• More Carcass Meat Yield

• Best Return on Your Investment

• Best Carcass Conformation and Meat Quality in the Industry

Visit www.aviagen.com/Ross to learn how Ross® 308 will deliver for you.

Office Matt Media (USA) LLC. 1713 E. Morgan Court Gilbert, Arizona 85295

Livestock & Poultry Middle East & Asia is designed to serve the fast growing livestock and poultry sectors in the Asia and Middle East region by providing the expert information to our readers in our four comprehensive issues in a year. It is circulated throughout Middle East region and worldwide in addition to the extra distribution at various Livestock, Poultry, Aquaculture and Agriculture Shows. The magazine provides editorial coverage on a wide range of topics which are of interest to industry professionals. Matt Media LLC

Sharjah Media City United Arab Emirates

Saad Adv. & Publishing LLC P O Box 25694, Sharjah United Arab Emirates

For the third consecutive year, Almarai has been recognized as the fourth most valuable dairy company worldwide for 2025 by Brand Finance, the industry leader in brand valuation.

This ranking follows a 20% yearly increase in the value of the Almarai brand, which reached $4.68 billion, making it the fastest-growing brand among the top five ranked globally.

Commenting on this achievement, Mr. Abdullah Albader, CEO of Almarai, stated: “We are proud to maintain a leading position among the world’s top dairy brands. This recognition reflects consumer trust in our products and our ongoing commitment to ‘Quality You Can Trust.’ It also reinforces Almarai’s role as a Saudi leader in the food and beverage sector, while supporting food security, sustainability, and

digital transformation in line with consumer expectations and Saudi Vision 2030.”

Almarai is the world’s largest vertically integrated dairy company and remains the leading food and beverage producer and distributor in the Middle East. Its high-quality products reach more than 150 million consumers daily across Saudi Arabia, the Gulf, Egypt, and Jordan.

Al Ain Farms Group (AAFG), the UAE’s largest national provider of protein and beverages, has signed a strategic joint development agreement with Finnish food-tech innovator FoodIQ to bring cutting-edge food manufacturing technology to the region for the first time. This partnership marks the first major public milestone for AAFG since its recent formation, signaling a bold new chapter in

local food innovation. Under the agreement, AAFG will be the first company in the world to implement FoodIQ’s patented Multi-Layer Cooker (MLC) technology on an industrial scale outside Finland, enabling the UAE to locally produce a new generation of clean-label, natural, and high-protein foods.

“At Al Ain Farms Group, our mission is to deliver quality, innovation, and sustainability for the future of food,” said Hassan

Safi, Group CEO of AAFG. “This collaboration not only puts the UAE on the global map for food-tech adoption - it also empowers us to rapidly meet growing consumer demand for healthier choices while using local ingredients. It is a milestone moment for our Group”

The MLC is a smart, modular food manufacturing system designed for flexible-batch production that can seamlessly switch between different highviscosity recipes - from yogurt to plant-based milk, cheese, and protein smoothies - all while preserving the nutritional value of real ingredients with no additives, no preservatives, and with significantly reduced energy use, water consumption, and minimal production waste.

Balady Poultry Company has signed a contract with Mohammed Abdulrahman Farhat Contracting Company to establish and implement a new poultry slaughterhouse in Wadi Al-Dawasir, with a daily production capacity of 500,000 birds and a total investment of 98 million Saudi Riyals.

The automated slaughterhouse will operate with the latest technologies, machinery, and equipment—starting from the reception of live birds up to the final product—raising the company’s total daily production capacity to 700,000 birds.

This project aims to increase production capacity and contribute

to achieving the Kingdom of Saudi Arabia’s food security goals. It comes as part of Balady Poultry’s future expansion plans, in line with its overall growth strategy, to provide the highest-quality poultry meat at the most competitive cost, thereby supporting economic development and keeping pace with the ambitions of Saudi Vision 2030.

• Meet your Buyers- Sellers, Impor ters & Expor ters, Manufacturers & formulators, intermediate manufacturers, packaging material suppliers.

• Network With More Than 1000+ Professional Visitors from World Over

• Oppor tunity for One -One Interaction Between the Buyers and Sellers

• Oppor tunity For Market Research & Access

• Gain Knowledge from Two Days plenar y sessions- listen to Industr y Exper ts, Scientist and Researchers

• Know about your competitors

• BSM & breakout rooms for one-one meetings.

BOUMATIC INTRODUCES THE MILKGENIUS IN-LINE MILK ANALYZER INTO IT’S GEMINI UP MILKING ROBOT AND MILKING SYSTEMS

BouMatic announces the release of the MilkGenius In-Line Milk Analyzer into it’s Gemini UP milking robot and other BouMatic milking systems. This is a result of the partnership between BouMatic and BROLIS, driven by a mutual goal to provide farmers with comprehensive solutions that ensure the wellbeing of their animals, increase yields and reduce costs.

The In-Line Milk Analyzer measures milk composition for each cow that is being milked and functions like a mini laboratory. When the milk flows through the tube an ultra-precise laser sensor continuously measures fat, protein and lactose. The completely automated system doesn’t require additional reagents or manually taken milk, saving precious time and costs for the dairy farmer.

The Dairy Industries Expo 2025, the UK’s leading event dedicated to dairy processing, packaging, and food safety solutions, is set to return to NAEC Stoneleigh on 29-30 October 2025. This essential two-day trade exhibition brings together key players from across the dairy supply chain, offering unparalleled access to cutting-edge technologies, expert insights, and networking opportunities.

As the only event of its kind in the UK focused exclusively on the dairy sector, Dairy Industries Expo 2025 will

welcome exhibitors showcasing the latest advancements in processing equipment, automation, packaging innovation, quality control, hygiene, and food safety technologies all under one roof.

The show is proudly organised by Dairy Industries International, the industry’s longest-running and most trusted media brand, providing deep sector knowledge and unmatched industry connections. With editorial and digital coverage before, during, and after the event, this year’s expo is set to deliver even greater value to both exhibitors and visitors.

“Participating in the Dairy Industries Expo was a rewarding experience for CEM Corporation. As innovators in moisture, fat, and protein analysis, the event provided the perfect platform to engage with decisionmakers across the dairy industry. The

Expo was well-organised, with strong footfall and high-quality attendees who were genuinely interested in technology that improves product quality and processing efficiency. We’ve already seen new business opportunities emerge from the connections made.

The 2025 edition will feature:

• Live equipment demonstrations across the show floor

• A free seminar programme covering topics like sustainability, smart processing, hygiene innovations, and regulatory changes

• Opportunities to connect with industry peers, suppliers, and decision-makers

Whether you’re a processor, supplier, or brand looking to stay ahead, Dairy Industries Expo is where the conversations and the connections begin. Start now!

Visitor registration is free and now open to secure your place, visit: www.dairyindustriesexpo.com

Over 1,200 business leaders from the food, feed, and sustainable mobility and materials sectors gathered at Bühler’s headquarters in Uzwil, Switzerland, to address the urgent challenge of building successful businesses that feed and move 10 billion people sustainably by 2050. Many key solutions are in place that meet these challenges. What is needed now is to multiply their impact at scale. On June 23 and 24, representatives from industry, business, and academia exchanged practical solutions to ongoing and emerging sustainability

challenges at the event – a unique platform designed to advance innovative approaches, foster meaningful partnerships, and put a spotlight on education and leadership. With the theme “Multiplying impact together,” the Networking Days 2025 highlighted the courage to navigate uncertainty and the solutions available now to build successful companies that bring positive impact at massive scale.

Speaking at the event, Bühler Group CEO Stefan Scheiber described the power of collaboration and cooperation to

multiply the impact of innovation. “Every breakthrough, partnership, and bold decision has the potential to create ripples – spreading knowledge, inspiring action, and driving progress,” he said. “But their true power lies in the multiplier effect: when these ripples connect, they create waves of change. By working together, businesses and industries don’t just add incrementally to progress – they accelerate it by compounding their influence and scaling solutions far beyond what any single effort could achieve.”

Orffa and Sea Forest announce an exclusive long-term distribution partnership, which includes distribution of the SEAFEED™ range of products in the European Union and other selected countries worldwide. Sea Forest’s SEAFEED™ supplement addresses one of the most significant challenges of our time: fighting climate change through the abatement of methane emissions via animal nutrition.

The SEAFEED™ range of products is designed to combat methane emissions in ruminants. By harnessing and recreating the power of the red seaweed Asparagopsis, the SEAFEED™ range of products is effective in reducing methane emissions to the highest extent, outshining currently

available alternatives. These products can be applied in dairy, beef, and small ruminant (sheep, goat) rations, either through premix and compound feed manufacture or directly on farm. The goal is to have widespread implementation to support the ruminant industry on its current path to a more sustainable future. Sea Forest has developed a unique process technology to ensure a standardized and consistent product that enables pragmatic application.

“We are thrilled to welcome Orffa as a partner, said Sam Elsom, CEO of Sea Forest. Our deep understanding of the bioactives found in Asparagopsis

has global impact and addresses an urgent worldwide need to reduce methane emissions.

Connecting with Orffa allows Sea Forest to reach out to industry partners and stakeholders across the European continent. Arno van der Aa, Director of Marketing Innovation of Orffa, comments”

The Food and Agriculture Organization of the United Nations (FAO), through its Virtual Learning Centers (VLCs), has launched a new open-access Arabic-language course titled “Climate Change Adaptation in the Livestock Sector.”

