With the winter solstice now behind us, we find ourselves past the halfway mark of what has been a particularly cold and wet winter across much of Australia. While the chill may linger, there’s comfort in knowing the days are once again growing longer, and that the year’s major events in the world of materials science are beginning to gather momentum.

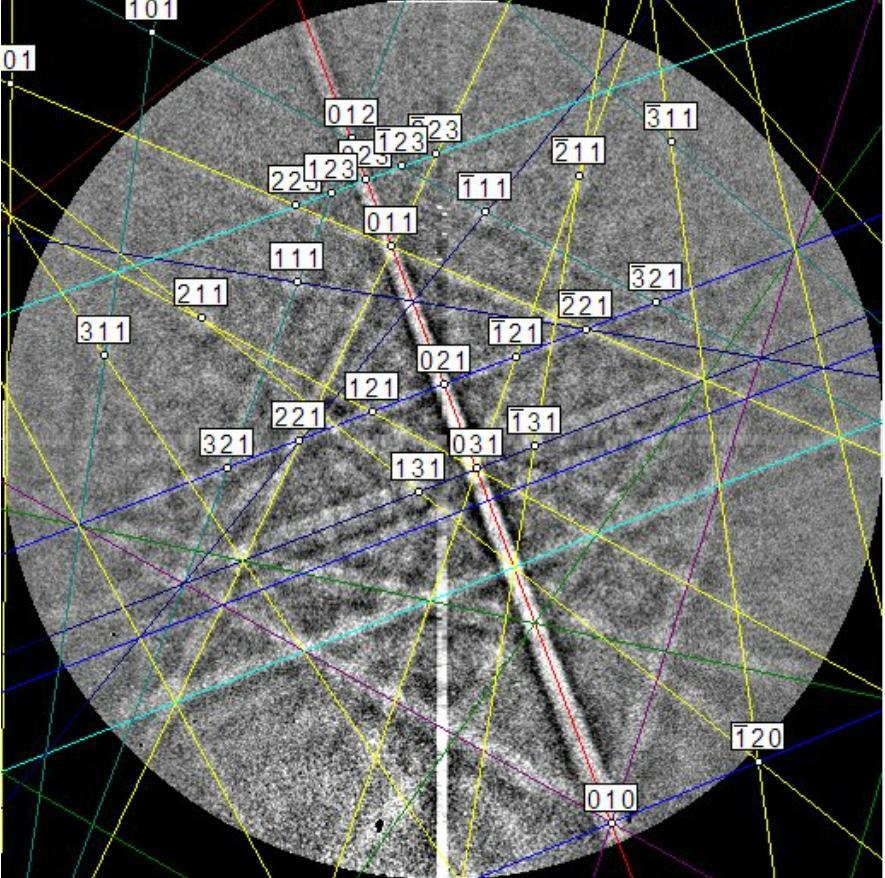

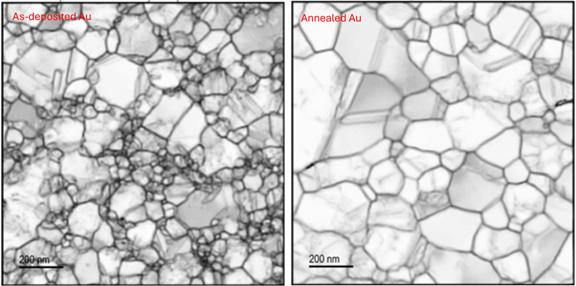

I’ve spent much of these winter months indoors, huddled in my office proofreading two PhD theses from my students, both nearing submission. While many of us in academia and research find ourselves increasingly caught in a whirlwind of administration, compliance, and an ever-growing list of approvals, I’ve found unexpected joy in returning to the core of our discipline—poring over diffractograms, scrutinising microstructures, and having in-depth discussions about materials behaviour.

It’s been a refreshing reminder of why we all started this journey in materials science in the first place. I hope that amid your own busy schedules, you too are able to reconnect with the scientific heart of our profession and find

moments of inspiration in your work. A highlight of the past few months has undoubtedly been the 2025 AsiaPacific International Conference on Additive Manufacturing (APICAM), held in late June and early July. I’d like to extend my heartfelt congratulations to Professor Ma Qian and Professor JianFeng Nie for once again delivering a world-class event. With 400 delegates, 12 conference themes, three full days of presentations, and an incredibly engaging poster session, APICAM continues to grow in reputation and impact.

On behalf of the Materials Australia Executive Committee, I’d like to express our sincere gratitude to the entire conference organising committee. Pulling together an event of this scale is no small feat, and your hard work and dedication are deeply appreciated by our members and the broader materials community.

I’d also like to acknowledge and thank RMIT University, our valued partner for APICAM. RMIT’s ongoing support of Materials Australia and our mission is instrumental to the success of events like these, and we are grateful for their continued collaboration.

Looking ahead, there’s more to get excited about. In August 2026,

Materials Australia National Office PO Box 19 Parkville Victoria 3052 Australia

T: +61 3 9326 7266

E: imea@materialsaustralia.com.au W: www.materialsaustralia.com.au

NATIONAL PRESIDENT Nikki Stanford

MANAGING EDITOR

Gloss Creative Media Pty Ltd

EDITORIAL COMMITTEE

Prof. Ma Qian

RMIT University

Dr. Jonathan Tran

RMIT University

Tanya Smith MATERIALS AUSTRALIA

ADVERTISING & DESIGN MANAGER

Gloss Creative Media Pty Ltd Rod Kelloway 0418 114 624

PUBLISHER

Materials Australia Technical articles are reviewed on the Editor’s behalf

PUBLISHED BY

Institute of Materials Engineering Australasia Ltd.

Trading as Materials Australia

ACN: 004 249 183

ABN: 40 004 249 183

B.Eng(Hons) Ph.D. CMatP

Australia will proudly host the 12th Pacific Rim International Conference on Advanced Materials and Processing (PRICM12) on the Gold Coast. PRICM is a globally recognised event, bringing together hundreds of materials science experts from across the Asia-Pacific and beyond.

The conference will cover the full spectrum of materials research and innovation, from functional and nuclear materials, to composites, battery technologies, computational materials science, and more. It will be an extraordinary opportunity to exchange ideas, learn from global leaders, and showcase the strength of Australian materials science on the international stage.

The PRICM12 website is now live, so I encourage you to explore the program themes, consider submitting an abstract, or register early to take advantage of early bird pricing. It promises to be one of the standout events on our professional calendar. Until next time, I wish you warmth, discovery, and continued inspiration in all that you do.

Best Regards

Nikki Stanford National President Materials Australia

This magazine is the official journal of Materials Australia and is distributed to members and interested parties throughout Australia and internationally.

Materials Australia welcomes editorial contributions from interested parties, however it does not accept responsibility for the content of those contributions, and the views contained therein are not necessarily those of Materials Australia.

Materials Australia does not accept responsibility for any claims made by advertisers.

All communication should be directed to Materials Australia.

- July 2025

Source: Sally Wood

The 2025 Asia-Pacific International Conference on Additive Manufacturing (APICAM)—the fourth of its kind to be held in the Asia Pacific region—was held in Melbourne from 30 June to 3 July.

APICAM was created to provide an opportunity for industry professionals and thought-leaders to come together, share knowledge and engage in the type of networking that is vital to furthering the additive manufacturing industry.

Attendees heard from some of the leading minds in the industry, who presented highly informative and engaging presentations on pressing issues, as well as the ways in which innovations can navigate challenges.

The Plenary Sessions included:

• Professor Dr.-Ing Christoph Leyens on Advanced materials and system technology developments for Additive Manufacturing

• Professor Huiping Tang on Progress in Metal Additive Manufacturing in China: from Powder Development to Industrial Applications

Just some of the keynote presentations included: Advances in Additive Manufacturing by Professor Paulo Jorge Da Silva Bartolo (Nanyang Technological University); Biomimetic and Adaptive Structures: Interface of Technology with Additive Manufacturing by Professor Laila Ladani (Arizona State University); Additive manufacturing process chain development of amorphous alloys for soft magnetic applications by Dr Isabella Gallino (Technische Universität Berlin); Design and Additive Manufacturing of a Lattice-Based, Ultra-Light Forearm Prosthesis by Associate Professor Matteo Benedetti (University of Trento); and Modelling of Implant Biocompatibility in Additive Manufacturing by Professor Lihai Zhang (University of Melbourne.

The keynote addresses were complemented by countless other presentations, across a variety of subject areas, including metal, polymer, ceramic and concrete additive manufacturing, bioprinting and biomaterials, digital manufacturing, modelling and simulations, and emerging additive manufacturing technologies.

The Poster Session gave attendees the chance to become better acquainted with the significant volume of technical and academic research being undertaken in Australia’s additive manufacturing industry.

Each technical poster was accompanied by the academic who created it, giving attendees the opportunity to discuss the research and have all their questions answered.

Our congratulations go to Patjaree Aukarasereenont (CSIRO) who won the award for best poster for Porous metallic structures: Alternative oxygen cathodes for Li-air batteries.

Sponsored by the CSIRO, the Conference Dinner at ZINC was a highlight of APICAM. The Dinner was an opportunity for industry professionals to get together in a more relaxed setting and to forge friendships that might otherwise be impossible.

Speakers at the Dinner included Dr Kathie McGregor, Research Director for the Advanced Materials and Processing Program in CSIRO Manufacturing, and a member of the Manufacturing Business Unit Leadership Team.

The Dinner also saw the presentation of the Materials Australia Silver Medal to Professor Jian-Feng Nie; Professor Barry Muddle was awarded Honorary Membership of Materials Australia; and Dr Tingting Song was awarded the Ian Polmear Early Career Research Award. Our congratulations go to all the award winners for their valuable contributions to our industry.

