ENDORSED BY SAPMA, SAPSDA, SAVAMA AND VAMCOSA

Unique Hydra-Cell pumps, for reliable seal flush applications

JAN/FEB 2024

At Xylem we are 100% about water, including delivering transformative solutions across the entire water cycle. We are pioneering our approach through 360 Performance solutions, delivering source-to-tap support, products, engineering expertise, and more for real value, efficiency, and lasting performance. Let’s Solve Water is more than a slogan, it is our mission! Discover 360 Performance, the cornerstone for a sustainable water future.

Presenting the Lowara e-IXP smart pump, designed according to ISO 2858 and 5199 standards to be the 360 Performance solution for industrial and multi-storey building applications due to its ability to be energy efficient, reliable and easy to maintain. At its core lies the ability to provide real-time data, empowering users with unparalleled insights into the system and efficiency. With proactive alerts, the e-IXP takes a 360 Performance approach to maintenance, ensuring timely interventions to prevent potential issues before they escalate.

e-IXP Centrifugal Pump

STANDARDIZATION MATCHES INNOVATION

SMART RELIABLE ENERGY EFFICIENT

Find out how we can solve water together.

On the cover

Invincible Valves, +27 (0) 11 822 1777, enquiries@invalve.co.za, www.invalve.co.za

Pipes, Pumps & Valves Africa

Managing Editor: Surita Marx

Tel: +27 (0) 87 700 9834

Cell: +27 (0) 83 281 5761

Email: info@pumpsandvalves.co.za

Web: www.pumpsandvalves.co.za

Sales: Peter Rametsi

sales@pumpsandvalves.co.za

Production Manager: Xane Roestroff

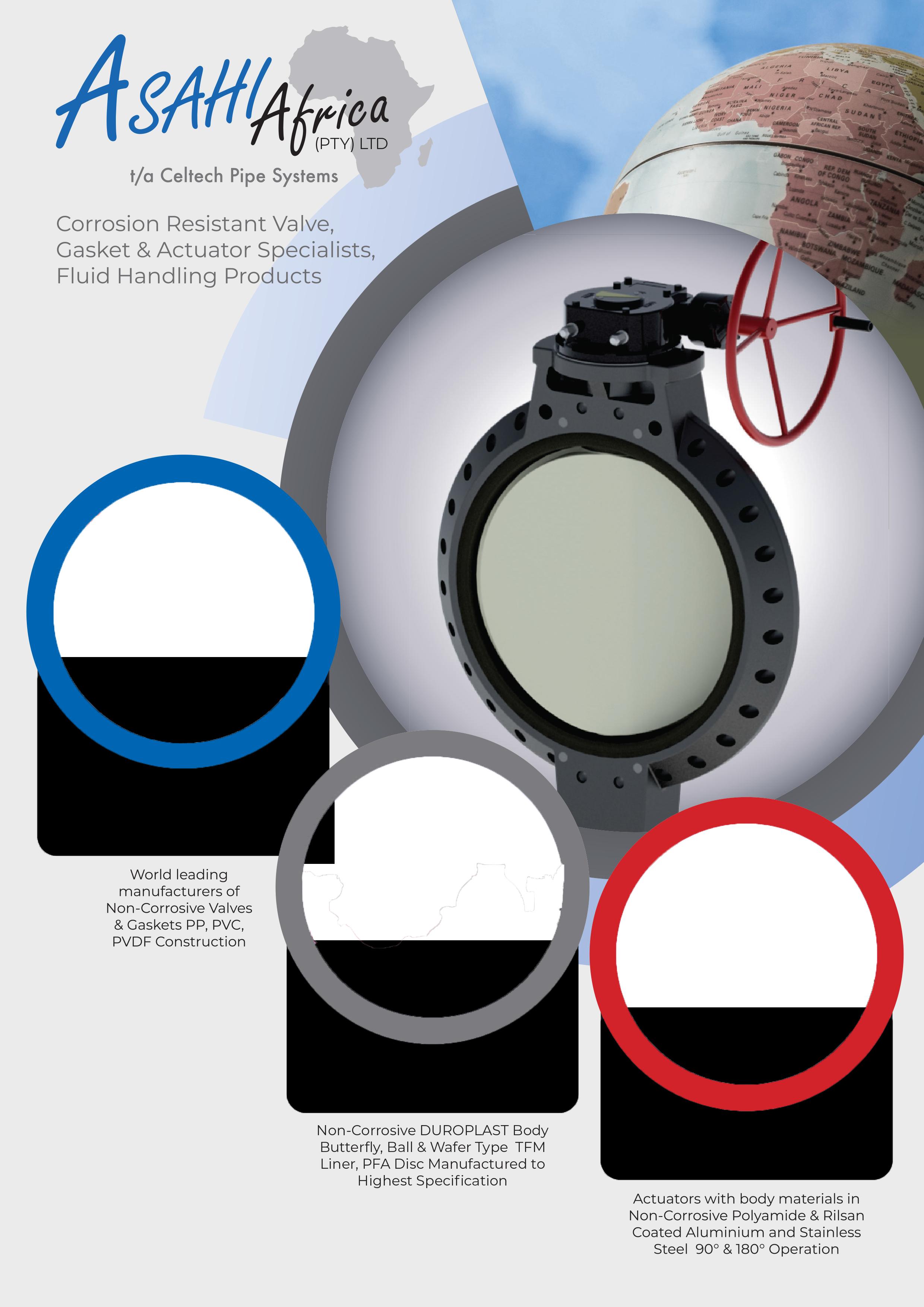

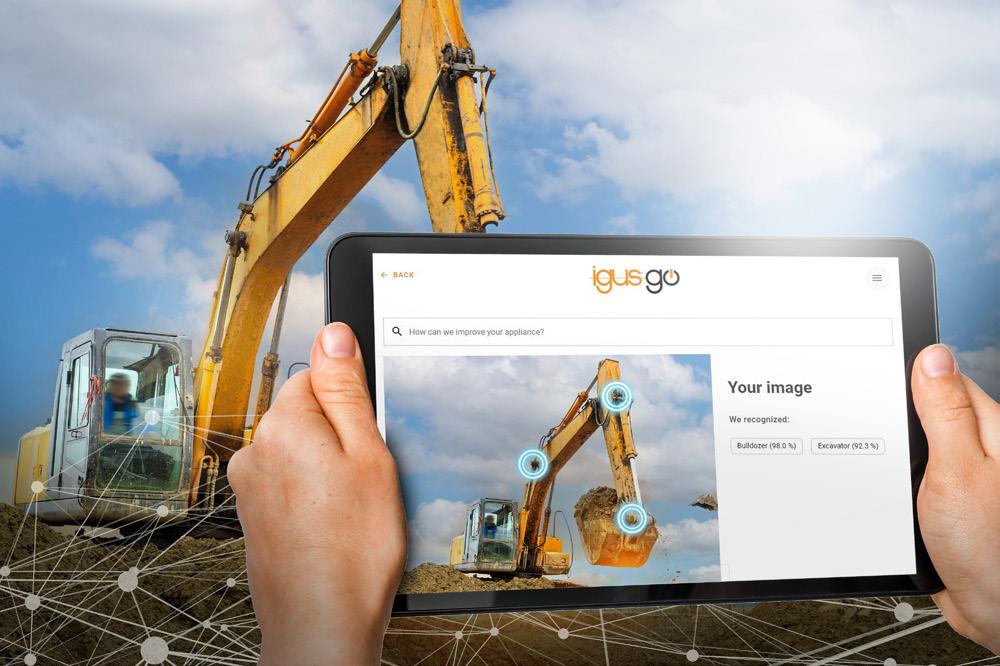

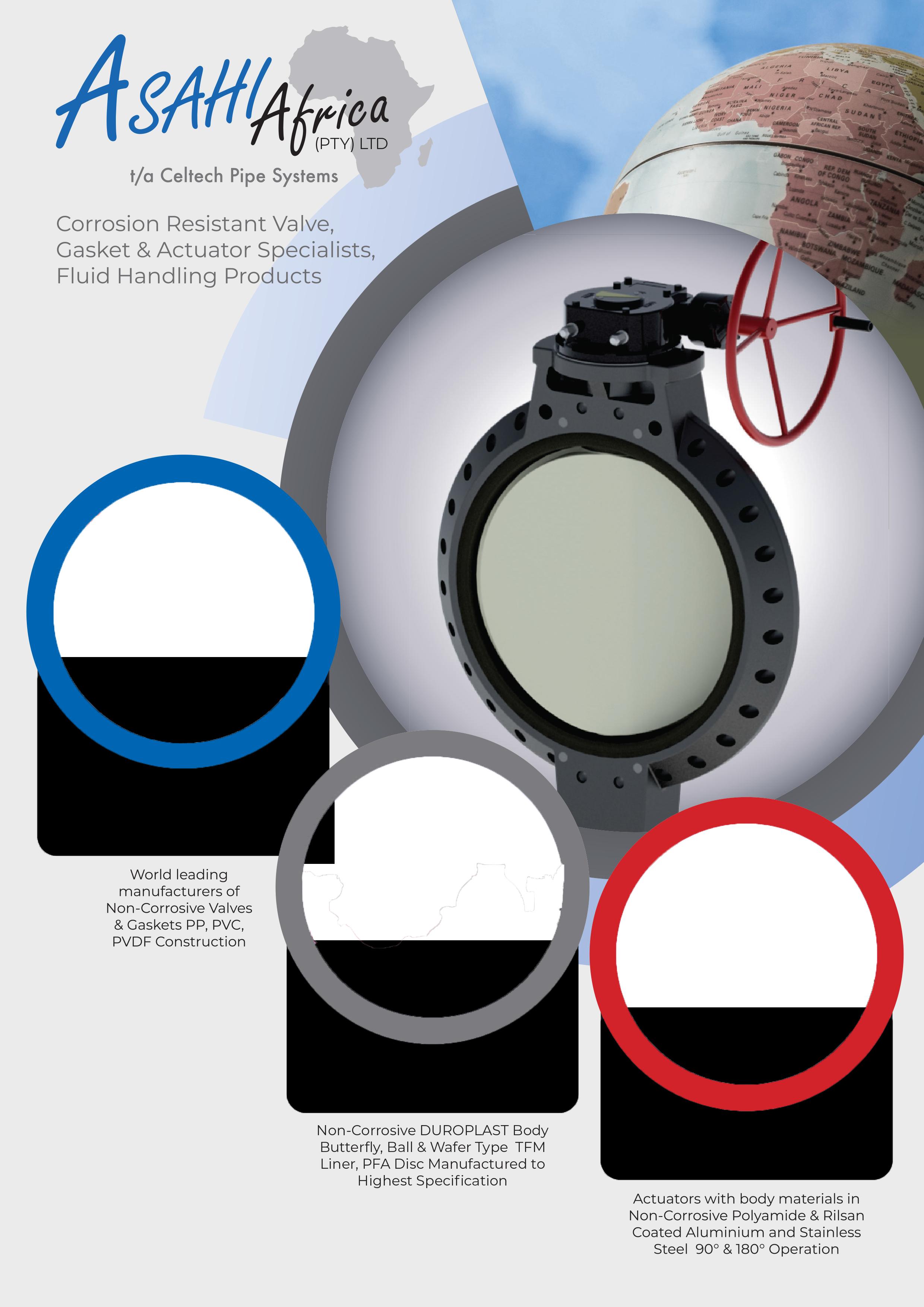

CONTENT Pipes, Pumps and Valves Africa - Jan/Feb 2024 3 Disclaimer: Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers SAPMA or VAMCOSA The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication. Advertisers Ainsworth Valves 21 Air & Vacuum Technologies 11 Amandla Pumps 29 Asahi Africa 37 Aumanat 27 Bauma China IBC Enserve 39 Golf Day 7 Industrial Valve Summit 17,41 Integrated Pump Technologies 35 Invincible Valves OFC,OBC KSB Valves 31 Machine Tool Africa 23 Marechal Electric CS Monitor Pumps & Systems 15 VacServe 13 Verder Pumps 19 Vesconite Bearings 45 Xylem IFC Zenzele Valves 9 COVER STORY A journey of innovation and dedication to customer satisfaction 4 Pipes Thermoplastic components by GF Piping Systems ensure a hygienic water supply on board a hospital ship 6 PUMPS The next evolution for concrete pump truck support 7 We help you save energy without compromising reliability 8 Grindex Bravo pump tackles tough slurry challenges head-on 12 Unique Hydra-Cell pumps, for reliable seal flush applications 14 Pump with the right accessories, advises IPR 16 Three food processing innovations piped in goodness 18 MQ Series pumps: versatility and flexibility through customization 19 Tapflo’s innovative submersible pumps solutions – technology meets efficiency 20 Optimizing motor controls for temporary surface pumps 22 Empowering pump operations CS Mechanical rotating solutions mobile diesel pumps shows its worth 26 How the IoT superhighway is supporting pump installations at mines 28 Tsurumi’s commitment to safety in pump design 30 VALVES Ceramic ball valves improve regulation and control of fluid flow 32 Pinch valves for efficient flow control 33 Shipbuilding is ready for a change of course 34 ENERGYValves: Ball valves 42 WATER Wastewater treatment a challenge Robuschi won 10 Lead the best water management with 360 performance 36 How engineering advancement is changing the way we manage water 38 PRODUCTS & SERVICES Elevate plant lubrication practices with new SKF Quick Lubrication Review tool 39 Metso launches Cross Flow Rotary Cooler to decrease water consumption and improve energy efficiency in pyro processing plants 40 Tega Industries expands offering to include capital equipment 41 igusGO App lets you design lubrication-free applications in seconds 42 BUYERS GUIDE 43

COVER STORY

A journey of innovation and dedication to customer satisfaction