As part of its broader climate change agenda, FAO works to support countries in building more sustainable, resilient, and low-emission agrifood systems. Through targeted interventions, policy support, and knowledge-sharing, FAO

helps integrate climate change adaptation and mitigation into agriculture, forestry, and fisheries. FAO emphasizes innovative solutions, inclusive approaches, and partnerships to address the urgent challenges of climate change while safeguarding livelihoods and ensuring food security.

This self-paced online course is designed to strengthen knowledge and build the capacities of stakeholders, practitioners, and students on the impacts of climate change on livestock production and how the sector can adapt to these challenges.

Through four interactive modules, participants will gain a comprehensive understanding of: Climate risks and global climate trends, and their potential impacts on livestock supply chains.

Strategies to facilitate livestock adaptation.

Tools and approaches to support climate change adaptation in the sector.

Monitoring and evaluation practices for livestock adaptation initiatives.

The course also includes real-world case studies that highlight successful experiences in mitigating the impacts of climate change. Aligned with the 2030 Agenda for Sustainable Development, it provides practical tools and knowledge to support climateresilient livestock systems.

The total study time is approximately three and a half hours, and learners can complete the modules at their own pace. A final assessment will allow participants to test their knowledge and earn certification.

Aviagen® is continuing to enhance its supply chain and its ‘global reach, local touch’ strategy by investing in a Grandparent (GP) operation for the production and distribution of Parent Stock (PS) in the Kingdom of Saudi Arabia (KSA). This is a fully-owned Aviagen investment and the project is currently in the early stages of development.

Aviagen continues to recognize the strategic requirement for local, dedicated supply bases to ensure that Aviagen and all of our customers are best prepared to meet the increasing demand for poultry meat in this important,

growing region. This investment will create a regional distribution hub for Aviagen brands, strengthening security of supply, and enhancing our ability to serve customers in KSA from a dedicated supply base within the region.

Saudi Arabia and the wider Gulf region present significant opportunities for the growth of poultry production and consumption. Aviagen is proud to support this development by investing in local breeding stock production within the Kingdom, aligning closely with Saudi Arabia’s Vision 2030 goals. With

its strategic location and strong potential for industry growth, Saudi Arabia is an ideal location for this investment, providing access to key neighboring Gulf markets.

Tom Exley, President, Aviagen TMEA, commented, “This strategic initiative reflects our ongoing commitment to the region, enabling us to deliver greater value to our customers through enhanced security of supply and tailored customer support. By investing locally, Aviagen is helping to strengthen the poultry industry and contribute to the region’s food security and economic development goals.”

EuroTier, the world’s leading trade fair for animal husbandry and livestock management, continues in 2026 as the premier platform for innovation, offering a comprehensive overview of advanced technologies and established industry standards. The event showcases pioneering solutions for cattle, pig, and poultry farming, while also expanding its focus to include sheep and goat husbandry, equine boarding, aquaculture, alternative proteins, and direct farm sales.

With a portfolio that spans the entire value chain of animal-based food production, EuroTier 2026 brings together products and services from across the industry. Key exhibition areas include genetics, feed, housing systems, climate and environmental technology, milking and cooling systems, manure management, transport logistics, farm

supplies, accessories, processing, marketing, and agricultural services. In times of increasing economic pressure and strong market competition, intelligent technologies are becoming indispensable. These technologies must be capable of combining efficiency, productivity, sustainability, and animal welfare within competitive systems. With its guiding theme “Intelligence in Animal Farming”, EuroTier 2026 demonstrates how this can be achieved: the foundations of success lie in smart solutions for animal housing equipment, feeding systems, milking technology, forage harvesting, slurry management, and logistics that are integrated, controlled, and connected through robotics, sensor technology, artificial intelligence, and big data, all operating on digital platforms and within automated systems.

In a groundbreaking achievement, the Abu Dhabi Agriculture and Food Safety Authority (ADAFSA) has been awarded the ISO 42001:2023 international certification for Artificial Intelligence Management Systems.

This marks the world’s first such certification within the agriculture and food security sector, and the first at the government level in the UAE. The milestone reinforces the nation’s regional and global leadership and reflects its commitment to adopting and advancing international best practices and standards. The certification encompasses the application of advanced AI technologies, such as intelligent analytics and machine learning algorithms to enhance the efficiency of agricultural operations

and food safety services delivered by ADAFSA. It underscores the Authority’s dedication to managing AI technologies responsibly and effectively, in alignment with the UAE’s digital transformation and sustainable development goals.

Omar Sultan Al Olama, Minister of State for Artificial Intelligence, Digital Economy, and Remote Work Applications, affirmed that under the guidance of its leadership, the United Arab Emirates plays a pioneering role in the development and adoption of global standards for responsible artificial intelligence. The UAE continues to lead globally in adopting AI and the latest smart technologies across various sectors, including agriculture and food security.

dsm-firmenich Animal Nutrition & Health (ANH) inaugurated a new feed additive plant in Jadcherla, Hyderabad, India. The strategic investment aligns with the Government’s “Make in India” initiative and strengthens ANH’s market leading position and growth

strategy in India and the AsiaPacific region.

The new facility features a manufacturing line for the world’s leading solutions in Mycotoxin Risk Management and a new warehouse, covering an area of 11,200 square meters. The new state-of-the-art feed

additive plant is equipped with advanced Bühler technology and adheres to the highest international standards in quality, safety and environment. It is built adjacent to ANH’s Jadcherla Premix Plant, which has been operating since 2018. Together, the two facilities form an integrated “Super Site”, enabling greater efficiency and faster service for customers.

Local manufacturing of Mycofix® Secure and Mycofix® Shield helps Indian farmers and feed producers in tackling increasingly complex mycotoxin challenges arising from climate change and improper harvesting conditions. Mycofix® solutions protect animal health and food safety by deactivating a broad spectrum of mycotoxins that contaminate farm animal feed.

The International Falcon Breeders Auction 2025, organized by the Saudi Falcons Club at its headquarters in Malham, north of Riyadh, wrapped up after 21 days with total sales surpassing 13 million riyals.

Waleed Al-Taweel, the official spokesperson for the Saudi Falcons Club, reported that 1,103 falcons were sold during the event, with 67 breeding farms from 23 countries participating, including 19 local farms. The auction showed strong growth compared to last year, with sales values up 23%, the number of falcons sold increasing by 27%,

participating countries growing by 21%, and breeding farms rising by 20% – demonstrating the event’s continued expansion since its inception.

Al-Taweel highlighted that the auction featured exceptional falcons, including this year’s most expensive falcon – a “Gyr Pure Super White” that fetched 1.2 million riyals. He emphasized that the auction has established itself as a trusted platform bringing together top-tier breeders and falconers from Saudi Arabia and internationally, fostering knowledge exchange and creating

new investment opportunities in this thriving sector.

The auction launched on August 5th, featuring local and international breeding farms in a highly competitive environment. The event included dedicated sections for breeding farms, falcon equipment suppliers, a “Future Falconer” pavilion, and interactive demonstrations by falcon breeders showcasing care and breeding techniques. This comprehensive approach made the auction a premier destination for falconry enthusiasts and professionals worldwide.

Algeria is the world’s third largest importer of milk powder. To strengthen future autonomy and food security in dairy products, the Algerian government – via its National Investment Fund – and Baladna Q.P.S.C. from Qatar entered a strategic partnership via the newly formed company subsidiary Baladna Algeria S.P.A. The partnership’s purpose is to finance and manage the construction of a state-of-the-art integrated dairy farming and milk powder production facility in Algeria’s Adrar province. The

locally produced milk powder is planned to meet about 50% of Algeria’s national milk powder needs, representing a significant step towards self-sufficiency.

Additionally, the project will create approximately 5,000 job opportunities for local talents. The facility will be the largest of its kind, located about 90 kilometers from the provincial capital. Construction will commence at the beginning of 2026, with first milk powder production scheduled to start in late 2027. Production volumes will be gradually expanded. When completed and fully supplied, this facility’s final capacity will amount to approximately 100,000 tons of milk powder per year.

“We are proud that Baladna and

the Algerian government are entrusting GEA to play a key part in this lighthouse project,” says Stefan Klebert, CEO GEA. “Not only are we building the world’s largest facility of its kind – we are also helping to strengthen regional food security and economic development. This project showcases the attractiveness of our technologies and products, underpinned by our extensive capabilities for large-scale process and plant engineering.”

”This engagement with GEA marks a milestone in the acceleration of the project. We are proud to attract the most prominent national and international expertise and renowned companies from all over the world to contribute to the completion of the project, following the highest international standards,” Mohamed Moutaz Al-Khayyat, Chairman of Baladna commented.

Cargill’s Animal Nutrition and Health business has opened its new retail feed facility in Granger, Washington. This milestone marks a significant investment in the Pacific Northwest, expanding Cargill’s capabilities to serve current and future ag retailers.

The new construction deliberately modernizes production practices using technology and best practices from the company’s vast footprint to ensure the safety of Cargill’s feed and people. Technologies implemented include automated bag check weighing, ultra-low tolerance mixing and dosing systems, AI-based bag

sealing assurance, pedestrian sensing mobile powered equipment, and full automation throughout all production lines.

“We are excited to see this new facility opened and operational at full capacity. Our presence in Granger is in response to the growing demand for animal feed in the west, as the trend of ranching and farming continues to rise, said Phil Graham, Managing Director, Cargill Animal Nutrition & Health North America. “We look forward to partnering with current and future ag retailers as the industry continues to grow.”

