Southern Roundup

Partners,

I can’t believe we are nearly finished with 2024. It feels like our Southern Seminar was just yesterday, but the last few months have flown by because they were filled with so many memorable moments—Construction Inclusion Week, craft appreciation events, Hispanic Heritage Month, Halloween, Thanksgiving, AOP planning, peer group meetings, project milestones, holiday parties—our list goes on and on. Make sure to check out all the great photos from these events that are featured throughout this newsletter.

In mid-November, I had the privilege of hosting my first “Coffee Break with Bryan” call with eight partners from across the region. In 2025, I’m going to be hosting these calls monthly to check in with partners in all roles and locations to see how you’re feeling and how our leadership team can support you and your peers.

During our first call, I asked everyone to share a workplace moment from the past year that they were excited to tell their families and friends about. It was exciting to hear what moments stood out to people, but one pattern stood out to me: every story was about connections and camaraderie. It was a great reminder to me that we need to continue to make time for the events and moments that build our culture, because those are often the ones that fill our cup and make lasting memories.

Toward the end of that call, I was asked for my advice for developing personal goals for 2025, since this is Year-inReview season when we have those conversations with our managers. My advice to them, and to you, is to marry your developmental and performance goals to our company’s strategic anchors.

- Operation Excellence: Are there any processes you can improve so we can execute more efficiently?

- Client Focus: What’s a relationship you can invest in next year?

- Top Talent: How can you be a talent multiplier? Is there an increased role for you to play with hiring or onboarding?

If you take these broad questions and personalize them by applying them to your role and your project(s), it should get the ball rolling on developing your goals.

Please enjoy a safe holiday season with your loved ones. Make those memories!

Bryan Kuster CEO, Southern Region

The Port Houston Wharf 4/5 team gathered to celebrate Pedro Sanchez Martinez winning Marine Craft Professional of the Year.

Our Lafitte team collected an astounding 7,279 pounds of food, setting a record for the largest corporate donation ever received by the Northeast Louisiana Food Bank!

Wendy Hatchell, Kamecia Mason and MJ Williams paused for a photo during the group’s community outreach project at Old City Park in Dallas on the final Day of Construction Inclusion Week. Partners gathered to help the staff at the historic park, located near our Southern Gateway project, decorate for the holiday season.

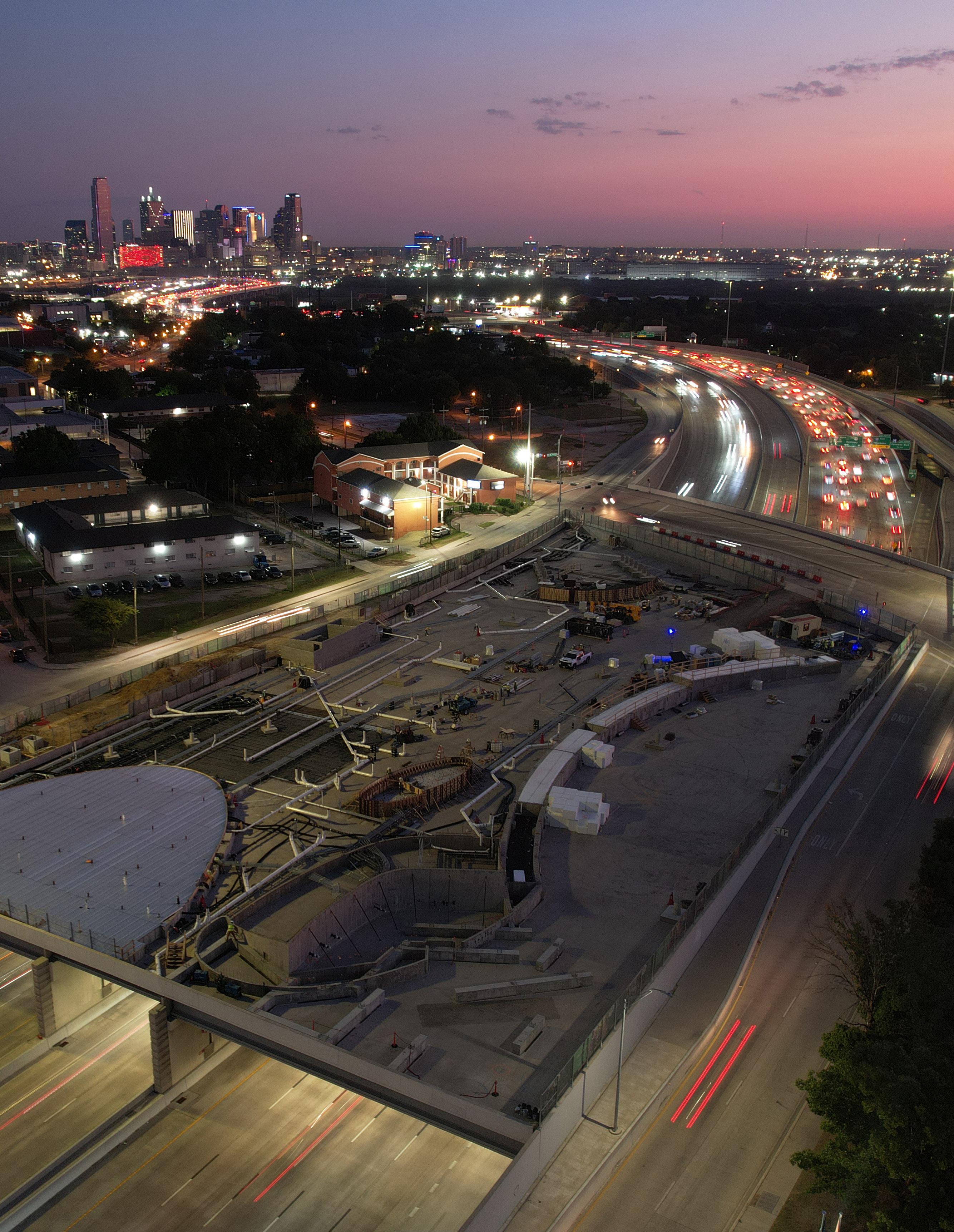

ABOUT THE COVER

Samsung's photo was a finalist for the MHI Photo of the Year Contest.

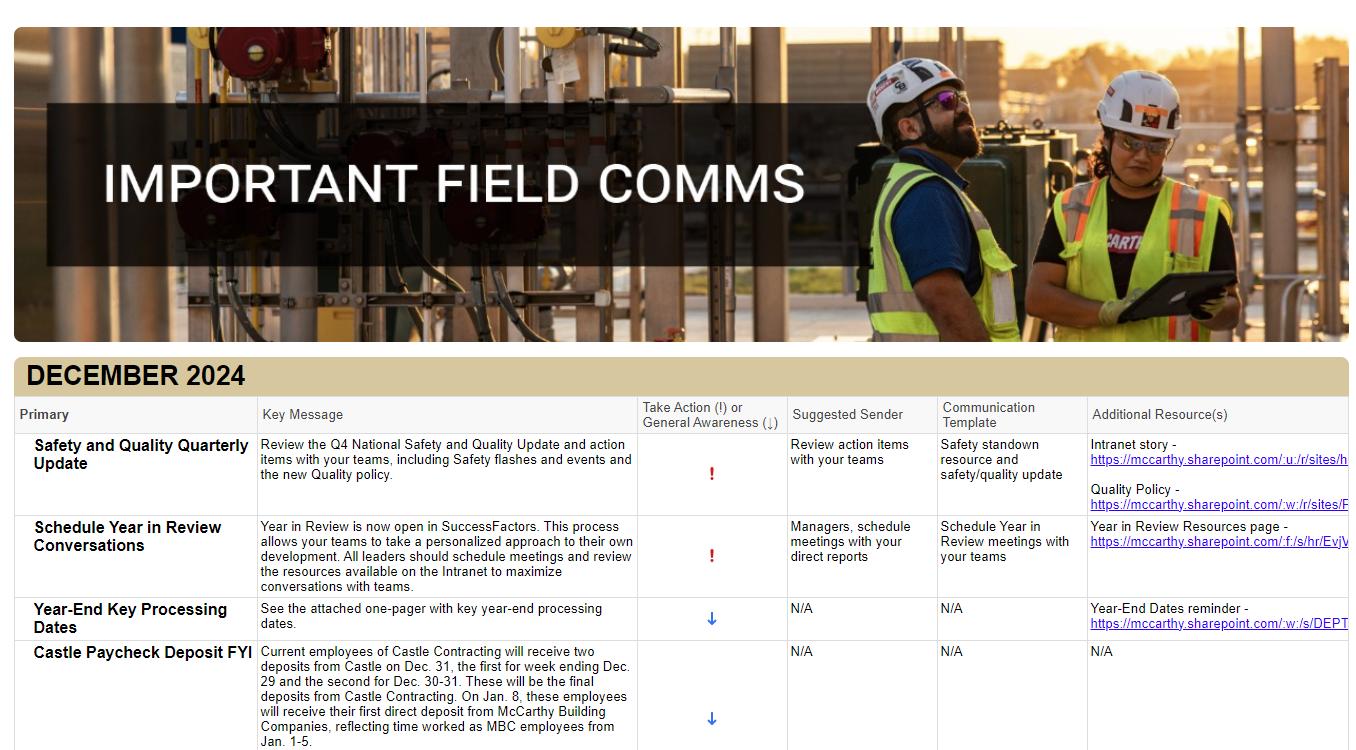

IMPORTANT DATES

December 24 Christmas Eve

December 25 First Day of Hanukkah (Dec. 25 - Jan. 2) Christmas

December 26 First Day of Kwanzaa (Dec. 26 - Jan. 1)

December 31 New Year’s Eve

January 1 New Year’s Day

January 14 Houston/Marine Q1 Huddle

January 15 Austin Q1 Huddle

January 23 Dallas/Civil Q1 Huddle

January 30 Atlanta Q1 Huddle

March 7 Stock Price Announcement

April 24 Genuine McCarthy Enterprises Annual Shareholders’ Meeting Shannon Lightfoot celebrates how we’re #BuildingAtlanta by sharing a selfie with our new McCarthy advertisements in Concourse C at Hartsfield Jackson Atlanta International Airport. Traveling through Atlanta this holiday season? Make sure to share your own pics in front of our new signage!