Of course, none of this would have been possible without our conference sponsors. Materials Australia would like to extend our gratitude to Joel, our Gold Sponsor; the CSIRO, our Dinner Sponsor; Flow-3D AM, our Program Sponsor; American Elements, our Lanyard Sponsor; Amiga Engineering, our Student Bursary Awards Sponsor; and Metal AM and Materials Science in Additive Manufacturing, our Media Partners.

Materials Australia would also like to thank all our exhibitors, including the Additive Manufacturing CRC, ATA Scientific, AXT, Bruker, DKSH, Emlogic, Emona, Evident Scientific, InssTek, LECO, Malvern Panalytical, Objective3D, Zeiss.

Last, but by no means least, Materials Australia would like to thank everyone involved in organising APICAM, including: Conference Chairs, Distinguished Professor Ma Qian and Professor Jian-Feng Nie; the Organising Committee including our conference secretaries Dr Tingting Song and Dr Jordan Noronha; and Tanya Smith, Executive Officer of Materials Australia.

CONFERENCE HOST

VENUE HOST

PROGRAM SPONSOR

GOLD SPONSOR

STUDENT BURSARY SPONSOR

LANYARD SPONSOR

DINNER SPONSOR

MEDIA PARTNERS

Source: Dr Steve Algie – S H Algie & Associates Pty Ltd

Dr Steve Algie described the retrospective failure analysis he had conducted into the root cause of a near-fatal car crash in which he had been involved.

The single-vehicle rollover occurred in 1981 in the UK, while Steve was driving a rented Morris Marina. The analysis was made possible by his chance rediscovery of a roll of unprinted black and white film, with clear photographs of damaged components from the wrecked car.

Steve was hospitalised with a concussion and has no memory of the event, other than that the steering had suddenly failed. However, his wife had recorded in her diary that while travelling on the A19 at 70 mph (110 km/h), the car suddenly veered right, then left, spun 180 degrees to the right, struck the median strip, rolled 360 degrees, and landed upright on the opposite carriageway. It was sheer luck that no other vehicles were involved in the crash, as the consequences could have been fatal for multiple parties.

The root cause of the crash was never determined at the time, but more than four decades later, prompted by the availability of the photographs, Steve reopened the "cold case." He applied a range of mechanical and materials engineering principles to reconstruct the likely sequence of mechanical failures that led to the crash.

The photographs showed that the front lower suspension arm had fractured through tie rod mounting hole. This was the first point of failure, and physical modelling with plasticine showed how the subsequent complex deformations of the front suspension components observable in the photographs had occurred in sequence during of the various phases of the rollover. This sequence was confirmed by estimates of yield, work hardening and ultimate strength properties of the materials likely to have been used in the components.

Central to the analysis was the Morris Marina’s front suspension design, which

used torsion bars and elastomeric bearings based the 1948 Morris Minor. The vehicle’s lower front suspension arms are a critical component but were apparently minimally designed for the relatively low stresses to which they subject in normal circumstances. However, as the photographs clearly show, this was the point of initial failure and a weak point in the design

The analysis considered how fatigue failure could have originated at the hole for the tie rod pin. By considering materials properties and road forces, Steve demonstrated that stresses from pothole impacts, or heavy braking could lead to crack propagation by low-cycle fatigue, making the front arm vulnerable to failure under ordinary steering forces. This created a "hairtrigger" situation, as the suspension would have continued to function apparently normally until the moment of final fracture, with no external warning to the driver of impending catastrophic steering failure.

Information now accessible online confirms that tie rod issues are a known weak point in the Morris Marina, though at the time not widely acknowledged as a serious failure risk.

Reflecting on the context of the early 1980s, Dr Algie noted that failure analysis was not routinely conducted for consumer vehicle accidents at the time, and the UK regulations around vehicle design and safety were far more relaxed than today’s standards. Even seat belts in the back were not mandatory in new cars until 1987.

The Morris Marina had a reputation for poor structural integrity, and its design reflected cost-cutting measures and outdated engineering decisions. Indeed, the Morris Marina now makes regular appearances in online lists and videos of ‘the worst cars ever produced’!

In summary, in terms of Failure Mode, Effects and Criticality Analysis, the failure mode of the front suspension arm was not just theoretically possible, but demonstrably real and potentially catastrophic. Exacerbating the situation, hidden and progressive crack propagation would not necessarily have been revealed in regular servicing. Thus, the design would surely not be acceptable today due to its susceptibility to a single point of failure, lack of redundancy, and undetectability of impending failure under standard maintenance practices.

Source: Dr Ibukun Oluwoye, Curtin Corrosion Centre

Dr Ibukun Oluwoye’s presentation started with an outline of the diverse degradation mechanisms that affect polymers and composites. He concluded by reviewing some current industry standards used to evaluate the suitability, performance, and durability of engineering polymers and composites under various environmental and operational conditions.

After gaining his bachelor’s and master’s degrees in mechanical engineering, in Cyprus, Ibukun completed his PhD studies at Murdoch University. This took him into the world of polymers and composites, with a focus on their chemical and mechanical properties. He has continued this line of research at Curtin University, which he joined in 2019, with a particular interest in degradation and service life prediction of polymer components in subsea environments. His work also extends to sustainable solutions for offshore infrastructure decommissioning, including the development of recycling pathways, and innovations in chemical resources and process safety. During a Fellowship at the University of Kyoto, he explored the behaviour of plastics, microplastics, and nanoplastics across diverse environmental systems.

Dr Oluwoye began his presentation by pointing out that mechanical properties of polymers generally increase with increasing degree of polymerisation, drawing attention to the widely differing quantities of energy associated with various types of chemical and intermolecular bonding. He also the noted that the mechanical properties of composite materials depend on the combined actions their components, which is especially relevant when one or more of these is subject to degradation.

He then turned to degradation pathways in polymers. These are typically complex and inhomogeneous. This is the case even in nominally single-component polymers because these polymers typically contain several functional additives, such fillers, plasticisers, stabilisers, colorants and flame retardants. Ibukun’s focus in this talk was on chemical, rather than biological degradation. Mechanisms include heat, photochemical reactions, notably UV-A radiation, and hydrolysis (e.g., of urethane bonds). Diffusion of molecules from the environment into the polymer, between the polymer chains, can result in swelling and chemical degradation. Such diffusing molecules include oxygen, water, carbon dioxide and methane. In general, solvents that contain molecules similar to those in the polymer cause more degradation, but diffusion is faster for chemically inert molecules, than for molecules that are reactive with the polymer. Diffusion rates are higher for amorphous than for semi-crystalline polymers.

With multiple modes of degradation, more than one mechanism can operate at the same time, and different mechanisms may apply in differing environments.

Consequently, loss of polymeric materials in, for example, subsea flowlines is not always expressible simply, such as mm/year. Temperature and light intensity decrease with depth below the surface, while currents control the concentration of suspended abrasive sand, which can remove degraded material from the surface, thus increasing environmental exposure. The resultant combination of bulk and surface degradation makes it difficult to predict expected life from limited trials. Nevertheless, standards, notably ISO 23936, have been developed for selection, qualification and assessment of polymeric materials for use in the oil & gas industry.

A key factor in testing is determining if the degradation is diffusion-limited, which governs whether the degradation is at the surface or in the bulk of the material. Particular challenges arise in accelerated ageing testing, which Ibukun illustrated with the analogy of an egg. Heating at 100°C results in a boiled egg; 25°C for 30 days makes a rotten egg; 37.5°S for 21 days produces a chicken. This behaviour does not follow an Arrhenius relationship!

In practice, additional complications arise because of the typically limited detailed characterisation of the polymers used, the effects of imposed stresses, and how the materials are stored prior to being put into service.

Questions from the audience showed that this was clearly a topic of great concern, not only in the oil & gas industry, but also in biomedical engineering. One interesting point was that diffusion-limited degradation is a reason for the persistence of microplastics in the environment; the surface area available for continued degradation diminishes as they get smaller.

The 12th Pacific Rim International Conference on Advance Materials and Processing will be held on the Gold Coast from 9 to 13 August 2026. PRICM is a series of triennial international academic conferences that focus on advanced materials and processing.

For more than 30 years, PRICM has served as an international stage for dissemination of current and emerging materials and processing, jointly organised by the Chinese Society for Metals (CSM), The Japan Institute of Metals and Materials (JIMM), The Korean Institute of Metals and Materials (KIMM), Materials Australia (MA), and The Minerals, Metals & Materials Society (TMS).

The first PRICM was held in 1992 in Hangzhou, China, and hosted by CSM. After the first conference, PRICM was hosted with great success in 1995 (Kyongju, Korea), 1998 (Hawaii, USA), 2004 (Beijing, China), 2007 (Jeju, Korea), 2010 (Cairns, Australia), 2013 (Hawaii, USA), 2016 (Kyoto, Japan).

PRICM has made a concentrated effort over the past 30 years to share the academic exchange of materials and processing to the worldwide arena, fast becoming one of leading academic forums for academics, researchers and engineers in the industry.

PRICM12 is set to take place at the cutting-edge Gold Coast Convention and Exhibition Centre. This dynamic venue will buzz with the exchange of ideas, industry insights, and provide an exciting opportunity for professionals to network and connect within the field.

PRICM12 aims to bring together leading scientists, technologists and engineers

from the Asia-Pacific region and around the world to discuss contemporary discoveries and innovations in the rapidly evolving field of materials and their processing. This event is also intended to foster stronger and closer interactions between materials practitioners and their international counterparts. This conference will cover most aspects of advanced materials and their manufacturing processes.

Symposium themes include:

• Advanced Steels and Properties

• Advanced Processing of Materials

• Structural Materials for High Temperature

• Light Metals and Alloys

• Additive Manufacturing

• Interfaces and Surface Engineering

• Materials for Energy Conversion, Generation and Storage

• Electronic and Magnetic Materials

• Biomaterials and their Applications

• Advanced Characterization and Evaluation of Materials

• High-Entropy Materials and Amorphous Materials

• Composites, Hetero-Materials, and Functionally Graded Materials

• Nano Materials and Nano Severe Plastic Deformation

• Modelling and Simulation of Materials and Processes and Artificial Intelligence

• Materials for Sustainability (Corrosion, Coating, Green Steel, Recycling)

Closing date for abstract submissions is 15 December 2025. Visit the website for more details.

