Rivian: Sustainable electric vehicle adventure driven by procurement

Boehringer Ingelheim: Healthy data creates a better world

iQuantum: A modern procurement platform for today’s business

UPG Enterprises: UPG Enterprises on digital transformation and automation

FEATURING: ASPENTECH SOPHOS IBASET | | | INTELEX

Feb 2023 | manufacturingdigital.com

Agricultural equipment manufacturers

0 0 0 0 1 1 A BizClik Brand

10 0 0 0 1 LEADERS2022 • LE A D SRE 2202 • SREDAEL2202 • EL A D ERS2022 • Creating Digital Communities OUT NOW Read now Don’t miss this Issue! The most influential people in Supply Chain

The Manufacturing Team JOIN THE COMMUNITY Never miss an issue! + Discover the latest news and insights about Manufacturing Global... EDITOR-IN-CHIEF HELEN ADAMS CHIEF CONTENT OFFICER SCOTT BIRCH MANAGING EDITOR NEIL PERRY PROOFREADER JESS GIBSON CHIEF DESIGN OFFICER MATT JOHNSON HEAD OF DESIGN ANDY WOOLLACOTT LEAD DESIGNER JORDAN WOOD FEATURE DESIGNERS MIMI GUNN SOPHIE-ANN PINNELL HECTOR PENROSE SAM HUBBARD JUSTIN SMITH REBEKAH BIRLESON ADVERT DESIGNERS JORDAN WOOD DANILO CARDOSO CALLUM HOOD VIDEO PRODUCTION MANAGER KIERAN WAITE SENIOR VIDEOGRAPHER HUDSON MELDRUM DIGITAL VIDEO PRODUCERS MARTA EUGENIO ERNEST DE NEVE THOMAS EASTERFORD DREW HARDMAN JOSEPH HANA SALLY MOUSTA JINGXI ANG PRODUCTION DIRECTORS GEORGIA ALLEN DANIELA KIANICKOVÁ PRODUCTION MANAGERS JANE ARNETA MARIA GONZALEZ CHARLIE KING YEVHENIIA SUBBOTINA MARKETING MANAGER DAISY SLATER PROJECT DIRECTORS CRAIG KILLINGBACK MIKE SADR MEDIA SALES DIRECTORS JAMES WHITE MANAGING DIRECTOR LEWIS VAUGHAN CEO GLEN WHITE

The threats of outdated technology in manufacturing and the rise of ESG in 2023

In Manufacturing Digital February 2023, we take a closer look at ESG in the sector and how the manufacturing industry is attracting young, talented professionals in the skills shortage

Hello and welcome back to the first edition of Manufacturing Digital 2023!

In this issue, we catch up with AspenTech’s Senior Director, Ron Beck, to hear about how the company is attracting young professionals into the manufacturing sector and how AspenTech is increasing its sustainability credentials. Meanwhile, John Shier, Senior Security Advisor at Sophos, shares his knowledge of ransomware and the results of Sophos’ ‘State of Ransomware in Manufacturing’ report.

Rashpal Mundi, Senior Partner Manager for iBASEt EMEA, discusses how the manufacturing sector is changing and the threats of using outdated technology. Lastly, Ben Henderson, Head of Product Solution Consulting at EMEA Intelex Technologies, explores the company’s ESG efforts.

Helen.Adams@bizclikmedia.com

FOREWORD manufacturingdigital.com 5 © 2023 | ALL RIGHTS RESERVED

“ In this issue, we discuss how the manufacturing sector is changing and the threats of using outdated technology ”

HELEN ADAMS

MANUFACTURING GLOBAL MAGAZINE IS PUBLISHED BY

Our Regular Upfront Section:

Factory of the Future

Rivian Sustainable electric vehicle adventure driven by procurement

AspenTech’s Ron Beck on sustainable manufacturing & AI 24 42

10 Big Picture 12 The Brief 14 Timeline: 2023 predictions for the manufacturing sector 16 Trailblazer: Blake Moret 20 Five Minutes With: Michael J. Zeto III Boehringer Ingelheim Healthy data creates a better world 50 CONTENTS

Digital Manufacturing John Shier, Senior Security Advisor at Sophos, on Ransomware Technology iBASEt’s Rashpal Mundi on the risks of outdated technology iQuantum A modern procurement platform for today’s business Sustainability Ben Henderson, Intelex Technologies,on ESG & sustainability SAP SAP’s Sam Castro on AI and risk resilience in manufacturing Top 10 Agricultural equipment manufacturers UPG Enterprises UPG Enterprises on digital transformation and automation Applovin Managing risk and growing the global app ecosystem 64 84 72 106 92 128 116 140

0 0 0 0 1 1 A BizClik Brand

OUT NOW Read now 10 0 0 0 1 LEADERS2022 • LE A D SRE 2202 • SREDAEL2202 • EL A D ERS2022 • Creating Digital Communities Don’t miss this Issue! The most influential people in Procurement

BIG PICTURE

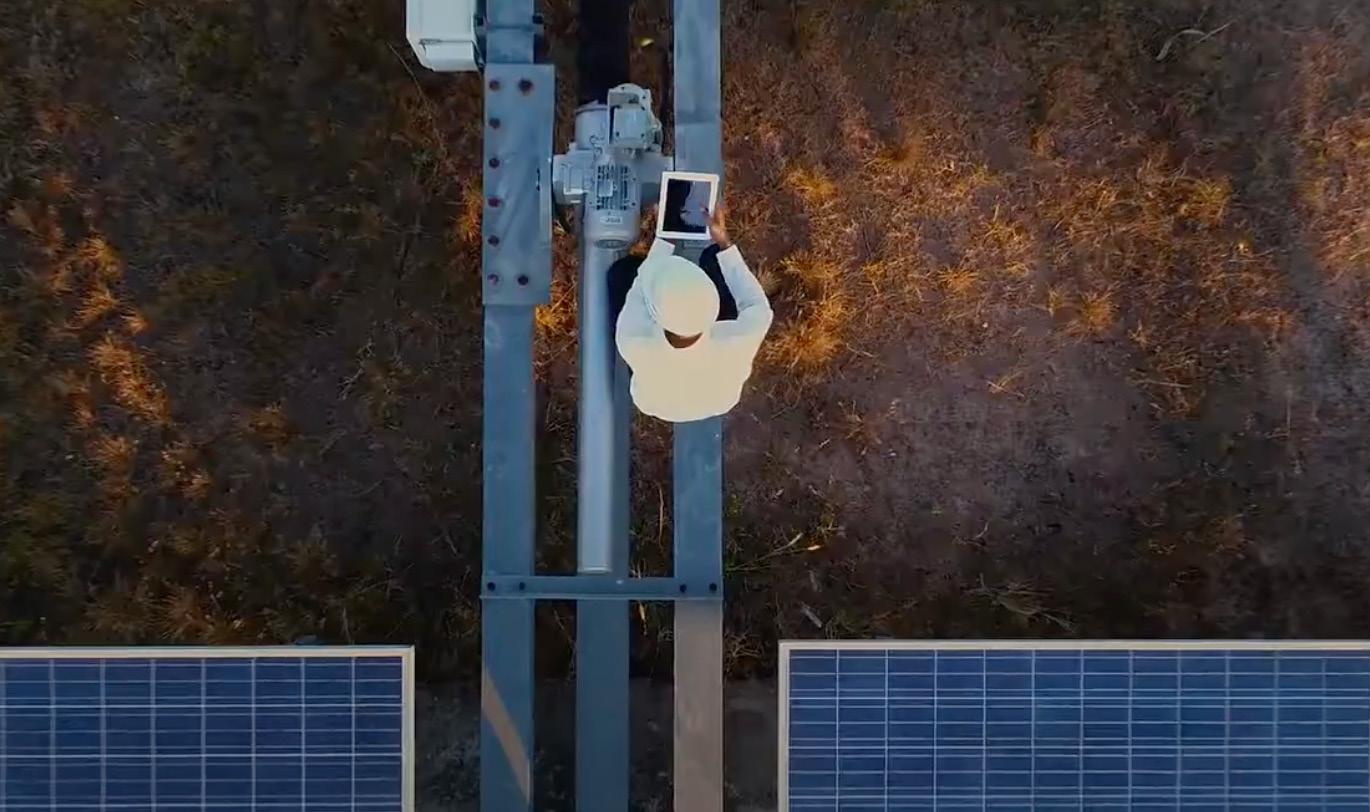

Colleagues using digital tablet and working in industry Brazil

To attract Gen Z talent, a commitment to digital can demonstrate manufacturing is a progressive industry in which to work. “This means using technology to eliminate repetitive tasks and provide crucial insight that fuels intelligent decision-making,” says Rashpal Mundi, iBASEt’s Senior Partner

Manager for EMEA.

Manager for EMEA.

10 February 2023

manufacturingdigital.com 11

THE BRIEF

READ MORE

ASPENTECH’S RON BECK ON SUSTAINABLE MANUFACTURING & AI

READ MORE

Many of AspenTech’s major customers have been struggling for the past two years with various supply chain disruptions.

“We see the opportunity to help these global companies adopt digital solutions, so they can support and achieve this agility,” says Beck.

AspenTech continues to maintain a substantial team conducting software testing and related work in its Shanghai location. Over the past five-plus years, AspenTech has also progressively expanded and added staff to its new team in Mexico City.

READ MORE

“We have found that there is a strong talent pool of the right kind of motivated and creative technical people in the Mexico City area that meet the profile of R&D support and other skilled resources we have been adding over the past few years, to support the company’s innovation in areas core to our company mission.”

At the beginning, we had a shell of a manufacturing plant. Now, we're fully operational, building three different vehicles.

Brad Hood

Director of Indirect Purchasing, Rivian

Our global database of suppliers allows customers to source from new diverse suppliers to meet their goals.

Hetal Mehta Founder and CEO, iQuantum Inc

The enterprise has to provide guidance to the manufacturing and supply chain teams as a whole

Sam Castro Solution Manager for Digital Manufacturing, SAP

12 February 2023

EDITOR'S CHOICE

BEN HENDERSON, INTELEX TECHNOLOGIES, ON ESG & SUSTAINABILITY

Ben Henderson, Head of Product Solution Consulting at EMEA Intelex Technologies, discusses the company’s ESG efforts and sustainability initiatives

IBASET’S RASHPAL MUNDI ON THE RISKS OF OUTDATED TECHNOLOGY

Rashpal Mundi, Senior Partner Manager for iBASEt EMEA, on how the manufacturing sector is changing and the danger of outdated technology

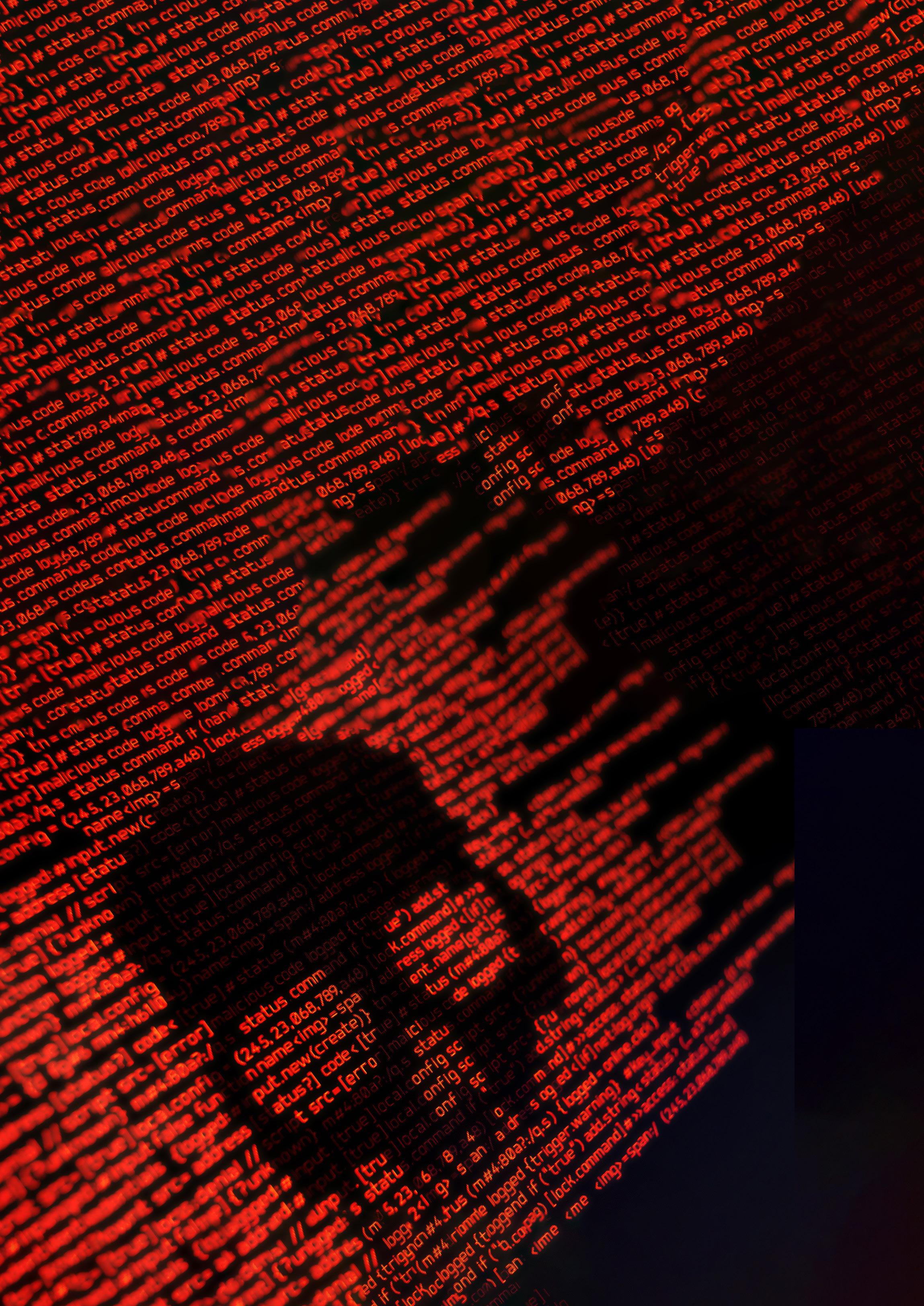

JOHN SHIER, SENIOR SECURITY ADVISOR AT SOPHOS, ON RANSOMWARE

John Shier is the Senior Security Advisor at Sophos. Here, he discusses ransomware and the results of Sophos’ ‘State of Ransomware in Manufacturing’ report

BY THE NUMBERS

93% of manufacturers believe a lack of digital investment poses the risk of going out of business

CONNECTED SECTOR ECOSYSTEMS

AVEVA’s CEO Peter Herweck & IDC’s Senior Vice President Bob Parker are fascinated by the rise of connected industry ecosystems & the industrial sector’s digital economy

CLOUD ASSESS

Rob Bright, CEO of Cloud Assess & manufacturing engineer, gives his Top 4 reasons why manufacturers cannot afford to overlook training practices in 2023.

