FULLY COLD APPLIED | NON COMPACTION | HIGH STRENGTH

IRONWORK SYSTEM INSTALLATION GUIDE:

Supporting Standards: CD534 Chamber tops and gully tops for road drainage and services. Specification for the Reinstatement of Openings in Highways Fourth edition Ironworks to meet BS EN 124-1:2015 through to BS EN 124-6:2-15, BS EN7903:2020

Ironwork cover or grate

OVERBAND/EDGE SEALER:

Magma UltraCrack L270 (optional) or use

EXPANTION JOINT - Recommended 40mm depth:

Magma UltraCrack L275 (optional)

SURFACE SYSTEMS - Recommended 40mm depth:

Magma PermaFyx L273/L274 | Magma HardMaster W672 |

MMA PRIMER

Magma DampCure (Required when wet/damp conditions)*

BACKFILL SYSTEMS:

Magma HardMaster W621 Flowable CD534

Magma HardMaster W615 | Magma HardMaster W910/W915

Magma Fyxeez Levelling system (optional)*

Frame Generally 150mm depth

BEDDING SYSTEMS - Recommended 25/30mm depth:

Magma HardMaster W620 Trowable CD534 | Magma HardMaster W668/W660/W690

SHIMPAC® ROADSHIMS® Levelling system (optional)*

Brick or Pre-Cast Concrete Chamber

*The new ironwork frame can be levelled up with the surface using Meon Fyxeez attached to the flange of the frame and adjusted until level. If the ironwork requires raising use SHIMPAC® ROADSHIMS® to build up to required level.

PLEASE NOTE: Only CD534 products can be used together and never with any other product not classed as CD534... Apart from the surface system. Standard bedding mortars can also be used for off strategic network installations.

Take care to ensure that the top edge of the frame is level with the intended final road surface, as failure to do so will result in excessive noise in service and/or potentially early failure of

• Ensure that bedding material is not obstructing the cover seating, cleaning off excess material where needed. Clean up any exposed areas of bedding material on the inside of the frame by pointing to a smooth finish.