N A V I G A T I N G

H O L I D A Y S T R E S S

Winter holidays bring joy but also stress from financial strain, busy schedules, and unrealistic expectations. The pressure for perfect celebrations and a cheerful yearend can worsen holiday blues. Managing expectations, setting boundaries, and practicing self-care like sleep, exercise, healthy eating, and mindfulness—can help you enjoy the season with less stress.

Potential Stressors

Family time, loneliness, isolation, overwhelming to-do lists, pressure to make it perfect, financial stress, food/drink-focused anxiety

-Find Your Joy

Tips to Help You Cope With Stressors

Take a moment to go outside, see a friend, or do something that brings you joy.

-Set a Routine

Create a routine that gives you time to do things you enjoy.

-Prioritize Sleep

Healthy sleep can help you be productive and improve your mood.

-Stay Connected

Maintaining strong relationships reduces stress and boosts well-being

-Embrace Gratitude

Find one thing to be thankful for every day.

-Say No

Only say yes to plans and activities that make you happy.

To get

Quality in Action

As we celebrate World Quality Day, let’s highlight some quality wins from across the Southern Region. As seen in many of these stories, a small process change can make a big impact.

Brookhaven Self-Performs Mass Timber Erection

The Brookhaven City Hall team took on mass timber erection as a new self-perform scope. McCarthy had never touched this scope before in the Southern Region. To ensure success, they strategically drew from our partners at 901 Cherry in NorPac and worked closely with Binderholz, the mass timber supplier.

Prior to breaking ground, key members of the Brookhaven team visited the 901 Cherry project site. They held in-depth meetings during planning to discuss shipping, install, and other lessons learned from their experiences. They also visited an active timber project in Baltimore and attended a mass timber conference to expand their understanding of best practices. A project mock-up was conducted with 10 timber connections, enabling the team to understand its approach before beginning full-scale erection.

Project leaders held a detailed preinstallation meeting with Brookhaven’s craft to walk them through the install process, share lessons learned, and set expectations for quality and execution. For each timber connection, they organized individual screw and dowel bags for each assembly, ensuring the correct components were ready for erection of each phase.

This proactive step minimized delays and reduced the chance for rework. As the timber arrived, they documented the condition of the pieces with photos and provided this documentation to Binderholz, addressing any concerns before installation. The team also monitored the moisture content of all timber members to mitigate any potential issues related to material performance.

At the start of the installation phase, a skilled installer from Binderholz, our mass timber supplier, came on-site for three weeks. He taught installation techniques, resolved some manufacturing issues, and helped the crews get into a rhythm. Throughout the installation, the team maintained a strong line of communication with Binderholz’s engineer and McCarthy’s structural engineers to ensure that any issues were addressed promptly, keeping install on track.

Through careful planning and leveraging the expertise of our partners and suppliers, the Brookhaven team successfully completed mass timber erection with no quality incidents. By streamlining our installation process and avoiding rework, we were able to improve productivity and save on labor cost.

Cattlemen II Utilizes Thermal Robot

The Cattlemen II Solar Project in Rosebud, Texas, received an autonomous mobile robot! This cutting-edge technology will patrol the site, utilizing state-of-the-art optical thermal imaging to identify quality issues. It will detect, report, and record these issues, ensuring our field team is always informed and proactive. This initiative is made possible through our partnership with OnSight Technologies.

Northside Hospital Renovation Team Saves Weeks with Proactive Meetings

The Second Floor Renovation at Northside Hospital in Alpharetta, Georgia was a fast-start project, which increases the potential for oversights and grey areas in the scope plans. McCarthy is working with Northside directly and coordinating with HLD (architect) and HLG (design team) to bring two new operating rooms online by the end of April 2025. This is a Certificate of Need project for Northside, so the timeline is driven by the operating rooms being completed on time.

Throughout the startup phase, our project team noticed several scope details on the different sets of drawings were overlooked or inaccurate, including the millwork scope. Worried about future project delays or errors, our team took the proactive step of scheduling an extra page-turn meeting with the architect, designer, and millwork subcontractor where they ironed out the inaccuracies. Eliminating the scope confusion early allowed us to release millwork material in time to meet scheduling needs.

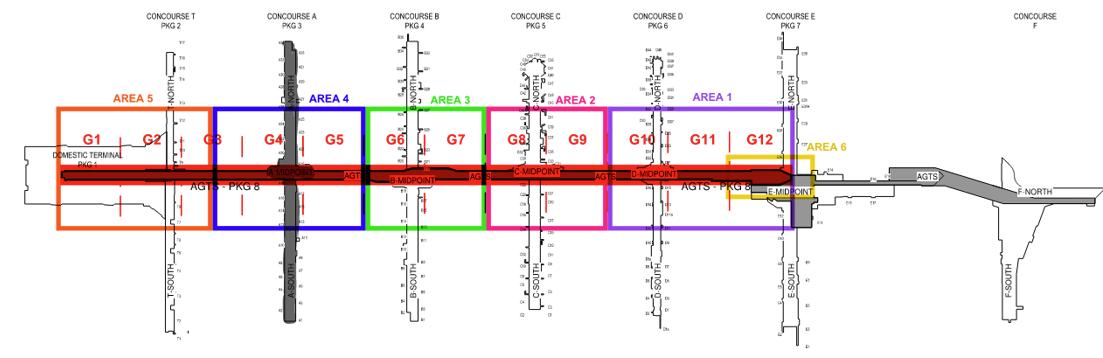

E Gates Navigates Fuel Shutdowns

Over at Atlanta’s E Gates project, they’ve had a handful of fuel shutdowns on this project that have all been successful, but one shutdown required the team to go above and beyond what was originally planned out. We had a change in the design to remove one of the old fuel hydrant pits since the new passenger boarding bring foundation changes now expanded over top. Our fueling subcontractor was demobilized after their work was completed and had to be coordinated through virtual meetings.

The fuel lines are the lifeline at the airport. Anytime we have to modify their system, this causes heavy disruption and has to be coordinated with multiple different entities at HJAIA, above any beyond a typical MEP shutdown. The coordination includes airlines, flight schedules, control tower, fuel farm, airport operations and more. One stray parked plane could ruin months of planning. The coordination process starts roughly two months before and isn’t fully finalized until the fuel farm receives their final schedule about a week before the planned date.

In this situation, fuel pumping trucks rotated out, working at night against a tight timeframe to clear 25k gallons of fuel. Fuel was pumped from two different gates across concourse E for more than two hours. Once drained, the welding crews were open to start their work. This shutdown included cutting and capping an existing line. In the background of this work happening, emergency fuel truckers stand by in case something goes wrong. (It’s similar to oxygen tanks from a healthcare perspective, but larger in magnitude.)

The work had to be completed, third-party tested and approved before the fuel line could be re-energized. The window was only roughly six hours to get everything done, which allows no room for errors.

For this shutdown, the team planned and performed the work flawlessly. The gates were all re-opened on time for the first departure out, with no delays to their schedule. It was a very successful shutdown and helped solidify to the client that we were the right partners for this project.