In addition to meeting the

growing needs of lifestyle and backyard farmers, this new retail feed facility:

• has the capacity to produce and package 120,000 tons of animal feed annually,

• brings 21 new jobs to the local community,

• eliminates more than approximately 2 million truck miles and 5,000 tons of CO2 annually,

• supports a wide range of feed forms including meals, pellets, crumbles, grains, textured, and blended products,

• serves multiple species such as equine, poultry, sheep, rabbits, and wildlife.

Kipster, a global leader in animal welfare and sustainable egg farming, announces the use of in-ovo sexing technology. This serves as an alternative to culling male chicks at hatch. The company is second in the U.S. to use this cutting-edge approach. It allows for the sex determination of chick embryos in hatching eggs during incubation. The eggs with males are immediately removed once identified. This prevents the hatching and culling of the dayold male chicks, as is common in the U.S. egg industry.

The U.S. egg industry kills over 350 million male chicks each year after they hatch because they are deemed useless. They do not lay eggs and are not bred to put on

as much weight as fast as broiler chickens. Opposed to the common practice of decades ago, when people consumed the by-product of egg farms as food — the male chickens. Nowadays, people eat predominantly meat chickens from the broiler industry.

Kipster’s goal is to give roosters a place in the food system. In doing so, the company makes use of all animals born into its poultry farms. Kipster is the very first commercial egg producer in the U.S. to not cull its male chicks when its U.S. farm opened in

2022. This approach is similar to Kipster’s practices in Europe. However, the company had to resort to doing so for the first time in 2024. This was due to a lack of suitable infrastructure and a retail market for males from breeds commonly used for egg production.

DuPont announced the launch of FilmTec™ Hypershell™ XP RO-8038 element—an advanced reverse osmosis (RO) solution engineered to meet the evolving needs of the dairy processing industry.

As dairy producers face increasing pressure to improve efficiency, reduce energy consumption, and maintain high product quality, FilmTec™ Hypershell™ XP RO-8038 element supports the production of high-quality dairy products that meet consumer demands for both performance and nutritional value. Designed specifically for the concentration and polishing of dairy process streams—including milk, whey, and lactose—this new RO element delivers exceptional performance, energy savings, and operational longevity. Advancements

to the membrane performance are providing up to 50 percent higher productivity and flow, or up to 50 percent less energy demand when operating at the same flux as other dairy membrane elements on the market, reducing both energy consumption as well as operating costs.

“FilmTec™ Hypershell™ XP RO8038 element represents a significant advancement in membrane technology for dairy applications,” said Noel Carr, Global Dairy Market Leader for DuPont Water Solutions. “With its innovative membrane chemistry and expanded active area, it empowers producers to achieve higher yields, lower costs, and more sustainable operations, contributing to an overall decrease in operational greenhouse gas emissions.”

FilmTec™ Hypershell™ XP RO8038 element delivers a range of key benefits that make it an ideal choice for dairy applications. Its expanded active membrane area boosts both productivity and element flow, while its ability to operate at lower energy demand—without compromising flux—can translate to significant operational cost savings. Designed to enhance the product quality and yield for milk, whey, and lactose streams, the element also supports higher recovery rates in polishing systems, creating less wastewater. Its extended membrane life and reduced replacement frequency contribute to lower overall costs. Furthermore, the FilmTec™ Hypershell™ XP RO-8038 element can ensure lower CAPEX and OPEX through higher efficiency and reduced chemical usage.

The Middle East, Africa Veterinary Congress (MEAVC) is set to make a highly anticipated return with its second edition from October 17–19, 2025, at the renowned Jafza One Convention Centre in Dubai. Following the success of its inaugural event in 2022, MEAVC 2025 to be held in the UAE promises to be an unparalleled gathering for the veterinary community across the region and beyond.

As the largest congress and exhibition of its kind in the

Middle East and Africa, MEAVC 2025 will bring together leading veterinary professionals, industry innovators, and academic experts under one roof to advance the field of veterinary medicine and education.

The congress is dedicated to promoting high-quality continuous professional development accessible to all veterinarians worldwide. For the first time in the Middle East, MEAVC 2025 will feature Continuing Professional Development (CPD) accreditation

by global leaders including the American Association of Veterinary State Boards (RACE), Germany’s Akademie für Tieraerztliche Fortbildung (ATF), and the Veterinary Continuous Education in Europe (VetCEE).

Dr. Margit Gabriele Muller, President of MEAVC 2025, commented: “It is incredibly exciting to return to Dubai and the UAE for the second edition of MEAVC, building on the momentum and success of our inaugural event in 2022. MEAVC 2025 is more than just a congress, it is a movement to elevate veterinary medicine across the Middle East and Africa. By uniting leading minds, global innovations, and CPD-accredited education under one roof, we are empowering veterinarians to deliver world-class care and to shape the future of animal health.”

To help United States cattle farmers improve breeding efficiency and genetic quality, the Foundation for Food & Agriculture Research (FFAR) and the University of Tennessee Institute of Agriculture (UTIA) are investing $705,871 through a FFAR Seeding Solutions grant to increase the success of in vitro embryo production (IVP), a process of fertilizing eggs from cows with desirable genetics in a lab and implanting the resulting embryos into surrogate cows. While IVP can breed cattle with select genes, it often has low success rates due to several factors affecting the

quality of the harvested eggs. Only 20–40% of eggs develop into viable embryos, and only half of those result in pregnancy. This research is investigating whether the supplement myoinositol, already shown to enhance fertility in women, can improve egg quality and increase IVP success in cattle.

Researchers led by Dr. Sarah Moorey, an associate professor of animal science at UTIA are investigating whether adding myoinositol to eggs in the lab improves fertilization and early embryo development. The research team is also examining whether

giving the supplement directly to donor cows increases the number and quality of eggs collected for embryo production. The findings from this grant could improve egg quality and pregnancy rates, enabling ranchers to breed higherquality cattle more efficiently.

“This study advances precision breeding technologies that are essential for the future of U.S. beef production,” said Dr. Jasmine Bruno, FFAR scientific program director.

“Improved IVP success rates support the beef sector’s goals of increased efficiency and continued economic viability.”

Under the patronage of the UAE Ministry of Climate Change and Environment, AgraME, the Middle East’s longest-running exhibition and conference dedicated to agriculture, animal farming, and aquaculture, is preparing for its most ambitious edition to date.

Taking place from 6–7 October 2025 at the Dubai World Trade Centre, the event will spotlight food security, resilience, and regenerative practices shaping the region’s agricultural future.

Aligned with the UAE’s National Food Security Strategy 2051 and its drive toward climate-smart farming, AgraME 2025 will highlight the latest innovations transforming food systems. With livestock and poultry representing vital components of the UAE’s agricultural economy, the exhibition will showcase advanced solutions designed to improve production efficiency, enhance

animal welfare, and strengthen biosecurity across the sector.

The UAE poultry industry has achieved significant progress in recent years, supported by modern farms, high-performance breeding, and precision feed technologies—helping the country move steadily toward greater self-sufficiency. At the same time, the livestock sector is adopting sustainable farming practices, precision nutrition, and veterinary advancements to meet rising protein demand across the GCC and wider Middle East. AgraME 2025 will provide a strategic platform for stakeholders to explore these developments and unlock new business partnerships.

Co-located with AgroFarm Middle East, a globally recognized brand in animal farming, AgraME will bring together industry experts, producers, suppliers, and investors under one roof. Covering a broad spectrum of

sectors—Agriculture, Aquaculture, Horticulture & Vertical Farming, Livestock Health & Nutrition, and Veterinary Equipment & Supplies—the exhibition ensures comprehensive industry engagement.

With a strong emphasis on animal healthcare and veterinary innovation, the conference program will feature thoughtprovoking keynotes, interactive panel sessions, and practical workshops. These discussions will place sustainability, animal welfare, and food safety at the forefront of regional agricultural priorities.

By bridging innovation with decision-making, AgraME 2025 reaffirms the UAE’s leadership in building a resilient, futureready food and agriculture sector, supporting both regional sustainability objectives and global food security ambitions.

The 42nd edition of Saudi Agriculture, the Middle East's premier B2B event for agriculture, food, aquaculture, packaging, and agro-industry, is set to take place from October 20 to 23, 2025, at the Riyadh International Convention & Exhibition Centre. This year's exhibition is poised to be the largest in its history, featuring over 420 exhibitors from more than 40 countries and attracting an estimated 27,000 visitors.

Under the patronage of the Ministry of Environment, Water, and Agriculture, Saudi Agriculture 2025 will showcase cutting-edge technologies

and solutions, highlighting innovations in farming, poultry, aquaculture, food processing and packaging, and agroorganic food sectors. The event aims to foster collaboration among entrepreneurs, industry professionals, decision-makers, and suppliers, providing a platform to expand businesses in the heart of the Middle East's most prominent and fastest-growing market.

A key highlight of the exhibition is the "Future of Agriculture International Summit," which will feature distinguished speakers such as Dr. James Morgan, Dr. Schmitt, Dr.-Ing. Martino

Celeghini, and Mr. Jorge, who will share insights on agricultural technologies and food security. Saudi Agriculture 2025 is not only a showcase of technological advancements but also a testament to Saudi Arabia's commitment to achieving food security and sustainable agricultural development, aligning with the nation's Vision 2030 goals.