At Invincible Valves, activity is constant and dynamic as the company continues to make significant strides in the valve manufacturing and reconditioning industry. The company's recent endeavours showcase a commitment to quality, efficiency, and selfsufficiency. Pipes, Pumps & Valves Africa, sat with Managing Director Pam du Plessis to learn more.

The Invincible Valves management team has been bustling lately despite challenges like a global pandemic, ongoing power cuts, water shortages, and a not-so-great economic situation. Instead of backing down, they saw this time as a chance to expand and improve their business as part of a broader growth strategy.

Consequently, they acquired a new factory near their current premises in Knights Germiston and established a new machine shop.

Du Plessis emphasises the importance of diversification in the business landscape. "Operating a business in South Africa is challenging, requiring the ability to navigate various obstacles at any moment. We are exploring new sectors by diversifying our business, expanding our service offerings, and broadening our product range. This approach helps mitigate dependence on a single market or industry, contributing to our resilience."

She says an integral part of the expansion and diversification strategy has been to reduce the company's reliance on third-party suppliers, addressing customer

demands for quicker turnaround times and absorbing some of the associated overhead costs.

"Our customers now demand faster turnaround times, and our new factory and machine shop enable us to meet those expectations. By handling more processes in-house, we absorb some of the price overhead and reduce outsourcing, resulting in improved turnaround times. This approach also grants us better control over the entire process and more effective cost management," she explains.

For months, the Invincible Valves team has been working diligently to renovate and upgrade the new factory. "We added to the building, creating a space conducive to reconditioning and manufacturing. The final certificates are being obtained, and the facility will be fully operational in 2024."

Du Plessis says despite the challenging conditions, she remains steadfast in her belief that through ongoing investment in their business and operations, they are making a difference, contributing positively to the economy, and providing employment and high-standard services in South Africa and across the African continent and globally.

Growing footprint

According to Du Plessis, the company has always been focused on having as broad a footprint as possible. "We don't just operate in South Africa but across Africa and the rest of the world. Our move to diversify, innovate and invest speaks to growing this footprint significantly."

The goal for 2024, she says, is to expand the business even more. And already, they are on track to do just that. The company recently completed a noteworthy project involving reconditioning valves for a uranium plant in Namibia. Invincible Valves' expertise saved the client a substantial 42% by reconditioning valves, making them fit for purpose and ensuring efficiency comparable to brandnew valves. This success reflects the company's dedication to cost-effectiveness and its ability to deliver on a global scale.

With the market going through ups and downs, price remains a crucial consideration for project owners.

"The valve industry is extremely price sensitive, and in the current economic climate, we forecast that reconditioning

4 Pipes, Pumps and Valves Africa - Jan/Feb 2024

Managing Director Pam du Plessis

Pipes, Pumps and Valves Africa - Jan/Feb 2024

of valves will see an increase, particularly in South Africa where this has not been a trend."

She says the company has also expanded into the rubber lining aspect of the business and is increasingly being used by other manufacturers for rubber lining valves. Having purchased a 10-meter-long autoclave, Invincible Valves can now rubber line pipes, addressing a need in the market.

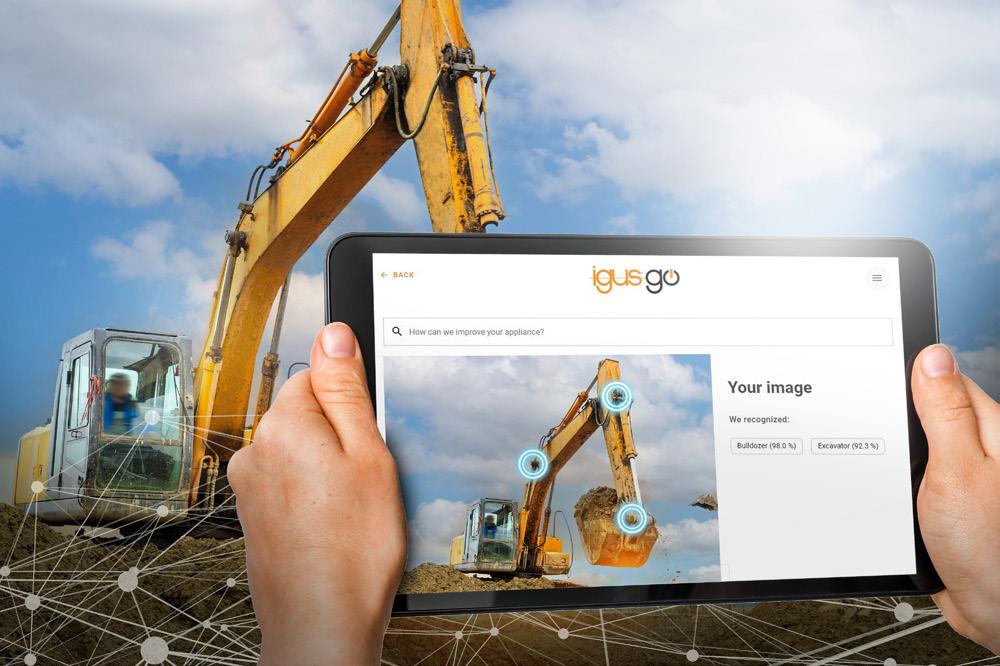

The acquisition of this equipment and the expertise and skills to rubber line further emphasises the company's commitment to diversification.