Registrations for PRICM12 are now open. Take advantage of the early bird rates and book now via the website: https://www.pricm12.org

The Gold Coast Convention and Exhibition Centre (GCCEC)

The Gold Coast Convention and Exhibition Centre (GCCEC) is Queensland's premier event venue, located in the heart of Broadbeach on the Gold Coast. Renowned for its ultramodern facilities, the GCCEC offers over 10,000 square metres of flexible event space, making it the ideal destination for conferences, exhibitions, and corporate events.

The GCCEC is conveniently located only 500 metres from golden beaches and is surrounded by multiple accommodation,

dining and entertainment options, providing industry professionals with the perfect blend of business and leisure.

The Gold Coast is one of Australia's most popular tourist destinations, welcoming over 12 million visitors each year. It offers a unique mix of culinary, cultural, and outdoor experiences, perfect for food lovers and adventure seekers.

Attendees are spoilt for choice with a selection of fine dining establishments and casual beachside cafes to dine from.

The region's diverse dining scene is complemented by nearby shopping and entertainment hubs such as Pacific Fair Shopping Centre and Broadbeach Mall.

Make the most of the pristine outdoor adventures like surfing at the nearby beaches or taking a hike through the breathtaking World Heritage Rainforest.

With over 300 days of sunshine each year, the Gold Coast’s favourable climate makes it an ideal destination for year round enjoyment, promising a unique and memorable experience for every visitor. www.pricm12.org

Maximise your visibility for your target markets by becoming a conference partner. Our marketing will ensure that your support and profile is raised with the over 1400 attendees coming to the PRICM12 Conference.

You can choose one of our partnership opportunities or talk to us about a tailored package to suit your needs. An early commitment will mean a greater exposure and a greater return on your investment.

For tailored packages contact: Organising Society

PROFESSOR JIAN -FENG NIE MONASH UNIVERSITY

AUSTRALIA

M +61 429 150 702

Email: tanya@materialsaustralia.com.au

Jian-Feng Nie is a professor of the Department of Materials Science and Engineering at Monash University. His research interests cover magnesium alloys, aluminium alloys, biodegradable metals, solidsolid phase transformations, applications of scanning transmission electron microscopy in materials characterization, and processingmicrostructure-property relationships in metallic materials. His publications include the 5th Edition of book “Light Alloys”, a chapter on light alloys in the 5th Edition of “Physical Metallurgy”, and over 200 papers in journals like Science, Nature, and Acta Materialia. He is editor of Metallurgical and Materials Transactions A, member of the Board of Governors, Acta Materialia Inc, and TMS Fellow.

MATERIALS AUSTRALIA

M +61 418 114 624

Email: rod@materialsaustralia.com.au

Where do you work and describe your job?

I am Vishnu Vijayan Pillai, a material science and engineering researcher with a master’s degree in Nanotechnology. Previously, I worked as a Research Engineer at Khalifa University, where I gained valuable experience in the field of advanced materials and their applications. After receiving the prestigious Australian Global Talent Visa, I relocated to Australia, embarking on a new phase of my career where I was awarded a Ph.D. scholarship from the Australian Research Council. This scholarship enabled me to pursue research at Swinburne University of Technology under the esteemed guidance of Dr. Nishar Hameed, Dr. Nisa Salim, and Dr. Peter Kingshott.

My Ph.D. research focuses on developing advanced graphene formulations for sensing intelligence in real-time Structural Health Monitoring (SHM) applications. Graphene’s exceptional properties make it a promising material for SHM, particularly in aerospace, defense, automotive, infrastructure, and renewable energy sectors. Additionally, I received a top-up scholarship from the Australian Defence Science Institute's RHD Grant program.

Apart from my research work, I am also the co-founder of Manhat, a deep

technology startup based in the United Arab Emirates and Australia. Manhat focuses on developing and deploying its patented 'natural water distillation' technology to provide sustainable water solutions for irrigation in inland and floating farms. Along with my former research supervisor, Dr. Saeed Alhassan, we aim to address water scarcity challenges by offering a solution that ensures clean water production without brine rejection. Our technology has attracted international recognition and accolades, making Manhat a promising player in the water sustainability sector.

What inspired you to choose a career in materials science and engineering?

My journey into the field of materials science and engineering was not entirely driven by inspiration at first. Rather, it was a conscious choice made during my early academic years. After completing my grade 12, a friend’s father introduced me to the field of nanotechnology. Intrigued by the possibilities it offered, I pursued an integrated master’s degree in Nanotechnology from Amity University, India.

It was during my research internships that my interest in materials engineering truly developed. The internships I undertook at Cochin University of Science and Technology (India), the Nanotechnology and Integrated Bioengineering Centre at Ulster University (UK), and my master’s thesis at the University of Montpellier (France) broadened my understanding of materials science and engineering. These experiences allowed me to explore the fascinating world of materials at the nanoscale and how innovative solutions could be developed to address practical challenges. It was this exposure to advanced research environments and diverse applications that ignited my passion for the field.

Who or what has influenced you most professionally?

Throughout my research journey, which spans over a decade, I have encountered numerous exceptional professionals who have left a lasting

impact on my career. I cannot attribute my growth and progress to a single individual but rather to a collective of inspiring mentors, colleagues, and seniors who have guided me along the way. The transition from academia to the startup ecosystem has been transformative. Seeing how technology can directly impact society has inspired me to drive research toward innovation. Co-founding Manhat has broadened my perspective on how research and technology can be translated into practical solutions to address pressing global issues like water scarcity.

What does being a CMatP mean to you?

It holds significant meaning for me as it represents both recognition and opportunity within the field of materials science and engineering. Achieving CMatP status is not only a testament to my qualifications and expertise but also a mark of credibility that signifies my commitment to maintaining the highest standards of professionalism and innovation in this dynamic field. CMatP offers an incredible platform to deepen my understanding of the materials ecosystem in Australia and beyond. It provides access to a vibrant network of professionals who are at the forefront of materials application and technology. This endorsement adds weight to my credentials, enhancing my visibility within the broader scientific and industrial community.

What gives you the most satisfaction at work?

The sense of accomplishment I feel when I successfully achieve or even exceed my goals is incredibly rewarding. It validates the time, energy, and dedication I've invested. Moreover, the journey of overcoming challenges along the way and finding innovative solutions to push the boundaries of what's possible adds even more meaning to the achievement.

What is the best piece of advice you have ever received?

The best piece of advice I've ever received came from my father: "Follow your passion. Never underestimate yourself." These words echo in my

mind whenever I'm feeling stressed, and they always fuel me with energy. My father has an incredible calmness about him. Even during his battle with cancer, when I was by his side throughout his treatment, he remained calm and took everything in stride. His resilience and unwavering positivity continue to inspire me.

What are you optimistic about?

I am optimistic about the potential of deep technology to address some of the most pressing global challenges. I believe that breakthroughs in materials science and engineering can significantly improve the quality of life for millions of people. I am confident that our continued research and development efforts will lead to impactful innovations that promote sustainability and resilience.

What have been your greatest professional and personal achievements?

With over eight years of research experience, I have had the privilege of working across leading institutions in India, the UK, France, the UAE, and Australia. My specialization in advanced materials has resulted in the publication of numerous journal articles and presentations at prominent international conferences, including ACS Boston.

Some of my most notable accomplishments include receiving the Australian Global Talent Visa and the UAE Golden Visa, which recognize my contributions to the field. As the co-founder of Manhat, I played a key role in securing international recognition and exposure through events such as Expo Dubai (2020), the World Future Energy Summit (2022), and the United Nations COP28 (2024). Manhat has been awarded the European Union Water Europe Innovation Award (2022), the Future 100 Award (2023 & 2024), and the Best Practices Award at Expo 2025 Osaka, Kansai, Japan. Additionally, I was awarded the Halcyon Climate Fellowship in 2024, which reinforced my commitment to sustainability.

My PhD research was selected to present at the prestigious European Materials Research Society (E-MRS) Spring Meeting, held in Strasbourg, France in May 2025.

This opportunity allowed me to share my research on smart coatings for sensing intelligence with an international audience of researchers and experts in the field

On a personal level, I consider my greatest achievement to be my role as a parent to two amazing boys, Dhruv and Daksh, alongside my supportive wife, Remya, who has been a constant pillar of strength throughout my journey.

Which has been the most challenging job/project you’ve worked on to date and why?

Every project I have undertaken presents its own set of challenges. However, there are a few specific experiences that stand out due to their complexity and the learning curve involved. Firstly, transitioning from a research background to the startup ecosystem was a significant challenge. When I co-founded Manhat, I had little to no business background and was initially unsure of how to navigate the

entrepreneurial landscape. However, through persistence, guidance from mentors, and continuous learning, I gradually adapted and succeeded in meeting our objectives. Leading a deep technology startup requires balancing research and commercialization, which remains a challenging but rewarding endeavor. Secondly, returning to academia to pursue a Ph.D. after working in the industry for several years presented challenges on both personal and professional levels. Adjusting to the rigorous demands of academic research, while reorienting my mindset from industry-driven objectives to long-term scientific exploration, was no small feat. On a personal level, balancing family responsibilities and maintaining a healthy work-life equilibrium added another layer of complexity. Despite these difficulties, my passion for research and the pursuit of knowledge has continued to propel me forward.

What are the top three things on your bucket list?