For more information or to register to visit, please visit https://saudi-agriculture.com/

As the global conversation around sustainability intensifies, the SOMMET DE L’ÉLEVAGE in France stands out as a concrete example of how livestock farming can adapt to meet environmental, social and economic demands. Now in its 34th edition, the SOMMET will take place from 7th to 10th October 2025 in ClermontFerrand, in the heart of the Massif Central – Europe’s largest grassland region and a cradle of pastoral excellence.

More than just an agricultural show, the SOMMET has become an essential event on the international calendar, attracting over 1,750 exhibitors and 120,000 visitors, including 6,000 international attendees from 96 countries. This year, the

spotlight is firmly on sustainability, innovation, genetics, and fostering meaningful exchange within the global livestock industry.

The full spectrum of livestock excellence

Visitors to the 2025 show will discover more than 2,000 animals representing 70 breeds of cattle, sheep, goats and horses.

National breed championships will be held for Charolais, Simmental and Montbéliarde cattle, showcasing the best of

French genetics. For four days, producers, researchers, breeders and technicians will converge on Clermont-Ferrand to present innovations and expertise across every sector of livestock farming.

The show’s strength lies not only in its scale but in the depth of its programme.

Discover why the SOMMET is known not just as a livestock show –but as the future of livestock farming

Over 140 conferences and symposiums are scheduled, addressing the most urgent challenges facing agriculture: climate resilience, economic transition, animal welfare, and rural vitality. A headline session will be delivered by Jean-Marc Jancovici, co-founder of The Shift Project, exploring the role of agriculture in the climate transition.

Each year, more than 6,000 foreign visitors from 96 countries arrive at the SOMMET to discover leading-edge innovations, make business contacts, and deepen their understanding of sustainable farming systems. For Middle East farmers, the event offers a unique opportunity to benchmark their practices, discover new equipment and genetics, and explore how European neighbours are tackling shared challenges.

The SOMMET’s International Business Club provides a warm and practical welcome for all foreign visitors. Services include free entry, guided tours with interpreters, access to the International Lounge, and B2B meeting facilitation with exhibitors. Free shuttle services run between the airport, train station, and the exhibition grounds.

One of the show’s most appreciated elements is its comprehensive farm tours programme. Every day, buses depart from the fairgrounds to 35 hand-picked farms and agriindustrial sites. These include beef and dairy farms, cheese producers, goat and sheep units,

a feed lot, a biogas facility, a cattle export centre and a meat research laboratory. A special visit to INRAE – the National Institute for Agronomic Research – offers insights into the future of livestock science and innovation.

Each year, the SOMMET honours a guest country, and in 2025, that spotlight will shine on Morocco. With its rich agricultural heritage and rapidly developing livestock sector, Morocco’s delegation will include farming leaders and entrepreneurs eager to exchange knowledge and forge partnerships. Their presence reflects a shared commitment to sustainable, cross-border cooperation in food production.

Benoît Delaloy, Managing Director of the SOMMET DE L’ÉLEVAGE, describes the event as more than a showcase. “The SOMMET is a forum where we reflect together on the future of farming. It’s about showcasing responsible livestock systems,

connecting people, and supporting the next generation of farmers in adapting to the world’s challenges.”

Alongside in-depth discussions and strategic business networking, the SOMMET maintains its vibrant, community-driven atmosphere. From the Charolais Grand Banquet to the festive AfterCow Party organised by young farmers, the event radiates energy, enthusiasm and a genuine spirit of togetherness.

In a new initiative, the SOMMET is also extending its reach beyond the four-day event. Through its year-round digital platform, Le Comptoir des Éleveurs (The Breeders’ Counter), participants can access exclusive content, participate in online discussions and remain part of the SOMMET’s professional community long after they leave Clermont-Ferrand.

Participation in the SOMMET DE L’ÉLEVAGE is free for international visitors who register in advance. To book your badge, view the programme, and sign up for farm tours.

The Middle East's food industry is changing fast, and VIV MEA 2025 will showcase this transformation like never before. Taking place November 25-27, 2025 at the Abu Dhabi National Exhibition Centre (ADNEC), this major trade show brings together global innovation with regional market needs. As food security becomes more important across the Middle East and North Africa, and sustainable food production grows in priority, VIV MEA 2025 positions itself as more than just a trade show—it's the key platform where the future of Middle Eastern agriculture takes shape.

VIV MEA has become the region's most complete platform, covering the entire food chain from animal feed to final products. The event

covers all areas of food production, including poultry, livestock, dairy, and aqua farming in one connected experience. This approach makes VIV MEA the perfect one-stop destination for industry professionals looking for solutions that work across different food sectors. The event's wide coverage reflects how modern food production works, where improvements in animal feed directly affect livestock health, where better dairy processing increases farm profits, and where sustainable practices must be used across all food sources. For visitors, this means access to complete solutions that can improve entire operations, not just individual parts.

The Poultry Marketing Round Table (PMRT) returns to VIV MEA 2025

with a critical focus on one of the industry's most pressing challenges: intelligent water management. Established in 2019 and organized by three global leaders—Middle East Agrifood Publishers (MEAP), VIV Worldwide/VNU Europe, and WATT Global Media—the PMRT has become a premier platform where academics, industry technicians, poultry producers, policymakers, and clients converge to address sustainability innovations. The roundtable's vision emphasizes that marketing is both science and art, bridging theoretical knowledge with practical applications to shape sustainable strategies for the poultry industry's future.

This year's edition, titled "Intelligent Water Use in Poultry Farming: From Intake to Impact," addresses a fundamental paradox facing global agriculture. The session will explore how water, an irreplaceable resource essential for bird health and biosecurity, must be managed with unprecedented intelligence and efficiency. Join this crucial dialogue on November 26, 2025, from 14:00–17:30 at ADNEC during VIV MEA, where industry leaders will discuss innovative approaches to water management that could define the sector's sustainable future.

