DIGITAL TWINS HELP INFOSYS REACH NET - ZERO

Infosys’ Raghavendra. K.A. is moving modern manufacturing towards net-zero with digital twins

Infosys’ Raghavendra. K.A. is moving modern manufacturing towards net-zero with digital twins

Manufacturing magazine is an established and trusted voice with an engaged and highly targeted audience of 2,000,000 global executives

Digital Magazine

Website Newsletters

Industry Data & Demand Generation

Webinars: Creation & Promotion

White Papers & Research Reports

Lists: Top 10s & Top 100s

Events: Virtual & In-Person

WORK WITH US

Welcome back to Manufacturing Digital! In this issue, we hear from Infosys, TT Electronics, Resilinc & Seclore, who discuss DFx trends, digital twins and net-zero, continuing global shortages, cybersecurity tools and more

As I write to you, Threads has just launched. If the Musk vs. Zuckerberg cage fight does happen, Manufacturing Digital will be ready to report on it! But till then, read on about how the manufacturing sector is growing.

Raghavendra. K.A., Global Head of Engineering, IOT & Blockchain practice at Infosys, explores the role of digital twins in modern manufacturing and how this can help to reach net-zero. Meanwhile Sanjeev Katiyar, Senior Engineering Manager at TT Electronics, discusses DFx trends and strategies and what they mean for the manufacturing sector. Bindiya Vakil, Founder of Resilinc, reviews the impact of COVID-19 on the supply chain and how global shortages continue to impact manufacturing. Vishal Gauri from data-centric security company Seclore breaks down cybersecurity tools and the CHIPS Act, while we celebrate the Top 10 smart manufacturing companies.

HELEN ADAMSHelen.Adams@bizclikmedia.com

“Sanjeev Katiyar, Senior Engineering Manager at TT Electronics, discusses DFx trends and what they mean for the manufacturing sector”

The modern manufacturing sector is growing with DFx trends, digital twins & cybersecurity genius

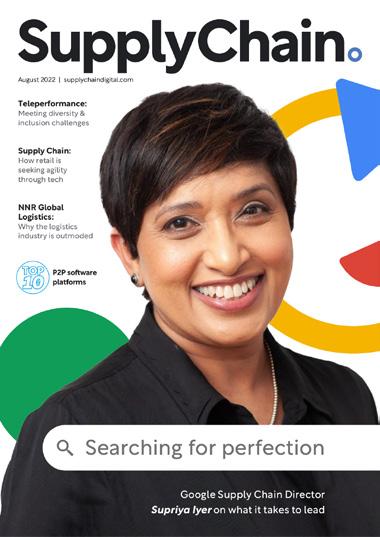

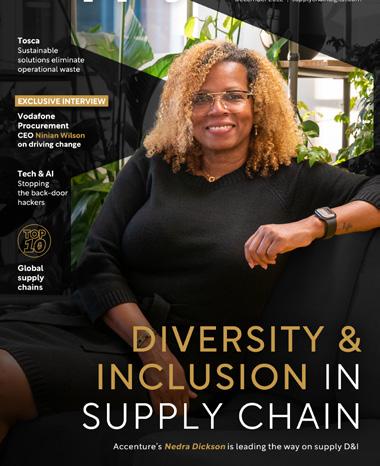

42 SUPPLY CHAIN

Design for Excellence Foundation at TT Electronics

68 DIGITAL MANUFACTURING

Bindiya Vakil, Resilinc CEO, explores the impact of COVID-19

76 SUSTAINABILITY

Infosys’ digital twins pushing businesses closer to net-zero

84 TECHNOLOGY

Seclore’s Vishal Gauri on cybersecurity & the CHIPs Act

92 TOP 10 Smart manufacturing companies

26 - 27 September 2023

Business Design Centre, London

SPONSORSHIPS GET YOUR PASS

In June, a sandstorm closed two ports along the Suez Canal. Then the ‘Seavigour’ oil tanker broke down, causing further disruption.

A few years ago, these incidents would have shaken manufacturers, but businesses are now prepared for the unexpected by diversifying their supply chains.

Jason Hehman, Client Partner at software development company

TXI, helps manufacturers solve business challenges. He tells us about technology’s evolving role in manufacturing and how the titanium economy can support a sustainable future in the sector

» I’m Jason Hehman, a Client Partner at TXI, and I help our clients tackle their most interesting and difficult business challenges by establishing trust among product teams and customers, breaking down internal silos, and developing resilient, innovative cultures. We provide pragmatic advice that helps guide leaders through the product innovation process — from new product discovery to delivery and beyond.

» TXI is a product innovation consultancy that builds engaging digital products to transform businesses. We’re unique in our space because of our commitment to engineering excellence, continuous discovery, and research-driven design thinking. We work with clients in healthcare, life sciences, digital health, biopharma, retail, education, and manufacturing.

We work to understand digital product user behaviors and needs, then build platforms and applications that help meet them. For manufacturers, this can involve engaging with their customers in new ways, understanding shifts in their ordering and purchasing processes, and developing new, innovative tools and product offerings that serve an evolving industrial market. And the result? Great process flexibility, increased productivity and revenue, and higher-quality production.

“Consumer and investor pressures for sustainability create opportunities for manufacturers to differentiate themselves by providing green alternatives”

» Coined by McKinsey consultants in a book with the same name, the titanium economy refers to a group of over 4,000 small-to-midsize industrial firms that have transformed their business with technology over the last decade. The average consumer doesn’t know their name, but they develop the parts and materials (think truck parts, plastic lumber, and color enamels) for things we use every day. Further, their business performance has rivaled that of flashier tech companies over the last decade.

These under-appreciated firms are developing a digital-first culture of innovation and using it to transform their operations with technology. As they shifted from traditional manufacturers to industrial technology companies, they didn’t just revamp old processes with automated equipment

— they’re adopting new ways of thinking that lead to new product applications, custom offerings, and sustainable manufacturing methods.

Q. HOW DOES TXI GUIDE INDUSTRIAL TECHNOLOGY PROS ON HOW TO DEVELOP PRODUCTS AND PROCESSES THAT BETTER SERVE THEIR CUSTOMERS?

» At TXI, we help our clients understand users’ needs and desires. Then, we help build a better, more tailored product for them. For example, together with an environmental monitoring solutions company, we discovered their clients depended on their sensors for security, but the sensors needed an upgrade in order to deliver on customer expectations.

To meet these needs, we developed wifi-connected hardware and a companion digital platform for realtime data analysis, visualization, and

“In the manufacturing space, we’re finding ways to help clients give their customers, supply chain partners & employees peace of mind”

process automation. This way, clients can ensure their environments are secure with modern, around-theclock monitoring for instant insight into environmental conditions (often at warehouses storing sensitive metals or pharmaceutical products).

By leveraging our clients’ expertinformed vision and deep industrial expertise within our product innovation framework, we deliver iterative products optimised for user desirability, technical feasibility, and business viability.

» At TXI, product innovation is a peoplefirst process. We start by understanding user needs and pain points, then we define and refine ideas in collaboration with users to arrive at the right solution. In the manufacturing space, we’re finding

new ways to help our clients give their customers, supply chain partners, and employees more peace of mind. By supporting an organisation-wide culture of innovation, we’re able to continuously find new ways to deliver value and keep our clients ahead of the curve.

» Naturally forward-thinking, titanium economy companies are leaders in decarbonising operations and accelerating green initiatives. Consumer and investor pressures for sustainability create opportunities for manufacturing companies to differentiate themselves by providing green alternatives to traditional materials and energy sources. Companies that are vocal about their sustainability progress also find it easier to align talent and supplier relationships with their values.

