LIA TODAY

and

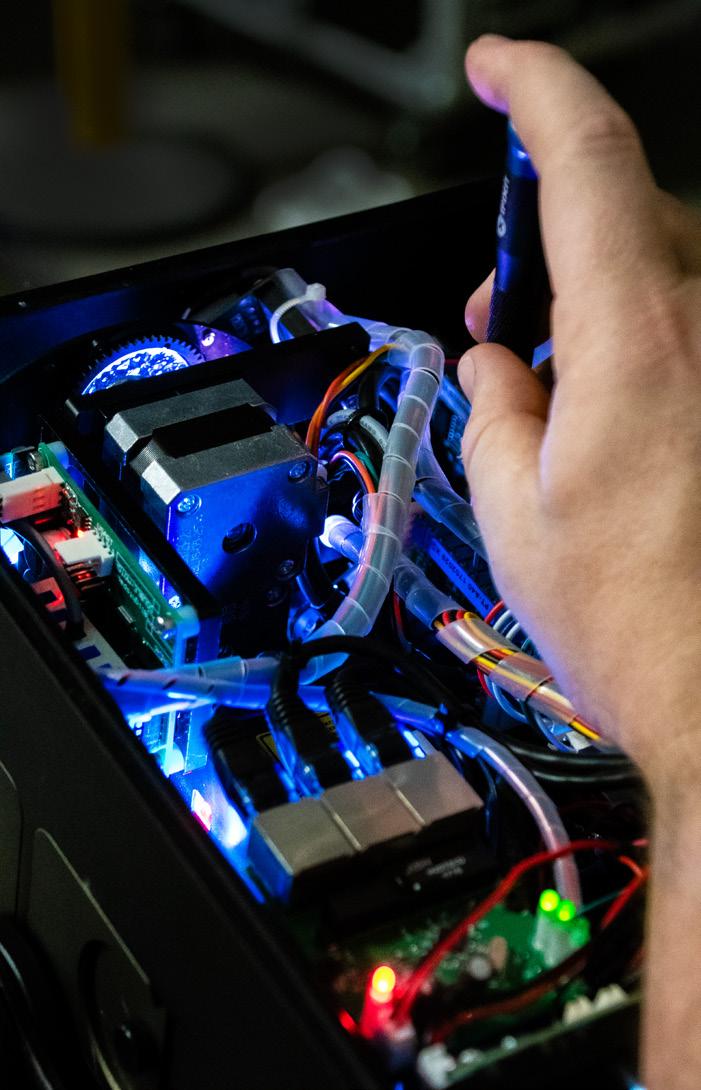

From sand-filled units to surprise electrical failures, the team tackles it all with precision.

The applications of lasers in materials processing and manufacturing are steadily increasing with newer high precision and high efficiency laser systems to improve production processes. Automation with integration of artificial intelligence (AI), machine learning and computer vision are the key factors in the surge of laser technology. Agile manufacturability with lasers are also drawing the manufacturers’ interest in customized solutions for catering to the unique design of parts in different industries. Rapid processing speed for cost-effective production, ability to process a variety of materials, and high precision in fabricating complicated designs are driving newer applications and indicating new directions for laser industries.

In addition to materials processing and manufacturing applications, other industries, including defense, telecommunications and healthcare, are increasingly implementing laser systems. Hybrid laser systems with multiple process capabilities, such as welding, cutting, drilling and additive manufacturing, by the same laser enhance the versatility and flexibility to produce a variety of products. Lasers play pivotal roles in microelectronics industries such as packaging, and manufacturing semiconductors, particularly, wafer inspection and lithography. Lasers offer precise operational methods for surgical procedures in the healthcare industries including cosmetic treatments, enabling minimally invasive surgery with improved medical results. Also the defense industries are constantly looking for laser systems to improve the precision and performance of their surveillance systems and other equipment. The ever growing demand on transferring large volumes of data faster in the telecommunications field requires innovations in the applications of fiber-optic lasers.

We’re making strong strides this year, and I’m encouraged by the increased engagement across the laser community. From recent industry events to upcoming milestones, LIA continues to advance our mission—and your involvement makes it possible.

Earlier this month, we celebrated the International Day of Light, commemorating Dr. Theodore Maiman’s groundbreaking first laser operation in 1960. As one of LIA’s 14 founding members, Maiman exemplifies the innovative spirit we strive to uphold. This celebration underscores our ongoing commitment to fostering innovation, safety, and excellence in laser applications worldwide.

Looking ahead, LIA will exhibit at Laser World of Photonics in Munich. If you’re attending, please stop by our booth—I look forward to discussing our latest efforts, including new partnerships and educational resources aimed at enhancing industry knowledge and expanding our global presence.

Additionally, I’m excited to announce that registration is now open for the 44th annual ICALEO, taking place in Orlando, Florida, from October 13–16, 2025. This year’s event promises outstanding technical content, impactful networking, and collaborative discussions that reflect our strategic emphasis on outreach, innovation, and education. I encourage you to register early and join us in shaping the future of our industry.

I also invite you to help recognize excellence in our community by submitting nominations for our annual LIA Awards, Board of Trustees, and LIA Fellows. Your nominations ensure we highlight and celebrate those driving progress and safety in our field.

If you’re seeking new ways to get involved, consider joining as an LIA member, volunteering on committees, or participating in our standards-development efforts. Your contributions directly strengthen our ability to lead effectively, improve operations, and deliver valuable services to our members.

Finally, it’s been rewarding connecting with many of you recently at UCF CREOL Affiliates Day, SPIE DCS, and RAPID + TCT. These conversations reinforce LIA’s essential role as a hub for collaboration and innovation across academia, industry, and government. Together, we’re building a stronger, more impactful community.