"Moving forward, our strategy remains centred on diminishing our dependence on external sources," Du Plessis elucidates. "This involves bringing the production of our actuators in-house. Considering the challenges at the ports, it's evident that we need to enhance our self-reliance.

Waiting weeks for containers to clear is not viable. Passing such costs to customers isn't always feasible, so we aim to minimise risks as much as possible."

The company has also invested in generators and is looking at various solar solutions to reduce the impact of loadshedding on our business.

Strong outlook for 2024

Du Plessis expresses excellent optimism for 2024. Despite South Africa gearing up for elections and the metals industry engaging in negotiations with unions over wage increases, she asserts that Invincible has a resilient and dedicated team that is steadfastly committed to delivering products of exceptional quality.

"We have confidence in our ability to attain our established goals. Our investments extend to both our facility and our team. With the right organisational culture in place, we are diligently working towards achieving our growth targets," she says. "We are incredibly customer-centric, dedicated to providing the best product, optimal pricing, and efficient lead times. When we talk about the customer being king at Invincible, it's not mere rhetoric; it's a philosophy we live by. Our Invincible range boasts a superior product, verified through extensive testing, including weight testing, where our product surpasses standard steel. Numerous successful projects substantiate our confidence in the superiority of our product, each speaking for itself in the long run. The recurring business we attract is the true testament to our quality."

Invincible Valves, +27 (0) 11 822 1777, enquiries@invalve.co.za, www.invalve.co.za

Pipes, Pumps and Valves Africa - Jan/Feb 2024 5

Thermoplastic components by GF Piping Systems ensure a hygienic water supply on board a hospital ship

The Global Mercy is a floating hospital that provides free medical and surgical care for people in Sub-Saharan Africa. For improved hygiene and operational safety, the international charity Mercy Ships selected ecoFIT and INSTAFLEX by GF Piping Systems for various water applications on board.

Mercy Ships has been providing high-quality and professional healthcare to developing countries for over 45 years. The Global Mercy, the charity’s latest ship, is 174 meters long and provides space for 600 volunteers, 199 beds for patients, as well as extensive facilities for medical training. As a result, the ship requires large amounts of water with daily usage averaging 60,000 liters. During construction of the vessel’s water installation, Mercy Ships

decided to forego the frequently used copper pipes in favor of two thermoplastic solutions by Swiss flow solutions provider GF Piping Systems.

In total, GF Piping Systems provided around 13.000 piping components, including ball valves, butterfly valves, and actuators. INSTAFLEX, a polybutene system designed for building technology applications, was selected for the hot and cold water installation as well as for the onboard water treatment system. At the same time, ecoFIT, a polyethylene system for use in a wide range of industrial applications, was installed for wastewater transportation.

The thermoplastic piping systems are corrosion-free and do not release any taste or pollutants, while smooth inner surfaces prevent issues such as limescale deposits. In addition, the lower weight of plastic has reduced the fuel consumption of the Global Mercy. Despite the challenges of the COVID-19 pandemic during which the ship was constructed, GF Piping Systems was able to offer technical support as well as on-site installation training.

GF Piping Systems, +27 21 702 0059, info@gf-africa.com, www.gf-africa.com

6

Africa - Jan/Feb 2024 PIPESPIPES

Pipes, Pumps and Valves

The next evolution for concrete pump truck support

Introducing FiberTech MultiPad Systems: the lightweight, easy way to support and stabilize concrete pump trucks. Enhancing the safety and efficiency of job sites always pays off.

People are better protected, work gets done faster, businesses take home more profits — and everyone enjoys more peace of mind. Toward these ends, we are excited to introduce our new FiberTech MultiPad Systems. Designed with the specific challenges of concrete pump operators in mind, the FiberTech MultiPad product line uses our proven FiberTech technology to create large outrigger support platforms from individual pads people can move by hand and more easily store on concrete pump trucks.

Kris Koberg, our CEO, shares the drive behind creating this new product: “Our concrete pumping customers have been asking for a solution that is larger, lighter, storable and can easily be assembled on the job site by a single operator. We have optimized FiberTech MultiPad Systems for component weight, storage, and handling, and are

their outriggers on job after job, rather than grappling with assembling dunnage from whatever they have on hand or find available on site.

An innovative solution for concrete pumps

We designed each MultiPad system to meet specific equipment requirements, while still being lightweight, easy to move, and easy to clean and store. By placing smaller individual pads to assemble a larger outrigger platform, operators can quickly create strong, stiff, and safe supports. Each MultiPad setup promotes the engagement of all parts of the system and provides quantifiable load and pressure distribution.

The MultiPad lineup includes six different configurations, each able to support various sizes of concrete pumps. These configurations offer a range of platform dimensions,

PUMPS

12 APRIL 2024 ERPM GOLFCLUB DAY GOLF AbaddayofgooddayattheGOLFbeatsa OFFICE! -36 FOUR BALLS -18 WATERING HOLES -REGISTRATION SPONSOR -LUNCH SPONSOR -DINNER SPONSOR +27 (0) 87 700 9834 golfday@liftingafrica.co.za BOOK YOUR SPOT

PUMPS

We help you save energy without compromising reliability

Pumping the 1.3 billion m3 of water used by industry each year consumes a lot of energy. Using Grundfos E-pumps instead of standard pumps can reduce the amount of energy consumed by on average 37% and are an example of how our solutions not only consume less energy but also use the available energy more efficiently.

How our net-zero approach helps industry with their sustainability agenda

Pumping the 1.3 billion m3 of water used by industry each year consumes a lot of energy. Industry is one of the most energy consuming sectors, and pump systems may account for up to 40% of industrial energy usage*. On average Grundfos E-pumps consume 37% less energy than standard pumps, which is good for your business and contributes positively to emissions reduction. Grundfos E-pumps are an example of how we develop solutions that not only consume less energy but also use the available energy more efficiently.

We are committed to taking even greater responsibility for the carbon that is emitted – not only when we manufacture our products but also for the energy they consume when in use. In fact, 99% of our CO2 emissions come from using the products we sell. By accelerating our own transformation to a net-zero future we are also helping our customers save energy.

Grundfos is the first water solutions company to receive validation of its 2050 net-zero target from the ScienceBased Targets initiative (SBTi). SBTi also validated our nearterm 2030 emission reduction targets.

SBTi

The science-based targets initiative (SBTi) drives ambitious climate action in the private sector by enabling organisations to set schience-based emissions reduction targets. Grundfos is the first water solutions company to receive full validation of its 2050 net-zero target from SBTi. SBTi also validated our near-term 2030 emission reduction targets.

E-pumps

Grundfos E-pumps are our extended product range with electronic variable frequency drives built into the pump motor.

This provides considerable advantages for optimising performance in a stand-alone pump.

Carbon net-zero

Grundfos is committed to a minimum of 90% emission reduction in operations and across the value chain by 2050. It is this ambition that has achieved full validation by SBTi. Our speed-regulated E-pumps, digitally enabled solutions and optimisation services are at the heart of these plans. Available for almost all processes found in the industry, these solutions make it possible for you to:

• Get immediate savings – on average 37.2% with an E-pump compared with a standard pump – from lower energy consumption and optimised processes

• Achieve emissions reduction without compromising reliability – an essential requirement in many factory processes

• Benefit with a partner who helps to develop energyefficient solutions for the future

Strengthen your business with solutions that support your sustainability agenda.

Grundfos South Africa, +27 (0) 10 248 6000, wcockcroft@grundfos.com, www.grundfos.com

8 Pipes, Pumps and Valves Africa - Jan/Feb 2024

Triple Offset Butterfly Valves

Double Offset Butterfly Valves

Rubberling Butterfly Valves

Wafer Type Butterfly Valves

Conventional Non-Return Valves

Tilting Disc Check Valves

Wedge Gate Valves

Resilient Gate Valves

Knife Gate Valves

Ring Needle Valves

Sleeve / Discharge Valves

Zenzele Valves SA company through the efforts of dedicated and historically disadvantage men and women manufacturing and supplying products and services of the highest standards and quality +27 (0) 11 028 4221 www zenzelevalves co za sales@zenzelevalves.co.za 1165 Domkrag str, Robertville, Florida, Roodepoort