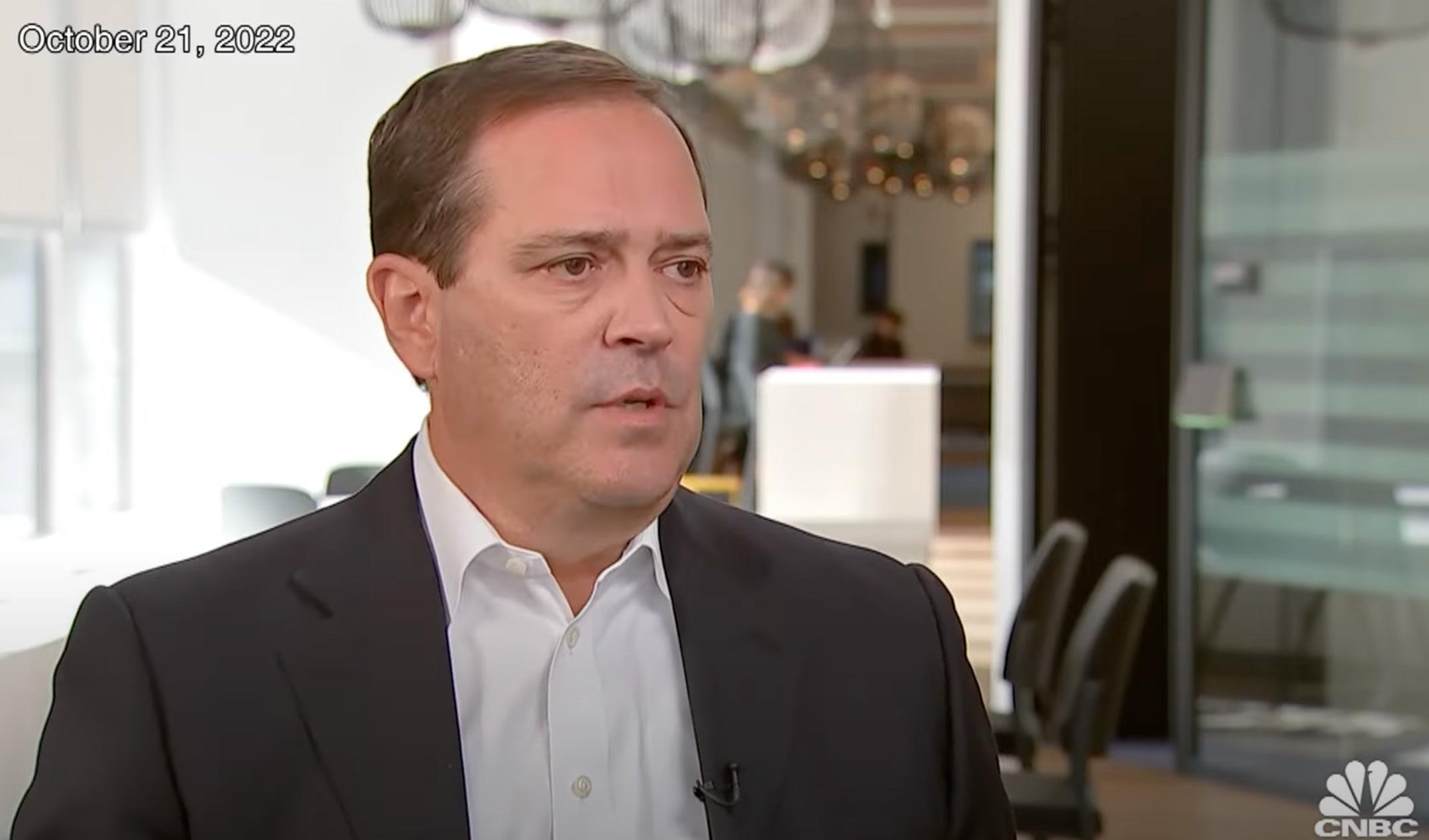

He previously served as Senior Vice President of Worldwide Operations

Chuck Robbins is the CEO of Cisco Systems.Chuck Robbins is the CEO of Cisco Systems, a multinational technology leader, specialising in networking hardware, software and telecommunications equipment. He assumed the role of CEO on July 26, 2015, succeeding John Chambers.

“I joined Cisco because I wanted to be a part of a company where I believed the possibilities were limitless,” Robbins said at the time. “Over the past 20 years, John Chambers’ vision and leadership have built Cisco into one of the most important companies in the world; a company fiercely committed to delivering for its customers, shareholders, partners and employees. I am focused on accelerating the innovation and execution that our customers need from us. Their success will continue to drive us.”

Robbins has spent the past eight years advancing Cisco's global sales and transformation.

Founded in 1984, Cisco has been changing the way people live, work, play and learn with its various products, solutions and services. Its most well known items include Cisco Silicon One, SecureX, Cisco Umbrella Security, Cisco Vision and more.

Robbins joined Cisco in 1997. Before becoming CEO, he held various leadership positions within Cisco, including Senior Vice President of Worldwide Field Operations and Senior Vice President of the Americas, where he worked on Cisco's global sales and go-tomarket strategy.

Robbins led Cisco through various transformations, from cloud computing to IoT, always with a focus on innovation and strategic partnerships.

One of Cisco’s most popular items is its video conferencing platform Webex, which is a part of 95% of all Fortune 500 company’s business continuity plans. When COVID-19 reached the USA, Webex’s teams planned for a worstcase scenario, where Webex would see a 200% increase in usage. This turned out to be an underestimate of how many businesses would need Cisco’s services.

Despite the opportunities of Webex and his focus on hybrid work, Robbins wants Cisco’s employees to view working in their office as ‘A magnet not a mandate… and it’s working because they’re showing up here’. As a CEO, Robbins has respected his employees' wishes for flexible working and dedicated himself to creating an intelligent workspace, which is adaptable, inclusive, supportive and secure.

However, sustainable business practices are not optional. Cisco’s investors have called for greater transparency in environmental, social and corporate governance reporting and Robbins is on board to deliver.

“THE OFFICE IS A MAGNET, NOT A MANDATE”

“I AM FOCUSED ON ACCELERATING THE INNOVATION AND EXECUTION THAT OUR CUSTOMERS NEED FROM US”

“We are at a critical moment in the history of our nation and the world,” he said in Cisco’s ‘ESG Ebook Spotlight on Environmental Sustainability’.

Through his committed leadership, Cisco is building an ESG-inspired corporate culture by educating staff, adopting a circular economy, making its goals public and constantly monitoring progress.

“There is so much we can do to seize the moment and create a more inclusive and sustainable world together. I remain hopeful for our future and am optimistic that together we can continue to drive change and leave a lasting impact for generations to come.”

Months before the arrival of Elon Musk, CEO of SpaceX and Tesla as well as the CTO of Twitter, Robbins visited

India to meet with the Prime Minister, Narendra Modi.

"We talked about our commitment to manufacturing here in India,” Robbins said. “We are going to be using this and viewing this as a global export hub as well. So we are building a full manufacturing node just as we have it in other places and we are really excited about it.”

Robbins announced future manufacturing plans for Tamil Nadu and described the energy in India as ‘incredible’.

Cisco is at the forefront of innovative software development and with Robbins’ leadership, the company will continue to deliver what its customers need - technical support and advanced technological services.

Cisco’s Webex is a part of 95% of all Fortune 500 company’s business continuity plans Webex’s teams planned for a worst-case scenario, where Webex would see a 200% increase in usage due to COVID-19. This turned out to be an underestimate.

WRITTEN BY: SEAN ASHCROFT

WRITTEN BY: SEAN ASHCROFT

PRODUCED BY: JAMES BERRY

PRODUCED BY: JAMES BERRY

Supply chain is a complicated industry that typically requires highly trained engineers to oversee, but pharmaceutical (pharma) supply chains take complexity to another level.

As well as the usual litany of supply challenges, pharma has distinct requirements on the handling of materials like a cold chain element, and also faces the perils of product recalls and compliance issues, because the field of medicine is just about the most regulated sector there is.

And then of course there’s the added pressure of how catastrophic any delays might prove, because the medicines being shipped are critical for ensuring patients have access to the medicines they need to maintain their health, or even keep them alive.

While there is a variety of permutations, the most prevalent today is the small molecule pharma supply chain. This chemical-based drug will typically begin with the sourcing of raw materials – active pharmaceutical ingredients – used to manufacture drugs. The manufacturing process involves several stages: formulation, quality control, packaging and labelling. Once the drugs are ready, they are shipped to warehouses or distribution centres, from where they are distributed to healthcare providers, pharmacies and hospitals.

For other forms, like biologics or vaccines, the supply chain is required to keep these volatile medicines stored at the right temperature and humidity, with tracking shipments to prevent counterfeiting and diversion.

To address such challenges, pharma companies are adopting digital technologies such as cloud, blockchain, artificial intelligence and the Internet of Things (IoT) to enhance transparency, traceability and efficiency in their supply chains.

One company that is helping pharma firms digitally transform operations is Microsoft,

“My role is about being a trusted business advisor to empower our top global customers with expertise and proven practices to accelerate their digital strategy”

MIKE J. WALKER EXECUTIVE DIRECTOR GLOBAL HEALTH & LIFE SCIENCES STRATEGY, MICROSOFT

and at the forefront of its offerings is Mike J. Walker, Executive Director, Strategy, Health & Life Sciences.

In his role, Walker is the strategy leader for Microsoft’s supply chain and manufacturing point of view on pharmaceuticals, med-tech and biopharmaceuticals.

“My role is about being a trusted business advisor to empower our top global customers with expertise and proven practices to accelerate their digital strategy,” he says. “Ensuring that these conversations are business-led with a keen understanding of the pharma business along with the external market risks. As with all industries, technology is always part of that conversation, but the key is to ensure that

TITLE: EXECUTIVE DIRECTOR, GLOBAL HEALTH & LIFE SCIENCES STRATEGY

LOCATION: UNITED STATES

Mike J. Walker is an entrepreneur, futurist, digital strategist, podcast host, global keynote speaker and a best-selling author with a specialty in helping business executives stay relevant in the digital economy.

Walker brings paradigm-shifting digital transformation by leveraging leading innovation practices through experiences with Fortune 500 leaders around the globe.

He has found success in driving pragmatic approaches to large scale problems, an ability to break down large complex challenges into something manageable, along with an insatiable need to bring teams together.

Currently at Microsoft, Walker leads a team focused on life science supply chains and manufacturing.

He acts as a trusted advisor to executives, helping them with some of their toughest challenges. This includes how pharma organisations digitally transform using digital ecosystems, digital twins, AI, IoT and blockchain.

How cloud-based supply chain management specialist Kinaxis is helping pharma navigate transformation, in partnership with Microsoft.

Microsoft’s Azure ecosystem is helping businesses modernise supply chains worldwide, and Kinaxis is at the heart of this important process. Kinaxis provides cloud-based supply chain management (SCM) software called RapidResponse, built on prescriptive AI and automation. This provides organisations with supply visibility and resilience. Supply chains are by nature complex, and involve many operational steps and activities – whether this is manufacturing, procurement or logistics.

