Introduction to Materials Science for Engineers 8th Edition

ShackelfordDomestic Instructors Solutions Manual

Section 7.4 - Thermal Shock

PP 7.4

In Example 7 4 the stress in an Al03 tube is calculated as a result of constrained heating to 1000C. To what temper• ature could the furnace tube be heated to be stressed to an acceptable (but not necessarily desirable) compressive stress of 2100 MPa? [er 7. I =Ee =E·AT or d7a or aooF • E "(s7ovenXz.raver·e·)

=%45c

• 7•(64s+as'= G70¢

PP 7.5 In Example 7.5, a temperature drop of 400°C was catastrophic for the alumina furnace tube If the design were changed to substitute a partially stabilized zirconia tube, would the 400°C temperature drop cause a fracture? [Pr7s

7.13

7.13. Whatwould be thestressdeveloped inamullite fur• nacctubeconstrained inthewayillustratedinFigure 7 6 ifit were heated to 1000 C?

7adl 7.2 - =5.3xv¢7»»»/6a)

7.6le G-five E=50-220 /P 9i; «rye e sh.:

Ole'=Ee =E7 = (R )Gs\r'·c')(too -2s'c

=25gMP%a(cad-sautve)

O,~ =(2ox»n)Gs.so°%")(tooo-25)'c

h =l,/4oP (o-posse ) O=

(passive)

7.14

Domestic Instructors Solutions Manual

7 14 Repeat Problem 7 13 for magnesia (Mgo).

T4le 77 e= 13.5-+./·c

7 le 6.+9- E= 20nm (%asked ya

O Ee= Ee7= (2oh)(r3.soc'koe-st

= 27%0MP (-vsstve)

7.15. Repeat Problem 7 13 forsilica glass

7 15

7.Ale 72 =0.507»»/..

7a.kle %. E=736P

O= Ee=ET

e)

=(73e.)6.5xto·er'oo-29)c

=35 %MP(p @ ssvve

7.16. A textbook on the mechanics of materials gives the following expression for the stress due to thermal expansion mismatch in a coating of (thickness a) on a substrate (of thickness b) at a temperature T:

•-5.a.-n.-·[-(;)-·(;']

where E and v are the elastic modulus and Pois• son's ratio of the coating. respectively; T is the temperature at which the coating is applied (and the coating stress is initially zero); and a, and a, are the thermal expansion coefficients ofthe coating and the substrate, respectively Calculate the room• temperature (25C) stress in a thin soda-lime--silica glaze applied at 1000C on a porcelain ceramic. (Take E = 65 x 10° MPa and v = 0 24 and see Table 7.2 for relevant thermal expansion data.) is

•

Note: The + )jdfe ksle ste (6au# 4 hyyhu, Av.d<pe-so cehj #.j cm.Ad pm co') ' y sokshfe).

e5]«-o-[r-»(+']

»"le e {>o

5 (-7).-.

-4s.pk4a,

Domestic Instructors Solutions Manual

•7.17. Repeat Problem 7.16 for aspecial high-silica glaze with anaverage thermalexpansioncoefficientof 3x 10c'.(Take E = 72 x 10' MPa and v = 0.24.)

l!J7.18. (a) A processing engineer suggests that a fused Si0, crucible be used for a water quench from 500C. Would you endorse this plan? Explain (b) Another processing engineer suggests that a sintered silicon carbide crucible be used for the water quench from 500°C. Would you endorse this plan? Again, explain

Domestic Instructors Solutions Manual

l!J7 19 In general, thermal shock is enhanced for materi• als with high values of fracture strength (MOR in Table 6.4) and thermal conductivity (k in Table 7.4) and low values of elastic modulus (E in Table 6.4) and thermal expansion (a in Table 7 2) This leads to a "figure of merit" for predicting relative thermal shock resistance (TSR):

TSR = (MOR x k)/(E x a)

Using data from the aforementioned tables (includ• ing, for comparison, the 100°C data fork), calculate the value of TSR for silica glass and fireclay refrac• tory, the highest and lowest data in Table 75, and comment on whether this figure of merit is consis• tent with the physical data

7.19 7SR = (nae «4) (Ea) F Sil.las

7sR _ (o4Mn.)(a.gs5.k) (730P2)(o.5to%%»/..·) hdy

7SR (s.2MP)(4/57/s».) (7%3)(s.sx to»/·)

=0.0407/0? /•

l!J7.20. Using the figure of merit in Problem 7.19, predict whether soda-lime-silica glass would have better or worse TSR than silica glass. 186

7.20 For so0.- lose -s/l7la

75& (son)L75ls..)

