ARCHITECTURE PORTFOLIO

Maggie Collopy

2021-2023

Maggie Collopy

2021-2023

ADDRESS

1809 E 13th St Tucson, AZ 85719

PHONE NUMBER

(480)760-1657

mcollopy@email.arizona.edu

https://www.linkedin.com/in/maggiecollopy-936421227/

TECH SKILLS + SOFTWARE

Woodworking + Machinery

Metalworking + Machinery

Varied 3D Printing

Laser Cutting

CNC

Rhino 3D

Grasshopper

Revit

SketchUp

WUFI

Illustrator

Photoshop

InDesign

Excel

Enscape

Lumion

Leadership in Projects

Decision Making

Eagerness to Learn

Team Management

Broad High-Level Skill Set

Quick-to-Learn

ENGLISH

Full Proficiency, Native Language

FRENCH

Intermediate Level, Basic Working Proficiency

UNIVERSITY OF ARIZONA

August 2018 - May 2023

Currently within my fourth year obtaining a Bachelor’s of Architecture. The program pursues a well-rounded understanding of the practice with an emphasis on studio practice and is NAAB accredited. I currently am standing with a 3.5 GPA pursuing an emphais on lighting.

CAPLA MATERIALS LAB SHOP MONITOR

August 2021 - August 2022

Emphasis on machine maintinence and learning but with experience in helping students with their own projects. When working, quick decision making, respect for students, strong external and safety awareness, and quick learning are imperative. Additionally has taught me to improve my own intuiton about my own work. Most work done on digital fabrication tools but experience with traditional machinery. I also gained experience through scheduling appointments.

180 DEGREES DESIGN + BUILD: SUMMER INTERN

June 2022 - August 2022

During my internship, I had worked extensively detailed construction documents, building mock-ups, and designing built-in components for the firm’s projects. Such components included a pivot door, acoustic sliding door, and a receptionist desk. Overall, it was a great learning experience and served as an excellent opportunity to expand my skills and witness the firm’s culture.

CAPLA TEACHING ASSISTANT

August 2022 - December 2022

Helped teach students how to improve their advanced 3D modeling skills and how to 3D print, setting up tutorials and providing one-on-one lessons. Additional duties included grading, professor correspondence, and attendance taking.

EXTRACURRICULARS

AIAS BOARD MEMBER

August 2022 - Present

Currently serving as an active member of the University of Arizona’s AIAS program. Attends chapter meetings and events. Currently serving as the director for fundraising.

FREEDOM BY DESIGN MEMBER

August 2021 - Present

Currently Serving as a member of the Freedom by Design Committee at the University of Arizona. Attends weekly meetings, particpates in mostly group work, and proposes fesible design solutions.

INTERLOCHEN CENTER OF THE ARTS SUMMER CAMP

2011 - 2017

Prestigious Arts Camp located in Northern Michigan that helped me immensely build my creative skillset and interact with well-merited professionals in the art world. Primary focus on visual arts and advanced drawing and painting, experience with animation.

PHILANTHROPY

NATIONAL CHARITY LEAGUE - SCOTTSDALE CHAPTER

May 2012 - May 2018

Persistent member of organization completing over 50 hours of charity work yearly. Assummed various board roles from corresponding to organizations and event planning.

