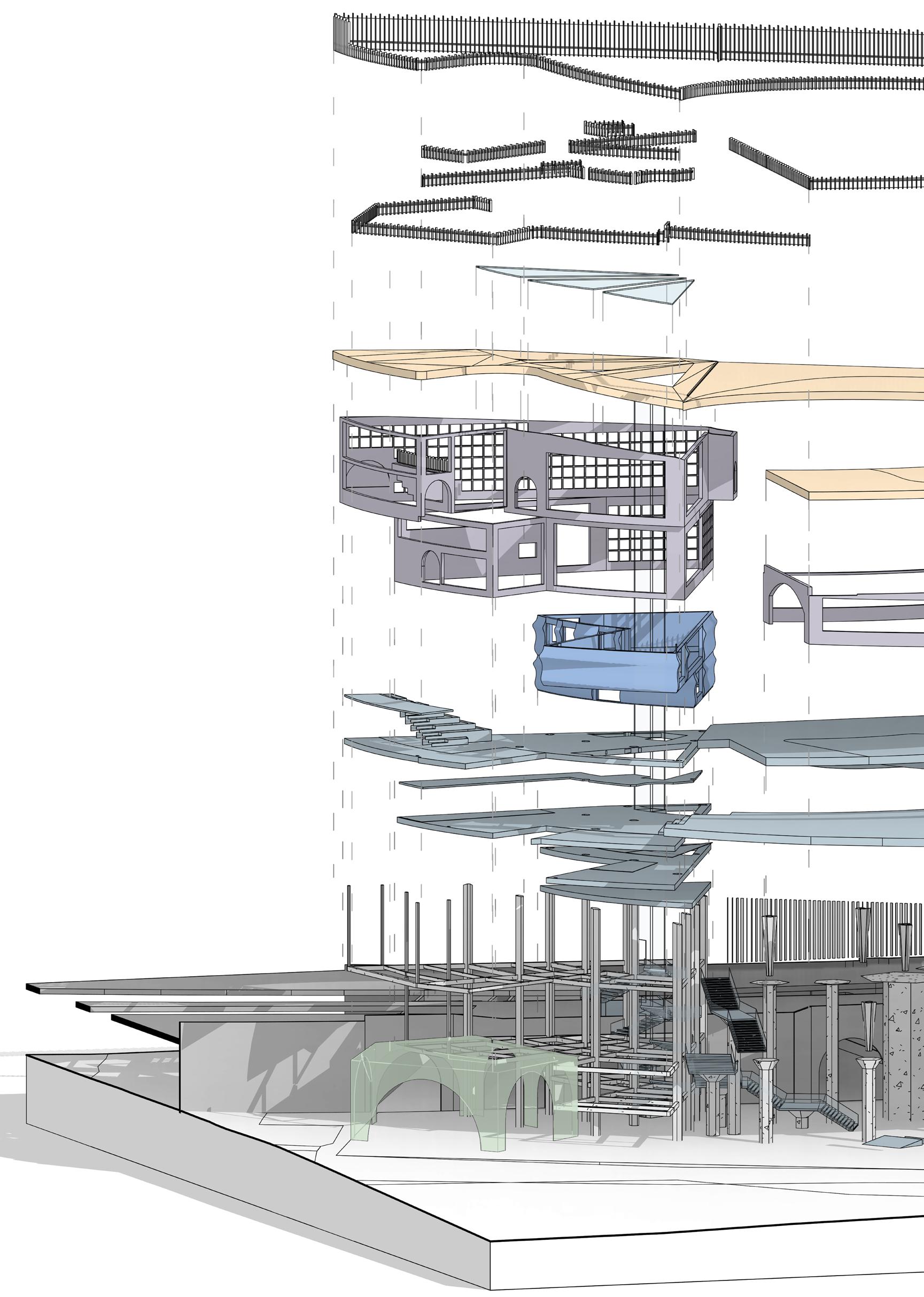

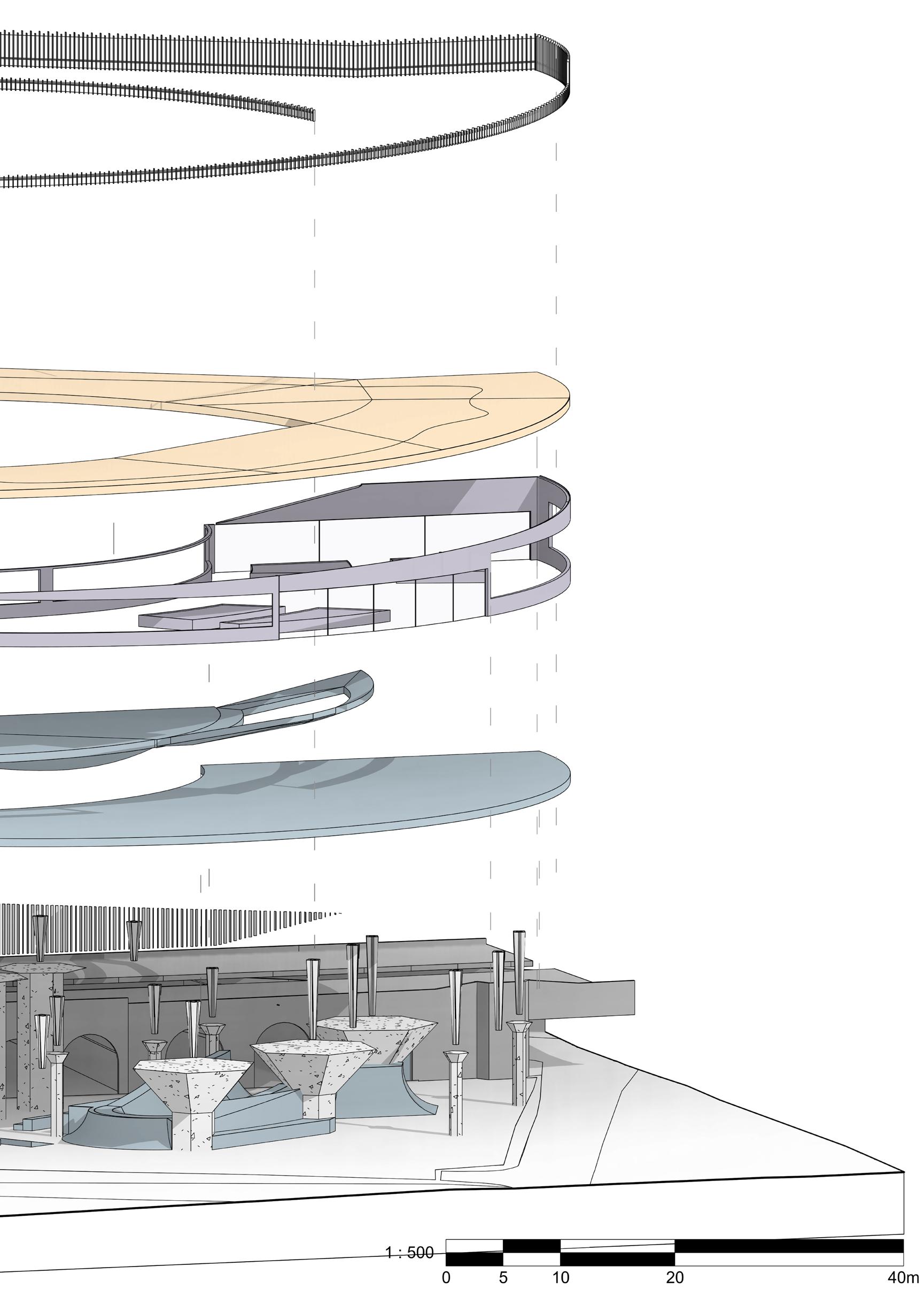

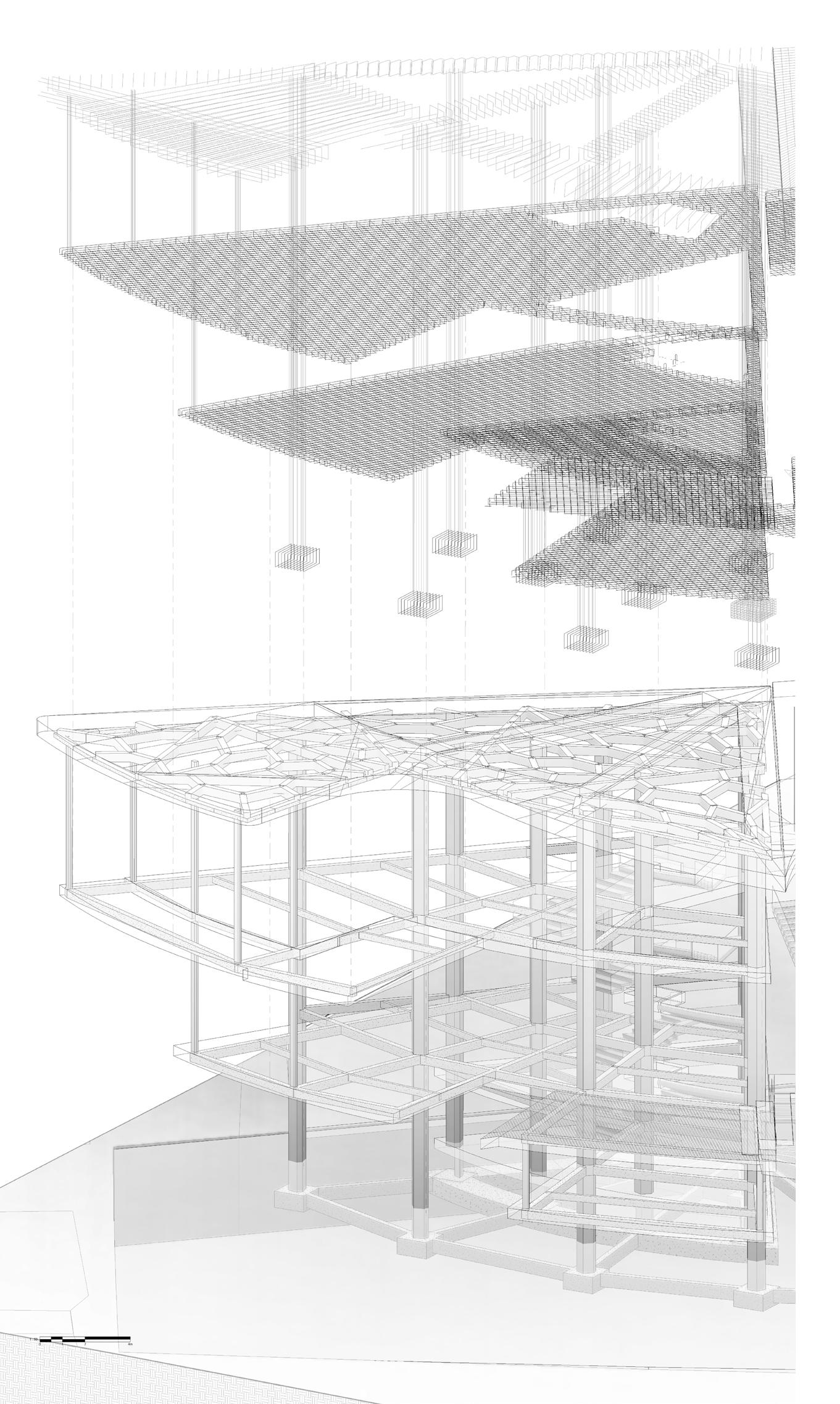

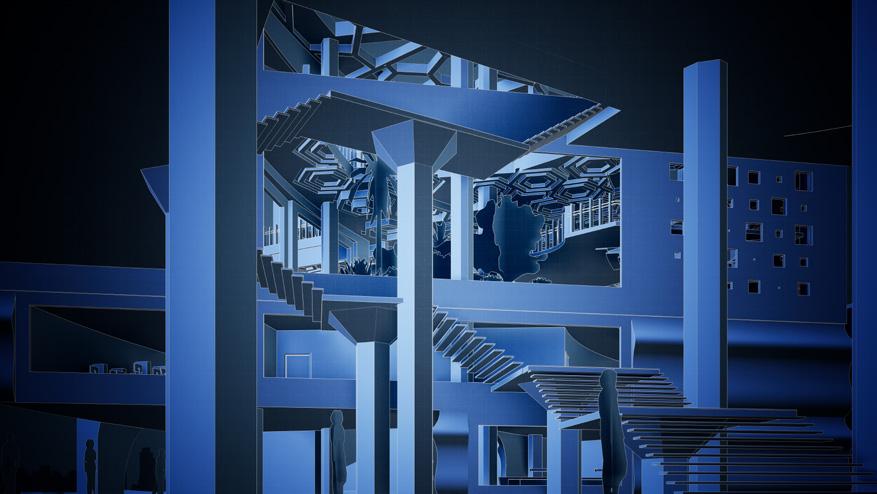

STRUCTURAL STRATEGY

MODEL 1 : 100

SOUTH EAST

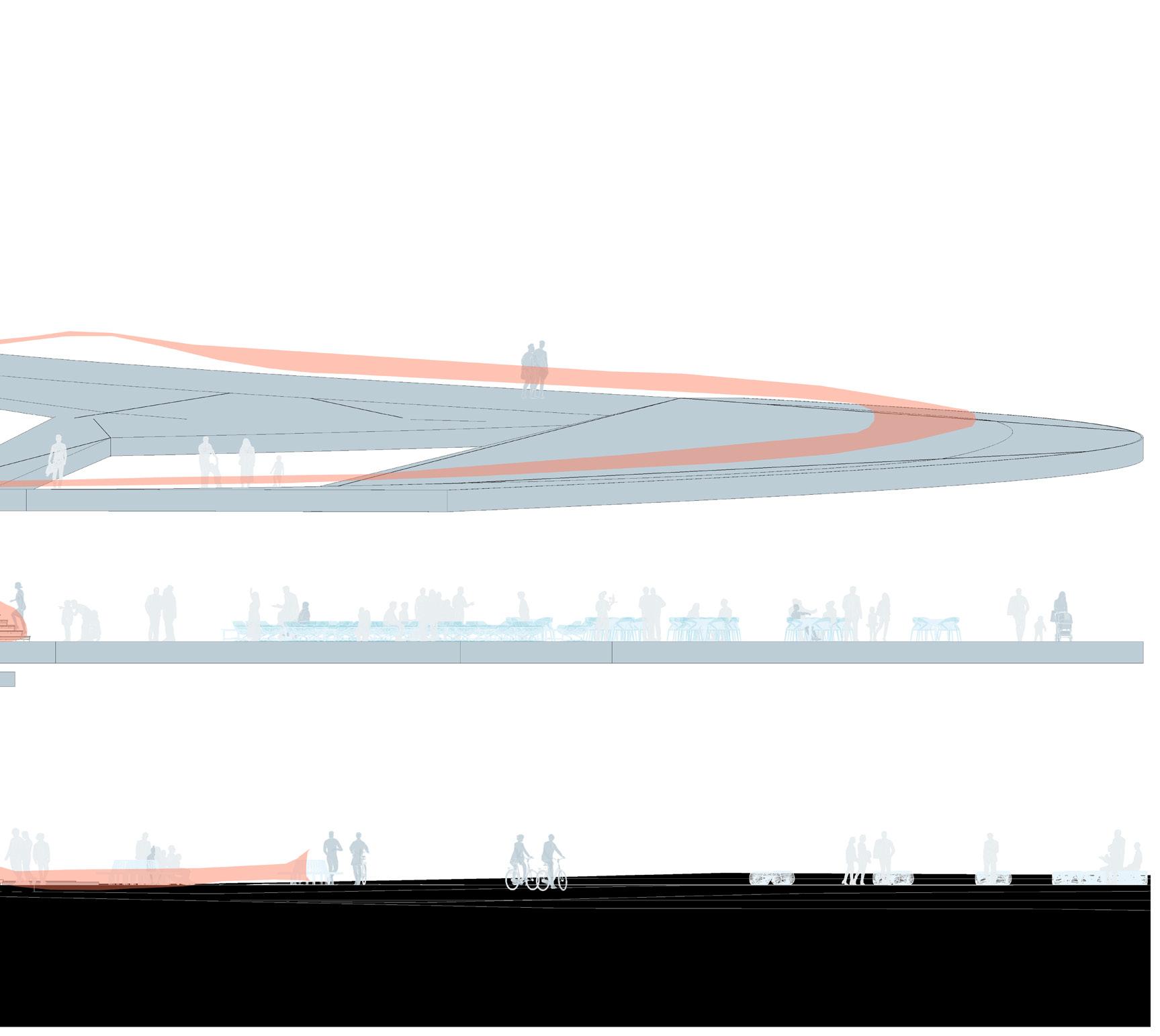

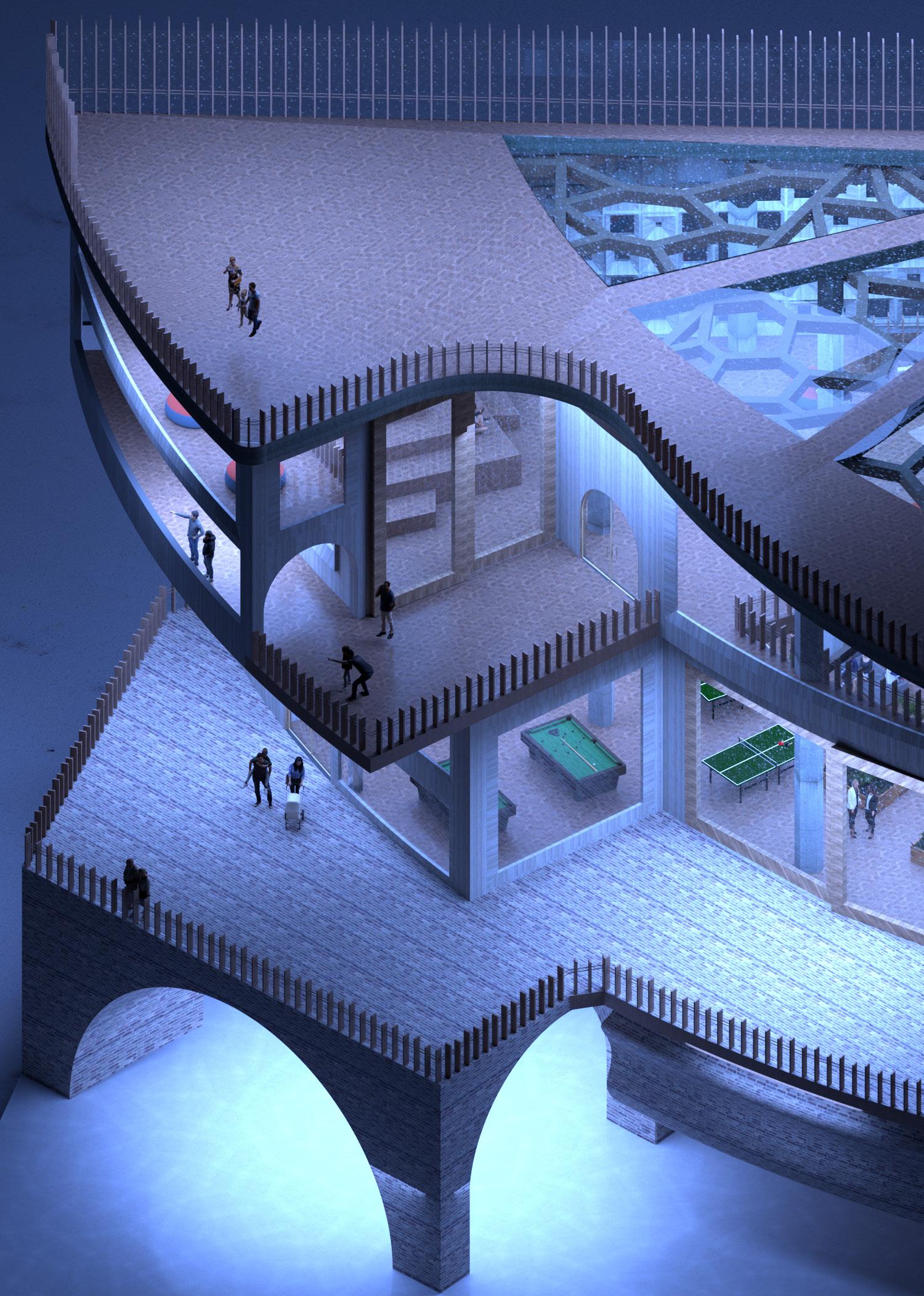

