PORTFOLIO

MAHLET ARGAW DEMISSIE

AUGUST2024

Msc. Mahlet Argaw Demissie

Architectural Engineer| Comutational Designer| BIM Specialist

mahletargaw.demissie@mail.polimi.it

Lecco, Italy

+393888604596

linkedin.com/in/mahlet-argaw-demissie

Experiance

AMAART, Desemzano Garda, Italy

Intern Project Architect, April 2024 - July 2024

Architectural Design, 3D visualization, BIM Modeling

FUV progettazione, Como, Italy

Intern Architect, Dec 2023 - Feb 2024

3D visualization For a Renovation Project

Bigar Builders And Developers, Addis Ababa, Ethiopia

Part-Time BIM Architect, Jan 2021 - Aug 2021

BIM Modeling and Technical Drawing Preperation

Eskinder Architects, Addis Ababa, Ethiopia

Project Architect, Nov 2019 - Aug 2021

Architectural Design, Facade Design, BIM Modeling, Technical Drawing Preperation, Supervise and coordinate Interior design Team, 3D visualization

YTH Architecture and Enginering Consulting P.L.C. , Addis Ababa, Ethiopia

Architect

May 2019 - Nov 2019

Architectural Design, BIM Modeling, Technical Drawing Preperation, 3D visualization

K2N Architecture and Enginering Consulting P.L.C. , Addis Ababa, Ethiopia

Graduate Architect,

Nov 2017 - May 2019

Architectural Design, BIM Modeling, Technical Drawing Preperation, 3D visualization

New Gate Architects And Consulting, Addis Ababa, Ethiopia

Intern Architectural Designer, June 2016 - Aug 2016

Architectural Design, 3D visualization

Narga Architects And Consulting, Addis Ababa, Ethiopia

Intern Architectural Designer, Sep 2015 - Feb 2016

Architectural Design, 3D visualization

Reference (Up on Request)

Professor Pierpaolo Ruttico, (Founder of Index Lab) pierpaolo.ruttico@gmail.com

https://www.indexlab.it/

Professor Masera Gabriele (Building Engineer, MEng PhD) gabriele.masera@polimi.it

Politecnico Di Milano, Lecco, Italy

Msc In Building And Architectural Engineering, Sep 2021 - July 2024 _ 110L/110(Cumlaude)

Addis Ababa University, Eiabc, Addis Ababa, Ethiopia

Bsc. In Architecture, Sep 2012 - Jul 2017

Education And Training Training

SMAC Scuola Manifattura Additiva, Coreglia Antelminelli,, Italy

Certificate ,July 2024 - Aug 2024

Skill

BIM + 3D Modeling + Computational Design Energy Simulation Visualization

Revit Architecture, Navisworks, Dynamo, Rhino, Grasshopper, Sketchup

Transys, Climate Studio,

Vray, Lumion, Twinmotion, Enscape, Adobe Creative Suite (Photoshop, Illustrator, Indesign, Premier Pro,)

Interest

Computational Design | Facade Engineering | BIM Coordination | Energy Simulation

Language

Amharic (Native), English (Proficient)

Adwa Museum 0Km Project

PROJECT INTRODUCTION

LOCATION - ADDIS ABABA, ETHIOPIA

SITE SIZE - 4000 SQ. M

PROJECT DESCRIPTION - the site is one of the most important areas of the city. The project covers 30,000km2. The center will accommodate principally the City hall and adjoining meeting halls, related public functions, Adwa Museum, cinema, cafe, art gallery and exhibition, library and others are integrated with the conference facility to create an important Civic Building in Addis Ababa.

Context

Level -2 Block C Section

Facade Design

Indoor

Ducatal Facade Detail Elevation

Ducatal Facade to Wall Connection Detail

IN-BETWEEN

Group Work

Task - Architectural Design and Technical Detailing

Located in heart of milan at close promiximity to the centrale station and well connected with the Milan city network. The site i s analysed on multiple layers inorder to help us understand and identify the key potentials and shortcomings. The layers analysed was void study analysis, accessibility and landuse analysis. and following conclusions is shown in the figures below.The key understandings are the site is located in a dense volume space with less open space ratio and narorw lanes with limited daylight in the area.

Optioneering is a process of balacing by proposing and comparing different options to select the most optimized option in terms of energy performance, daylight, cost, embodied carbon, ..etc.