JUne

AUgUst

september

medicAL LAser sAfety officer

Virtual (Zoom) - June 21-22

cALcULAting LAser system hAzArds

Virtual (Zoom) - August 4-8

indUstriAL LAser sAfety officer

Novi, MI - August 13-14

medicAL LAser sAfety officer

New York City, NY - September 6-7

LAser sAfety officer

Niagara Falls, NY- September 29-October 1

LAser sAfety officer with hAzArd AnALysis

Niagara Falls, NY- September 29-October 3

LAser sAfety officer

november

december

Orlando, FL- November 3-5

LAser sAfety officer with hAzArd AnALysis

Orlando, FL- November 3-7

medicAL LAser sAfety officer

Virtual (Zoom) - November 8-9

indUstriAL LAser sAfety officer

Santa Clara, CA - November 19-20

cALcULAting LAser systems hAzArds

Virtual (Zoom) - December 15-19

Recently purchased a new laser?

Request an in-house training to ensure your staff knows how to run the system safely and correctly.

LiA coUrse highLight: indUstriAL LAser sAfety officer

AUGUST 13-14, 2025 NOVI, MICHIGAN

Designed to keep you on the leading edge of safety training requirements and program administration, this course teaches a non-mathematical approach to facilitating the duties of a Laser Safety Officer.

Our Industrial LSO course was designed for all levels of experience involved in industrial, and manufacturing applications of lasers. This course meets all LSO training requirements outlined by the Z136.9 Safe Use of Lasers in Manufacturing Environments standard and OSHA.

This course is worth 16 CECs by AAHP and 2.0 BLS CM points by the Board of Laser Safety.

Johns Hopkins University - Homewood, Laconia School District, SENAI-SC, University of Kansas EHS Dept

To find out more about becoming a corporate member, email membership@lia.org or visit lia.org/membership/corporate

Already an LIA member? Ask about joining our Facebook group!

1. Photonics West - Jan 27-29, 2025 (San Francisco, CA, USA)

2. ILSC - March 3-6, 2025 (Orlando, FL, USA)

3. ILAS - March 26-27, 2025 (Kenilworth, UK)

4. AORN - Apr 5-8, 2025 (Boston, MA, USA)

5. RAPID + TCT - April 8-10, 2025 (Detroit, MI, USA)

6. SPIE DCS - Apr 13-17, 2025 (Orlando, FL, USA)

7. ASLMS - Apr 24-25, 2025 (Orlando, FL, USA)

8. CLEO - May 4-9, 2025 (Long Beach, CA, USA)

9. LAMP - June 10-13, 2025 (Ise-city, Mie-prefecture, Japan)

10. Laser World of Photonics - June 23-27, 2025 (Munich, Germany) - LIM - June 23-26, 2025 (Munich, Germany)

11. ASSP - July 22-24, 2025 (Orlando, FL, USA)

12. FABTECH - Sept 8-11, 2025 (Chicago, IL, USA)

13. ICALEO - Oct 13-16, 2025 (Orlando, FL, USA)

14. OR Managers - Oct 28-30, 2025 (Las Vegas, NV, USA) Cooperating Conferences

October 13-16, 2025 - Orlando, Florida

The 44th annual International Congress on Applications of Lasers and Electro-Optics (ICALEO) will be returning to Orlando, Florida! We are excited to host you at the beautiful Caribe Royale on October 13-16, 2025.

Conference Registration: Standard Registration runs through August 13, 2025. Be sure to register early before pricing increases!

Advance Program: Get a sneak peek of what you can find at this year’s event in the digital Advance Program. Hear a welcome message from our General Chair Stefan Kaierle, get an overview of the agenda, learn about the conference highlights, and more!

Company Opportunities: There are still opportunities to highlight your company at the event with sponsorships and exhibit space! Taking place on Tuesday, October 14th after the day’s sessions, the Exhibitor Reception is your opportunity to capture the full attention of attendees and forge lasting connections that can drive your business forward. Contact marketing@lia.org or visit icaleo.org for more information.

Hotel Group Rate: Stay at the conference hotel for a discounted rate! Uncovering a Floridian escape where the sun is warm and the welcomes are even warmer at the Caribe Royale Orlando. Attendees receive free breakfast, wifi, networking, and more!

Subscribe to our mailing list at icaleo.org/subscribe for the latest updates.

Make the most of conferences and professional events with networking tips from laser industry experts Eliana Fu (TRUMPF) and Neil Ball (Directed Light). In this webinar, the chairs of ILC 2024 share their insights into making professional connections in real life as you grow your career. Whether you are a new professional or simply seeking advice on growing your career in the laser industry, this 30-minute webinar is for you.

Don’t miss future webinars by subscribing at lia.org/webinars

Topics covered include, but are not limited to: High Power Laser, Fiber Laser, Ultrafast Optics, and Terahertz Tunable Function Devices.

Guest Editors: Hanbin Wang, Xinyang Su, and Shuai Li

« Deadline: 10/31/2025

Topics covered include, but are not limited to: Ultrashort laser-material interaction, Femtosecond laser crystallization, Selective crystallization, Laser enhanced crystallization or Laser induced crystallization, Multilayer thin films, Electrical properties, Two temperature model, Flexible electronics, Wearable electronics, and Metrologies & material characterization.