+27 (0) 11 474 6180

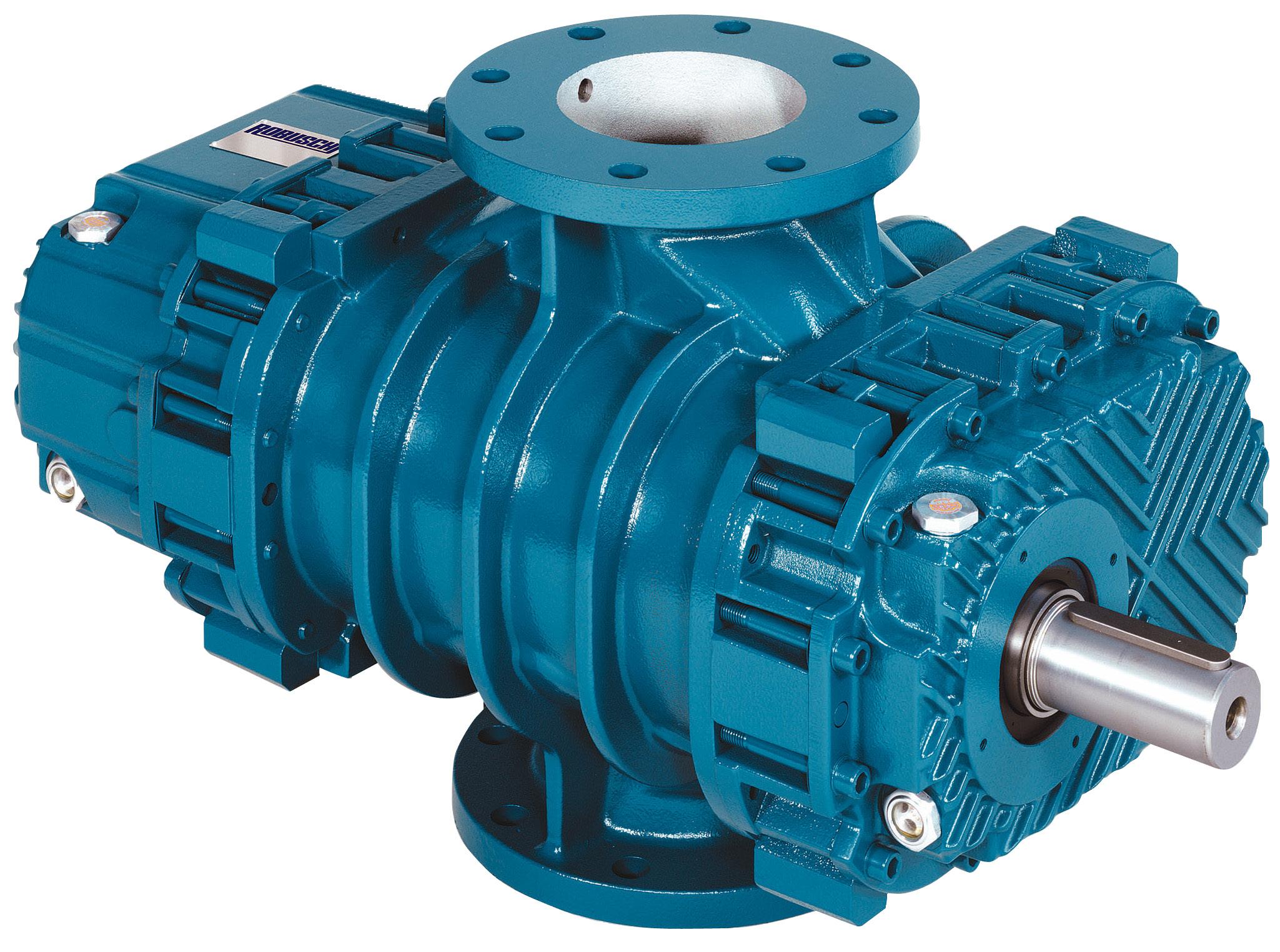

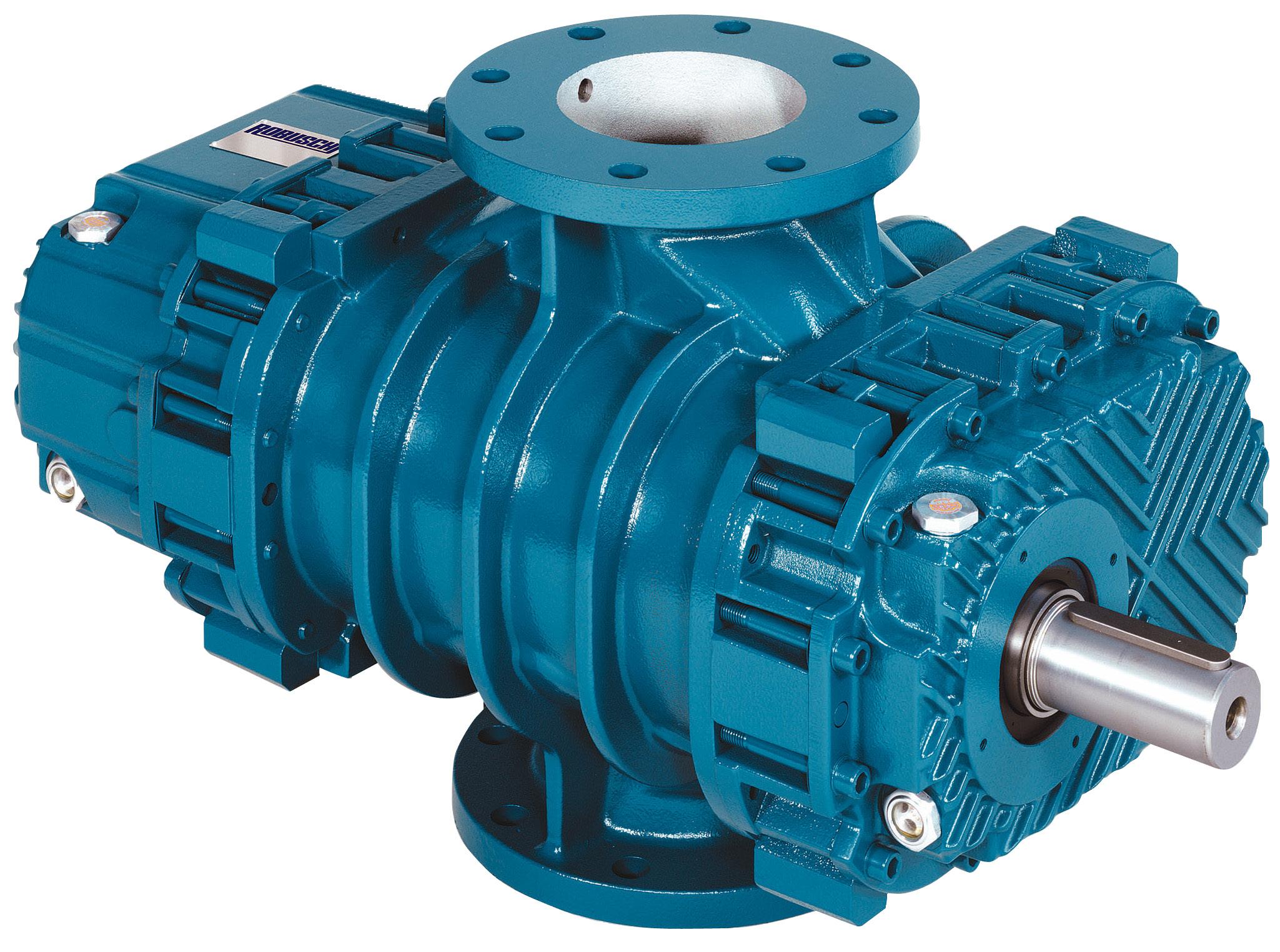

Wastewater treatment a challenge Robuschi won

Improving the management of an MBBR system and reducing its energy consumption with Robuschi technology. Wastewater treatment is something of a customisation task, where the solution has to be tailor-made for the individual paper mill.

Surely, when the challenge takes the form of limited space and a need to discharge safely into surface water, the answer is a plant design that combines innovative biological technology with a screw compressor. Wastewater treatment in a paper mill can be optimised in a number of ways, but having to adapt an existing system set-up, where there are limits due to the plant configuration, undoubtedly complicates the job. It can always be done though. The secret lies in finding the technological solution that best fits the particular features of the site. That’s what happened in Lucca, at the plant of one of the leading corrugated cardboard manufacturers of the paper industry - Toscopaper. Robuschi, in partnership with Italprogetti (which looked after the engineering side), supplied the waste water treatment technologies, working to offer the best solution for the real system needs in terms of efficiency, reliability and easy maintenance.

Biofilm Technology

The task was to intervene on an existing system that no longer met the development needs of the paper mill. The solution was developed by Italprogetti (www. italprogetti. it), deciding to use a type of technology that it had so far applied only in the field of municipal waste water treatment, adapting it in this case to the specific plant characteristics. We’re talking about an MBBR (Moving Bed Biofilm Reactor). «With this type of biological treatment,» explains Daniele Bacchi, Head of the Waste Water Treatment Sector for Italprogetti, «bacterial colonies - able to clean the water by breaking down the organic matter in it - aren’t free to move around in the water; they remain attached to special plastic supports called ‘carriers’. These, in turn, are kept in motion inside the reactor thanks to the stirring action of the aeration process whose job is to provide the system with the oxygen needed for the treatment, by injecting compressed air. Special grilles installed in the biological reactor prevent the carriers from emerging along with the treated water. This avoids

any risk of biomass loss apart from the excess which, spontaneously detaching itself from the carriers, is then taken away by the biological system.