SITE ANALYSIS

Step #2 Mass Formation

Landmark Mixed Use Night Life

Step #3 Continuity

Contineous Skin

Courtyard

Step #1 Open Spaces

Connectivity

Shape Optimization + Energy Consumption

A - Main Entrance

B -Entrance Courtyard

C- Green Terrace

D - Office Tower

E - Leisure Complex

F - Second Entry/Exit

Building Section North Elevation

Schematic Design

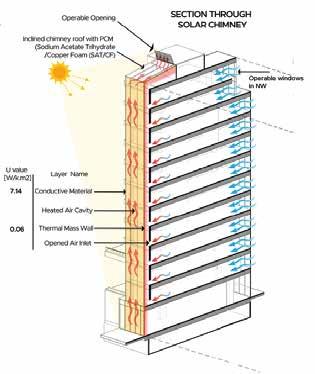

Winter

Passive Strategies

Winter Garden (traps the solar geat and increase t empratue during winter)

Summer

Passive Strategies

(allows heat exchange with the enviromnent due to the north side orientation and plantation)

Solar chimney

Shading Optioneering

Analysis

Vertical Optioneering

DAYLIGHT ANALYSIS

After applyiing vertical, results show that we got better annual sun exposure and a good opportunity to reduce glare probability on the two views of the co-working space. For each one we choose the seats near the glazing as they are closere to overlit areas.

1

X , Y , Z ) : 16.33 , 11.8 ,

2 ( X , Y , Z ) : 6.53 , 5.76 , 35.2

View 1

View 2

View

View

ACP Rainscreen Facade Technology

Opaque

Detail

1. Soprema XPS Polystyrene Insulation 120mm thick

2. Air/Water Barrier Membrane, 3mm

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

5. Hilti bracket fastening bolt

6. 2mm thick Thermostop

7. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

8. Plastic clip

9. S- section aluminum extrusion

10. Aluminum z-section horizontal sub-structure

11. Polypropylene Anchors with 60mm diameter to \ x Insulation Aluminum horizontal pro le of Adjustable fastener with locking system

1. Soprema XPS Polystyrene Insulation 120mm thick

2. Air/Water Barrier Membrane, 3mm

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

5. Hilti bracket fastening bolt

6. 2mm thick Thermostop

7. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

8. Plastic clip

9. S- section aluminum extrusion

10. Aluminum z-section horizontal sub-structure

11. Polypropylene Anchors with 60mm diameter to \ x Insulation Aluminum horizontal pro le of Adjustable fastener with locking system

12. 300mm RCC shear wall

13. Soprema XPS Polystyrene Insulation 100mm thick

14. Anodized Aluminum, U Pro le extruded section (150X250X4MM) Pro le Wall bracket/sub-structure with exible xing

15. Aluminum gutter 200mm diameter

16. L pro le anodized aluminum pro le 180x80z10mm

17. Hilti bracket fastening bolt

18. aluminum T-pro le plate 2mm thick

19. Anchoring bolt

20. Plastic board thermal separation

1. Soprema XPS Polystyrene Insulation 120mm thick

2. Air/Water Barrier Membrane, 3mm

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

5. Hilti bracket fastening bolt

6. 2mm thick Thermostop

7. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

8. Plastic clip

9. S- section aluminum extrusion

10. Aluminum z-section horizontal sub-structure

11. Polypropylene Anchors with 60mm diameter to \ x Insulation Aluminum horizontal pro le of Adjustable fastener with locking system