INTEGRATION CHALLENGES

Up to 90% of manufacturers struggle with integration challenges, meaning that when disruption occurs, they struggle to react effectively, says Arjun Khanna, Chief Technology & Innovation Officer at Kallik.

CHINESE MANUFACTURING

According to CNBC Supply Chain Heat Map data, manufacturing orders from the USA for China have decreased by 40%.

U P D O W N

FEB 2023

manufacturingdigital.com 13

2023 PREDICTIONS THE MANUFACTURING SECTOR

Research shows that 43% of people give up on their New Year's Resolutions after just one month, but these five leaders from the manufacturing sector know that the industry must harden its resolve to accelerate important transformations throughout 2023 to carry the sector into the future

Ford Motor

Autonomous vehicle development

In 2020, Detroit-based automaker Ford Motor said that it expected autonomous vehicle development to rise to US$4bn through to 2023.

"Ford has made tremendous progress across the self-driving value chain — from technology development to business model innovation to user experience,” said then-CEO

Jim Hackett.

White Label Loyalty

Use data and technology to build customer loyalty

Achile Traore, CEO of White Label Loyalty, said he believes that manufacturing brands should use data and technology to build customer loyalty in 2023.

“Research suggests that by 2023, over 60% of consumers will expect companies to be able to anticipate their needs and make relevant recommendations,” he said.

TIMELINE

14 February 2023

FOR MANUFACTURING

Decarbonisation

Industrial companies are now realising that they have to start making progress towards their decarbonisation goals.

“We believe 2023 will be a year when many industrial organisations will look closely at their emissions and take tangible steps to reduce them,” said Berk Birand, Co-founder and CEO of Fero Labs.

Important trends for manufacturing playbooks

Paul Wellener, Vice Chair of US Industrial Products & Construction Leader at Deloitte LLP, shared his thoughts: “Our newly released 2023 Manufacturing Outlook highlights five important trends for manufacturing playbooks in the year ahead: managing uncertainty; tackling workforce shortage; driving supply chain resiliency; scaling smart factory initiatives; and developing sustainability.”

Rob Bright, CEO of Cloud Assess & manufacturing engineer, offered his reasons as to why manufacturers cannot afford to overlook training practices in 2023.

“With the manufacturing industry under increasing pressure to find a solution to the ongoing skills shortage, 2023 will be a crucial year for those looking to improve business performance.”

Training practices

Deloitte

PREDICTIONS

Cloud Assess

manufacturingdigital.com 15

Fero Labs

Name: Blake Moret

Job Title: CEO Company: Rockwell Automation

Blake Moret became the President and Chief Executive Officer of Rockwell Automation in 2016. In his role, he leads productivity and sustainable initiatives across the biggest industrial automation and information company in the world.

At Rockwell Automation, the mission is to accelerate the quality of life through more efficient production, smart manufacturing and sustainable options. An investment in Rockwell Automation’s technology is an investment in the future of manufacturing.

Moret’s vision for one project, The Connected Enterprise, is to use information to assist industrial companies in their productivity. “Manufacturers are looking for new ways to leverage technology to reduce their environmental footprints,” says Moret.

TRAILBLAZER

Moret has worked at Rockwell Automation for 38 years 16 February 2023

is the CEO of Rockwell Automation – and a trailblazer. Here’s why

manufacturingdigital.com 17

Mechanical engineering and volunteer work

Moret is a graduate of Georgia Institute of Technology, where he studied a Bachelor's Degree in Mechanical Engineering 1980 –1985. After completing this, he arrived at Rockwell Automation and worked across sales and business management roles until 2002.

From then up until 2005, he worked as Director of Electronic Operator Interface Business, then moved to Customer Support and Maintenance until 2007, where he led the control products and solutions across the business segment of Rockwell Automation. Up until 2011, Moret worked as Vice President. He was then promoted to President and Chief Executive Officer in 2016, and Chairman and Chief Executive Officer in 2018.

Moret has also served as Chair of the Board for the Manufacturing Institute of the National Association of Manufacturers and is a member of the Board of Directors for the Urban Ecology Center. He is on the Board of Directors of the United Way of Greater Milwaukee and Waukesha, and is also on the Advisory Board of the Woodruff School of Mechanical Engineering at Georgia Tech.

Over his 38 years at Rockwell Automation, Moret has seen a huge rise in sustainable manufacturing and is racing to meet it across the company.

Sustainable efforts in the workplace and the world

Rockwell Automation, along with many other manufacturers, suspended operations and

TRAILBLAZER

“Manufacturers are looking for new ways to leverage technology to reduce their environmental footprints”

18 February 2023

– Blake Moret

sales in Russia and Belarus following the invasion of Ukraine. Though sales in these countries total less than 0.5% of Rockwell Automation’s total revenue, the company has said that it will continue to pay salaries and benefits for its Russian team.

“Rockwell Automation joins the US government and the global community in condemning Russia’s attack on Ukraine and its citizens,” said Moret. The company made a financial donation to Project HOPE, which offers humanitarian aid to Ukrainian refugees. Further to this, Rockwell Automation has matched employee donations for Project HOPE while supporting local volunteer efforts.

Within the company, Moret is prioritising sustainable initiatives. “Manufacturers are looking for new ways to leverage technology

to reduce their environmental footprints,” Moret said. “Intelligent devices, combined with innovative sustainability and energy management software, provide new levels of insight to reduce energy demand and increase efficiency.”

Moret believes that real-time energy management is within reach, from monitoring to embedded AI tools that offer closed-loop optimisation. In using a standard energy data model, Moret hopes that energy intensity and other key performance metrics can be measured and improved.

“This simple, yet impactful, insight allows businesses to de-energise the equipment when not in use, reducing both costs and greenhouse gas emissions.”

manufacturingdigital.com 19

MICHAEL J. ZETO III

Boingo designs, builds and manages wireless networks to help enterprises streamline operations, improve business outcomes, and bolster the bottom line.

QHI MICHAEL, TELL US ABOUT YOUR PATH TO CCO AT BOINGO?

» I joined Boingo Wireless in 2020 as the SVP of Global Strategy, leading our worldwide strategy, business development and new business creations. I was a senior member of the executive team, guiding the company through the pandemic, a private equity transition and the launch of Boingo’s highly anticipated private network offering. In 2021, I stepped into the role of Chief Commercial Officer.

Prior to Boingo, I worked at AT&T, leading the emerging business portion of AT&T IoT. I created the smart city business, public private partnerships, and several other businesses in new categories for the company. I was focused on driving successful utilisation of 5G and IoT applications.

QTELL

US

ABOUT BOINGO AND THE WORK YOU DO?

» Wireless networks have changed from a single source needed by an enterprise to multiple types of connectivity required to run the entire business.

We start by asking, ‘What outcomes do you need to accomplish?’ From there, we develop a network that specifically serves that company’s unique needs and drives business outcomes. In short, we design, build and manage converged networks that can include all technologies or solutions – such as 5G, DAS (distributed antenna systems), Wi-Fi or CBRS to meet growing connectivity needs. It sounds complex because it is. Enterprises work with Boingo to bring all technologies together – an increasingly challenging goal.

FIVE MINUTES WITH...

BOINGO WIRELESS CHIEF COMMERCIAL OFFICER

20 February 2023

QWHAT SKILLS HAVE YOU DEVELOPED TO STAY AHEAD OF THE GAME?

» First and foremost, I believe in listening to those around you –both colleagues and customers. Having empathy for them and what they're going through is essential. This way, you’re able to develop solutions that really meet the outcomes they're trying to drive. I've also learned that whatever your role, you’ve got to be agile. We've seen a heightened need for agility over the past three years, and I don't think it's going to stop. We need to quickly pivot, act with velocity, think creatively and collaborate.

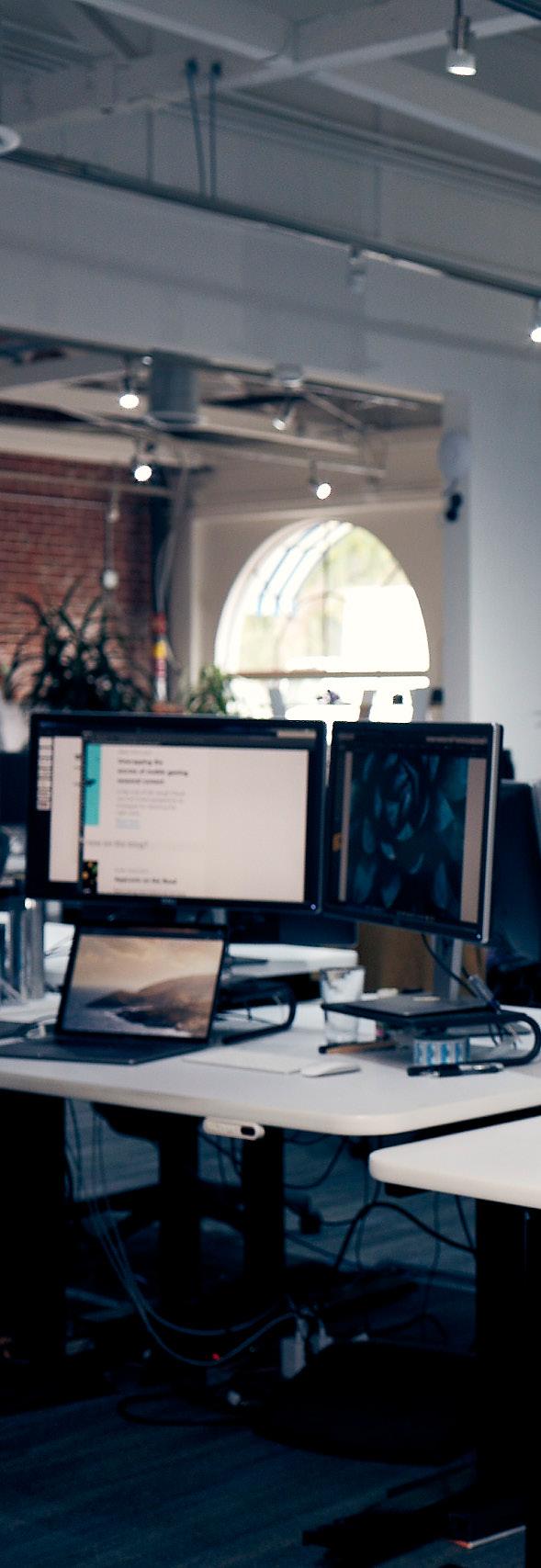

QHOW IS DIGITAL TRANSFORMATION IMPACTING MANUFACTURING?

» Over the last eight to ten years, we’ve talked a lot about IoT, Industrial IoT, and how machines are connecting things that weren’t previously connected. Digital transformation can be as basic sounding as moving file-keeping from paper to electronic, or it can be as complex as the use of digital twins for virtual simulations and product testing.

In the last couple of years, the need for digital transformation in every industry has accelerated. Now, connectivity is a key component in providing a stronger bottom line, bigger ROI and more agility.

QWHAT ARE THE BIGGEST CHALLENGES AHEAD FOR MANUFACTURERS?

» As far as challenges go, manufacturers are going to continue to focus on balance. The macro environment is saying that you need to be profitable and deliver for your shareholders, yet all the public markets are facing increases in costs and experiencing issues in the supply chain.

Manufacturers need to find other ways to drive profit, because there's only so much elasticity in the market. That's where you're going to see a lot of focus on increasing efficiencies through digital transformation.

FIVE MINUTES WITH...

22 February 2023

“WE HANDLE THE NETWORK SO OUR PARTNERS CAN FOCUS ON THEIR BUSINESS”

QWHAT SHOULD IT TEAMS BE DOING TO SOLVE THESE PROBLEMS?

» Reliable, fast, secure connectivity is key. It’s the common thread through every solution. Connectivity drives positive productivity gains, efficiency and business innovation. Determine the business outcomes you need and work with a connectivity partner who can execute your strategy.

QHOW DOES BOINGO SUPPORT MANUFACTURERS AND THEIR BOTTOM LINE?

» At Boingo, we serve as trusted advisors and partners. We come in and stand side-by-side with you. We evaluate the outcomes you want to drive and help you develop a strategic roadmap for solutions. We then design, build and manage that for you. We know wireless today is complex. We know it is challenging. We also know you just want it to work, and work well. We handle the network so our partners can focus on their business.

QWHAT TIPS DO YOU HAVE FOR THOSE WHO ARE GETTING A BUSINESS STARTED?

» Outcomes are different for each industry and each business. Take time to know who your customer base is first and build your strategies around their needs.