Customised Solution

“We’ve renewed an existing water pre-treatment process with a biological solution that meets the needs of the paper mill, thereby creating an efficient new system” says Daniele Bacchi, Head of Italprogetti’s Wastewater Treatment Dept. This is a decidedly important aspect, especially in the paper industry where the traditional processes with activated sludge with a sedimenter produce sludge flocs that are particularly lightweight and so don’t settle well. The risk of dragging the biomass along with the treated water is considerable. “In these conditions, the use of MBR technology (even in the case of running problems, dosing errors, etc.) ensures the persistence of the bacteria in the tank and therefore the recovery of the system, restoring optimum conditions in a short time and reducing the volumes in question by 2 or 3 times compared with traditional technology”. And that’s not all. The type of effluent also displayed certain distinguishing aspects: a high inlet COD, a high fraction of organic substances with poor biodegradability, and a high concentration of calcium. “These needs called for not only an MBBR system but also the adoption of other technological solutions to prevent the substantial low-biodegradable fraction from invalidating the outlet COD result and to prevent the calcium from falling onto the carriers, limiting their effectiveness”. To resolve the problem, the last of the three MBBR reactors installed in series was given over to the recycling of the activated sludge. “This meant the low-biodegradable fraction of COD could be kept under control, while the calcium level was managed by carefully monitoring the pH in the reactors and dosing a product that prevents it from falling.” The result is a system with capacity rates of 1000m3 per day, with a COD of about 4,500mg/l on the inlet and 80-100mg/l on the outlet - far below the limit value for the authorisation of discharge in surface waters (160mg/l).

10 Pipes, Pumps and Valves Africa - Jan/Feb 2024 ADVERTORIAL

Robuschi Roots blowers / exhausters are some of the finest in the world – Made in Italy.

The ROBUSCHI RBS range of low-pulse, tri-lobe blowers & exhausters with pressures up to 1bar & vacuum levels to -500mba Flow rates from 240m3/hr up to 10,400m3/hr.

Air & Vacuum

r for Robuschi vacuum pumps oots blowers & er packages –ll made in Italy.

PeriBest Peristaltic pumps offer extremely heavy duty design for the most demanding applications up to 10 bar. roller

, operation and

A&VT = ADDING VALUE TOGETHER info@vactech.co.za 011 318 3241/2/3/4 www.vactech.co.za

Grindex Bravo pump tackles tough slurry challenges head-on

Pumping slurry is a demanding task for any pump due to the abrasive nature of the materials involved. The wear and tear on pump components can result in high maintenance and repair costs, leading to costly production downtime.

Additionally, the accumulation of excess sediment can cause operational difficulties. In such challenging conditions, the Grindex Bravo pump range shines as an ideal solution.

This is according to Justin Bawden, Key Account Manager at Integrated Pump Technology, who says that Grindex Bravo pumps are specifically designed to excel in applications where pumping fluids with high concentrations of abrasives, such as sand and stones, is required.

“These pumps are renowned for their robustness and reliability. One of the standout features of the Grindex Bravo pump is its agitator, which efficiently mixes and suspends solids, allowing the pump to transport them effectively,” he says.

To tackle the wear problem head-on, the Bravo range features hydraulic components made from hard iron, one of the toughest materials available. This ensures durability and reliability, even in the face of extreme wear and tear.

Bawden says the Grindex Bravo pumps come packed with features that enhance their performance and ease of maintenance. The pumps are designed for dry pit applications, thanks to a cooling jacket, reducing the risk

of overheating. A ready-to-install cartridge seal minimises downtime during repairs and assembly. The inclusion of a leakage sensor helps prevent further damage, saving on maintenance costs. The large inlet can handle solids of varying sizes, while the hard iron impeller and pump housing maximise durability and performance. A single adjustment sleeve unit allows for easy impeller adjustment, and the agitator efficiently stirs up sand, sludge and solids in suspension.

The Bravo range is not only rugged but also versatile and is capable of handling liquids with pH values ranging from 5.5 up to 14. The 22 kW pump can be fitted with a SMART unit with a built-in plug and pump, eliminating the need for external starter boxes. The pump is further protected by phase-failure guards, temperature guards and phasesequence control, ensuring safe and efficient operation.

Bawden says that every pumping application is unique, and the experienced team at Integrated Pump Technology can help select the appropriate pump unit based on specific parameters. “This ensures that the most suitable and efficient unit is deployed for the task at hand. The exceptional durability of Grindex Bravo pumps allows them to thrive in tough and challenging environments, providing reliability when it matters most.”

In addition to their durability, these pumps are designed for energy efficiency, leading to long term savings in energy consumption and making them a cost effective solution when considering the total cost of ownership.

Moreover, Integrated Pump Technology ensures that replacement parts are readily available, either directly from the company’s head office or through its strategically located network of distributors. “This swift access to parts minimises downtime and reduces repair turnaround times, ensuring that pumps are back in action as soon as possible,” Bawden says.

Grindex slurry pumps offer an effective solution and outstanding value, making them an excellent choice for industries such as quarries, mines, dredging and cleaning of settling ponds that require pumps with high durability. Each component of the Bravo pump is engineered for maximum endurance and reliability.

With trained distributors strategically placed across the country and southern Africa, Integrated Pump Technology provides expert support for installation and maintenance, significantly reducing downtime.

Integrated Pump Technology, +27 (0) 11 894 2906, sales@pumptechnology.co.za, www.pump-technology.com

12 Pipes, Pumps and Valves Africa - Jan/Feb 2024

PUMPS

FRESE P/T PLUGS

P/T plugs are installed in valves and are used for measuring pressure and temperature. The P/T plugs are designed for flowmeters or pressure meters using needle system.

FLOW & THERMAL CONTROL

FRESE ALPHA

The ALPHA range of flow limiting dynamic balancing valves has been developed for use in a wide range of applications for the accurate and efficient distribution of flow in heating and cooling systems.

FRESE ALPHA CARTRIDGE

The ALPHA cartridge reacts to pressure fluctuations in the system ensuring that the differential pressure across the pre-adjustment unit is kept constant. This ensures that the maximum flow limit is achieved in accordance with the design.

FRESE SIGMA

The SIGMA Compact is an externally adjustable dynamic balancing valve that provides simple, accurate & reliable flow limitation & isolation in heating & cooling systems. The SIGMA Compact can be used instead of traditional double regulating valves and can be installed in both variable flow systems and constant flow systems.

CIRCON / TEMCON

CirCon and TemCon are control valves designed for domestic hot water installations with circulation. The Valves are constructed in stainless steel AISI 316 for all parts in contact with water, to secure the highest resistance against corrosion. The valves automatically control the temperature of the water that circulates through the valves. TemCon is equipped with a by-pass located outside the thermal part of the valve. TemCon is used in hot water installations with bacterial problems, e.g. Legionella.

