A pump built for every construction & mining job ENDORSED BY SAPMA, SAPSDA, SAVAMA AND VAMCOSA MAR/APR 2023 EMPOWERING YOUR IDEAS

Our valves fulfill the highest of standards and are designed for many years of safe and reliable operation. Our service specialists regularly check, monitor and maintain all relevant system components - depending on what has been agreed. Our modular framework agreements offer you individual service and spare parts concepts. And we even go one step further. We additionally check systems for efficiency in order to reduce operating costs and increase productivity. For example, with the SES System Efficiency Service.

ZTS GATE VALVE GATE VALVE AKG - A/AKGS - A NORI 500 BOA - H Contact our dedicated Valves Sales Engineers for all your Valve requirements Tel: 011 - 876 - 5600 • E mai l: info - za@ksb.com KSB Pumps and Valves (Pty) Ltd www.ksb.com/en-za Your Level 1 B-BBEE Partner

We offer valves for precision processes - and demanding applications.

STAALWEDGE GATE VALVE AKDS/AKD

On the cover

STM Riduttori South Africa, +27 (0) 10 141 5710, sales@stmafrica.co.za, www.stmspa.co.za

Pipes, Pumps & Valves Africa

Managing Editor: Surita Marx

Tel: +27 (0) 87 700 9834

Cell: +27 (0) 83 281 5761

Email: info@pumpsandvalves.co.za

Web: www.pumpsandvalves.co.za

Sales: Peter Rametsi

Email: sales@pumpsandvalves.co.za

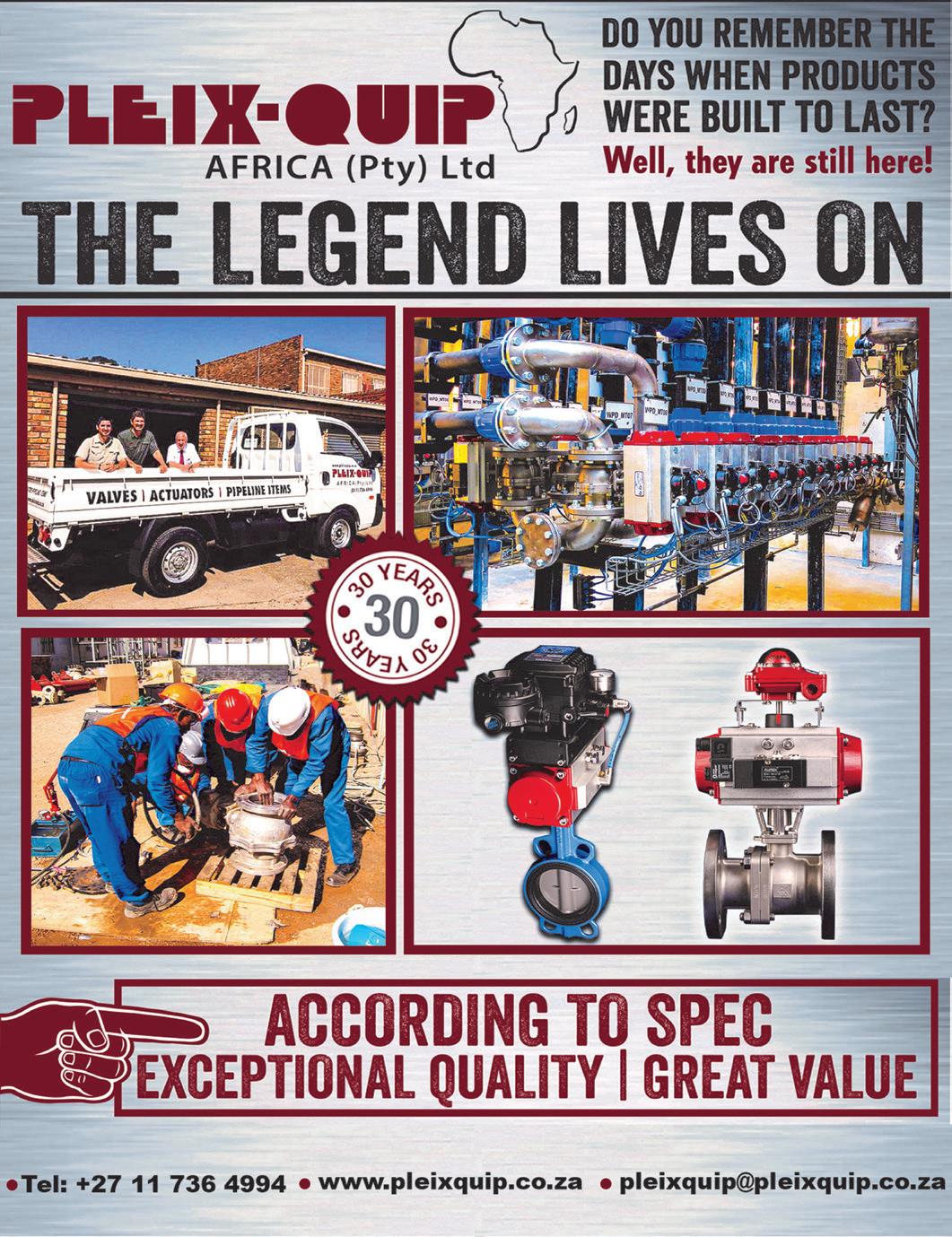

Production Manager: Xane Roestroff

CONTENT Pipes, Pumps and Valves Africa - Mar/Apr 2023 3 Disclaimer: Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers SAPMA or VAMCOSA The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication. Advertisers Big 5 IBC Bilfinger 13 BMG 39 Bray 24 Cyclone Industries 35 EMV Africa 23 Golf day of the year invitation 29 IFAT 33 Integrated Pump Technology 41 Invincible Valves OBC KSB IFC, 19 KZN KITE 31 Pleix-Quip 42 STM Riduttori SA OFC Vega 21 Verder Pumps 15 Vesconite 45 Xylem 7 COVER STORY Going above and beyond delivering customer satisfaction 4 BEARINGS New labyrinth seals avoid galling and failures 6 Going green at Nampo 8 PUMPS IPR’s success leads to expansion into new facilities 12 In-house capability puts Weir Minerals out front 14 Verderflex Dura 80 Hose Pump: The next generation peristaltic hose pump 15 A pump built for every construction and mining job 18 Erwat pursues greater efficiency with WEG motors 20 Support for Grindex range grows with African expansion 22 World’s best vacuum seals tested but not touched 24 Lifting Africa & Pipes, Pumps And Valves Africa Golf day 2023 29 Mastering fluid power efficiency with industrial IOT 26 The magnet makes the difference in these high-efficiency pump motors from Franklin Electric 28 KSB and sustainability of energy 30 4 benefits of digital twin technology for water utilities 32 VALVES Emerson’s new flushing ring design reduces maintenance and improves differential pressure measurement accuracy 41 WATER Future-proofing your facility’s water systems 34 Carlsberg taps into process water reuse with onsite treatment 36 A unified approach to water and wastewater challenges 40 ADVERTORIAL How to find reliable lubrication solutions for coastal environments 10 Keeping it clean: why sliding vane pumps work well in soap manufacturing 16 INDUSTRY NEWS IFAT Africa is back! Diarise and book your stand now 42 BUYERS GUIDE 43

Going above and beyond delivering customer satisfaction

In a world of increasing uncertainty companies are striving to not only meet the needs of their customers but to exceed their expectations. Pipes, Pumps and Valves Africa met up with Lyle Browne, Managing Director at STM Riduttori South Africa, to find out more about this and other industry trends.

In order to ensure customer satisfaction, customised solutions have become increasingly necessary. Companies that listen to their customers and understand their unique needs can provide tailored products and services that fit their specific requirements. This approach not only helps to retain existing customers but also attracts new ones.

The importance of implementing tailored solutions has become even more critical in today’s global economic environment. The outbreak of the Covid-19 pandemic resulted in significant market changes worldwide, and the aftershocks are still being felt, explains Browne. Moreover, ongoing geopolitical unrest, high inflation, and persistent interest rates have added to the complexity of the situation.

As a result, many original equipment manufacturers struggle to maintain balance in arguably the most uncertain period of this century. Browne says that companies that can provide customised solutions tailored to their customers’ needs have a competitive edge despite the challenges.

“While the local market may appear relatively stable and consistent at present, there is no denying that we are operating in a vastly different environment in the post-Covid era,” he says. “The pandemic fundamentally changed the way we live and work, and the ripple effects of this global crisis continue to impact businesses across all sectors.”

As a result, companies have had to adapt and pivot their strategies to remain competitive in this new reality. “At our company, we place a significant emphasis on building strong customer relationships. To us, a client is more than just a number, regardless of the size of their operations. We strive to provide a personalised, oneon-one experience that is both easy and efficient for our customers. Our commitment to excellent customer service is at the core of everything we do, and we believe that this sets us apart.”

According to Browne, prioritizing customer relationships is especially crucial in our industry. Where we offer a wide

range of power transmissions solutions such as inline, planetary, bevel helical, parallel shaft mount gearboxes as well as specialised electric motors such as brake motors in various voltage options.

“Building strong relationships with both customers and suppliers is critical, and effective communication plays a vital role. Ongoing conversations are key to understanding the unique needs and requirements of each customer, and this approach helps to ensure that we can provide that tailored solution they require.”

Keeping up with the times

In today’s price-sensitive environment, an increasing number of customers are no longer simply sticking with their regular equipment suppliers, says Browne. “Instead, there is a growing trend to shop around and seek out companies that can provide unique services that meet their specific needs. As a result, even smaller equipment companies are gaining attention from customers who are looking for personalised and tailored solutions.”

He says the ongoing war in Ukraine significantly impacted South Africa. “Most of our products are imported from Europe. With the war, many European countries experienced shortages in raw materials as much of it was in Ukraine. This forced OEMs to find alternative suppliers and it has led to a delay over an extended period in markets around the world including South Africa.”

Flexibility and adaptability, says Browne, are crucial in today’s business landscape. “While price and equipment quality will always be important factors, exceptional customer service is what sets companies apart. In particular, after-sales service for parts and repairs is a critical component of providing a comprehensive customer

COVER STORY

4 Pipes, Pumps and Valves Africa - Mar/Apr 2023

experience.” Browne emphasizes that, while it may be challenging for suppliers to maintain an inventory of all spare parts, it is their approach to customers and their ability to handle difficult situations that can make all the difference.

Addressing challenges head-on Loadshedding has become an inescapable topic of conversation for businesses in South Africa, as it has had a profound impact on productivity and revenue across a wide range of sectors.

Browne acknowledges the significant challenge that loadshedding poses, emphasizing the need to remain adaptable in the face of this ongoing issue. He notes that businesses can instantly feel the impact of loadshedding, especially when the country transitions from Stage 4 to Stage 6.

Additionally, the current exchange rate presents another challenge that businesses must contend with. Despite these challenges, Browne underscores the importance of maintaining open lines of communication with customers and staying flexible to meet their evolving needs.

In these uncertain times, staying ahead of the curve has become more crucial than ever. To achieve this, he says, they dedicate a significant number of resources towards continuous research and development of our products.

“We remain extremely optimistic about our growth prospects. Our products are of high quality and speak for themselves, providing a strong foundation for our future success.”

“Additionally, we are always exploring opportunities to expand our footprint by entering new markets and breaking into new areas. We remain committed to going the extra mile for our customers, making a difference in the industry and paving the way for continued growth.”