Learn more at boingo.com

“CONNECTIVITY DRIVES POSITIVE PRODUCTIVITY GAINS, EFFICIENCY AND BUSINESS INNOVATION”

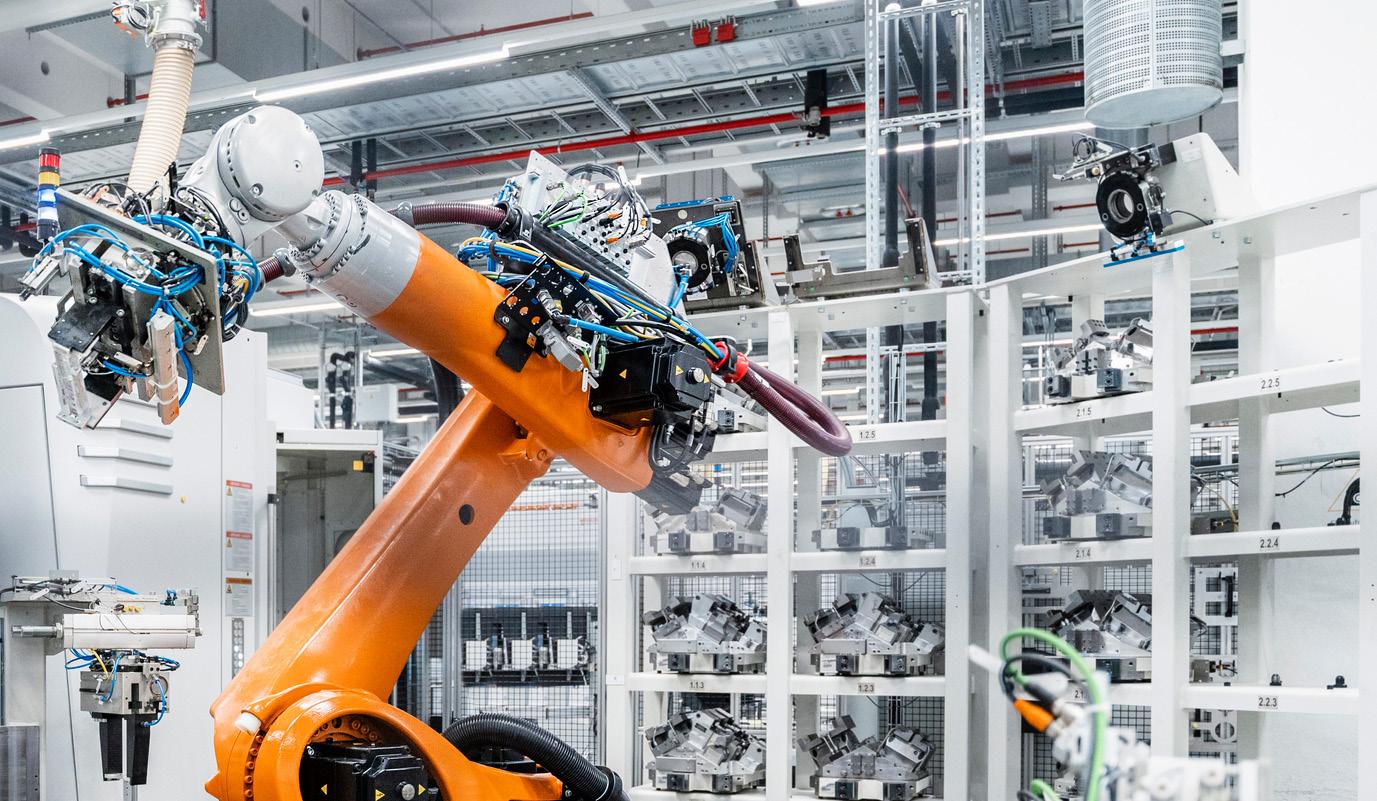

Sustainable electric vehicle adventure driven by procurement

WRITTEN BY: TOM SWALLOW

PRODUCED BY: MIKE SADR

WRITTEN BY: TOM SWALLOW

PRODUCED BY: MIKE SADR

24 February 2023

manufacturingdigital.com 25

Brad Hood, Director of Indirect Purchasing at Rivian, on the benefits of a ‘blank canvas’ and how the EV manufacturer implements sustainable procurement

Anyone harbouring a passion for adventure and sustainability will no doubt have heard of the company leading the market for electrified pickup trucks.

Not only does Rivian boast sustainability credentials across its entire business, it’s also a business built with the planet at the forefront of all its activities. Yet, while there are many exciting aspects to highlight, the critical element of Rivian’s story is the “design and development of categorydefining electric vehicles”, in the words of the company’s Director of Indirect Purchasing, Brad Hood.

We often see the company through the consumer lens. Thousands evangelise the clean, robust, unique style of the Rivian R1T and R1S—its pioneering EVs, the pinnacle of the environmentally and socially responsible business.

Founded in 2009, the Rivian story began with a vision for sustainable mobility. As an automotive enthusiast himself, the company’s founder, RJ Scaringe, saw that the two things he lived for—cars and nature— were not compatible in the long-term. This conclusion formed the very basis of the company, which holds an integral place in the electrification of automotive.

manufacturingdigital.com 27 RIVIAN AUTOMOTIVE

Procurement drives a sustainable electric vehicle adventure

“He created a product that was a more sustainable alternative to the fossil-fuelburning carried out by internal combustion engine vehicles. He really wanted to facilitate a transition to more neutral energy transportation, not only for our generation, but for our kids', kids’, kids,” says Hood.

“It's a multi-generational purpose that goes beyond any one of us, which is what drives the overall culture at Rivian: we're here for something bigger than ourselves.”

Of course, there’s more to Rivian vehicles than the fact they run on electric propulsion. The company prides itself on sustainable sourcing and leveraging a circular system, right from the design stage. Its batteries can be easily removed for either recycling or ‘second life’ applications. When it comes to the interiors, vegan leather and other animal-free materials are used, with mid-life repairability in mind.

Beyond the product itself, sourcing also involves the unique procurement of oceanharvested plastics for its dunnage containers and other packaging solutions. Such actions earned the company the 2022 Excellence and Reusable Packaging award from the Reusable Packaging Association.

“If we are working on an e-sourcing event or an auction, we can leverage these templates”

28 February 2023 RIVIAN AUTOMOTIVE

BRAD HOOD DIRECTOR OF INDIRECT PURCHASING, RIVIAN

“We use the most sustainable products we can and when we went public, 1% of the company went to the Rivian Forever Fund,” says Hood.

“We think about how to operate responsibly within the plant. When we began the conversion of the old Mitsubishi plant to the new Rivian plant, we used some of the old steel to make tables, a mezzanine—and we even repurposed old robots as a door holder for the conference room.

“We reused things, and maybe went above and beyond. Instead of scrapping it, instead of getting rid of those materials, we thought, ‘how can we repurpose that and reuse them?’.”

Indirect procurement provides the operational foundations

As a new entrant to the automotive industry in 2009, Rivian was built with sustainability in mind. And being a new business gave the company a competitive edge to not only grow, but advance the use of new technologies and lean processes.

Hood explains that when he joined the organisation in 2018, the procurement function was significantly smaller than it is today, but this has allowed the company to take an approach that is driven by technology.

“When I joined, there were 500, 600 employees. There were about three people within our department,” Hood says. “Now, the total company size is more than 20 times that.”

BRAD HOOD

TITLE: DIRECTOR OF INDIRECT PURCHASING

INDUSTRY: OIL & ENERGY

LOCATION: DETROIT, USA

Brad shifted careers from manufacturing and production planning to procurement after graduating from Western Michigan University with a major in Integrated Supply Chain Management. After spending most of his procurement career in consulting, he joined Rivian at the tail-end of their stealth mode in 2018 to help build their procurement department. Rivian has experienced tremendous growth since then, which includes the indirect procurement team that Brad leads. This has proved both Rivian and Brad the opportunity to grow the procurement organisation in the same manner as Rivian talks about designing the vehicles, from a blank

10,000+ Number of employees

2009

Year founded

“At the beginning, we had a shell of a manufacturing plant. Now, we're fully operational, building three different vehicles with multiple different variations in Normal, Illinois.”

manufacturingdigital.com 29 RIVIAN AUTOMOTIVE

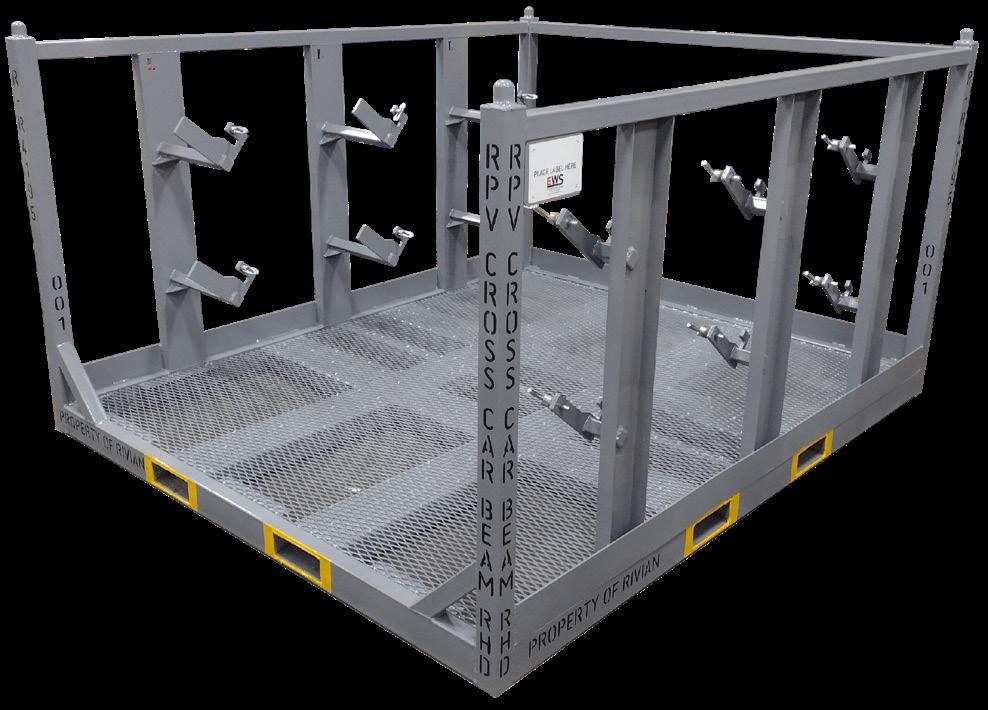

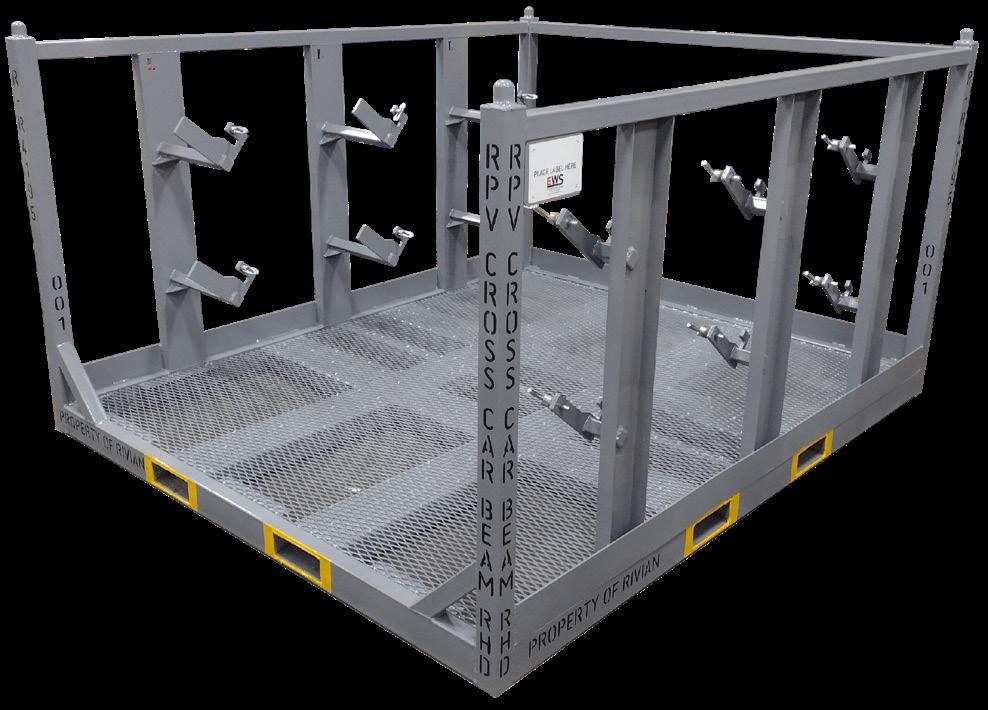

PROVIDING RETURNABLE PACKAGING SOLUTIONS

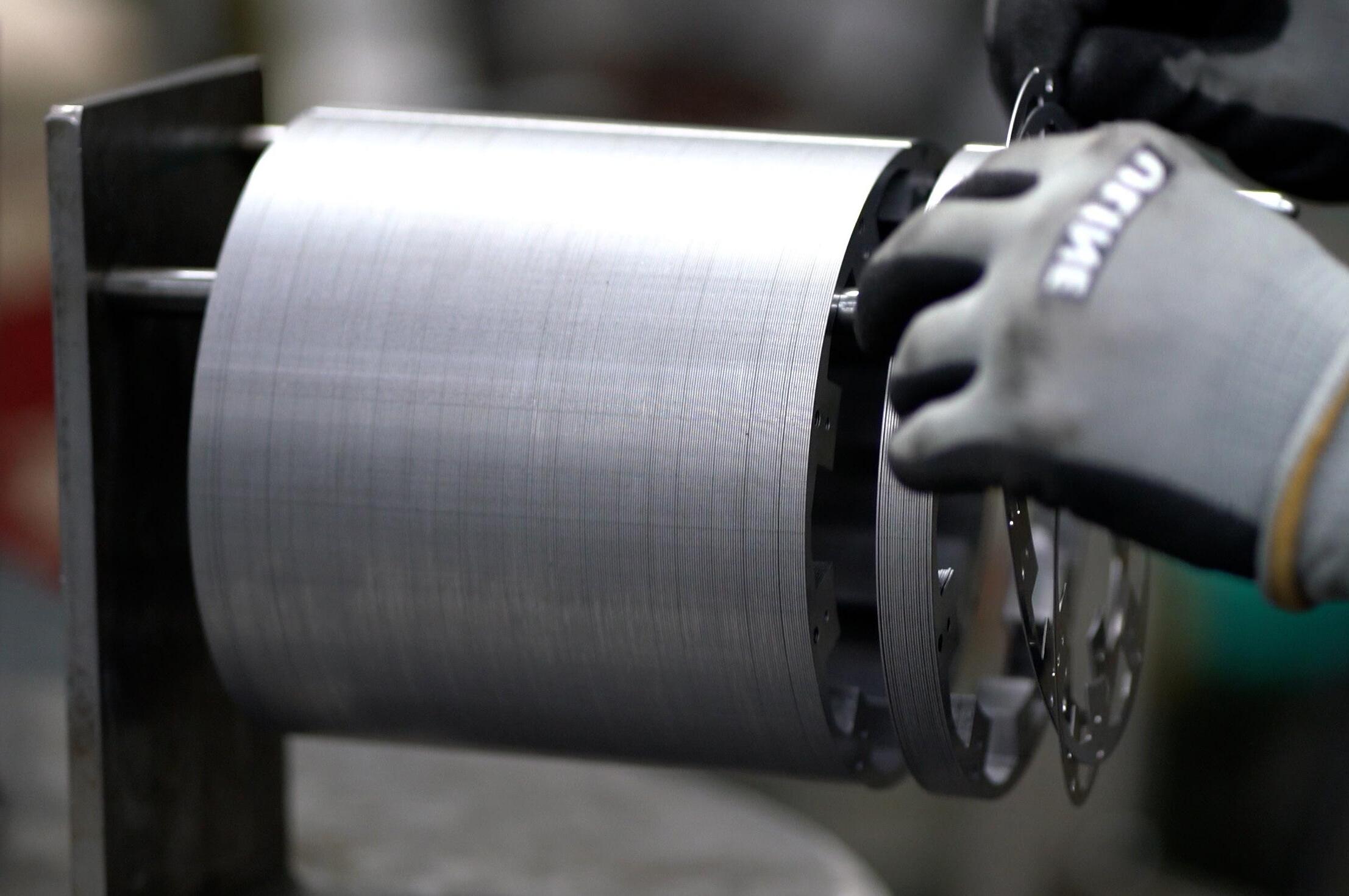

Essex Weld Solutions is a global company servicing customers across North America.