(6t3)(7.0,07%»/.e)

= 0.42 x%? 7/s

721 As pointedout inthe feature box in ths chapter, the thermal protection system for NASA's Space Shut• tle Orbiter iseffective duetoits exceptional thermal• insulation properties. Calculate the heat flow (per square meter) across a 50-mm-thick ceramic tile with anouter surface temperature of 700C and an inner surface temperature of 30C, given a thermal conductivity of0.0837 J/(s m -K).

a er

£--4A11 2 7e: )

l5 z )(i.)(wc-so))

=--(a08s75l)(5oKo?

= -412 703 7 . =-1.24W (k st,d .wets dfasshlo I'c = 1)

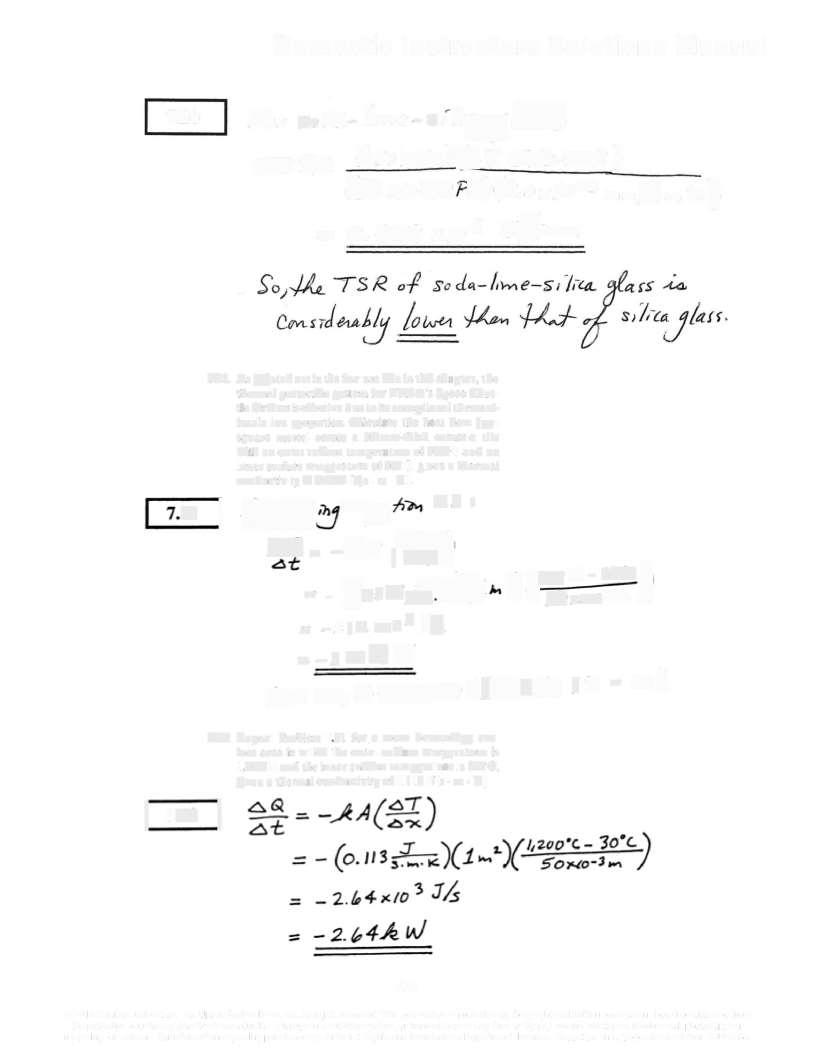

7.22. Repeat Problem 7.21 for a moredemanding sur• face area in which the outer surface temperature is 1,200Cand the inner surface temperature is 30C, given a thermal conductivity of 0.113 J/(s m K).