+27 11 827 1536 135 Snapper Rd, Wadeville www.vacserve.co.za info@vacserve.co.za

PUMPS

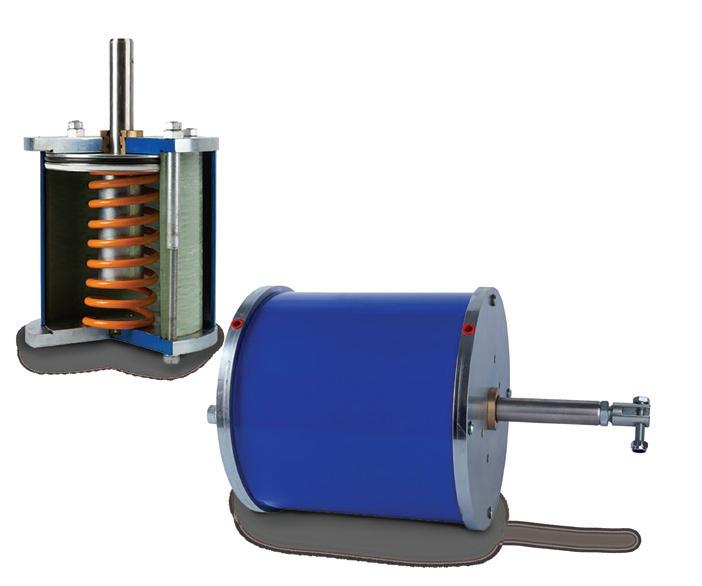

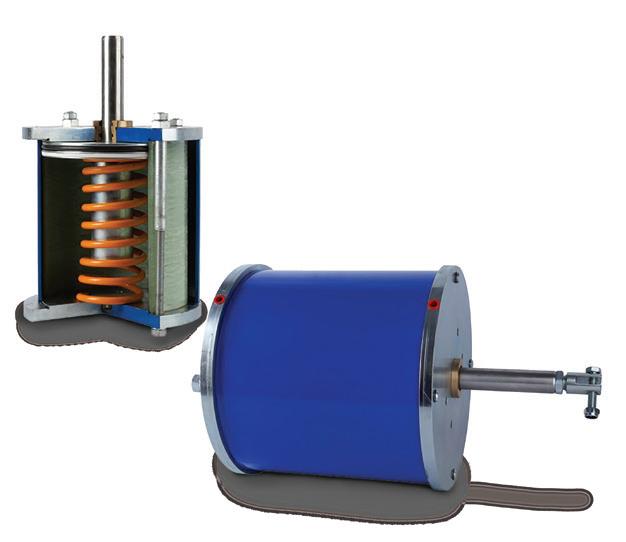

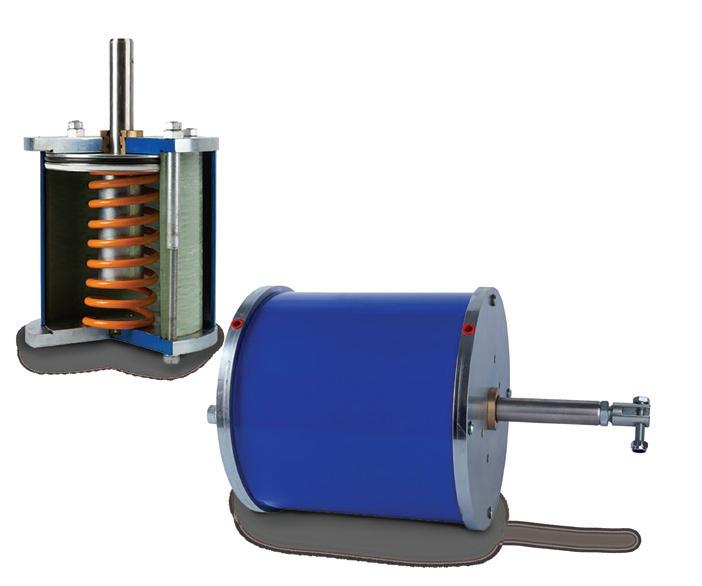

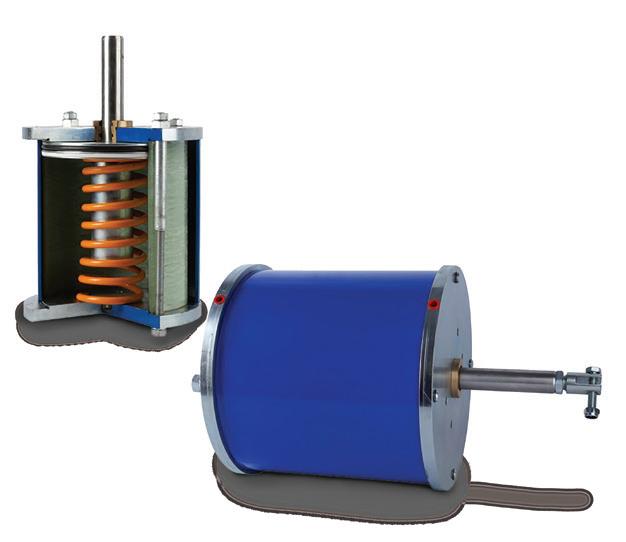

Unique Hydra-Cell pumps, for reliable seal flush applications

Hydra-Cell pumps exhibit several unique features that make them exceptionally wellsuited for seal flush applications in a variety of industrial settings.

Seal flush systems play a crucial role in maintaining the integrity and functionality of mechanical seals in pumps that handle challenging fluids, such as those that are abrasive, corrosive, or high in temperature.

Here’s a more detailed exploration of the characteristics that set Hydra-Cell pumps apart in seal flush applications:

Seal-less design: Hydra-Cell pumps are characterized by their seal-less design, a fundamental aspect that distinguishes them from traditional sealed pumps. Conventional pumps often rely on dynamic seals to prevent fluid leakage and ensure proper operation. However, these seals are prone to wear over time, leading to potential leaks and increased maintenance requirements.

In contrast, Hydra-Cell pumps feature a seal-less design, eliminating the need for dynamic seals. This design choice offers several advantages for seal flush applications.

Firstly, it significantly reduces the risk of seal wear, ensuring a longer life for the pump and minimizing the potential for leakage, which is critical when dealing with hazardous or expensive fluids. Additionally, the absence of dynamic seals

eliminates the need for external lubrication, simplifying maintenance requirements and reducing operational costs.

Multiple diaphragm design: Hydra-Cell pumps utilize a multiple-diaphragm design, a key feature that contributes to their reliable and pulsation-free operation. In seal flush applications, maintaining a consistent and controlled flow of the flush fluid to the mechanical seal is crucial for optimal performance.

The multiple-diaphragm design ensures that the flow is smooth and free from pulsations, preventing any adverse impact on the mechanical seal.

This design feature is particularly beneficial in seal flush systems where pulsations can lead to uneven distribution of the flush fluid, potentially compromising the effectiveness of the seal.

The ability of Hydra-Cell pumps to deliver a steady flow enhances the efficiency of the seal flush process and contributes to the overall reliability of the pump.

Hydraulicly balanced : Hydra-Cell pumps incorporate a hydraulic balance system that equalizes pressure on both

14 Pipes, Pumps and Valves Africa - Jan/Feb 2024

sides of the diaphragm during operation. This hydraulic balance minimizes stress on the diaphragm, resulting in increased durability and a longer diaphragm life. In the context of seal flush applications, where consistent and prolonged pump performance is essential, this hydraulic balance system enhances the reliability and longevity of Hydra-Cell pumps.

By reducing stress on the diaphragm, the hydraulic balance system also contributes to the pump’s efficiency in handling challenging fluids. The balanced design helps maintain the integrity of the diaphragm, even in the presence of abrasive or corrosive materials, ensuring sustained performance in demanding operating conditions.

Ability to handle abrasive and viscous fluids: Seal flush applications often involve fluids that are abrasive or highly viscous, posing challenges for traditional pumps. Hydra-Cell pumps are well-known for their robust construction and the ability to handle a wide range of fluids, including those with highly abrasive particles, corrosive fluids and fluids containing up to 40% non-dissolved solids and particulate matter up to 800 microns without the need for fine filtration

The pump’s design allows it to handle abrasive fluids without significant wear and tear on the pump components. This feature is particularly advantageous in seal flush systems, where abrasive particles can be present in the flush fluid. The resilience of Hydra-Cell pumps in the face of abrasives ensures a longer operational life and minimizes the need for frequent maintenance.

Moreover, the pumps’ capability to handle viscous fluids is crucial in seal flush applications where the flush fluid may have a higher viscosity. The pumps maintain their efficiency and performance even when dealing with fluids that would pose challenges for other pump types, making them versatile for various industrial processes.

Energy efficiency: Energy efficiency is a critical consideration in pump applications, and Hydra-Cell pumps are designed with this in mind. The pump’s seal-less and multiple-diaphragm design contributes to reduced friction and energy losses during operation.

In seal flush systems, where continuous and reliable operation is essential, energy efficiency becomes a key factor in minimizing operating costs.

The energy-efficient operation of Hydra-Cell pumps not only reduces power consumption but also contributes to a more sustainable and cost-effective solution for seal flush applications. This efficiency is particularly significant in

industries where pumps operate continuously or where energy costs are a major consideration.

Versatility in fluid compatibility: Hydra-Cell pumps are known for their versatility in handling a wide range of fluids, including corrosive chemicals, high-temperature liquids, and abrasive slurries. In seal flush applications, where the nature of the pumped fluid can vary widely, this versatility becomes a valuable asset.

The pumps’ ability to adapt to different fluid compositions makes them suitable for diverse industrial processes. Whether the seal flush system is dealing with aggressive chemicals in a chemical processing plant or abrasive slurries in mining operations, Hydra-Cell pumps provide a reliable and adaptable solution.

The versatility in fluid compatibility is not only a testament to the robustness of Hydra-Cell pumps but also an assurance that these pumps can seamlessly integrate into various industrial settings with differing fluid requirements.

Compact and lightweight design: Hydra-Cell pumps maintain a compact and lightweight design without compromising on performance or durability. This feature is particularly advantageous in seal flush applications where space constraints or specific installation requirements may exist.

The compact design allows for easy integration into existing systems, and the lightweight nature facilitates straightforward installation and maintenance. In situations where available space is limited or where mobility is a consideration, the compact and lightweight design of Hydra-Cell pumps becomes a practical and efficient solution.

The seal-less design, in particular, addresses the common challenges associated with dynamic seals, offering a solution that minimizes maintenance requirements and enhances overall system reliability. Whether dealing with abrasive particles, corrosive chemicals, or hightemperature fluids, Hydra-Cell pumps provide a robust and adaptable pumping solution for seal flush applications across a range of industries.

Flow rates up to 600 l/min , and pressures up to 350 bar, available in a wide range of materials.

Monitor Pumps and Systems, +27 (0) 11 6183860, sales1@monitorpumps.co.za, www.monitorpumps.co.za

Pipes, Pumps and Valves Africa - Jan/Feb 2024 15

PUMPS

Pump with the right accessories, advises IPR

When a customer needs a dewatering solution, they might not always be able to specify the exact accessories that must accompany the pump to get the best outcome – which is where IPR can help.

“With our wide range of accessories, and our depth of experience in dewatering and slurry pumping, we can advise our customers on what they need,” says Steve du Toit, Sales Manager at IPR. “We can provide these requirements from our extensive stockholding of pump accessories, so that our recommended solution does the job when it is installed.”

Common accessories in pumping solutions include lay-flat hoses, suction hoses, foot valves, HDPE piping and hose flotation devices, explains Du Toit. These must all be sized and specified according to the demands of the selected pump and the duty that the application demands.

“Correct sizing of pipes – according to their internal diameter – is one of the essential starting points,” he says. “Lay-flat hoses can be used on the discharge end, while rigid pipes are necessary for the suction side.”

Flow meters may also be required, to provide customers with an accurate rate of water flow at the discharge point of the pump. This is vital information to demonstrate that the expected volumes of water are being removed for the customer’s purpose; it may also be a requirement of the customer’s water use licence.