As someone who enjoys traveling, my bucket list includes experiences that are meaningful and personal. The first and most cherished item on my list is visiting Japan to witness the breathtaking beauty of Mount Fuji. This has been a longstanding dream of mine, and I look forward to embracing a peaceful moment surrounded by its serene landscape. Secondly, I wish to travel to New Delhi with my mother to visit Amity University, where I completed my Master’s in Nanotechnology. Due to various reasons, my mother was unable to visit my university during my academic years. Taking her to see the place where I spent a significant part of my academic journey would be a moment of pride and fulfillment. Lastly, there is a third goal that I wish to keep close to my heart for now. It is a goal that holds profound personal and professional significance for me—something that resonates deeply with my aspirations and values. While I prefer to keep it under wraps for the time being, it is a vision I am passionately working toward, and I hope to see it come to fruition in the near future.

The following members of Materials Australia have been certified by the Certification Panel of Materials Australia as Certified Materials Professionals.

They can now use the post nominal ‘CMatP‘ after their name. These individuals have demonstrated the required level of qualification and experience to obtain this status. They are also required to regularly maintain their professional standing through ongoing education and commitment to the materials community.

We now have nearly 200 Certified Materials Professionals, who are being called upon to lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

Dr Ivan Cole ACT

Dr Syed Islam ACT

Prof Yun Liu ACT

Dr Avik Sarker ACT

Dr Olga Zinovieva ACT

Prof Mohammad Asaduzzaman Chowdhury Bangladesh

Dr Rajib Nandee Bangladesh

Mr Debdutta Mallik EGYPT

Prof. Jamie Quinton NEW ZEALAND

Dr Amir Abdolazizi NSW

Dr Edohamen Awannegbe NSW

Prof Julie Cairney NSW

Prof John Canning NSW

Dr Phillip Carter NSW

A/Prof Igor Chaves NSW

Mr Peter Crick NSW

Mr Seigmund Jacob Dollolasa NSW

Prof Madeleine Du Toit NSW

Dr Ehsan Farabi NSW

Prof Michael Ferry NSW

Dr Yixiang Gan NSW

Mr Michele Gimona NSW

Dr Bernd Gludovatz NSW

Dr Andrew Gregory NSW

Mr Buluc Guner NSW

Dr Ali Hadigheh NSW

Dr David Harrison

NSW

Dr Alan Hellier NSW

Mr Simon Krismer NSW

Prof Jamie Kruzic NSW

Prof Huijun Li NSW

Dr Yanan Li

A/Prof Xiaopeng Li

NSW

NSW

Prof Xiaozhou Liao NSW

Dr Hong Lu NSW

Dr Tim Lucey NSW

Mr Rodney Mackay-Sim NSW

Dr Warren McKenzie NSW

Mr Edgar Mendez

NSW

Dr Ranming Niu NSW

Dr Anna Paradowska NSW

Prof Elena Pereloma NSW

A/Prof Sophie Primig

Dr Gwenaelle Proust

Miss Zhijun Qiu

Dr Blake Regan

Mr Ehsan Rahafrouz

Dr Mark Reid

Prof Simon Ringer

Dr Richard Roest

Dr Bernd Schulz

Dr Luming Shen

Mr Sasanka Sinha

Mr Robert Small

Mr Frank Soto

Mr Michael Stefulj

Mr Carl Strautins

Mr Alan Todhunter

Ms Judy Turnbull

Mr Jeremy Unsworth

Dr Philip Walls

Dr Alan Whittle

Dr Richard Wuhrer

Dr Vladislav Yakubov

Mr Deniz Yalniz

Prof Richard Yang

Mr Andre Van Zyl

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

NSW

Dr Michael Bermingham QLD

Mr Michael Chan QLD

Prof Richard Clegg QLD

Mr Oscar Duyvestyn QLD

Mr John Edgley QLD

Dr Jayantha Epaarachchi QLD

Dr Jeff Gates QLD

Mr Payam Ghafoori QLD

Mr Mo Golbahar QLD

Mr David Haynes QLD

Mr Nikolas Hildebrand QLD

A/Prof Mainul Islam QLD

Dr Janitha Jeewantha QLD

Dr Damon Kent QLD

Mr Jeezreel Malacad QLD

Mr Michael Mansfield QLD

Mr Sadiq Nawaz QLD

Mr Bhavin Panchal QLD

Mr Bob Samuels QLD

Mr Ashley Bell SA

Ms Ingrid Brundin SA

Mr Neville Cornish SA

Prof Colin Hall SA

Mr Brendan Dunstall SA

Mr Mikael Johansson SA

Mr Rahim Kurji SA

Mr Andrew Sales SA

Dr Thomas Schläfer SA

Dr Christiane Schulz SA

Prof Nikki Stanford SA

Prof Youhong Tang SA

Mr Kok Toong Leong SINGAPORE

Prof Klaus-Dieter Liss USA

Dr Muhammad Awais Javed VIC

Mr Michael Bourchier VIC

Dr Christian Brandl VIC

Dr John Cookson VIC

Dr Minh Nhat Dang VIC

Miss Ana Celine Del Rosario VIC

Dr Yvonne Durandet VIC

Dr Mark Easton VIC

Dr Reza Emdad VIC

Dr Peter Ford VIC

Mr Bruce Ham VIC

Dr Shervin Eslami Harandi VIC

Dr Shu Huang VIC

Mr Long Huynh VIC

Dr Jithin Joseph VIC

Mr. Akesh Babu Kakarla VIC

Mr Russell Kennedy VIC

Dr Poom Kettalard VIC

Mr Daniel Lim VIC

Dr Amita Iyer VIC

Mr Robert Le Hunt VIC

Dr Thomas Ludwig VIC

Dr Roger Lumley VIC

Dr Gary Martin VIC

Dr Srikanth Mateti VIC

Dr Siao Ming (Andrew) Ang VIC

Mr Glen Morrissey VIC

Dr Khurram Munir VIC

Prof Jian-Feng Nie VIC

Dr Mostafa Nikzad VIC

Dr Chrysoula Pandelidi VIC

Dr Eustathios Petinakis VIC

Mr Vishnu Vijayan Pillai VIC

Dr Leon Prentice VIC

Prof Muhammad Mehran Qadir VIC

Dr Dong Qiu VIC

Mr John Rea VIC

Miss Reyhaneh Sahraeian VIC

Dr Christine Scala VIC

Mr Khan Sharp VIC

Mr Mark Stephens VIC

Dr Graham Sussex VIC

Mr Pranay Wadyalkar VIC

Dr Wei Xu VIC

Dr Ramdayal Yadav VIC

Dr Matthew Young VIC

Mr Angelo Zaccari VIC

Dr Yuman Zhu VIC

Mr Mohsen Sabbagh Alvani WA

Dr Murugesan Annasamy WA

Mr Graeme Brown WA

Mr John Carroll WA

Mr Sridharan Chandran WA

Mr Conrad Classen WA

Mr Chris Cobain WA

Mr Stuart Folkard WA

Mr Toby Garrod WA

Prof Vladimir Golovanevskiy WA

Mr Mark Hamilton WA

Mr Paul Howard WA

Dr Paul Huggett WA

Mr Ivo Kalcic WA

Mr Srikanth Kambhampati WA

Mr Ehsan Karaji WA

Mr Ka-Seng Leung WA

Mr Mathieu Lancien WA

Dr Evelyn Ng WA

Mr Deny Nugraha WA

Mrs Mary Louise Petrick WA

Mr Johann Petrick WA

Mr Biju Kurian Pottayil WA

Prof Andrew Ruys WA

Dr Mobin Salasi WA

Mr Daniel Swanepoel WA

Dr Kishore Venkatesan WA

Source: Materials Australia

Accreditation as a Certified Materials Professional (CMatP) gives you recognition, not only amongst your peers, but within the materials engineering industry at large. You will be recognised as a materials scientist who maintains professional integrity, keeps up to date with developments in technology, and strives for continued personal development.

The CMatP, like a Certified Practicing Accountant or CPA, is promoted globally as the recognised standard for professionals working in the field of materials science.

There are now well over one hundred CMatPs who lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

Benefits of Becoming a CMatP

• A Certificate of Membership, often presented by the State Chapter, together with a unique Materials Australia badge.

• Access to exclusive CMatP resources and website content.

• The opportunity to attend CMatP only networking meetings.

• Promotion through Materials Australia magazine, website, social media and other public channels.

• A Certified Materials Professional can use the post nominal CMatP.

• Materials Australia will actively promote the CMatP status to the community and employers and internationally, through our partner organisations.

• A CMatP may be requested to represent Materials Australia throughout Australia and overseas, with Government, media and other important activities.

• A CMatP may be offered an opportunity as a mentor for student members.

• Networking directly with other CMatPs who have recognised levels of qualifications and experience.

• The opportunity to assume leadership roles in Special Interest Networks, to assist in the facilitation of new knowledge amongst peers and members.

A Certified Materials Professional is a person to whom Materials Australia has issued a certificate declaring they have attained all required professional standards. They are recognised as demonstrating excellence, and

possessing special knowledge in the practice of materials science and engineering, through their profession or workplace. A CMatP is prepared to share their knowledge and skills in the interest of others, and promote excellence and innovation in all their professional endeavours.

The criteria for recognition as a CMatP are structured around the applicant demonstrating substantial and sustained practice in a field of materials science and engineering. The criteria are measured by qualifications, years of employment and relevant experience, as evidenced by the applicant’s CV or submitted documentation.

Certification will be retained as long as there is evidence of continuing professional development and adherence to the Code of Ethics and Professional behaviour.