STM Riduttori South Africa, +27 (0) 10 141 5710, sales@stmafrica.co.za, www.stmspa.co.za COVER STORY

- Mar/Apr 2023 5

Pipes, Pumps and Valves

Africa

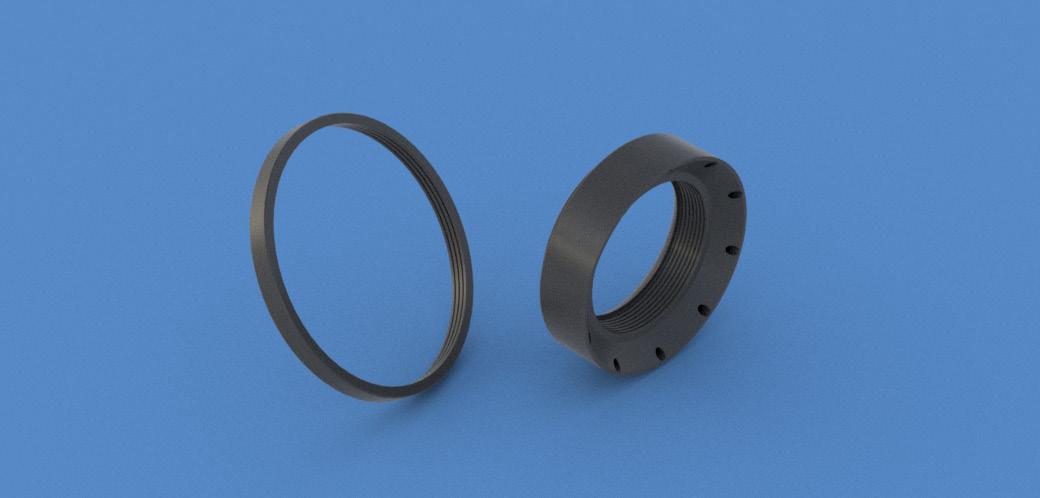

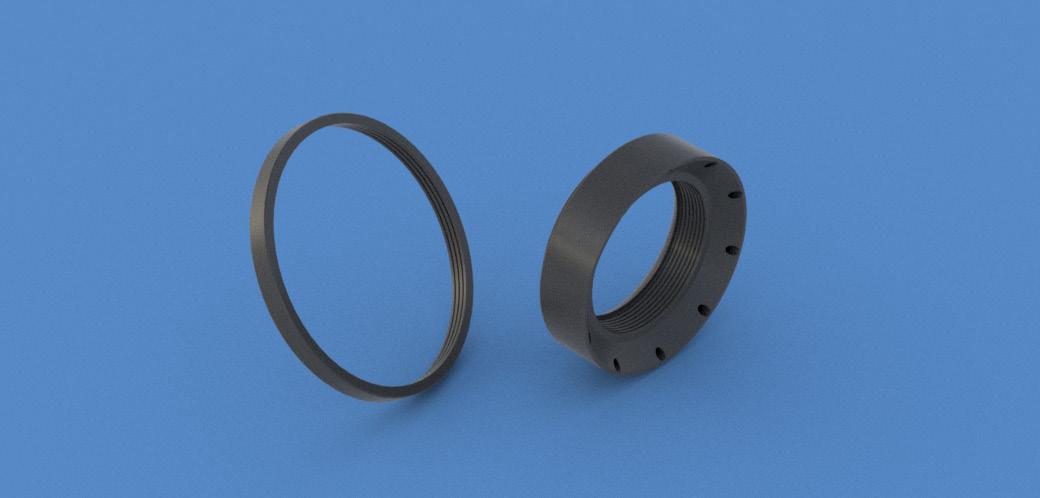

New labyrinth seals avoid galling and failures

Labyrinth seals can now be ordered from Vesconite Bearings using client specifications. This follows the supply and successful use of Vesconite labyrinth seals by several large pump original equipment manufacturers in multiple labyrinth seal designs over the past 10 years.

Labyrinth seals are mechanical seals that provide a long path for water to flow through to prevent leakage. As the name suggests, these seals may be composed of a large number of grooves acting as labyrinth chambers. The labyrinths help reduce the leakage flow through the seals.

Vesconite bearing materials have proved valuable in these seals as they are self lubricating. As a result, during shaft rotation, when parts of the seal come in contact with the shaft, high temperatures and even galling are avoided. This is unlike traditional stainless steel and bronze labyrinth seals, where contact leads to high frictional forces, rapid increases in contact temperatures, galling and even catastrophic pump failures.

Vesconite labyrinth seals can also be designed to optimise their performance. Since there is no threat of galling, close

clearances can be applied. This is important since the smaller the clearance, the lower the flow of water past the seal and the higher the efficiency of the pump.

Vesconite bearing materials offer the advantage of being more economical than their stainless steel counterparts, and much quicker to machine.

Vesconite can be machined easily to produce complicated grooves for water limiting flow and for securing the seal, and have completely replaced stainless steel parts in many pump applications.

Vesconite, +27 (0) 11 616 1111, vesconite@vesconite.com, www.vesconite.com

6

and Valves Africa - Mar/Apr 2023 BEARINGS

Pipes, Pumps

Follow us on:

WORLD’S FIRST WASTEWATER PUMPING SYSTEM WITH INTEGRATED INTELLIGENCE

This revolutionary system delivers optimal performance while reducing your total cost of ownership. It also offers unparalleled flexibility and simplicity on a whole new level. You might even say it thinks for itself. We invite you to enter a new era in wastewater pumping with Flygt Concertor.

One powerful solution. Unlimited possibilities .

Going green at Nampo

BMG is changing things up at Nampo this year having only an outside working exhibition stand that will highlight the importance of ‘Going Green’ in agriculture.

The Nampo show – which is the largest agricultural expo held in South Africa every year – will be held from 16 to 19 May 2023, close to Bothaville, Free State.

“The theme of BMG’s stand (C21) this year is “BMG Going Green,” where we will highlight our initiatives to reduce our carbon footprint. This initiative includes the launch of the latest BTC pillow block’s biodegradable packaging, that excludes any plastic material, resulting in a saving of about 300 000 plastic bags a year,” states Carlo Beukes, Business Development Manager, Agricultural, Automotive and Lubrication divisions, BMG. “In addition, BMG’s online shopping platform is successfully moving traditional commercial processes away from paper and is gaining popularity with farmers as a convenient way to procure engineering and agricultural products.

“BMG specialists will showcase our latest products and technologies at our outside stand and visitors will see working demonstrations of technologically advanced products, that form part the company’s eco-friendly initiatives to reduce carbon footprint.

“Working displays include components for agricultural fruit packhouses, like food-grade conveyor belts, pneumatics

and variable speed drives. We will also be showcasing new products, including Liqui Moly oil kits and additives, designed specifically for new bakkies, like the Hilux GD-6, Land Cruiser and Ranger brands. Also on display will be the Rat-Ban, Silencer Cleaner and ceramic-based Ceratec from Liqui Moly, as well as Cummins individual filters and kits for bakkies and large agri implements, including John Deere, Case and New Holland.

“A major attraction to our stand each year, is the distinctive range of BoerSlim clothing that reflects BMG’s BoerSlim/ Smart Farming programme, where the team assists farmers to embrace advancements in agricultural machinery. Through this initiative, we offer sustainable solutions that focus on effective food production, the correct use of suitable equipment for specific tasks and the efficient application of the latest technologies.

“What’s important for BMG at Nampo this year is the successful completion of the two-phase upgrade of our inhouse BTC bearing block unit (BBU) and housing range of products, which is manufactured exclusively for BMG, to stringent quality and safety specifications.”

Originally the BTC range was developed for light to medium

8 Pipes, Pumps and Valves Africa - Mar/Apr 2023 BEARINGS

rotating equipment applications, including packhouses and small conveyors in the agricultural sector and general industry. However, with the recent manufacturing processes and material upgrades, BTC bearings and components are perfectly suited for heavy-duty farming applications, for hammer mills, crushers and spreaders.

BMG specialists emphasise that design improvements and quality enhancements of BTC BBUs require selection of the correct lubrication solutions, to ensure optimum efficiency and extended service life of the system. A top-quality EP2 grease is compatible with most local greases and will ensure a longer operating lifespan.

BMG’s extensive range of agricultural products includes the recently launched BTC Lemken harrow discs and hub bearing units, that conform with OEM quality specifications. The company has also launched the Liqui Moly Guntec range, bakkie oil and fuel additives, as well as new solar panel operated Variable Speed Drive (VSD) units that will be on display. Also on show will be bearings and oil seals, power transmission components, light industry conveyors, tools and equipment, hydraulics and fluid technology, as well as all electronics equipment.

All BMG agricultural products are available from the company’s national branch network, as well as through BMG’s online shopping platform.

BMG’s online shopping portal adds value to the company’s service offering and makes shopping for engineering components even more convenient - especially with rising fuel costs. This digital procurement platform enhances convenience for farmers, who can still rely on technical support and personal care from BMG specialists.

Over 75 000 BMG products are available on this platform, including bearings, seals, fasteners and power transmission components, as well hand and power tools, abrasives, brushware, spanners, wrenches and sockets. Added to this are agricultural-specific components, including PTO shafts, planter and coulter bearings.

A highlight for visitors at Nampo 2023 will be the invitation from BMG to enjoy a cup of freshly brewed coffee at the stand, which is almost the best comfort in freezing conditions in Bothaville’s Winter.

BMG, +27 (0) 11 620 7558, carlob@bmgworld.net, www.bmgworld.net

Pipes, Pumps and Valves Africa - Mar/Apr 2023 9 BEARINGS

How to find reliable lubrication solutions for coastal environments

Oxidation, rust, corrosion, and water exposure can be significantly higher along South Africa’s coastal belt. So much so that coastal conditions are often classified as “extreme condition environments”. This doesn’t have to mean, however, that components operating in coastal plants will always have a shorter lifespan or run less efficiently than their inland equivalents.

The key to extending the life of any piece of equipment is protecting it using the right lubrication products in the correct quantities and at the appropriate frequency.

Lubrication Engineers (LE) South Africa has long-standing relationships with clients in many different industries in South Africa’s coastal areas and has seen immense improvements in its clients’ equipment lifespans and performance where the right lubrication is applied, and preventative maintenance devices are used.

Llewellyn Owen, National Sales Manager at LE explains that it’s essential to work with a client to understand their challenges to find the right solution for their specific needs. This is particularly important in coastal areas where clients have to factor in the environmental impact on wear and tear and contamination. Beginning with an onsite equipment assessment, a trained lubrication consultant should be able to recommend lubricants, application methods, usage amounts, and drain or lube intervals to ensure effective maintenance.

Protecting coastal equipment

Preventative maintenance and LE’s aftermarket reliability solutions (ARS) also form an important part of this approach.

“The better we can help a client in protecting and extending the life of their assets, the better the client’s business does, and the more money the client makes, because they don’t have continuous issues with downtime. They can achieve their targets as far as asset life is concerned. We find that the predictions that are set out are often exceeded by implementing these systems when running a high-spec, appropriate lubricant,” explains Owen.

One example of this is enclosed gearboxes. Owen says that many imported enclosed gearboxes don’t have adequate level monitors or sight glasses on them, or their sight glasses get contaminated over time and it becomes difficult for operators to see what is happening inside the gearbox. LE’s Duolec® Industrial Gear

Oil solutions have proved to be an excellent and extremely reliable solution for coastal applications in enclosed gearboxes.

“We have cases where we have gearboxes using one of the Duolec® lubrication that have now been running for more than 22 years… the way that this Duolec® Industrial Gear Oil product keeps oxidation away from metal parts and gears is

absolutely mindboggling,” Owen adds.Preventative devices, such as LE’s High Humidity Desiccant Breathers, can also be a very helpful ARS tools when installed on gearboxes, pumps, transformers, and lubricant reservoirs. They help to exclude large amounts of airborne contamination when these assets “breathe”. Where storage tanks and working assets are subjected to continuous temperature changes and large fluctuations in humidity it is critical to investigate preventative measures to combat potential problems and implement them. ARS tools can play an important role in this regard.

Owen adds that different industrial and agricultural applications require lubrication that will help get the best out of equipment and get the best returns for clients on the lifespan of their machinery. “Every industry has its own troublesome or problematic machine or component,” he says.