Our focus is the development and global supply of custom and standard automotive racking products. Essex Weld Solutions is a “Full Service Manufacturer” of custom automotive containers from bins to racks. We offer Designs, Prototypes, and high-volume production. This ensures superior quality control, something our customers expect and deserve.

LEARN MORE

FULL SERVICE CUSTOM RACK MANUFACTURER

Essex Weld Solutions began with a handful of customers and a production plant in Essex, Ontario. From the start, people were our strength. We have selected a team with a focus on integrity and trust, which is the foundation that we have built our reputation on. Keeping our customers’ needs at the center of every decision is what has led us to strive for excellence in everything we do. These values have been instilled in all our team members ensuring we all work together towards these goals.

Twenty years later, we have expanded to multiple locations across three countries. Our Canadian plants include Leamington and Essex, Ontario. We also have American plants in Laurens, South Carolina and Warren, Michigan as well as one plant in Durango, Mexico. All locations boast on-site engineering and full production capabilities so that we can provide in-house concepting, designing, prototyping, and large-scale production allowing us to be a one stop shop for our customers’ projects.

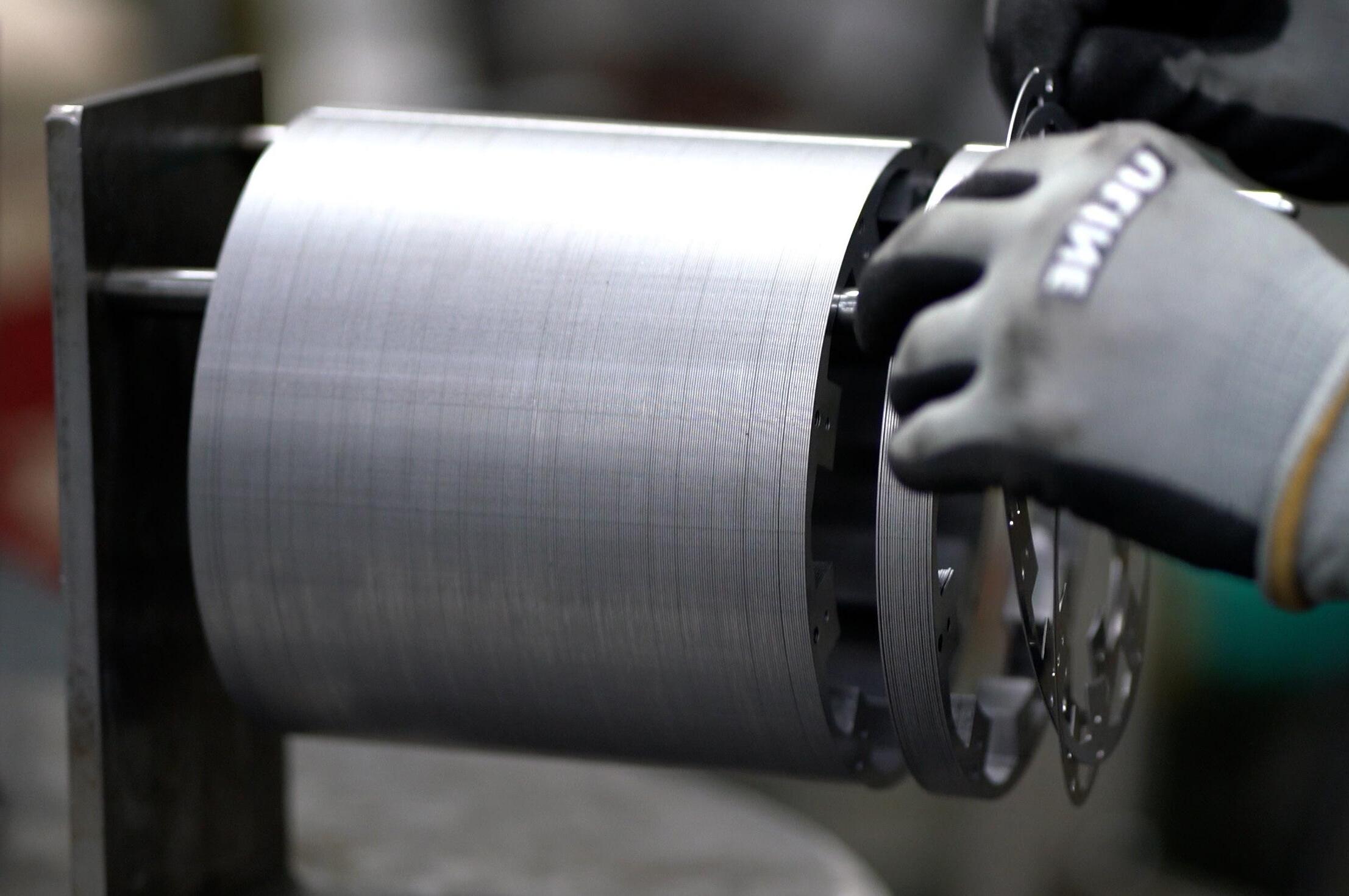

Over one-hundred years of combined experience has taught us that investing in the latest manufacturing technology is necessary to provide top quality products. Our plate and tube lasers, break presses, robotic welders, and full powder coat system allow us to maintain high standards across all locations. Our manufacturing process is monitored from concept to delivery using

our own ERP system, Edata+, with real time inventory levels, production status, and barcode tracking labels. This enables us to maintain inventory of common materials at all locations and efficiently control quality and delivery timing.

Our innovative approach to the everevolving world of manufacturing means we never stop improving the service we provide our customers. As manufacturing shifts to a greater integration of robotic production lines, we have developed a Metrology team that exclusively handles the precise quality control required for those projects. These continuous improvement efforts allow us to expand our capabilities so that we can better serve our existing customers, and reach out to new ones, as their needs change, especially as the shift to Electric Vehicles continues.

RIVIAN AUTOMOTIVE

The story behind sustainability Rivian entered the automotive industry at an interesting period. The company was very much undergoing its formation when major carmakers first started thinking about EVs, which, at the time, were seen as a ‘nice-to-have’.

With a passion for automotive and a desire to protect nature in all its glory, Rivian’s CEO, RJ Scaringe, set about building his dream: a vehicle with no limits and an adventurous edge that would allow drivers to explore harmlessly, reinvigorating their love for the environment.

The company first piqued interest with its two EV models. The R1T, its pickup truck model, and the R1S, which leverages the same great technology in an SUV body. In 2022, the company reached a major milestone with the announcement of it supplying electric delivery vans to Amazon—the initial quantity being 10,000, with potential for the e-commerce giant to expand this to 100,000.

Rivian cultivating a business on what was seemingly a blank canvas meant that the company worked through many challenges in its indirect procurement function to ensure that it remained true to its roots.

The solutions adopted by the company were pivotal. They allowed the team to focus on more hands-on tasks, alleviating the need for human input in the day-to-day processes.

“We had the opportunity to build an organisation that is truly best-in-class, from the ground up. We don't have to change any old behaviours; we can create new ones, and in the right manner, too. Balancing the two of those meant knowing

32 February 2023

what we needed to do daily versus what was required to build a foundation for the future.

“This was the biggest challenge, balancing the short-term and long-term needs. There are so many day-to-day requirements, but we must be able to balance the day-to-day work, while building the foundation of the organisation we desire to build.”

Another major challenge that wreaked havoc on all supply chains—and inevitably affected Rivian—was the COVID-19 pandemic, which meant navigating a remote-working environment while scaling and taking on new team members across the globe.

“We're fully operational, building three different vehicles with multiple different variations down in Normal, Illinois”

BRAD HOOD DIRECTOR OF INDIRECT PURCHASING, RIVIAN

manufacturingdigital.com 33

Intelligent tech needs ingenious humans

With data, automation, and AI, we help organizations transform and build value across the board. Explore how people and companies are reimagining supply chain networks at accenture.com Let there be change

These trying times meant the company had to adapt to onboarding and training the team online, without knowing when new starters would come into contact with their colleagues.

As a result of these challenges, the company adopted ‘category cards’ to create ease in the purchasing process. This is just one of the ways in which the company streamlines the onboarding process, automating indirect procurement processes to allow a smaller team to manage more purchases.

36 February 2023 RIVIAN AUTOMOTIVE

BRAD HOOD DIRECTOR OF INDIRECT PURCHASING, RIVIAN

“When you log in, you see the category, you select that category, and it gives you a brief description to tell you if you can buy it from a catalogue—so we can drive more spend to a catalogue—or it gives you a direction to reach out to a purchasing manager or supplier,” Hood explains.

“That way, we can touch more spend with a smaller team, increasing the addressability of the spend and continuing to educate the rest of the organisation to drive spend to our preferred buying channels.”

Further sourcing platforms used by the company provide further standardisation of indirect procurement processes. This includes supplier negotiation preparation, which can largely be templated—as Hood explains.

“If we are working on an e-sourcing event or an auction,

we can leverage these templates. “Automatically, a quantitative proposal comes in and we can analyse that based on our previous price paid, other proposals, market intelligence,” says Hood.

“We can look at that pretty quickly and find any outliers, identify where the best quantitative values are and work with our stakeholders as we incorporate the qualitative aspects. These tools really allow us to work faster.”

While businesses would often apply the term ‘digital transformation’ to their operations, it seems Rivian is beyond this, ensuring that technology is embedded into all processes from the earliest possible stage as part of its strategic approach to growth.

“It's a multi-generational purpose that goes beyond any one of us, which is what drives the overall culture at Rivian”

manufacturingdigital.com 37 RIVIAN AUTOMOTIVE

A Tour of the Rivian Plant | Go behind the scenes with founder RJ Scaringe

“It can standardise things and reduce errors but, for us, it allows us to actually promote and enrich the daily operations of those working in data-entry roles. They've now gone into more category management roles and supporting student sourcing, as well as those roles where we can marry technology and experience,” Hood explains.

Leveraging partnerships to integrate more technology

As the company looks to ramp up the production of EVs, technology will become an integral component in allowing the organisation to scale its operations and meet demand.

The company will continue to add value to its services sustainably, with

manufacturingdigital.com 39 RIVIAN AUTOMOTIVE

“We use the most sustainable products we can and try to be more sustainable with the materials of the vehicles”

40 February 2023 RIVIAN AUTOMOTIVE

BRAD HOOD DIRECTOR OF INDIRECT PURCHASING, RIVIAN

sourcing playing an integral role in reducing emissions down the supply chain. As the company expands its own charging network, technology will allow personnel more time to explore renewable energy sourcing, making sure that Rivian customers are charging up with clean energy.

Meeting its strategy for success hinges on its use of data in the procurement functions to standardise processes and focus on saving costs, time, and limiting negative

climate impact—with the overarching aim of eliminating it. As such, the procurement team will look at supplier spend and consider whether its dollars are going towards the desired suppliers.

While much of the technology adoption and integration is carried out in-house, Hood explains that technology partners will be leveraged by Rivian to meet demands unique to its processes.

Hood says: “We understand what we want to do in theory—on a whiteboard—but how do we integrate that into the actual software that’s more commonplace?”

In trying to answer this question, the company has been able to push technologies to their absolute limits, which is a benefit to Rivian, but also the partner that supplies that solution—making Rivian a testbed ripe for procurement solutions.

manufacturingdigital.com 41

ASPENTECH’S RON SUSTAINABLE MANUFACTURING

AspenTech’s Senior Director Ron Beck is working hard to draw in young professionals to the manufacturing sector & build sustainability within the company

WRITTEN BY: HELEN ADAMS

Today, a lot of young, talented professionals entering the workforce are ranking the purpose of the company they might work for as a strong element of their career selection process.

Ron Beck, Senior Director at AspenTech, is aware that for manufacturing companies, this translates into young workers understanding their company’s drive around sustainable manufacturing and sustainable products.

“Manufacturing commitments to zero carbon, circularity, and the digitalisation that enables them are proving to be a powerful driver in recruiting the next generation into jobs where they can make a difference,” says Beck.

AspenTech is a leader in asset optimisation software and assists industrial businesses in running their operations more safely. The company is also focused on smart manufacturing – especially in regards to the chemicals it uses,

42 February 2023

BECK ON MANUFACTURING & AI

manufacturingdigital.com 43 FACTORY OF THE FUTURE

A BizClik Event: Get tickets Sponsor opportunities 26-27 SEPTEMBER 2023 EXHIBITION & CONFERENCE – BUSINESS DESIGN CENTRE Watch our 2022 Showreel

minimising plastic waste and putting cloud data to effective use – one level of which is automation.

“Data is expensive – so how do you make intelligent use of it? AI helps us do that,” says Beck. “We have a long-term vision, a selfoptimising plant roadmap of how to use the least energy possible and save money.”

The company was founded in 1981 in Bedford, Massachusetts. Beck joined the company in 2007 as a Product Marketing Director. “We have very strong leadership in our company,” he says proudly.

Beck also volunteers with the Water Resources Advisory Committee. As Chairman, he works to protect groundwater and correctly manage stormwater and wastewater.