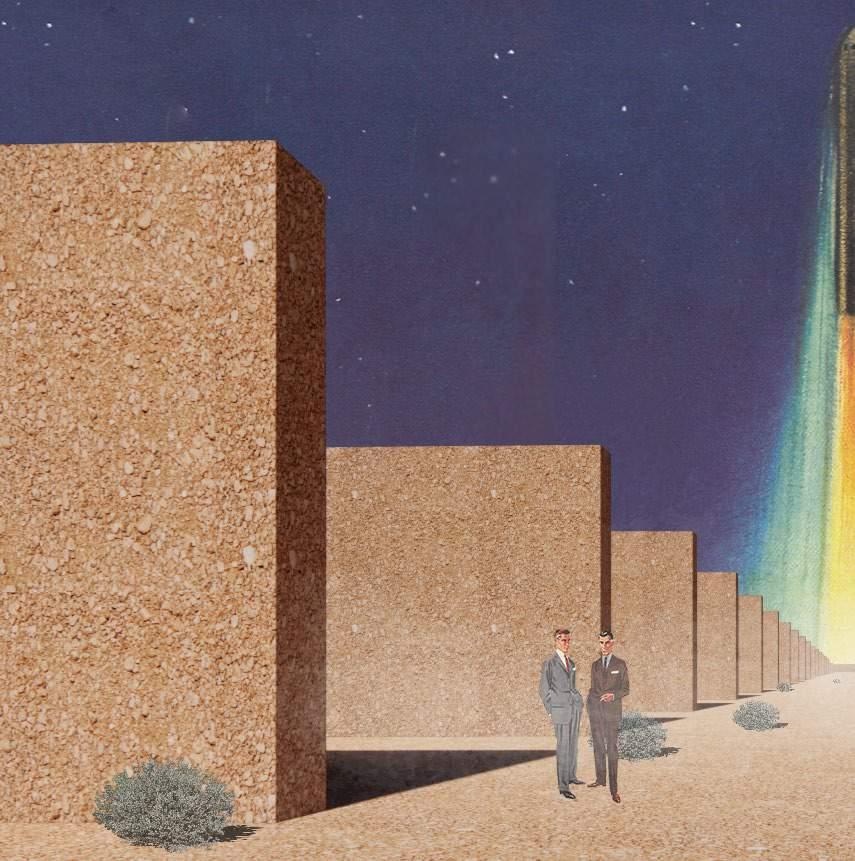

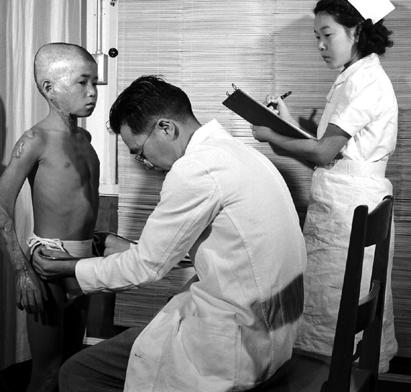

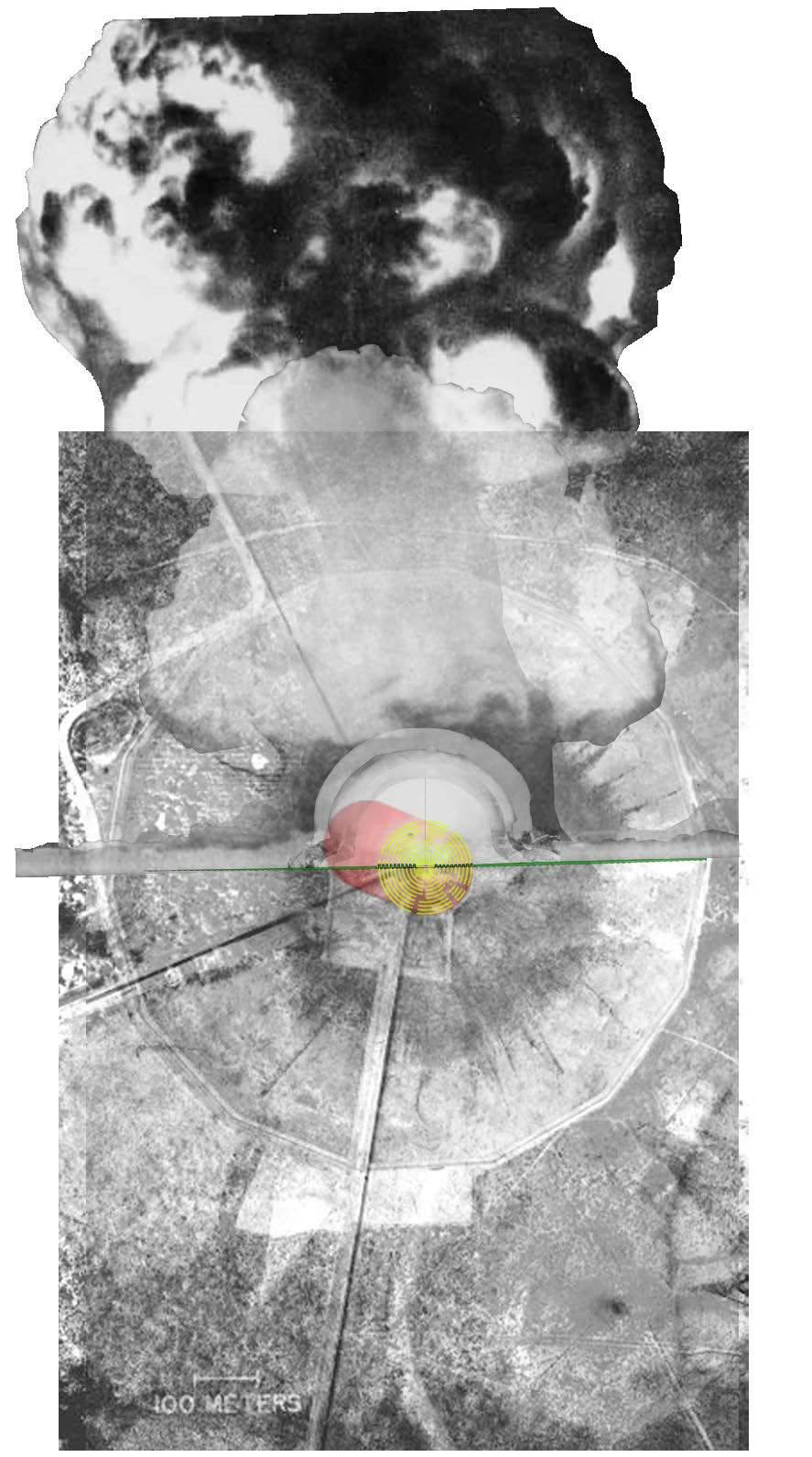

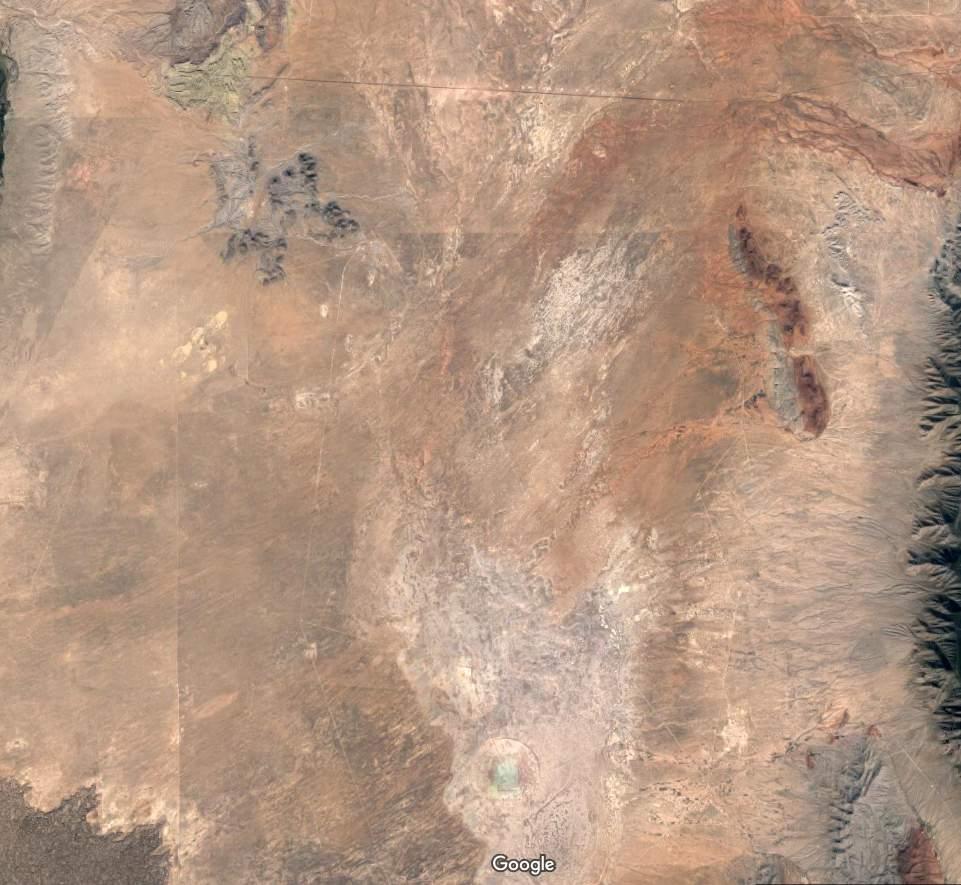

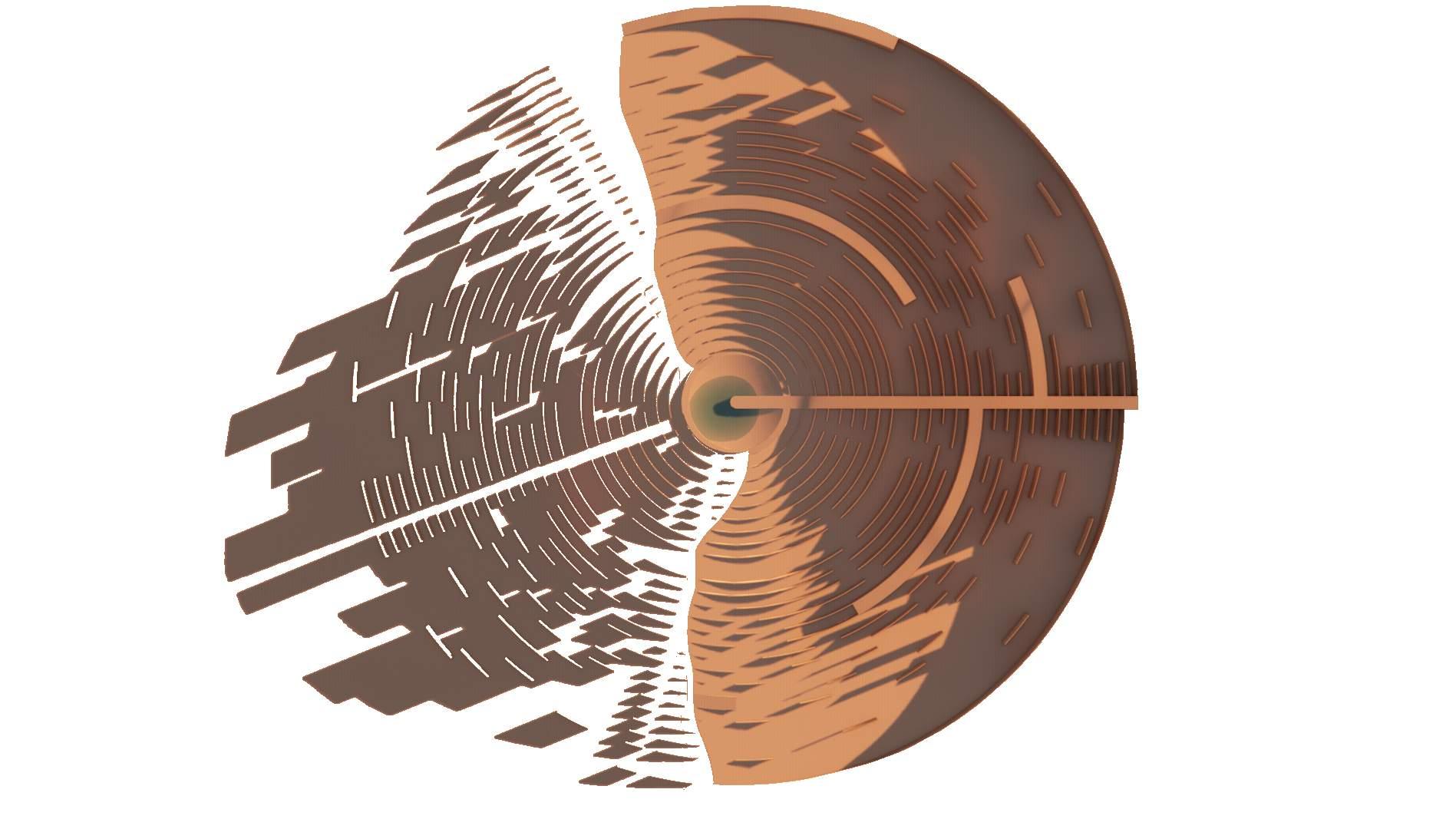

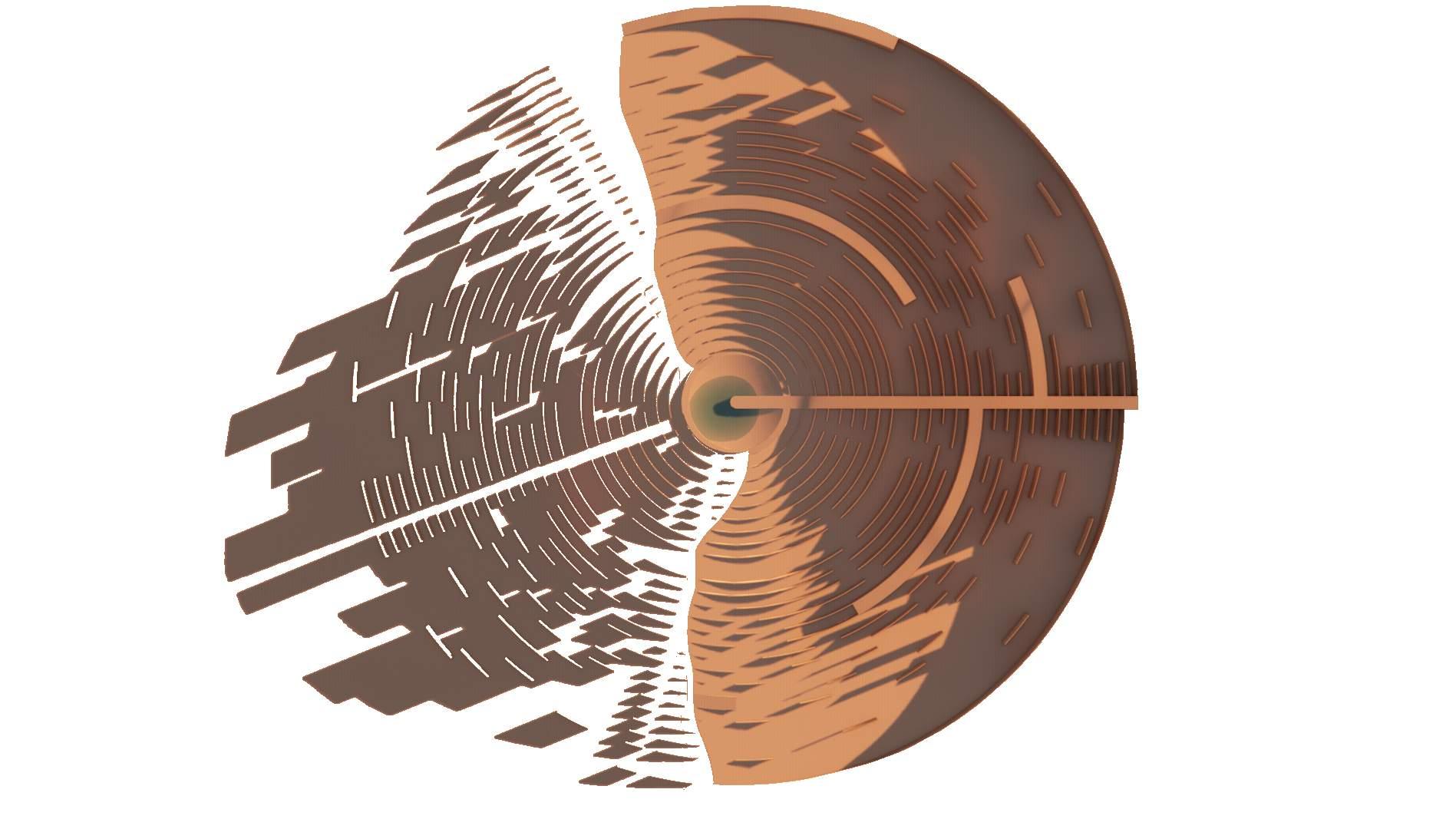

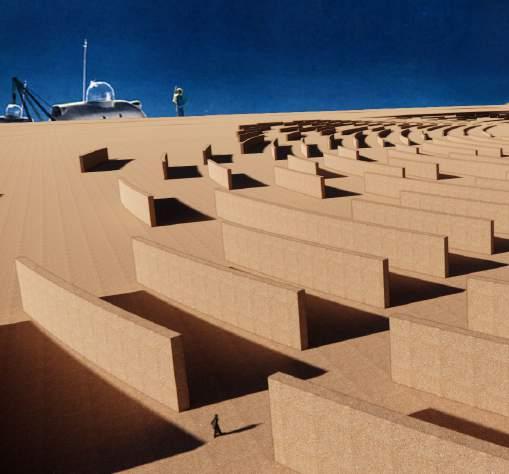

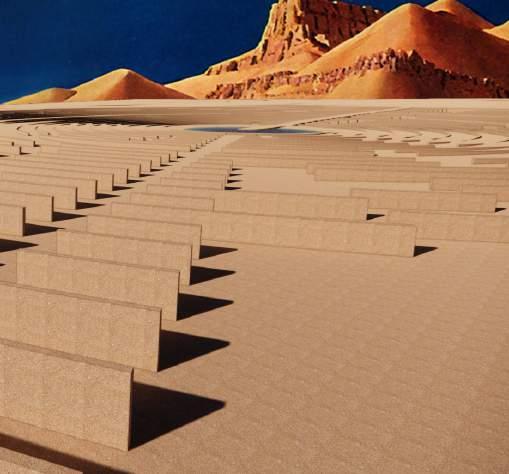

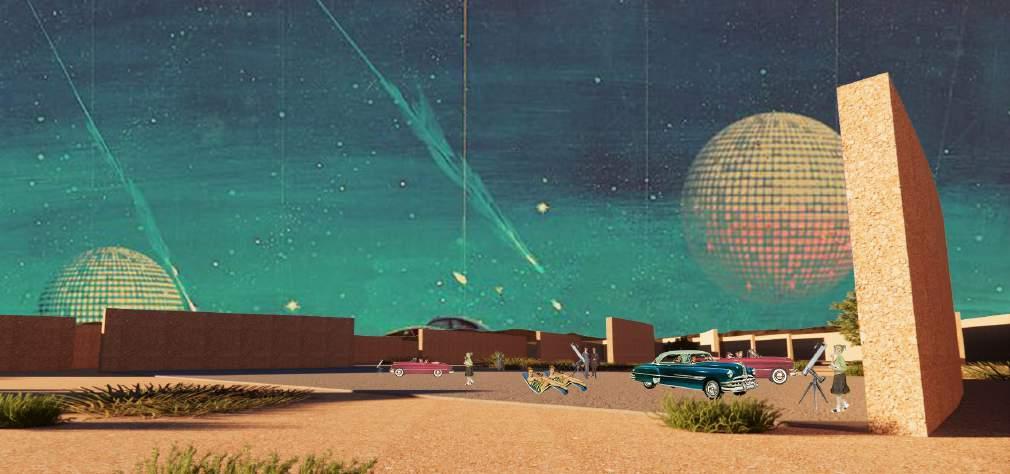

The atomic age was a time of curiousity, innovation, renaissance, and wonder. Sparked leading to the moon landing and nuclear energy. However, as quick as we were moving, hundreds of thousands have been affected by radiation from nuclear tests and governments place to recognize the lives lost from across the globe, having them journey through mist flame. However, to best encapsulate its scale and presence, a literal approach to the concentrating around the entire half-mile diameter physically altered site, exposing the