Ismaili Smooths Out the Many Hard Surfaces

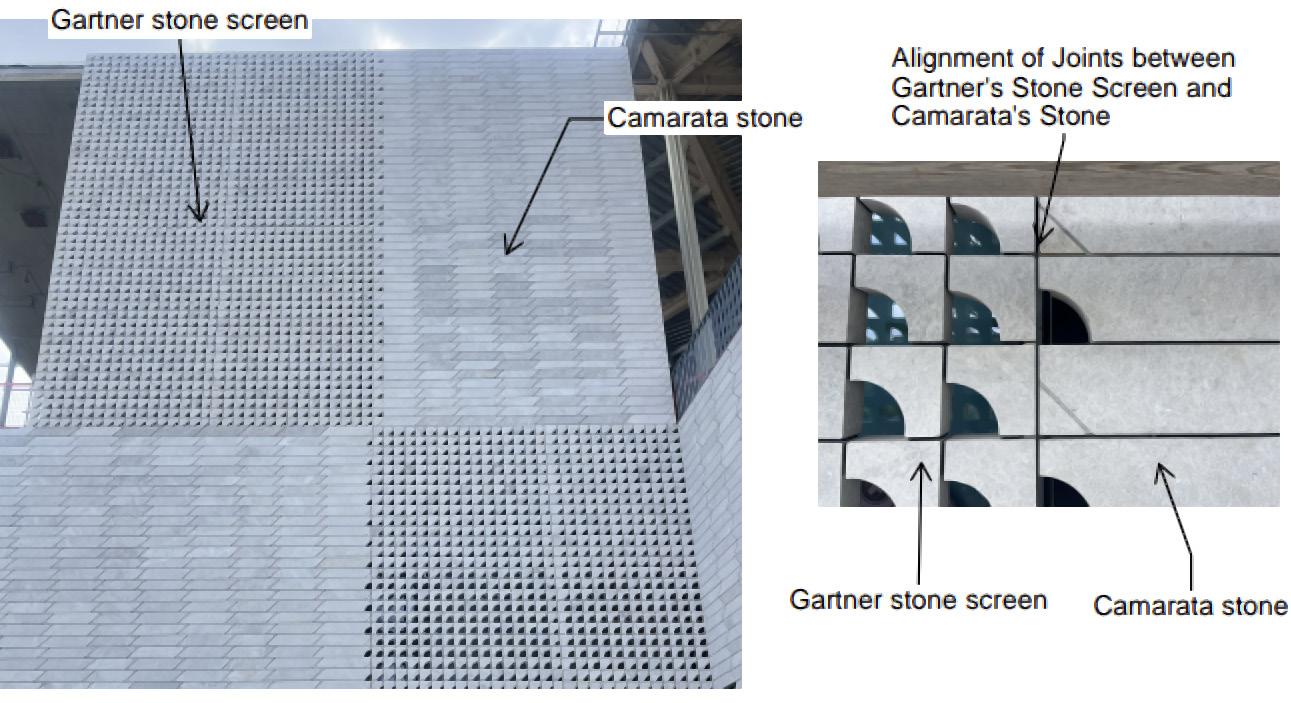

The stone façade at the Ismaili Center Houston has been a challenging coordination effort due to the involvement of two subcontractors, each managing distinct yet interconnected scopes using the same Turkish marble. Gartner’s scope includes large scale stone screens that are sent from a quarry in Turkey for fabrication in Germany. They are shipped as fully fabricated screens of stone in roughly 16’x10’ pieces that have virtually no adjustment in the field. Camarata’s scope is a more traditional stone façade that includes individual pieces fabricated in Italy. The pieces are installed on an aluminum girt system, allowing greater field tolerances.

The two stone scopes interface at numerous locations throughout the building so effective coordination was crucial during the preconstruction and submittal processes. This was especially of concern to the architect and owner. Throughout the process, McCarthy traveled to both Germany and Italy with the design team and owner to review mockups, test color variations in the stone, and understand the two fabrication processes.

This proactive approach during the early stages of the project has significantly contributed to the smooth execution of both scopes in the field, ensuring that the design intent is maintained while meeting the practical requirements of the construction process.

Mayhill Saves Money, Time

In addition to the marble challenges, the site concrete package is a major self-perform scope at Ismaili. The site is 11 acres with architectural elements throughout, including a monumental stair, five fountains, 13 unique courts and garden spaces, and a 10’ concrete privacy wall enclosing the entire site. The landscaping areas hold significant architectural value to the owner and design team due to the importance of garden spaces within the Ismaili community.

Coordination for this scope began back in preconstruction with regular calls with the landscape architect Nelson Byrd Woltz (NBW). Through early coordination with them, the site concrete team was able to successfully complete the north end of the site and is well on their way to completion at the central and south areas.

The McCarthy site concrete craft team has done an exceptional job keeping quality at the front of their minds. They have been able to overcome many challenges and have ultimately produced an extremely high-quality product. NBW and the owner have been very outspoken with their praise for the site concrete finishes. NBW has even requested McCarthy as the contractor for a future project coming to the Houston area.

At the Mayhill project, they partnered with Southeast Grinding (SEG) by leveraging a previously established relationship. They were onboarded quickly and mobilized for self-perform work on the bridge. They then pivoted to grind the roadway even though it was a different subcontractor’s scope. The paving sub DDM agreed to a back charge to share the cost, and the team was able to complete the entire project during a two-day mobilization. Cost share / back charge agreement made SEG productive because they didn’t have to remobilize for a different contractor.

SEG was great to work with and ended up at just over half of their contract value. With the back charge to DDM covering some of the cost, the total cost to McCarthy was about 33% of what was expected.

Walton County Coordinates Shallow Electrical Underground

West Georgia Electric bid all their conduit and raceway to be installed underground. Our project team ran into a procurement issue with getting the structural precast panels started, so we made the decision to proceed with all underground work to pour concrete slabs prior to precast coming on-site.

Our McCarthy team and BIM team reached out and got West Georgia’s modeler and Metromont's engineers on a series of meetings. Heavy BIM coordination was required between West Georgia, Metromont, and McCarthy to allow the hundreds and hundreds of shallow conduits to pass over the foundations where the precast panels would sit in the future. Blockouts were made to the panels under strict conditions of clearance

from structural components. Metromont provided parameters West Georgia had to meet to a certain clearance from foundations connections and cast in place prestressed cables. All submittals had to be expedited and approved to ensure locations of boxes, such as fire alarm, owner provided equipment, etc. were captured within these precast panels.

West Georgia was able to release their underground work early to complete two months of shallow conduit work before precast panels arrived on site. Blockouts in the precast panels when they arrived on site lined up well with the majority of the crossing conduits and were erected with limited conflict with electrical.

Barry Rose Team Digs into the Details

SBR excavation planning started by leveraging our national partners, utilizing Yard-provided equipment with elevation control, and planning truck routing. The survey team checked to ensure we did not overexcavate, and we did the final cut with a GPS-equipped dozer. The survey confirmed we had cut to the final elevation. By avoiding overexcavation, minimal final rolling was needed to achieve compaction. We passed density testing and remained 20 percent under budget on labor, equipment, and trucking costs.

HJAIA Fire Life Safety AGTS

The Fire Life Safety Project is a joint venture with New South and Synergy (NSMS), and we self-performed the firestopping as a subcontractor. One of the primary scopes of the project was the renovation of all emergency egress stairwells that included door replacement, painting, and fireproofing. Before beginning work on these areas, the project team created a contractor quality control plan where we set up several preparation and installation inspection checklists to give ourselves a standard to work by. The checklists included observations such as verifying openings were clear of materials before installation; verifying the minimum thickness of the fill was achieved; and identifying any areas requiring firestopping labels.

Coordinating with the self-perform team, the project delivered an end product that the owner and design team were very happy with, commenting on how good the work looked. Even a scope most would consider very minor can have a big impact when we take the time to make sure it is done correctly.

CentrePort

Trail Develops Individual Work Packs

The detailed individual work packs for the CentrePort Trail have been recognized as a new standard for the Southern Civil Business Unit. These plans have enabled the team to gain an understanding of project requirements, identify unknowns within the scope of work, and establish effective sequencing.

Before starting any work, the team made a big push to fully understand both City of Fort Worth and TxDOT Specifications. During this process, many discrepancies in the specs were identified, shared with the owner and resolved early to avoid any confusion or clashing during the execution phase. To ensure alignment between all parties involved, the team created an ITP (Inspection and Test Plan) to have a formal document detailing all requirements that must be fulfilled.

With a better understanding of the “what,” the team focused on the “how.”

The team broke down all major items related to the scope of work and created an Individual Work Pack Tracking Log. This log was developed to break out the scope into more manageable components. Through this process, we came across many unknowns that assisted with early RFIs and clarifying specific means and methods that will be required.

After the “what” and “how,” we moved into strategic sequencing and a well-organized logistical plan that allowed us to execute efficiently. Guided by these individual work packs, the CentrePort Trail Project is ahead of schedule and anticipating an increase in profit margin.

Sea Center Texas Streamlines Submittal Process

The engineer, Garver, put their specifications together using their existing boilerplate library without much effort toward making them project specific. The submittal register generated from these specs included 212 items, and we were limited to no more than six per day or 20 per week per the engineer’s “mass submittals” definition. The McCarthy team exerted a lot of effort reviewing the specifications to identify any planned submittals that could be considered not applicable to the actual scope of work. Discussions were held weekly with the engineer, which resulted in 112 of the original 212 submittals being deleted, essentially cutting staff administrative time by 50 percent on this task. With only a two-person team on site, that freed up lots of time for field supervision, safety oversight and other administrative tasks.

Samsung Fab 1 Adapts Welding Plan

Initially, the project plan involved constructing the main modules inside the FAB1 building, which presented significant obstacles due to space constraints and the presence of more than 50 subcontractors working in close proximity. Recognizing the need for a more effective approach, we shifted our strategy to pre-assembling portions of the modules at the McCarthy laydown area outside the building.

By performing welding and assembly in a controlled environment, we enhanced the quality of our work. This innovative method allowed for better oversight and reduced the risk of defects associated with the challenging conditions inside the FAB1 building.

The change in strategy resulted in a notable increase in our production rate. The ability to focus on assembly without interruptions and constraints led to a 42 percent improvement in overall productivity, going from assembling 108 feet of structural steel in five days to only 3.5 days. Constructing the modules in the laydown area significantly improved worker safety. The controlled environment minimized risks associated with working alongside multiple subcontractors and allowed us to implement more effective safety protocols.

Pre-assembling any part of the main modules had not been considered part of the execution plan as the client had, from the get-go, stressed how they had never been able to do that on any of their previous projects due to size constraints. Our McCarthy team, was able to come up with ways to pre-assemble the steel bases in sections, facilitating assembly inside the building. The team also identified a safer way to lift several 2D Unistrut frames to the second floor at the same time, enhancing the schedule.