Moving manufacturing to Mexico

Many of AspenTech’s major customers have been struggling for the past two years with various types of supply chain disruptions. This has led companies to seek more agility and flexibility to adjust supply chains as economic and geopolitical factors change. A strategic component of this is much more pervasive digitalisation to provide such agility across the value chain.

“We are seeing the opportunity to help these global companies adopt digital solutions at a much more sophisticated and pervasive level, so they can support and achieve this agility,” says Beck. “Some of this is enabled simply by broader adoption of existing technologies. Some of this will happen through companies taking advantage of the integration and work flows we have built into the technology, but companies have been slow to adopt.

“MANUFACTURING COMMITMENTS TO ZERO CARBON ARE A POWERFUL DRIVER IN RECRUITING THE NEXT GENERATION, WHERE THEY CAN MAKE A DIFFERENCE”

manufacturingdigital.com 45 FACTORY OF THE FUTURE

RON BECK SENIOR DIRECTOR, ASPENTECH

Some will happen through innovative ways of solving staffing shortages through re-skilling, digital and online training methods, and organisational excellence.”

AspenTech continues to maintain a substantial team conducting software testing and related work in its Shanghai location, where the company gave out food baskets to their employees during the lockdown. The company also has another office location in Beijing.

Over the past five-plus years, AspenTech has progressively expanded and added staff to its relatively new team in Mexico City.

“Success has spawned success,” says Beck. “We have found that there is a strong talent pool of the right kind of motivated and creative technical people in the Mexico City area that meet the profile of the R&D, support and other skilled resources we have been adding over the past few years

to support the company’s innovation in areas core to our company mission –in particular with respect to the use of digitalisation in support of operational excellence and sustainability.”

Partnership with Emerson for expansive manufacturing

Last year, AspenTech teamed up with industrial machinery manufacturing company Emerson, which bought 55% of AspenTech. Beck believes that the key to their work has been the strong synergies that have blossomed from their partnership, already beginning to bear fruit, as well as the almost completely complementary nature of the offerings of the two companies.

“One key synergy area is in the area of electrification,” says Beck. “As the oil and gas, chemical, and mining industries work

46 February 2023 FACTORY OF THE FUTURE

RON BECK SENIOR DIRECTOR, ASPENTECH

to electrify their most energy-intensive processes while simultaneously integrating renewables into their sites and business portfolios, the synergies of the renewables’ automation and sensor strengths of Emerson alongside the energy optimisation and digital grid management strengths

of AspenTech will be increasingly important.”

A second key synergy area is in carbon capture and storage – another element of research for young, talented professionals who are job-hunting in the manufacturing sector.

“CCS projects are end-to-end projects, from carbon source to carbon capture, from transport to subsurface geological formation storage to long-term monitoring,” says Beck. “Effective execution, scaling and economics of the projects will take full advantage of the capabilities of AspenTech to provide design, optimisation and monitoring software. Emerson will provide the automation and monitoring systems and programme execution.”

“WE HAVE FOUND THAT THERE IS A STRONG TALENT POOL OF THE RIGHT KIND OF MOTIVATED AND CREATIVE TECHNICAL PEOPLE IN THE MEXICO CITY AREA”

manufacturingdigital.com 47 FACTORY OF THE FUTURE

RON BECK SENIOR DIRECTOR, ASPENTECH

48 February 2023

“EFFECTIVE EXECUTION, SCALING, AND ECONOMICS OF PROJECTS WILL TAKE FULL ADVANTAGE OF THE CAPABILITIES OF ASPENTECH AND EMERSON”

In addition to this, AspenTech is currently seeing considerable adoption of a timely solution comprising multiple AspenTech tools together: a carbon emissions decision-support solution.

“This is a high-value solution positioning, comprising multiple existing AspenTech products implemented together for customers looking for actionable insight around their carbon emissions landscape,” explains Beck. “This decision-support solution empowers a company to get an actionable, birds-eye view of their carbon emissions through the mobilisation of underlying data and models. Companies today are challenged in understanding their carbon emissions across all their assets – as well as in detail within assets – in a timely, accurate enough manner to enable better operating decisions to reduce carbon emissions day-to-day.”

This new solution can and does achieve that. Up until today, companies have been using spreadsheet-based approaches that are manual, lack transparency and slow to compile. AspenTech has innovated an approach that will provide the same ultimate answer to regulators, but in a real-time manner that enables agile decision making at each asset, and with units within an asset.

“Companies will be able to report accurately and auditably but, more than that, have insight into the performance of their enterprise, with decision support to predict future performance and look at scenarios that will optimise their operations between sustainability, profit, delivery to customers, and safety.”

AspenTech is starting the ground work now to be a more competitive business partner – and employer – in the future.