Having the right lubrication partner gives maintenance teams access to expert advice, skills, and technology to help them solve any challenges that arise. For example, marine application lubrication can be particularly tricky (for example, on fishing boats and boat trailers). LE has developed a range of products specifically designed for these applications. For example, LE 1498/9 is a waterproof grease that is suitable for marine use as it is not affected by saltwater.

In the coastal agricultural industry, equipment like crop sprayers require a lubricant in the gearbox that can handle not only the environmental issues, but also constant water ingress. “In these instances, you need to have a high-quality lubricant that can separate from water easily, yet still protect the moving parts. LE’s high quality multi-viscosity EP gearbox oils outlast the majority of other lubricants offered in this market,” says Owen. “We like to think of ourselves as a headache tablet. Regardless of the difficulty a client might be experiencing, whether it be a lubricant, solution problem or a heat problem, we are able to assist our clients in solving or greatly reducing their downtime and improving their productivity,” he says.

Lubrication Engineers, +27 (0) 11 464 1735, gavin@lubricationengineers.co.za, www.lubricationengineers.co.za

10 Pipes, Pumps and Valves Africa - Mar/Apr 2023

Pipes, Pumps and Valves Africa - Mar/Apr 2023 ADVERTORIAL

- Mar/Apr 2023 11

Pipes, Pumps and Valves

Africa

IPR’s success leads to expansion into new facilities

Having become a leading force in dewatering pump rental and sales, IPR has expanded into new premises that will also allow for its future growth.

Formerly known as Integrated Pump Rental, IPR is now located in Hughes, Jet Park, with an expanding fleet of pumps and a wide brand offering. IPR managing director Lee Vine says the move is another step in the company’s ongoing success in meeting customer’s dewatering and dredging needs across a range of sectors.

“We are excited to be in larger premises that allow us to keep abreast of market demand,” says Vine. “As IPR’s rental focus has evolved to include pump sales, this has also contributed to the need for more extensive infrastructure.”

He highlights that the new premises include sales offices, a design and engineering department and a fully functional assembly and build facility. There is also a dedicated servicing and repair shop, and parts warehousing with all fastmoving consumables plus other wear items. A testing facility is available for diesel driven and submersible pumps. The new workshop includes a 10 tonne overhead gantry crane to facilitate movement of heavy equipment.

“The expansion into these premises has also been driven by our larger brand offering,” he says. “This has recently grown further with our appointment as master distributor of Atlas Copco dewatering pumps in the Southern African region.”

The company’s success to date has been based on its focus on quality brands, backing these up with an expert team that delivers the highest standards of service excellence. IPR has also developed solutions locally that have developed a strong following in the market.

These include the SlurrySucker and SlurryBlaster for dredging and hydromining applications – specially designed for removing silt from ponds and accumulated sediments inside dams.

“Our vision remains to become the leading pump dewatering and dredging specialist, and our move into these large and well-equipped premises is another positive development in that direction,” says Vine.

“With our combined sales and rental offerings, we are committed to help customers reduce their total cost of ownership – by offering a solution that suits their situation.”

IPR, +27 (0) 87 759-8654, admin@pumprental.co.za, www.pumprental.co.za

12 Pipes, Pumps and Valves Africa - Mar/Apr 2023 PUMPS

intervalve

WE MAKE VALVE SUPPLY WORK

Bilfinger Intervalve Africa (Pty) Ltd. is one of the enterprises in Bilfinger Power Africa (Pty) Ltd., the South African subsidiary of German based Bilfinger SE. For years, we have been adding value to the power, mining, paper pulping and broader industry through comprehensive valve supply, valve maintenance and heat treatment solutions. www.intervalve.bilfinger.com

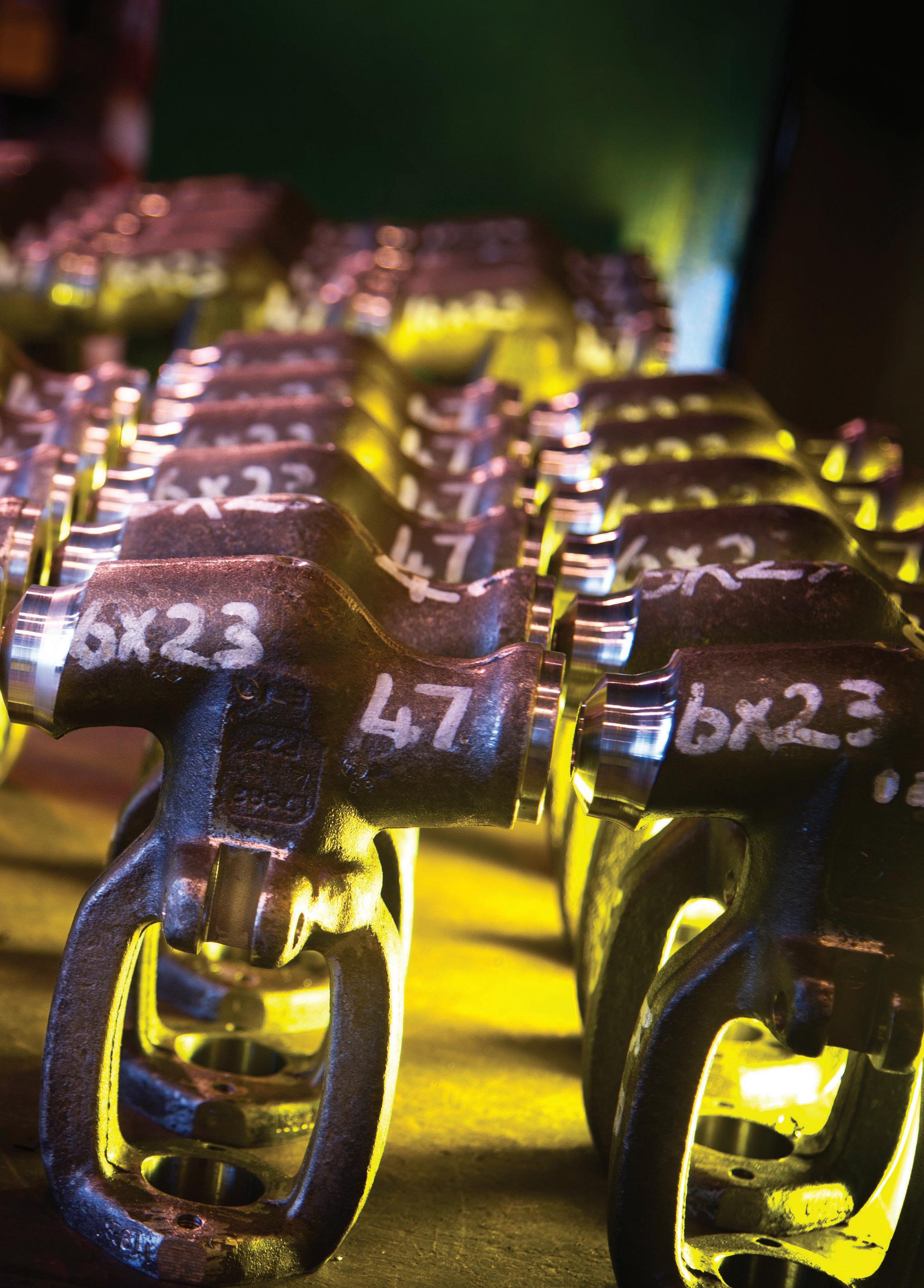

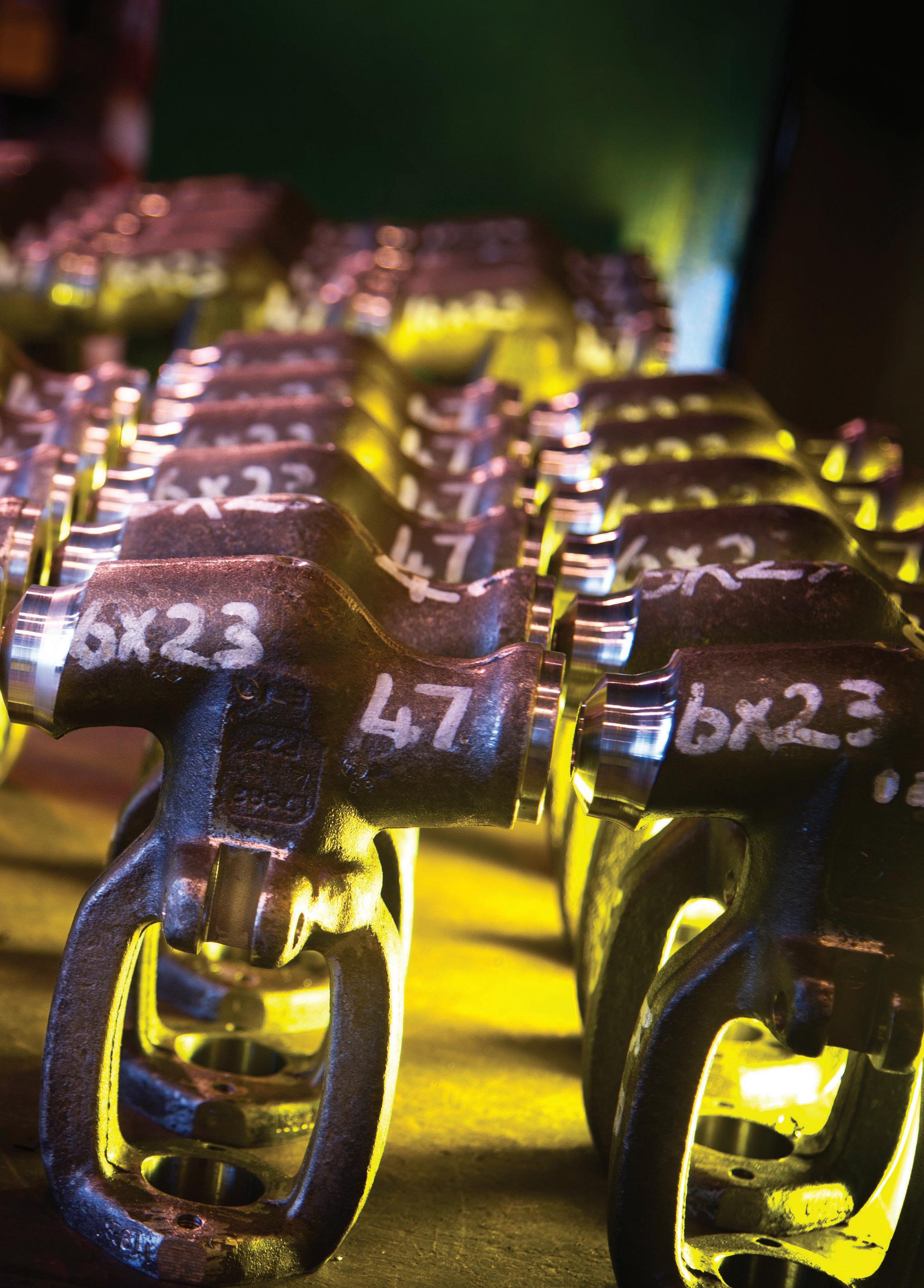

In-house capability puts Weir Minerals out front

As mining projects look to optimise their pump and process performance while minimising risk, there is good reason why Weir Minerals Africa is regularly awarded the lion’s share of large execution projects.

According to Marnus Koorts, general manager pump products at Weir Minerals Africa, the company wins about 95% of the process projects in the mining sector today for which it bids.

“Our success has everything to do with how we leverage our full design, engineering and manufacturing capability,” says Koorts. “This level of expertise and infrastructure is something that few of our competitors can match; indeed, we are the only pump manufacturer in Africa with this integrated resource base.”

He adds that most of its product offering is manufactured in-house. This internal capability gives the business a distinct advantage in developing and implementing custom designs and complex solutions. It also provides closer control over quality and can radically improve lead times.

“An important differentiator for us is our two foundries –our Heavy Bay Foundry in Gqeberha and another in Isando which includes our innovative Replicast plant,” he says. “These two facilities give us greater reliability in our supply chain and scheduling, reducing the risk of late deliveries that could delay customers’ project roll out.”