A critical aspect of our quality assurance process involved extensive inspections conducted by third-party Certified Welding Inspectors (CWIs). McCarthy performed around 50 inspections, covering approximately 1,000 Complete Joint Penetration (CJP) welds. We achieved an impressive 100 percent acceptance rate, demonstrating our commitment to maintaining the highest quality standards throughout the project.

The lessons learned from the Samsung FAB1 project have equipped McCarthy with a valuable new approach to pre-assembly of modules. This method not only allows us to expedite the assembly process, but also enhances client satisfaction by delivering high-quality results more efficiently. We’ll implement this strategy in future projects, leveraging our experience to streamline operations and improve outcomes.

Southwest Team Plans Successful RTU Drop

The Southwest Airlines Dallas team accomplished a significant milestone by successfully installing 12 rooftop units (RTUs) at the Southwest Airlines Technical Operations building. Given the challenging interior location of the installation site, the team utilized five state helicopters to place the units precisely where needed. This complex operation required meticulous planning and coordination. Using work plans and continuous meetings with the helicopter company and the trade partners, the team developed a plan to successfully replace these units with an emphasis on quality and safety in about three hours. This quick execution allowed for a minimum disruption of the building’s HVAC system.

GTRI Executes Core & Shell Quality Win

The scope of work for the GTRI project consists of building a Secure Compartmentalized Information Facility (SCIF) for GTRI’s clients. At the beginning of the project, the team sat down with McCarthy personnel who had previously built a SCIF for GTRI and understood the process behind these projects. The group discussed the difficulties they encountered, specifically with a security consultant used by GTRI that had a history of creating new rules and requirements that continuously hindered the progress of the project and resulted in rework continuously throughout the project. The same consultant was assigned to the new project.

Due to the communication between the new McCarthy team and the old McCarthy team, we were able to engage this consultant early in the project and identify key issues before they were covered up. The primary example of this is located on the second floor. One of the SCIF requirements is that a “false lid” is built over the top of the facility. The MEP hangers must be mounted to the structure and penetrate the lid for MEPs to be connected. The consultant informed us that using steel threaded rod that penetrates through the false lid is no longer an acceptable means of hanging MEPs. By catching this early in the project, the team prevented significant rework on the second floor. If the false lid had been installed with these steel rods, the entire false lid would have needed to be removed and reinstalled to rework the hangers.

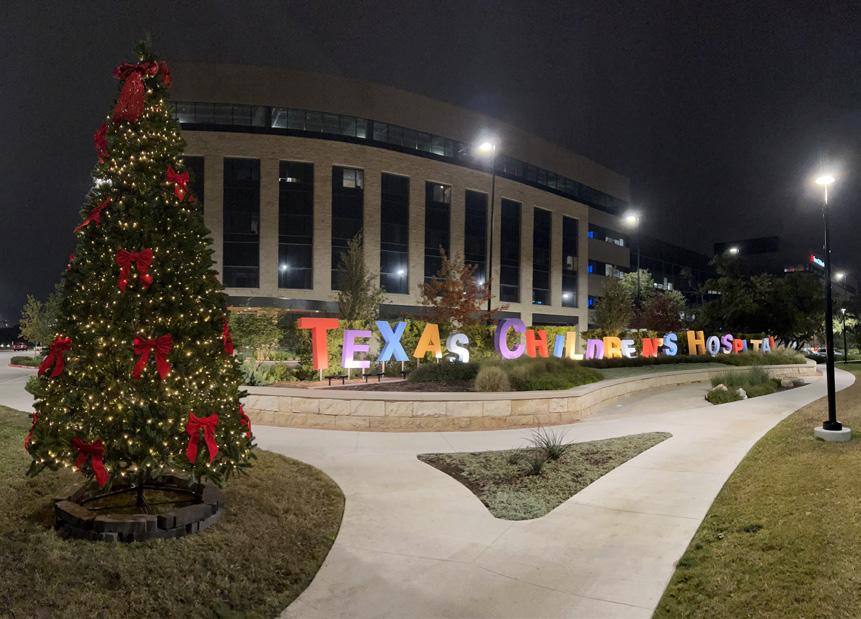

TCH

Expansion

Austin North Campus SSG Emergency Center

During the planning phases of performing trenching for underground utility work at the TCH North Austin Emergency Center SSG project, we were faced with a discrepancy between the provided contract drawings and as-builts supplied. This discrepancy had existing utilities shown to tie into multiple locations that differed from what was installed. There was also an existing column footing interfering with the proposed new plumbing install location. By finding these discrepancies prior to saw cutting, we were able to adjust the layout and prevent extra work/rework.

It was a reminder to always verify as-builds with contract documents prior to any critical work and to have as-builds readily available for the team while ensuring the trade partners have access to these documents.

Safety Update Section 01

JOIN THE MVP CHALLENGE!

December 2 nd - January 31 st

The MVP Challenge serves as an empowering initiative to strengthen the safety culture across our projects, aiming to significantly reduce incidents and injuries. This program fosters a spirit of friendly competition among Southern Region projects, enhancing hazard recognition and encouraging the reporting of unsafe acts. By generating valuable data through documentation, we can identify trends and implement proactive risk mitigation strategies.

As we approach the end of 2024, let's harness the momentum from the MVP Challenge to finish the year strong. Together, we can create a safer work environment and set the stage for an even more successful start to 2025. Let’s commit to prioritizing safety, recognizing hazards, and taking action now to ensure a thriving and secure future for all our teams.

Areas of Focus

• MVP / THA checklist participation and quality

• Unsafe Observation Reported

• Positive Reinforcement

Awards

Awards will be given based on project team size, total project worker hours (during the competition window) and participation—the more members of the team who participate, the more likely that project is to win. Each team member on a winning project receives a prize.

AWARD CATEGORIES:

• 1st Place - $200 Gift Card to the McCarthy 1-stop shop.

• 2nd Place - $75 Gift Card to the McCarthy 1-stop shop.

• 3rd Place - $25 Gift Card to the McCarthy 1-stop shop.

A Safe Holiday Season

During the busy weeks of holiday festivities, it’s easy to get distracted. Maintaining a proactive safety mindset is essential to prevent accidents. Let’s continue to prioritize our safety by staying focused on the task at hand, especially on our job sites.

Key Safety Actions

There are two critical tasks we need to do to keep being successful this holiday season:

•Pre-planning and THA Usage: During the THA process, emphasize the importance of staying focused and being mindful of the task at hand, as distractions will pose hazards.

•Jobsite Coverage Plans: A full understanding of the notice of protocols, red folder/digital red folder.

o Each safety lead will be sending out the local clinic information to share in your coverage plan.

o Please call your Regional Safety Lead with any questions you may have over the holidays.

5 MOST FAILED ITEMS

1. Is trash/debris located in a designated collection bin or organized into piles for removal?

2. Is pathway clear of slipping/tripping hazards, cords, and debris?

3. Is the employee wearing the proper gloves to protect their hands according to the Safety Guidelines policy?

4. Proper eye protection being worn?

5. Is material properly stacked as not to fall over?

20,984

Our people Section 02

Development & YIR Tips | Seminar Recap | Service Awards

Our Austin partners, including Raul

and Ruth Milan, hosted a trunk for kids at their local Travis County Sheriff's Office Annual Trunk-or-Treat. Shoutout to the TCH team who made the jail sign come together with supplies they already had on site—it ended up being a very popular photo opp with the trunk-or-treaters!

Saucedo, Carmen Gust,

We Grow Together

Here are McCarthy, your development is designed to be a collaborative process. Though you’re encouraged to own your own development, you don’t have to do it alone. Working together with your manager, the Year-in-Review process is a key piece of the Employee-Manager Connection (EMC) puzzle to help align on current and completed priorities while laying out 2025 goals.

Year in Review meetings are a perfect time to reflect on performance, provide constructive feedback, celebrate achievements and lay the path for future growth opportunities. YIR meetings should be conducted between Dec. 2 and Jan. 31. Goals should be inputted to success factors between Jan. 1 and March 31.

As a manager, how can you prepare?

•Input priorities, development goals and any additional comments in SuccessFactors. This information will directly populate the Year in Review form.

•Confirm that your direct reports are correct in SuccessFactors. If a change is required, let your regional HR partner know as soon as possible.

•Review the recorded training and resources for managers that are available on the Year in Review intranet page, They will not only help you navigate the system and understand the process but also provide tips for an effective feedback conversation.

•Document your conversation in SuccessFactors so that it's easy to reflect and revisit what was discussed.

As an individual contributor, how can you prepare?

•Input priorities, development goals and any additional comments in SuccessFactors. This information will directly populate the Year in Review form. Need some ideas? Check out Bryan Kuster’s goal-setting advice on p. 2.

•Confirm that your manager is correct in SuccessFactors. If a change is required, let your manager or regional HR partner know as soon as possible.

•Review the recorded training and resources that are available on the Year in Review intranet page. They will provide tips for an effective feedback conversation.

•Document your conversation in SuccessFactors so you can have a way to reflect and revisit what was discussed between you and your manager.

Huge Congratulations to Our Fall Promotions

In case you missed it, nearly 70 Southern partners earned promotions this fall. Read more about each partner’s journey on Insider.

Abigail Saenz

Adam Hernandez

Adriana Womack

Alejandro Villarreal

Alex Toth

Amanda Major

Amanda R. Rodriguez

Andrea Wingenroth

Anna Campbell

Avery Johnson

Brad Minyard

Brandon Henderson

Brock Boyd

Bryan Butler

Caitlin Safford

Caroline Suess

Carter Schmid

Cesar Mendoza

Chad Berchak

Chris Jett

Christopher Proodian

Connor Mitchell

Corey Everitte

Daniel Arguelles

Daniel Hunt

Derek Rees

Drew Hoffman

Dylan Fuller

Ethan Waldroup

Fabian Flores Pina

Freddie Taylor Jr.