7 23

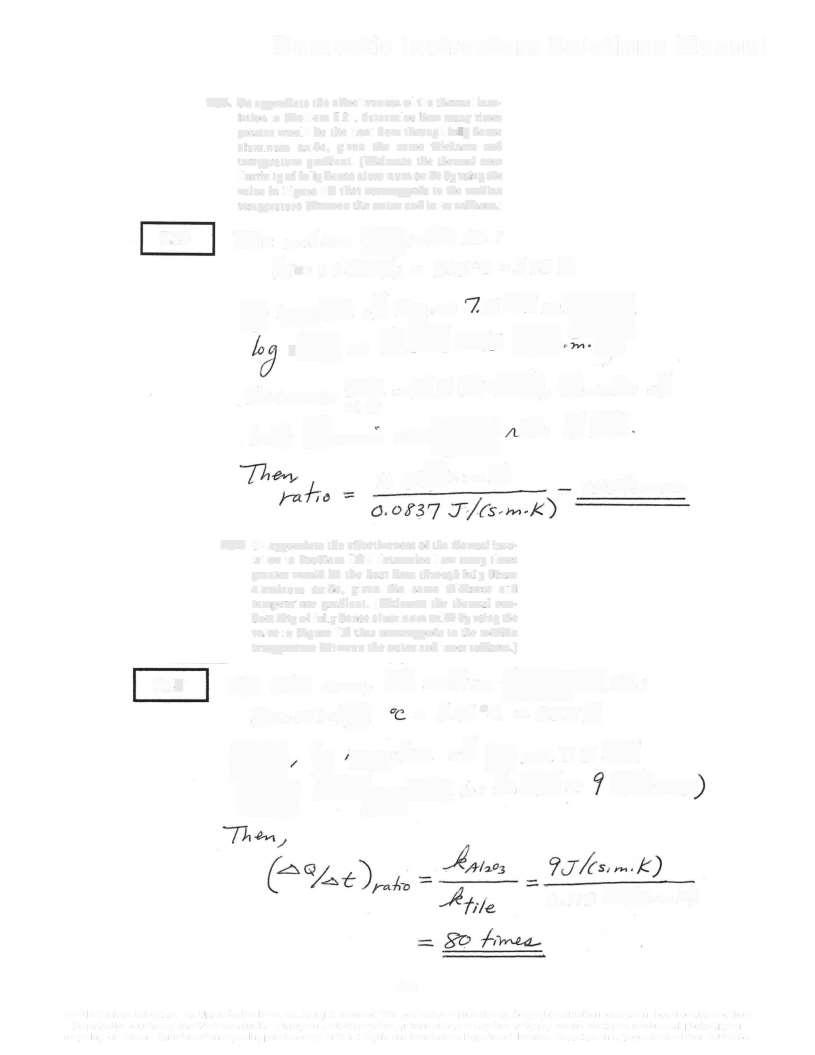

7 23 To appreciate the effectiveness of thethermal insu• lation in Problem 7 21, determine how many times greater would be the heat flow through fully dense aluminum oxide, given the same thickness and temperature gradient (Estimate the thermal con• ductivityof fullydense aluminum oxide by usingthe value in Figure 7.5 that corresponds to the median temperature between the outer and inner surfaces)

The )edra 4epoch»e i {

(7oo +3)/2 = 365°€=638kK 8»rh

7.24. To appreciate the effectiveness of the thermal insu• lation in Problem 7 22, determine how many times greater would be the heat flow through fully dense aluminum oxide, given the same thickness and temperature gradient. (Estimate the thermal con• ductivity of fully dense aluminum oxide by usingthe value in Figure 7.5 that corresponds to the median temperature between the outer and inner surfaces.)

7.24 T 4a cse, Ke eda lepechwei:

(2s+30)/a = 615°C =&&8K