Guest Editor: Ayesha Sharif

« Deadline: 12/31/2025

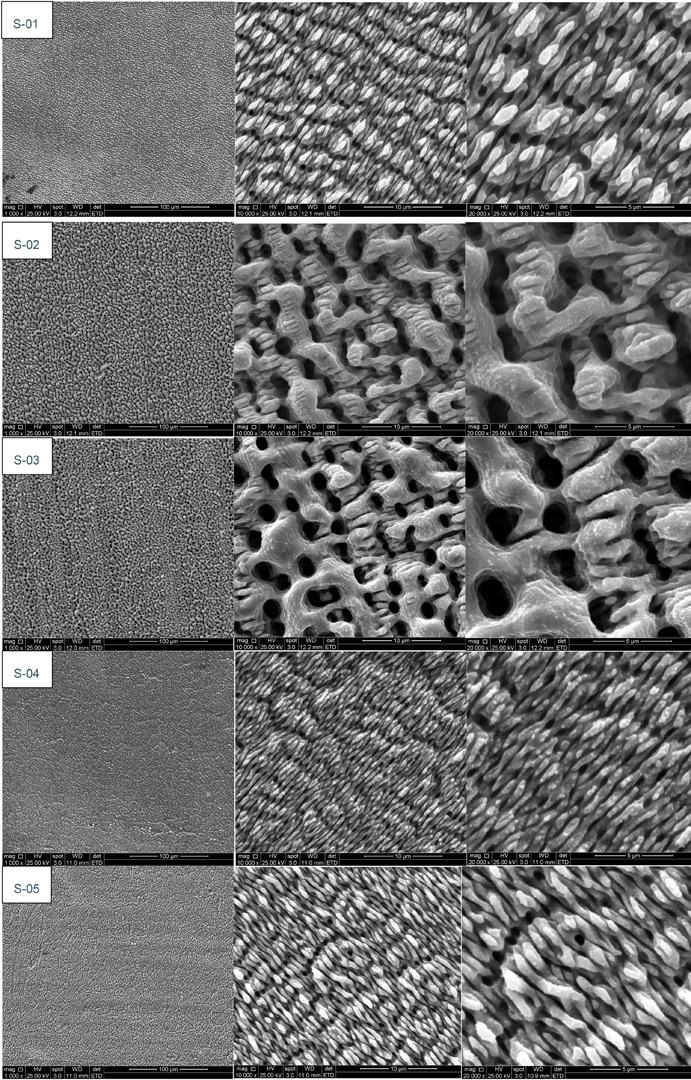

Image: SEM images for the five types of etched coupons, where the bar on the first, second, and third columns of images are 100, 10, and 5 μm, respectively.

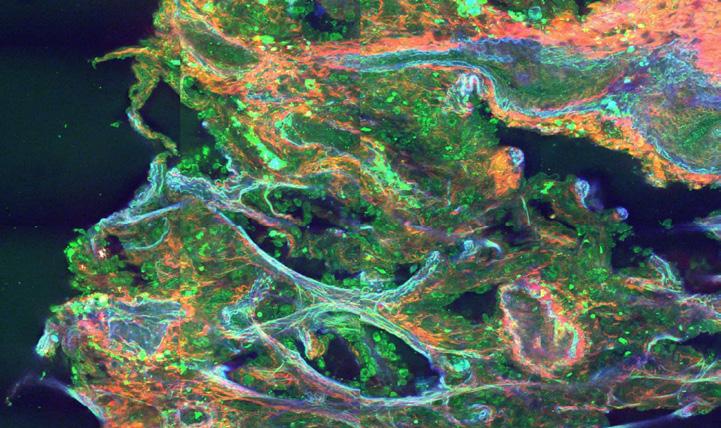

Aswathi Soni; Amanda Gardner; Gale Brightwell; Lan Le-Ngoc; Sebastiampillai Raymond

This study evaluated the potential of using laser-textured metal surfaces (etched coupons) designed and manufactured using an ultrafast laser to prevent bacterial attachment. The etched and unetched surfaces were compared for bacterial attachment against Escherichia coli AGR5151 and Brochothrix thermosphacta NZRM 3320 at high (~8 Log colony-forming unit (CFU)/coupon) and low (~5 Log CFU/coupon) inoculum levels. For B. thermosphacta, one out of the five etched surfaces showed significantly (p < 0.05) lower attachment by 0.2–1.3 Log CFU/coupon using the high inoculum, whereas four out of five etched surfaces exhibited significantly (p < 0.05) reduced attachment compared to the control with the lower inoculum. Similarly, for E. coli, three surfaces demonstrated significantly (p < 0.05) lower attachment by 0.7–1.2 Log CFU/coupon with the high inoculum and four surfaces showed lower attachment by 0.1–1.4 Log CFU/coupon compared to the control with the lower inoculum. Only one type of etched surface/coupon was common in its ability to reduce attachment for both the bacteria tested. It can be concluded that the bacterial strain being targeted can be one of the major factors that determine the efficacy of these surfaces to inhibit attachment. The findings also suggest a potential link between effectiveness and surface characteristics like roughness and wettability.

J. Laser Appl. 37, 012042 (2025) - https://doi.org/10.2351/7.0001535

Access to the JLA is free to LIA Members! Visit JLA Online: pubs.aip.org/lia/jla

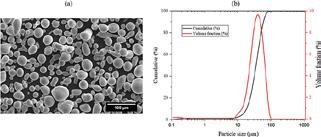

Laser powder bed fusion of a nanocrystalline Finemet Fe-based alloy for soft magnetic applications

S. Sadanand, M. Rodríguez-Sánchez, A. Ghavimi, R. Busch, et al.

J. Laser Appl. 36, 042029 (2024) - https://doi.org/10.2351/7.0001391

Development of embedded graphitic-sandwich structures in single-crystal synthetic diamond via ultrafast laser micromachining

Brian K. Canfield, Alexander Terekhov, Trevor M. Moeller, Lino Costa, et al.