Contact Materials Australia today: on +61 3 9326 7266 or imea@materialsaustralia.com.au or visit our website: www.materialsaustralia.com.au

With over 23 years of expertise, Mark Hamilton is a seasoned Project Quality Assurance Engineer/Inspector and Manager specializing in onshore and offshore infrastructure and resource projects. His portfolio includes major LNG ventures such as Gorgon, Wheatstone, and Ichthys, working with global leaders like Rio Tinto, CPB, John Holland, woodside and Chevron, he has also spent significant amounts of time in a variety of Infrastructure and tunnelling projects, including Melbourne metro tunnel, LXRP and the Westgate project. Mark excels in commissioning, completions, and optimizing Quality and Project Management Systems, integrating sustainability and ESG principles. Passionate about innovation and R&D-driven product enhancements which aim to delivering sustainable construction Outcomes for the End user. A strategic thinker with highlevel commercial acumen, Mark is committed to reshaping Australia's construction sector through lean methodologies, critical thought leadership, and cutting-edge technological and material adoption. He has also published works within a variety of construction fields.

Where do you work and describe your job?

Recently I was involved with Rio Tinto’s Sustaining Capital Team, where my

work spanned across the Greater Tom Price, Marandoo, and Western Turner Region. Initially, I joined as a Quality Assurance Engineer, primarily focusing on the QC component of QAQC within project delivery. My career trajectory has been shaped by years of experience as a Welding and Coatings Inspector, as well as roles in consulting and business development.

Over time, my role evolved significantly with a primary focus moving to QA aspect of systems and product. I began integrating sustainable solutions into our processes, focusing on systems innovation and product advancements. Sustainability has become the core pillar of my work, ensuring that projects align with operational excellence principles, particularly through Kaizen methodologies and digital transformation.

Currently, I am spearheading several projects that have the potential to optimize the green energy landscape, not just within Australia but on a global scale. The pursuit of sustainable innovation in engineering is an ongoing journey—one that I am eager to see unfold.

What inspired you to choose a career in materials science and engineering?

In Middle school my focus was to become a Marine Biologist as I loved the Water and Environment and had

the most amazing teacher Jim Blakslee (Shoutout Jim). I pursued many different options post schooling including the armed forces, although eventually decided on a career in Engineering and welding. I Have always been drawn towards materials makeup and the quality systems and processes that are required to deliver a product that is both versatile and design compliant, without compromising the pragmatic needs of the end user.

Who or what has influenced you most professionally

My philosophy for the past 20 + years of my career has been if you are the smartest person in the room, you are potentially in the wrong room. Something which I still actively pursue. this has aided my knowledge and skillset immensely. It’s so vitally important to have a mentor or coach. I started my career in the agriculture sector and slowly progressed, welding initially then Material inspection and testing. In many ways I have been extremely fortunate to of worked with the skills of yesteryear and have been able to bring portions of that knowledge into the current digital age.

I remember the first engineering draftsman I worked with—he drafted designs by hand. It was for an engineering company of about 120 people. His name was Brian White from Danum Engineering. We worked on

various defence contracts, including those with the former Tenix Defence, and served as the principal contractor for Shell for several years. It was a fantastic place to work. The opportunity to learn from experts whose skillsets have all but gone from construction (excluding Special class welding). Is something I will always remember. These were the craftsmen of a bygone era—blacksmiths, machinists, fitters, welders, and those who built steam engines by hand—masters of their trade whose knowledge and craftsmanship had to be seen.

I’ve had the privilege of working with outstanding managers and engineering teams across a range of disciplines, from infrastructure, oil and gas, and mining to academia. More recently, I’ve been involved in exploring alternative materials for waterway management and estuary habitats—an initiative that is shaping Australia’s coastal and waterway management plan.

The coatings industry is also seeing incredible advancements, with EonCoat emerging as a game-changer. Its unique self-healing Vivianite layer, combined with a ceramic shield, makes it the sustainable choice for cost efficiency and environmental safety. I’m also currently working with some outstanding Sustainability led development projects. It’s too early to discuss in Granular detail although once they evolve, will be great to share amongst the community.

I was especially fortunate to have a Quality Manager on the West Gate Tunnel project who expanded my knowledge in ways I never imagined, introducing me to new perspectives and management approaches.

May he rest in peace.

I’ve been incredibly fortunate to work with the people I have and becoming a part of the Materials Australia community seems a fantastic way to contribute the knowledge and attitudes they shared with me.

Which has been the most challenging job/ project you’ve worked on to date and why?

That’s a great question. It’s difficult to single out just one project as the most challenging, as each comes with its own complexities and opportunities. The Melbourne infrastructure

Above: Post Metrology spooling for Woodside GWF 2. King bay Karratha

Below: Stick built Ship loader for Utah Point common user facility 2009 Australian marine complex fabrication and erection the commissioned at Utah Point in Port Hedland.

projects—including the Metro Tunnel, LXRP, and West Gate Tunnel—stand out as some of the most demanding I’ve worked on. These large-scale initiatives involved multiple vested interests, competing priorities, making navigation particularly challenging. At the same time, they offered unparalleled opportunities. That project had some advanced civil additives and accelerants which Fred Andrewsphaedonos was instrumental in developing many decades ago. Helping teams understand welding processes and material requirements also allowed us to share knowledge of the craft in meaningful ways.

Beyond infrastructure, I found my time with Civmec and BAE Systems equally demanding. Working with Clough on offshore hookup and commissioning projects for Chevron and Inpex was another major challenge. Being handed a set of process and instrumentation drawings for an offshore platform and asked, ‘Tell us what’s missing,’ was an intense but rewarding experience.

More recently, I’ve observed a growing trend toward over-engineering, which I find concerning. While precision and safety are crucial, this approach is driving construction costs to unsustainable levels. Thoughtful design is essential—there’s no one-size-fitsall solution. Our building industry is a prime example of this issue, further compounded by rising material costs.

What does being a CMatP mean to you?

It’s an honour, love this community!! We are on the cusp of amazing technological developments from coatings and steelmaking to 3D printing and development environmentally friendlier products and circular economies of scale! The development and manufacturing of them locally is a big focus of mine. There is some outstanding development occurring right here in Perth, alongside our mind-boggling talent. Support from Academia Australia wide including UWA, ECU, Curtin, AOU, UON and Melbourne University and no doubt many more is helping develop the materials space at a rapid rate.

Also, internally from all the major organisations. Neo Smelt is a great example of this. As are the scholarships from the Curtain corrosion centre.

What is the best piece of advice you have ever received?

My job has been very intense at many stages throughout my career, be open to what the universe has in store for you. Once you have climbed one mountain, you are at the bottom of the next. Overall trust your intuition and do what makes you happy.

What are you optimistic about?

That we will provide and deliver on generational leadership, unlocking downstream resource value to create wealth and ownership for our communities. By adopting community ownership models and leveraging generational wealth, we can drive research and develop cuttingedge manufacturing facilities. This progress will rely on support from local and international partners. As we embrace the digital age, I believe our advancements will accelerate rapidly. A company I’m involved with has developed systems and processes to facilitate and guide this type of work. Lets see.

What have been your greatest professional and personal achievements?

Having the conviction to pursue what I love. I have been involved in many world firsts regarding construction achievements from Oil and Gas heavy

lifts to deepest deployment on ocean floors, the largest tunnelling systems in the southern hemisphere and some unique additive manufacturing approaches.

Being able to tie my initial career options into the sustainable construction and Environmental approaches provides a great sense of achievement. Without doubt the support I have received from my family and amazing support network, none of

this would have occurred. Experience is life’s greatest teacher.

What are the top three things on your “bucket list”?

1. To see a Hydro power project In Westen Australia’s Pilbara, encompassing a true circular economy approach. Supporting the business that are already there. And developing some new ones to support our future. I believe we need to place far greater emphasis on materials and R & D across all facets of our community Including agriculture.

2. Material sustainability and assurance processes should remain a key consideration in investment decisions shaping our economic future. This extends to job creation and manufacturing for Australian prosperity. With advancements in robotics and automation set to transform sustainability, there is a valuable opportunity to explore and embrace.

3. To be remembered as a good father to my children, amazing husband and to be driver for Sustainable construction processes and Materials manufacturing.

The new H2Secure concept from NETZSCH is an innovative solution for safely and precisely characterising materials in hydrogen-rich environments. Traditional thermal analysis systems are not fail-safe when using flammable gases like hydrogen above the LFL (low flammability limit). As hydrogen becomes central to sustainable energy and industrial processes, understanding how materials behave when exposed is vital.

H2Secure ensures utmost safety without compromising measurement precision. It's designed to facilitate complex oxidation-reduction cycles within a single measurement, providing deep insights into material behaviour. For example, in the direct reduction of iron ore (a key step in decarbonizing steel production), H2Secure facilitates safe experiments in up to 100% hydrogen. As shown in the thermogravimetric analysis (TGA) plot in Figure 1, increasing the concentration of hydrogen significantly reduces the reduction time compared with lower H2 concentrations. In the context of the blast furnace process, this finding underscores the potential advantages of utilising higher hydrogen concentrations to enhance the reduction efficiency of iron oxides. Traditional blast furnace operations primarily rely on carbon-based reductants, which lead to significant CO₂ emissions. By integrating hydrogen, especially at higher concentrations, the reduction process can be accelerated, potentially lowering energy

consumption and reducing carbon emissions.

Safety is paramount with H2Secure, featuring precise hydrogen regulation, continuous monitoring of H2 and O2 concentrations, and automatic inert gas purging. The central H2Secure box processes safety information and controls gas flows, with fail-safe mechanisms including automatic inert gas purging in case of power failure or vacuum leak. NETZSCH’s commitment to safety is underscored by H2Secure’s TÜV certification.