With Weir Minerals Africa’s large team of hydraulic engineers, there is also considerable in-country capacity

to support engineered-to-order (ETO) requirements. This enhances the value of early stage collaboration with customers, where the company can offer insights and guidance on pump and process related issues even at concept stage. This, emphasises Koorts, makes it easier for project managers to pre-empt technical challenges later.

The world class facility in Isando is one of Weir Minerals’ technology hubs for a range of its pump brands including the Warman DWU and Envirotech range. As a result, it is able to export significant volumes of this equipment to sister companies worldwide.

“While many competitors rely on distributors and agents to deal with customers, Weir Minerals Africa has over the years established an extensive branch network across the continent,” he says. “This footprint ensures our direct contact with customers, so that they receive the same high level of service irrespective of their location. They also have direct access to our highly skilled and experienced product experts.”

Weir Minerals Africa, +27 (0) 11 617 0700, onlinesales@weirminerals.com, www.minerals.weir

14 Pipes, Pumps and Valves Africa - Mar/Apr 2023 PUMPS

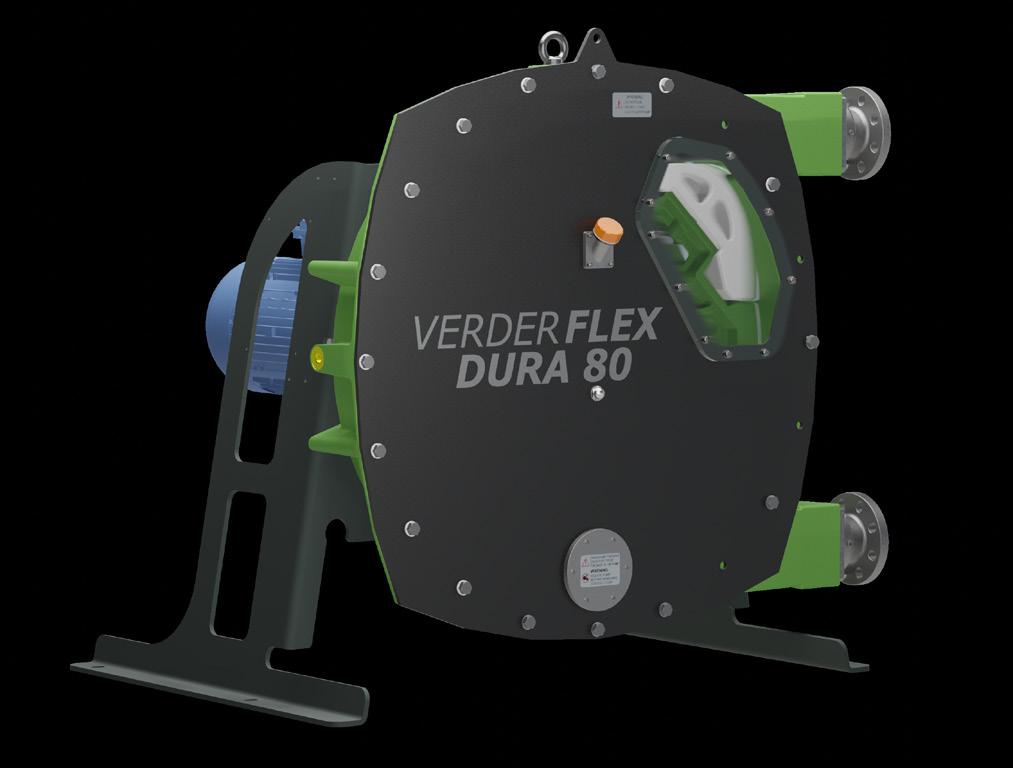

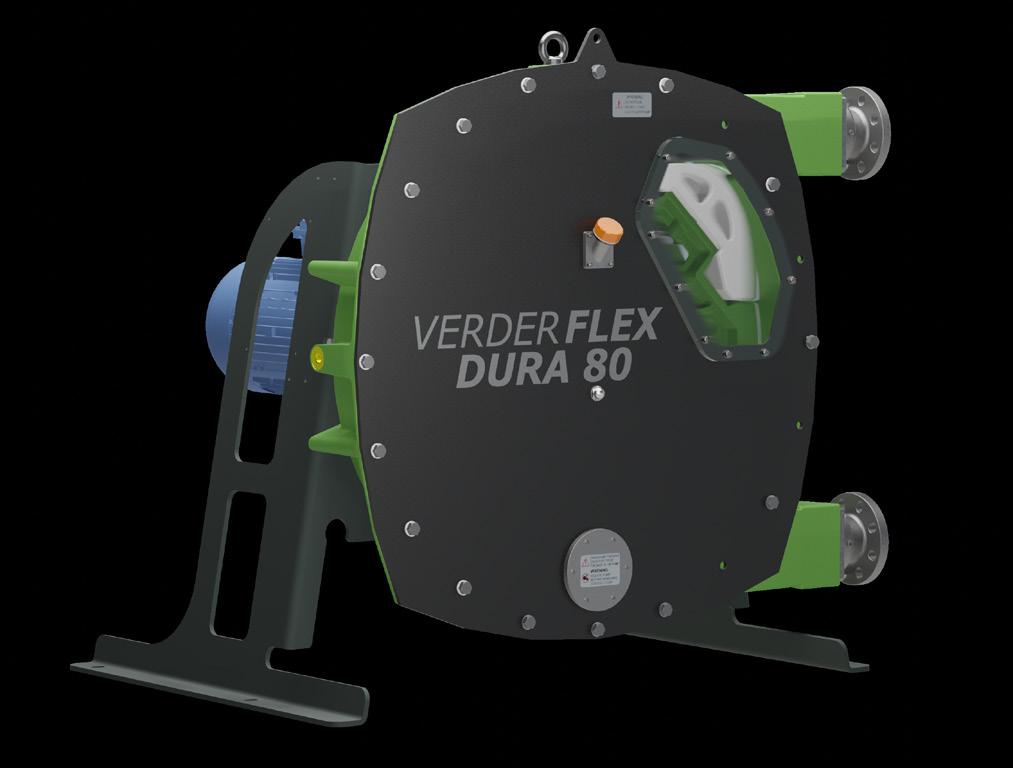

Verderflex Dura 80 Hose Pump: The next generation peristaltic hose pump

Verder Liquids is proud to announce the release of the Verderflex DURA 80 Hose Pump, specifically designed and constructed to meet market demand. Based on feedback from our users in the field, our R&D team has developed a next-generation peristaltic hose pump with increased functionality, designed for even easier use in the field.

We have taken our VF80 generation pump, improved its flow capacity and added features that address the suggestions made by users. Our newest member of the DURA pump family boasts key features that make for added user-friendliness, including:

• The lifting point, for supporting the front cover if it needs removal.

• The lubricant filling point, allows easy access for this task without requiring the removal of other bolting.

• The access cover at the bottom of the front panel, to allow for cleaning of any debris during hose change and ensure that the new hose has the best hose service life.

“These improvements are more than just a simple update,” says Darryl Macdougall, Managing Director, Verder Pumps South Africa. “They increase the functionality of the pump and make the user's life easier. Our R&D team focused not only on responding to user feedback but on technical advances to improve overall performance when developing this pump.”

The DURA 80 has market-leading swept volume and is designed for applications such as metering and transfer duties with a focus on sludges, slurries and abrasives. It follows the same principles as its celebrated predecessor, with a shoe moving along a peristaltic hose to provide the pumping action. This principle ensures that it can achieve good pumping success with sludges and slurries because the contact point for the ‘On’ and ‘Off’ of the shoe to and from the hose is gentler than a roller contact point, reducing contact point loading.

With all these added features and improvements, the DURA 80 offers key benefits such as:

1. Class leading performance up to 42m3/hr and pressures of up to 16 bar.

2. Minimised downtime and reduced cost of ownership.

3. In-situ hose change/simplified spares holding requirement.

4. Self-priming (capable of a suction lift of 9.5 mwc), dry running.

5. Low shear design ideal for abrasive/solid slurries.

6. Seal-less and valveless pumping operation with directly proportional flow stability and repeatability.

“The principle behind this technology is to improve the efficiency and save the end user money by looking at Total Cost of Ownership (TCO), which equals upfront costs and lifetime operation. For the end user it is not just buying the pump but the working life and ease of use,” says Macdougall. The DURA 80 is now available across Verder Group’s operational footprint, including in South Africa and Africa.

Verder, +27 (0) 11 704 7500, info@verderliquids.com, www.verderliquids.com

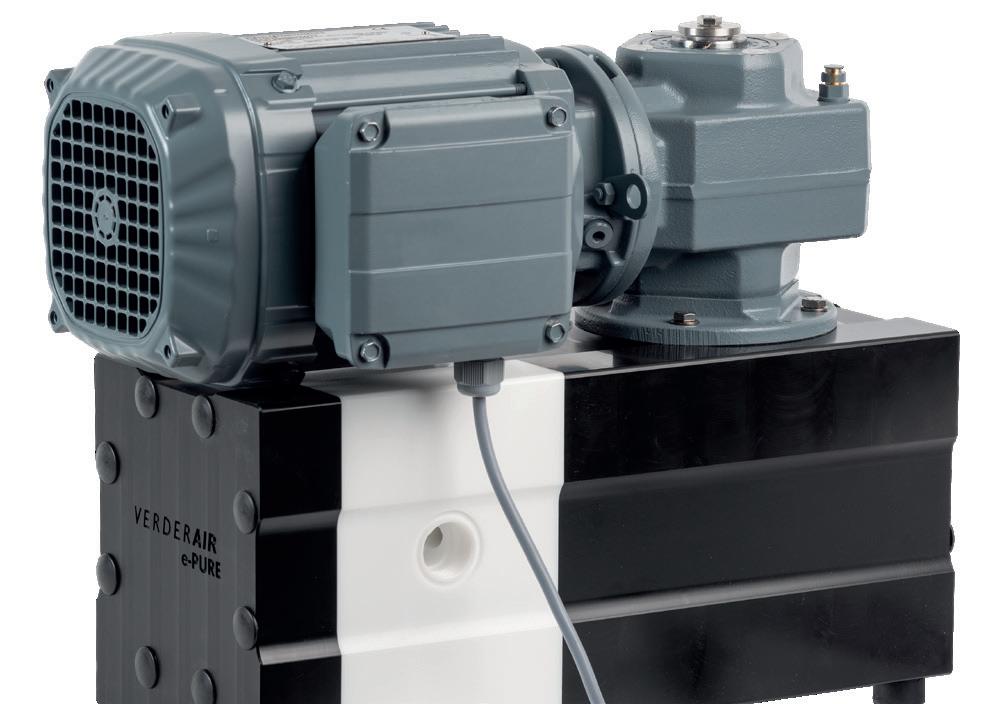

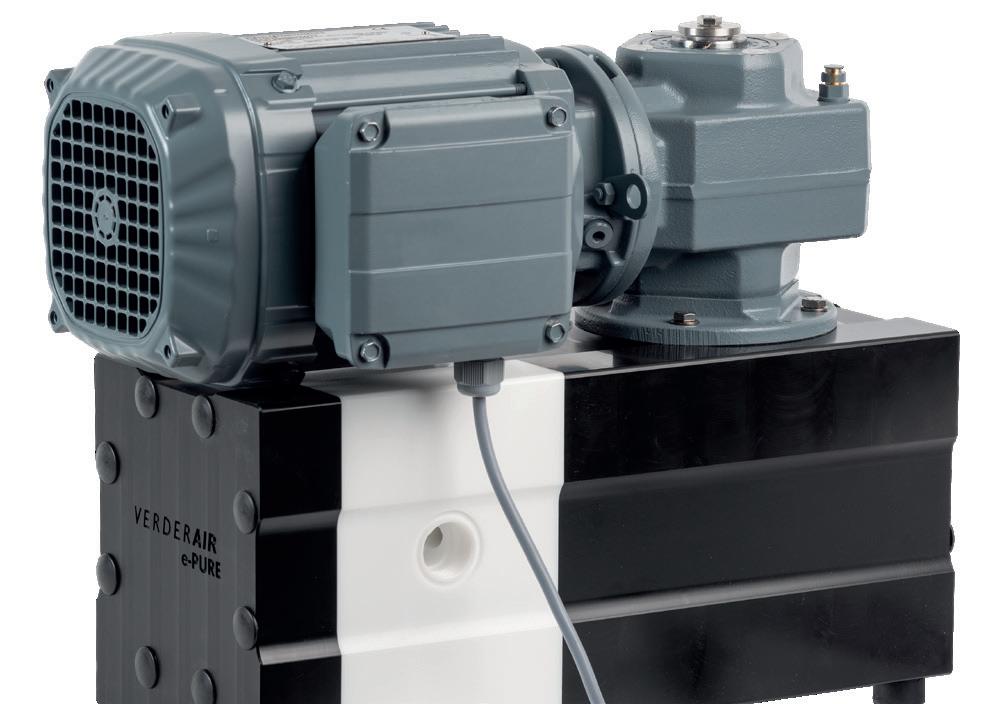

Pipes, Pumps and Valves Africa - Mar/Apr 2023 15 PUMPS VERDERAIR e-Pure Electrically Driven Double Diaphragm Pumps for the transfer of chemicals & abrasives VERDER PUMPS SOUTH AFRICA (PTY) LTD TEL +27 (0)11 704 7500 MAIL info@verder.co.za WEB www.verder.co.za VA_Advert_SA_180x65mm.indd 1 4/18/2023 3:56:25 PM