J. Laser Appl. 36, 042074 (2024) - https://doi.org/10.2351/7.0001548

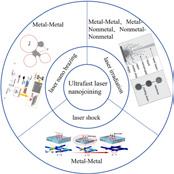

Research status and applications of different nanomaterials system based on ultrafast laser nanojoining technology

Wei Chen, Yi Ma, Libin Lu, Yingchun Guan

J. Laser Appl. 37, 021201 (2025) - https://doi.org/10.2351/7.0001733

SIMULTANEOUS TWO- AND THREE-PHOTON IMAGING ENABLES RAPID CANCER DIAGNOSIS

A Netherlands-based start-up is developing a compact, portable, multiphoton microscope that creates pathology-quality images in real time, without the need for sample fixation or staining.

Read more

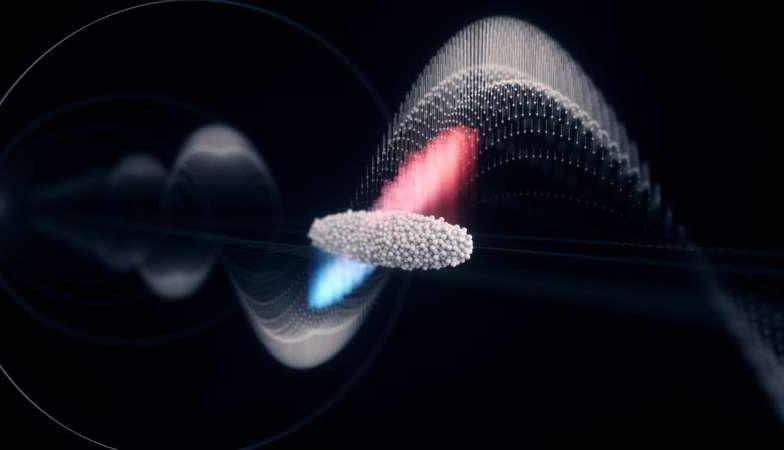

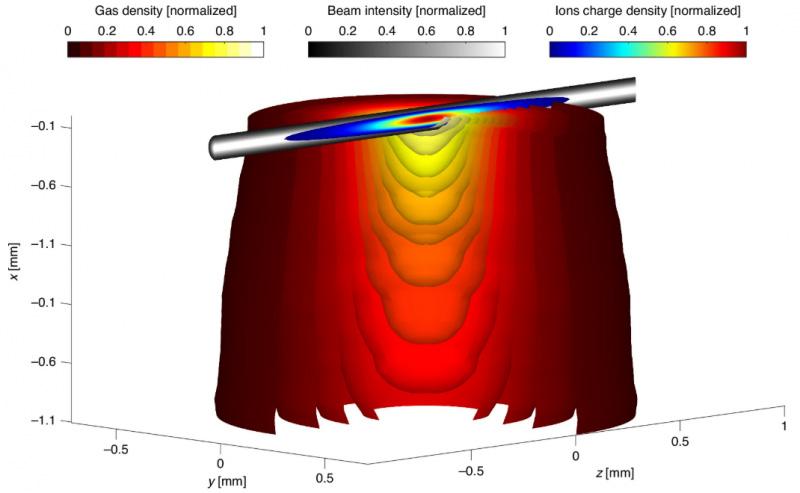

LASER PLASMA ACCELERATOR ACHIEVES ENHANCED ELECTRON BEAM QUALITY FOR PRACTICAL APPLICATIONS

Using a clever correction system, a research team was able to significantly improve the quality of electron bunches accelerated by a laser plasma accelerator, bringing the technology a step closer to concrete applications.

Read more

PHYSICISTS ACHIEVE BREAKTHROUGH IN MEASURING ULTRAFAST LASER PULSES

A research team from Ben-Gurion University of the Negev has successfully measured and characterized extremely powerful laser pulses lasting just a few femtoseconds - an achievement that overcomes a decades-old challenge in strong-field physics and attosecond science.

Read more

“LASERS JUST GOT UNSTOPPABLE”: QUANTUM TRICK TURNS CHAOTIC LIGHT INTO ULTRA-STABLE BEAMS THAT BREAK THE RULES OF MODERN PHYSICS

In a revolutionary breakthrough, scientists have developed a method to transform noisy lasers into stable beams, defying traditional physics and opening new avenues for high-precision photonics technologies.

Read more

Follow @LaserInstitute on social media for industry news.

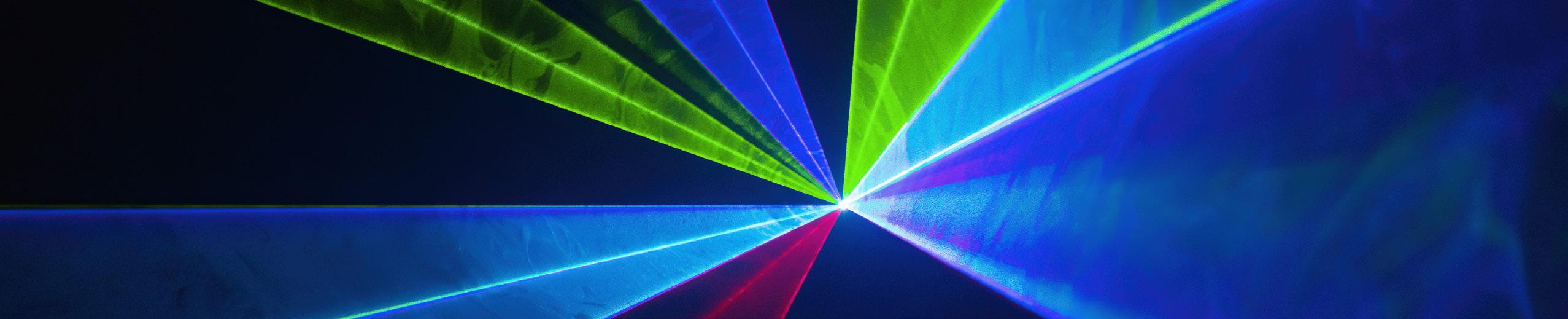

Behind every flawless laser show is a methodical reset process. At ER Productions, the de-prep and quarantine teams in Las Vegas inspect, clean, test, and repair lasers between tours to ensure peak performance and safety. From sandfilled units to surprise electrical failures, the team tackles it all with precision. Their standardized procedures and sharp diagnostic skills are what keep the show running long after the final beam fades and before the next show can amaze.