H2Secure is now available for the STA 509 Jupiter ®, STA 449 Jupiter ® and TMA 512 Hyperion® series. For more information, please visit http://netzs.ch/h2secure

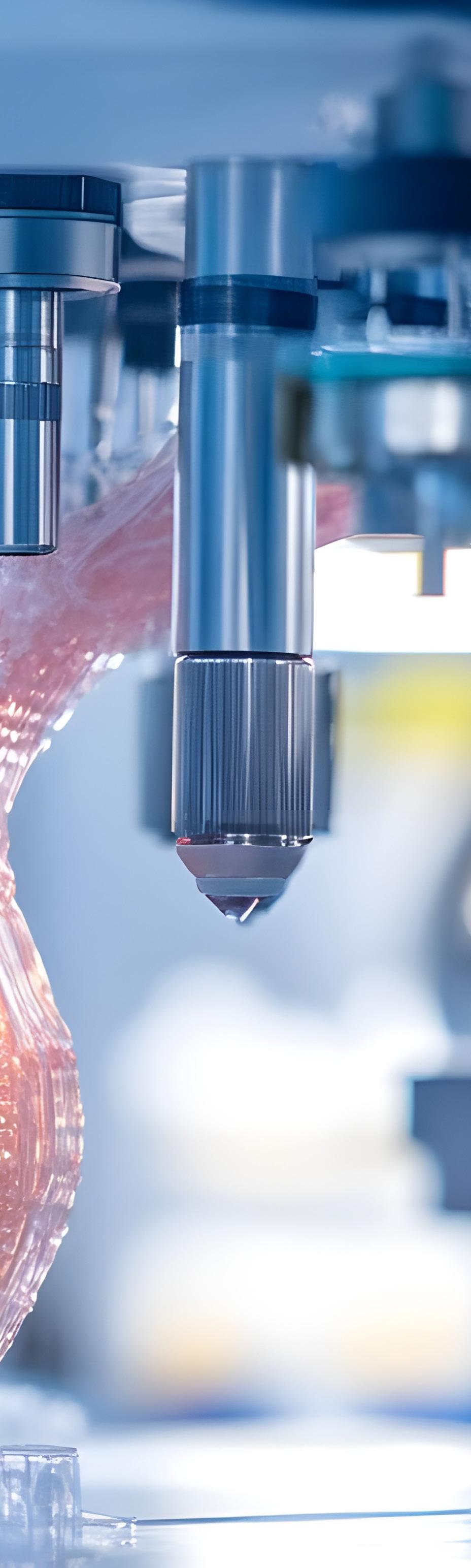

It's no secret that food and garden waste make great compost, but now researchers at Deakin University, Barwon Water and RMIT are working together to explore how it can be used for agriculture and battery production.

The project will transform biosolids from wastewater treatment and household wastes into a biochar product for commercial use.

With many of Australia’s landfills nearing capacity, and organic waste being the second biggest contributor, there’s lots of ways that we can ‘waste not, want not’.

A recent study by Deakin University’s Faculty of Science, Engineering, Building and Environment (SEBE) is demonstrating benefits to soil health that could live on for hundreds of years and help to reduce greenhouse gases.

“This Recycling and Clean Energy Commercialisation Hub (REACH) trailblazing project will build on Deakin’s international research exploring what the optimal formulations for biochar are for the Geelong region’s soil conditions to produce high-value cereal and legume crops,” said Deputy Dean, Deakin’s Faculty of SEBE, Professor Lambert Brau.

The REACH research project is an important step in Barwon Water’s plans to develop Regional Renewable Organics Network facilities at its Black Rock (Connewarre) and Colac Water Reclamation Plants to produce biochar, a carbon-rich charcoal-like material made from controlled heating of organic matter.

“The many superpowers of biochar can be demonstrated by monitoring increased nutrients and moisture available to boost plant growth and also the microorganisms that live in the soil surrounding plant roots,” said Professor of Environmental Engineering, Wendy Timms.

Using a combination of lab, greenhouse and farm trials at Deakin University’s Waurn Ponds Campus, different biochar formulations will be developed to support soil fertility and crop yields. Detailed assessments of the costs, benefits and potential impacts of its use in agriculture will also be explored.

“We’re accelerating our research to unlock high-value commercial applications for biochar, at our Black Rock water reclamation plant in Connewarre,” Barwon Water Managing Director Shaun Cumming said.

“Through our Regional Renewable Organics Network project, we’re supporting building a circular economy in the Geelong region, revolutionising waste management to turn organic waste into sustainable products like biochar, which enrich soils and capture carbon, benefiting local farmers and households,” he said.

The root of biochar’s superpowers doesn’t just end in the soil. Barwon Water’s REACH project will also explore how biochar could be introduced as a new sustainable source for Australia’s battery supply chain through Deakin’s

(L to R): Deakin Associate Professor Nolene Byrne, Professor Wendy Timms, Research Fellow Aydin Enez and Barwon Water Managing Director Shaun Cumming.

Institute for Frontier Materials.

“We’re exploring if biochar can be used as the anode active material within sodium-ion batteries,” Associate Professor Nolene Byrne said.

“If we are successful, sodium-ion batteries could become a safer, cheaper alternative for the lithium-ion batteries we use to store solar energy in our grid storage and home batteries,” she said.

“Biochar is looking promising as a next generation battery material, and through this project we’ll continue to explore what biochar composition will enhance battery performance.”

Barwon Water’s Regional Renewable Organics Network project aims to process approximately 60,000 tonnes of biosolids from Barwon Water’s Water Reclamation Plants, 40,000 tonnes of organic food and garden waste, 14,000 tonnes of municipal green waste and commercial and industrial organic waste annually.

Professor Kalpit Shah from RMIT University, said: “We are delighted to be working with Barwon Water and Deakin to transform biosolid waste into biochar suitable for use in the energy and agriculture sectors and contribute to the development of Australia’s circular economy.”

Barwon Water Managing Director Shaun Cumming said it is exciting to have leading thinkers from the water industry, Deakin and RMIT working together to explore how waste can be used to make our communities more sustainable.

“We’re delighted that through this collaboration we’ll be leading the charge to establish Victoria as a hub for the development of sustainable technologies, underscoring the vital role that the water sector can play in recycling resources for the circular and new energy economy.”

Backed by a $50 million grant from the Australian Government’s Trailblazer Universities Program, with industry and university support, REACH is facilitating the development of greener supply chains and the move to a circular economy.

FACE Consulting is a specialist asset integrity and materials engineering consultancy, purpose-built to address the emerging needs of assetintensive industries. Headquartered in Queensland, FACE works closely with clients to solve complex problems, enhance understanding, and eliminate risk, with a focus on flexibility, efficiency, and timely results.

FACE Consulting is a specialist in asset integrity and materials engineering consultancy, built to meet the evolving needs of assetintensive industries. Headquartered

We also provide Residual Life Assessments for critical components such as boiler tubes and high-energy piping, using techniques like Field Metallographic Replication (FMR) to assess material degradation onsite. The result? Better maintenance planning, reduced downtime, and longer equipment life.

Our Reverse Engineering services deliver deep insights into performance, materials, and design intent, while our Expert Witness services offer clear, impartial, evidence-based opinions that can help resolve disputes before costly

Source: ATA Scientific

Powder flowability is a critical parameter in a wide range of industries, including pharmaceutics, food, mining and additive manufacturing. Yet, predicting powder flowability remains a challenge as it is not governed by a single property but a result of multiple interacting factors, including particle size and shape, density, moisture content, electrostatics, and surface chemistry [1].

From consistent dosing of APIs in pharmaceutical tablets to even spreading of powders in 3D printing, predictable powder flow is crucial. Poor flowability causes processing inefficiencies, blockages, segregation or poor compaction. Flow behaviour heavily influences production scalability: processes optimised for small-scale R&D may only seamlessly transition to large-scale manufacturing by addressing flow variability. Traditionally, industries rely on measuring static bulk properties such as angle of repose and Hausner ratio, which is insufficient to predict flow under dynamic conditions. In addition, these manual measurements are dependent on operator handling and present challenges particularly with cohesive powders due to factors such as irregular surfaces and sample presentation inconsistencies. [2].

In contrast, the FT4 powder rheometer directly measures powder flowability in accordance with ASTM standard D7891. With the ability to also measure powder compressibility, permeability and density of powders, the FT4 enables you to accurately predict how a powder will behave in real processing environments. Most importantly, the measured results can be fed to the accompanying hopper designer software to accurately predict optimal hopper profile and dimensions, thus rending the FT4 a complete tool for troubleshooting powder flow issues.

Case Study: Sticky Gypsum powder

To help demystify the complexity of factors that influence the flowability of powders, ATA Scientific together with their partners MalvernPanalytical recently held a series of workshops across Australia, bringing together researchers, engineers, and quality managers to explore how cutting-edge instrumentation can be used to characterise and control powder flow. Participants had the opportunity to perform measurements first-hand on Morphologi 4, Mastersizer 3000+, and FT4.

One of the attendees tested three gypsum samples with the hope of understanding observed differences in flow behaviour between different batches of product. Measurements on the Mastersizer 3000+ Ultra showed minimal differences between the particle size distribution of the three samples.

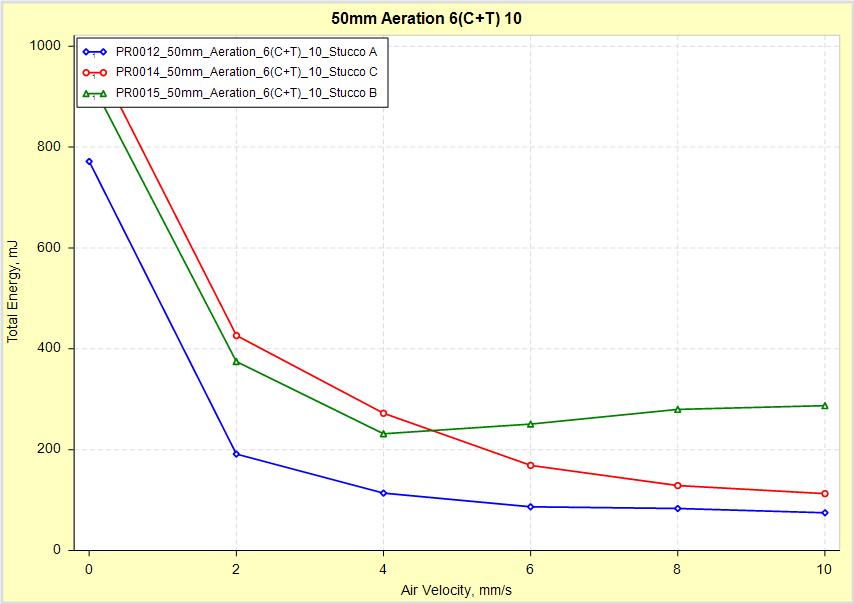

Stucco sample A (blue) was a reference sample with known behaviour. Stucco samples B and C were processed in a different mill under varying conditions and were observed to have different flow properties. Despite similar PSD’s Sample B (green) was observed to adhere to the hopper post-processing. Stucco sample C (red) had less problems with adhering to processing equipment, but still displayed different behaviour to the reference sample (A)

The powders were then tested on the Morphologi 4 to obtain quantitative data in terms of 15 different morphological parameters.