Using RapidResponse, planners can create disruption scenarios – such as severe weather events, material shortages or major surges in demand – and use this to make informed decisions, with business outcomes, customer needs and sustainability in mind.

Giovanni Pizzoferrato is Kinaxis CTO and helps define the technology strategy of its customers globally. “We are an amazing global team of engineers and experts,” he says. We are grounded in a ‘people matter’ culture built over nearly 40 years.” It’s a culture Kinaxis brings to its customers through Microsoft Azure,

the cloud computing platform that facilitates access, management and development of applications and services through global data centres. Kinaxis is a Microsoft Independent Software Vendor partner, and co-sells RapidResponse through the Azure Marketplace, where businesses seek out Azure-optimised software solutions.

“We work closely with Microsoft’s industry verticals teams, and interoperate with the MS Supply Chain Frameworks and Cloud Solutions,” explains Pizzoferrato. In terms of pharma supply chains, Kinaxis helps some of the world’s leading pharma companies manage supply chain complexities that are unique to areas like biotechnology, cell and gene therapy, medical devices and over-thecounter medicines. “The regulatory environment is very complex in pharma,” says Pizzoferrato, “so our software uses embedded, attribute-based planning specifically for this challenge.”

He adds that “expiry management” is another critical part of the pharma landscape. “Planners use RapidResponse to get a clear view of what’s on-shelf, what’s about to expire, what the demand patterns look like and what supply plans will meet consumers’ future needs.”

those technology conversations are focused on how strategically relevant they are to your businesses long-term goals. Once we know that, we can have a conversation on how to maximise the value potential of those technologies. That is what really matters for my client’s executive teams.”

Typically, Walker partners with “decisionmakers” – C-suiters both on the business and technical sides of pharma organisations.

The most challenging aspect of the role, he says, is “the pace and the sheer amount of change happening”. He adds: “When you peel back the onion you find each has subtly different business drivers, different cultures, different personalities and leadership styles. It requires you to employ a level of emotional intelligence to your approach. ‘This is the right answer’ is something that never flies.

Microsoft helping pharma supply chains navigate change

‘I am like a counsellor, only without the couch’

“Instead, provide the executive with a framework to work within and let them drive the conversations based on the guided journey and lots of questions. I am there to shepherd them through proven practices, almost like a counsellor, only without the couch.”

Another challenge stems from the nature of the pharma industry itself.

Walker says: “What most needs changing in pharma supply chains is the legacy mindset and a culture of risk aversion. These organisations fall into the trap of thinking they can’t do something because they’ve always done it that way. With this mindset they don’t ask the right questions.”

Questions, he says, such as: How do we create this experience within the bounds of the rules? Will the market dynamics change that would make this a viable solution? What is the level of risk tolerance we are willing to take? How can we partner with the regulatory bodies to influence change?

On the latter point, Walker says that, in his experience, regulatory bodies like the FDA are “very willing to hear you out if you've got a compelling approach to solving industry challenges”.

As for barriers to digital transformation, Walker says that here things are playing out just as they have in other sectors.

“I see lots of barriers other industries have gone through and have overcome,” he says. “It just takes time. The nice part of having a cross-industry background is I've seen how other supply chain organisations have dealt with this level of change.”

This is why Walker likes to take biopharma clients to visit Microsoft customers in other fields, such as consumer goods. He has also taken them on visits to brewing giant ABinBev Anheuser-Busch.

“Brewing beer is very similar to what a biologics organisation does,” he explains, “so showing them what is possible in a less complex environment is a worthwhile thing to do.”

Technology obsolescence is another hurdle, 65% of manufacturing environments run outdated operating systems, he says.

“Even though the intent is to update technology and software, if you’ve got manufacturing equipment running Windows XP on devices supporting your biologics

manufacturing lines, you can’t just shut it down and replace it because that could impact the entire batch worth millions of dollars.”

He adds that from a strategy perspective the challenge is “to not only fix the current problem, but to create an evergreen model that prevents obsolesce from happening to begin with”.

Of course, some of the barriers to transformation in pharma differ to other sectors, particularly around regulation. The FDA’s Drug Supply Chain Security Act (DSCSA), a single federal framework for tracing prescription medications through the supply chain, is challenging the pharmaceutical sector to reach data transaction targets by November 2023.

“We need visibility across the entire value chain, and you can't do that in a sequential, linear, compartmentalised way”

MIKE J. WALKER EXECUTIVE DIRECTOR GLOBAL HEALTH & LIFE SCIENCES STRATEGY, MICROSOFT

“There is much less scrutiny on manufacturing a beer versus a vaccine,” says Walker. “Medicine is treated very differently not only from a supply chain perspective but also from a manufacturing and a sourcing perspective.”

Pharma regulatory environment is unique

He adds: “The entire supply chain looks a little bit different, and the regulatory environment is unique. In an automotive company's supply chain, for example, they don't necessarily have to tell a regulatory body the specific specs of the machines that they will use to make that product.“

And of course, like all businesses across all sectors, pharma organisations are getting

hit from all sides. There’s a rising need to be more sustainable, materials cost more, increased energy costs – especially in Europe – which drives the impetus to do more with less cost. They're also getting hit from a geopolitical perspective, like the war in Ukraine but also, says Walker, economically from a global trade and tax perspective.

“In China for example, there is an increase in operating costs of doing business in China, especially for manufacturers with aspects like minimum wage increasing between 30% and 65% in recent years. Tax rates are also higher across the board due to a unified corporate tax, and with China’s new cybersecurity and privacy regulations, they

have the potential to transform how pharma companies conduct business in China. The most pressing question I hear from pharma executives is, should we stay or should we go.”

Walker also points out that the pharma industry is being disrupted by smaller biotech firms, along with tech-savvy companies. He likens what’s happening here to how Uber and Lyft have changed the taxi business.

“It’s the same in the pharma industry, where you've got countless small biopharmas that, from an R&D perspective, are pumping out way more patents than the traditional players.

“A lot of that has to do with their ability to be nimble and they also leverage technology at its fullest. With the bigger organisations you've got a big ship to turn, and you've got a lot of moving pieces.”

Technology is a conversation for later in the relationship

Technology is vital, but Walker says it is “always a conversation I have later in the relationship”. But it is very much a conversation that needs to be had, because many supply chains as they stand are simply ill-suited to being digitally transformed.

“Supply chains can be very linear,” he says. “The connections between the ecosystem of partners can be brittle and fragile, and there is a growing need to make sure supply chains are modular, dynamic and provide transparency across the entire value chain –and you can't do that in a sequential, linear, compartmentalised way with technology.”

He adds: “You have to do it in a way now that is much more decentralised than what it was before. There's a significant amount of processes around reconciliation of data that is introduced because of that.”

“

Many of my customers are regional ecosystem hubs that serve specific markets”

MIKE J. WALKER EXECUTIVE DIRECTOR GLOBAL HEALTH & LIFE SCIENCES STRATEGY, MICROSOFT

Walker observes that this requires “an ecosystem approach” – supported by a common “data fabric” that allows organisations to digitise their supply chains in a meaningful way.

On this note, Walker has partnered with Kinaxis, a ‘visionary leader in supply chain’ solutions, according to analyst firm, Gartner.

Walker believes that leveraging the power of the Microsoft Azure cloud platform together with Kinaxis' solutions will provide pharma organisations with an agile and autonomous supply chain platform,

which are essential in today's rapidly changing business environment.

He says: “This combination of capabilities enables a digital ecosystem platform for pharma supply chains that uses advanced analytics and artificial intelligence to analyse data from across the supply chain, including suppliers, customers, and internal systems.

“It can also integrate with other systems, such as ERPs, MES, CRMs, and logistics systems, to provide a comprehensive view of the entire supply chain.

Walker recounts a past conversation he had with a pharma company.

“They were talking about how one of their key priorities is to digitise all instances of paper use,” he says. “On the surface

“But I asked if this meant putting scanners into their factories at each process-step to make sure that all paper was scanned, and then entered into a document management system.

“Then I asked if they wanted instead to solve the root problem, which was fundamentally how to reinvent the business process and how data is handled.” This, he says, requires a rethink of the organisations’ relationship with data

Walker says he knows of pharma organisations that are leveraging digital twins for an end-to-end view of their supply chain. But does this tick all the boxes that need to be ticked, even? Probably not, he feels.

“When you look at these digital twins there's different levels and types. You have layers of digital twins that coexist within an organisation. Some represent the asset itself. Some represent the people and the interaction. Some represent the process, and others represent the facility or the

Walker says that what is needed, and often lacking, is a strategy around creating “a common data platform that is able to create digital threads to connect all of this data”, and “a full genealogy of everything that was involved in the creation of all these layers of digital twins”.

What makes Microsoft unique is our commitment to industry specific standards

and communities, such as the Open Manufacturing Platform, the OPC Foundation, the Digital Twins Consortium and our innovative partner ecosystem, coupled with composable and extensible solutions that seamlessly connect people, assets, workflows and businesses processes. Our technology is giving businesses more intelligence and visibility than ever before and making operations more adaptable.

Looking at the bigger geopolitical picture, Walker says pharma companies are changing the shape of their businesses, by stepping away from globalisation.

“I've heard from four very senior executives in the pharma supply chain that globalisation as an approach is dead,” he says. “Now it's more about de-globalisation and modularity. Many of my customers are creating an ecosystem of ecosystems strategy whereby they are regional ecosystem hubs that serve specific markets. However, each one of these is still loosely connected and provides a level of autonomy but also flexibility.”