An aspect of a big laser show that people might forget about is the part that happens after the show has already gone on. In order for the next big show to happen, the lasers first need to be de-prepped and made perfect to go out on the road again.

“What we do is take in the gear, we check to make sure everything is returned that went out and then we check for damages, testing everything and then get it brand new and ready to go out for the next tour,” says Becky Prough, the De-prep Manager in Las Vegas for ER Productions.

“The first step is the appearance of the unit. Does it look damaged? Does it look like it needs anything

other than testing and cleaning?” Becky’s team assumes nothing when each piece of equipment comes back, and each laser is unpacked, cleaned, tested, and realigned. Even if at first glance it seems like nothing is wrong.

ER’s de-prep manual allows even returning tour technicians to step in and follow standardized procedures. Firmware updates go through a dedicated vetting chain before rollout. Training is structured around group sessions followed by hands-on learning under supervision. And internal communication flows freely between departments. “The complexity of the lasers doesn’t matter for de-prep either,” Becky says. “They’re all the same. Whether you have a laser with one diode of each color or a laser with 60 diodes of each color, the process is the same.”

Even minor damage can develop into performance issues on stage, so Becky and her team follow every step. Even when turnarounds are tight, like receiving a laser and sending it back out on the same day, Becky says that safety trumps all. “Does everything exist on the unit that needs to be there to make it safe? That’s our main priority. We won’t compromise on that.”

What happens if ER’s de-prep does find something broken? It heads straight to quarantine. “Just like quarantine for humans. When something gets broken, it comes here to be fixed. And my job in quarantine is the doctor that helps

them get out,” says Lexi Martin, ER Productions Las Vegas Quarantine Technician.

Lexi’s role is equal parts repair specialist, detective, and analyst. She keeps a mental list of common failures and digs into the root causes. Her most-used tool? “A digital multimeter,” she says firmly. “It’s the easiest tool to use and is great for finding when there’s a bad component on a board, for finding if a wire going from point A to point B is actually connected. Tells me everything I need to know.”

ER’s quarantine isn’t just about fixing what’s reported. Around 10% of the time, Lexi uncovers additional faults that weren’t caught on tour. Issues that could have jeopardized the next show if left unchecked.

“One time a Kinekt came back and when it went through deprep it sounded like a maraca,” she laughs, recalling a laser with a blown Peltier that looked “like someone stabbed it with a screwdriver.” Despite the extensive

“When both ER’s de-prep and quarantine departments work seamlessly together, the result is a tight, reliable system that gives every laser its best shot at flawless performance. With each repair, alignment, and inspection, they’re not just maintaining hardware. They’re guaranteeing that the next show that happens won’t have any issues from the start.”

damage, she salvaged the parts and got the unit back in rotation. “That’s the part I love. Solving complex problems no one else could figure out.”

Though Lexi never quite figured out how that unit was damaged, especially with show reports saying that it was working perfectly, she figures it had something to do with transport. Because the most common culprit is everything happening around the unit, not the actual use of the unit itself.

Tours that pass through coastal venues, snowy states, or countries with rough infrastructure tend to send back lasers coated in grime or shaken out of alignment. “The fans do tend to pull in sand,” says Lexi. “The good thing is, for the most part, the cooling part of the unit and the compartments that hold the core electronics are separate.”

Becky agrees, noting that beach gigs, Latin American tour legs, and northern states tend to stress the gear more than average. “Has

nothing to do with the people or the venues whatsoever. It’s more the nature of the show and nature itself. Do you have enough time to load in? Is every hand capable? Where did this laser go and come from? If your laser’s been bouncing in a truck across Montana’s potholes, we’re going to find something off when it comes back.”

When both ER’s de-prep and quarantine departments work seamlessly together, the result is a tight, reliable system that gives every laser its best shot at flawless performance. With each repair, alignment, and inspection, they’re not just maintaining hardware. They’re guaranteeing that the next show that happens won’t have any issues from the start.

Becky’s leadership and Lexi’s technical precision are instrumental to this process, reflecting the kind of dedication that keeps ER’s reputation at the forefront of live laser production. “The feeling of finding the problem and fixing it and turning it on and it works perfectly is one of the best feelings in the world. The feeling of accomplishment,” Lexi says. For the audience at a sold-out stadium, the laser show is a spectacle. But for our team behind the scenes, it’s the magic of being able to rehabilitate the machine behind it all that’s truly entrancing.

ER Productions is an international, award-winning laser and special effects specialist with an extensive portfolio spanning high-profile events, advertising campaigns, television productions, and world tours. With offices in Dartford, Lancaster, Las Vegas, Ibiza, Sydney, and Riyadh, ER Productions continues to lead the industry in innovation, safety, and cutting-edge visual experiences.

The Laser Institute’s John McCormack reflects on the history and impact of the International Day of Light, celebrated on May 16th.

2025 marks the sixty-fifth anniversary of Dr. Theodore Maiman successfully operating the first working laser. On May 16th, 1960, Dr. Maiman’s ruby laser emitted mankind’s first coherent light and ushered in a new era of science and physics. This day was declared The International Day of Light by UNESCO in 2017 and was first celebrated the following year. It is celebrated annually to commemorate Dr. Maiman’s first successful firing of his laser and its transformative impact of lightbased technologies on our lives and the world around us.