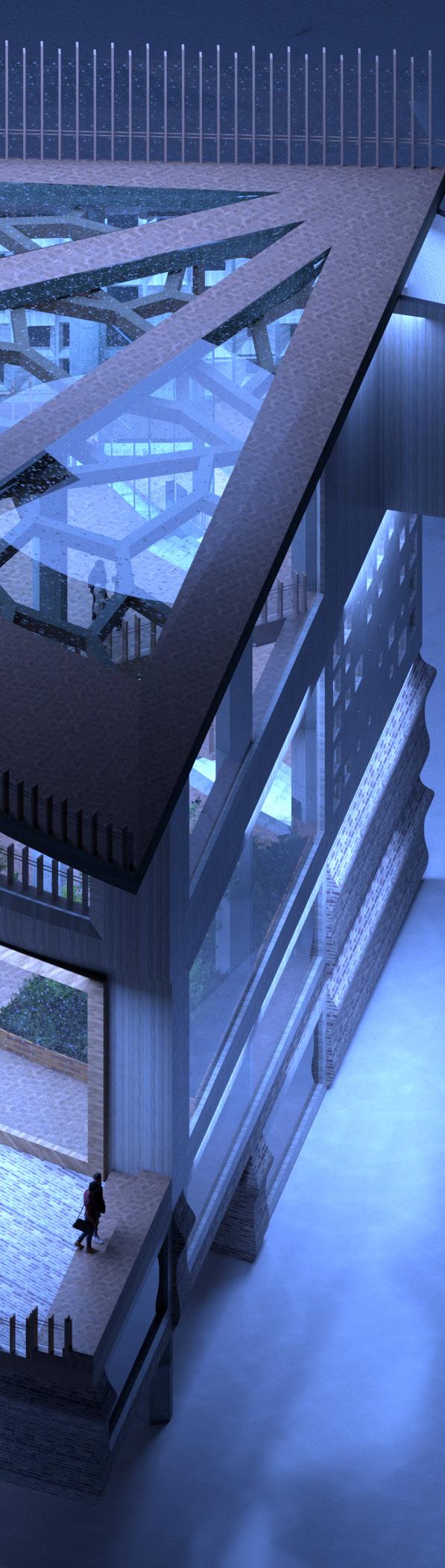

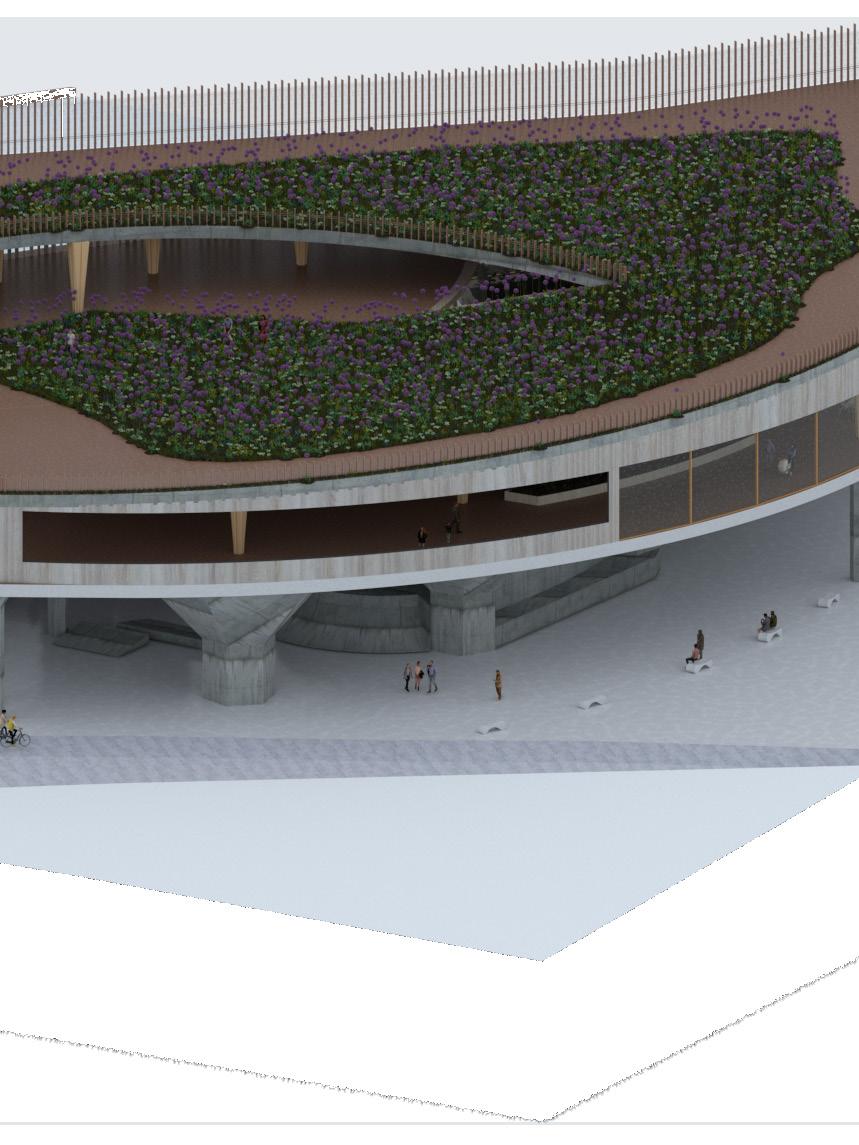

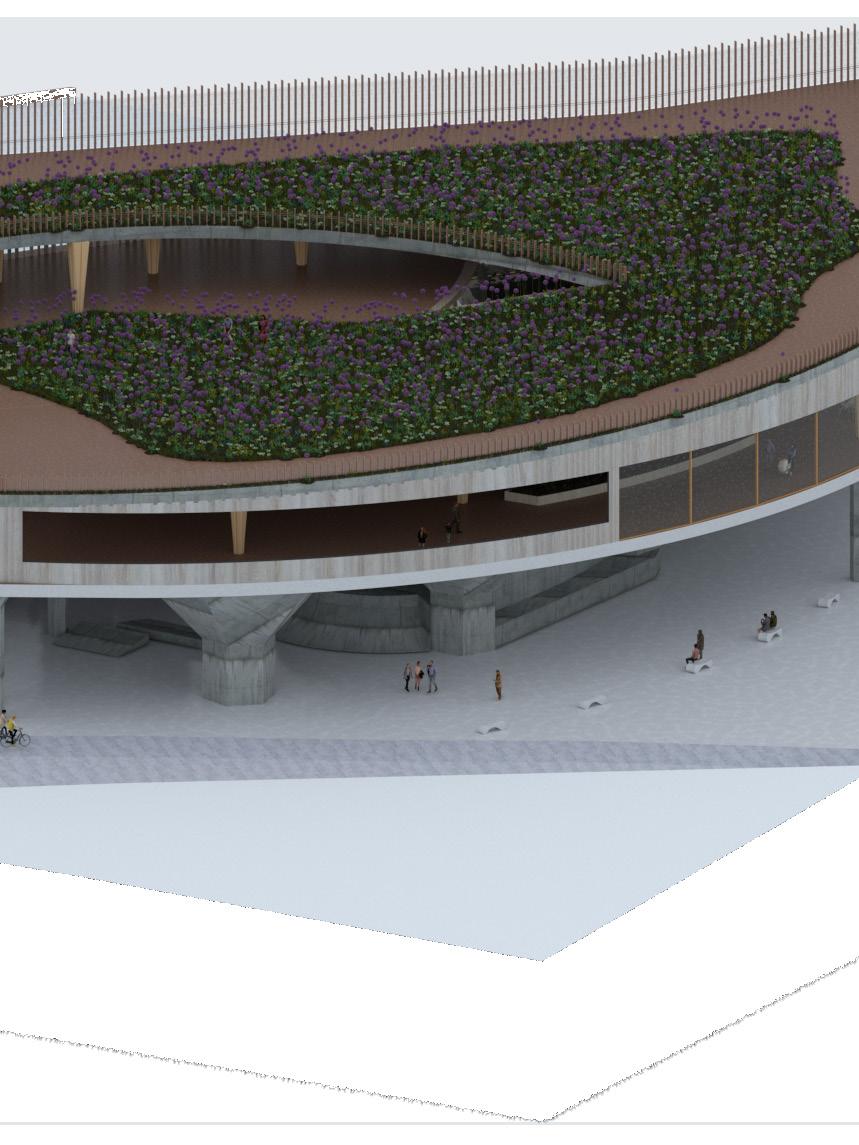

The project will consist of one main structure where the community centre will be based to the West of the site and an elevated park area to the East. The main material used for the structure of the two areas is concrete as it can maintain heavy loads. Rebar will be placed inside to support the frame of the structure and enable connections. Beams and columns will also utilise Epoxy in order to connect and provide high strength and adhesion properties between the two elements. The windows will be triple glazed and have a wooden frame which will be varnished to withstand the elements.

The community centre will consist of 4 Levels, including the ground floor, and will harbour a range of activities. The top two floors will be aimed at providing an area in the city where people can come and spend time as well as providing a space for events, the exterior façade will be wood in order to contrast with the bottom half and echo the elevated park’s green aspects. Whereas the lower floors will be dedicated to providing an area for admin and educational work as well as a reception area, the interior and exterior finish will be thin 15mm thick brick in order to bring out and fit in with the prevalent material of the area used on the neighbouring train track arches and buildings, while not adding much weight to the structure.