well beyond the physical site as markers are made up to 250 miles away (as far as windows of personal reflection, reflecting the dicotomy on our innate curiousity of the universe beyond noted that this project is entirely conceptual and delved more into the site’s research-driven radiation. This was meant to explore atmosphere and emotions rather than specific architectural

Sparked by Trinity, Americans and the world alike were catapulted into age of science, moving, someone had to get left in the dust and experience the debris. Since Trinity, governments across the globe have taken little accountability. This memorial exists as a mist and path, to come together and dream of a brighter future around the eternal site was necessary. Series of concentric earthen walls surround the bomb’s epicenter the reality of the radiation from a physical perspective. However, decrepit walls extend windows rattled). On the main site, areas are divided into public use spaces and spots beyond us and grounded presence of those affected by the carnage. It should be research-driven relationship to light and the metaphyiscal understanding of the inability to see architectural detail.

CE: Trinity Plutonium Finishes Decaying

Fill = ~6” deep (topsoil)

original trinitite extent (loose) 1/4” thick

original trinitite extent (fused) 1/4” thick

ORIGINAL CRATER (expelled earth, no trinitite) ~300’

HIROSHIMA 64 kg Uranium 15 kT yield

War Begins 26,000

Fill = 4’ deep (topsoil)

MODERN ENCLOSURE 715’

TRINITITE EJECTA EXTENT (rained on Earth, trinitite pieces ) ~2500’

MODERN ENCLOSURE EXTENT ~2500’

FUSED TRINITIE EXTENT (heated earth, trinitite surface) ~1100’

NAGASAKI 6.4 kg Plutonium 21 kT yield

March 12th, 1947: Cold

WWII

Japan Surrenders, Ending

Original Crater: 4’-0” deep hyperbolic crv.