Keeping it clean: why sliding vane pumps work well in soap manufacturing

Equipment composition, performance capable of handling varying viscosities, materials

By Mark Pyk

By Mark Pyk

Soaps and detergents serve as an imperative part of our lives, one that would make life much more challenging without modern advances. Before the days of stacked shelves with a wide variety of cleaning choices, soaps were simply a combination of boiled fats, oils and ashes.

During World War I, however, a shortage of fats lead to the invention of synthetic detergents, which evolved into manufacturers producing the varieties we see today.

Soap and detergent production now consists of merging fatty acids with alkali, glycerin or sulfuric acid. While that sounds straightforward, the production process is anything but.

The soap and detergent market has four segments –laundry and fabric washing; household cleaners; personal cleansing products; and dishwashing cleaners. With this variety of cleaners, manufacturers need equipment that can process a wide range of raw materials, each with its own complexities.

If manufacturers want a reliable way to handle the varying materials in soap and detergent processing, then their best bet is to use positive displacement sliding-vane pumps. This article will review why sliding vane pumps are well suited in this application.

Bring on the soap

The composition of sliding vane pumps makes them ideal for soap and detergent manufacturing, especially over comparable pumping technologies.

Sliding vane pumps feature a rotor with retractable vanes that protrude and retract as the rotor operates. This setup creates chambers for liquid to pool into, while the next vane pushes it to the discharge side of the pump.

Its composition alone makes sliding vane pumps useful in soap and detergent processing. The self-adjusting sliding vanes sustain the pump’s volumetric performance, making the pump energy efficient while also preventing product slip.

While vanes do wear over time, a worn vane simply protrudes further out of its rotor slot, ensuring that tight internal clearances remain consistent. The pump’s ability to sustain volumetric consistency ensures that it will run effectively and efficiently over its lifetime.

Another feature of the sliding vane pump is the lack of metal-to-metal contact, commonly found in other pumping technologies, such as gear pumps. When metal-to-metal contact occurs frequently, the possibility of pump friction

and galling increases. Sliding vane pumps don’t suffer from these problems due to their construction, which also aids in the pump’s longevity.

Sliding vane pumps are also known for their ability to handle a wide range of liquid viscosities. This attribute is useful in soap and detergent processing because of the variety of raw materials with varying viscosities.

Sliding vane pumps can handle liquids with viscosities as low as 0.2 cP and as high as 22,500 cP, while also experiencing no adverse performance effects when processing liquids between 3 to 100 cP and 100 to 5,000 cP.

Sliding vane pumps also can handle liquids with small particulates up to 25% concentrations, a useful attribute when disposing of waste fats after manufacturing soap.

This ability stems from shear-sensitive open flow paths within the pump chamber and slow internal flow velocities that gently pass solids through the internal flow stages.

The particles are not moved violently through the pump casing, as is the case with pump styles that rely on high internal flow velocities to operate effectively.

Another attribute beneficial to sliding vane pumps is their self-priming ability and their suction lift capabilities. This pump technology can create an internal vacuum strong enough to strip and lift valuable soap and detergent materials out of the lines, pumps and tanks.

Operators don’t have to worry about losing raw materials and processed ingredients inside their equipment.

Sliding vane pumps also are available in materials that work well with the soap and detergent manufacturing process. Housings are available in stainless steel or ductile iron, while the vanes themselves can be made from a variety of materials that pair well with soaps and detergents.

Conclusion

Soap and detergent manufacturing is not a simple process, but sliding vane pumps are one of the most compatible pumping technologies in these applications.

Their ability to handle multiple liquids with different viscosities, as well as their volumetric efficiency and consistency with several raw materials, make them a reliable choice for manufacturers.

Blackmer, mark.pyk@psgdover.com, www.psgdover.com

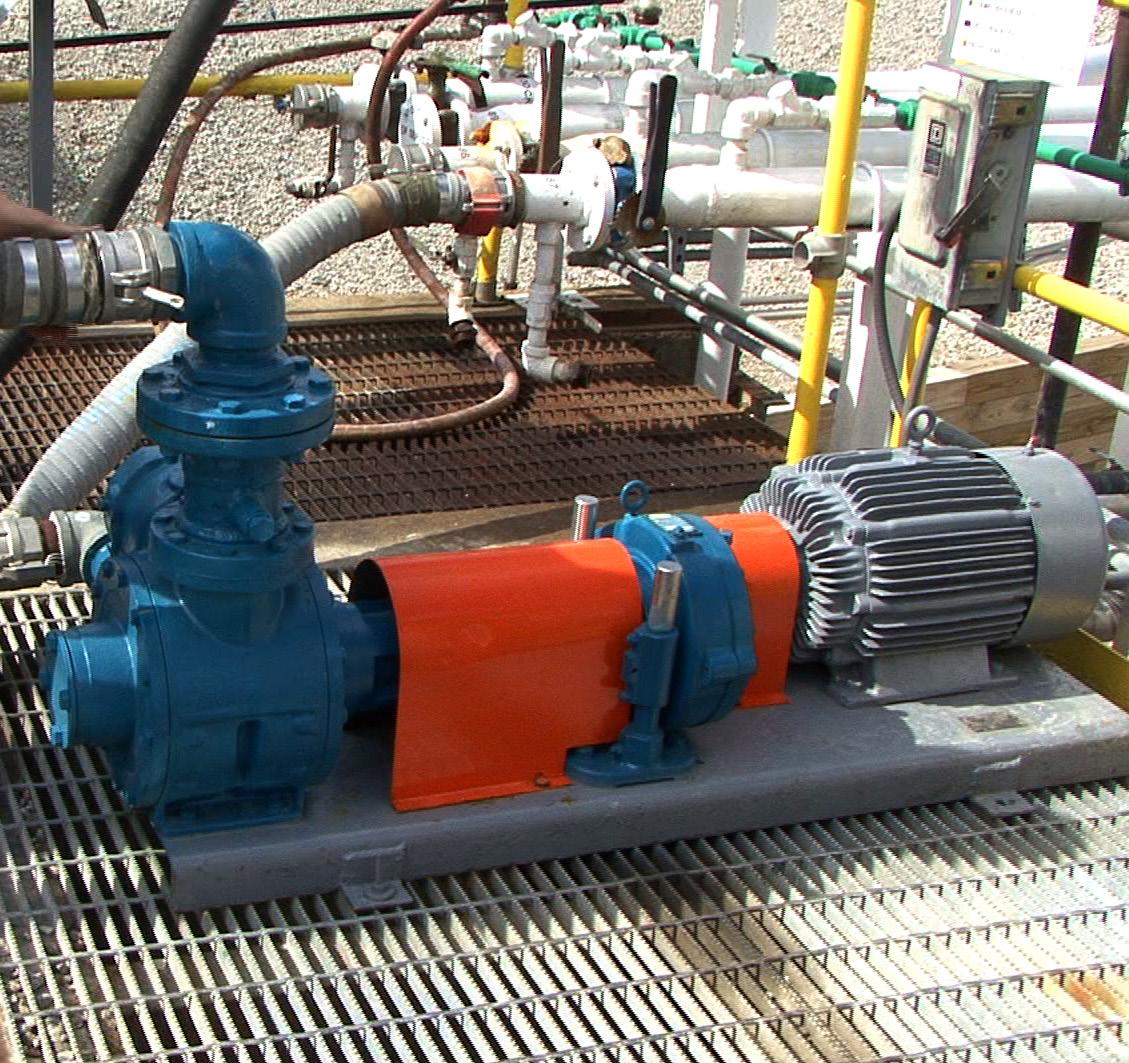

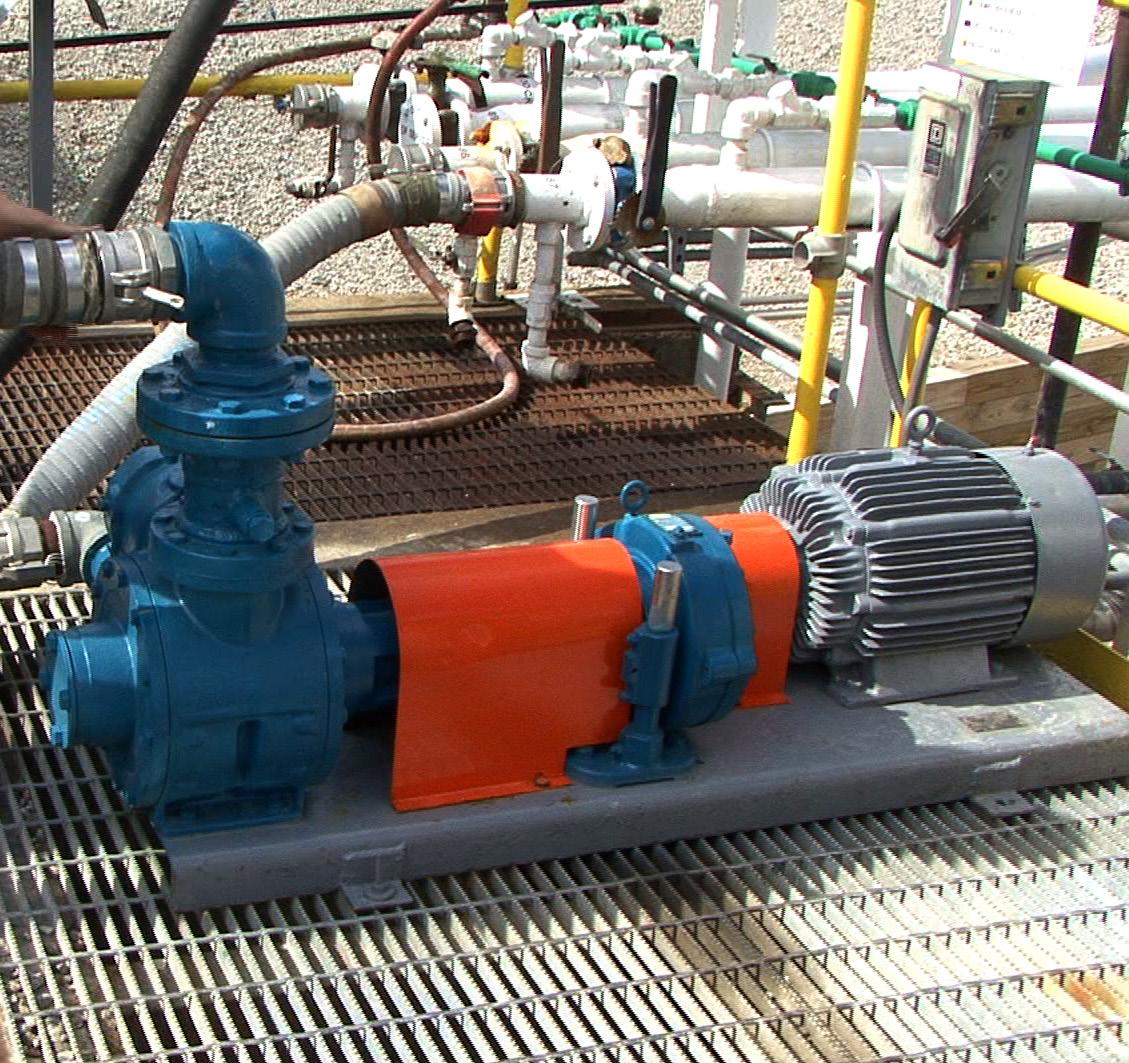

A pump built for every construction and mining job

Tsurumi Pump brought its diversified product line to Conexpo 2023, The company plans featured pumps and technologies from its vast product lines including construction and mining products and demonstrated that it has a product for nearly every application that needs a pumping solution.