Walker references McDonalds here because “they solved this problem in the fifties with the franchise model”.

He adds: “Why make every one of your factories unique and bespoke when you can create a franchise model that provides speed, modularity, and flexibility through a common set of methods and standards? For example, maybe it would be possible to take an oral solid dose drug and make the manufacturing and supply chain 90% standard across all applicable factories.

“This also gives you a level of nimbleness and agility in the marketplace that you won't have in linear supply chains with bespoke factories.”

WRITTEN BY: HELEN ADAMS

WRITTEN BY: HELEN ADAMS

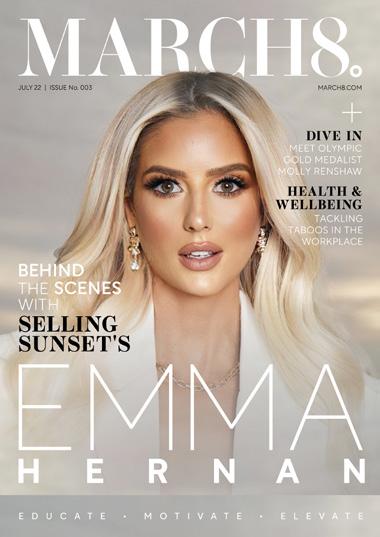

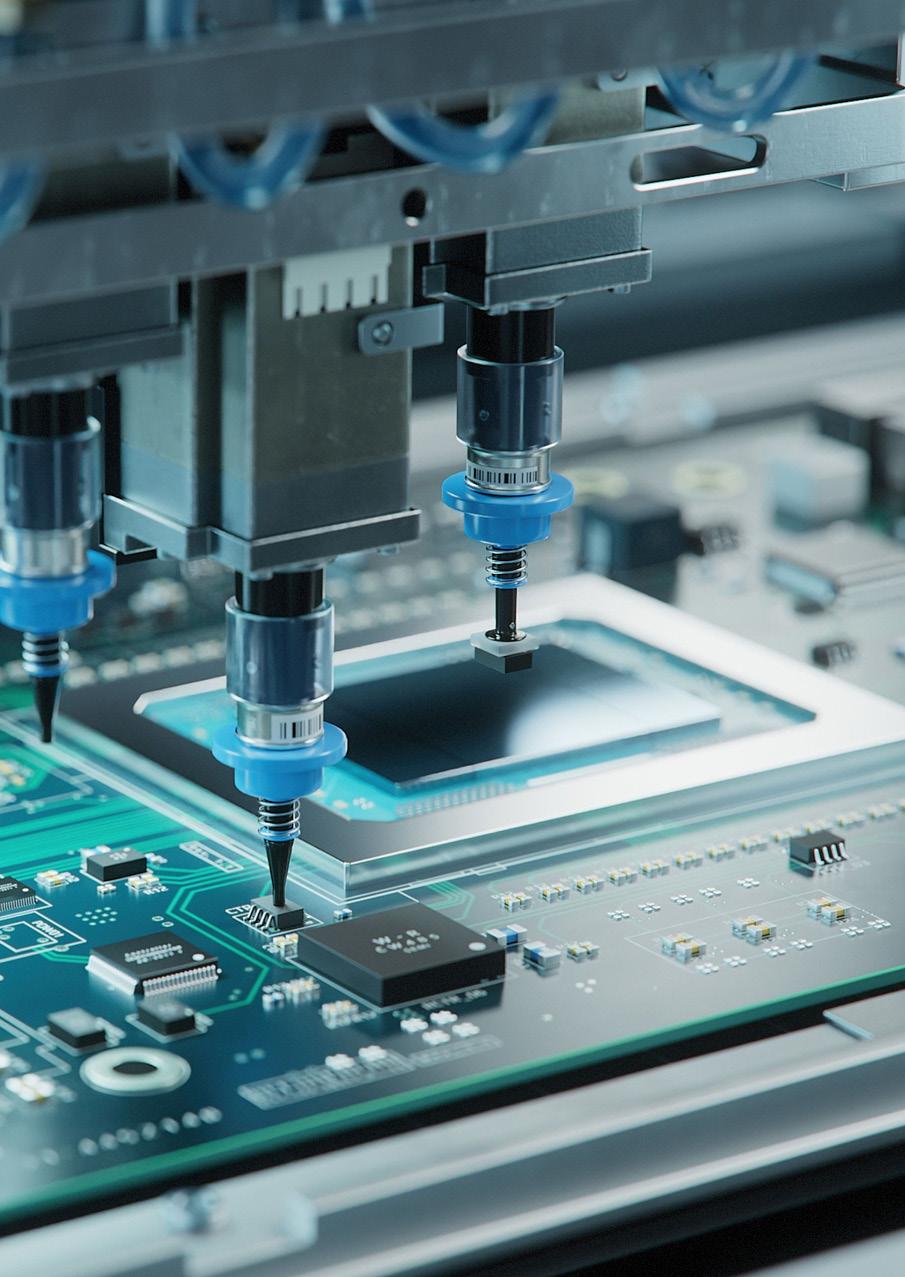

Sanjeev Katiyar, Senior Engineering Manager at TT Electronics, explores manufacturing success with a Design for Excellence Foundation

Agood product is more than its design. It’s the end-to-end process, including manufacturing, that brings a solid design to market. In the quest for better manufacturing processes – a goal common among producers of engineered systems – Design for Excellence, more commonly known as DFx, is a widely established framework of methods, guidelines and standards for creating better-quality products.

“Ideally, this framework is applied at the concept design phase, enhancing development as early as possible to produce higher quality products, reduce cost and shorten development cycles,” says Sanjeev Katiyar, the Senior Engineering Manager at TT Electronics. “Larger corporate entities expect DFx as a fundamental service from their Contract Electronics Manufacturer (CEM), yet smaller designers may be less aware of its import.”

Katiyar has more than 25 years of progressive experience in the electronics manufacturing space, featuring immersive exposure to both OEM and contract manufacturing. He currently serves as the SMTA Ohio Valley Chapter President.

In his current role at TT Electronics, a global provider of engineered technologies for performance-critical applications, Katiyar leads technology roadmap realisation in six

focus areas: automation, PCBA technology, coating materials, material handling, digitiastion and NPI COE.

Partnership is at the heart of DFx, especially in regulated markets such as aerospace, defence and healthcare.

“It’s not cliché to say that partnership matters in these arenas – adding critical value

where OEMs face a deficiency of in-house expertise even as they simultaneously face supply chain and time-to-market obstacles,” said Katiyar. “It’s in this complex and highly volatile landscape that partnership has become its own new frontier, with collaboration proving a powerful design strategy.”

The DFx process not only creates an ideal opportunity to determine and correct issues in new products, but also those related to mature, or already developed products. Because defects, the need for new parts, or the restructure or redesign of a PCB often

occur with mature products, DFx can interject feedback that drives the most reliable product.

According to Katiyar, a template for DFx methods could include:

• Goal-specific design methods target different phases of a product’s lifecycle. The “x” is the area of focus, such as product design specs, supply chain and testability

• Lean design processes, utilising lean manufacturing principles to eliminate waste

• Identification of problems and needs

• Analysis of solutions

• Optimisation for efficiency and performance (for example, a shorter time to market results in fewer development costs).

“Creating a manufacturing ecosystem built for future advances and product longevity is crucial to long-term success”

SANJEEV KATIYAR SENIOR ENGINEERING MANAGER, TT ELECTRONICS

says Katiyar. “Capabilities include sensors, power management solutions, connectivity technologies and vertically integrated global manufacturing solutions.”

TT has 25 sites worldwide with 5,000 employees. In the global manufacturing solutions business, TT supports customers with end-to-end services from prototype development and NPI support, supply chain solutions and full systems integration.

Subcontractor relationships in the electronics industry can reduce costs and shorten development cycles.

“Great engineering design practices start with careful consideration of the product requirements to reduce delays and redesign costs later,” Katiyar said. “Here, you don’t know what you don’t know, and this is where collaboration plays a highvalue role. Depth of partnership adds competitive value in the form of reduced costs as well as development timelines.”

Consider that factors such as FDA approval of medical devices or the Size,

Weight, and Power (SWaP) concerns common to next-generation defence electronics require unique insight.

“These and many other industry-specific challenges can present unanticipated roadblocks to developing an excellent product, already complex due to the nature of performance-critical applications such as surgical navigation, automation and electrification.”

Any design trade-offs are best determined and planned early in the design process, negotiating the smoothest and fastest path to market. When competitors have more

“TT Electronics solves electronics challenges for a sustainable world, serving customers in healthcare, aerospace, defence, electrification and automation,”

resources and a deeper in-house talent pool, it’s crucial to capitalise on partnerships that can level the playing field.

“Design for manufacture, for test, for supply chain – these all fall under the DFx banner and represent value-added engineering solutions that minimise quality issues and ultimately bring about speed to market,” Katiyar said. “Establishing a cohesive approach that permeates design thinking from engineering to procurement, operations, commercial, legal, marketing and c-suite affects comprehensive value in the design process. This is also how OEMs

“The DFx framework itself provides the interface between design and manufacture to ensure a smooth transition to production”

SANJEEV KATIYAR SENIOR ENGINEERING MANAGER, TT ELECTRONICS

and product developers can tap into a deep well of industry knowledge they may not otherwise access – and increase focus on time-to-market goals and product longevity as an integral part of their design and manufacturing processes.”