Bombing September 2nd, 1945:

Hiroshima + Nagasaki

Bombing August 6th + 9th, 1945:

July 16th, 1945: Trinity

TRINITY

May 8th, 1945: V-day

Commits Suicide

April 30th, 1945: Hitler

Project Begins

Founded, Manhattan

6.2 kg Plutonium 25 kT yield Spring, 1943: Los Alamos

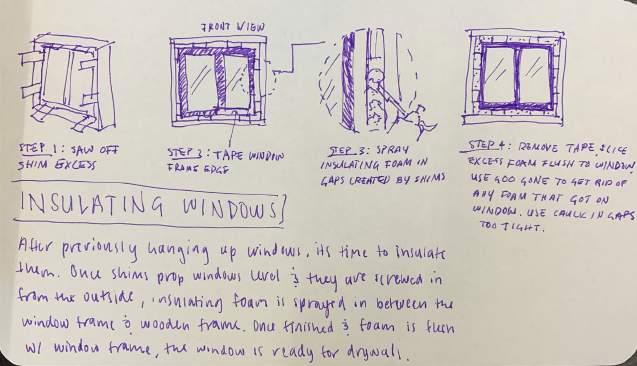

WINDOW INSTALLATION: Prevoius semester made gaps in between window and CMU and wood frame too large. In order to best accompany, windows were spaces using 1/2 in nuts and additonal 2 x 4s were nailled into existing ones to minimize bending of window brackets.

ADDITONAL PHOTOGRAPHS:

Top Left: Polycarbonate Window Final Installation

Top Middle: Screwing in Interior Door

Top Right: Drop Ceiling Framing

Bottom Left: Journal Entry

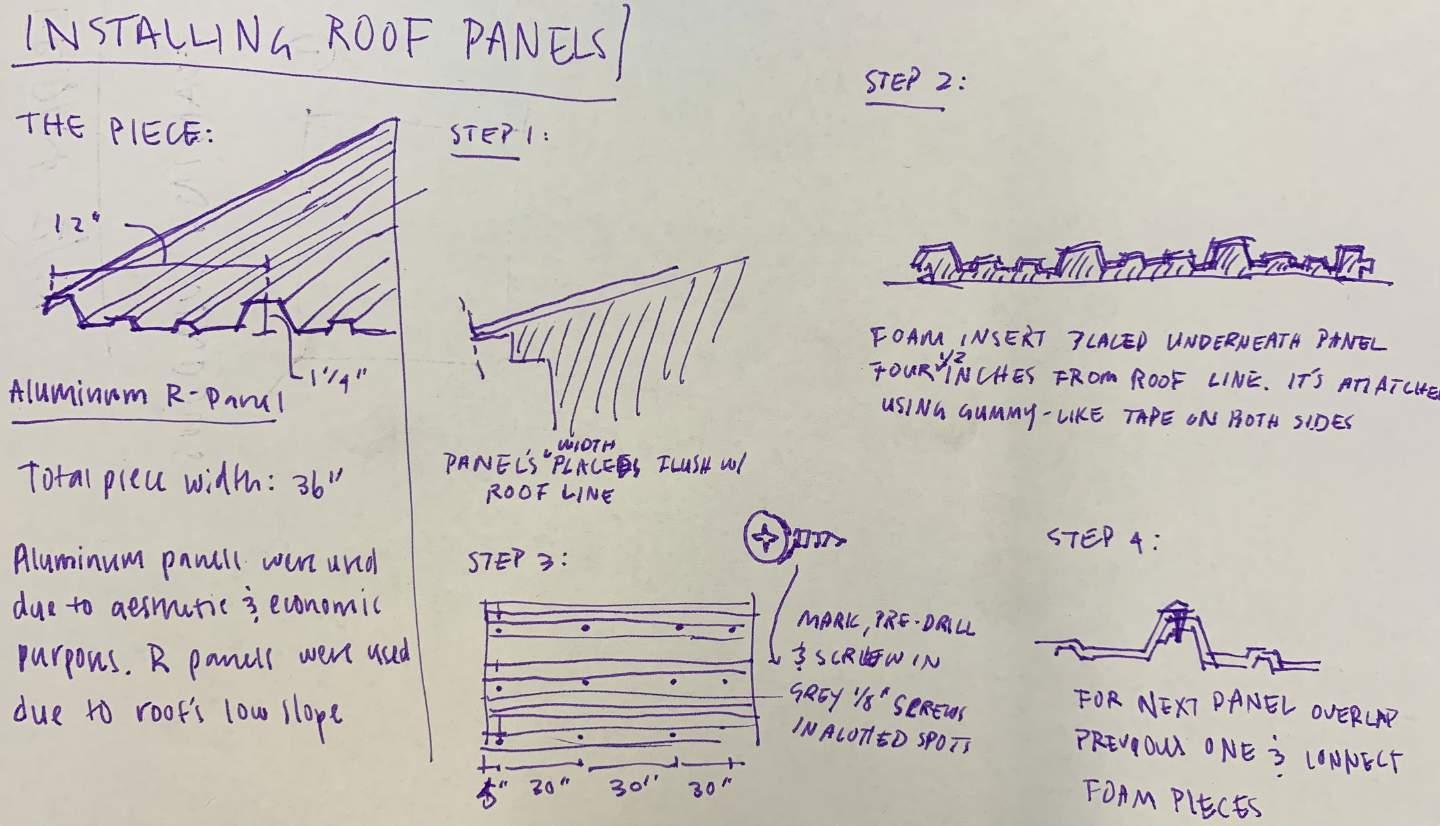

ROOF PANEL INSTALLATION: Installing roof panels has been the most involved process that I have been involved in so far related to on-site work. The picture above shows an page from my journal explaining the process. Photos below show the process of marking out holes to fit extruding pipes. Since boots protecting the pipes are circular, one large hole allow for large gaps in the panel making it much easier for the roof to rot. My task was to mark where the holes needed to be with utmost precision. Measuring from the edges of the panel, and using my tape measure as a guide, the holes ended up exactly where they needed to be.

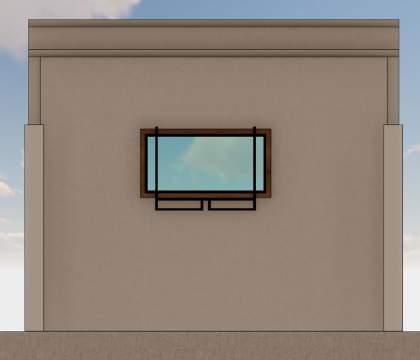

Continuing the work of the previous semester’s, our classes task is to finish construction of Rowhouses 3 + 4. Under the hand of Professor Mary Hardin, students are tasked with the physical construction of the building. This work includes installing roof panels, glass and polycarbonate windows, insulation, building framing and so on. The building portion requires a lot of hands on education, constant use of power tools and construction equipment, and quick learning and problem solving. On top of all the on-site building work, interior design practice also takes place. My current task is to design, budget, and draw up construction documents for builtins for the bathroom of Rowhouse 3 along with another student.