2: Malvern Morphologi 4 adds a vital layer of understanding through automated, high-resolution image analysis of particle shape and size. Stucco A sample imaged.

Comparison of the various morphological aspects like particle circularity, elongation, and roughness showed no significant differences between the three powders (below). However it was noted that Stucco C was closer to Stucco A than Stucco B based on size and shape parameters.

The true differences in flow behaviour between the three samples were revealed after measurements were performed on the FT4 powder rheometer.

Figure 3: Morphological parameters on the left measured are very similar for the 3 stucco samples. Software identified the width as the most differentiating factor but the frequency plot overlay on the right shows little difference.

Results from shear stress test in Figure 4 showed that Stucco A exhibited significantly less shear stress to yield in response to increasing compressive stress. This indicates samples B and C have a higher internal friction (ie. are more cohesive) than sample A under load.

Results from Compressibility testing in Figure 5 show that samples B and C have higher compressibility, meaning that Sample A has a higher bulk density. This is also reflected in results from Permeability testing in Figure 6. Sample A has a higher pressure drop (lower permeability) when passing air through the powder bed with increasing normal loads than B and C.

Aeration test data in Figure 7 shows that sample A is easier to fluidise and transport pneumatically. Sample B will be the most difficult to fluidise and transport pneumatically and Sample C is in the middle.

Conclusion: A Toolkit for Optimising Powder behaviour

Flowability cannot be understood in isolation. By combining particle size (Mastersizer 3000+), shape and morphology (Morphologi 4), and functional performance testing (FT4 Powder Rheometer), researchers and manufacturers can diagnose problems and predict outcomes.

As materials become more complex and processing demands increase, tools that provide deep, reliable insights into powder behaviour will be essential. ATA Scientific’s commitment to providing access to the most advanced analytical technologies and ongoing support offers a valuable platform for knowledge exchange, training, and collaborative problem-solving.

These technologies are available for demonstrationLimited time only - To book contact ATA Scientific or visit www.atascientific.com.au.

ATA Scientific Pty Ltd

Ph: +61 2 9541 3500

enquiries@atascientific.com.au www.atascientific.com.au

Reference:

1. Malvern Panalytical. Correlating powder flow properties to improve process understanding. [online] Available at: https:// www.malvernpanalytical.com/en/learn/knowledge-center/articles/ ar120601correlatingpowderflowproperties [Accessed 17 Jul. 2025].

2. Malvern Panalytical. FT4 Powder Rheometer – Freeman Technology. [online] Available at: https://www.malvernpanalytical.com/en/products/ product-range/freeman-ft4 [Accessed 18 Jul. 2025].

Easy, fast powder flow and rheology characterisation with automated analysis to ensure precise powder performance, consistency and quality in 3D -printed components. FT4 is a universal powder flow tester offering four categories of methodologies: Bulk, Dynamic Flow, Shear (in accordance with ASTM D7981) and Process.

Easy, fast powder flow and rheology characterisation with automated analysis to ensure precise powder performance, consistency and quality in 3D -printed components. FT4 is a universal powder flow tester offering four categories of methodologies: Bulk, Dynamic Flow, Shear (in accordance with ASTM D7981) and Process.

Fully automated imaging system measures particle size, particle shape and chemical identity, all in one platform. Size and sphericity of powders and contaminant identification with Raman Spectroscopy.

Fully automated imaging system measures particle size, particle shape and chemical identity, all in one platform. Size and sphericity of powders and contaminant identification with Raman Spectroscopy.

Fully automated imaging system measures particle size, particle shape and chemical identity, all in one platform. Size and sphericity of powders and contaminant identification with Raman Spectroscopy.

Particle Size and Particle Size Distribution Analysis

Market-leading particle size analyser (10nm to 3.5mm) for wet and dry samples. Built-in expertise (SOP Architect/Size Sure) informs critical decision making throughout R&D and manufacturing processes.

Market-leading particle size analyser (10nm to 3.5mm) for wet and dry samples. Built-in expertise (SOP Architect/Size Sure) informs critical decision making throughout R&D and manufacturing processes.

Market-leading particle size analyser (10nm to 3.5mm) for wet and dry samples. Built-in expertise (SOP Architect/Size Sure) informs critical decision making throughout R&D and manufacturing processes.

High Resolution Imaging & Elemental Mapping

Desktop Scanning Electron Microscope (SEM) with fast, easy -to-use interface. Ideal for large samples up to 100mm x 100mm. Live element identification using integrated X-Ray (EDS) detector.

Desktop Scanning Electron Microscope (SEM) with fast, easy -to-use interface. Ideal for large samples up to 100mm x 100mm. Live element identification using integrated X-Ray (EDS) detector.

Desktop Scanning Electron Microscope (SEM) with fast, easy -to-use interface. Ideal for large samples up to 100mm x 100mm. Live element identification using integrated X-Ray (EDS) detector.

To enter, simply visit our website https://www.atascientific.com.au/awards-events-training/current-award/

To enter, simply visit our website https://www.atascientific.com.au/awards-events-training/current-award/

To enter, simply visit our website https://www.atascientific.com.au/awards-events-training/current-award/

Source: Sally Wood

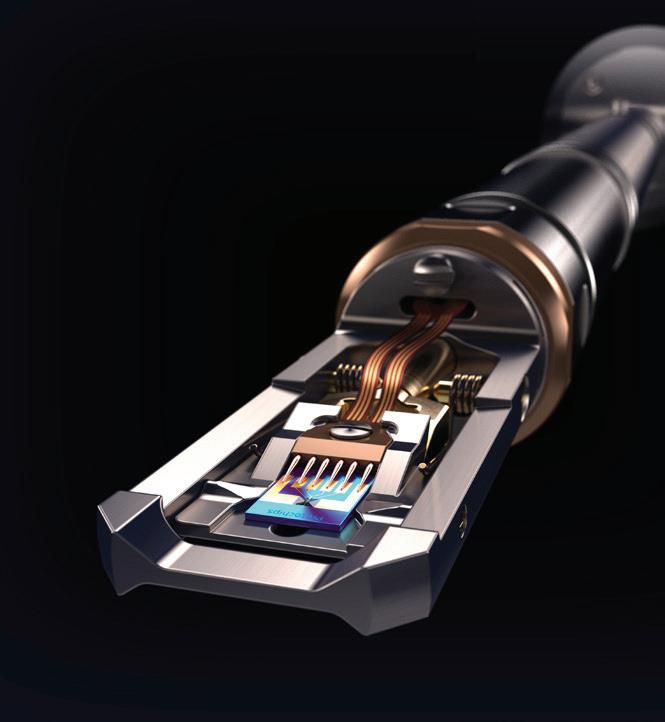

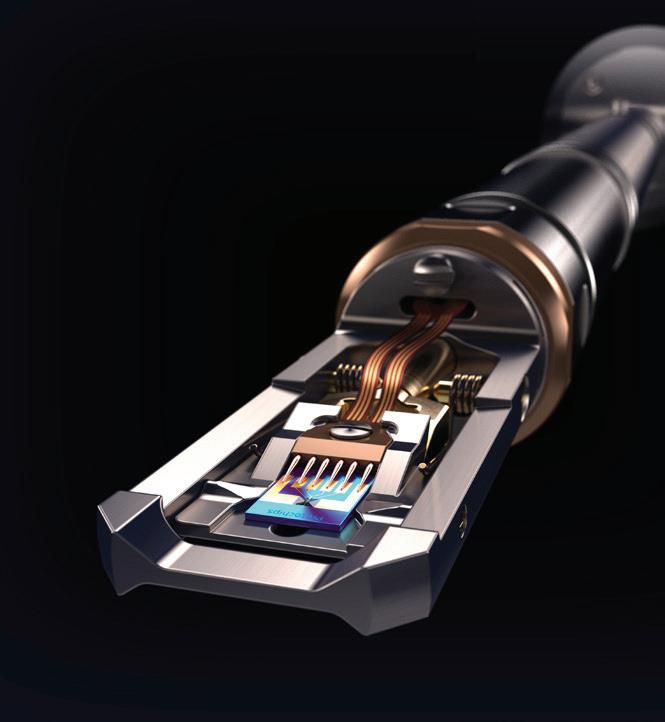

Quantum computing engineers have brought the world a step closer to building practical, largescale quantum computers.

UNSW Sydney quantum engineers, in collaboration with University of Sydney scientists, have developed new technology that effectively reduces the size of the circuits required to run a silicon-based quantum computer.

The move paves the way for more quantum information to be packed into a smaller footprint.

The work is part of a partnership between two startups – UNSW spinout Diraq, and University of Sydney startup Emergence Quantum. The milestone is a crucial step towards integrating Diraq’s silicon ‘quantum dot’ technology with the mature processes of the semiconductor industry to achieve utility-scale quantum computers that can tackle problems with true societal and commercial value.

Quantum bits (or ‘qubits’) must be held at cryogenic temperatures, very close to absolute zero (–273.15 °C), to preserve their information. But they also need to be controlled and measured by complex electronics built from circuits found in laptops and smart phones known as complementary metal-oxide semiconductor (CMOS).

