INTEGRATED STUDIO

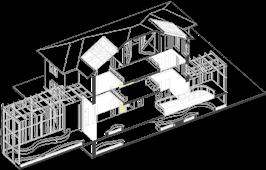

LOCATION - ADDIS ABABA , ETHIOPIA

SITE AREA - 300SQ M

PROJECT DESCRIPTION

the aim of this project is to develop an architectural project starting from the design development stage to the construction details drawing. the client of the project is a taxi driver and the assigned material ofconstruction is timber.

Plan View

Section and Elevation View

Interior View

Exterior View

RENOVATION PROJECT

The renovation site is a part of abandoned buildings that are intended to be part of an innovation and training center. The main development of the innovation center is through the learning process. the main purpose of these buildings is to be a part of the basic work of the innovation center that incorporates the community and facilitates community engagement. In consideration of this the site incorporates a museum (Building 1) connecting the entrance of the innovation center to the learning zones. Following the landscape and slope of the site a forest school for children (Building 2&3) emersed in the green landscape around. In addition, a youth center (Building 5) is integrated with the surrounding public outdoor plazas. Finally is a leisure complex (Building 4) that includes restaurants and a view tower.

BUILDING 1

Renovation Strategy

New Addition

Passive Strategy

Expelling stagnant air through atriums that allow hot air to exit the building envelope, by which it accelerates the air circulation through the envelope.

1- Lightweight structure.

2- Integration with Nature

Nature Passing through the building.

1- Accelerating Natural Ventilation

1- Lightweight structure.

2- Integration with Nature

Nature Passing through the building.

1- Accelerating Natural Ventilation

Functional Layering

Renovation Strategy

Passive Strategy

Functional Layering

IN-BETWEEN

Located in heart of Milan at close proximity to the centrale station and well connected with the Milan city network. The site i s analyzed on multiple layers in order to help us understand and identify the key potentials and shortcomings. The layers analyzed was void study analysis, accessibility and land use analysis. and following conclusions is shown in the figures below. The key understandings are the site is located in a dense volume space with less open space ratio and narrow lanes with limited daylight in the area.

Optioneering is a process of balancing by proposing and comparing different options to select the most optimized option in terms of energy performance, daylight, cost, embodied carbon, ..etc.

SITE ANALYSIS

Site Plan

Shape Optimization + Energy Consumption

Architectural Conceptual Design

Architectural Plan

Architectural Elevation

Building Section

North Elevation

Building Section

North Elevation

Architectural Elevation

Front view 3d render

Rear view 3d render

Schematic Design

Winter

Passive Strategies

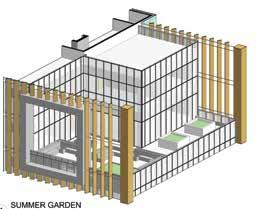

Summer

Winter

Passive Strategies

Summer

(allows heat exchange with the enviromnent due to the north side orientation and plantation)

Solar chimney

Garden (traps the solar geat and increase t empratue during winter)

Solar chimney

Garden

Solar chimney

Garden (traps the solar geat and increase t empratue during winter)

Solar chimney

Garden

Envelope Glazing Optioneering

Shading Optioneering

Daylight Analysis

Energy Analysis

Angle 0º Angle 60º

in this process the risk of glare is identified to be more in the Angle 0º option than the Angle 60º shading allignment

Before After application of shading system

DAYLIGHT ANALYSIS

Co working space located in 8th floor (elevation 34m) is the base line for optioneering for daylight analaysis due to its L shape which recives solar radiation from morning till the after noon and is double oriented twords the sun radiation of Milan’s climate

DAYLIGHT ANALYSIS

SHADING OPTIONEERING

After applyiing vertical, results show that we got better annual sun exposure and a good opportunity to reduce glare probability on the two views of the co-working space. For each one we choose the seats near the glazing as they are closere to overlit areas.