The pump manufacturer focused on the quality and reliability found throughout its entire product line, which is strengthened by an extensive inventory of pumps and parts. “Tsurumi prides itself on having dewatering pumps capable of handling large flows and pumps able to generate over 700 ft of head,” said Glenn Wieczorek, Tsurumi America’s managing director-president. “We offer pumps from less than 1 hp to 250 hp, built from corrosion-resistant materials to withstand the most challenging conditions found in construction and mining operations everywhere. We manufacture pumps for every challenge!”

Corrosion-resistant and agitator lines

At this year’s Conexpo, Tsurumi highlighted its corrosion-resistant models and units that are equipped with agitators at the end of the motor shaft, which are ideal for the construction industry. The agitators allow for the transmission of fluid, sand, sludge and slurry to move along seamlessly. Visitors will also see cutaway displays and tank demonstrations of products.

Tsurumi adopts industry-leading engineering standards on the manufacturing of its products, which results on time-tested reliability across multiple sectors. High-quality components made with durable materials such as the patented oil lifter, silicon-carbide seals and high-chrome impellers make Tsurumi pumps ideal for a great number of jobs — from mining to industrial to residential applications. “Our significant growth in the past three years has only made us more cognizant of the important role we play in the construction and mining industries. Our attention to manufacturing detail and dedication to our parts inventory are just two aspects that we’re very proud of,” Wieczorek said. “We’ve made a significant effort over the years to boost our logistical capabilities to ensure customers have the pumps they need whenever and wherever.”

Tsurumi (America), elsab@tsurumiamerica.com, www.tsurumipump.com

PUMPS

18 Pipes, Pumps and Valves Africa - Mar/Apr 2023

You choose. We sup ply.

Our wide range of standard pumps and valves provides plenty of scope for individual demands. You can select the materials, hydraulic systems and drives. When you’re facing complex tasks, we’re with you from Day One – whether you want planning guidance, specially designed components or help with commissioning. But see for yourself. Test our products for quality and versatility, and discover why KSB is so often first choice.

KSB Pumps and Valves (Pty) Ltd

www.ksbpumps.co.za

tel: +27-11-876-5600

Standardised Customised Systems-based One provider

Our technology. Your success. Pumps n Valves n Service

Erwat pursues greater efficiency with WEG motors

WEG premium efficiency electric motors from Zest WEG are assisting South African water utility ERWAT to respond positively to rising electricity costs at its water treatment plants.

The roll out of WEG’s reliable W22 low voltage (LV) motors at ERWAT’s plants will also contribute to improving the general performance of the plants, according to Dillon Govender, sector specialist in public sector business development at Zest WEG.

“Our WEG W22 motors are constantly improving in terms of their energy efficiency,” says Govender. “Not only have we made our WEG IE3 top premium efficiency motors in this range available to the local market, but now also offer our WEG IE4 super premium efficiency motors at no extra cost.”

Key to ERWAT’s decision to install these motors was Zest WEG’s local assembly plant and high levels of local inventory which ensures quick and reliable supply. Another factor was the standard five-year warranty that Zest WEG provides with the motors. The company also equips the motors to withstand the demanding conditions of operating within the water sector, he says.

“It is important that our W22 motors are readily available ‘off the shelf’ to ERWAT, so there is no delay in delivering the equipment as and when they need it,” he explains. “Our warranty provides peace of mind, giving ERWAT the certainty that these motors will provide maximum uptime for greater plant productivity.”

Govender highlights the value of staying abreast with energy efficiency gains in motor technology as a high proportion of the total cost of ownership is the running cost – which is mainly the cost of electricity.

He notes that the energy savings when using the WEG IE4 super premium efficiency motors reduce their payback times to as little as a year. From this perspective alone, it does not make commercial sense to keep repairing older, less efficient motors.

“In addition to reducing energy consumption, these WEG LV motors also reduce the carbon emissions related to electricity generation in South Africa,” he says. Migrating from the W22 IE3 model to the W22 IE4 is also seamless, as the critical dimensions do not change. The WEG W22 IE4 super premium efficiency motors are designed according to the DIN EN 50347 standard which means it can replace an IE1, IE2 or IE3 motor with similar frame sizes, and as a result no modifications are required when mounting the motors to the base plate.

To operate effectively in a water treatment plant, the motors must also withstand the wet, damp or corrosive environment. This could require solutions ranging from the use of specialised epoxy paint and internal tropicalisation measures, to the supply of canopies for vertical applications.

“Water treatment plants in South Africa also have to contend with the disruption of regular loadshedding, which can reduce their ability to treat the required volumes each day,” says Govender. “This means that these operations can no longer afford unplanned downtime.”

He concludes that the installation of WEG’s W22 LV motors will ensure not only higher energy efficiency, but also greater reliability for smoother and trouble free pumping.

20 Pipes, Pumps and Valves Africa - Mar/Apr 2023 PUMPS

Zest WEG, +27 (0) 11 723 6000, info@zestweg.com, www.zestweg.com

80 GHz level sensor with fixed cable connection (IP68) www.vega.com/vegapuls All advantages of the radar technology: RADAR ULTRASONIC IS THE BETTER

Support for Grindex range grows with African expansion

As the demand for market leading Grindex pumps steadily increases, official distributor of this dewatering pump brand, Integrated Pump Technology is growing its support capacity to keep customers well served.

“Our expansion into the SADC region and beyond has been built on the proven quality of rugged Grindex pumps underpinned by the strength of our support services,” says Justin Bawden, Key Account Manager at Integrated Pump Technology.

“We have therefore been continually building our growing network of agents and developing their expertise to support our end-customers.”

The company’s Grindex distributorship in Southern Africa has been so successful that its recent five-year renewal from its principals included another seven countries into which it will expand: Angola, Gabon, Kenya, Malawi, Rwanda, Tanzania and Uganda. Bawden highlights that incountry representation – with good local stockholding and accredited repair facilities – is key to the current strategy.

“We have always prioritised our customer support, and work closely with our distributors so they are equipped

to meet and exceed customer expectations,” he says. To ensure there is sufficient stockholding close to customers, Integrated Pump Technology holds extensive stock at its Johannesburg headquarters. It also engages regularly with its distribution network to analyse customer demand and trends in each region. This, Bawden says, allows the right stockholding levels to be planned within easy reach of customers.

“This way, we make sure we keep the right equipment and fast moving consumable parts stocked and available, ensuring a quick turnaround time and less downtime for the customer,” he says. Rapid response time is always important, especially in countries like DRC and Zambia which have some of the wettest mines in the world. Any disruption in dewatering activity can lead to mining operations being flooded, equipment damaged and production time lost.” The company also looks for distributors with suitable workshop facilities, so that all

22 Pipes, Pumps and Valves Africa - Mar/Apr 2023 PUMPS

servicing and repair work can be conducted regionally to the OEM specification. This engineering quality that these workshops deliver, he argues, is vital to minimising future downtime on the customer’s site and preventing production losses.

Training and skills transfer are other important aspects of how Integrated Pump Technology empowers local distributors.

Such skills development is done either at their head office or in-country, and is conducted by experienced experts from the Johannesburg operation.

“Our strategy is to grow with the local communities in which we operate, engaging and developing talent from those areas – to serve that customer base with above average support,” says Bawden.

“With our combined expertise and resources, we can help customers identify and implement sustainable solutions to their most challenging applications.”

He explains that the performance and longevity of the Grindex range of pumps is considerably enhanced by Integrated Pump Technology’s hands-on approach.

“With well trained technicians located close to customer sites it is easy to conduct regular maintenance and servicing to OEM standards, and this definitely reduces the total cost of ownership for mines and plants,” he says.

Good communication is also an essential part of Integrated Pump Technology’s formula for successful relationships with customers. Not only can distributors communicate their needs directly with the Johannesburg head office, but Integrated Pump Technology can engage the Grindex experts abroad to help resolve any technical queries.

“We back up our training with valuable user manuals and equipment documentation that help distributors and customers to ensure that Grindex pumps are optimally selected, operated and maintained,” says Bawden. “Where customers make it possible, field service teams can also conduct on-site work for certain kinds of repairs.

Our focus is on reducing downtime for the customer –wherever the site is located, and contributing to them achieving the lowest total cost of ownership.”

Integrated Pump Technology, +27 (0) 11 894 2906, sales@pumptechnology.co.za, www.pump-technology.com

PUMPS PUMPS

and Valves Africa - Mar/Apr 2023 23

Pipes, Pumps

ENERGY_VALVES_95x180_PUMPS AND VALVES_AWP.indd 1 2023/02/20 11:23

World’s best vacuum seals tested but not touched

TorqSense, a non-contact digital torque monitoring system that could guarantee an infinite lightness of touch has proven to be the only way to test the seals of super high performance vacuum systems.

The ultimate fields of precision manufacture, such as electronics, biophysics and thin film deposition where tolerances are measured in atoms, are often conducted in hard vacuum to remove airborne contaminants and avoid the performance reducing effects of tiny air movements. However the vast majority of vacuum chamber designs require seals for rotary drive shafts (called rotary feedthroughs) and ‘feedthroughs’ for the passage of materials, components, tools and finished products.

In high vacuum applications conventional seals are unlikely to be able to achieve the performance specifications required, so magnetic fluid seals are used.

A ferrofluid is a stable colloidal suspension of sub-domain magnetic nano particles in a liquid carrier. The particles, which have an average size of about 100Å (10 nm), are coated with a stabilising dispersing agent (surfactant), which prevents particle agglomeration even when a strong magnetic field gradient is applied to the ferrofluid.

With over thirty years of experience producing seals for the world's most demanding applications, Ferrotec of Woolwich in London is able to optimise ferrofluid materials for the most extreme performance requirements and incorporate them into bespoke vacuum system designs.

“About half of our work is to bespoke design,” says Jeff Lewcock of Ferrotec, “and we have to test every seal to the nth degree to meet out customers specifications.

To test the feedthrough it is mounted onto a vacuum chamber that is connected to a helium leak detector. Helium is then spayed onto the feedthrough and the leak rate observed during static and dynamic running.

As part of the test the starting and running torque of the seal are measured and the power loss through the seal is calculated. These readings allow Ferrotec to troubleshoot the individual seal, analyse the design’s performance

HIGH PERFORMANCE FLOW CONTROL SOLUTIONS

Bray offers a complete portfolio of flow control solutions to handle your most challenging applications.

and add to Ferrotec’s knowledge base. “With the sort of tolerances we work to we needed a torque sensor that didn’t add any extra drag to the whole seal mechanism, so we were delighted to discover Sensor Technology’s noncontact TorqSense,” says Jeff.