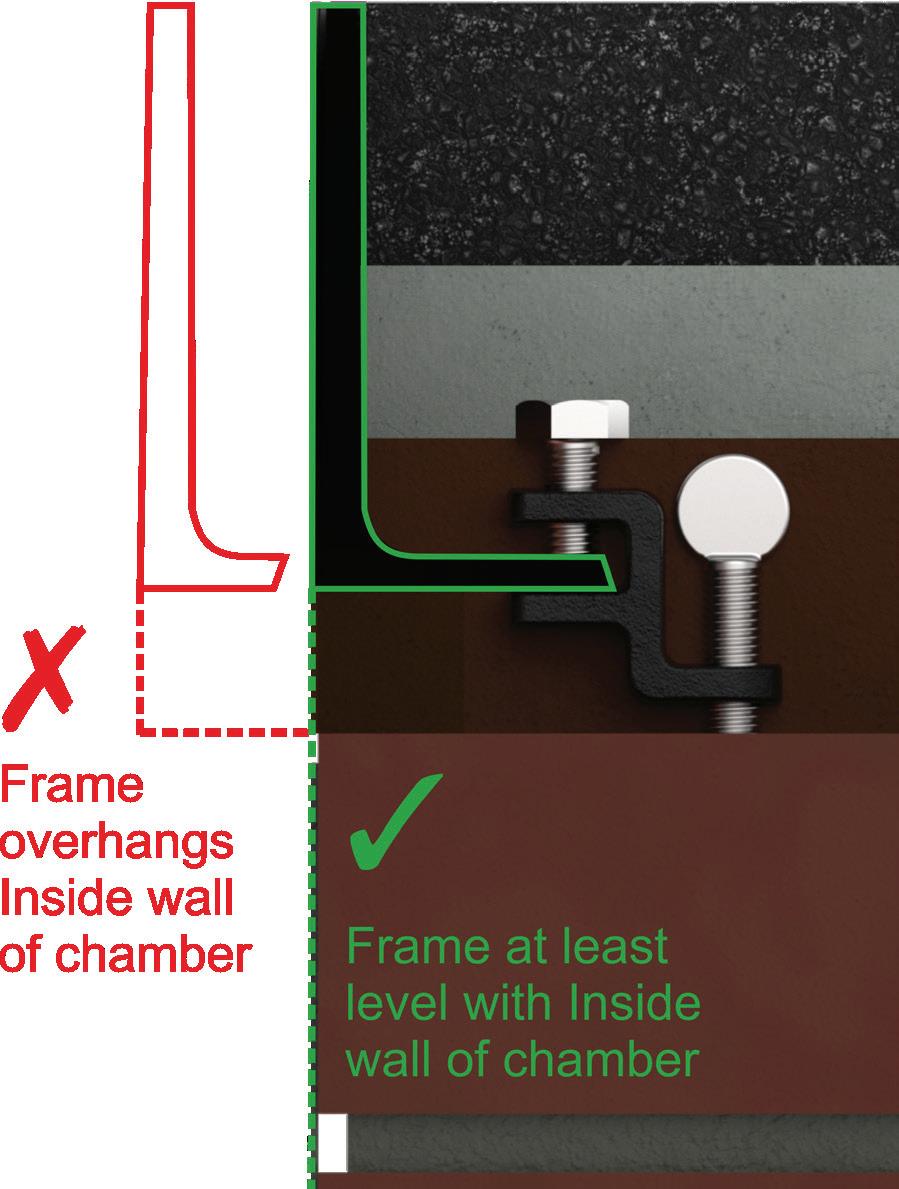

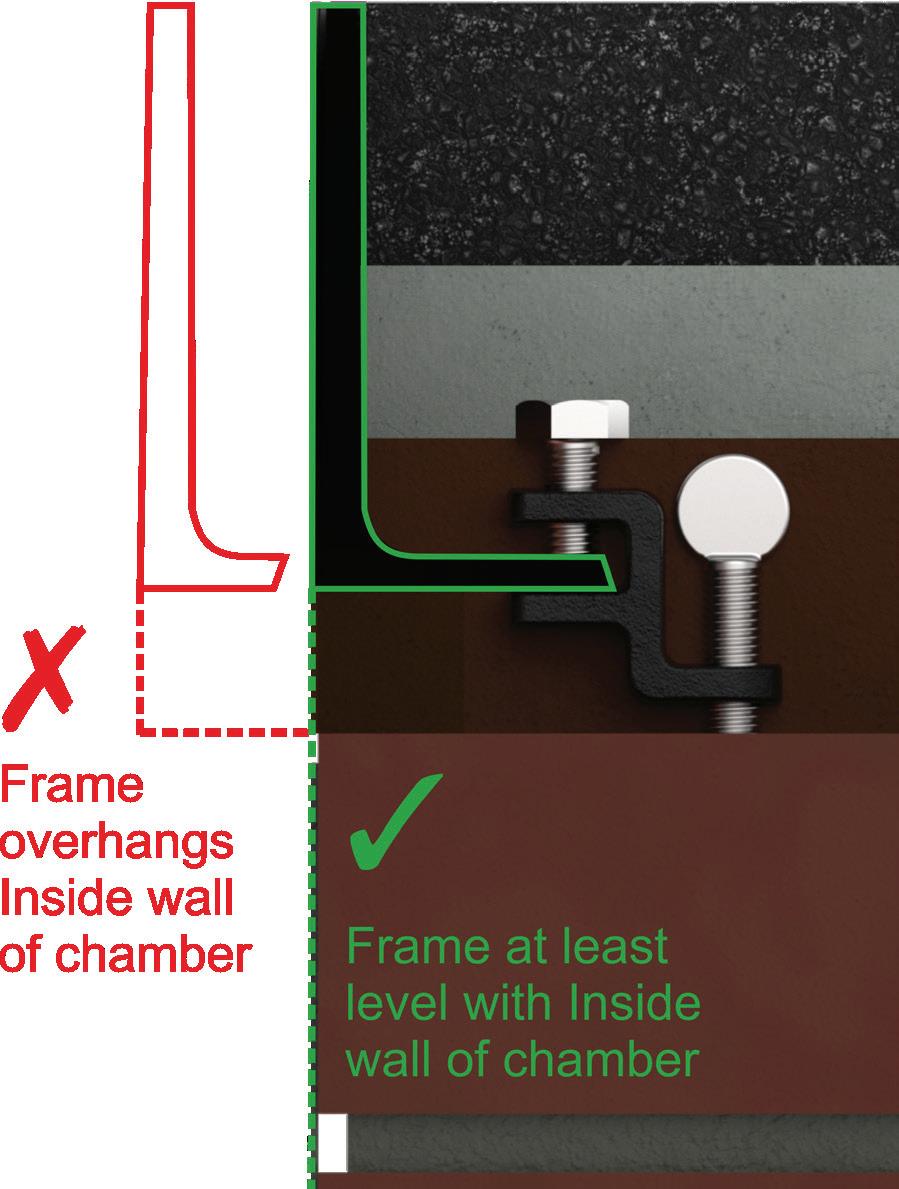

Ensure that the inside of the frame is at least level with the inside of the chamber. This allows the frame to disperse stress through the frame flange and the bricks. If the frame overhangs the chamber any force could cause the installation to crack & fail.

• Standard bedding mortars can also be used for off strategic network installations. Examples include our Magma HardMaster W660 and Magma HardMaster W690.

DAMMING/BEDDING

MATERIAL SYSTEMS

BACKFILL MATERIAL SYSTEMS

SURFACE COURSE MATERIAL SYSTEMS

ASPHALT SURFACE CONCRETE SURFACE

6mm Aggregate

HRA 20mm Chippings

LEVELLING SYSTEMS, OPTIONAL SYSTEMS AND RECOMMENDED TOOLS

MMA PRIMER (ONLY WHEN WET/DAMP)

EXPANSION JOINT & OVERBANDING

LEVELLING SYSTEMS RECOMMENDED TOOLS

INSTRUCTIONS FOR NEW INSTALLATIONS:

Chamber & Bedding: The chamber construction should be made up of 2-4 courses of class 2 engineering bricks laid English bond or from pre-cast concrete seating rings. If possible remove the covers or grates from the frame prior to installation. Bedding should be achieved using one of the following 3 methods of Ironwork Grades, using the materials stated in the table.

Ironwork Grade: We have broken this down to Off Highway Grade Ironworks, which are Groups 1 and 2 that are in pedestrian areas and occasional vehicle use. Standard Grade Ironworks, which are Groups 3 and 4 that are Kerbside installation and standard use roads. Highway Grade Ironworks, which are Groups 5 and 6 that are for High use carriageways, trunk roads & motorways, high wheel load areas and aircraft pavements. (Groups are categorised by strength, 6 being the most formidable)