This approach has an impact, not only internally, but also on external forces, such as the global electronics supply chain. Resiliency here can make or break a product design; this is ideally addressed at the earliest stage of development. However, it is partnerships that are the not-so-secret ingredient, effectively supporting redesigns and adjusting schedules by avoiding or eliminating surprises.

“It’s this source of creative and experienced thinking that also mitigates risk in the supply chain with proprietary tools, software platforms and artificial intelligence that can be accessed as needed.”

As the electronics industry faces growth in subcontractor relationships – in contrast to onsite manufacturing resources that may have been more common in years past – Katiyar believes that it is essential to share insight and feedback on the processes between the design and manufacture of a product.

“There are always variables to consider, but DFx increases confidence that products are reliable, testable and facilitates a faster time to market,” said Katiyar. “The DFx framework itself provides the interface between design and manufacture to ensure a smooth transition to production.

“Creating a manufacturing ecosystem built for future advances and product

#WeAreTT: TT ElectronicsWill you join us?

longevity is crucial to the long-term success of any product. Trouble is, it’s not always obvious that these things don’t necessarily exist. It may not be until product testing fails, an upgrade is required, or a supply chain is disrupted that the core elements of a design will be revealed to be unnecessarily complex and costly.”

Here, partnership can make all the difference – collaborating early and at every stage of the product life cycle ensures that the product is designed correctly from the outset.

“This is high-value engineering and testing at its best, and can be documented in the bottom line.”

At TT Electronics, the team is focused on continuous collaboration with their customers to help them achieve their goals.

“Larger corporate entities expect DFx as a fundamental service from their Contract Electronics Manufacturer (CEM)”

SANJEEV KATIYAR SENIOR ENGINEERING MANAGER, TT ELECTRONICS

6 - 7 December 2023

1,000+ Virtual Attendees

2 Day Learning and Networking Event

30+ Acclaimed Speakers

6 Interactive Panel Discussions

The Manufacturing stage is here, and it’s putting on an exclusive 2-day virtual event for the industry.

Join Manufacturing Digital LIVE on 6 and 7 December for a two-day virtual event, where the brightest minds in Manufacturing will grace the stage.

Experience a unique opportunity for knowledge sharing, learning, and networking with industry professionals from all corners of the globe.

Dive into the innovative networking platform, Brella, to build meaningful connections, schedule meetings, and prepare yourself for the immersive LIVE stream about to unfold.

There are more than 30 internationally acclaimed leaders that you can’t afford to miss!

Covering five key themes, the event will showcase engaging presentations, interactive sessions, panel discussions and fireside chats, facilitating deep learning and exploration: Factory of the Future, Sustainability, Digital Manufacturing, Tech & AI and Women in Manufacturing.

Mark your calendars, set your reminders, and get your complimentary pass to Manufacturing Digital LIVE!

It’s time to connect with like-minded professionals who share your passion for innovation and growth.

WRITTEN BY: ILKHAN OZSEVIM

PRODUCED BY: TOM VENTURO

WRITTEN BY: ILKHAN OZSEVIM

PRODUCED BY: TOM VENTURO

What happens when an international technology catalyst – itself composed of many companies – undergoes its own technological transformation, and makes that transformation the heart of its processes?

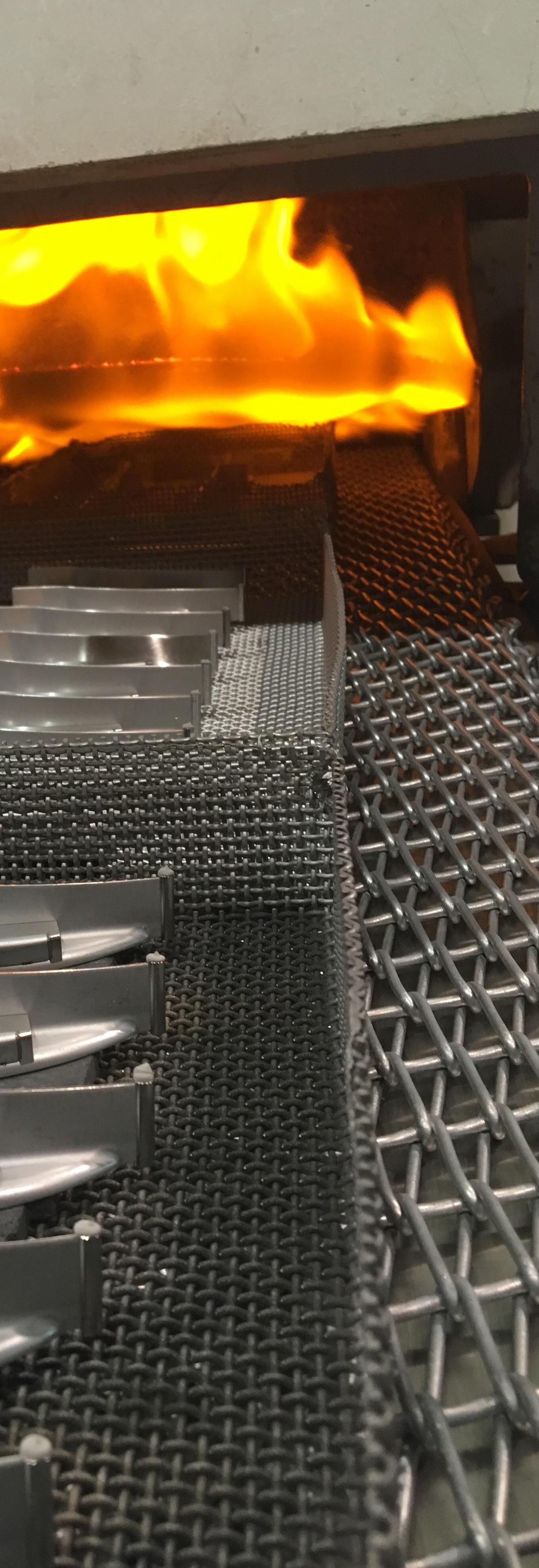

Kymera International is a leading specialty material manufacturer, focused on the production of diverse particles and special alloys for a perfusion of technology requirements with truly global applications.

The company’s core activity involves atomising different metals to create small particles used in powder metallurgy – particles which serve as the building blocks for manufacturing alloys, pastes and other materials that meet specific client needs – across a multitude of industries.

One of Kymera’s distinguishing features is its ability to provide a customised mix of products tailored to the unique requirements of its clients. Whether the need is for high RPM, extreme temperature tolerance, rigidity or flexibility, Kymera leverages its research and development capabilities to create alloys and powder mixtures that fulfil these demands.

Their products find applications in a wide range of industries, including metallurgy, medical, aerospace, defence and electronics.

Kymera’s reach: Truly global Kymera International operates through two major lines of business: engineered materials and surface technologies.

Under the engineered materials segment, the company provides specialised materials to meet specific requirements. In the surface technologies segment, Kymera International combines its material expertise with advanced surface treatment technologies to offer comprehensive solutions that enhance the functionality and durability of materials.

With 16 sites worldwide, Kymera International is a global player in the industry. The company’s extensive network includes nine North American sites and seven overseas sites, all working together to form the unified entity that is Kymera International. This global presence allows the company to leverage its diverse resources and expertise to serve clients around the world effectively.

“Combining human expertise with AI-generated insights, Kymera strives to achieve more precise sales forecasting, contributing to overall business success”

GABOR SZENTIVANYI CHIEF INFORMATION OFFICER, KYMERA INTERNATIONAL

TITLE: CHIEF INFORMATION OFFICER

COMPANY: KYMERA INTERNATIONAL

Gabor Szentivanyi is a global Information Technology leader with 25 years of cross functional experience within the manufacturing industry.

As the Chief Information Officer at Kymera International he has successfully implemented an M&A optimised IT strategy with heterogeneous ERP strategy which includes a centralised global data warehouse and reporting platform, a DoD-compliant IT infrastructure and Cybersecurity solution, all while growing into new markets.

Previously, as Vice President at Element Solutions Inc Gabor led IT Merger and Acquisition activities, Szentivanyi managed global IT services, and optimised a widely diversified infrastructure. He also held various IT leadership roles in France at COTY Inc. and Bonduelle S.A., implementing enterprise-wide solutions and driving

Szentivanyi is a multilingual professional with fluency in four languages and a deep understanding of diverse cultures. He holds an Electrical Engineering and Masters of Business Administration degree and maintains a robust IT strategy, M&A, and enterprise transformational

GABOR SZENTIVANYI CHIEF INFORMATION OFFICER, KYMERA INTERNATIONAL

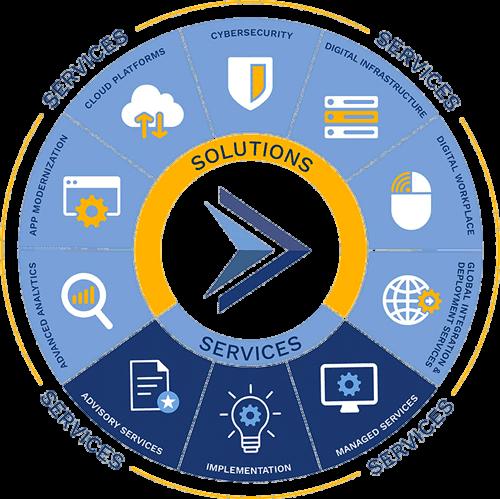

COLLABORATE. CONNECT. CONVERGE.