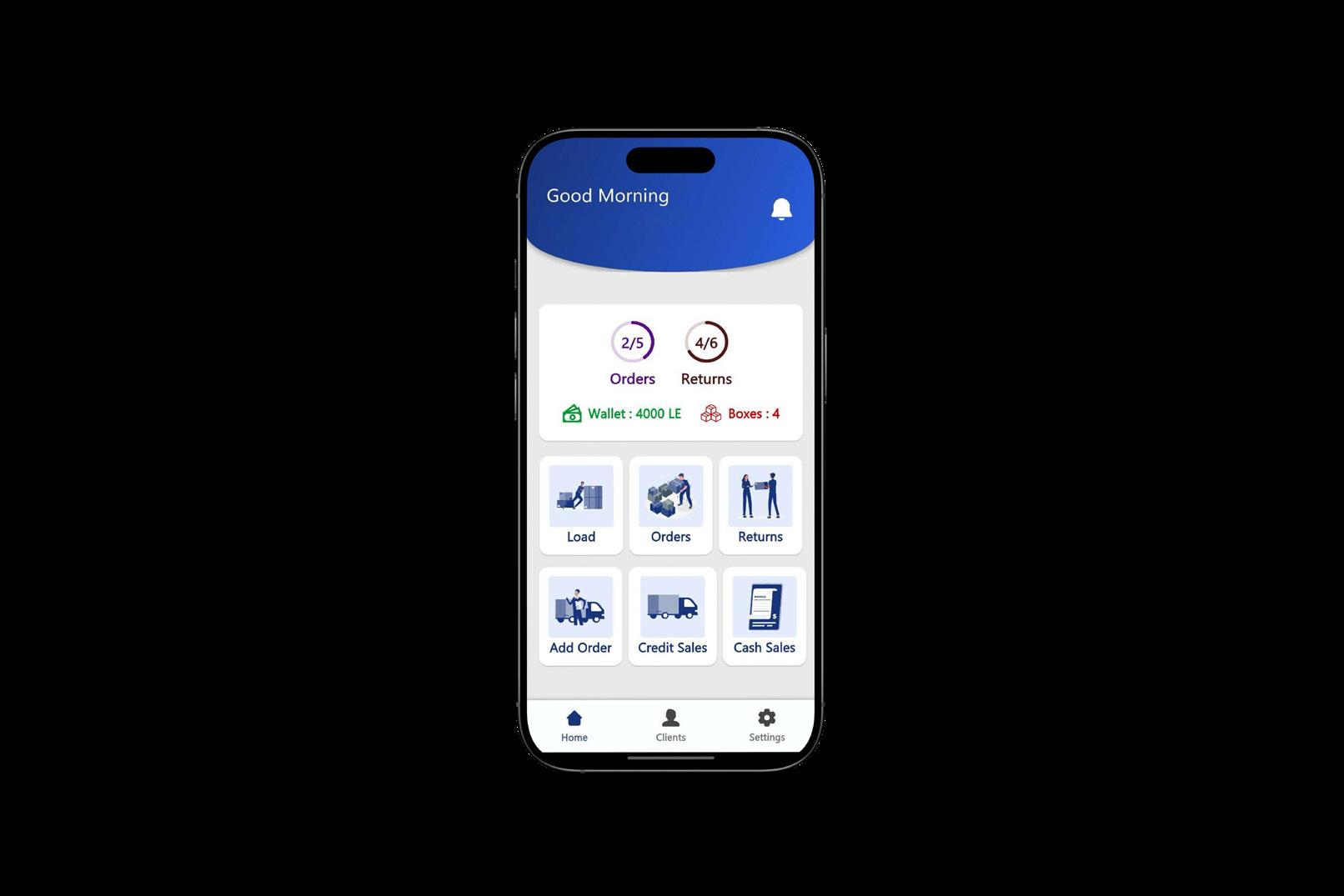

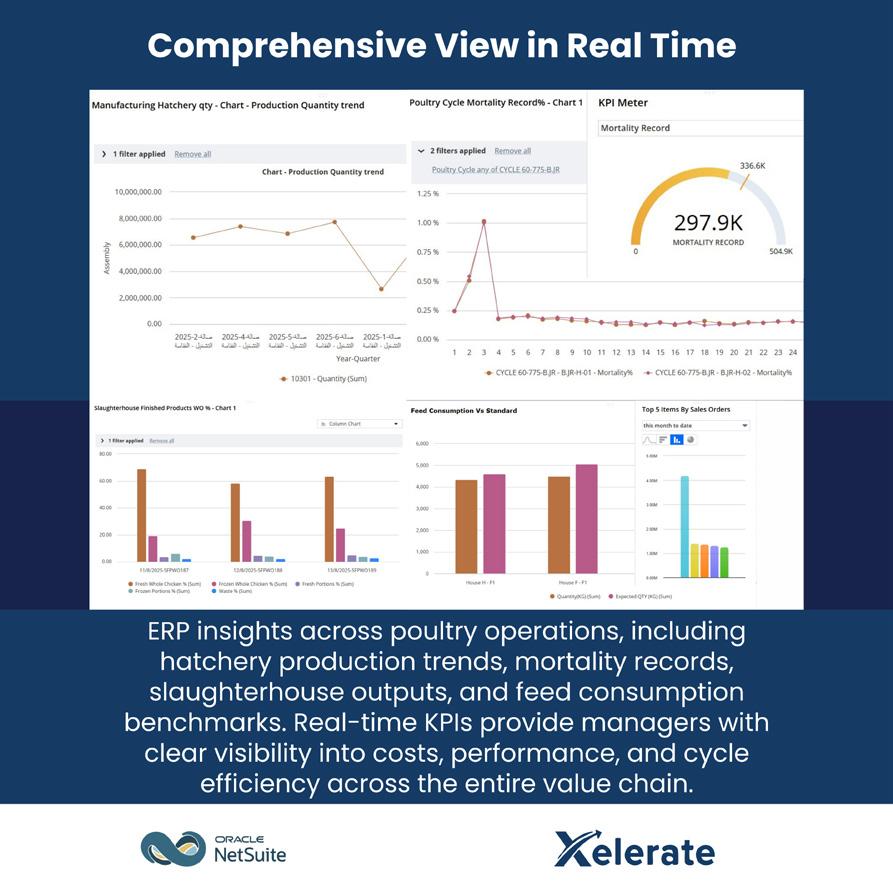

For poultry and livestock producers across the region, the race is no longer just about scale — it’s about control, efficiency, and traceability. From farm to feed mill, hatchery to slaughterhouse, the complexity of modern agribusiness leaves little room for error. That’s where XELERATE comes in.

As an official Oracle Solution Partner, XELERATE has carved a niche as one of the few technology providers in MENA blending deep industry expertise with the world’s leading cloud ERP platform, Oracle NetSuite. The result is a set of smart, sectorspecific frameworks designed to tackle the pressures of highvolume operations — from rising feed costs to regulatory compliance and biosecurity demands.

Nowhere is the impact more visible than in poultry. The XELERATE NetSuite Poultry Management System connects every stage of the value chain: farms, feed mills, hatcheries, slaughterhouses, even fleets and van sales. The platform tracks everything — feed consumption, flock health, mortality rates — while delivering cost and margin analysis down to the bird or kilogram. Hatchery performance, from incubation through chick placement, is integrated into the same dashboards that record slaughterhouse output and quality checks. Fleet trips are logged for egg and bird transfers, while van sales integration ensures distribution data flows seamlessly

back into finance and inventory modules.

The technology is not just about oversight; it’s about insight. By consolidating operational data into one integrated system, producers can forecast demand, manage procurement with accuracy, and reduce losses that would otherwise erode margins. Mobile apps extend this intelligence into the field, giving farm managers and sales teams instant visibility.

Taryah Poultry in Saudi Arabia partnered with XELERATE to modernize its operations with Oracle NetSuite. In less than two years

since going live, the company has achieved smooth, integrated performance across its entire value chain — from farms and feed mills to processing and sales. The system continues to drive growth, efficiency, and visibility, proving the long-term impact of a unified ERP tailored for poultry operations.

As agri-businesses across MENA navigate volatile markets and stricter regulatory landscapes, solutions like XELERATE’s are proving that digital transformation isn’t a luxury — it’s a necessity.

For more information,

www.xelerate.org | info@xelerate.org

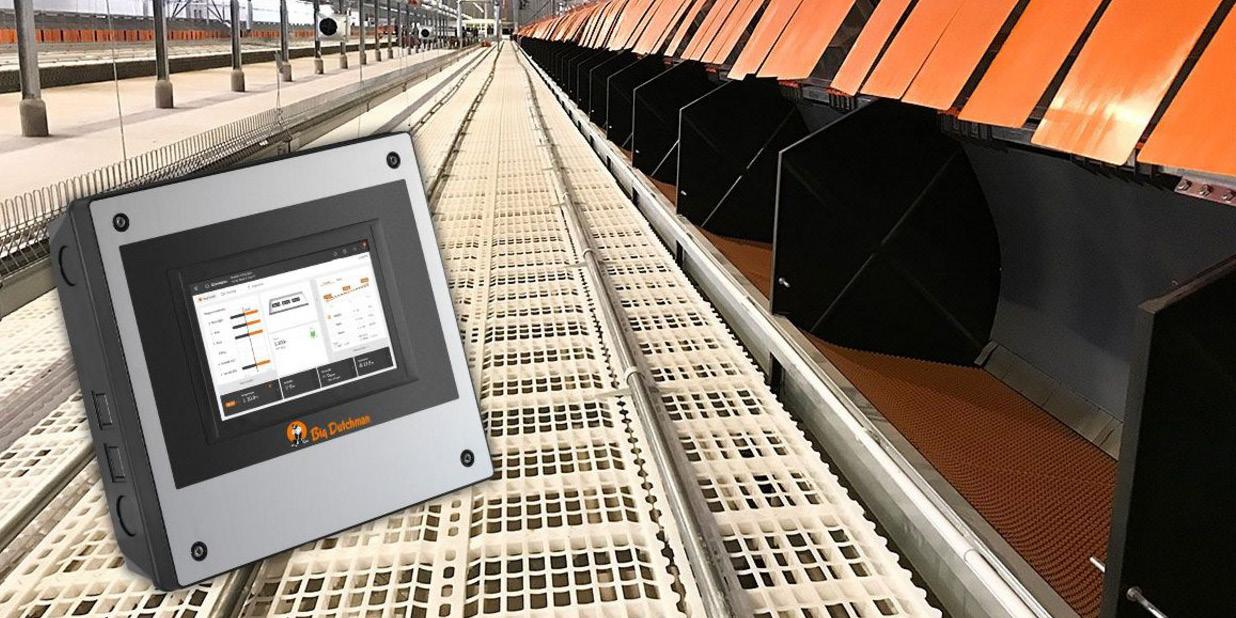

Big Dutchman introduces Nesca 2.0, a currently unique solution for broiler breeder managers: the nest-integrated scale determines the females’ weight automatically, every time they visit the nest to lay eggs. Touching or interrupting the hens is not necessary. The result: an extensive data overview and weight determination without stress for both humans and birds. Big Dutchman developed Nesca 2.0 specifically for the Relax nest.

Nesca 2.0 takes several hundred individual measurements every day. These data provide an extremely accurate picture of weight development, flock uniformity and bird health: a real improvement on the usual manual sample taken once a week. The innovation enables poultry producers to monitor weight developments exactly, to take well-founded

decisions regarding feed adjustments and to reduce the workload while still enhancing welfare.

The scale is controlled by the ViperTouch management system, a true Big Dutchman classic. The versatile computer offers poultry producers many attractive features, including controlling the time at which weights are recorded and configuring userspecific settings.

Of course, not just new buildings can be equipped with this system. Nesca 2.0 can also easily be integrated into existing houses with the Relax-Nest.

• significantly reduced workload for broiler breeder managers

because there are virtually no manual weighing tasks left, saving time and labour costs;

• early reaction to weight fluctuations: due to the high data frequency, management measures (e.g. feed adjustments) can be quickly implemented;

• customised weighing periods so the Viper computer can limit the weighing time to e.g. the morning before feeding starts, for even more accurate results;

• option for a combination with other Viper functions: the weighing data can be viewed in the overall context of the house and be linked to other parameters, such as feed consumption and the house climate.

For more information, visit www.bigdutchman.com

Small in size, big in impact – Ridder drive systems are the hidden power behind modern farming.

Every day, farmers worldwide rely on systems that keep barns and storage facilities running. Often, it’s the smallest components that make the biggest difference:

• A ventilation flap that opens at the right moment.

• A feeder line that lifts smoothly.

• A nest expel system with perfect timing.

Ridder drive systems ensure these vital functions happen reliably—every single time.

animal health, or crop quality.

Ridder gearmotors are engineered specifically for agriculture, not adapted from industry. That means robust, easy-to-install solutions designed to:

• Control airflow for optimal climate.

• Lift feeders and drinkers at exactly the right time.

• Power nest expel systems for smooth egg collection.