“There are also the electrical components to consider, so the pump control systems need to be designed to suit the pump and its application,” he says. “Measurement devices such as gauges on the suction port and delivery port are also important to monitor that the pump is operating at

optimal efficiency.” He highlights that IPR offers a custom range of accessories, and spends time carefully assessing each customer’s specific site conditions and technical infrastructure. This ensures that all aspects of the solution are attended to, with high quality accessories provided wherever necessary.

With the growing focus on environmental impact management, Du Toit points to the value of accessories such as dewatering bags.

These porous bags catch and retain sediments and other material that could contaminate the natural environment. At the same time, they allow cleaner water to seep out, facilitating dewatering in a responsible manner.

“Among the most important accessories are the flotation devices for our hoses and pumps,” he says. “On diesel driven self-priming units, for instance, we recommend that customers use suction hose floats to prevent the hose end from sucking in mud and stones – resulting in damage to the pump unit itself.”

Similarly, with submersible electric pumps it is advisable to use a pump flotation device (PFD). This ensures that the pump is always just below the surface of the water.

It therefore does not become buried in mud or silt, which could undermine its performance and cause mechanical damage. The use of a PFD also makes it easy to locate the pump, while the floats show where the discharge piping and electrical cable is positioned at all times.

Another protection measure that IPR can provide is a non-return valve, which is installed in the discharge pipe in close proximity to the pump. This ensures there is no backpressure on the pump from water in the pipe; this type of pressure can cause serious damage such as shaft breakage when the pump is started.

“With a submersible pump, there is also the danger of this pressure causing the pump impeller to spin in the wrong direction when started – causing the impeller to loosen,” he says.

Finally, he recommends that the accessories used with pumps should always be of a high quality. The risk of malfunction is costly and well beyond the savings on a cheaper item, emphasises Du Toit, and ‘buying cheap’ invariably leads to ‘buying twice’. For this reason, IPR invests only in quality accessories that customers can rely on.

IPR, +27 (0) 87 759 8654, admin@pumprental.co.za, www.pumprental.co.za

PUMPS 16 Pipes, Pumps and Valves Africa - Jan/Feb 2024

5 TH

Three food processing innovations piped in goodness

In a world that is still adapting to post-COVID 19 consumer demands for farm-toplate freshness, variety and convenience, there are two factors that continue to drive innovation in food technology: the need for safe and shelf-stable food.

These drivers are further fuelled by the need to achieve environmentally sustainable production facilities – and contribute to individual company, sector and national carbon reduction targets and net zero objectives while remaining profitable. To achieve all this, the food manufacturing industry must continue to seek out innovative solutions to industrial processing operations. The challenges of population growth, climate change, and shifting consumer demand puts technological innovations at the forefront of processing food in more prudent and sustainable ways. And there are three key innovations that are replacing heat and chemicals to keep food not only fresh but safe and are already shaping the future of food processing.

The first is high-pressure processing, which rapidly kills vegetative microbes and inactive viruses while denaturing enzymes that can cause food to spoil. This batch process applies high pressure of as much as 100 000 psi after packaging, minimising food treatment time and preserving nutrition and flavour.

Fermentation, though far from a new food preservation process, is another area in which innovative technologies are key to improving sterility, preventing crosscontamination and ensuring scalability. The newest application of fermentation is the production of cultured (or cell-based) and mycelial protein products, which alleviate the pressure on large scale animal husbandry to produce enough animal protein to ensure food security. At the same time, alternative protein production technologies like this reduce the greenhouse gas emissions produced by animal protein production. Though not exactly mainstream yet, sterility is paramount in this kind of production facility, where clean in place (CIP) and sterilisation in place (SIP)

are crucial. The third innovation, aseptic processing and packaging, removes the need for refrigeration during transport and on store shelves for a variety of animal and plant-based products, liquid eggs, puddings, soups, vegetable purees, and bulk ingredients. The improvements in shelf stability are achieved by filling sterilised containers, in a sterile environment, with product that has been sterilised, usually by heating and then cooling before filling. This kills microbes in the food and prevents them from being reintroduced during packaging.

Pumping solutions are often overlooked as an opportunity for improved shelf stability, environmental improvements, cost reduction and production capacity improvement. But they are integral to every industrial processing facility. The right high-pressure – in the case of high-pressure processing – or hygienic pump solutions is also crucial to successfully implementing these innovations in food safety.

First and foremost, the pumping solution cleanability requirements must be designed to meet international and local hygiene standards – including clean in place (CIP) and sterilisation in place (SIP) – as these can present many challenges for processors. Aseptic processing, for example, requires well-coordinated operations, as well as highly sterile and controlled environments. This is where hygienic pumps with a modular design can be integrated, allowing for streamlined disassembly, cleanability and reassembly.

Cross-contamination – a particular risk in fermentation processing facilities – can be mitigated against through careful selection of equipment to maintain the highest hygiene standards. Fit-for-purpose hygienic pumping solutions that have been designed and built to eliminate any risk of contaminants during production are necessary for producers who want to stay ahead of the advances in fermentation technology.

As the food and beverages industry continues to evolve to ensure that food is safe, shelf stable and tasty, manufacturers must ensure their processes are reliable, repeatable and error-free. Integrating the right equipment is critical to food safety and sustainable production.

Because the technical aspects of selecting the right pumping solutions for specific applications can be complex, food and beverage processors should look to a trusted and reputable brand that can offer not only a wide range of pumping solutions but solutions that are long-lasting, cost-effective and efficient – because they are 100% fit-forpurpose for the application.

Verder Pumps South Africa, +27 (0) 11 704 7500, info@verder.co.za, www.verderliquids.com

18 Pipes, Pumps and Valves Africa - Jan/Feb 2024

PUMPS

MQ Series pumps: versatility and flexibility through customization

Tsurumi Pump’s MQ Series stands as an exceptionally engineered product designed to meet a diverse range of project bid specifications. Hydraulic options within the MQ Series cover a wide spectrum of conditions, offering impellers in numerous trims to pinpoint operating duty points.

It features five distinct impeller styles: open channel, chopper, vortex, grinder and high head. The MQ Series offers extensive customization options, making it a versatile solution for various applications. The customizable features in each MQ pump style include motor size, discharge flange type, construction materials, paint and coating, condition monitoring sensors, cable length and installation accessories. Additionally, pumps are available in wet or dry styles depending on application. This flexibility ensures that the pumps can be precisely tailored to meet the unique requirements of any project.

Standard construction materials for the MQ Series include cast iron motor housing and wet end, dual silicon

carbide mechanical seals, and Viton elastomers. For more demanding applications, Tsurumi offers alternative materials, such as stainless steel pump housings and impellers, as well as bronze impellers for corrosionprone environments. The Molib-techTM coating option provides an extra layer of protection against abrasives without compromising pump clearances and performance. Installation options for the MQ Series cater to the varied needs of the wastewater industry. Dry pit applications benefit from a closed-loop cooling system, circulating a glycol-water mix around the motor through a stainless steel double jacket. This system keeps cooling fluid separate from pumped fluid. Additionally, dry pit pumps can be installed in both vertical and horizontal orientations. Wet pit configurations come with guide rail systems for new installations, guide rail adapters for existing setups, and free-standing base assemblies for flexible installations.

The MQ Series is equipped with standard condition sensors, including bi-metal thermal overload switches and dual moisture probe. Additional monitoring sensors, such as RTDs, bearing vibration monitoring and moisture probes, communicate with the pump’s control panel for comprehensive condition monitoring and early issue detection. Tsurumi goes a step further by offering custom control panel solutions, positioning itself as a single provider for the entire pump system. Tsurumi’s MQ Series pumps deliver exceptional customization options and allow for superior performance across a broad spectrum of applications in the wastewater industry. With a commitment to innovation and versatility, these pumps stand as a reliable choice for diverse project requirements.

Tsurumi Pumps SA, +27 (0) 82 404 4743, enquiries@tsurumipumpsafrica.com, www.tsurumipumpsafrica.com

Pipes, Pumps and Valves Africa - Jan/Feb 2024 19 PUMPS

VERDER is the manufacturer of VERDERAIR® and PACKO® pumps VERDER PUMPS SA TEL +27 (0) 11 704 7500 MAIL info@verder.co.za WEB www.verderliquids.co.za VERDER The perfect pumps for food and beverage processing 24-VR-AD_Hygienic_SA_180x65mm.indd 1 2/19/2024 1:23:03 PM

Tapflo’s innovative submersible pumps solutions – technology meets efficiency

Tapflo, a renowned global supplier and manufacturer specializing in diaphragm pumps, centrifugal pumps, and various industrial equipment, introduced its line of submersible pumps to its diverse product range.

This latest addition to Tapflo’s offerings aimed to address a variety of pumping needs, catering to applications involving rainwater, groundwater, and liquids containing soft particles, fibrous materials, as well as those with sand and abrasive particles.

Tapflo’s submersible pumps boast a range of features designed to ensure efficient and trouble-free pumping and is available in different sizes and capacities. Jason Andrew, Managing Director for South Africa, says “The pumps offer versatility to suit various operational requirements and noteworthy features include models equipped with a level control float switch or sensor for automated and economical duty cycles, ensuring optimal performance.”

Discover a diverse selection of high-performance pumps designed to meet your specific pumping needs. Tapflo’s product line includes drainage pumps, dewatering pumps, and sludge and slurry pumps, each engineered for optimal efficiency in distinct applications.