Sensor Technology , info@sensors.co.uk, www.sensors.co.uk

24 Pipes, Pumps and Valves Africa - Mar/Apr 2023 PUMPS

BRAY.COM

Bray Controls Africa (Pty) Ltd Unit 11, ABC Business Park Mastiff Rd, Linbro Business Park Sandton 2090, South Africa Telephone: +27

10 007 3222

Lifting Africa & Pipes, Pumps And Valves Africa

Golf day 2023

Thank you to all our Sponspors:

25 Lifting

- Sep/Oct 2022

Africa

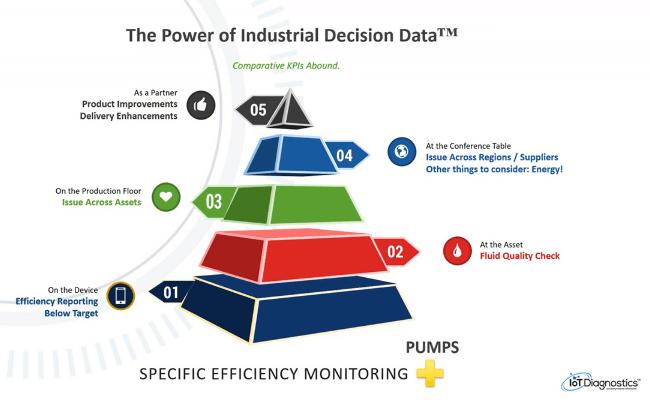

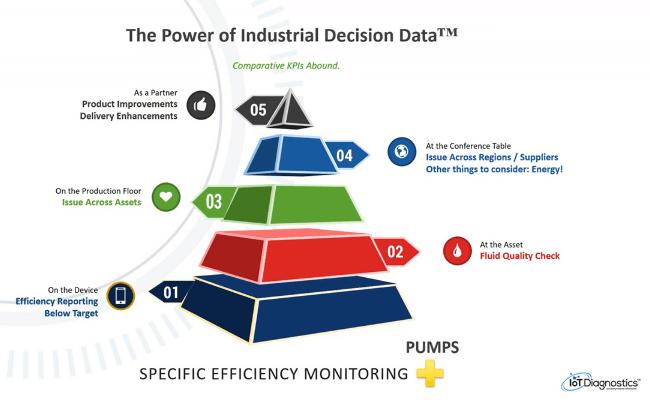

Mastering fluid power efficiency with industrial IOT

This is both a simple and deceptively dense question for production managers, engineers, and maintenance personnel. Without any operating or performance data, the answer to this question remains straightforward; they’re either working or they’re not. But we know that there is a large chasm of performance between “working” and “not working”.

Historically, we would pull out a piece of paper or go to a spreadsheet and run efficiency calculations to determine how much work and how much waste we’re seeing. Consider then also the drive for better efficiencies across not only our pump sensors but also our overall equipment effectiveness across entire fluid power systems -- we know work and waste is everywhere. To date, this has placed a hefty time tax on how much effort we spend chasing down this information. We now understand how deceptively dense the “how are your pumps?” question truly is.

With the advent of the Digital Age and the Industrial Internet of Things (IIoT), can we answer the pump question more confidently than ever? Can we introduce a new way to master fluid power efficiency and “erase the waste”?

The easy answer is yes.

Mastering fluid power efficiency in the age of IIoT requires alignment in believing that efficiencies are amplified by the sum of their parts – every time new insights and information are layered upon existing information, the picture of efficiency gains higher resolution. However, the real value of the IIoT is in how quickly, safely, and predictably we can obtain that information, and then how we use it! We can reliably use that data to build realtime efficiency models that are constantly running in the background. If we tie that back to work and waste from a time management standpoint, glancing at a dashboard to see a real-time efficiency metric is about as efficient as

it gets. Peak efficiency is gained by not just knowing the performance characteristics of one component, but how that component works in an entire fluid power ecosystem. While seeing a standalone case pressure reading in realtime from a pump can be helpful, when that is layered with a real-time flow reading, the information has more context. Your overall insights gain more credibility if you also have real-time fluid characteristics being monitored like contamination. Layer on real-time filtration monitoring and you have a digital fluid power efficiency hub at your fingertips.

Pump efficiency monitoring using industrial iot

Traditionally, if you wanted to see how a pump is working or not, you would grab a bucket, a hose and a stopwatch. This was one way to check flow rates and overall efficiency. There is an opportunity to get beyond that world and have a more harmonious, connected interface. Imagine now that instead of just a traditional pump, you have a smart pump or a smart device connected to a pump, acting as a sensor. That smart device is generating information for you in real time about that pump, down to the pump's volumetric efficiency (VE). The manufacturer recommends that at any given time, you should be at an 85 percent VE or higher coming out of the case drain but suddenly, one of your pumps starts to trend at a 78 percent VE out of a case drain. So now, you're operating at seven points below what the manufacturer recommends. With today's IoT, you're

26 Pipes, Pumps and Valves Africa - Mar/Apr 2023 PUMPS

going to get an alarm or a notification about that. Now that you understand that it's operating below efficiency, you've got to start thinking about some decisions that you need to make. Are you still satisfied with the level of production? You can start to change production decisions in real time. But you have this piece of information here now, and what do you do with it? What's really important to take away from this is how you use the data. You could start asking many questions about your oil condition and take action to clean and filter the oil. Then you can start making operational decisions for your production. You can then look across the entire manufacturing plant or plants to see if this same product is having the same 78 percet VE — determine if it’s plant-wide or fleet wide.

Now you've gone from an asset specific to a systemic look at the pump and its fluid quality. You can use this data globally if you have fleets or plants all over the world, instead of individuals in each plant monitoring and gathering and sharing data. This can be used to now make company-wide decisions. All this started from a singular piece of efficiency data at this point. And then we ultimately get to the very top of the pyramid, which gets us to an interesting piece of monetization as well. Because inside the organization may not be the only people that care or want to see that data. What if it's actually the pump — the pump itself? Shouldn't the OEM of that pump know that it's just not quite working as it should be in the application environment that it's in?

What we see with the IoT is the more that we generate that information back to the OEMs, they can continue to engineer out why this stuff fails in the first place. Because engineers can’t get out into the field and understand how equipment works in the highly varied environments of traditional off-highway or factory floor level machines, generating post installation information back to them allows them to make the smarter design decisions around how their products work.

Establishing real filtration efficiency

Hydraulic filtration preventative maintenance is usually based on a schedule or based on the pop-up indicators that tell you a filter is nearing the end of its life — that as the element continues to collect dirt and water particles, it gets less and less effective and then it ceases to be effective

before you need to go into bypass. In this case, the filters could have been used past their effectiveness, thus reducing efficiency. Or, all filters are simply changed out on a schedule, so you're going to have filters that probably didn't need to be replaced and you’re wasting money. What if your filter was actually able to sensor and tell you at the exact moment, or maybe 10 or 5 percent before it reached peak efficiency? If you use smart filtration, you will be replacing the filter at the right time, every time. This has generated at least 33 percent cost savings for organizations that are deploying system-wide filtration management with the IoT.

What is lubrication efficiency?

Up next is lubrication — is your fluid working for you as well as it should? There are always opportunities to gain more information about your fluid health. You may take a fluid sample or a colour patch test and send it to a lab, and a report is generated. Testing and labs are important pieces of the lubrication management puzzle. But the problem is you can't just look at one piece of that fluid. The baseline for hydraulic fluid is that it should be clean, cool and dry. You can keep contaminants out, keep water out, and keep your fluid at the right temperature. But depending on what industry you're in, you may need to understand more about your additive packages, metal ingress, fluid oxidation, etc. Here, the viscosity index is not the only answer. It’s important to consider all factors when trying to achieve lubrication efficiency.

This is why the narrative starts to change when you have more efficient data coming in and you have a bigger, better, broader picture on how to manage your equipment, fleet, factory, floor, whatever it may be. Backing out to this narrative allows you to question your system reliability, preventative maintenance plans, lubrication management, vibration monitoring and even the commodities you use. Stack those on top of each other and you start to get more and more insightful information. IFPE,

Pipes, Pumps and Valves Africa - Mar/Apr 2023 27

PUMPS

hsun@conexpoconagg.com, ShowMediaServices@aem.org, www.ifpe.com

The magnet makes the difference in these high-efficiency pump motors from Franklin Electric

Pumps with permanent magnet motors and VFDs deliver attractive return on investment in high-duty-cycle applications.

High-efficiency equipment has become a focal point in the clean-water and drinking water sectors as utility leaders strive to be better stewards of energy and water resources. That focus extends to the pumping systems that move wastewater through collection systems and into treatment processes, and that draw drinking water from wells and reservoirs and fill the tanks and towers that hold water for distribution.

The objective is to create pumping systems that deliver financial savings while performing reliably and intelligently, providing long service life, and saving on maintenance.

Toward these ends, pump manufacturer Franklin Electric offers high-efficiency submersible pumping systems built around the company’s MagForce permanent magnet motors.

The company cites PM motors as a proven technology used in applications from industrial to residential. PM motors have rotors made with rare earth magnets that perform with no slip. Because the rotors require no electricity to become magnetized, the motors are more efficient.

The savings on energy can quickly offset the higher initial costs. For example, motors with a 94% efficiency rating can provide a payback of less than two years in long or continuous duty applications. Brandon Schumm, product manager for large submersible motors with Franklin

Electric, talked about the technology in an interview with Treatment Plant Operator.

What was the market impetus for this type of pumping system?

Schumm: We had customers with high-duty-cycle applications running 24/7 or very close to that. They understood that if there was a way to get better efficiency out of the pump or motor, they could save on operating costs.

PM motors were not new to the world, so we looked into that technology and incorporated it into submersible motors. The pump is still the same. The difference is the high-efficiency motor we’ve added to the system.

Was there any particular challenge to marrying PM motors to submersible pumps?

Schumm: The design was a little tricky because we’re confined to a certain diameter in submersible applications. In aboveground settings with a PM motor, you can change the geometry and get bigger, wider and longer. But working within a limited diameter for going down a well does pose a few design challenges.

Is the efficiency advantage due to the use of the rare earth magnets?

Schumm: Yes. With traditional induction motors, you have

PUMPS 28 Pipes, Pumps and Valves Africa - Mar/Apr 2023

to add energy as electricity to make that internal magnet. With PM motors, you eliminate that added energy because the magnet is already there.

Where would these high-efficiency pumps typically be found in drinking water or wastewater treatment plants?

Schumm: Municipal drinking water plants are our main focus, but these motors could be used in any highduty-cycle application. PM motors are more expensive than induction motors, and you have to overcome that up-front cost. If you have an application where a pump is running 30-40% of the time or more, that’s a good opportunity to look at this solution.

How much more efficient are pumps with PM motors versus induction motors?

Schumm: It depends on the size of the pump, but anywhere from 8 to 12 percentage points more efficient. So where an induction motor might be 8283% efficient, pumps with these high-efficiency motors can get into the low to mid-90s.

Beyond energy efficiency, what advantages do these pumps have?

Schumm: Because you’re pulling less current for the system, you can look at downsizing other components. In wire sizing, for example, in the past you might have used a 6-gauge wire.

Now, because the motor is pulling less current, you can use a smaller-gauge wire. You might even be able to downsize the variable-frequency drive or the filtering. Another benefit is the capacity for higher speed. Based on the frequency coming in, which in our market is 60 Hz, pumps and motors spin at about 3,450 rpm due to the slip that’s inherent with an induction motor where you have to create that internal magnet. With the magnet already present in the PM motors, you can get up to 3,600 rpm. We consider that a boost in performance.

Are there any benefits related to size or configuration?

Schumm: In some systems we can reduce the weight and the length by almost half. I was on an install recently where a customer was using one of our 250 hp motors.