manufacturingdigital.com 49 FACTORY OF THE FUTURE

HEALTHY WORLD HEALTHY DATA CREATES A BETTER WORLD

50 February 2023

PRODUCED BY: KRISTOFER PALMER

PRODUCED BY: KRISTOFER PALMER

manufacturingdigital.com 51 BOEHRINGER INGELHEIM

WRITTEN BY: GEORGE HOPKIN

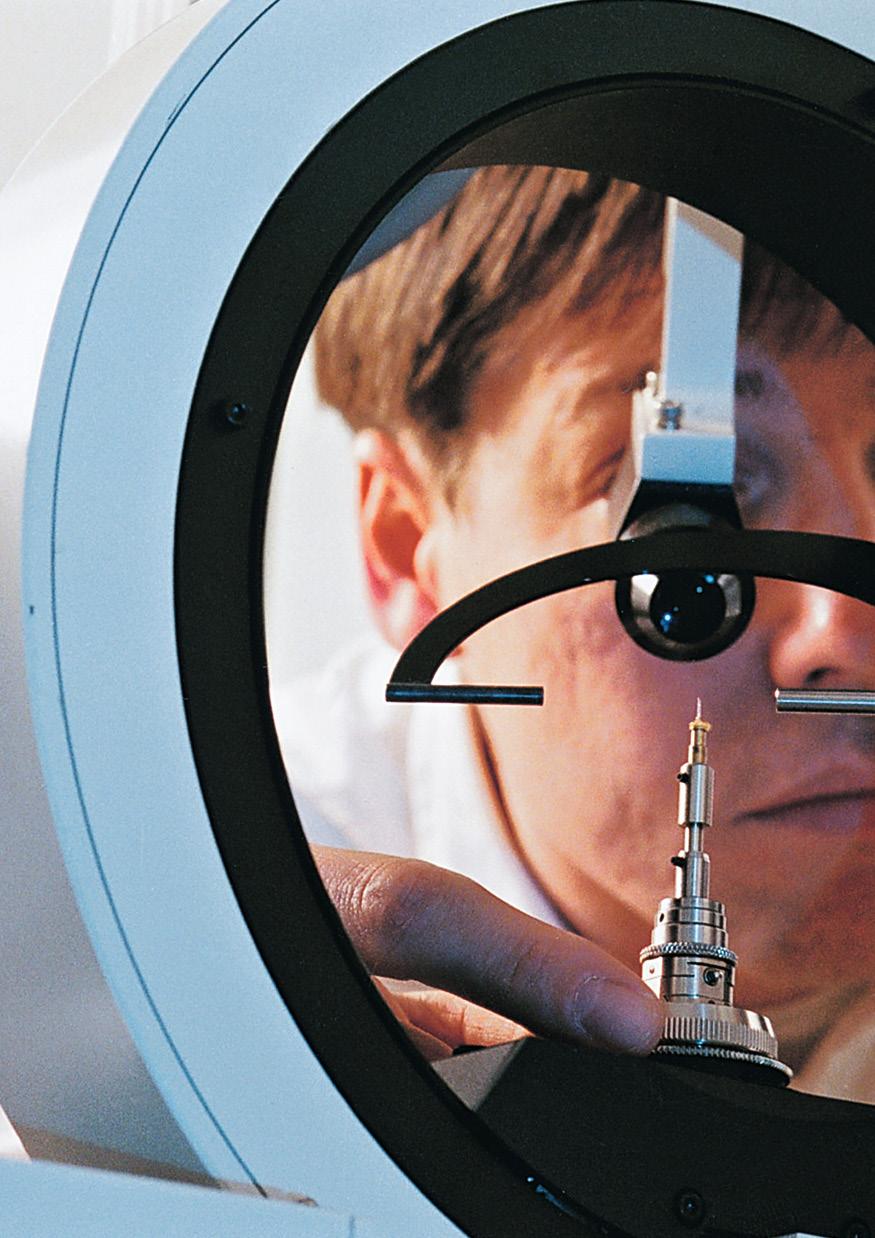

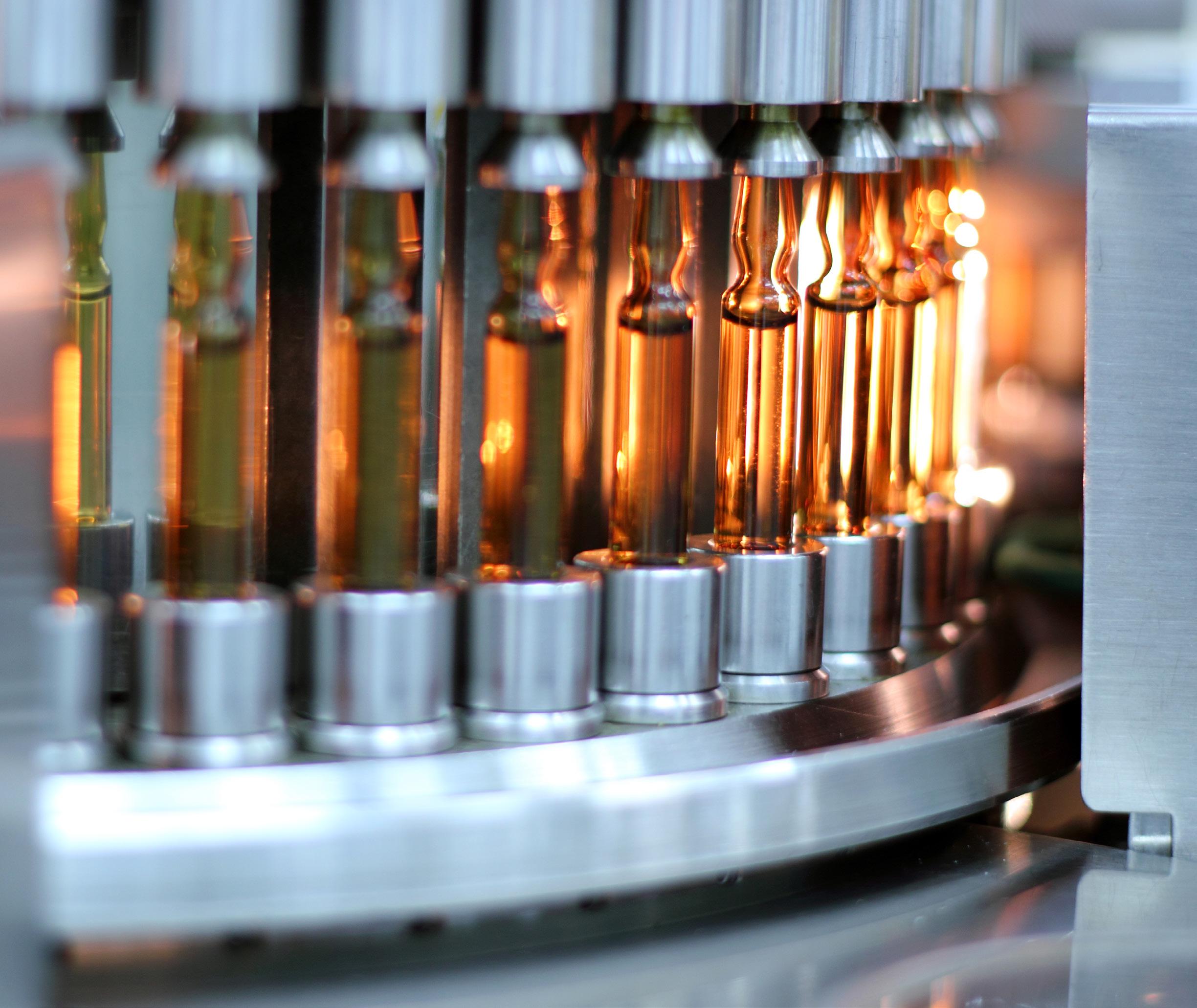

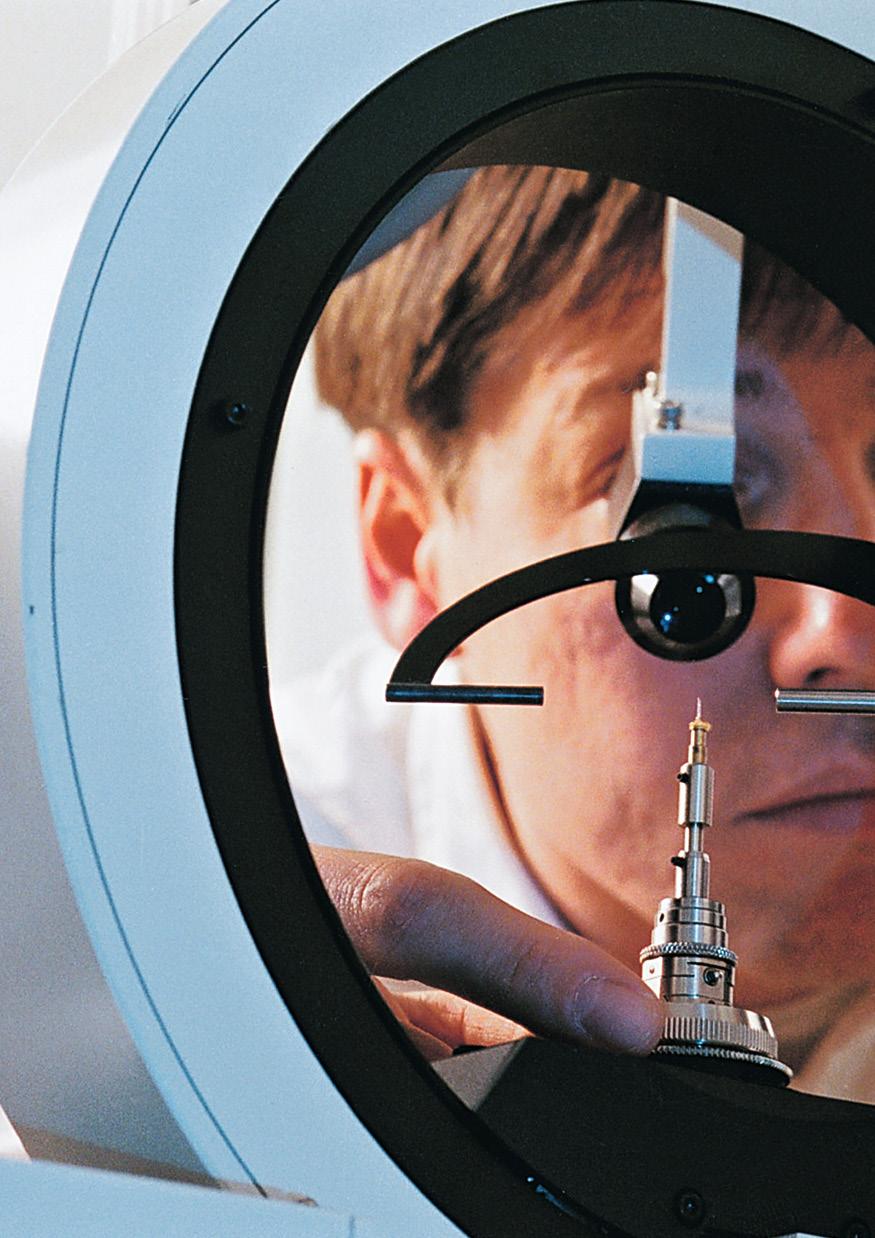

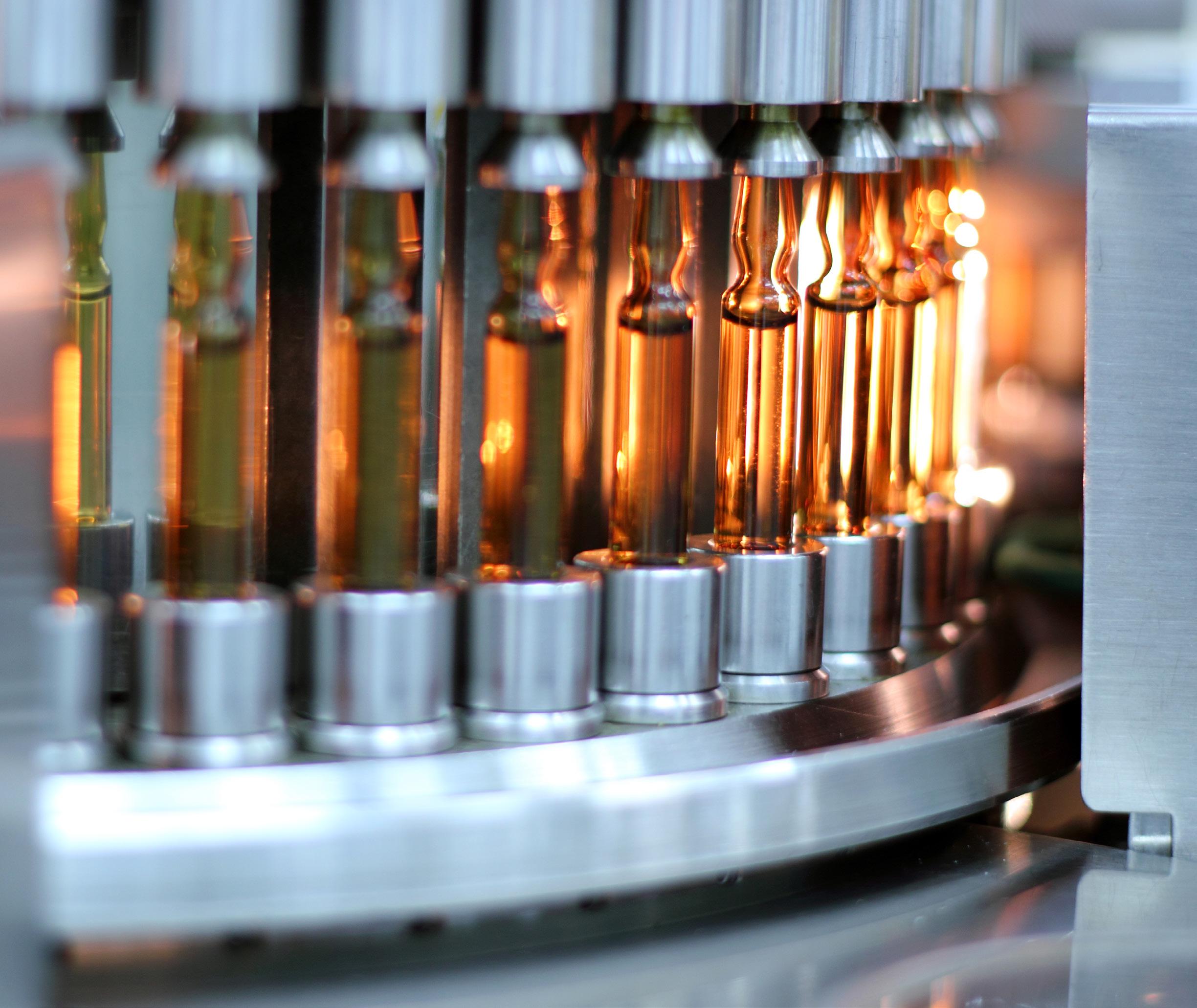

Boehringer Ingelheim’s Head of Data Management, Bruno Rizzuti, explains how Big Pharma builds a better world with tech innovation throughout the enterprise

Humanity faces serious challenges in 2022: climate change threatens the planet; global health crises have exposed vulnerabilities in society; communities are being marginalised; and demographic trends are creating new pressures on healthcare worldwide. To meet these challenges, pioneering familyowned Boehringer Ingelheim is working on breakthrough therapies with the hope of transforming lives.

First established in Germany in 1885 and now one of the top 20 pharmaceutical companies in the world, Boehringer Ingelheim specialises in areas of unmet medical need in three business areas: Human Pharma, Animal Health, and Biopharmaceutical Contract Manufacturing.

Boehringer Ingelheim strives to develop improved therapies, healthcare products and services to ensure we all live in a better world. The company has plans to increase the scope of its social and environmental ambitions, aiming to explore what more can be done to contribute to a sustainable world and a healthier future.

The company attributes its success to scientific innovation, including investments in sustainable healthcare and technology to accelerate industry improvements.

Boehringer Ingelheim is currently pursuing more than 390 research collaborations in the

52 February 2023 BOEHRINGER INGELHEIM

CAPGEMINI HELPS BOEHRINGER INGELHEIM TOWARDS DATA-DRIVEN DECISIONS

The Dataland program was initiated to create the end-2-end data ecosystem that powers Boehringer Ingelheim's needs for data-driven decisions and to enable the use cases that drive innovation and efficiencies now and in the years to come. Capgemini supported Boehringer on their journey to the AWS cloud and in the implementation of use cases across all business domains.

Learn more

CAPGEMINI HELPS BOEHRINGER INGELHEIM IN A WORLD OF DATA

Ruth Lütticken, Director of Life Sciences, Data Science & AI, Capgemini, explains how data management is helping Boehringer Ingelheim to transform lives

Pioneering family-owned Boehringer Ingelheim is making use of cutting-edge data management services provided by Capgemini in its work on breakthrough therapies.

Boehringer Ingelheim specialises in areas of unmet medical need in Human Pharma, Animal Health, and Biopharmaceutical Contract Manufacturing. As part of its Dataland program, Boehringer Ingelheim invests in data-related initiatives to strengthen its foothold in the digital world. Leveraging data has the potential to transform drug development and the patient experience. Several units within the organisation were already successfully working with data, but Boehringer Ingelheim wanted to scale its usage across the entire company. This ambition required a strong technology foundation and modern infrastructure, as well as clear processes and responsibilities in the area of data governance.

“It is a cloud-based ecosystem that we’re building for our data needs not just for today but the years to come in the future,” explains Boehringer Ingelheim’s Head of Data Management, Bruno Rizzuti. “This project is designed to create a trusted environment not only for our regular use cases but also for those that require more, let’s say, flexibility and the capabilities that the technology in the cloud can provide.”

“There are many exciting use cases for data and human pharma,” says Ruth Lütticken, Director of Life Sciences, Data Science & AI, Capgemini. “I think since Covid 19, everybody knows how important that step is in developing new tracks.

Here the change was for the global feasibility managers at the country level to select a certain trial site for a certain trial phase.

So many factors and data will have to be considered, and this gives them a predictive modelling solution which is using internal but also external data to allow them to have data-driven site identification, which means they can reduce the time for the trial.” Learn

more

life sciences' community – representing more than 50% of its pipeline projects – and the company’s animal health business is now the second largest in the world, with more than 200 products for dogs, cats, horses, pigs, cattle and poultry.

To add to this, Boehringer Ingelheim is also investing €35bn in health innovation to tackle non-communicable diseases, as well as an additional €250mn in partnerships to combat emerging infectious diseases. Through its flagship initiative Making More Health, it has partnered with Ashoka, the largest global network of social entrepreneurs. To mitigate the environmental impact of its growing business, Boehringer Ingelheim has

committed to becoming carbon neutral in its operations and halving its resource footprint by 2030.

Driving innovation across the enterprise with advanced technologies

Boehringer Ingelheim is driving innovation across the enterprise and has focused on advanced technologies to discover new ways of introducing technology to core business processes. Big Data and analytics powered by AI allows the company to build new models and predictive tools that can have far-reaching impact on production processes, improving the quality, connectivity and availability of patient solutions.

“WE WORK TO MAKE HUMANITY BETTER, RIGHT? TO MAKE THE LIVES OF PEOPLE AND ANIMALS BETTER EVERY DAY”

Boehringer Ingelheim

56 February 2023 BOEHRINGER INGELHEIM

BRUNO RIZZUTI HEAD OF DATA MANAGEMENT, BOEHRINGER INGELHEIM

Bruno Rizzuti joined Boehringer Ingelheim in 2014 and took up his role as Head of Data Management in 2020. "I moved into the pharmaceutical industry when I was very young," says Rizzuti. "I had been working as a consultant on analytical processing systems, working with many clients in the pharma industry – which is how I got to know the industry so well – and then moved to Boehringer Ingelheim."

Inclusiveness in the industry has been a draw for Rizzuti, being one of the main reasons he joined the industry. “Big Pharma companies listen to their employees, as well – this is something you can immediately tell when you join a pharma company,” says Rizzuti. “Whether at Boehringer Ingelheim or another company, the standard in the industry is that the employee's voice is heard, based on the notion that this is important because happy people give better results."

Innovation is another attractive, industrywide aspect of the profession, according to Rizzuti. "You cannot survive in pharma if you don't innovate. You must innovate in new treatments and in new therapeutic areas. This is an industry that has innovation at its essence. And that also makes it a wonderful place to grow; you always have new challenges."

BRUNO RIZZUTI

TITLE: HEAD OF DATA MANAGEMENT

INDUSTRY: PHARMACEUTICAL

MANUFACTURING

LOCATION: BARCELONA, SPAIN

Bruno Rizzuti is currently the Head of Data Management & Data Engineering at BoehringerIngelheim with an extra passion about working culture, data-driven mindsets and technology scouting. His studies include Data Engineering, Data Science, Project Management and a little bit of Economics. In his free time, he exercises, studies technology, reads and plays videogames.

With over a decade of experience in Data & Analytics in the Big Pharma Industry and viscerally passionate about technology, he has his focus every day in what he considers the two most valuable assets of any organisation: People and Data.

52,000

Global workforce

130 Markets served by Boehringer Ingelheim

EXECUTIVE BIO

BOEHRINGER INGELHEIM

Migrating to the cloud is a journey and a huge paradigm shift

One of the biggest tech-related challenges facing the industry today is migrating to the cloud, not only from a technology perspective but also from a cultural perspective, says Rizzuti.

"When you embark on a journey to build an ecosystem and a data analytics platform that will serve you for the next five to 10 years, that’s a huge paradigm shift in comparison to how we've been doing things in analytics since the 80s and 90s."

The industry needs the kind of mindset changes that have already been introduced by data-driven professionals. “But you can't expect everybody in every position to have that mindset. One of the biggest changes that we're seeing nowadays is that it used to be enough for IT people to be on top of technology. Now, you need everybody on board to make such a change. And that requires an educational and cultural component in our IT roles.”

Rizzuti plays a key role in the area of data ingestion, which includes crucial data governance issues that should be incorporated into business planning at all stages.

“YOU CANNOT SURVIVE IN PHARMA IF YOU DON'T INNOVATE; YOU MUST INNOVATE IN NEW THERAPEUTIC AREAS”

manufacturingdigital.com 59 BOEHRINGER INGELHEIM

BRUNO RIZZUTI HEAD OF DATA MANAGEMENT, BOEHRINGER INGELHEIM

"Who will consume this data, for what purpose, and for how long? What are the different usages of this data? Having that in mind beforehand is key,” he explains. “Sometimes, people will jump into action without having a clear definition of who the data owner is, what the usage of this data will be, and what is the intended purpose – but all of that information is needed to provide the best tools to make the best of it. Otherwise, you end up having a 'data swamp' instead of a 'data lake', which eventually replicates errors from the past."

Global product teams work to uncover ideas and solutions

Boehringer Ingelheim has a workforce of more than 52,000 employees serving over 130 markets. In Germany, the company's New Therapeutic Concepts team in Biberach is introducing data and analytic tools to the early-stage drug discovery process. By working with some of the early findings and connecting those across projects, Boehringer Ingelheim can identify patterns that have the capacity to help multiple product teams uncover ideas and solutions that speed up the development process.

BOEHRINGER INGELHEIM

“THIS IS AN INDUSTRY THAT HAS INNOVATION AT ITS ESSENCE. AND THAT ALSO MAKES IT A WONDERFUL PLACE TO GROW”

60 February 2023

BRUNO RIZZUTI HEAD OF DATA MANAGEMENT, BOEHRINGER INGELHEIM

In Ingelheim, the company's Farmer team works with devices, data collection and systematic analytics to identify and isolate early signs of health problems that risk spreading through animal herds. The underlying data generated will simultaneously help identify inefficiencies that impact yields and farm productivity.

Meanwhile, the Mobinostics team is working with vets to develop mobile diagnostic and treatment solutions that allow greater reach and greater speedto-treatment for remote farms all over the world.