False colour

Intolerable glare

Disturbing glare

False colour

DAYLIGHT ANALYSIS

Application of light shelves

A light shelf can, depending on its design and building’s location, pereform more than one task of a daylighting system.

Use of interior vegetation

vegetation that is hanged from the cieling and covers the fenesterations below the applied lightshelves will reduce the overlitification and probable glare.

Facade Technology Detail

1.300mm RC shear wall

2.Soprema XPS Polystyrene Insulation 125mm thick

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4.S- section aluminum extrusion

5.Extruded aluminum blades

6. 2mm thick Thermostop

7.Hilti blade mounting bracket

8.Aluminum z-section horizontal sub-structure

9.200mm rigid foam PUR alu coating

10.Plastic board thermal separation

11.Concrete ber board

12.Hilti bracket fastening bolt

13.Air/Water Barrier Membrane, 3mm

14. Anodized Aluminum Box-section mullion 90x 75x 5mm

15.Floor drain channel for terrace

16.S- section aluminum extrusion

1. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

2.S- section aluminum extrusion

3. 2mm thick Thermostop

4. Anodized Aluminum, U Pro le extruded section (150X250X4MM) Pro le Wall bracket/sub-structure with exible xing

5. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

6.Soprema XPS Polystyrene Insulation 125mm thick

7.Soprema XPS Polystyrene Insulation 100mm thick

8.300mm RC shear wall

9.Soprema XPS Polystyrene Insulation 125mm thick

10. Aluminum horizontal pro le of Adjustable fastener with locking system

11.Air/Water Barrier Membrane, 3mm

12.FIXING FASTENER

13. Anodized Aluminum Box-section mullion 90x 75x 5mm

14. BIPV panel 36mm with aluminum galvanized back sheet

15. Anodized Aluminum, U Pro le extruded section (150X250X4MM) Pro le Wall bracket/sub-structure with exible xing

16.Hilti blade mounting bracket

17. 2mm thick Thermostop

ACP Rainscreen Facade Technolo- Opaque Facade Detail _1

Facade Detail _Exploded 3D

1.Soprema XPS Polystyrene Insulation 120mm thick

2.Air/Water Barrier Membrane, 3mm

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

5.Hilti bracket fastening bolt

6. 2mm thick Thermostop

7. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

8.Plastic clip

9.S- section aluminum extrusion

10.Aluminum z-section horizontal sub-structure

11. Polypropylene Anchors with 60mm diameter to \ x Insulation Aluminum horizontal pro le of Adjustable fastener with locking system

1.Soprema XPS Polystyrene Insulation 120mm thick

2.Air/Water Barrier Membrane, 3mm

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

5.Hilti bracket fastening bolt

6. 2mm thick Thermostop

7. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

8.Plastic clip

9.S- section aluminum extrusion

10.Aluminum z-section horizontal sub-structure

11. Polypropylene Anchors with 60mm diameter to \ x nsulation Aluminum horizontal pro le of Adjustable fastener with locking system

12.300mm RCC shear wall

13.Soprema XPS Polystyrene Insulation 100mm thick

14. Anodized Aluminum, U Pro le extruded section (150X250X4MM) Pro le Wall bracket/sub-structure with exible xing

15.Aluminum gutter 200mm diameter

16. L pro le anodized aluminum pro le 180x80z10mm

17.Hilti bracket fastening bolt

18.aluminum T-pro le plate 2mm thick

19.Anchoring bolt

20.Plastic board thermal separation

1.Soprema XPS Polystyrene Insulation 120mm thick

2.Air/Water Barrier Membrane, 3mm

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

5.Hilti bracket fastening bolt

6. 2mm thick Thermostop

7. Anodized Aluminum, U Pro le extruded section (650X55X2.5) Pro le Wall bracket/sub-structure

8.Plastic clip

9.S- section aluminum extrusion

10.Aluminum z-section horizontal sub-structure

11. Polypropylene Anchors with 60mm diameter to \ x Insulation Aluminum horizontal pro le of Adjustable fastener with locking system