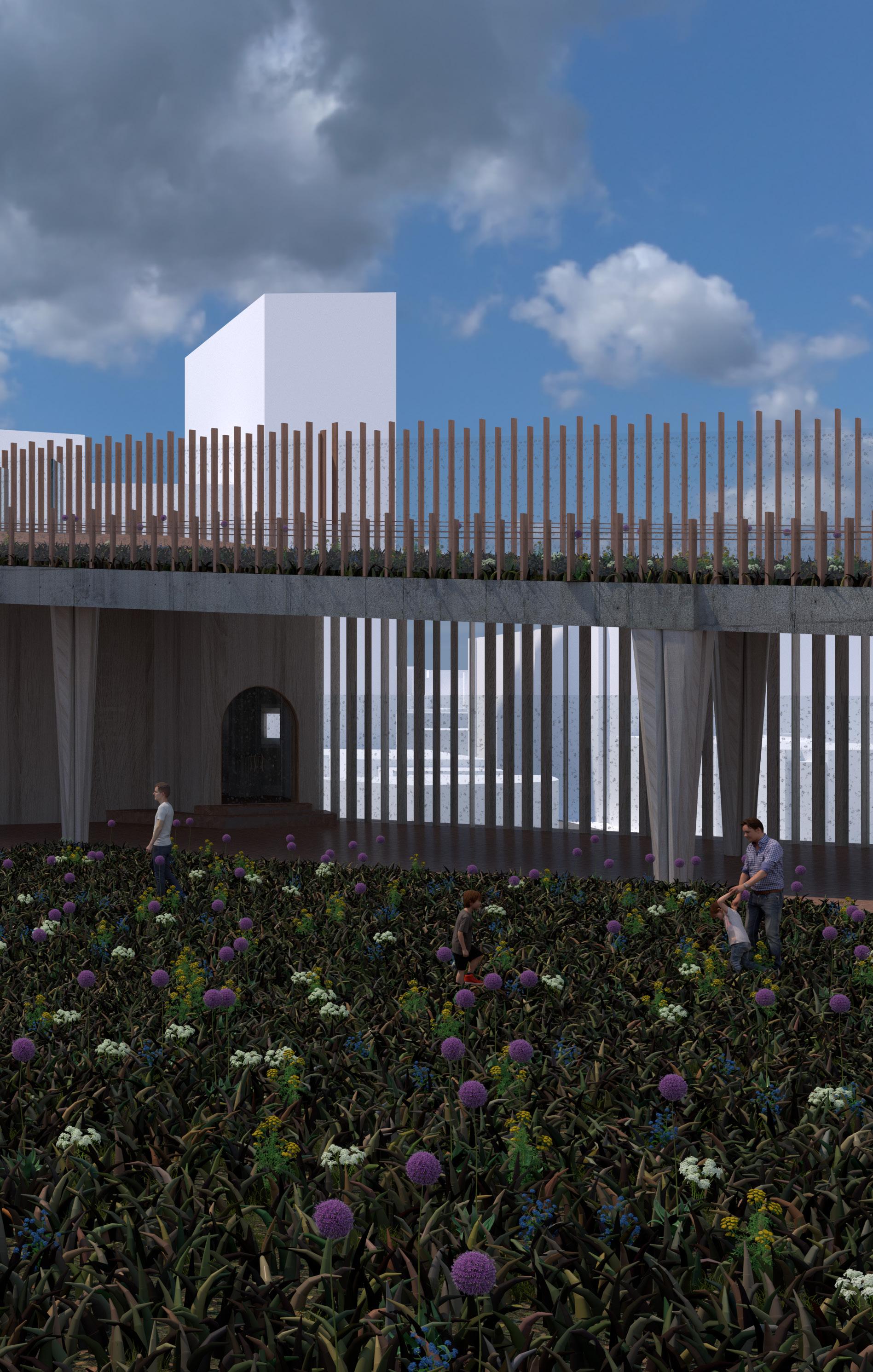

The elevated park to the West will consist of 3 levels. Starting at the community centre’s second level it will connect the structures and allow access to a covered café area in which plants are planted. The next level will connect the top floor of the community centre and be a green space, this will connect up to the roof as can be seen in South East Section 1:1000.

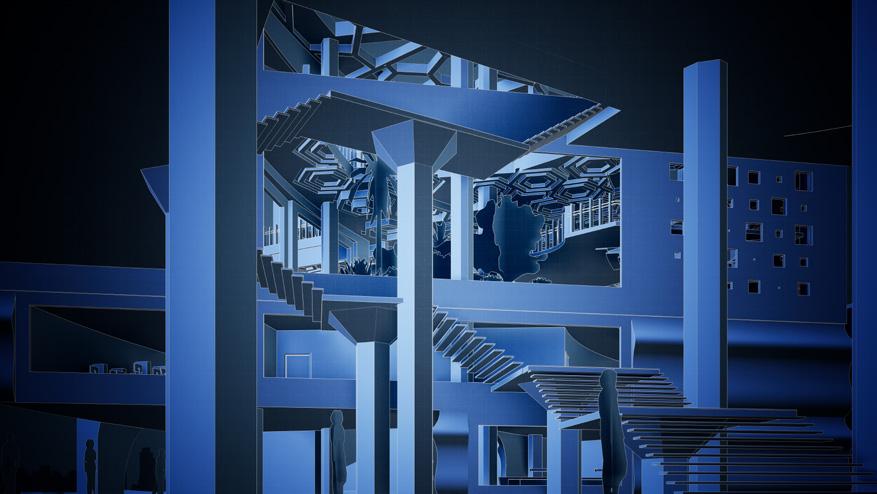

The choice of concrete was made for a number of reasons. Due to the height of the building, 22m, wood could not be used for the structure of the building as regulations limit wood structures to 18m in the UK. Steel and hempcrete was also considered for the structure of the building due the high strength and mixed shapes which can be produced with the materials. However, the high availability and ease of production of concrete will allow for a reduced carbon footprint in the production of the material. Furthermore, concrete is a material which is readily used in construction and will be for a long time therefore, it’s important to find more sustainable ways of using the material in construction. Consequently, the project will employ new methods in order to mitigate and explore ways in which concrete can be used in more sustainable ways. Concrete was also chosen due to its high durability and permeability; the UK is prone to a variety of climates such as rain and occasional snow throughout the year as well as wind and sun therefore the durability of the element is important. The material is also fire-resistant and absorbs heat, allowing for natural heat regulation within the building.

The negative effects of concrete have been thought about when creating the building structural envelope as it does lead to adverse effects on the environment. However, the ability to locally source concrete and new methods being found which reduce the carbon footprint of concrete will lead to greater benefits than sourcing materials from overseas ensuring a high operational carbon footprint, which other methods of construction would entail.

The general shape and aesthetic of the building fits concrete better as well and will ensure a cleaner and more robust building feel than the mix of steel and hempcrete as previously proposed. Eliminating the risk of corrosion and pesticides while keeping the maintenance of the building minimal, which will lower running costs associated with the community centre which is crucial as the goal is not the generate profit but to create an area for the community within the city.

STRATEGY

STRUCTURAL MODEL

1 : 50

SOUTH EAST

Columns allows deadload to be transfered down.

Beams allow deadload to be transfered along.