Ingelheim is also home to the company's BRASS (Benefit Risk Assessment System) project, which uses AI to conduct an initial analysis of adverse reactions to medications that have already been approved –identifying potential side effects and undesirable events – and offer a valuable decision-making tool for those working in pharmacovigilance, helping them process each case more quickly.

In Vienna, Austria, Boehringer Ingelheim's Smart Process Design team is leveraging the power of data to strengthen yields in previously unpredictable biopharma manufacturing.

manufacturingdigital.com 61

62 February 2023

Also in Vienna, the Biomarker-Based Patient Population project empowers experts within the company to identify biomarkers to better characterise patient populations for clinical studies. Being able to process and analyse large amounts of data creates the potential to select the right drug for a patient.

Based in Buenos Aires, Argentina, PetPro is one of the company's first digital products that directly addresses end users’ needs. PetPro Connect has been developed in close collaboration with the company's Animal Health business to connect pet owners and veterinarians, organise follow-up appointments via video chat, quickly and easily order medication refills, and benefit from bonus programmes.

Over in Spain, the company's Pathological Speech Processing team – based in Sant Cugat del Vallés, Barcelona – develops digital tools that facilitate the process of speech and language processing (SLP) by using machine learning and disease-customised algorithms. This will be used to analyse speech and language patterns, which can consequently be analysed to predict the development of mental diseases, such as the risk of dementia.

More Health, More Potential and More Green at Boehringer Ingelheim

Boehringer Ingelheim has defined three areas: More Health, More Potential and More Green – which are at the heart of a framework the

company calls Sustainable Development For Generations. The framework incorporates established initiatives, building these into more ambitious goals to increase the company’s impact on health, society and the planet. In doing so, Boehringer Ingelheim generates greater long-term economic and social value for stakeholders, the communities they serve and employees.

Through these focus areas, Boehringer Ingelheim can contribute to the creation of solutions for global challenges and help enable sustainable change. The impact in each area reflects its core business and aligns with the United Nations’ Sustainable Development Goals (SDGs). Sustainable development goes hand-in-hand with the company’s planning principles of taking responsibility for communities and the environment.

Big Pharma has big aims and ambitions, providing a daily incentive for everyone working in the industry at every level. "We work to make humanity better, right?" asks Rizzuti. "To make the lives of people and animals better every day. That's a difficult model to reject. It's definitely something that immediately gives you a sense of purpose when you're working in such an industry. It's a life science; it's all about taking care of people, taking care of animals.”

“IT USED TO BE ENOUGH FOR IT PEOPLE TO BE ON TOP OF TECHNOLOGY. NOW, YOU NEED EVERYBODY ON BOARD”

manufacturingdigital.com 63 BOEHRINGER INGELHEIM

BRUNO RIZZUTI HEAD OF DATA MANAGEMENT, BOEHRINGER INGELHEIM

JOHN SHIER, JOHN SHIER, SENIOR SECURITY ADVISOR AT SOPHOS, ON

John Shier is the Senior Security Advisor at Sophos. Here, he discusses ransomware and the results of Sophos’ ‘State of Ransomware in Manufacturing’ report

WRITTEN BY: HELEN ADAMS

WRITTEN BY: HELEN ADAMS

64 February 2023

Since the COVID-19 pandemic, pets video-bombing online meetings have amassed millions of views. As such, when I meet John Shier on a video call, he’s not alone. “This is a little French bulldog that we're dog-sitting, and every once in a while he gets a little excited!”

Dog-sitting in Toronto is not Shier’s full time occupation – he is a Senior Security Advisor and Senior Research Scientist at software development company Sophos.

“I'm usually a Senior Security Advisor for the press, but what that really means is I work in the office of the Chief Technology Officer as a liaison as well as those of all the different research groups within the organisation,” Shier explains. “We have our Sophos labs that do threat research, our Sophos AI team, an anti-exploit team, and our MDR group, which generates intelligence through the activities that they do monitoring our customers' environments. A subset of that is the Rapid Response Group, which is our Incident Response Investigation Group.”

Shier takes all of that information, synthesises it and then contextualises it within the security industry. “I look at what we are seeing as a broader industry; how does that fit and how does security itself fit within it? The idea is to be able to hopefully provide advice on how to better protect individuals and companies, as we're all trying to navigate this crazy digital world.”

manufacturingdigital.com 65 DIGITAL MANUFACTURING

Get reliable network coverage and security protection, fast.

A modern network must be able to respond easily, quickly and flexibly to the growing needs of today’s digital business. Must provide visibility & control of applications, users and devices on and off the network and Intelligently direct traffic across the WAN. Be scalable and automate the process to provide new innovative services. Support IoT devices and utilize state-of-the-art technologies such as real-time analytics, ML and AI. And all these must be provided with maximum security and minimum cost.

This is the power that brings the integration of two cloud managed platforms, Cisco Meraki and Cisco Umbrella. This integration is binding together the best of breed in cloud-managed networking and Security. cisco.com

cisco CiscoSecure CiscoSecure

Sophos is a global leader and innovator of advanced cybersecurity solutions, which includes managed detection and response as well as incident response services. The company has a broad portfolio of endpoint, network, email and cloud security technologies that enable companies to better protect themselves and defeat cyber attacks.

Threats behind manufacturing cyber attacks

The difference between a cyber attack and a ransomware attack is simple: information gained in a ransomware attack is kept from the public and offered back to the victim for a price, whereas in a cyberattack, there is no offer of negotiation. But who are the people committing these attacks – pariah states or a lone wolf with a grudge or financial incentive to wreak havoc?

“IF A LARGE MANUFACTURER LIKE THAT GOES DOWN FOR ANY LENGTH OF TIME, THEN IT HAS THESE RIPPLE EFFECTS THROUGH THE SUPPLY CHAIN”

“IF A LARGE MANUFACTURER LIKE THAT GOES DOWN FOR ANY LENGTH OF TIME, THEN IT HAS THESE RIPPLE EFFECTS THROUGH THE SUPPLY CHAIN”

manufacturingdigital.com 67 DIGITAL MANUFACTURING

JOHN SHIER SENIOR SECURITY ADVISOR, SOPHOS

In Sophos's ‘State of Ransomware in Manufacturing’ report, they asked 5,600 respondents across 31 countries

68 February 2023

“I would say that it's fairly rare to have nation states behind ransomware attacks that are for profit,” says Shier. “Nation states are generally after information, they're not really in it to make money; they're gathering intelligence, state secrets, intellectual property and information about activists.”

Metal manufacturer Aurubis was hit by a cyberattack last year. “They believe it’s a part of a broader attack against the manufacturing sector – and this has impacted some of their IT systems,” he says.

But Shier saw one silver lining: based on the company's reporting, the Environmental Protection side of the business was only minimally impacted. “They were still able to ingest materials and ship materials. If a large manufacturer like that goes down for any length of time, then it has these ripple effects through the supply chain.”

Aurubis is the EU’s largest supplier of copper, so a delay in their production could have a fairly large domino effect on the manufacturing sector.

“Ransomware is a financially motivated crime, with individuals who are a part of an affiliate network.” In such cases, affiliate networks are the creators of the ransomware that provide the actual software doing the encrypting. They also provide other services like payment and negotiation services, as well as dashboards for victim management.

“There's another tool called X matter, which is also a data stealing tool that is being used by several different groups,” explains Shier. “It could be a single person that's part of this affiliate programme or it could be a bunch of people. You can also be part of more than one such programme. There's a whole bunch of these ransomware groups; as a group or an individual, you can participate in many

of these schemes. Generally, they take anywhere from 10-20%, then the affiliates themselves get the rest of the profit.”

Sophos's ‘State of Ransomware in Manufacturing’ report

Every year, Sophos conducts a global survey about the IT and security industry.

“We asked 5,600 respondents across 31 countries about what they wanted to find out more about. The answer was ransomware, the one threat that just refuses to go away.”

Sophos found that 55% of companies in manufacturing were hit in the reporting year of 2021, versus a global average of 66%.

“That's good in relative terms, because they're below the global average, but over half of the sector is getting hit and attacks appear to be increasing.”

Sophos also asked whether those who were hit by ransomware attacks paid the ransom or not and how much they paid. 33% paid, versus a global average of 46%.

“RANSOMWARE IS THE ONE THREAT THAT JUST REFUSES TO GO AWAY”

“RANSOMWARE IS THE ONE THREAT THAT JUST REFUSES TO GO AWAY”

DIGITAL MANUFACTURING manufacturingdigital.com 69

JOHN SHIER SENIOR SECURITY ADVISOR, SOPHOS

JOHN SHIER SENIOR SECURITY ADVISOR, SOPHOS

“This is not an indictment or criticism of the companies themselves, but this means that 33% of those companies are directly funding criminals. Sometimes, you just have to because it's incumbent on the survival of your business, so we fully understand that.”

A lot of this has to do with whether the company has reliable backups or cyber insurance.

Overall, Shier failed to find the results surprising.

“The problem I have as a jaded security guy that's been in this industry a little too long is that some of this stuff was not shocking to me. If you have a vulnerable service or exposed system, you will be found out by cyber criminals.”

For Shier, the results confirmed what he already knew – everybody is a target.

“THE IDEA IS TO BE ABLE TO PROTECT INDIVIDUALS AND COMPANIES, AS WE ALL NAVIGATE THIS CRAZY DIGITAL WORLD”

“THE IDEA IS TO BE ABLE TO PROTECT INDIVIDUALS AND COMPANIES, AS WE ALL NAVIGATE THIS CRAZY DIGITAL WORLD”

70 February 2023 DIGITAL MANUFACTURING

manufacturingdigital.com 71

A modern procurement platform for today’s business

manufacturingdigital.com 73

PRODUCED BY: MIKE SADR

IQUANTUM

WRITTEN BY: ILKHAN OZSEVIM

iQuantum is a global technology platform that uses AI & ML to enable innovation and procurement focusing on supplier diversity and ESG

Hetal Mehta is the founder and CEO of iQuantum Inc., a modular, modern procurement platform. As the leader of iQuantum’s woman and minority owned business, Hetal works closely with all internal teams, customers, partners, and the iQuantum Advisory Board of industry champions and practitioners.

Hetal Mehta’s journey into the industry

For many years, Mehta worked as a developer and consultant to procurement teams. Through that experience she recognised the need for a more sophisticated and user-friendly procurement solution, “one that does all the efficient and effective consolidations, automation and workflows – but also helps guide alignment between buying decisions and larger strategic corporate goals like increased diversity,” she says.

“My in-depth experience and understanding of supplier diversity led me to realise that customers struggle with finding appropriate suppliers and are prone to continuing business with existing ones – even if that is not ideal.

“With iQuantum our goal is to leverage machine learning and AI to provide a modern procurement platform with access to the largest global supplier database that includes diverse and sustainable supplier options. This helps customers build a more resilient and robust supply chain.”

iQuantum’s unique selling point

iQuantum Inc. is a modern Source-to-Pay platform designed to meet today’s procurement needs for Supplier Relationship Management, Diversity and ESG Sustainability tracking and reporting. They provide the tools and transparency to align spend decisions to strategic corporate goals.

74 February 2023

IQUANTUM

manufacturingdigital.com 75

HETAL MEHTA CHIEF EXECUTIVE OFFICER, IQUANTUM

Mehta says: “There is no single provider on the market who competes with us pinto-pin.” iQuantum is the only SaaS platform to provide:

• Complete Supplier discovery to Pay on one platform WITH modern ESG and full diverse supplier management.

• New supplier discovery from a database of millions of global suppliers to increase supply chain resilience and support new product introduction (NPI) sourcing

• Integrated supplier communication and collaboration with in-built Chat and conversation storage for future reference and context

• Modern approach to complete strategic sourcing for indirect, direct and new product introduction with internal team collaboration

• Rich contracts, procurement, and spend management analytics

• Integrated Tier 1 & Tier 2 Diversity and ESG Sustainability reporting and benchmarks

76 February 2023

“Prioritising diversity in your employees and your supplier base as a part of ESG is integral to the growth and future trajectory of the company – employees, leadership, investors, stakeholders, and customers seek brands that are improving their profiles”

• Government and Customer reporting along with Subject Matter Expertise by fine-tuning their diverse spend tracking and achieve the elite Billion Dollar Roundtable or BDR

• Diverse and small supplier visibility to iQuantum’s Fortune 500 customer base, including support for supplier marketing of their products and catalogues

• Modular licensing approach and enterprise interoperability to accommodate each customer’s needs, budgets, and existing system investments

• Single code base for quick implementation, easy maintenance, and simple configuration with a sophisticated, userfriendly user experience

• Access to global database of suppliers including diverse/non-diverse and green suppliers for procurement to add to supply chain and achieve savings

• Better alignment, reduced risk, and increased compliance across procurement, finance, and corporate legal

HETAL MEHTA

TITLE: CHIEF EXECUTIVE OFFICER

LOCATION: IQUANTUM

Hetal holds a BS in Electrical Engineering, and, prior to founding iQuantum, she logged more than 15 years of IT consulting experience with financial firms on Wall Street. Her technical background combined with her sharp domain expertise has been instrumental in building iQuantum; engaging industry-leading customers, attracting and mentoring top engineering talent, and delivering top-class business results, she has driven iQuantum’s growth over the years. Hetal Mehta has been recipient of Steve Awards and Women of the

IQUANTUM

HETAL MEHTA CHIEF EXECUTIVE OFFICER, IQUANTUM

The importance of diversity in procurement and supply chain and the role of iQuantum McKinsey reported that working with diverse suppliers leads to an 8.5% in cost savings, which is more than the 3 - 7 % savings most procurement organisations realise.

“Prioritising diversity in your employees and your supplier base as a part of ESG is integral to the growth and future trajectory of the company – employees, leadership, investors, stakeholders, and customers seek brands that are improving their profiles,” says Mehta.

Qualified diverse suppliers bring savings and better service to customers. Procurement leaders have recognised this, and are looking at ways to increase their diverse supplier base (increasingly Tier 1 and Tier 2 diversity reporting is becoming a mandate across different industry verticals).