Fredy Cardenas

Guillermo Silva

Harris Hansen

Jason Palfreyman

Jason Wait

Javelle Redmond

Jordan Attar

Jose Talamantes

Joseph Duncan

Josh Voss

Juan Pegueros

Justin Key

Kyle Armstrong

Lester Juneau

Lindsay Anderson

Logan Manuel Lucinda Butler

Marco Guardiola

Margarito Gonzalez Pareja

Mariana Perales

Melanie Lyssy

Michael Bond

Michelle Nash

Mike Williams

Nancy Vasquez

Nisha Mohd

Omar Mendoza

Oscar Barrera

Richard Sewell

Introducing Our New Southern SVP Ops

Riley Durham

Rishabh Bhattacharya

RJ Sayler

Robert Sanchez

Rowdy Mitchell

Sheree Coe

Tanner King

Travis Stevenson Yazan Zakaria

We’re excited to welcome Eric Hoffman to our Southern Region as Senior Vice President of Operations. Eric joins us after a successful run as VP Ops for SoPac’s Newport Beach office. Eric is backfilling the role occupied by Scott Lawrence, who is transitioning to Southern Chief Operating Officer. Scott and Eric’s new roles are effective Jan. 1, 2025.

With 18 years of experience at McCarthy, Eric brings a broad understanding of all roles on the Operations side of our business. He started his career as a PE and worked his way up quickly, eventually leading the Loma Linda University Medical Center Campus Transformation team that won the Roger Burnet Award in 2021. Most recently, Eric was VP Ops for the Newport Beach office, overseeing more than $1 billion in projects and helping the Newport Beach office triple its revenue during the past two years.

WE'RE HIRING!

• Concrete Estimator

• Civil Project Manager

• Quality Manager

• Marketing Manager (or Dallas Preferred)

• Civil Project Director

• Project Scheduler

• Civil Superintendent – (Underground Utility/Traveler)

• Regional Accountant

• Project Accountant

• Graphic Designer

• Concrete Superintendent

• Project Quality Manager

• Concrete Estimator

• Marketing Coordinator

• Drywall Assistant Project Manager

GOING FOR THE GOLD

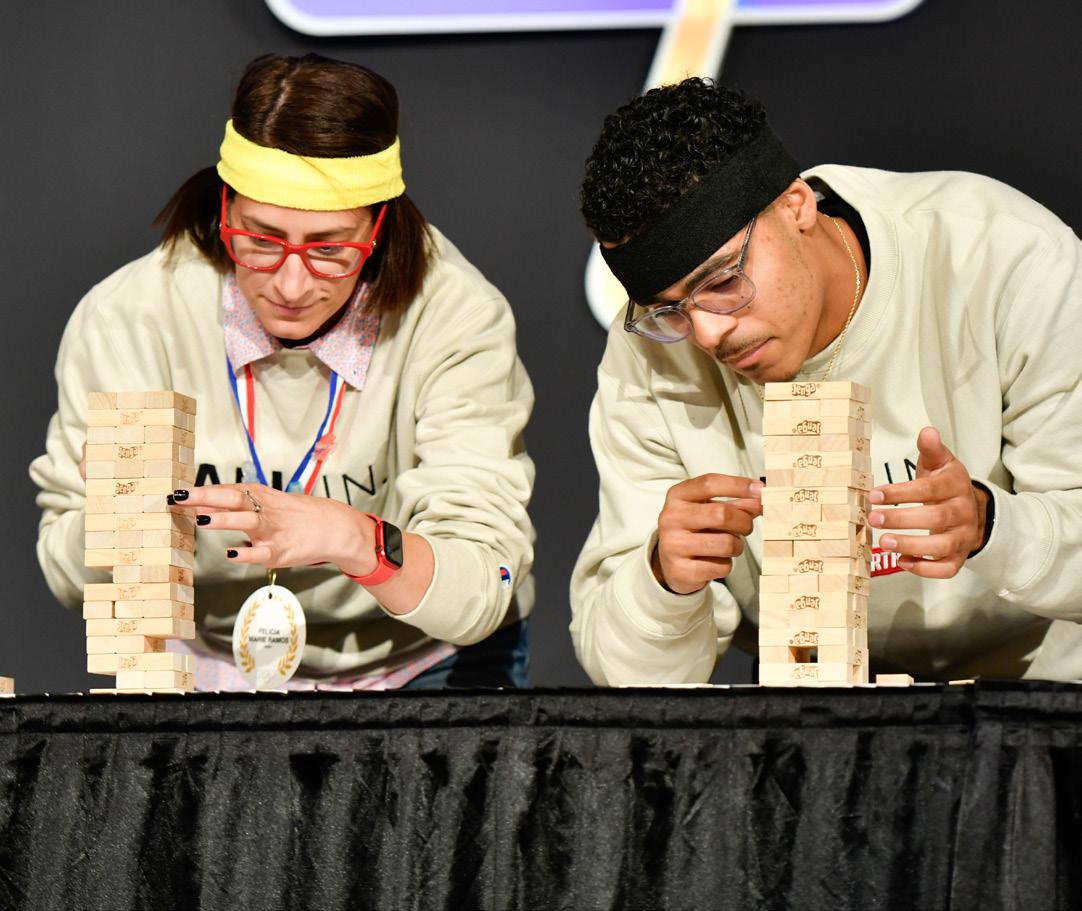

We had so much fun at our Olympics-themed Southern Seminar!

Sean Blakemore and Ruby Rueda were the hilarious and dynamic hosts of the Gold Medal Games, a series of onstage minute-to-win-it skits starring volunteer members of the first-ever Southern Night Live cast.

Our Heart Hats partnership for the Fall Seminar was with the Special Olympics of Texas and Georgia. We sponsored the Fall Games in both states, and the banners signed at Seminar were proudly displayed at both events.

Ikenna Okeke spoke with Kristen Severs during the panel discussion focused on development.

Felicia Ramos and Isaiah Lavigne battled it out at Jenga during the Gold Medal Games.

Toward the end of Seminar, we celebrated Bright Arrow Solar as the 2024 Large Melvin winner. Both our Large and Small Melvin winners will go on to compete for the prestigious Roger Burnet Award, announced at the Genuine McCarthy Enterprises Shareholders' meeting in April 2025. View the winners from all regions.

Congratulations to the Port of Houston Authority – Rehab of Container Yard 4/5 for its Small Melvin win!

We issued the Ultimate McCarthy Challenge in August, and three projects made the podium! Brookhaven took home the gold medal, followed by Houston Methodist Cypress with the silver and LBJ with the bronze.