A T

REBAR

E

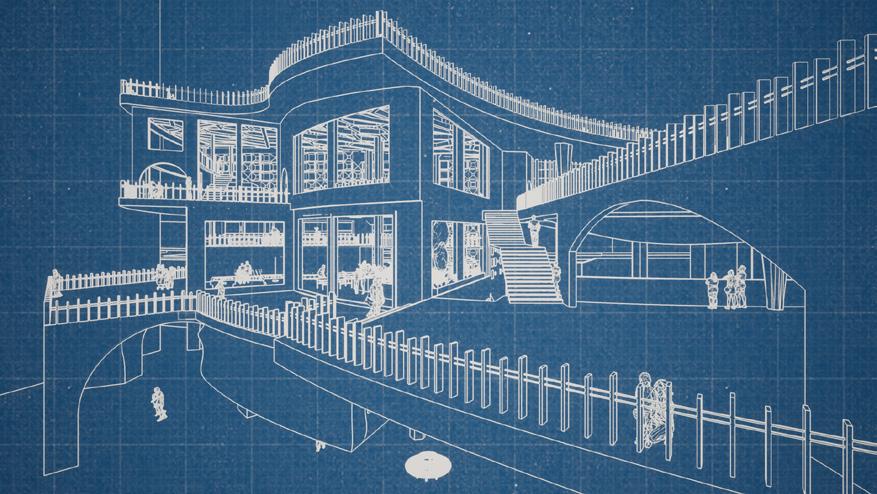

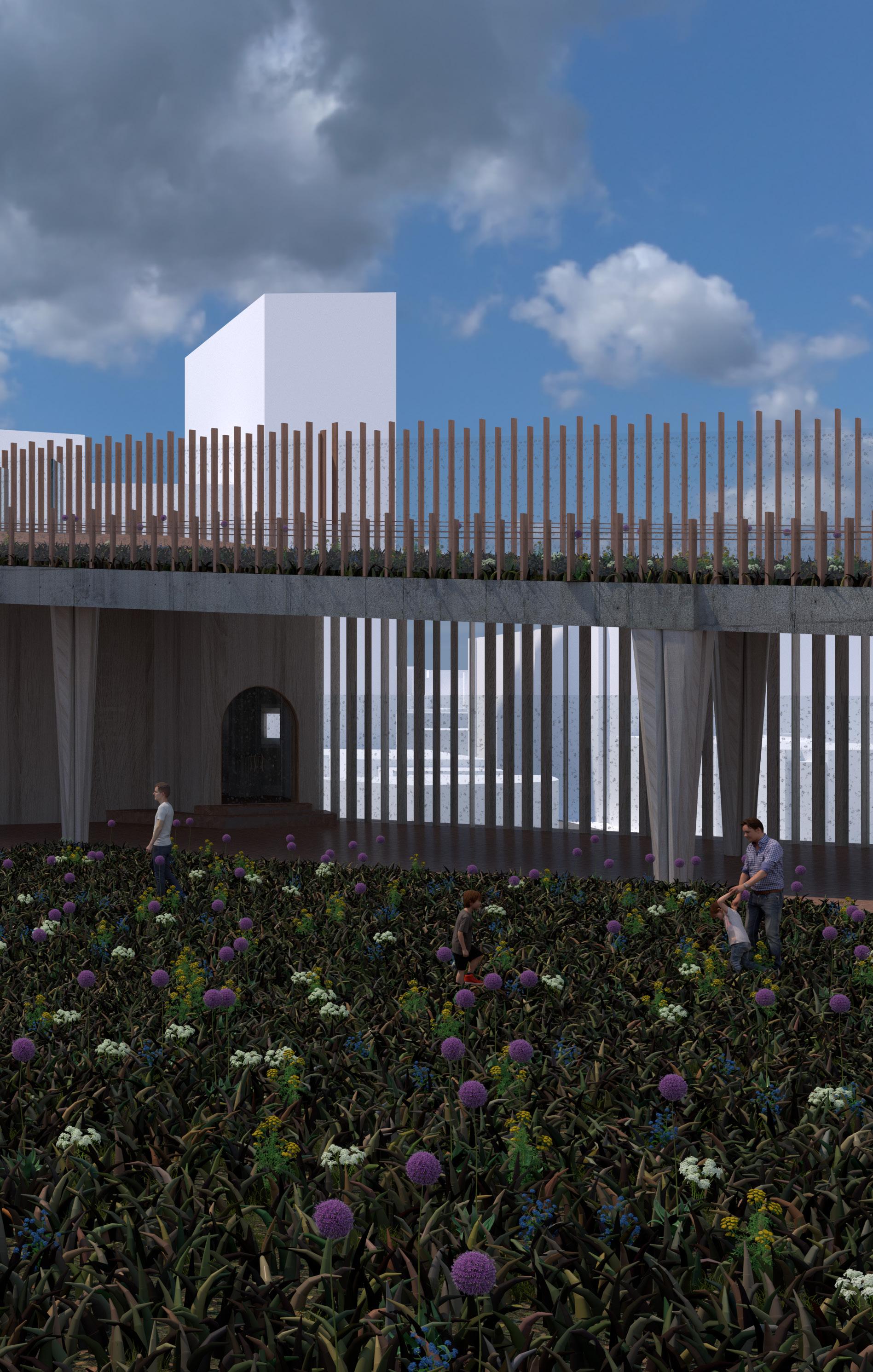

VISUALISATION

Inside Passing Train Rainy Day

Blueprints Ground Floor View of Community Center Blueprints of Community Center 2nd Floor Height Ground Floor Entrance

Elevated Park View of Community Center

Elevated Park View of Community Center

C E N T R A L Z O N E

2023

YEAR 3 MISCHA MCLAUGHLIN

MAY

PORTFOLIO

A. Vegetation.

B. Substrate.

C. Draniage Layer.

D. Filter Layer.

E. Waterproofing Membrane.

F. Concrete.

G. Gutter.

H. Wood Floor with Waterproof coating.

A.

B.

C.

D.

E.

F.

A. Vegetation.

B. Substrate.

C. Draniage Layer.

D. Filter Layer.

E. Waterproofing Membrane.

F. Concrete.

G. Gutter.

H. Wood Floor with Waterproof coating.

A.

B.

C.

D.

E.

F.

Elevated Park View of Community Center

Elevated Park View of Community Center