In barns and crop storage, every movement counts. Even the slightest deviation can affect climate,

Barns and storage facilities are demanding environments—dusty, humid, and in constant operation. Ridder drives are made from high-

grade materials, require minimal maintenance, and are built to last. The result: no surprises, no downtime—just consistent, quiet power.

Unlike industrial motors adapted for agriculture, every Ridder drive is developed from the ground up for livestock and crop storage:

• Rugged – Withstands tough barn conditions.

• Easy to install – Designed with farmers and installers in mind.

• Perfectly matched – Tailored to each facility’s needs.

• Ventilation systems: Automated, precise control of inlets, flaps, tunnel doors, and curtains.

• Winching systems: Reliable lifting and adjusting of feeders, lines, and curtains.

• Nesting systems: Unmatched timing for efficient egg collection and flock management.

Farmers today must produce more with fewer resources, while safeguarding animal welfare and crop quality. Automation and smart technology are essential. Ridder drive systems directly support these goals—helping to preserve harvests, protect animal welfare, and improve efficiency. At Ridder, we know our drive systems may be small—but their impact is huge. That’s why farmers across the globe trust us.

For more information, visit www.ridder.com

SunRise is a globally recognized specialist in rendering equipment, dedicated to transforming animal by-products into valuable resources through advanced processing solutions. Established in 2016, we have rapidly grown into an industry leader, offering innovative and efficient systems that optimize sustainability, performance, and operational excellence.

With a state-of-the-art manufacturing facility spanning 140,000m² and a team of over 120 skilled professionals, including more than 20 experienced engineers, SunRise provides tailored solutions for the animal protein and fat processing industry. Our expertise extends across slaughterhouse waste treatment, kitchen waste processing, and sludge reduction, ensuring environmentally responsible and high-yield operations.

SunRise integrates cutting-edge European technology and rigorous quality standards to develop precision-engineered equipment that enhances efficiency and reduces environmental impact. Our comprehensive project management system covers every stage, from design and manufacturing to installation, commissioning, and after-sales support. We work closely with clients to deliver customized solutions that meet specific operational needs while adhering to the highest industry standards.

Innovation is at the core of our business. Our dedicated R&D team continuously advances rendering technology to improve energy efficiency, maximize resource recovery, and

ensure compliance with global environmental regulations. As a high-tech enterprise, we are committed to driving industry progress with intelligent automation, superior material durability, and innovative process designs.

Beyond providing top-tier equipment, SunRise offers 360° professional support, including technical consultation, system optimization, and long-term maintenance services. Our global footprint continues to expand as we serve clients across various markets, including Asia, Europe, and Middle East.

At SunRise, we don’t just supply equipment—we deliver complete rendering solutions that empower businesses to achieve maximum efficiency, sustainability, and profitability. Partner with us to experience the future of rendering technology today.

For more information, visit www.sunriserendering.com or email sales@sunriserendering.com

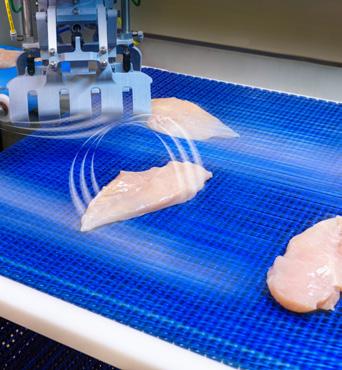

Portioning breast fillets for QSR products requires precise positioning before cutting. Only then it is possible to create the high-yield base products that form the foundation of QSR menus: sandwich fillets, strips, and cubes. JBT Marel’s new RoboOptimizer takes over this crucial step by robotizing the loading of the portion cutter. It ensures perfect positioning, reduces giveaway, saves labor, and paves the way towards an operator-free environment.

RoboOptimizer is a vital component in the breast meat process. It eliminates the need to arrange fillets manually before cutting. As each fillet has its own unique shape, RoboOptimizer analyzes it and determines the best orientation, for example to create strips of precise length. A larger fillet will be angled differently to prevent strips from becoming too long. This complete control brings considerable yield improvements and higher product quality.

No more manual handling

Thanks to this robotized positioning of every fillet, it becomes easier to meet strict specifications. For this, detecting left and right fillets is key. As JBT Marel’s Product Specialist Morten Dalqvist explains:

“The difference between left and right fillets is crucial for product acceptance, rejection or downgrade. For chicken sandwiches, left and right detection ensures the correct shape. For strips, cutting with the meat fibers prevents overstretching and keeps product quality high during tumbling and coating.”

Thanks to its built-in smart software, RoboOptimizer also prevents faulty products from disturbing the smooth product flow. Loose trimmings, offcuts, overlaps, or out-of-range products are automatically rejected through the fast-acting

belt gap. “RoboOptimizer’s intelligence knows exactly when to skip a product. This unique feature prevents wrong products from entering the process and ensures reliable operation at all times,” adds Morten Dalqvist.

Integrated solution for QSR lines

RoboOptimizer shows its true strength in an integrated setup. A processing line combining JBT Marel’s RoboOptimizer and I-Cut 122 TrimSort systems opens up a lot of opportunities for creating a wide variety of high-quality whole-muscle breast meat products. The portion cutter receives only products with consistent length, width, height, and weight. This unique line can then produce one sandwich fillet, two fillets, a fillet with strips, or several strips from a single fillet.

For more information, visit marel.com/robooptimizer

Raising bigger chickens for deboning and further processing has long been a challenge in Saudi Arabia’s demanding climate and challenging farming conditions. Yet, Tanmiah Food Company, together with McDonald’s Saudi Arabia, continues to defy expectations and raise the bar, setting new industry benchmarks through a strategic partnership committed to excellence. This strategic partnership with McDonald’s Saudi Arabia focuses on promoting the supply of locally sourced poultry to one of the world’s largest and most recognized quickservice restaurant chains, reinforcing both companies’ dedication to quality and local agricultural development.

As pioneers in leading quality, animal health, and nutrition, Tanmiah leverages advanced, techenabled environmental controls and stringent farming practices to consistently produce bigger birds

that meet the highest standards of food safety and regulatory compliance. Today, Tanmiah stands as the region’s only poultry supplier recognized for reliably raising bigger chickens for further processing, which meets the highest standards of food safety and quality.

This capability not only serves the local market but also enables Tanmiah to supply McDonald’s restaurants across a wider region, reinforcing Tanmiah’s role as a key contributor to Saudi Arabia’s self-sufficiency goals and McDonald’s commitment to offering fresh, high-quality, locally sourced poultry. To support growth stemming from the McDonald’s partnership, expansion plans in KSA are under exploration.

Commenting on the partnership, His Highness Prince Majed Fahed Al Saud, Co-CEO of McDonald’s Saudi Arabia, stated: “At McDonald’s Saudi Arabia, we

take great pride in our unwavering commitment to supporting the national economy and advancing local content by empowering our local suppliers. This partnership with Tanmiah is a testament to our shared commitment to localizing poultry production, aligning with Vision 2030, and ensuring the highest standards of quality, safety, and sustainability across every stage of our supply chain.”

“Our partnership with McDonald’s Saudi Arabia reflects a shared vision to empower local agriculture and redefine poultry excellence,” said Zulfiqar Hamadani, CEO of Tanmiah Food Company. “This collaboration is more than a supply agreement; it’s a step forward for food security, innovation, and sustainability practices in the Kingdom. We are proud to play a pivotal role in building a resilient, world-class halal protein ecosystem.”

Together, Tanmiah and McDonald’s Saudi Arabia are driving advancements in poultry production, optimizing supply chain efficiency, and responding to the growing demand for premium, locally raised poultry in the quickservice restaurant (QSR) sector. This partnership reflects a shared vision to elevate industry standards, strengthen local agriculture, and champion sustainable practices— ultimately enhancing the customer experience. This alliance also marks a significant step forward in advancing the Kingdom’s food security goals and elevating Saudi Arabia’s status as a global leader in halal protein production.

Both Tanmiah and McDonald’s Saudi Arabia express their gratitude to the Ministry of Environment, Water and Agriculture for their continued support in making this achievement possible.

The importance of poultry farm hygiene

Hygiene is a key part of managing any poultry farm. Dust, feathers, and manure can build up in cages, creating the perfect environment for harmful bacteria and viruses to grow. These pathogens can spread quickly, causing illnesses that harm bird health and reduce farm profits.

Many farms still rely on manual cleaning, but this method has its limits. Humans can miss spots or fail to clean thoroughly, and hiring workers for this task can be expensive. Additionally, cleaning by hand exposes workers to potential health risks.

To make cleaning easier and more effective, automated solutions like the Venus 2.0 cagecleaning robot are becoming popular. This type of robot can clean 24/7, providing consistent hygiene throughout the farm.

Unique features of Venus 2.0

• Setting cleaning programs

via the app makes the process more convenient and simpler. Through the app, users can set the height and width of the nozzles and the cleaning times for each row of cages.

• The nozzles can be adjusted to clean the inside of the cage, its ceiling, bottom, egg conveyor, and feed trough.

• By automating cleaning tasks, farms can rely less on manual labor, lowering costs and allowing workers to focus on other jobs.

The robot moves up and down the aisles between cages, spraying high-pressure water or cleaning solutions. When the robot finishes one row, it automatically slides down to move to the next row of cages. Farmers can control how often the robot cleans and adjust the angle of the nozzles for better results.

farming, automating the cleaning process provides a structured approach to sanitation, which is essential in breaking the cycle of contamination that can lead to disease outbreaks and financial losses.