Converge Technology Solutions is a services-led, software-enabled, IT & Cloud Solutions provider focused on delivering industry-leading solutions.

Our global solution approach delivers advanced analytics, application modernization, cloud platforms, cybersecurity, digital infrastructure, and digital workplace offerings to clients across various industries.

Kymera International’s vision is rooted in creating innovation and value in every particle it produces. The company takes great pride in its ability to manufacture tiny, precise, high-quality particles.

“With a strong emphasis on quality control and continuous improvement, Kymera International ensures that each particle is produced with the utmost competence and advanced technology,” says Gabor Szentivanyi, Chief Information Officer (CIO) of Kymera International.

Szentivanyi brings a wealth of experience and expertise

Szentivanyi’s journey in manufacturing began in 1998. Since then, he has dedicated a significant portion of his career to working with companies involved in the manufacturing of various products.

Recognising the intrinsic connection between manufacturing and information technology, he naturally gravitated towards IT activities. His extensive experience in both domains has positioned him well as the CIO of Kymera International, with a focus on taking the organisation to the next level.

his role. With a professional journey spanning more than two decades, Szentivanyi’s career has primarily been focused on the manufacturing industry. His passion for creating tangible products and his love for IT led him to pursue a path in manufacturing, where he could witness the physical output of his work.

“Our commitment to excellence extends not only to our products, but also to our resources, guaranteeing that our clients can rely on Kymera International as a trusted and dependable partner,” he adds.

In leveraging big data analytics, Kymera International has embarked on a transformative journey to streamline its

operations and enable data-driven decisionmaking. Recognising the limitations of its previous approach, Kymera International has embarked on a transformative journey to leverage big data analytics in its operations.

“When I first joined as CIO, I observed that the company had multiple independent enterprise resource planning (ERP) systems spread across its entities,” says Szentivanyi. “Each facility operated with its own set of specifications and requirements, resulting in fragmented data management.

“To address these challenges and unlock the potential of data-driven insights, I spearheaded an IT strategy focused on consolidating and integrating the disparate ERP systems. Instead of opting for a single, standardised ERP solution, we pursued a heterogeneous ERP approach topped with a central data warehouse that welcomes and hosts all data of the enterprise.”

The operational domain of Kymera is naturally extensive – compounded by its dive into big data and analytics – and this extent requires a robust cyber security environment. In recognition of the everincreasing importance of cybersecurity, Kymera International places a strong emphasis on maintaining robust security measures. As a company with a longstanding history and a vital role in providing critical materials to various industries, cybersecurity is paramount.

The company also recognises that being a reliable and sustainable company requires a proactive approach to cybersecurity, going beyond the minimal requirements and ensuring the highest level of protection for its operations, customers, clients and partners.

Furthermore, following the recent announcement of a merger with TSS and the expansion into new markets (including the US Department of Defence), Kymera International is poised to seize additional opportunities. This strategic move will allow them to enhance existing products and develop new materials and solutions that may not be readily available within North America – giving Kymera a comparative advantage and opening up new avenues for growth.

The heterogeneous ERP strategy allows each entity to automate local business processes according to its unique needs, while ensuring that global reporting and visualisation could be achieved through a common data warehouse. The company’s primary objective is to establish a single source of truth – a comprehensive data warehouse that hosts transactions from all ERP systems and other important systems.

GABOR SZENTIVANYI CHIEF INFORMATION OFFICER, KYMERA INTERNATIONALWith a strong emphasis on quality control and continuous improvement, Kymera International ensures that each particle is produced with the utmost competence

Having a central repository enables the standardisation of data across geographies and provides the foundation for generating valuable insights. By consolidating and harmonising data from various sources, Kymera International aims to shift from mere data representation to data-driven insights, empowering business leaders to make informed decisions and steer the company effectively.

With this new data infrastructure in place, Kymera International significantly reduces data latency. Instead of relying on weeks-old data, the company now operates with the previous day’s business data from all geographies. This real-time access to accurate and relevant information allows for proactive decision-making and a

deeper understanding of market trends. By identifying and analysing these trends at an early stage, Kymera International gains a competitive advantage and can align its operations with evolving market demands.

The real value of Information Technology Szentivanyi says: “The value of IT lies in the transition from raw data to actionable insights. By providing leadership with a clear understanding of ongoing trends and future directions, IT becomes a driving force for the company’s success.”

This shift from a rear-view mirror perspective to a windshield-view enables Kymera to proactively navigate the dynamic landscape of the industry and stay ahead of the competition.

From Excel spreadsheets to spreading excellence: Cloud-based data warehousing and business intelligence

In the past, many Kymera employees stored vital data in Excel sheets on their local hard drives. Gaining momentum in the digital era, Kymera recognises the need to move away from this traditional approach. The company is focused on encouraging its workforce to embrace Power BI, a powerful business intelligence tool, as a central platform for data visualisation and analysis. By utilising Power BI, employees can access up-to-date information in real-time, ensuring they have the latest insights necessary for informed decision-making.

Shifting from a culture of file ownership to embracing cloud-based solutions comes

“The integration of AI algorithms with historical data empowers employees –among others, the sales team – to make accurate and reliable forecasts”

with its challenges. Kymera acknowledges the initial hesitation and concerns around trusting data stored in the cloud. To address this, the company is actively working to build trust in the technology by emphasising its reliability, security and convenience.

“The goal,” says Szentivanyi, “is to create a seamless and secure connection experience, whether employees are working from the office, a coffee shop, or even while enjoying personal activities”.

“Kymera is determined to ensure that its workforce has constant access to business-critical information through a variety of devices, be it a computer, tablet or a mobile phone.”

Another key aspect of Kymera’s digital transformation is the establishment of a unified digital infrastructure. Prior to this transformation, Kymera operated with diverse computing and collaboration platforms due to various acquisitions.

“The value of IT lies in the transition from raw data to actionable insights”

GABOR SZENTIVANYI CHIEF INFORMATION OFFICER, KYMERA INTERNATIONAL

Szentivanyi identified the need to consolidate these platforms into a single, reliable and globally accessible solution.

“This unification enables enhanced collaboration, seamless communication and elevated levels of cybersecurity,” he says. “Kymera selected its most suitable networking and remote access solution to provide secure connections for its employees, regardless of their location, ensuring data privacy and protection.”

Kymera is committed to fostering a healthy work-life balance for its employees. The digital workplace initiatives, driven by Szentivanyi, not only aim to improve productivity, but also prioritise the wellbeing of the workforce by enabling hybrid working. The company provides the necessary tools and technologies that allow employees to connect and work efficiently from anywhere, without sacrificing security or incurring additional costs.

Moreover, Kymera invests in continuous cybersecurity training for its employees, raising awareness about the importance of cybersecurity both inside and outside the office. By creating a secure and flexible work environment, the company ensures its employees can focus on their responsibilities both professionally and privately, as they are equipped with the necessary cybersecurity competency.

The adoption of cloud-based data warehousing serves as a foundation for Kymera’s future growth and innovation.

“By centralising and consolidating data in the cloud, Kymera creates a unified repository that facilitates more effective data analysis and enables the application

of advanced technologies such as artificial intelligence (AI) and machine learning,” says Szentivanyi. “The integration of AI algorithms with historical data empowers employees – particularly the sales team –to make accurate and reliable forecasts. Combining human expertise with AI-generated insights, Kymera strives to achieve more precise sales forecasting, contributing to overall business success.”

Szentivanyi highlights that, as a manufacturing company, Kymera faces unique challenges in adopting new technologies due to its preference for solid, cost-effective solutions with clear return on investment.

“Manufacturing has often been considered a late adopter of technology,”

he continues, “but recent events such as the COVID-19 pandemic and cybersecurity threats have shifted perspectives. The integration of IT and manufacturing is crucial, presenting numerous opportunities for automation and value creation. By combining expertise in technology, data and manufacturing processes, I believe that significant improvements can be achieved, significant enough to transform the manufacturing industry.”

Discussing Kymera’s partnership with Converge Technology Solutions Corp, Szentivanyi commends the company’s diverse expertise and its approach based on trust. He says the long-standing relationship between Kymera and Converge has yielded successful results, particularly in the development of a complex data warehouse solution. Szentivanyi highlights

Converge’s guidance and ability to futureproof the solution, providing Kymera with the necessary technology infrastructure to implement artificial intelligence and automated forecasting.

“The partnership has enabled us to exceed our IT commitments and support continuous improvement and growth,” he adds. “Blueshift is our important partner in cybersecurity. Their approach to ensuring the security of our IT systems instils confidence in our cybersecurity measures.”

Looking ahead, Kymera International anticipates further acquisitions, adding new companies and thus additional potentially different ERP solutions to the mix.

These new acquisitions can rapidly connect to the data warehouse and add to

the overall information package. The company aims to maximise the utilisation of its data warehouse and Power BI dashboarding automation, transitioning from traditional spreadsheets to comprehensive global insights.

“Improving or replacing certain ERPs to capture relevant, currently non-existing, but much needed data and enhance data governance is also going to be important,” Szentivanyi concludes.

“Kymera aims to address the emerging challenges of data governance and master data management through a collaborative and non-intrusive approach, striving for a global solution that meets local requirements in all of our operating locations.”