Traffic Light System: The Ironwork System of products are catergorised into different layers of the installation. Damming/Bedding system is labeled Red, Backfill Systems are coloured Amber, and the Surface System is coloured Green. Please note that the Flowable Backfill Systems can be usd to incase the flange of the ironwork and fully embedding to the surface substrate before backfilling.

HIGHWAYS GRADE:

Installation Materials

Levelling System

Ironwork frame levelling System

Fyxeez

40N/mm² in Compressive Strength SHIMPAC® ROADSHIMS® Levelling system

Damming/Bedding Mortar

20N/mm² in 60 - 90min Compressive Strength

Magma Hardmaster W660 or W690

20N/mm² in 60min Compressive Strength

Magma Hardmaster W668

40N/mm² in 180min Compressive Strength

Magma Hardmaster W620

Backfill Material

20N/mm² in 90min Compressive Strength

Magma Hardmaster W910/915

20N/mm² in 90min Compressive Strength

Magma Hardmaster W615

40N/mm² in 180min Compressive Strength

Magma Hardmaster W621

Surface Course

Asphalt Surface Course

Magma Permafyx L273 - 6mm or HRA

Concrete Surface Course

Magma Permafyx L274

Concrete Surface Course

Magma Hardmaster W672

Expansion Joint/Edge Seal

Expansion Joint (Optional)

Magma UltraCrack L275

Overband/Edge Seal (Optional) Magma UltraCrack L270

OFF HIGHWAYS GRADE:

Groups 1 & 2, A15 & B125

(Pedestrian areas and occasional vehicle use)*

STANDARD GRADE:

Groups 3 & 4, C250 & D400 - Type 2, 3 & 4 Roads

(Kerbside installation and standard use roads)*

Type 1 Roads, CD534, Groups 5 & 6, E600 & F900

(High use carriageways, trunk roads & motorways, high wheel load areas, aircraft pavements)*