Moreover, automation supports resource management by optimizing time and labor. Tasks that traditionally require significant human effort can be streamlined, allowing workers to focus on other aspects of farm management. This shift not only enhances productivity but also reduces the physical strain on workers.

The role of automation in farming is not just about replacing manual processes — it represents a step toward smarter, more sustainable agricultural practices. By adopting automated systems, farms can better adapt to the increasing demands for efficiency, biosecurity, and environmental stewardship in modern agriculture.

For more information, visit www.kohshin-s.jp

Dr.T.Kotaiah, Indbro Research & Breeding Farms Pvt.Ltd. Hyderabad

Native chickens -90% of the eggs available for human consumption in India came from Native chickens roaming in the rural back yards before 1960. Per capita availability was less than 10 eggs. The eggs were moving to urban areas from rural areas.

Commercial Hybrid poultry chick - started coming in to India after 1960. By the year 2000 commercial poultry went to 85%. The per-capita

availability is at 80+ eggs. The commercial poultry grew around cities. Eggs moved from urban to rural. The total layer bird population stands at 340millions, producing 12billion eggs. India is the 3rd largest egg producer in the world after China (1300million layers) and USA (370 million layers). The commercial hybrid chicks are produced from the Grand parents of a Brand. Eggs are sold in numbers. Not graded or Branded.

Rural poultry - The per capita consumption is 80+ eggs. The target is 180

eggs. Government of India is promoting Rural back yard poultry to produce the 100 eggs. This will enhance the nutritional status of the people living there and also will help in earning additional income to the Rural house wife. Dual purpose “Low Input technology birds” in the names of Vanaraja, Giriraja, Gramapriya etc. are supplied to replace the typical native birds.

There has been a change in the economy of Rural India after 2010.

• The Road connectivity and electricity to villages improved.

• The educated youth, Senior citizens and the house wives are

JULY-SEPTEMBER 2025

looking for earning some money.

• Banks are operating in rural areas lending money.

• Medium and Small scale Poultry production operations started at the rural areas.

• National Livelihood Mission supply 4weeks reared dual purpose, multi coloured birds under subsidy. The state governments promoted “Mother units”. To rear the birds up to 4weeks.

The growth in rural poultry after 2018 has been estimated as 40% over earlier year, while the commercial broiler production grew at 10% and egg layers at 6%.

• Eggs are promoted as a nutritious food for all ages, after the removal of cholesterol taboo. Eggs are Included in midday meals for school children and in Hospitals for patients.

• Free range rural produce is considered Organic and antibiotic free.

• Animal Welfare –The large poultry farms have to reduce the capacity by 25%, giving more space in cages.

• The cost of Poultry feed inputs are going up. Poultry farming in rural areas with local ingredients or low cost ingredients and free range rearing reduces the input costs.

• Bringing poultry under Pollution control board, prior approvals for erecting commercial farms are limiting their growth. Giving a fillip to Rural Poultry.

• Government’s aim to double the income of farmer is encouraging small scale animal farming.

• Fast growing broilers reaching 2kg weight in 35days also cast aspersions on the

consumer. Consumers suspect use of antibiotics, steroids and chemicals to achieve the fast growth. The fast growing broiler meat also has issues like woody breasts and white striped meat. There is a shift to slow growing birds. Research also indicates that slow growing chicken is tastier and healthier.

• Native chicken is sold at much higher price than the broiler. Almost two times. The organic label can earn even more.

The above issues are encouraging small farmers towards Animal Farming. Low cost housing and easy farming is the need of the day.

Native chicken growing slow is being paid higher than even Low Input Technology Birds. The native Aseel chicken of Andhra Pradesh which is basically a fighter bird, is in demand all over south India.

The attributes of Native Aseel chicken are:

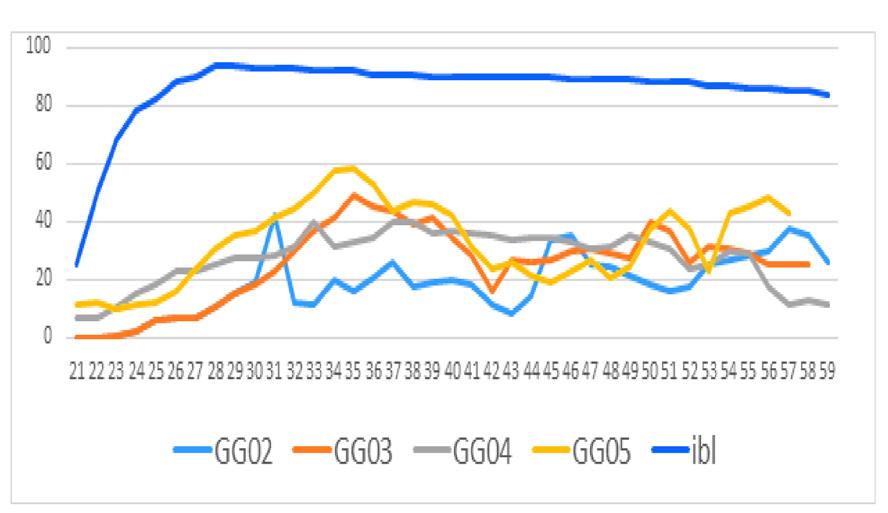

The production of four generations of native chicken(GG) and improved layers (ibl) is shown below.

• Tall legs, Ability to run & fly short distances – Helps in escaping from the predators.

• Multi - Coloured to camouflage.- Gets mixed up in the green bushes.

• Pea comb for specific identity.

• Hard meat, less fat, Atractive Colour, High Water Holding capacity & superb taste.

• The urban consumers are

ready to pay Rs500 to 600 per kg against the broiler price of less than Rs200.

• Government wants the native birds to be preserved.

• The Native chicken has been deteriorating fast. Egg size is small. The Native chicken lay about 15 eggs. Develop broodiness to hatch the eggs. Mothers the chicks for one

month. Thus laying only 15 eggs in 3 months and 60 eggs in a year. Large number of chicks cannot be produced.

• Hybrid crosses of Natïve chicken with the improved birds are good for both weight gain and laying.

• Farmers are rearing the birds for 6weeks under confined areas by feeding 1kg commercial feed and vaccines to protect them from known common viral diseases. They continue under confined conditions with low cost grower feed till they are sold.

Six Weeks birds are also reared in free range orchids. The birds eat insects, green leafy grass, kitchen and market vegetable waste. Farmers supplement commercial feed to achieve faster growth.

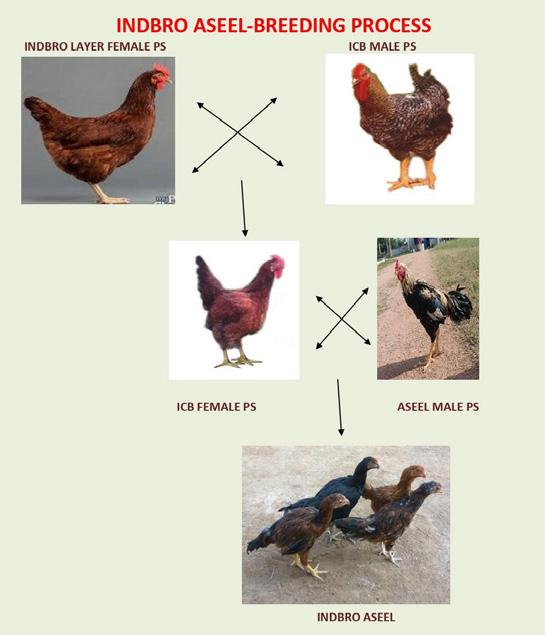

Indbro

& Breeding Farms Pvt.Ltd. is producing one such cross with 50% Aseel, 25% brown layer and 25% coloured

The egg productivity is very poor. The egg size has gone down. Chick size is small & mortality is high. The growth is very slow.

The production parameters of various genotypes.

The Meat characteristics of various genotypes were studied.

broiler genetics.

Genetic Improvement of Native Chickens

There is a need to preserve and improve the native chicken. Collect birds with good attributes. Study the health status & market requirement. Selective breeding work with in the closed population to improve the productivity. There is a move to register the available breeds and strains in India under conservation of genetic resources.

Breeding Program

Physical selection for body weight and confirmation is done at 90 days. Single cage facility to study the birds individually. Selection of birds will be based on 1. Age at Sexual maturity, 2. Weight at 18 weeks, adult weight, Number of eggs and Egg weight.

Should we retain the broodiness? Some rural families want birds for self propagation.

Producing Pure Asseel and is not be viable unless the chicks are priced very high. Crossing the Asseel male with commercial layer variety will be viable. If Aseel birds are reared for Meat production Broiler genetics is needed. A three way cross, Asseel+ Brown layer + Coloured broiler.

The birds look like native, taste like native and viable as a business proposition. The chicks, eggs & meat should be available in large quantities at reasonable cost.

Indbro Aseel

• The INDBRO ASEEL

look like native birds in body confirmation, comb type and capacity to run and fly.

• The growth is faster. 80days to market. They produce 160 eggs in place of less than100 eggs. Egg size is better.

• The adult body weight is 2200gms instead of 1300gms.