12.300mm RCC shear wall

13.Soprema XPS Polystyrene Insulation 100mm thick

14. Anodized Aluminum, U Pro le extruded section (150X250X4MM) Pro le Wall bracket/sub-structure with exible xing

15.Aluminum gutter 200mm diameter

16. L pro le anodized aluminum pro le 180x80z10mm

17. Hilti bracket fastening bolt

18. aluminum T-pro le plate 2mm thick

19. Anchoring bolt

20. Plastic board thermal separation

21. Cement screed with 1% drainage slope

22. Soprema XPS Polystyrene Insulation 100mm thick

23. Roof Air/Water Barrier Membrane, 3mm

24. Terracota Roo ng Tiles, Dim: 300X200X10mm

Opaque Facade Detail _2

1.Parapet Top AlucoBond Panel Clad Finish

2.Anchor Bolt & Plate Assembly

3.Anchor Gutter Bar

4. 12mm Exterior Wall Cement Board Cladding

5.Water Barrier Membrane 3mm

6.Grey Flex Backer seal & Sealant

7.ICF Italia Metal Internal Spacer

8.8mm Horizontal Reinforcement Bar

9.200mm Concrete Infill

10.Water Barrier Membrane,3mm/spray type

11. ICF Italia Rigid XPS Insulation Exterior Panel

12.12mm Vertical Reinforcemnt Bar Inserts

13. ICF Italia Rigid XPS Insulation Interior Panel

14.Backer Seal @ Sealant

15.Steel Wall Flashing

16.Soprema XPS Crank Strip

17. Connecting Stirrups from Isokorb Thermal Bridge Installation

18. Balustrade Thermal Break with reinforcement, Dim:200x120x250 mm, Type: SchöckIsokorb® XT type A

19. Anticracking Mesh-6mm Dia Reinforment at150mmx150mm grid spacing

20.Concrete 175mm

21.XPS Insulation inside the steel deck sheet

22. Rebar Connection from ICF Wall to Steel Deck Concrete Slab

23. C aluminium channel for false ceiling suspension

24. Expansion Joint between I Beam to Concrete wall connection

25.IPE 600 I beam

26. Steel Stud for supporting interior wall finish

27.12mm Gypsum Plaster Board Interior

28. Aluminium Substructure for suspended false ceiling

29. PolyEthylene Membrane for Protection of Insulation, 1.5mm Thk

30.Cement Screed with 1.5% slope

31.18mm Thk Ceramic Tile

BIPV Panel Rainscreen Facade Technology

1.Soprema XPS Polystyrene Insulation 120mm thick

2.Air/Water Barrier Membrane, 3mm

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4. Anodized Aluminum Box-section mullion 90x 75x 5mm

5.Plastic board thermal separation

6. 2mm thick Thermostop

7.Hilti bracket fastening bolt

8.Plastic clip

9.Extruded aluminum section 2mm thick

10.Box section horizontal pro le 50x70x3mm

11.ORAS GS horizontal pro le

12. Aluminum horizontal pro le of Adjustable fastener with locking system

13. BIPV panel 36mm with aluminum galvanized

1.Soprema XPS Polystyrene Insulation 120mm thick

2.Air/Water Barrier Membrane, 3mm

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4. Anodized Aluminum Box-section mullion 90x 75x 5mm