Bindiya Vakil, CEO and founder of Resilinc, discusses the impact of COVID-19 on the supply chain & the global shortages impacting manufacturing

WRITTEN BY: HELEN ADAMSThe chip shortage crisis that began in 2020 has disrupted the supply of virtually everything we use in our daily lives. The rapid growth in demand for electronic devices, due to remote working, online education and the increased use of technology especially, has outstripped supply.

Shortages and limited production capacity have also hit the automotive sector. Moreover, some commodities like steel, palladium or nickel essential to semiconductor production have been impacted by the attack on Ukraine.

While this has caused a range of problems for businesses, others have risen to the challenge of solving them.

Bindiya Vakil is the CEO and founder of Resilinc, a world leading supply chain mapping, disruption sensing and data analytics solution company. As a graduate of MIT with a Master in Supply Chain Management, Vakil previously worked at Broadcom and Cisco. She is a founding member of the Global Supply Chain Resiliency Council and a member of the Advisory Board of the MIT Centre for Transportation and Logistics. She founded Resilinc in 2010 and now having worked in the sector for over 20 years, she has a wide understanding of supply chain risk management and supply chain resiliency.

Over a period of 12 years, Resilinc has mapped suppliers and sub-tier suppliers across 200 countries and now offers insight into data spanning one million sites and four million parts and raw materials.

“What’s more, with the help of our knowledgeable experts, we issue special reports including extensive data, key conclusions and practical tips for strengthening manufacturing supply chains.”

A modern network must be able to respond easily, quickly and flexibly to the growing needs of today’s digital business. Must provide visibility & control of applications, users and devices on and off the network and Intelligently direct traffic across the WAN. Be scalable and automate the process to provide new innovative services. Support IoT devices and utilize state-of-the-art technologies such as real-time analytics, ML and AI. And all these must be provided with maximum security and minimum cost.

This is the power that brings the integration of two cloud managed platforms, Cisco Meraki and Cisco Umbrella. This integration is binding together the best of breed in cloud-managed networking and Security. cisco.com

Prior to the conflict, Russia accounted for 37% of the global supply of palladium, vital to the metal connections between semiconductors and circuit boards.

“In fact, 90% of the world’s production of neon gas, also used in semiconductor

manufacturing, originated in Ukraine prior to the invasion,” explains Vakil. “This has put an additional strain on existing supply chains as alternative sources are rare.”

At present, however, the situation appears to be more stable, but while some industries are showing signs of recovery, others are still in trouble.

“Advanced chips in particular will remain highly sought after and shortages are expected to persist through 2023 and into 2024,” says Vakil. “With a significant number of advanced chips produced in Taiwan – which had a 66% market share in 2022 –supply will continue to be focused within a few countries, namely Taiwan China and the United States.”

Through her experience, Vakil knows how to support global supply chains: Gaining deep multi-tier supply chain visibility,

“COVID-19 was a wake-up call for supply chain managers. It highlighted the importance of having full visibility into their supplier networks”

BINDIYA VAKIL CEO AND CO-FOUNDER, RESILINC

Prior to the conflict, Russia accounted for 37% of the global supply of palladium, vital to the metal connections between semiconductors and circuit boards

maintaining good supplier relationships and implementing advanced monitoring and planning techniques.

“These are all effective ways to identify potential risks and take timely action to mitigate any losses,” she says. “What’s more, investing in technology-based supply chain risk management solutions will improve a company's agility and responsiveness in times of crisis.”

The COVID-19 pandemic has posed unprecedented challenges to global supply chains. Companies have experienced major disruptions from the demand side, all the way to raw materials and people labour shortages, as well as delivery delays and international trade restrictions.

“This situation has generated tangible financial losses on a global scale,” says Vakil. “Even the largest manufacturers with endto-end processes in place, dependent on a group of sub-suppliers spread across the globe, haven’t escaped this turmoil.

“To make this point clearer, a threeday fire at a semiconductor plant in Japan shut down production lines for six months.

“Because of COVID-19, the usual safety, cleaning and maintenance procedures weren’t completed, contributing to a surge in factory fires post-COVID-19”

BINDIYA VAKIL CEO AND CO-FOUNDER, RESILINC

“Over 100,000 organisations partner with Resilinc to take their supply chain risk management programmes from reactive to resilient... They are able to do so thanks to our multi-tier mapping capabilities along with our EventWatchAI platform, which monitors millions of news and social feeds globally, across 100 languages, for potentially disruptive events.”

The price of some chips surged from US$5 to US$110 in just a few days and this cost sourcing organisations tens of millions of dollars. Because of the pandemic, the usual safety, cleaning and maintenance

procedures on site could not be carried out, contributing to a surge in factory fires post-COVID-19. A supplier risk assessment on this particular Japan site later revealed that it didn’t have automatic sprinklers or a fire suppression system.”

The Taiwan Semiconductor Manufacturing Company (TSMC) controls about a fifth of global semiconductor manufacturing capacity and yet even they have experienced shortages of materials and workers, highlighting that issues heightened by the pandemic continue to impact supply chains.

In contrast, businesses that invested in mapping and monitoring their supply chains ahead of the pandemic emerged in far better shape.

“COVID-19 was a wake-up call for supply chain managers. It highlighted the

“Investing in technologybased supply chain risk management solutions will improve a company's agility and responsiveness in times of crisis”

The Journey of an Idea to Innovation: Bindiya Vakil (CEO, Resilinc)

WATCH NOW

BINDIYA VAKIL CEO AND CO-FOUNDER, RESILINC

importance of having full visibility into their supplier networks. If companies know which suppliers, sites, components and products are at risk, they can prepare for and mitigate the effects of possible disruptive events,” says Vakil.

Over the next 12 months, she expects to see the introduction of new legislation, as well as diversification. More and more countries will recognise the challenge in the semiconductor market, with the UK government unveiling a new £1bn semiconductor strategy to strengthen the supply chain and increase its resilience.

“As countries try to become more selfsufficient, they invest in new partnerships, build long-term plans and expand their infrastructure as well as capacities. At the same time, while tensions between the West and China grow, decision-makers

look to Japan – as evidenced by the recent announcement of the UK's semiconductor partnership with Japan – with the US looking to bring manufacturing back to American soil.

“What will be crucial for the overall situation of the global supply chain is new legislation, like the recently approved EU Corporate Sustainability Due Diligence Directive or the German Supply Chain Due Diligence Act,” said Vakil. “Businesses will need to increase their efforts in a number of areas to comply with new policies and make sure they have supply chain management practices in place. These include mapping all of their suppliers in the network, having visibility beyond the largest suppliers, and monitoring them for potential ESG risks in order to do their due diligence and comply with new regulations.”

Raghavendra. K.A., Global Head of Engineering, IOT & Blockchain practice at Infosys, on the road to net-zero with digital twins & modern manufacturing

WRITTEN BY: HELEN ADAMSRaghav Karinja is the Global Head of Engineering, IOT and Blockchain practice at IT service Infosys.

Based in Bangalore, India, Infosys was founded in 1981, with a goal to be a leader in next-generation digital services and consulting. Now, Infosys has 343,000 employees globally and a revenue of USD$1bn.

In his role, Karinja helps clients in their digital transformation journey across their product life cycle. With more than two decades of consulting and programme leadership experience, he continues to be a hands-on practitioner helping clients navigate their transformation journey, through initiatives like smart connected products and operations, digital threads, servitisation and smart spaces.

Here, he discusses how the manufacturing sector can reach net zero, the role of digital twins and innovative technology solutions.

Infrastructure development in the past and for the cities of tomorrow promises economic and social advancements across communities. However, Karinja points out that historically, it also drives up carbon emissions and adversely impacts the environment in myriad ways.

“Amidst a global recognition of the climate change crisis, it is now an organisational imperative to have sustainability principles at the core of their infrastructure development initiatives and with a target date of 2044, nearly three-quarters of organisations have set a net-zero goal,” explains Karinja.

Organisations that are committed to sustainability are increasingly efficient, use fewer resources, create less waste to generate more revenue and produce higher returns on investment.

Manufacturing is a lucrative target for cybercrime. As a large industry with valuable data and a growing IoT attack surface, your data is of direct value to hackers.

However, Karinja knows that one of the challenges of investing in sustainability has been the lack of insight into the organisational processes.

“Digital twins can provide real-time insights into any physical entity, subsystem, system, process, or an ecosystem, allowing for a transparent validation basis for the strategic KPIs. It helps in monitoring and optimising the sustainability performance indicators in real-time or near real-time across the life of an asset.”

Despite being around for decades, digital twin technology is now increasingly being harnessed across industries and geographies. It is being adopted by organisations to design and build more sustainable infrastructure for the future that aligns with their ESG considerations.

Karinja sees that digital twin technologies also have huge potential in planning smart cities and their ecosystem which includes factories, infrastructure, transport, communication networks and more.

“Right from the design phase, the digital twin helps evaluate various trade off studies on materials, designs, and other processes to improve the fidelity

“Digital twins can provide real-time insights of any physical entity, subsystem, system, process, or an ecosystem”

RAGHAVENDRA. K.A GLOBAL HEAD OF ENGINEERING, IOT & BLOCKCHAIN PRACTICE, INFOSYS

of models substantially and arrive at the best possible options. These ‘As designed KPIs’ of assets can be continuously evaluated with the ‘As constructed KPIs’ during the construction phase – reducing the gaps if any in a short time with minimal resources.