Unlike qubits, these circuits are usually designed to work at room temperature, not at cryogenic temperatures. And if they are placed close to the qubits, they can heat them, degrading their performance. The control system can be separated from the qubits by long cables, but the millions of qubits required for practical quantum computing render this solution impossible.

Emergence Quantum has solved this challenge by designing ‘cryoCMOS’ technology that functions at millikelvin temperatures, and together, Diraq and Emergence

have now shown that this cryoCMOS control circuitry does not compromise the performance of Diraq’s qubits.

UNSW Engineering Professor Andrew Dzurak, also Diraq’s founder and CEO, said the advance offers Diraq a means of precise control without degrading qubit quality.

“It’s a key piece of the quantumcomputing puzzle, and one that will accelerate our progress towards a machine that can solve the kinds of problems that are unthinkable with today’s computers,” he said.

The research began as an academic endeavour between the University of Sydney and UNSW Sydney, in collaboration with Diraq. Publication of the paper in Nature comes shortly after the formation of Emergence Quantum, a new venture founded by Professor David Reilly and Dr Thomas Ohki at the University of Sydney, formerly part of Microsoft.

The partnership between Diraq and Emergence Quantum has been cemented by Diraq’s recruitment of Dr Samuel Bartee, Reilly’s former student.

“It’s extremely exciting to be part of this work, to be involved in the development of such powerful technologies, and to sit in this hotspot of quantum computing research — Sydney really is a remarkable place for a quantum engineer to be at the moment,” Dr Bartee said.

Diraq’s qubit technology is the ideal testbed for Emergence Quantum’s cryo-CMOS system. Last year, Diraq published a paper in Nature showing that its qubits can operate with high fidelity at 1 degree above absolute zero. This deviation from zero might seem small, but it has a remarkable impact on the possibilities for control, because it relaxes the tight heating constraints imposed on other qubit materials.

With these ‘hot qubits’ in hand, and Emergence Quantum’s cryo-CMOS control solution to minimize additional heating, Diraq is positioning itself to scale up to the millions of qubits required for practical quantum computing.

Prof. Reilly said the Emergence Quantum team wanted to catalyse the scaling of quantum technologies.

“Our team has long realized the need to more tightly integrate qubits with control systems, and now with Emergence Quantum, we are positioned to deliver real hardware solutions to researchers and companies across the quantum landscape,” he said.

The fact that Diraq’s technology is inherently compatible with the CMOS industry makes it easier to integrate innovations like Emergence Quantum’s circuitry. It also minimizes the investment required to realise quantum computing’s extraordinary potential by leveraging the decades of research and trillions of dollars already spent on CMOS R&D.

The ultimate goal is a computer like no other — one capable of accelerating progress in crucial areas such as drug discovery to enhance global health, and the design of innovative materials that can combat climate change.

Source: Sally Wood

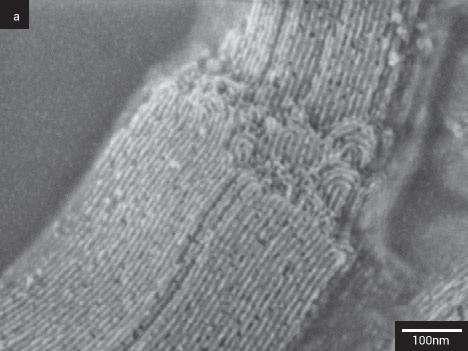

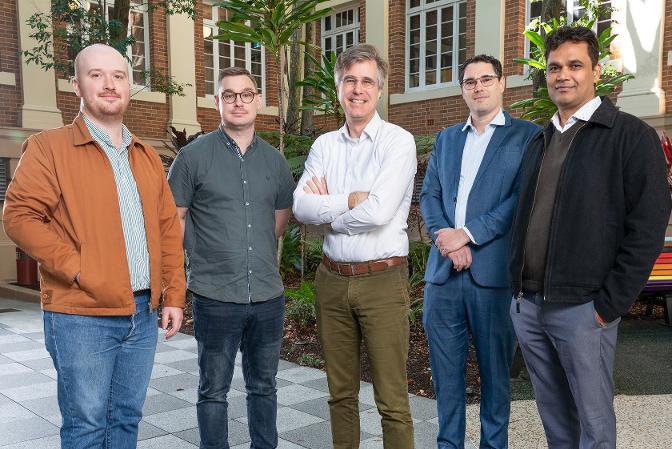

Researchers from RMIT University and CSIRO, Australia’s national science agency, have unveiled a method to significantly extend the lifetime of quantum batteries – 1,000 times longer than previous demonstrations.

A quantum battery is a theoretical concept that emerged from research in quantum science and technology. Unlike traditional batteries, which rely on chemical reactions, quantum batteries use quantum superposition and interactions between electrons and light to achieve faster charging times and potentially enhanced storage capacity.

In a new study, researchers have successfully tested a new way to extend the life of a quantum battery.

Study co-author and RMIT PhD candidate Daniel Tibben said they were inching closer to a working quantum battery.

“While we’ve addressed a tiny ingredient of the overall piece, our device is already much better at storing energy than its predecessor,” he said.

Developing quantum batteries in the lab remains challenging.

Previous devices demonstrated impressive charging speeds but struggled with rapid discharge rates, losing stored energy almost as quickly as they charged.

For this study published in PRX Energy, the team built and studied five devices, which worked best when two specific energy levels aligned perfectly, allowing energy to be stored more efficiently.

The best performing device was able to store energy for 1,000 times longer than the previous demonstration, improving the energy storage from nanoseconds to microseconds.

The team says while this might not sound like a long time, the breakthrough proves the concept

and builds a strong foundation for future research.

Study co-author and RMIT chemical physicist Professor Daniel Gómez said their study marks a significant advancement for quantum batteries and paves the way for improved designs.

“While a working quantum battery could still be some time away, this experimental study has allowed us to design the next iteration of devices,” Gómez said.

“It’s hoped one day quantum batteries could be used to improve the efficiency of solar cells and power small electronic devices.”

CSIRO’s Science Leader Dr James Quach, who led the previous experiment, also co-authored this paper.

“Australia is leading the way in experimental quantum battery research and this work is a significant advancement,” Quach said.

Gomez and his team at RMIT have engaged industry partners to

collaborate on designing the next iteration of prototypes.

The team conducted the research in RMIT’s world-class Micro Nano Research Facility, a hub uniting diverse, high quality micro and nano technology research across multiple disciplines.

Funding was provided by the Australian Research Council, the European Union and an RMIT University Vice-Chancellor’s Senior Research Fellowship.

By Dr. Cameron Chai and Dr. Kamran Khajehpour

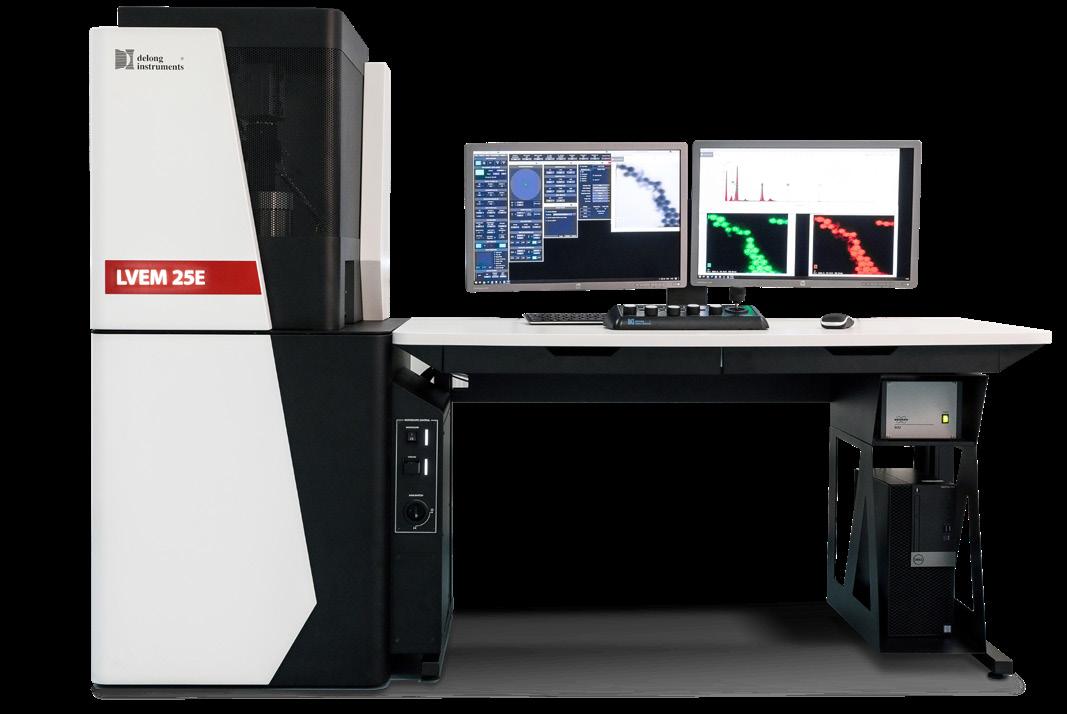

TESCAN have recently launched the MIRA XR, their latest ultrahigh-resolution SEM-EDS solution designed for fast, precise materials analysis across industry and research. The MIRA XR bridges the gap between conventional FEG SEMs and UHR systems.

Key features of the new MIRA XR include:

• BrightBeam™ source for subnanometer imaging at low keV

• Dual Essence™ EDS for up to 50% faster elemental analysis

• Wide Field Optics™ for 40% faster navigation

• In-Flight™ Automation for simplified operation at all user levels

• MultiVac™ mode for beam-sensitive samples

This combination of features ensures you can generate ultra-highresolution SEM data at least 30%

faster than conventional systems. This includes real-time elemental mapping with no shadowing artifacts thanks to the Dual Essence EDS system.