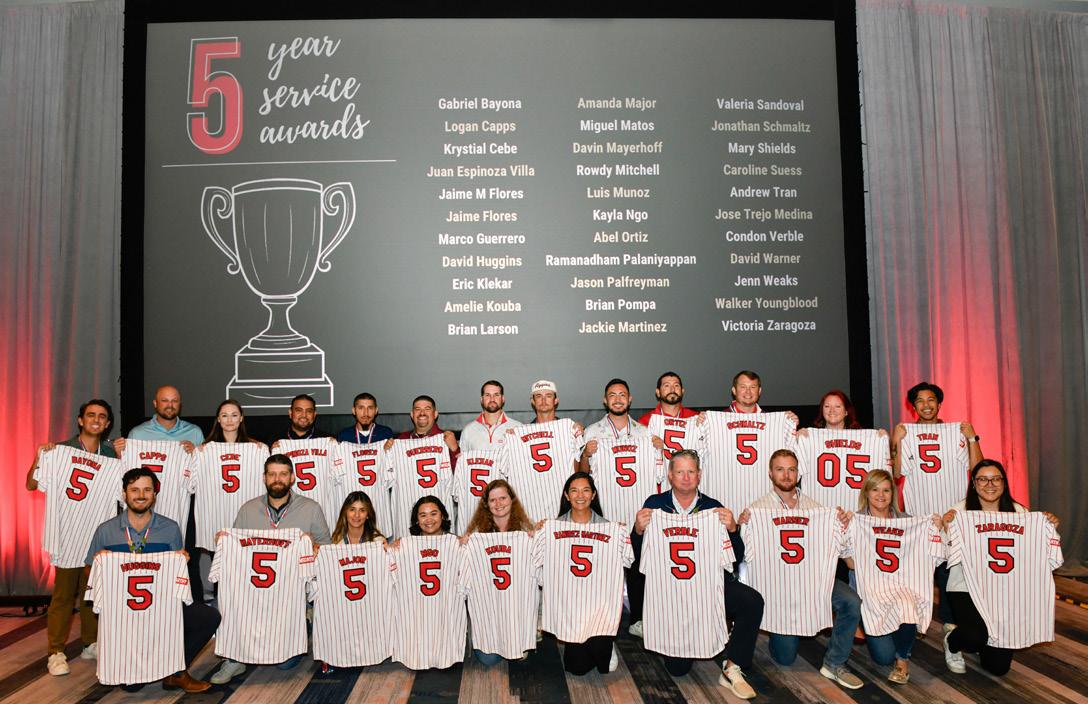

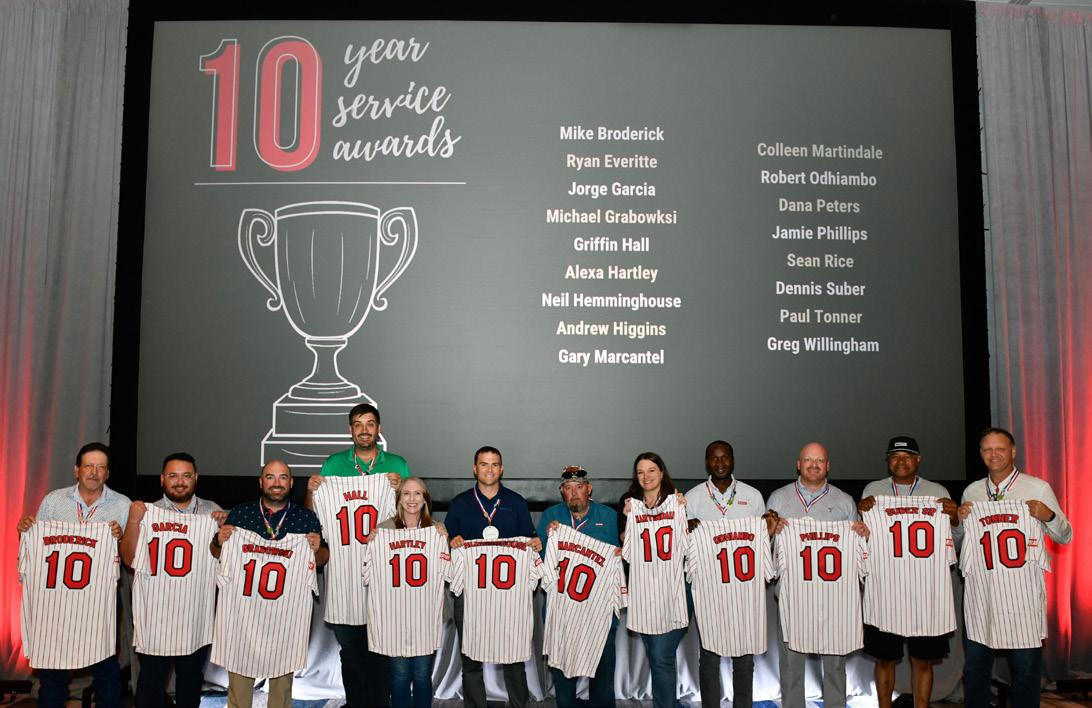

CELEBRATING YOUR SERVICE

Huge congratulations to our service award winners!

Years

Years

Years

Years

Years

To celebrate his remarkable 35 years of service, Buddy Dickey’s friends put together this awesome video tribute.

"Reaching these milestones is a testament not only to their personal dedication but also to the shared values that make our company strong. Dez, Danny, Al, Wes, Michael and Buddy exemplify the heart of our culture:

We, Not I: They’ve shown time and again the power of collaboration, putting team success ahead of individual recognition.

All In: Their unwavering commitment to our goals reflects a passion and determination that inspire everyone around them.

Genuine: Through their authenticity and integrity, they have built trust and lasting relationships that drive us forward.

Staying with a company for 15 years or more is rare, and it speaks volumes about the culture we’ve built together. It’s a powerful reminder of what we can achieve when we live by our values and support one another.

Please join us in congratulating our partners on these remarkable achievements and in thanking them for their profound impact on our journey. Here's to many more years of shared success!"

- Bryan Kuster, CEO, Southern Region 5 Years

Dazarene Randall and Danny Mignano

Michael Ladner

Wes Moncrief and Al Gomez

FALL SEMINAR 2024

THE LATEST FROM MCCARTHY HOLDINGS INC (MHI)

National Safety Update | Q4 2024

Read the full report to see our national safety metrics, and pay particular attention to these urgent calls to action:

• Review Safety Flashes and discuss how each may have an impact on your project.

oChin Straps on Helmets

o Tower Crane Near Miss

• Review Ladder Policy, Subcontractor Safety Compliance and Hazard Communication Program so we can gain consistency across our regions.

oUtilize the resources available to support these policies:

» Ladder Safe Access Alternative Approval Form

» Safe Access Alternative Approval Ladder Tags

» Subcontractor Safety Program Compliance Checklist

» OSHA Hazard Communication Program Training & Certification

Regional Overview

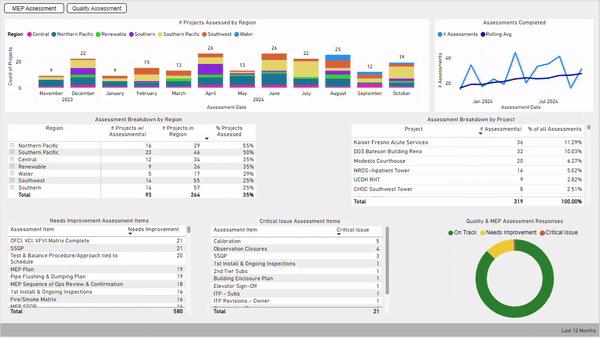

National Quality Update | Q4 2024

This report is packed full of interesting metrics and some highlights from the year, including the first-ever Quality Townhall! We want to draw particular attention to these resources:

• New Quality Design Resource Page: Visit to learn more about available Quality Design resources such as checklists, flashes, and yardage books.

• Pre-Installation Procedure: Outlining the process for the pre-installation meeting for all definable features of work (scopes of work), whether being performed by a trade partner or being self-performed.

• MEP Requirements Page: It went live earlier this year and continues to evolve.

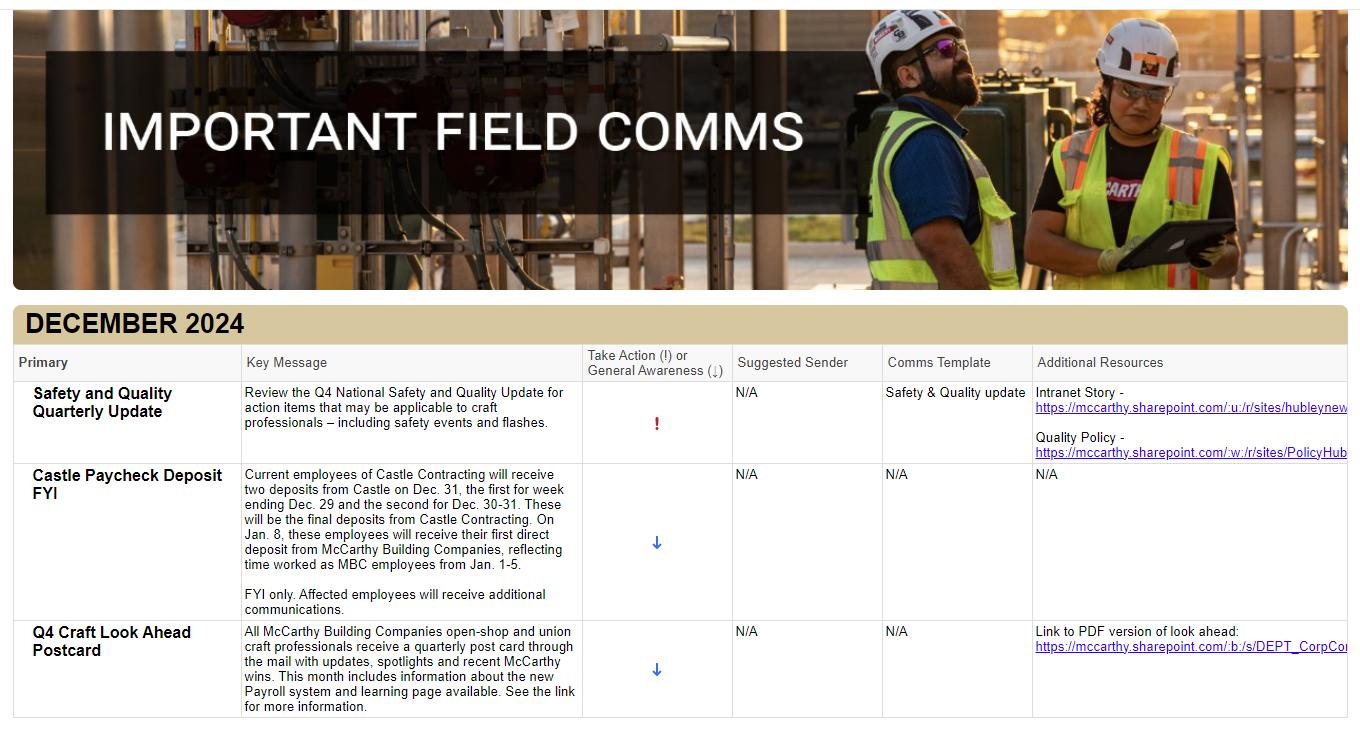

Field 411 Action Plan

Keep an eye on your email inbox for a new resource, the Field 411 Action Plan. It’s a one-stop communication tool for project team leaders designed to help keep everyone informed and on the same page. This tool helps those who lead project team members or craft professionals know the big items happening companywide each month that they should reinforce in team meetings or 1:1s. The tool contains key focus items, communication templates to help them share information, and additional resources for questions, and there are two separate versions each month: one for PDs, PMs, and APMs, and one for Sups and ASups.

IN THE NEWS:

Brookhaven City Hall Tops Out

All In at Piedmont Newton

Congratulations to the team for not only finishing the Piedmont Newton ICU at an extremely accelerated schedule while finishing another portion of the project (Wound Care) at the exact same time! Completion of this enabling project allows the team to move on to the final stage of the overall scope, a 10-bed renovation of existing patient rooms. The continued diligence by this team has allowed Piedmont to nearly triple the size of this last phase to renovate even more beds for patient and staff satisfaction.