Although I spent much time building around the site, my most noteworthy work came from my contributions to the rowhouse three bathroom. With the help of another student, we co-managed the layout of the existing space, the decor selection, the built-ins’ design, and much of the installations. However, I spearheaded the tile layout design and the construction of all the built-in furniture pieces. This included the window sill, medecine cabinet, and the vanity.

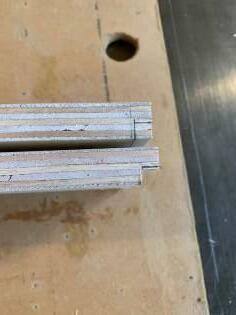

Each piece of built furniture was made with birch plywood with a cherry wood trim added around the edges of the vanity. The towel holders on the cabinet and the window sill and the vanity’s feet were personally welded from hot-rolled steel pipes and spray painted. All wooden surfaces were coated in several layers of polyurthane to protect it from water damage.

Some design challenges included having to resize and minimize the design of the window sill after poorly fitting on site, completely rebuilding the front face of the medicine cabinet, and redesigning the vanity for vubbies instead of drawers. Overall, this project taught me a lot about furniture construction from negotiating with several parties on design choices to learning how to weld.

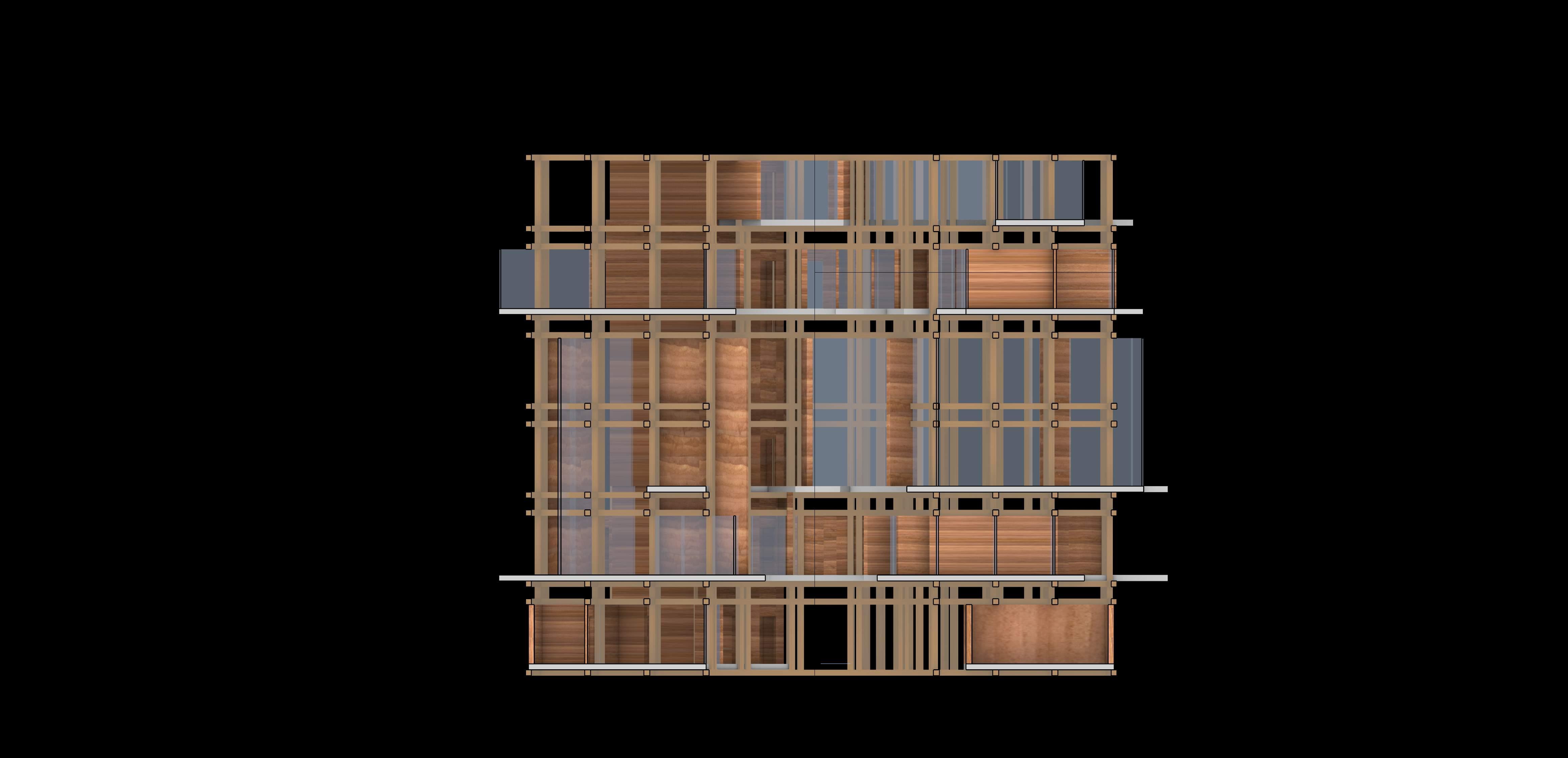

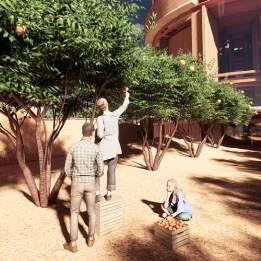

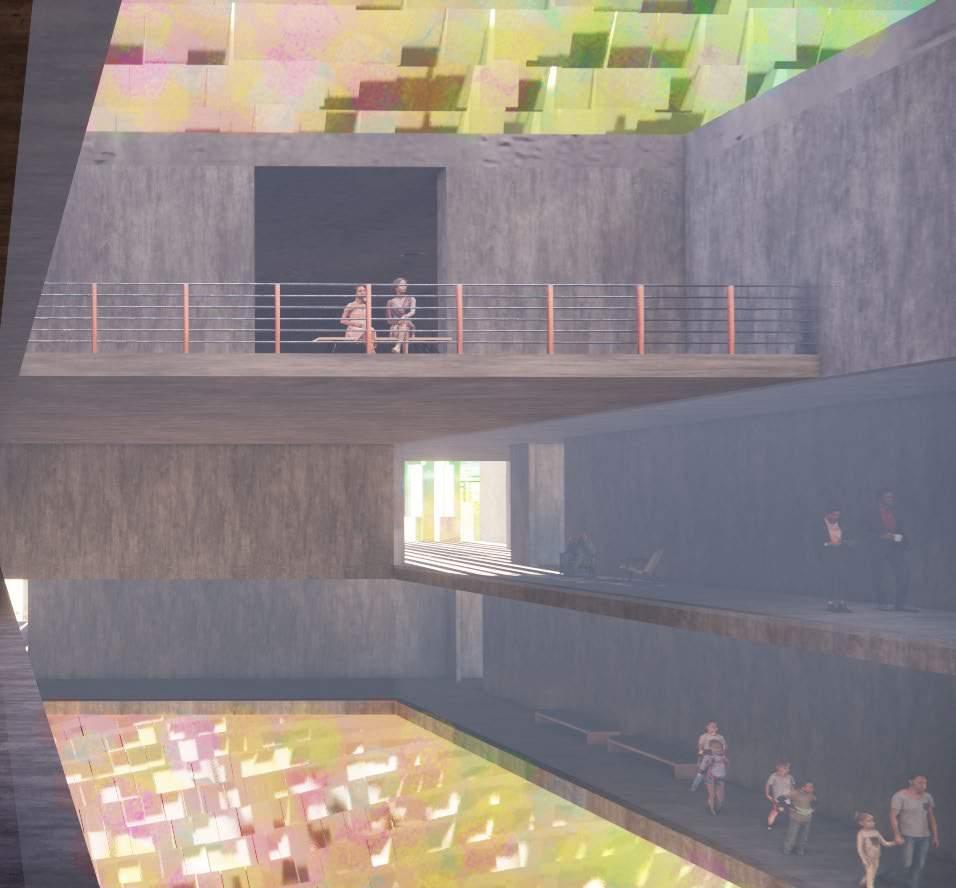

ROOT DOWN in the heart and a true ring shaped outdoor cafe floor at ground both a cafe lab, and challenges such a black zero net energy. and spaces, ventilation,

DOWN is a mixed used building that accomates institutional, educational, commercial, and public uses. Located heart of culture of Tucson, Arizona, Root Down serves as a beacon for public integration, educational exposition, true example of how buildings can be sustainably. Overall, it encompasses 21,334 sqft throughout 5 full or split shaped floors. The bottom level, fully enveloped in the earth and most accessible to the public, is split into a public cafe and an inaccessible (to public users) service corridor. The lobby and admin spaces encompass the second ground level, which also includes the archive. The third floor encompasses a fully public sphere encompassing cafe and event space. The fourth floor is used for educational purposes comprised of a classroom, water quality meeting spaces. The final level is solely comprised of the hydroponics indoor farm. Overall, this building challenges the local cultural notions of interior and exterior and how these spaces can be blended and not treated in black and white manner. This is while embracing natural phenomena and still allowing the building to achieve energy. This integration concept through exterior and interior ideas is executed through the explosion of levels spaces, allowing for natural plant life to penetrate through the building in flora pots and better design for passive ventilation, lighting, and water management.

Thin vegetated slices challenging interior/exterior logic and encouranging unorthodox circulation