12. 300mm RCC shear wall

13. Soprema XPS Polystyrene Insulation 100mm thick

14. Anodized Aluminum, U Pro le extruded section (150X250X4MM) Pro le Wall bracket/sub-structure with exible xing

15. Aluminum gutter 200mm diameter

16. L pro le anodized aluminum pro le 180x80z10mm

17. Hilti bracket fastening bolt

18. aluminum T-pro le plate 2mm thick

19. Anchoring bolt

20. Plastic board thermal separation

21. Cement screed with 1% drainage slope

22. Soprema XPS Polystyrene Insulation 100mm thick

23. Roof Air/Water Barrier Membrane, 3mm

24. Terracota Roo ng Tiles, Dim: 300X200X10mm

1. Parapet Top AlucoBond Panel Clad Finish

2. Anchor Bolt & Plate Assembly

3. Anchor Gutter Bar

4. 12mm Exterior Wall Cement Board Cladding

5. Water Barrier Membrane 3mm

6. Grey Flex Backer seal & Sealant

7. ICF Italia Metal Internal Spacer

8. 8mm Horizontal Reinforcement Bar

9. 200mm Concrete Infill

10. Water Barrier Membrane,3mm/spray type

11. ICF Italia Rigid XPS Insulation Exterior Panel

12. 12mm Vertical Reinforcemnt Bar Inserts

13. ICF Italia Rigid XPS Insulation Interior Panel

14. Backer Seal @ Sealant

15. Steel Wall Flashing

16. Soprema XPS Crank Strip

17. Connecting Stirrups from Isokorb Thermal Bridge Installation

18. Balustrade Thermal Break with reinforcement, Dim:200x120x250 mm, Type: SchöckIsokorb® XT type A

19. Anticracking Mesh-6mm Dia Reinforment at150mmx150mm grid spacing

20. Concrete 175mm

21. XPS Insulation inside the steel deck sheet

22. Rebar Connection from ICF Wall to Steel Deck Concrete Slab

23. C aluminium channel for false ceiling suspension

24. Expansion Joint between I Beam to Concrete wall connection

25. IPE 600 I beam

26. Steel Stud for supporting interior wall finish

27. 12mm Gypsum Plaster Board Interior

28. Aluminium Substructure for suspended false ceiling

29. PolyEthylene Membrane for Protection of Insulation, 1.5mm Thk

30. Cement Screed with 1.5% slope

31. 18mm Thk Ceramic Tile

ADAPTIVE FACACDESTUDIO

Acadamic Work _Group Work

Task - Facade Design and Parametric modeling

Provide motion to the structure throught geometry without the implementation of energy source. Inspiration of auxetic material behavior

Experimentation and Implementation of bimetal sheet as a facade cover. The metal strip react to temperature change, bend when its cooled or hit.

Site Selection

Solar Study

Understand and suggest the application of auxetic structure at building scale. Create a new facade system