78 February 2023 IQUANTUM

“Every purchase made needs to be aligned to strategic corporate goals and help to move the needle. Increased government regulation and consumer scrutiny of corporate brand spending has increased the need for a new procurement approach”

She says: “We see these two tiers in Manufacturing, and in Law firms it typically comes from customers setting goals to win RFPs, while for the Healthcare and Pharmaceutical industry the stimulus comes from the government and encourages organisations to negotiate diversity goals and to report them annually.”

iQuantum’s automated customer and government reporting solution is helping customers achieve this. “This automation,” says Mehta, “and our in-depth subject matter expertise in exclusion criteria rules, is also helping customers achieve their goals and get on to the prestigious Billion Dollar Roundtable BDR. Our global database of suppliers allows customers to source from new diverse suppliers to meet their goals.”

How iQuantum tackles modern business challenges

Businesses today need help driving alignment across divisions and teams. Core brand values and strategic goals need to be surfaced in all corporate decisions – but most importantly in spend decisions. Mehta says: “There is a critical need to meet the diversity spend and ESG sustainability goals being set by leadership and closely tracked by government regulators and investors.

“Our customers like to work with us due to our commitment to customer success, our responsiveness to customer needs and our budget-friendly pricing.” This approach relates to the findings in the McKinsey report concerning better savings and an enhanced overall experience when working with diverse suppliers.

manufacturingdigital.com 79

iQuantum: A modern procurement platform for today’s business

Supporting women-owned businesses

iQuantum has subject matter experts to partner with diverse businesses (women, minority, veteran, disabled, LGBT) around the globe to provide guidance on the certification options and process; enriching their supplier profiles to maximise their reach and relevance to upcoming RFQs (Request For Quotes) RFPs (Request For Proposals) and RFIs (Request For Information), or Direct Material Sourcing.

Mehta says: “We also assist certified businesses in getting catalogue-ready, to simplify enterprise purchasing of their products. Our regular supplier outreach, newsletter supplier spotlights and social media channels promote and support women, minority, and other certified businesses. It’s part of our mission and our DNA.”

Adapting to procurement developments

Procurement needs today have changed. They need a platform which addresses

McKinsey reported that working with diverse suppliers leads to an 8.5% in cost savings, which is more than the 3-7% savings most procurement organisations realise.

80 February 2023

IQUANTUM

HETAL MEHTA CHIEF EXECUTIVE OFFICER, IQUANTUM

today’s modern challenges of Diversity and ESG Sustainability tracking. “Every purchase made needs to be aligned to strategic corporate goals and help to move the needle,” Mehta says.

“Increased government regulation and consumer scrutiny of corporate brand spending has increased the need for a new procurement approach.”

“Customers benefit from our “Only Buy What You Need” approach which helps them avoid paying for unused functionality. Our rapid onboarding makes the user experience better and decreases the time to ROI.”

“If you are looking for a modern modular procurement platform to meet today’s procurement needs, iQuantum is the solution.”

manufacturingdigital.com 81 IQUANTUM

“Our customers like to work with us due to our commitment to customer success, our responsiveness to customer needs and our budgetfriendly pricing”

Quantum’s Strategy

iQuantum’s Strategy is best seen according to 3 main facets -

1. For Diversity, their approach is two-fold. Firstly, they want to help companies find, on-board and buy from diverse suppliers easily. Secondly, they aim to help diverse suppliers gain exposure to potential customers by giving them a platform to market their products and services

2. For ESG, iQuantum’s goal is to help make this an integral part of the company and not just an afterthought to meet reporting requirements. For example, they help companies assess their GHG emissions footprint early in their product development when designing new products or building new facilities

3. For Source-to-Pay, iQuantum’s goal is to make the entire process seamless. They provide a single platform upon which companies can execute all aspects of procurement, ie Finding suppliers (Q-Discovery), Qualify (via RFx and Direct Material Sourcing for Manufacturing), Onboard (Contracts), Procure (Order Management), Monitor (SRM), and Control (Spend Analytics), but also allow modular consumption. They also aim to help companies preserve their existing investments, if they require, by integrating with any systems they may already have installed

iQuantum’s outlook for the future

The Diversity market is moving from being driven by government mandates, to one where it is an integral part of company strategy. Mehta believes that iQuantum is, “in the early stages of realising the full potential of this market.”

She says: “For ESG, this is truly a nascent but swiftly developing market.

Companies simply don't have a good way of assessing their GHG footprint, and we are one of the few solutions that can help them achieve this. We see considerable promise in helping companies assess their environmental footprint.”

In the Source-to-Pay space, iQuantum’s customer conversations have proved that legacy procurement providers are not only unable to meet today's modern business requirements, but also have yesterday's UX. Mehta says: “We are solving this problem.”

82 February 2023

IQUANTUM

Finally, on the subject of regulations, Mehta says: “There are regulations going into effect and being defined every single day. We are keeping a constant eye on any changes that may impact rules, reporting, and best practices.

“iQuantum always keeps the SEC, SBA, CDP current, and up-to-date, helping customers to adapt and remain agile to the changing environment.”

HETAL MEHTA CHIEF EXECUTIVE OFFICER, IQUANTUM

manufacturingdigital.com 83

“There is no single provider on the market who competes with us pin-to-pin”

84 February 2023 TECHNOLOGY

IBASET’S MUNDI ON THE RISKS OF OUTDATED TECHNOLOGY

Rashpal Mundi, Senior Partner Manager for iBASEt EMEA, on how the manufacturing sector is changing and the danger of outdated technology

WRITTEN BY: HELEN ADAMS

Rashpal Mundi, Senior Partner Manager for iBASEt EMEA, on how the manufacturing sector is changing and the danger of outdated technology

WRITTEN BY: HELEN ADAMS

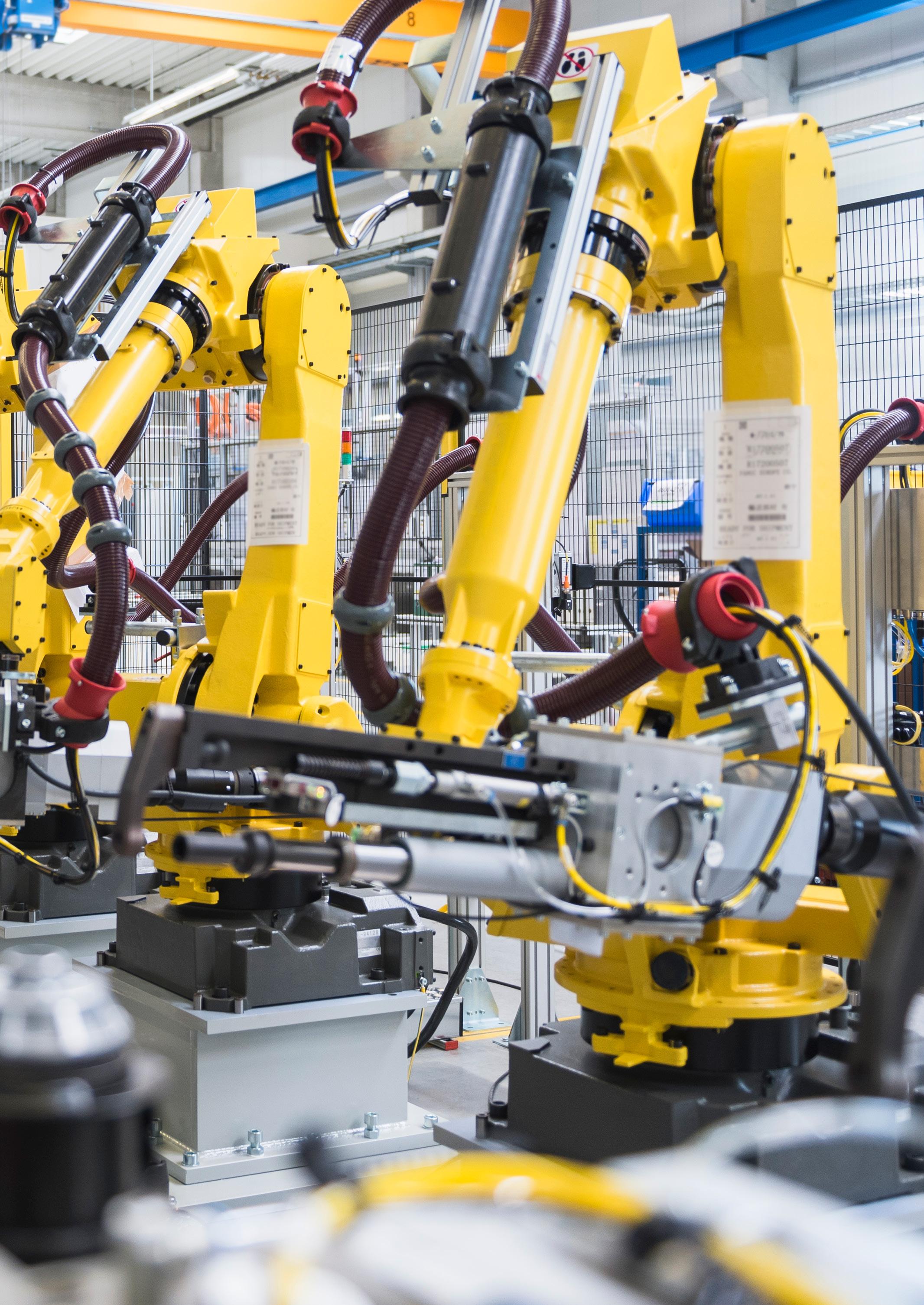

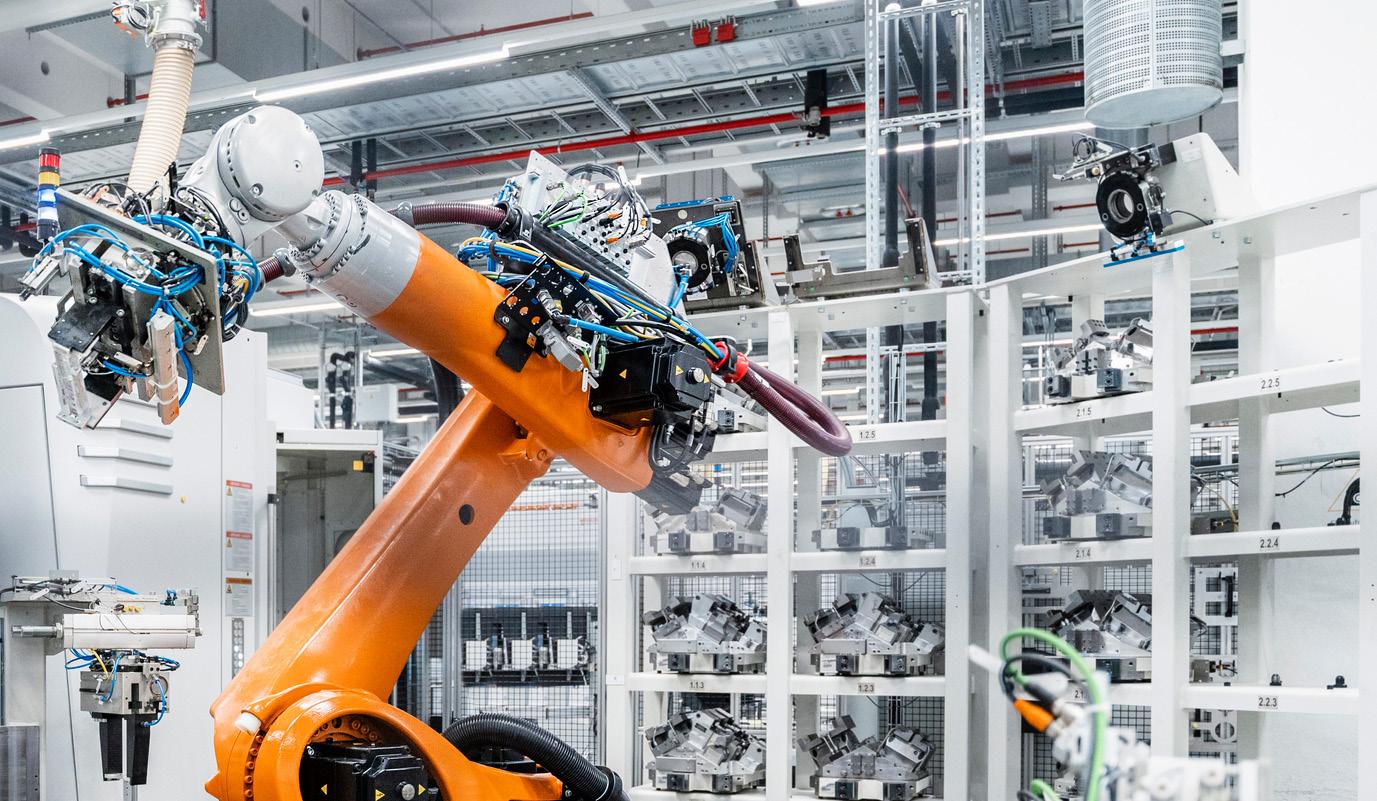

Many of the most notable changes to the manufacturing industry over recent years relate to Industry 4.0. As manufacturers embark on their digital transformation journeys, new software, devices, and robotics have completely transformed the way manufacturers operate. The rapid influx of technologies and new processes has forced manufacturers to implement new

methods and procedures, often relating to the way they manage and utilise data.

The web of Industry 4.0 is only going to grow over the coming years, meaning huge amounts of data will be generated. This means it is essential that manufacturers secure a single source of truth for their data, while providing employees across the organisation access to the tools they need to analyse and make sense of it. If organisations

manufacturingdigital.com 85

Smart Factory. Smart Defense. Digital Security for Manufacturing.

Manufacturing is a lucrative target for cybercrime. As a large industry with valuable data and a growing IoT attack surface, your data is of direct value to hackers.

Learn more

cannot accurately examine their data then any insight will be lost, which will mean that making intelligent, data-driven decisions will be extremely difficult.

One such company simplifying how complex products are built and maintained is iBASEt. The company is on course to accelerate manufacturers’ move away from paper-based and manual processes to become digitally-enabled businesses. With iBASEt, the likes of Airbus, BAE Systems and Rolls Royce are

on a journey from the factory floor to a finished product, as efficiently as possible.

Rashpal Mundi recently joined iBASEt as Senior Partner Manager for EMEA. The company was a natural fit for him, having spent more than two decades working in the UK manufacturing sector.

“I have worked across the ERP and PLM solutions space, specialising in Aerospace & Defence and Automotive customers,” says Mundi.

“I spent almost a decade at Dassault Systèmes before my most recent position at Majenta Solutions, a Dassault valueadded reseller.”