International Day of Light is administered annually from the International Basic Science Programme of UNESCO and an overview provided on their lightday.org states, “The International Day of Light is a global initiative that provides an annual focal point for the continued appreciation of light and the role it plays in science, culture and art, education, and sustainable development, and in fields as diverse as medicine, communications, and energy. The broad theme of light will allow many different sectors of society worldwide to participate in activities that demonstrates how science, technology, art and culture can help achieve the goals

of UNESCO – education, equality, and peace.”

In 1968, Dr. Maiman and other laser pioneers founded the Laser Industry Association, which would become the Laser Institute of

America (LIA) in 1972, and he would go on to serve as one of LIA’s first board of directors. Dr. Maiman’s life and legacy lives on in the present-day mission of the LIA and its mission to “foster lasers, laser applications, and

laser safety worldwide.” LIA is committed to using collaborative efforts in order to create a better future for the laser industry by promoting the use of lasers and laser safety through education, publications, conferences, and workshops. Through our various programming, we consistently identify solutions to professional challenges by facilitating a collaborative environment for industry partners and experts. At LIA, we leverage our organization’s global network to deliver highly accessible and impactful solutions to our members around the world. We believe in the importance of sharing new ideas about lasers and laser technology. As we look at this year’s International Day of Light theme “Light, Innovation, Society” we are reminded that as the use of light continues to push the limits of the human mind, we must continue to collaborate and find solutions that connect us all through the innovation of light.

The use of light reaches so much farther than we can imagine and touches our daily lives in ways that we’ve never thought to appreciate. Photonics (the science and technology of light) is wide-reaching in our daily lives and reaches across industries that we have grown to rely on such as telecommunications,

May 16 th on

“Light touches every aspect of UNESCO’s mandate. From accelerating the free flow of science, technology and information to promoting cultural diversity and heritage protection, all our efforts serve a single goal: to unite the common goods of education, science and culture, to create a brighter future.”

– Ms. Audrey Azoulay, Director-General of UNESCO on the occasion of the International Day of Light, 16 May 2025.

medical technology, manufacturing, electronics, vision, AI, quantum computing, and so much more. Even our cell phones are powered using photonics and lasers, for example: the use of infrared lasers can assist in 3D sensing, Facial ID can use a VCSEL laser, and laser cutting is used in cell phone manufacturing – and this is barely scratching the surface of how we use light and light-based technology in our everyday lives. On lightday.org, there is a page dedicated to how the science and technology of light can help create a better and more sustainable

future with a list of 17 Light and Sustainable Development Goals that showcase how the use of light can transform our today into a better tomorrow.

The celebration of International Day of Light is just a start. We come together every year on May 16th to share stories of recent innovations, of light and how it affects our daily lives, of the future technologies we are working on and hoping to have a breakthrough. The use of light not

only can change the lives of those we hold dear, but it can shape a better future. If we use light as a source to come together and join hands, the future is limitless. This year we celebrate the intersection of light and quantum science, and as stated on unesco. com, “Light is one of the most basic and important parts of the universe. It’s also where the journey into quantum science, the branch of science that studies how the tiniest particles in the universe behave, begins. From the glow of heated objects to the puzzling behavior of tiny particles of light, light has helped us discover how the quantum world works.” The future is bright with the use of light and light-based sciences. Here’s to a year of “Light, Innovation, Society!” For more information about International Day of Light, please visit www.lightday.org.

As part of a quarterly op-ed, Geoff Shannon of Laser Markets, Inc investigates and shares his insights of current market trends and the state of the laser industry. This feature looks into where we can look for growth ahead.

As the global economy navigates strategic uncertainty, we endeavor to figure out where to put the chips on the growth roulette table. Before looking ahead, let’s take a quick lighthearted look back at the notable growth highlights over approximately the last 20 years. We start things off with the dotcom boom and bust that put the V in volatility - one day you were discussing volume lasers or systems for photonic devices manufacturing the next week the entire department disappeared, true story. The solar boom fueled by massive government grants created arguably the largest number of uncompetitive companies ever, however, a big tip of the hat to First Solar as last man standing. The iPhone expansion years, when a certain fruit company asked you to sign NDAs that held you personally liable, as in your house! Then gave you the privilege to provide free R&D with the carrot of hundreds of units, that very rarely materialized. But every design cycle we would jump through the same hoops again!

Additive Manufacturing found the road very rocky as the industry tried to pivot from prototype to production, and it became a feeding frenzy for too many system builders where only laser OEMs and scan head suppliers made any profit. The struggle continues.

More recently, EV’s - an industry driven by government regulations rather than customer demand, may save the day via hybrids and energy storage. Which brings us to the current AI & semiconductor

markets which are on a bit of a roller coaster.

So, looking ahead, where would I place some chips?

Healthcare, comprising Life Sciences and Medical Device Manufacturing (MDM), is driven by a growing aging global population willing to pay for longer and better lives – a winning formula for growth. Focusing on MDM, which may not be the biggest market with a global total addressable market (TAM) around $300M but delivers 5%+ CAGR since the dawn of time, is only going to get better and bigger.

Laser welding is finally gaining momentum after being in the shadow of laser cutting for so many years. Crucially, unlike laser cutting, laser welding is seen by customers as a valueadd process therefore garnering higher margins. The seemingly continuous drop of fiber lasers $/W particularly in the 1-5kW power level is fueling growth and penetration into other welding technology markets. The predicted massive global short fall in skilled welders over the next few years coupled with cost-effective motion and robotic equipment will continue the ramp.

And of course, last but certainly not least the Ultra Short Pulse (USP) laser. No surprise that laser OEMs in this space are investing. And what’s not to like - out of this world processing capability that is now becoming seriously compelling, again as the $/W falls. And not just for the 1kW hero products for parallel processing and emerging markets such as functional surfaces but also the sub 100W power

levels that perhaps have the greatest opportunity to penetrate traditional machining markets and carve out new green field markets in polymer processing.