Chris Jett posted on our Southern Region Teams channel about the positive message he received from William Love, Executive Director of Operations at Piedmont Newton Hospital, about our partners

Caitlin Safford and Erik Walls: “Your local team on the ground has been doing an outstanding job of managing the projects, and we greatly appreciate their efforts. I know Erik and Caitlin have put in some long hours and weekends to keep things on track.”

Fall Fest at Fowling

Our Atlanta team recently hosted a McCarthy Fall Fest for partners and their families at Fowling Warehouse. It was a festive day with face painting, a make-your-own hard hat station, tie-dyeing, and, of course, a fowling (football + bowling) competition for the adults. They got to celebrate the craft professionals and hand out the Craft Professional of the Year awards.

Atlanta Team Wins Safety Award

Congrats to the Atlanta team on winning two awards at ABC of Georgia's 2024 Safety Awards Luncheon: the Georgia Award for Safety Excellence and the prestigious Diamond STEP Award! The Diamond STEP Award is one of the highest honors in safety. According to ABC's 2024 Safety Performance Report, companies that earn the Diamond STEP Award are, on average, nearly six times safer than the industry average, with an 83% reduction in total recordable incident rates.

PFW Hosts Wine Tour

Partnership for Women - Atlanta wrapped up the year with a wine tour in North Georgia.

Trunk or Treat!

The Austin team was a hit at the Travis County Sheriff’s Office Annual Trunk or Treat thanks to its amazing DIY jail photo opp and the very popular squishy hard hats that were a hot commodity with the trick-or-treaters.

Samsung FAB1 Modules Major Milestone Alert

On Nov. 8, the McCarthy team in Taylor, Texas reached a major milestone of successfully passing our final inspection on our lateral modules! This achievement is a direct result of the dedication and hard work of many individuals involved throughout the course of this project.

A special thank you to our Quality Manager, Paul Martinez, whose leadership was critical to the team’s success with all inspections and quality tracking, and to all the supporting team members, including, but definitely not limited to: Huggins, David Huggins, Justin Key, Bryan Smith, Marco Guardiola, Omar Carrasco, Benton Banowsky, Fabian Flores, and Baker Hix. We also owe many thanks to the outstanding craft partners who worked on-site in Taylor, as none of this would have been possible without their commitment to excellence and dedication to their craft!

Reaching this milestone is the culmination of 1.5 years of hard work for the whole project team. This project is a true example of McCarthy's "All-In" spirit, bringing together multiple business units (Commercial, Water, Marine, MCIndustrial, Civil) and regions (Southern, Central, Southwest) to make this project a success for McCarthy.

Again, we cannot thank those involved in this project enough — both staff and craft partners who contributed to this project from preconstruction through punch list completion. Every individual’s effort, no matter how small, has brought us to this moment of great success. Thank you!"

- Kevin Howie

TCH Decks the Halls

Our craft professionals took the lead on lighting up the outside of TCH this season, installing and decorating a beautiful tree with McCarthy-red bows!

PFW Hosts Pizza Making Class

Partnership for Women had a packed house for its pizza-making class at Austin in November. The group got educated about the history of Neapolitan-style pizza before taking its place behind the counter to make and toss their own pies! The evening was topped off with dessert pizza, so everyone went home happy and full.

Team Earns Safety Award

Our McCarthy team was honored with the National AGC & Texas Bluebonnet Safety Award in Austin, TX recognizing our exceptional safety performance.

Datta Yoga Makes Progress

Our Civil team is working with a new client on the Datta Yoga Center Retention System and Parking Lot. It’s a four month, $1.7M project on the exterior of the Hindu temple. They recently installed a Contech CMP Storm Drainage System.

Congrats to Civil Craft Winner

Civil celebrated Filiberto Zamudio on winning Civil Craft Professional of the Year.

Centreport Trail Hosts Family Day

The CentrePort Trail project recently hosted Family Day, where its dedicated craft workforce, City of Fort Worth representatives, and Landtec Engineering teams brought their families to enjoy a day together. The event was filled with delicious tacos, fun games, and exciting raffle prizes. Everyone also participated in a full site walk, which offered a close-up view of the project’s progress.

IN THE NEWS:

-McCarthy-Vaughn JV Starts $5B Pediatric Health Campus (from constructiondive.com)

-Construction Begins on $5B Pediatric Hospital Campus in Dallas’ Southwestern Medical District (from BizJournals.com)

Mvp Team Celebrates Two NPC Groundbreakings

The New Pediatric Campus hosted its official groundbreaking ceremony Oct. 1 featuring Dallas sports legends Dirk Nowitski, Troy Aikman and our very own MVP leaders. Then, on Oct. 29, the project team gathered for the (un)official groundbreaking ceremony, bringing together the owners, design team, and construction partners for a commemorative drone photo at the project site. The celebration continued at Community Brewery, where team members shared in a well-deserved happy hour. After investing years of preparation and 120 days of meticulous Target Value Design, it was exciting for the team to mark the transition from planning to action.

PFW Hosts Concrete Master Class at NPC Site

Partnership for Women hosted an on-site Concrete Master Class at the NPC site in Downtown Dallas, offering a unique opportunity to learn new skills while connecting with other women in the construction industry.

The day began with a guided site walk around NPC, where attendees got a firsthand look at the progress of this exciting project. Then they built formwork, assembled walls, and poured concrete into personalized Dude molds they could take home. A special highlight was creating a custom MVP concrete sign that will proudly be displayed in the project trailers.

Dallas Partners Serve

Community During CIW 2024

On the last day of Construction Inclusion Week, Dallas partners worked on two service projects. At Old City Park in Dallas, they participated in a Community Clean-Up at Old City Park, helping prepare the park for its annual holiday decorations. In Frisco, they dug trenches and laid over 720 feet of wattle for erosion control at Monarch Park.

NPC Hosts Thanksgiving, Decorates Christmas Tree

The McCarthy/Vaughn Partnership (MVP) team has been spreading cheer this holiday season, hosting its first MVP Thanksgiving potluck dinner and decorating a holiday tree at Children’s Medical Center Plano.

Ismaili Self-Performs Concrete Sandblasting

Ismaili took an entrepreneurial mindset and decided to self-perform the sandblasting of the sitework concrete. It required a lot of coordination from the time the flatwork began to be poured, and it was critical to think ahead when performing the saw cuts so the pattern would align properly.

Cypress Celebrates Successful Inspection Milestone

After a three-day inspection with the Texas Health and Human Services Commission (HHSC), the Houston Methodist Cypress project passed our state healthcare inspection, paving the way for licensing! Houston Methodist is now focused on completing their activation and training their staff so they can start serving the Cypress community in early 2025.

Since breaking ground in May 2022, the project team has gone ALL IN to achieve milestone after milestone. The team successfully turned over both MOBs on time (with MOB 1 coming a month early) and achieved substantial completion of the hospital 1.5 months early. While keeping this accelerated schedule, the project team completed 2.7 million safe hours, ensuring everyone stepping foot on the site was able to go home safely every day.

Houston Honors Craft Pro of the Year

Gerardo “Flaco” Hernandez was recently honored as Houston’s Craft Professional of the Year. He has made his mark on every recent major project in Houston including NWPPP, Ismaili, Cypress, and now LBJ.

LBJ Helps Out Settegast Neighborhood

As its outreach project for Construction Inclusion Week, the LBJ project team and our Houston office put the final touches on a Heart Hats project that helped with the first phase of renovating a local event center. The Eden Event Center is located in Settegast, a neighborhood near LBJ whose residents face many environmental concerns which has led to lower life expectancies than the average Houstonian. The overall vision for this renovation is to eventually provide the local residents with a clinic and education space. Phase I is done!

Marine Dream Team

The McCarthy Marine team participated in the 9th Annual Park to Port Bike Ride sponsored by the Port of Houston, cycling 20 miles round-trip along the Bayou Greenway trail, starting at Hermann Park.

Marine Honors Craft Pro of the Year

The Port Houston Wharf 4/5 team gathered to celebrate some key achievements, with a special focus on awarding Pedro Sanchez Martinez the outstanding accomplishment of Marine Craft Professional of the Year!

Currently a foreman overseeing waterside operations, Pedro’s journey with McCarthy began in April 2013 as a carpenter on the Velasco project. His hard work and leadership were recognized, and he was promoted to foreman on the Barbour's Cut CY1/2 project in October 2019. Since then, he has continually exemplified excellence and commitment.

In addition to celebrating Pedro’s award, the team marked several milestones, including the completion of the drilled shaft operations and the Landside Crane Beam, as well as the Waterside Crane Beam, which is now over 50 percent complete and progressing smoothly.