When the technician, who was rather short, went to bolt the motor to the pump, he said, “This is the first time I’ve been able to reach the bolts and not have to use a ladder.”

How do you relate the efficiency of these pumps to prospective customers?

Schumm: Many municipalities have had visits from energy consultants, and the first thing they do is look at the ceiling and say, “If you want to save energy, change all your lighting to high-efficiency LEDs.” So to better relate, we created a calculator showing that if you were to switch to a high-efficiency MagForce motor, it’s equivalent to replacing X number of lightbulbs with LEDs. The calculator can also show reduced carbon footprint.

What role do VFDs play in these high-efficiency pumping systems?

Schumm: You must use a variable frequency drive with this type of motor. When you go to start up the motor, you have to know the phase alignment. If you just applied energy over the line without a VFD in place, the motor would lock itself up. You need a VFD to get it spinning and to have that phase alignment when it is operating.

Can you cite an example of an application where these pumps proved beneficial?

Schumm: A municipality in Germany was using an inductionmotor-driven pump over the line. To get the correct flow, they would throttle the flow out of the pump.

The motor was spinning all the time and they were essentially restricting it so as not to produce more flow than they needed. We set them up with a high-efficiency system with a VFD.

They were able to downsize the pump, and with the VFD they could vary the speed depending on the flow requirement. We cut the power consumption in half. We attributed about 80% of the savings to the VFD, and the other 20% to the PM motor.

What is the size range for this line of motors?

Schumm: We run the whole gamut. We start out at 1.5 hp and go clear up to 300 hp. Our 8-inch and 10-inch designs are where we see municipal and industrial applications going. The 8-inch motors range from 75 to 175 hp, and 10-inch units from 250 to 300 hp.

Franklin Electric, +27 (0) 11 723 6500, info@franklin-electric.co.za,

R 2 500 Excl Vat

PUMPS

Africa - Mar/Apr 2023 29

Pipes, Pumps and Valves

( ( ( ( ( ( ( (

(

(

for more info

( (

( ( ( (

(

KSB and sustainability of energy

As the mining industry in Southern Africa continues to grow, there is an increasing need for pumps and valves that are bigger, more energy-efficient and sustainable.

KSB Pumps and Valves, a leading manufacturer of pumps and valves, has been at the forefront of this movement, designing and manufacturing pumps that are specifically built to meet the needs of the mining industry. With a focus on sustainability, KSB is leading the charge when it comes to providing equipment that can handle a variety of mining conditions, is easy to maintain, and can provide a long wear life.

“In addition to our focus on sustainability, KSB also dedicates time and energy to minimizing downtime on our mining pumps which is achieved through a range of measures, including the use of high-quality materials and manufacturing processes, as well as extensive testing and quality control procedures,” said Rob Bond, KSB Pumps and Valves, area manager for mining in Southern Africa. This in turn ensures that KSB pumps are built to last, with minimal need for maintenance or repairs.

Global expertise

But when issues do arise, KSB's after-sales service is there to provide support and assistance. With a global network of service centers and technicians, “KSB can provide rapid response times and quick repairs, minimizing downtime and ensuring equipment is up and running as quickly as possible,” says Rob. This commitment to after-sales service is a key part of KSB's approach to sustainability, as it helps to extend the life of their pumps and reduce the need for replacement or disposal.

“One of the biggest challenges facing the mining industry is the need to operate in a sustainable and environmentally friendly manner. To meet this challenge,

we have focused on developing pumps and valves that are designed to reduce energy consumption and minimize the environmental impact,” says Rob.

By using the latest technology and materials, KSB has been able to produce pumps that are more energy-efficient, while still delivering the high performance that the mining industry demands. KSB's after-sales service is also focused on preventative maintenance, with a range of services available to help customers keep their pumps and valves in top condition.

From regular inspections and maintenance schedules to training and technical support, KSB's after-sales service is designed to help customers get the most out of their equipment, while also reducing the environmental impact of their operations.

Customer centric

“We have 37 production sites in 18 countries and nine foundries on three continents. Plus, we have over 3500 worldwide service staff ready to assist you wherever you may be. KSB Mining has proven it is well-equipped to offer our partners a complete package of products and services. We use our expertise to make our customers’ experience easy and successful. We provide exceptional and unparalleled customer service.”

KSB Pumps and Valves South Africa, +27 (0) 11 876 5600, Annett.Kriel@ksb.com, www.ksb.com

30 Pipes, Pumps and Valves Africa - Mar/Apr 2023 PUMPS

Four benefits of digital twin technology for water utilities

Municipal water & wastewater,water utilities,making waves,digital solutions. Everyone is talking about digital twin technology, but what are its most practical applications and benefits for water utilities? Let’s take a look.

What is a digital twin? A digital twin brings together data and an operational model to help operators understand how a physical asset, process or system should be performing. It helps to provide insights and predict performance under changing conditions, which ultimately helps water utilities increase productivity and efficiency. Essentially, in a digital twin data is integrated to detect and diagnose anomalies, test different scenarios, and predict outcomes specific to those scenarios. In comparison, traditional models for simulating infrastructure can be costly to build and don’t readily assimilate live data. Today, sophisticated machine learning tools can better represent infrastructure by automatically calibrating to match historical data.

Digital twin technology delivers benefits at four levels for water utilities:

Visibility

At its most basic level, a digital twin shows operators what is happening within an asset, process or system right now. At this level, operators must take action based on their visibility of current operations.

Scenarios

At this level, the digital twin is capable of processing variables to predict an outcome, but it still requires the operator to manually optimize the asset, process or system.

Recommendations

In more sophisticated applications, the digital twin generates multiple scenarios and provides operational recommendations to achieve set performance indicators. The operator then chooses a course of action based on these recommendations.

Control

When combined with decision support systems and water system expertise, the digital twin has the potential to deliver autonomous, optimized control, freeing up operators to focus on other tasks.

Ultimately, a digital twin is an enabling technology – not a solution – and its potential is only realized in how the data is applied.

In the more sophisticated applications described above, digital twin technology is coupled with advanced data science, hydroinformatics and water system expertise to create a powerful decision support system.

This “supercharged” digital twin sets utilities up to meet their communities’ needs reliably, affordably, and sustainably.

Xylem, makingwaves@xyleminc.com, www.xylem.com

32 Pipes, Pumps and Valves Africa - Mar/Apr 2023 PUMPS

Future-proofing your facility’s water systems

When it comes to maintaining a building’s water systems, facility managers are often the first to hear about issues related to water pressure – from showers and faucets that aren’t performing as expected in tenant-occupied spaces to commercial units like restaurants, hotels, schools and healthcare facilities that rely on water to keep their businesses running.

When a property suffers from low water pressure, installing a pressure boosting system can offer a cost-effective solution. A pressure boosting system is defined as a device or machine that helps increase the pressure of a fluid at the established flow rate of the current water delivery system. Pressure boosters for water typically increase pressure from a positive (gauge) pressure to a higher level. Pressure boosting pumps can have simple on/off control, pressure-based control – like a differential pressure switch – or an advanced electronic controller like a smart starter variable frequency drive (VFD) or programmable logic controller (PLC).

Knowing you need a pressure boosting system is only one part of the equation. Selecting the right system for your application is just as critical – and determining what will deliver the “right” balance of benefits for your property’s needs. At the most basic level, pressure boosting systems are selected based on flow demands and budget. Yet these variables are only one part of the equation. Facility managers also need to think about scalability, flexibility and long- and short-term maintenance. If you’re looking into the merits of a pressure-boosting system, ask yourself these questions:

Is the System Scalable?

Consider this example: A building owner leases space to a clothing boutique. After several years, the boutique owner moves out and a restaurant moves in. Two years later, a laundromat wants to occupy the space. A scalable pressure-boosting system can accommodate these varying needs without a costly overhaul. These systems will allow a facility team to seamlessly expand the quantity of booster pumps after the initial installation.

Is the System Flexible?

In the previous example, different tenants required different needs. What if one tenant’s needs fluctuate throughout the days and week? If a laundromat has 50 machines, but only operates an average of 10 on a weekday and all 50 on the weekends, how does the pressure boosting system respond? Do you run your initial spec against the max need of 500 gpm or the average need of 50 gpm? The right pressure boosting system can help you do both.

An electronic controller – such as a variable frequency drive (VFD) with an integrated programmable logic controller (PLC) – can maximize usage of a system’s pumps

34 Pipes, Pumps and

Africa -

WATER

Valves

Mar/Apr 2023

at different times. As water demand increases, the system instantly accelerates the motor to the proper speed ensuring the water pressure stays constant from fixture to fixture. When it comes to booster pumps, variable speed is the best solution and allows you to operate across an entire performance area, hitting the exact duty point you want to meet. The performance of the system isn’t limited to one single curve that constrains you. Instead, a pumpdedicated VFD allows for a range of possibilities. They can help with energy savings as well.

Is the System Easy To Set Up & Operate?

“Plug and play” capabilities are sometimes an overlooked part of selecting a pressure boosting system. However, most people do not want to choose a system that requires an advanced engineering degree to install. With the right system, installers should be able to determine how much water is required to be boosted to the desired constant pressure output, and the system comes packaged ready to boost. They only need to make traditional connections on the pipe circuits.

Pressure boosting pumps that come as part of a complete package are often designed for easy installation, operation and durability. In these packages, PLC interfaces are optional. With preconfigured and pump-dedicated VFDs, complexity is taken out of the equation. Also look for equipment that is wet-tested and set prior to shipping so the only adjustment needed, if any, would be to the desired pressure. Look for systems that are easy to return to factory settings using a phone app or through the provided memory card within the HMI, if desired.

Is the System Easy To Maintain?

Service also factors into reliability. The less you have to service a system, the more the system is working for end users. This is especially important in applications where

constant water delivery is critical such as a system that’s installed in a hospital or other essential business. If a system does require maintenance, how difficult is it to reach and access? When annual or semi-annual electrical inspections are needed, a system with quick disconnects can assure that maintenance is possible without timeconsuming service interruptions.

One final consideration that overlays both reliability and maintenance is durability. You want to assure that your pressure boosting system can withstand the environment where it’s being used. Are the controller, pump and motor fully encapsulated if need be?

What Else Is Important to the Tenants in Your Buildings: Size, Noise, etc.?

Any time you add equipment to a building, you need to consider the space it occupies. Whether the system is going on a production floor or in a tiny maintenance room, floor space is critical, and a 200 square foot pressure boosting system is a lot different than one that takes up a few square feet next to a wall or affixed to a ceiling. This is particularly true in locations with expensive real estate. Anytime that equipment runs, you need to consider how it runs and what that means for usage: does it run hot or loud? Systems that operate in the background – without tenants even knowing they are there – is important. Look for systems that have a small footprint and promise quiet operation. Self-contained systems often win in these areas and offer easy install without a lot of extra time for setup.

Franklin Electric, +27 (0) 11 723 6500, info@franklin-electric.co.za, www.franklin-electric.com

Pipes, Pumps and Valves Africa - Mar/Apr 2023 35 WATER

Carlsberg taps into process water reuse with onsite treatment

Carlsberg brewery wants to cut its water use by 50% by 2030. The initiative, Zero Water Waste, is part of Carlsberg’s Together Towards Zero program. In its production facility in Fredericia, Denmark, Carlsberg has developed a Total Water Management treatment plant with consultants, universities and technology providers like Grundfos.

The onsite facility treats used process water from mainly cleaning purposes, purifies it to drinking water quality and sends it back to the brewery to be reused as process water. The plant recovers and reuses 90% of its process water.

The situation

Water is an essential ingredient to produce beer. No water, no beer. Most of the water used traditionally, however, does not end up in the beer. At the Carlsberg facility in Fredericia, Denmark, around 60-65% of the total water usage goes to mainly cleaning purposes – everything from equipment, floors and surfaces to pipes and tanks to bottle and can washers and more, including cooling towers and boiler plants. This is called process water.