Talking about growth, and with Laser Munich on the horizon, a few words about Europe, and of course mostly Germany. Where have you been for the last 3 years, we miss you! Germany has not posted a growth manufacturing Purchasing Manager Index (PMI) since June 2022. Whether recent upticks are the green shoots of recovery or not, at least there appears to be some light at the end of the tunnel. Those heading to Laser Munich enjoy great conversations, great beer, and stupidly large pretzels. Prost!

Geoff Shannon, PhD Laser Markets Inc

Over 30 years of laser applications, product and market experience, Currently as Principal of Laser Markets offering marketing consulting services for lasers and laser systems.

The mission of the Board of Laser Safety (BLS) is to provide a means for the recognition of laser safety professionals through certification and to promote competency in the field of laser safety. BLS certification will enhance the credibility of a designated Laser Safety Officer, and demonstrate that individuals serving in the field have agreed to adhere to high standards of safety and professional practice. For the employer, having a CLSO or CMLSO on staff demonstrates duediligence and helps to ensure legitimacy and adequacy of the laser safety program, validating the company’s dedication to a safe working environment for all employees.

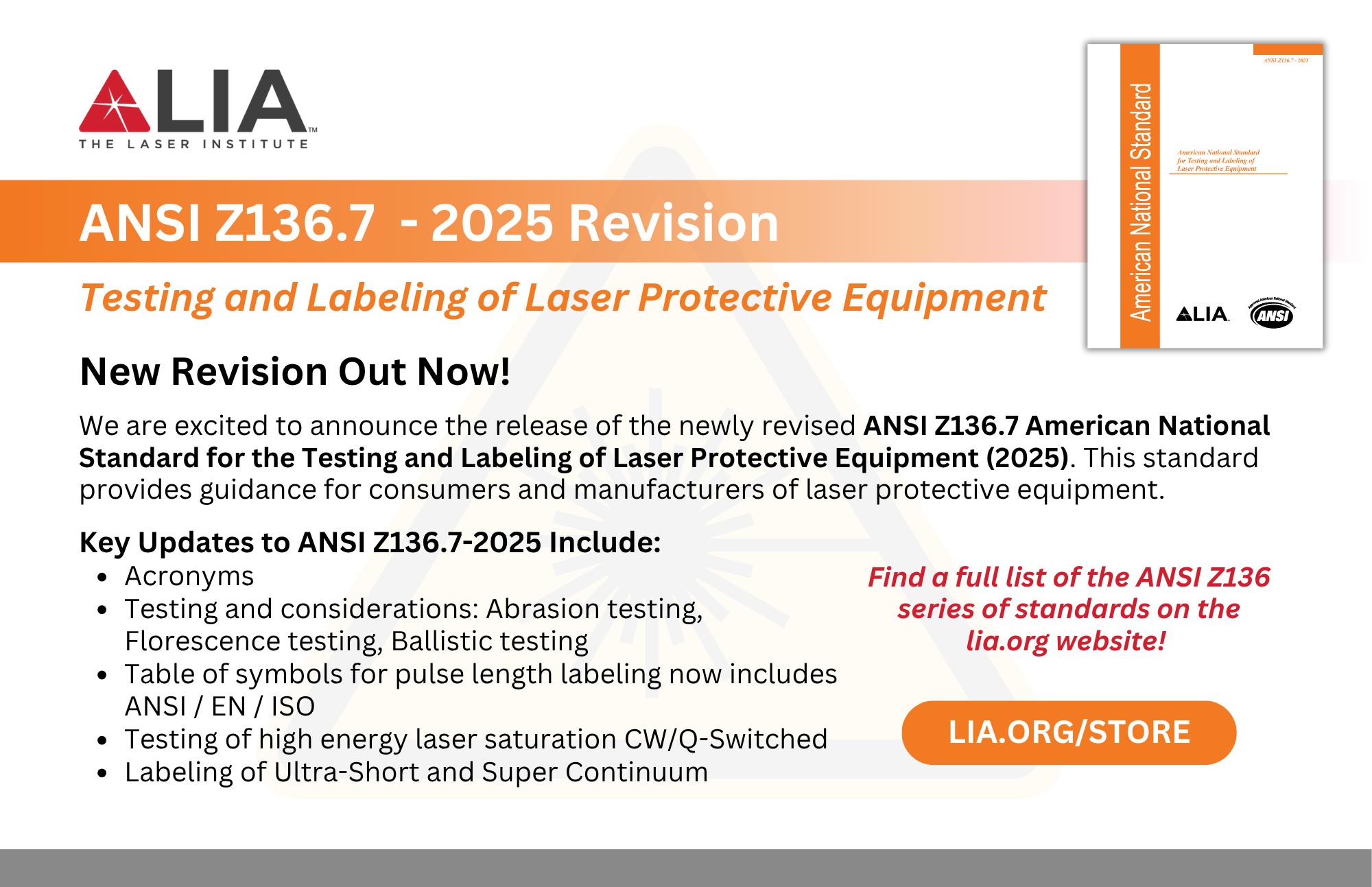

The newly revised ANSI Z136.7 (2025) has officially been released!

This standard provides reasonable and adequate guidance for consumers and manufacturers of laser protective equipment. It contains recommendations for testing and labeling laser protective materials and protective equipment such as eye protection, barriers, and windows designed for use with lasers and laser systems that operate at wavelengths between 180 nm and 106 nm.

Updates to the 2025 revision include testing of high energy laser saturation CW/Q-Switched, labeling of ultra-short and super continuum, and more.

Find these new standards, as well as the rest, on our website at lia.org/store

Whether you’re a Certified Laser Safety Officer (CLSO) or Certified Medical Laser Safety Officer (CMLSO), adding your credential to LinkedIn boosts your credibility and visibility in the industry.