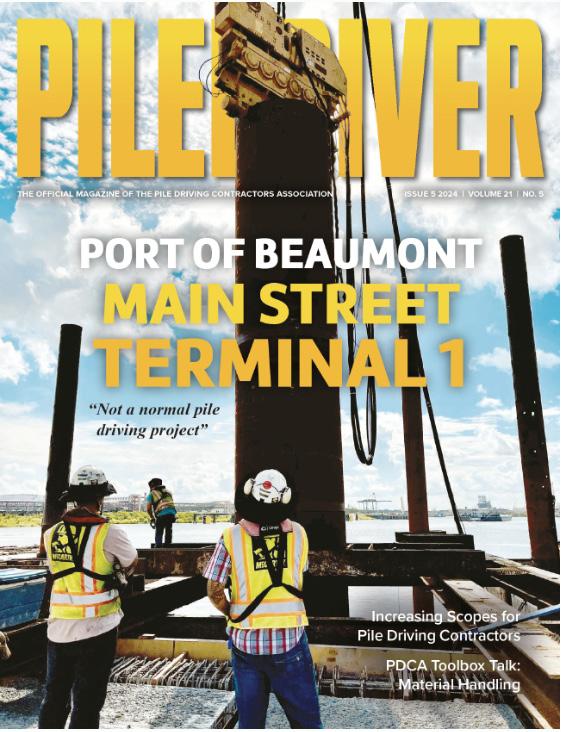

Port of Beaumont Honored by ENR

Port of Beaumont Main Street Terminal 1 won the 2024 Best Project Award from Engineering News-Record Texas and Louisiana Region in the Best Specialty Construction category. Now this project is a finalist for the national Best of the Best Awards in April 2025 in NYC!

Marine Lands the Cover of PileDriver

Did you catch the October issue of PileDriver with Port of Beaumont on the cover? Make sure to read the article!

Renewable Energy

2024 Southern Region Sales Goals

RE RINGS BELL ON RWE WATERLOO FOR 100TH WIN

On Friday, Dec. 12, the Renewable Energy team rang the bell on an exciting new win in Austin, Texas. They'll be partnering with our Civil and self-perform electrical teams on this $160M job with the potential for BESS to be added. This marked the 100th win for our national RE team and the first time the group has broken $2B in sales! Our Southern region sold $707M in RE work in 2024.

Top Opportunities

RE Rings the Bell on Jones City 1 & 2 + BESS

In case you missed it, the Renewable Energy team rang the bell on a big win during our Southern Seminar! Jones City 1 & 2 is a $360M project that marks our sixth partnership with Lightsource BP. The project has a total size of 500 MW, with Phase 1 delivering 270 MW and Phase 2 providing 230 MW. Additionally, it includes a 200 MW/2HR Battery Energy Storage System (BESS).

$360M 12.25% Dc. 2024 PROJECT VALUE EST. CONSTRUCTION START DATE

Lafitte Sets Records with its Thanksgiving Donation

Lafitte organized a site-wide food drive for Thanksgiving, collecting 7,279 pounds of food. It was a record for the largest corporate donation ever received by the Northeast Louisiana Food Bank! NELA Food Bank serves 12 parishes across Louisiana, where food insecurity impacts one in five people and one in three children.

Stoneridge Participates in Career Day

The Stoneridge Solar team recently participated in the Thorndale High School Annual Career Day in Thorndale, Texas. This proud Pink Battalion spoke to more than 200 high school students in attendance about the construction industry and career opportunities at McCarthy.

Lafitte Celebrates Construction Inclusion Week, Halloween

Lafitte is always down for a good time! They enjoyed biscuits during a CIW breakfast and busted out some solid costumes for Halloween.

The Dates

Our Water partners are welcome to attend any of the Q1 business unit huddles that are convenient to their location. Every huddle will include updates from our national markets. Submit your questions ahead of time.

Houston & Marine BU Huddle | January 14

Austin BU Huddle | January 15

Dallas & Civil BU Huddle | January 23

Atlanta BU Huddle | January 30

Crane Assembly in Texas

Barry Rose put together its first crane on Dec. 9, a big day for the project!

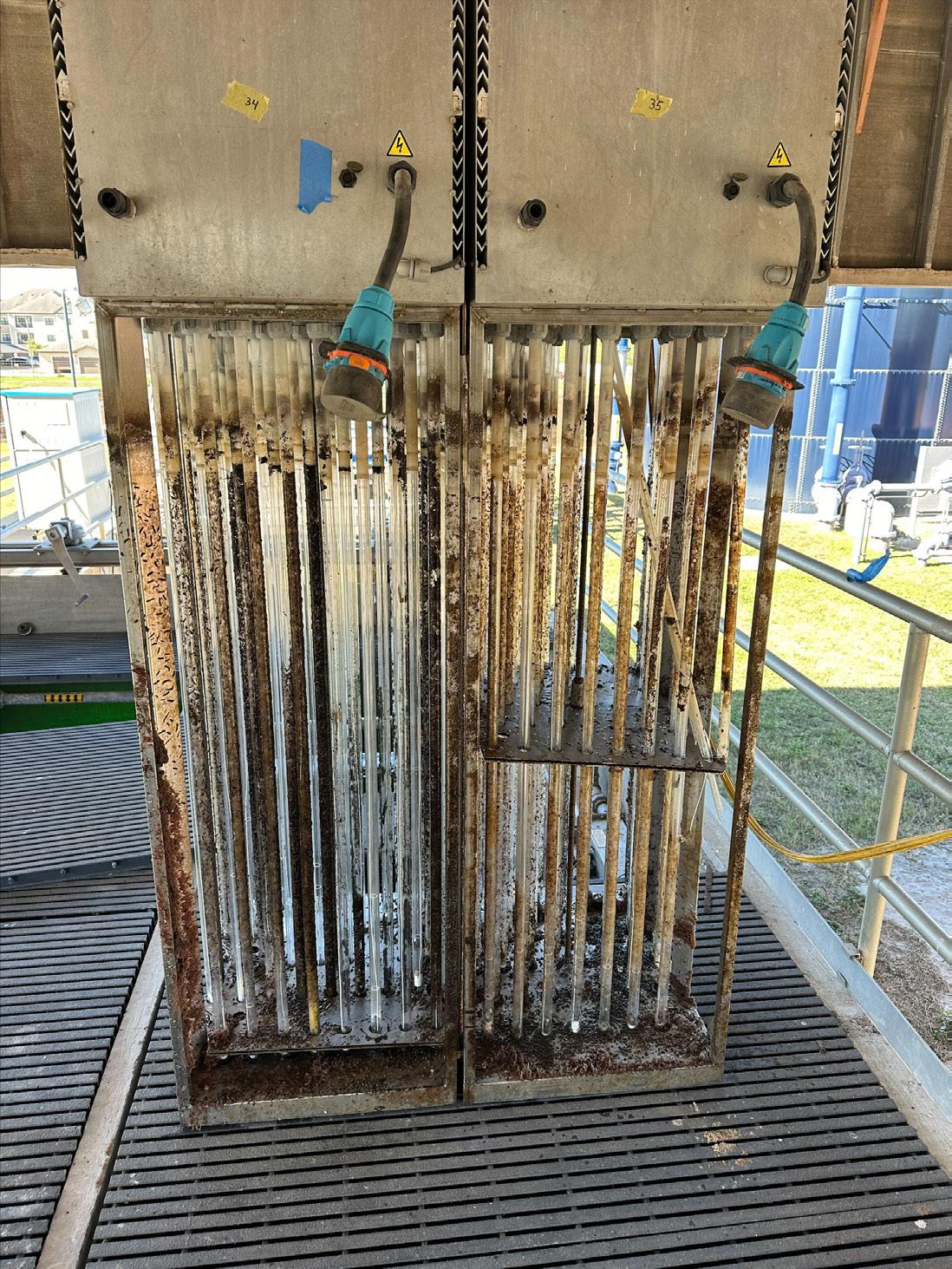

Who Doesn't Love a Good Before and After?!

“Big thanks to the Water SSG Team, who spent a late night responding to an emergency request at the City of Pearland’s Reflection Bay Facility. The plant needed 420 out of 480 UV bulbs replaced \to get back into compliance before Texas Commission on Environmental Quality (TCEQ) assumed operation of the facility. This was high margin work, but most importantly, it showed our team’s dedication to working across the total project life cycle to deepen relationships. Special shout out to Christopher Clements, Juan Ramirez and Reece Brooks for their hard work and dedication.”

-Jake Stones

Barry Rose Hosts Startup SMEs

In mid-October, the Barry Rose team and Channelview office partners gave the Startup SMEs a tour of the site between workshops finalizing the playbook.

The Yard

Yard Pilots Small Tools Program

The Yard wants to shift the paradigm from small tools as a consumable to assets that we leverage across the region. This would allow us to take more advantage of National agreements in place:

• Rebates

• Early Pay discounts

• Trade-Ins / warranties

• Latest tech & safety features

So far through 2024:

• 915 tools procured

• 421 requests for tools

Participating Projects:

• Lafitte

• Crane BESS

• Barry Rose

• CY 6&7

• Spilman Island

• LBJ

• NPC

Interested in the program? Utilize the Southern Small Tooling and Repairs Request Form.

Learn More About Equipment Management Program

The Equipment Management Program is an optional program where the Yard manages all equipment on your site, including third-party rentals. If you need a piece of equipment, the Yard will source the best deal, maintain contact with the third-party vendors, schedule PMs while tracking usage and future needs.

Like with the Small Tools Program, this allows the Yard to maximize its national agreements with vendors like United, Sunbelt and Sun State. It gives us the benefit of data collection so we can better determine what pieces of equipment make sense for us to own vs. renting. Through this program, the Yard is learning which assets have the best return.

• 96 pieces of equipment being tracked through the program

• 34 that we own

• 62 rented from third parties

Participating Projects:

• NPC

• Lafitte

• Crane BESS

• LBJ

• Barry Rose

Check out this striking drone photo of the Southern Gateway Park submitted to our McCarthy Intranet Photo of the Week contest by Hamaad Chaudry.