“Digital twins enable better collaboration and real-time information exchange between the design department and the construction site which improves stakeholder experience, project efficiency, and quality of work. Additionally, since for high value assets, the operations phase continues for several decades, comparing ‘As designed KPIs’ and ‘As operated KPIs’ via digital twins allows real-time insights and information on the operations and health

of the asset. This helps in managing the cost of operations, energy consumption, carbon footprint, and waste management.”

According to projections by the United Nations, two-thirds of the planet’s population will be in urban areas by 2050. The number of megacities is also expected to grow from 31 today to 43 by 2030. One of the critical needs therefore is to reduce the exponentially growing carbon footprint attributed to modern society and restore planetary stability.

“Using digitalisation as a core fabric to facilitate transformations across the built environments helps in developing

environmental resilience. Acceleration of responsible, people-centred digitalisation can identify, design and implement and realise practical sustainability megatrends. Designing and building infrastructure in a digital world enables organisations to track carbon emissions and conserve resources more efficiently.”

Karinja sees that a digital infrastructure is central to the net zero push enabled by sustainable supply chains, smart monitoring and controls, as well as strategic implementation across all aspects of cities and communities to transform the urban landscape, including human settlements, natural environment and the built environment.

“The digital twin helps evaluate various trade off studies on materials, designs and processes to arrive at the best possible options”

RAGHAVENDRA. K.A GLOBAL HEAD OF ENGINEERING, IOT & BLOCKCHAIN PRACTICE, INFOSYS

“An integrated, holistic conception of sustainability needs to incorporate the needs and aspirations of all stakeholders and support the organisational vision.”

“To that end, the United Cities Global Framework was developed and tested in extensive cooperation with the private sector, investors and finance institutions, international agencies, academic institutions, NGOs and local and central governments,” explains Karinja. “It includes setting up city innovation labs, enabling ecosystem labs to scale green industrial city projects, developing partnerships with other global actors, ensuring citizen involvement and implementing urban operations with digital twins.”

Innovative technology solutions and advanced city simulations allow for a systematic and holistic approach to urban development that aligns with climate targets and sustainability development goals. Advanced city simulation labs also enable data-driven understanding of endto-end operations to make financial and risk assessments sense of sustainability goals.

“While innovation by private enterprises and investors push public institutions to act with speed and scale, public-private partnerships (PPPs) are essential for taking a holistic approach towards ESG,” says Karinja. “PPPs bring together skillsets from the private sector and resources at scale from the public sector.

“Digital twins are a key technology to drive sustainability across the enterprise and provides holistic value on sustainability by balancing social, environmental and economic imperatives while allowing businesses to benefit from sustainable and circular economy designs in the long term.”

“Digital twins enable better collaboration and real-time information exchange between the design department and the construction site”

RAGHAVENDRA. K.A GLOBAL HEAD OF ENGINEERING, IOT & BLOCKCHAIN PRACTICE, INFOSYS

Raghav Karinja is a Global Head of Engineering, Infosys has 343,000 employees globally and a revenue of USD$1bn

WRITTEN BY: HELEN ADAMS

WRITTEN BY: HELEN ADAMS

Seclore is a data-centric security company headquartered in Santa Clara, California. At its core, the company helps enterprises protect their most sensitive IP. Founded on the principle that traditional cybersecurity methods that focus on securing networks and devices are no longer sufficient, Syclore aims to be the leading provider of ‘data-centric security’.

The company has globalised and expanded to other markets, including North America and now has more than 2,000 customers across nearly 30 countries that use the Seclore platform to protect their most sensitive information and digital assets, within and outside the organisation’s boundaries.

Vishal Gauri is President of the Americas at Seclore. He joined the company in 2021 and is based in San Francisco.

“Prior to Seclore, I’ve worked in venture capital and IT. Earlier in my career, I worked on developing semiconductor processes and equipment at Novellus Systems and am the inventor/author of 18 patents in that area,” Gauri explains. “At Seclore, we serve a variety of industries and work with many of the biggest names in semiconductor manufacturing in the United States to protect intellectual property and prevent data theft.”

Since Gauri entered the industry, cybersecurity has changed dramatically. According to Gauri, there are a multitude of factors behind this.

"First, it is that data has never been more strategically important to enterprises — IP and proprietary data are the lifeblood of businesses, representing organisations’ greatest competitive differentiation,” he explains. “At the same time, organisations have

6 - 7 September 2023

Business Design Centre, London

SPONSORSHIPS GET YOUR PASS

never been more globally distributed and increasingly work with an extensive network of third-party collaborators – everyone from designer software [EDA], and foundries, to capital equipment manufacturers.”

This means security teams must protect a much wider surface area, as sensitive company data is constantly on the move, passing from individual to individual, inside and outside the enterprise.

“The dagger is this though: while the state of cybersecurity has changed quite radically in recent years, many of the prominent cybersecurity tools and methods used today are the same ones used decades ago and it’s leaving organisations vulnerable.”

In August of 2022, the Biden administration signed the CHIPS and Science Act into law. It promised to strengthen American manufacturing, supply chains and national security.

“This CHIPS Act will invest in research and development, science and technology, and the future workforce to keep the US a leader in emerging industries, including nanotechnology, clean energy, quantum computing and AI,” says Gauri. “Since being signed, the US has seen investments in and openings of chip facilities in North Carolina, New York, Arizona, Utah, Kansas and California.

“The more the U.S. can depend on technology within its borders, the less risk in the global supply chain”

“This ramping up of chip production will boost American semiconductor research, development and production as the US currently only produces around 10% of the world’s supply of semiconductors. The growth will help the US maintain a competitive technological edge by lowering the costs of chips and creating new American jobs.”

The promise of jobs is proving popular with the local populations where the chip facilities are being built. Furthermore, for those who have been battered by the supply chain disruptions of the past three years, the CHIPS Act is a welcome sign that the manufacturing sector has learned a lesson and is investing in a smoother future.

Since the COVID-19 pandemic, manufacturers have investigated reshoring opportunities as a solution to supply chain disruption.

“The more the US can depend on tools and technology within its borders, the less risk they have when there are disruptions or disturbances in the global supply chain,” says Gauri.

Impacted by varying sanctions, material supply and border controls from various countries, the global supply chain is dependent on several factors to operate smoothly.

“If the US can manufacture more components and products within the country

itself, it mitigates American risk when any of those factors are disrupted internationally.”

However, there remain many cybersecurity risks surrounding US chip production. For Gauri, data security is synonymous with national security in the chip industry.

“The chip designs, product roadmaps, IP, process equipment and other proprietary information of new US fabs will be of incredible interest to adversaries,” says Gauri. “This is already a concern. Just last fall, the Biden administration enacted new rules to curb China’s access to certain US chips, for fears that they could be used

Seclore Song | "Access Denied" at Cybersecurity Summit Nashville

WATCH NOW

Seclore Song | "Access Denied" at Cybersecurity Summit Nashville

WATCH NOW

“Many of the cybersecurity tools and methods used today are the same ones used decades ago. It’s leaving organisations vulnerable”

VISHAL GAURI PRESIDENT OF THE AMERICAS, SECLORE

as components across China’s military infrastructure. The expectation is that these rigs will become even bigger targets moving forward.”

One of the greatest vulnerabilities comes from third-party risk. US chip manufacturers work with several third-party vendors, often sharing sensitive data (including chip IP) with those parties.

“To ensure that data is thoroughly protected, manufacturers must extend their security and risk management infrastructure to their vendors, advisors, sub-contractors and partners,” Gauri explains. “They’ll want to maintain security and control of information wherever it travels, prevent unauthorised users from accessing and misusing the information and maintain complete visibility over all activities performed by all users on all sensitive information regardless of where it is stored.”

Over the next year, Seclore will continue to build out its North American footprint, invest in product innovation and educate the market about the importance of data-centric security.

“Rather than depending on endpoint or perimeter security tools that become impractical once the data leaves the organisation, security teams must focus on embedding security into the data itself.”

This is a major paradigm shift for most organisations and Seclore wants to provide the tools and resources to help lead the way.

“The state of cybersecurity has changed quite radically in recent years”

VISHAL GAURI PRESIDENT OF THE AMERICAS, SECLORE

The USA currently only produces around 10% of the world’s supply of semiconductors

Siemens, ABB, Schneider Electric, Honeywell, Robert Bosch, Rockwell Automation, Mitsubishi, General Electric & Danfoss are our Top 10 smart manufacturers

WRITTEN BY: HELEN ADAMSSmart manufacturing refers to the use of advanced technologies, data analytics and automation in the manufacturing process.

In the dynamic world of modern industry, smart manufacturing has emerged as a powerful force, reshaping traditional production and driving unprecedented efficiency, productivity and innovation.

Spanning various sectors including machinery, electronics and energy, this article unveils our Top 10 smart manufacturing companies leading this transformation – Siemens, ABB, Schneider Electric, Honeywell, Robert Bosch, Rockwell Automation, Fanuc, Mitsubishi, General Electric & Danfoss. These industry leaders have embraced the opportunities of smart manufacturing – here’s why.

20,000 employees

CEO: Kim Fausing

Revenue: €11bn

Danfoss is a global leader in energy-efficient and climatefriendly solutions that uses smart manufacturing technologies to reach its goals.