5.Plastic board thermal separation

6. 2mm thick Thermostop

7.Hilti bracket fastening bolt

8.Plastic clip

9.Extruded aluminum section 2mm thick

10.Box section horizontal pro le 50x70x3mm

11.ORAS GS horizontal pro le

12. Aluminum horizontal pro le of Adjustable fastener with locking system

13. BIPV panel 36mm with aluminum galvanized backsheet

14.300mm RC Shear wall

15.Soprema XPS Polystyrene Insulation 100mm thick

16.Glass anchor

17.Aluminum-blind rivet

18.aluminum T-pro le plate 2mm thick

19.Anchoring bolt

20.XPS Polystyrene Insulation 50mm thick

21.L pro le anodized aluminum pro le 180x80z10mm

22.Aluminum gutter 200mm diameter

1.Soprema XPS Polystyrene Insulation 120mm thick

2.Air/Water Barrier Membrane, 3mm

3. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

4. Anodized Aluminum Box-section mullion 90x 75x 5mm

5.Plastic board thermal separation

6. 2mm thick Thermostop

7.Hilti bracket fastening bolt

8.Plastic clip

9.Extruded aluminum section 2mm thick

10.Box section horizontal pro le 50x70x3mm

11.ORAS GS horizontal pro le

12. Aluminum horizontal pro le of Adjustable fastener with locking system

13. BIPV panel 36mm with aluminum galvanized backsheet

14.300mm RC Shear wall

15.Soprema XPS Polystyrene Insulation 100mm thick

16.Glass anchor

17.Aluminum-blind rivet

18.aluminum T-pro le plate 2mm thick

19.Anchoring bolt

20.XPS Polystyrene Insulation 50mm thick

21.L pro le anodized aluminum pro le 180x80z10mm

22.Aluminum gutter 200mm diameter

23.Cement screed with 1% drainage slope

24.Soprema XPS Polystyrene Insulation 100mm thick

25.Roof Air/Water Barrier Membrane, 3mm

26.Terracota Roo ng Tiles, Dim: 300X200X10 mm

BIPV Panel Rainscreen Facade Detail _2

Facade Elevation

1.Soprema XPS Polystyrene Insulation 100mm thick

2.Soprema XPS Polystyrene Insulation 125mm thick

3.300mm RC shear wall

4. BIPV panel 36mm with aluminum galvanized back sheet

5.Plastic board thermal separation

6. 2mm thick Thermostop

7.Hilti bracket Sleeve Anchor

8. Anodized Aluminum u-pro le-section mullion 90x 75x 5mm

9.Extruded aluminum section 2mm thick

10. Anodized Aluminum Box-section mullion 90x 75x 5mm

11.Floor drain channel for terrace

12.Cement screed with 1% drainage slope

13.Polished Ceramic 4mm nish

14.Cement screed with 1% drainage slope

15.Soprema XPS Polystyrene Insulation 125mm thick

16.Air/Water Barrier Membrane, 3mm

17.L-pro le connecting plate

18.Perforated aluminum plate for drainage

19.Air/Water Barrier Membrane, 3mm

20.Steel deck slab

21.Plastic wall screw anchor bolt

22.C-pro le horizontal steel stud

23.I-section standard beam for stair

24.Expansion joint 20mm

25.Plastic board stair cover

26.Anti-slippery stair nish

27.C-pro le steel stud

28.Non-slippery stair nish

29.Aluminum fastening plate

30.Aluminum extrusion pro le

31.300mm RC shear wall

32.C-pro le steel stud

33.Gypsum panel internal nish

34.Plastic wall screw anchor bolt

35.Aluminum z-section horizontal sub-structure

36.Soprema XPS Polystyrene Insulation 125mm thick

37. Anodized Aluminum Box-section mullion 90x 75x 5mm

38. ALUCOBOND ACP Panel, 4mm - 0.5mm thick two aluminum cover sheets and a mineral- lled polymer core

39.Suspended Grid Aluminum T pro le

Adwa Museum Zero Km Project

PROJECT INTRODUCTION

LOCATION - ADDIS ABABA, ETHIOPIA

SITE SIZE - 4000 SQ. M

PROJECT DESCRIPTION - the site is one of the most important areas of the city. The project covers 30,000km2. The center will accommodate principally the City hall and adjoining meeting halls, related public functions, Adwa Museum, cinema, cafe, art gallery and exhibition, library and others are integrated with the conference facility to create an important Civic Building in Addis Ababa.

TASK ON PROJECT - Building Design, Facade Design, Interior Design

Site Organization

Site Plan

Block A

Block B

B-Section

Level-2 Bloc k B

B-Section

Level-2 Bloc k B

Facade Design

Facade Design