Auxetic Element Mechanics

Closed Auxetic Facade

MS Frame+Wood Louver

Balcony Floor Lintel Frame

Mild Steel Anchor To Wall

Electro-mechanical Actuator For Auxetic Structure

Auxetic Joints

Auxetic Frame Structure

Bimetal Folded Surfaces

Bimetal sub-structure

Open Auxetic Facade

Lintel Frame

Bimetal Folded Surfaces

Auxetic Frame Structure

Auxetic Joints

Bimetal sub-structure

MS Frame+Wood Louver Balcony Floor

Electro-mechanical Actuator For Auxetic Structure

Mild Steel Anchor To Wall

Mild Steel Anchor To Wall

Sunpath – Summer drybulb temperature diagram

Daylight Analysis

Annual DGP

Int ol erabl e: 44%

Di s t urbi ng: 20%

Perc ept i bl e: 9%

Im perc ept i bl e: 27%

Int ol erabl e & Di s t urbi ng DGP i s 64%

DGP at 12.30 pm of 21 of Jun

Int ol erabl e: 18%

Di s t urbi ng: 11%

Perc ept i bl e: 11%

Im perc ept i bl e: 60%

34% of i nt ol erabl e and di s t urbi ng DGP dec reas ed

Int ol erabl e: 26%

Di s t urbi ng: 12%

Perc ept i bl e: 18%

Im perc ept i bl e: 44%

26% of i nt ol erabl e and di s t urbi ng DGP dec reas ed

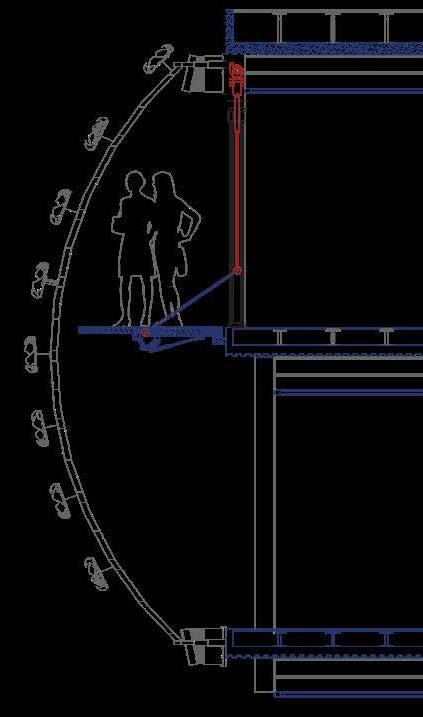

Technical Details

Section Of Closed Auxetic Frame

Frame Kinematics

Mild Steel Anchor To Wall

Motor Arrangment Above

Balcony Door Lintel For Balcony Slab Actuation

Lintel Frame

Pulley System Encased Inside ACP Cover Panel

SS YLSCRBKF Hinge

MS Frame+Wood Louver

Balcony Floor

Concrete Extension (Extra Support For Balcony)

Auxetic Frame Joint Detail

Auxetic Frame And Bimetal Surfaces

Auxetic

Bi-Metal Elevation

Actuator Detail

Bi-Metal Connection Detail

Section Of Open Auxetic Frame

Mild Steel Anchor To Wall

Motor Arrangment Above Balcony Door Lintel For Balcony Slab Actuation

Lintel Frame

Pulley System Encased Inside ACP Cover Panel

MS Frame+Wood Louver Balcony Floor

SS YLSCRBKF Hinge

Concrete Extension (Extra Support For Balcony)

Bimetal Surfaces

Auxetic Frame

Mild Steel Anchor To Wall

Computational Workflow

NE US NEXUS - FINAL THESIS PROJECT

Exploring Advanced Design and Fabrication Methodologies for a Free-form Shading Element through Algorithmic Programming, Robotics and Machine Learning

Academic Work _Group Work

Task - Facade Design, computational design, optimization, fabrication

The project Investigates the exploration of advanced fabrication methodologies for complex, free-form shading elements in building facades. Emphasizing the integration of algorithmic programming, robotics, and Augmented reality (AR) and performance based analysis. Through detailed case studies and practical implementations, we demonstrate that employing advanced technological methods in fabrication not only streamlines the design-to-fabrication pipeline but also significantly enhances the adaptability, sustainability, andperformance of architectural facades.

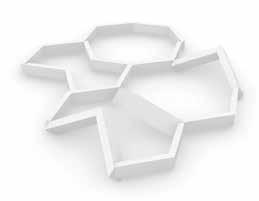

Pattern Inspiration for complex geometry

Erwin Hauer Pattern Mobius Loop

Parametric Design Process

Facade configuration determined based on the opening location

Planar facade pattern definition with uniform pattern module

Facade surface

Rationalization for pattern application

Final 3-dimensional pattern application with module customization

Optioneering Parameters

Panel Thickness

Panel Depth

Number of Panel

Facade Glass Ratio Centre position

Performance Based Facade optioneering

Multi-Objective

Optimization

Outcome of MOO

• Wallecei Plug-in for GH for MOO

• NSGA-2 evolutionary algorithm

• Increased speed of analysis due to usage of ML model for Daylight analysis

1.00

space with parteo front

objective

Documentation and Optimization

Stiffness optimization with Galapagos

Technical Detail

Technical Detail

Assembled view

Steel profile for locking module

Assembled Side view

Augmented Reality integration

Advantage

Facilitate for Complex Assembly Process

Attain Precision

Time Efficiency

Prototype

Size 1.2m x 1.2m

Material

•Metal sheet

•Steel Spacers

•Rivets

Used methodology -

•Cnc Cut and

•Hand Assembled

Fabrication Methodology 2 - Incremental Sheet Forming(ISF)

Required Tools

Rationalization of complex shape

Robot Tool Path Creation Assembly Detail and Process

1.5mm thick shading elements x6 (Aluminium, ISF process)

M8x8mm

welding screws (Stainless steel)

Round coupling nut (x6) with M8x8mm welding screws (x10) (Stainless Steel)

Steel Back Plate (3 mm thick)

Profile-to-plate

slot connector (3 mm thick)

M8 expansion screws (x6, stainless steel)

2x M8 screws (Stainless Steel)

Shading elements

End effector - Robot calibration Table and robot Calibration

End effector - Robot calibration

Incrementing process

Mahlet Argaw Demissie

August|2024

mahletargaw.demissie@mail.polimi.it

Lecco, Italy

+393888604596

linkedin.com/in/mahlet-argaw-demissie