For more information, visit www.indbro.com

The UAE's commitment to food security and sustainability initiatives is set to receive a significant boost with the imminent entry of núaFEEDs, an innovative Australian agri-tech company. Having completed its registration in the UAE, núaFEEDs is poised to launch a facility that will convert surplus bread waste into highquality, nutritious, sustainable livestock feed—addressing one of the region’s biggest challenges: Food waste. The company chose the UAE as the launchpad for its international expansion, drawn by the country’s bold sustainability vision, commitment to food security, and forward-thinking circular economy initiatives.

núaFEEDs arrives in the UAE

with a proven track record spanning over 25 years from its family-operated facility in Western Australia. The company, led by Chava and Eric Berrill, has pioneered a unique solution that addresses three critical challenges across the supply chain: the rising and unpredictable cost of livestock feed, the increasing volume of food waste, and the cost of disposing of waste.

The benefits of núaFEEDs' entry into the UAE market are multifaceted for both industry and government. For those with grain-based food waste, such as major retail chains, food manufacturers, and bakeries, partnering with núaFEEDs offers lower disposal costs for food waste, streamlined collection processes, and

tangible accredited reductions in greenhouse gas emissions and water consumption. Each tonne of bread diverted from landfill avoids more than 500 kg of equivalent CO 2 and saves 13 cubic meters of water embedded in grain production. This aligns directly with the UAE government's mandates and climate goals, enhancing the sustainability credentials of participating businesses.

For livestock farm owners and feed buyers, núaFEEDs offers a stable, lower-cost, and highnutrition feed alternative. With traditional feed commodity prices subject to significant annual fluctuations, núaFEEDs' fixed-price, locally sourced solution will provide muchneeded stability and reduce dependency on imports, thereby strengthening the UAE's food security. The company's commitment to rigorous biosecurity standards, forged under Australia's strict biosecurity regulations, further assures top-tier quality and safety.

Government and regulatory bodies, such as the Ministry of Climate Change and Environment (MOCCAE), the UAE Food Security Office, and Abu Dhabi Agriculture and Food Safety Authority (ADAFSA), are key stakeholders who will find núaFEEDs' solution highly beneficial. The project directly supports the National Food Security Strategy 2051 by reducing reliance on

imports, promoting local feed alternatives, and contributing to waste reduction goals.

The UAE, with its arid climate and limited arable land, relies heavily on imported feed ingredients for its approximately 4.8 million head of livestock and 44 poultry

JULY-SEPTEMBER 2025

farms. Meanwhile, in the GCC region alone, 18 million tonnes of imported food end up in landfills (approximately 19% of that comes from cereals and grains), wasting valuable nutrients and contributing significantly to greenhouse gas emissions. núaFEEDs' innovative

approach focuses on isolating grain-based waste, and transforming it into livestock feed. This process not only diverts waste from landfills but also retains the nutritional quality of the bread, creating a product that can outperform traditional grains like barley in terms of protein and energy content – at a competitive cost to animal feed consuming industries

núaFEEDs' entry into the UAE market represents a tangible step towards greater food security and a more circular economy –where valuable resources are kept within the food chain, food waste and carbon emissions are reduced, and local food production is enhanced. The company's long-standing expertise and innovative approach are set to make a significant contribution to the UAE's sustainability vision.

Forage crops are the foundation of global dairy and livestock nutrition. As demand for consistent, high-quality feed grows across the Middle East and beyond, JR PREECE INC stands at the forefront, producing and exporting premium forage that supports animal health, dairy productivity, and food security.

Based in California’s Imperial Valley—one of the most productive forage regions in the world—JR PREECE INC cultivates more than 10,000 acres of farmland. We specialize in Alfalfa Hay, Bermuda Grass, Oat hay, Sudan Grass, and Klein grass, produced through a blend of tradition, experience, and modern agronomy. Careful water management, soil health programs, NIR & WET Lab Testing and precise harvesting ensure every bale meets the nutritional standards required by

leading dairies worldwide.

• Nutritional Value: High protein, digestibility, and optimal RFV for top herd performance.

• Sustainability: Efficient irrigation and conservation practices that protect soil and water resources.

• Compliance: Adherence to global export and phytosanitary standards for smooth delivery.

Quality forage is more than feed—it is the foundation of milk production. By delivering consistent supply year-round, JR PREECE INC helps dairies balance rations, improve efficiency, and secure longterm stability in an increasingly competitive market.

With integrated logistics through our affiliated export and

transportation companies, we manage the full supply chain— from field to port. Each year, we export tens of thousands of metric tons of forage to customers across the Middle East and Asia, including Oman, the UAE, Saudi Arabia, Qatar, Kuwait, Jordan, Vietnam, Japan, Korea and Taiwan.

Our mission is clear: to advance forage production for the next generation. By combining agronomic expertise, sustainable practices, and global partnerships, JR PREECE INC remains committed to delivering premium forages supporting livestock producers and strengthening food security worldwide.

For more information, JR Preece Inc www.jrpreece.com

Email: farm@jrpreece.com WhatsApp: +1 323 300 0739

Fraunhofer IGD will join other leading international exhibitors at the AgroFarm Middle East 2025 event, showcasing its latest research on digital crop and livestock farming. At booth G12 in the German Pavilion, Fraunhofer IGD will demonstrate how artificial intelligence, imaging, and sensor technologies can promote more sustainable and efficient practices in plant production, animal health, and food safety.

Health Monitoring in Livestock and Aquaculture

Fraunhofer IGD’s expertise in imaging and AI-based analysis benefits livestock farming as well. Applications include detecting lameness and vital parameters in dairy cows, performing ultrasound-based pregnancy

diagnostics, and monitoring behavior. Fraunhofer IGD also contributes to modern, sustainable animal production methods, such as larval quality control in black soldier fly farming, health monitoring in poultry, and innovative aquaculture solutions.

AI-supported monitoring allows for early detection of stress symptoms in strawberries grown in polytunnels. This enables timely interventions that stabilize yields and improve fruit quality. Advanced AI models reliably detect and identify weeds, supporting biodiversity monitoring and enabling spot-spraying instead of large-scale treatments. In sugar beet cultivation, dronebased monitoring can identify

biotic stress factors, such as Cercospora leaf spot, with high precision. Spot-spraying techniques ensure that treatments are limited to the affected areas, reducing chemical use while maintaining crop health and protecting the environment.

In forestry, Fraunhofer IGD uses image analysis and remote sensing to identify tree species and evaluate their health. Existing technologies can also be applied to additional crop-management challenges, such as palm weevil infestation.

Fraunhofer IGD will also present innovations in food safety. Using a combination of AI, hyperspectral imaging, and satellite data, it is possible to detect wheat diseases associated with mycotoxin accumulation. These solutions provide early warning and specific recommendations to ensure that only safe, clean raw materials enter the food supply chain.

For more information, visit www.igd.fraunhofer.de

Heat stress is a significant challenge for dairy farmers, as it can severely impact the well-being and productivity of cows. Dairy cows, particularly highyielding ones, generate substantial metabolic heat, rendering them vulnerable to heat stress. When the ambient temperature combined with humidity exceeds the thermoneutral zone for dairy cows, it results in decreased feed intake, reduced milk production, and impaired reproductive performance.

Natural antioxidant sources, such as grape polyphenols, have shown clear efficacy in reducing the impact of heat stress on animals. Grape polyphenols must be rigorously selected and standardized to ensure proven

and consistent efficacy. Nor-Feed carried out a study to evaluate the impact of supplementing grape polyphenols with a specific by-pass formula to dairy cows challenged to heat stress.

The immune-modulating properties of grape polyphenols also play a vital role in maintaining animal well-being under heat stress. Indeed, with grape extract supplementation, an improvement in thermoregulatory responses is observed, with a decrease in rectal temperature and reduced panting respiration.

By reducing oxidative stress, grape polyphenols help in alleviating inflammation and

sustaining the cows’ immune function, which is often compromised during heat stress. Notably, research indicates a reduction in somatic cell counts in milk, which is indicative of enhanced udder health and overall immune resilience among supplemented cows (Amato et al., 2025).

Moreover, rumen-protected polyphenols have shown to fortify the innate immune response, with increased neutrophil and monocyte activity, helping cows to combat infections more effectively. This physiological resilience is vital for maintaining health and performance during prolonged periods of heat stress.

For more information, visit www.norfeed.net

More and more dairy farmers are choosing robotic milking because of labor savings, improved cow comfort, and valuable data insights. The M2erlin milking robot from Fullwood JOZ perfectly responds to this. This robot is designed for maximum flexibility in every barn and optimal results in milk production, animal health, and ease of use.

The M2erlin stands out with its unique Twin-entry/Twin-exit concept. This double entry and exit enable a natural cow flow without queues or bottlenecks.

Additionally, it offers a compact separation possibility. Cows can easily be selected for pasture or straw pen without the need for extra separation gates—a win-win.

Another advantage of the compact robot box and the double entry and exit is the wide range of installation options, such as side-by-side, tandem, parallel, or head-to-head setups. Ideal for both new and existing barns.

The M2erlin is equipped with

exclusive Streampulse milking technology. This system creates a longer milk column and lower vacuum during the resting phase, resulting in a calmer milking process, healthier teats, and higher milk yield. On average, 50% of the milk is milked in the first two minutes. That’s speed and efficiency.

The M2erlin is built with the cow in mind. The open box ensures the cow stays in contact with the herd, preventing restlessness. The exceptionally quiet electric robot arm and the natural entry and exit make the milking process stressfree. The result: a relaxed cow that performs better.

Smart FULLSENSE milking robot software

The M2erlin is supported by our smart FULLSENSE

milking robot software. This software translates complex data into clear insights and concrete recommendations, such as realtime updates on milk production, cow health, milk quality, and feeding strategy—all in one userfriendly dashboard.

For more information, visit www.fullwoodjoz.com