Step 1: Go to Your LinkedIn Profile

Step 2: Scroll Down to the ‘Licenses & Certifications’ Section

Step 3: Fill Out the Certification Details

That’s it! Your certification now appears under your profile’s Licenses & Certifications section.

After adding your certification, create a post to share your achievement and tag the Board of Laser Safety on LinkedIn!

You can earn BLS CM Points by reading laser-related peer-reviewed academic journal articles. Points for journal article reading are claimed in Category 9, Other Activities.

Record your reading using the Journal Article Verification Worksheet and have it signed by your supervisor. Attach it to your Certification Maintenance Worksheet as evidence of completion.

You can earn 0.25 CM points per hour of reading for a maximum of up to 2.0 CM points in Category 9. Visit our website for details.

Write for BLS!

Looking for a way to earn BLS CM points for free? BLS is inviting CLSOs and CMLSOs to share laser safety knowledge with the laser community in it’s newsletter! Published article submissions are worth 0.5 BLS Certification Maintenance (CM) points in Category 3. For more information on guidelines and regulations, email us at bls@lasersafety.org.

Board of Laser Safety 12001 Research Pkwy, Suite 210 Orlando, FL 32826

Toll Free: 1.800.345.2737

Telephone: +1.407.985.3810

Email: bls@lasersafety.org

Website: www.lasersafety.org

If you’ve ever searched online for “LSO certification,” you’ve probably come across training courses that promise to certify you as a Laser Safety Officer just by attending. It’s a common marketing tactic—and an easy source of confusion for those new to the field. Many well-intentioned professionals walk away from training thinking they’re certified, when in fact, they’ve only completed the first step.

Let’s clarify the difference between a certificate of course attendance and professional certification—and why it matters.

When you complete a laser safety training course, you usually receive a certificate of attendance. This document confirms that you were present, participated in the training, and often passed an internal quiz or review. It’s a valuable credential that shows you’re committed to learning and staying current in your field.

However, a certificate of attendance is not the same as being certified. It means you’ve been exposed to the material—but not necessarily that you’ve mastered it or applied it in practice.

Certification through the Board of Laser Safety goes several steps further. It is a formal recognition that you have both the knowledge and real-world experience to perform effectively as a Laser Safety Officer (LSO) or Medical Laser Safety Officer (MLSO).

LSOs who are certified through the Board of Laser Safety have:

• Taken a BLS-approved LSO training - this is where your certificate of course attendance comes in

• Documented, hands-on experience in laser safety responsibilities - minimum 1-year

• Passed the proctored certification exam that assesses your mastery of the knowledge every LSO should have

• Committed to continuing education or periodic recertification to stay current

This process ensures that certified professionals meet a consistent, high standard of competence—one that employers and peers can trust.

We often hear from individuals who were told they were “certified” after attending a course, only to later find out they still need to go through the actual certification process. This misunderstanding isn’t their fault—it stems from vague or misleading language used by some training providers.

If you’ve completed a course and are actively working in the field, certification is the natural next step. It builds on your training and validates your expertise in a way that a certificate of attendance simply can’t.

If this is the first time you’re hearing about the difference, you’re not alone. The terminology can be confusing, especially when training advertisements use “certification” loosely. At the Board of Laser Safety, we’re committed to helping you navigate that landscape and get the recognition you’ve earned. If you have questions about your status or whether you’re ready to pursue certification, don’t hesitate to reach out. You’ve already invested in your education—let’s make sure that investment leads to the professional recognition you deserve.

Check out the guest article guidelines below and get in touch with an editor today!

Content: We are always looking for great newsworthy content that covers challenges and innovations in the field of photonic materials processing, laser safety, and laser market trends. This is not a paid opportunity, but does carry the benefit of publishing your work on a platform that is read by thousands of your peers. All article topics should be confirmed with an LIA TODAY editor before writing your article. Please email your article ideas to liatoday@lia.org and an editor will be in touch with you.

Potential Categories: Safety, medical applications, research and development, laser applications fundamentals, history, business, and other categories.

Potential Industries: Energy storage, aerospace, DoD non-aerospace, automotive, medical devices and biotechnology, microelectronics and IC fabrication, Internet of Things, research and development, and other industries.

Style: The tone should be editorial and informative; it should not sound like a sales pitch. It should be comprehensible by a broad audience of readers with low to expert experience with the topic, so it is important to include examples and simple explanations alongside any technical language.

Length: 600 - 1500 words

Text: Please use standard fonts such as Arial, Calibri, or Times New Roman. Fonts, font sizes, and line spacing will be reformatted by LIA for the final piece. Grammar and mechanics will be edited to the LIA style guide by LIA, but please be mindful of spelling and grammar as you are writing so that your message is clear.

Headline: Please include two newsworthy headlines suggestions for your article using action verbs.

Images & Figures: Please include images to be used with the article. Submit as an email attachment (PNG, GIF, JPG, JPEG) (min. 1000px in width or height). Images should also be placed in the body of the text where the author would like them to appear in the final article. All figures or images should include captions.

Deadlines: All material is due no later than two weeks prior to the scheduled publishing date. Check with an editor for your deadline.

Note: LIA reserves the right to abstain from publishing a submitted article for any reason.

•Full text as a Word Document

• Abstract: A 50 – 100 word summary in plain language

•Two (2) headline suggestions using an action verb

•Article 600 – 1500 Words

•Images with captions placed in the body of the article

•Article references when applicable

•Short author bio (full title, company, 50 words)

•(optional) Professional headshot of author

•Images attached in one of the accepted file types (.png, .tiff, .jpeg, .jpg) (min. 1000px width or height).

VIEW SUBMISSION FORM

VIEW SUBMISSION FORM