VEGETATION INFILTRATION

Vegetation penetrating through Interior redefining spatial character

INTEGRATED CIRCULATION

Through tight hallways, program,

BIOPHILIC INTEGRATION

Vegetation penetrating through Interior

PROGRAM INTEGRATION

Interior Views for Programmatic Interplay

CIRCULATION and vegetation

CULTURAL INTEGRATION

Bike Path connected to MSA Annex through architectural moments

COMMUNAL INTEGRATION

Donating produce to local food banks

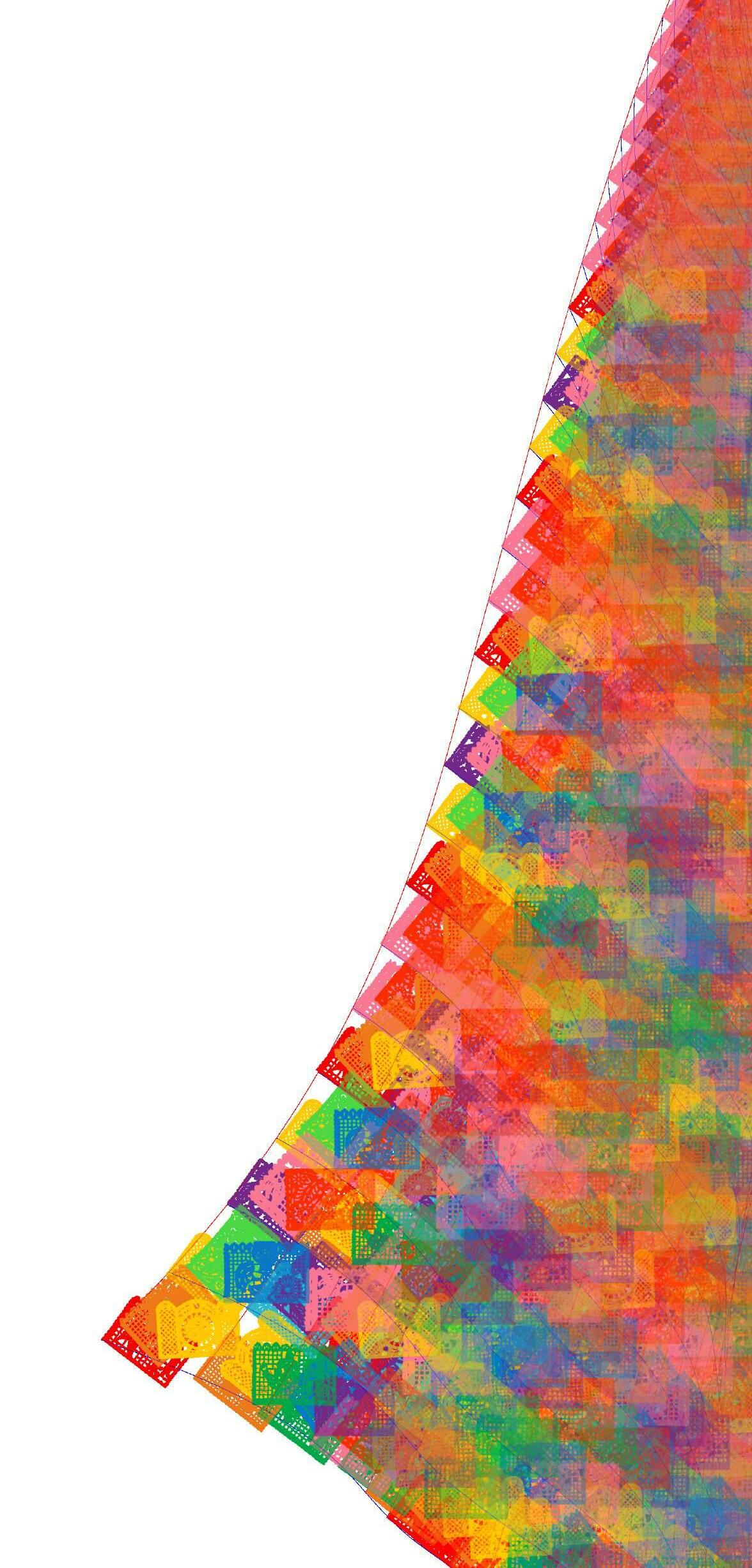

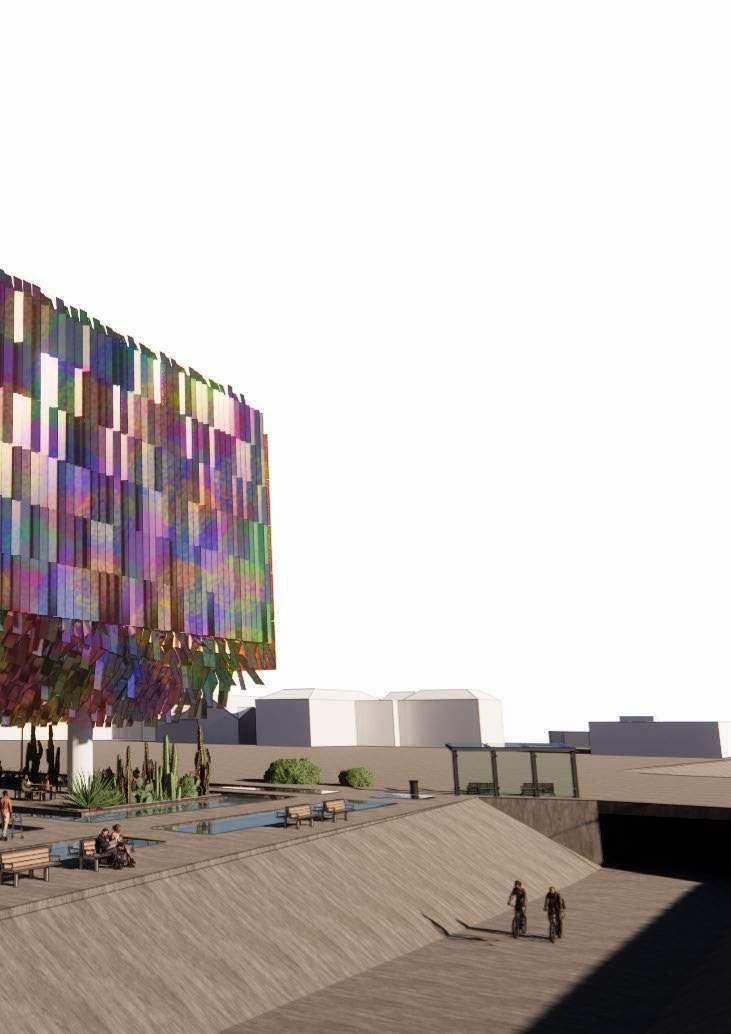

This Museum dedicated to Dia de los Muertos aims to enscapsulate the feelings gratitude through a slow transformative procession into an intimate space. Inspired this building utilizes a modulated screen of lightweight, dynamic metal sheets order to best enhance the user experience. Additonally, the hollowed interior more smooth procession into an environment where one can truly feel the embrace

feelings of love, loss, and Inspired by the papel picado, that encases the museum in and elevation allows for a embrace of the building.

R O D E A R

The museum is designed around an interior hole that decreases in size as it extends upwards. This was done to represent a separation and relationship between personal space and view into the space. The more personal the space is, the more constricted the view is into that space. The “Wrapper” creates a physical barrier between the most communal space, the entrance courtyard, and the most intimate, the art spaces. In turn this creates an inaccessible void that can only be looked at from the inside.

To emphasize the museum’s intimacy, the building can only be entered or directly looked into from the interior.

Annodized PVF Alluminum Composite Panels

Reinforced Concrete Roof Slab

2” Gypsum Board

Reinforced Concrete Floor Slab

Laminated Plywood Sheathing

Eroded Copper Cladding

2” Gypsum Wall Board

Terracotta Tile Flooring

Two-Layered Glass Window Steel Cladding Supports

Reinforced Concrete Spiral Column

Ground Level Concrete Slab

Annodized PVF Alluminum Composite Panels

Reinforced Concrete Roof Slab

2” Gypsum Board

Reinforced Concrete Floor Slab

Laminated Plywood Sheathing

Eroded Copper Cladding

2” Gypsum Wall Board

Terracotta Tile Flooring

Two-Layered Glass Window Steel Cladding Supports

Reinforced Concrete Spiral Column

Ground Level Concrete Slab

3. Roof: Reinforced Concrete Slab

4. Interior: Reinforced Concrete Floor Slabs and Walls

5. Interior “Hole” and West Facade: Glass Curtain Walls

6. Exterior Facade: Copper Panel Cladding

7. Structural Support: Reinforced Concrete Spiral Columns

2. Wrapper Skeleton:

2” x 4” Laminated Steel Beams

3. Roof: Reinforced Concrete Slab

4. Interior: Reinforced Concrete Floor Slabs and Walls

5. Interior “Hole” and West Facade: Glass Curtain Walls

6. Exterior Facade: Copper Panel Cladding

7. Structural Support: Reinforced Concrete Spiral Columns

2. Wrapper Skeleton:

2” x 4” Laminated Steel Beams

FLOOR FOUR

Permanent Art

Space...............................17002 sqft

Bathroom.......................779 sqft

Utilities............................677 sqft

FLOOR THREE

Workshop.......................5525 sqft

Conference Rooms.....5577 sqft

Offices.............................1409 sqft

Bathroom........................779 sqft

Utilities............................677 sqft

Temporary Art Space..6356 sqft

FLOOR TWO

Classrooms...................7911 sqft

Lecture Hall..................4122 sqft

Offices.............................1995 sqft

Bathroom.......................779 sqft

Utilities............................677 sqft

Conservation Space....2756 sqft

FLOOR ONE

Lobby..............................4350 sqft

Restaurant....................5577 sqft

Bookstore......................1822 sqft

Bathroom.......................933 sqft

Utilities............................789 sqft