Tapflo’s drainage pumps are equipped to handle even the toughest conditions, capable of draining down to 1 mm water level on flat surfaces. Offering reliability and versatility, these pumps are ideal for various drainage applications.

Andrew adds, “When faced with the task of pumping spring water, rainwater, groundwater, or water carrying sand, our dewatering pumps rise to the occasion.”

For applications involving abrasive materials, Tapflo’s sludge and slurry pumps are a perfect choice. These pumps are designed with a semi-vortex impeller and agitator in strong chrome alloy, effectively minimizing sludge clogging and ensuring smooth operation.

As a leading player in the pumping solutions industry, Tapflo continues to prioritize innovation and quality in its product offerings. The expansion into submersible pumps underscores the company’s commitment to providing comprehensive solutions that meet the evolving needs of its global customer base.

Andrew concludes, “We invite businesses, industries and homes seeking reliable and efficient submersible pumping solutions to explore this product line. With a track record of excellence and a commitment to customer satisfaction, we remain dedicated to delivering cutting-edge solutions for diverse pumping requirements.”

Tapflo, +27 (0) 31 701 5255, sales@tapflo.co.za, www.tapflo.co.za

20 Pipes, Pumps and Valves Africa - Jan/Feb 2024 PUMPS

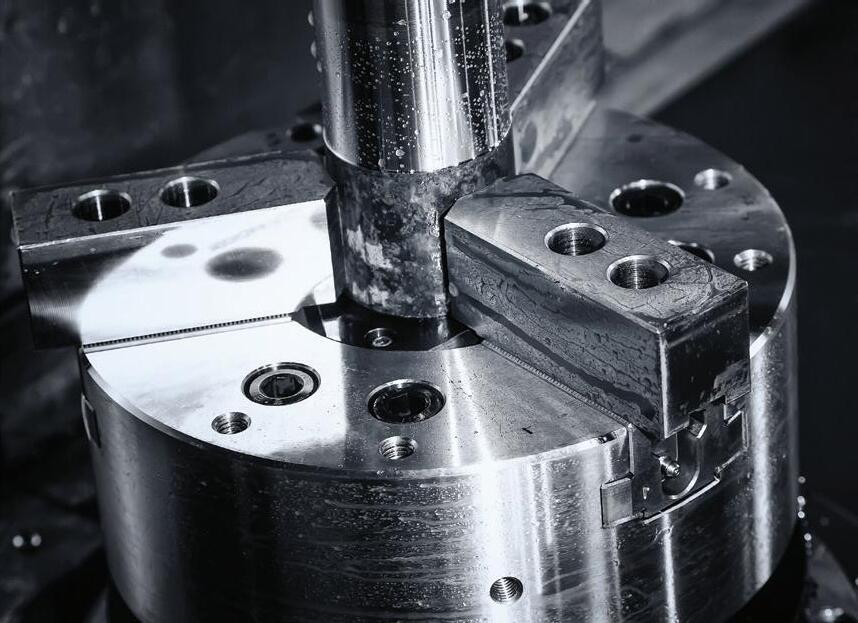

PRODUCTS

SERVICES

www ainsworthvalves com TM (PTY)LTD.

DEUTERONOMY 28:13

Globe

Check

Gate Valves,

Valves,

Valves, Ball Valves, Butterfly Valves, Knife Gate Valves, Pinch Valves, Diaphragm Valves, Flanges, Pipes, Gaskets, Blots and Nuts, Actuators, etc

Refurbishment on and off site , Repacking for Low emission requirements Modifications (extensions, metal seat

, Pressure Testing

Certifying of General Valves , Testing and Certifying of Safety Relief Valves , Flange Drilling , Valve Sandblasting, General Welding and Turning, Servicing of Gearboxes, Product Design, Specialist custom designed valves and spares Ex-Stock of valves

Fire Protection, Pulp & Paper, Mining, Sugar, Food & Beverage, Water, Iron & Steel, Power Generation and other industries LOCAL & IMPORTED MANUFACTURED VALVES ABOUT US WE OFFER CONTACT US Ainsworth Valves supplies and manufactures a full range of O.E.M. valves, and several specialized products We specialize in the manufacturing of new valves & refurbishment of old valves. + 27 (0) 10 020 8388 sales@ainsworthvalves.com 48 Kindon Road, Robertsham ,Johannesburg, South Africa , 2091 REFURBISHMENT OF VALVES &

Valve

etc )

and

INDUSTRIES

Optimizing motor controls for temporary surface pumps

Pump owners and operators are tasked with finding turnkey, temporary surface pumping solutions that boost efficiency without sacrificing performance, durability, uptime or ease of use.

This push for efficient performance is making electric pump packages very popular. Electric pump packages provide tremendous versatility – offering incredible benefits in terms of variable speed operation and motor control. In surface applications, the speed options offered through a variable frequency drive (VFD) give users more flexibility in what the pump can do, offering a speed range comparable to, or better than, a diesel engine – while eliminating the maintenance and emissions challenges of a Tier 4 engine. However, VFDs have historically fallen short on portability. They are often used in permanent installations (such as pump stations) where they are installed indoors in a single location. VFDs also include sensitive electrical components that are at risk of failure if exposed to harsh conditions like vibration, debris, temperature and other fluctuations. Moving the VFD might also mean reprogramming it for different applications – requiring skilled labor that’s not always readily available. So is it possible to optimize motor control, even when the surface pump you’re using is being moved and re-staged constantly? The answer comes down to the way the unit is engineered and the features it offers. Consider how these VFD features overcome concerns about portability – and assure the system you choose delivers optimized performance and durability, even in temporary applications.

The power in easty-to-use control interfases

In the past, VFDs paired with electric-driven pump packages could only be set up and operated by users with advanced technical training and experience. In contrast, their diesel motor-driven counterparts were easy to setup and use due to control panels with auto modes and straightforward operation. Now, VFDs feature easyto-use interfaces, like Pioneer Pump’s SmartPrime™, that overcome any knowledge barriers to quickly get pumps operational. A system like SmartPrime, offered on Pioneer Pump’s new portable ElectricPAK™ VFD, adds a control interface that has been built and configured specifically for temporary surface pumping applications. It features color graphics and displays much like an app found on a tablet or phone. SmartPrime allows the VFD to recreate the autostart mode experience that diesel engine users are used

to. The simple-to-operate touchscreen handles all aspects of startup and operation from a streamlined central hub with easy-to-navigate graphics. It also allows for simple monitoring without the need for complex keypad setup and programming.

Sensors & control modes

When evaluating the interface of a VFD, consider the options available in terms of sensors and control modes. What types of monitoring features are designed into the system?

From a usability standpoint, consider these questions:

• Can operators adjust pump parameters using simple onscreen tools?

• How do operators fine-tune their parameters based on their specific surface dewatering control preference, whether it’s level transducers, float switches, or a pressure transducer?

• Is it possible to see real-time pump conditions in a simple, graphic interface?

• Are alternate analog controls available so users can operate the panel with tactile pushbuttons and doormounted speed potentiometer?

• Does the unit track and log alarms onto a useful database?

Another major benefit is that there’s no programming learning curve for new VFD users who are used to working with diesel-driven packages. A customized user experience like this also allows users to spend less time commissioning and programming the drive – and more time up and operational. These variables can make a big difference in terms of the efficiency the system provides. For example, with an interface like SmartPrime, if a user needs to maintain a depth of eight feet in a wet well, the system can be programmed to automatically adjust speed to achieve this. A transducer will send a signal to the VFD to provide real-time feedback that enables the VFD to alter the motor speed to maintain the desired level.

If this unit is later moved to another pumping location, this level can easily be adjusted or reprogrammed as needed.

22 Pipes, Pumps and Valves Africa - Jan/Feb 2024

PUMPS

Quick-connect power cables

Quick setup for temporary pumping applications is not only convenient – it can often be essential when pumps are deployed for emergency water removal. An easy-to-use interface will help with this, but the pump itself also needs to offer plug-and-play setup.

With ElectricPAK, plug-in locations are housed on the outside of the drive to streamline power, float and transducer installation. The system integration also streamlines motor setup with package identification numbers, so there’s no need to search for separate input parameters. Features like these can save countless hours on frontend set up as well as teardown.

UL rating

Since electricity can be dangerous if not handled correctly, it’s important that any VFD used in outdoor and portable situations offer safe operation.

When selecting a VFD or a VFD-supported package, look for safety ratings, such as UL Certification 508A. The Underwriters Laboratory (UL) independently tests equipment under various use situations.

Products earn the UL Listed seal if they meet nationally recognized safety and sustainability standards. This includes being free from a reasonably foreseeable risk of fire or electric shock, even with equipment that’s setup and moved repeatedly.

Standalone skids vs. Mounting to package

One final consideration is the unit itself and the overall long-term portability needs. Is it better to have the VFD standalone on a skid or mount it to a package? In a standalone situation, the VFD will be less prone to vibration from the pump system. It can also be moved around to various pumps if its primary pump is undergoing maintenance.

An integrated system will be optimized to work together and provide for secure transport within a jobsite or from one jobsite to another. Systems like these will be invaluable in emergency situations – like hurricane recovery zones. In both a standalone or skid-mounted situation, a total pump package can be engineered and tested to perform across a range of ambient temperatures.

It can also be configured to address specific concerns, like high sun exposure or heat. This is especially important given that the cause of nuisance trips in the field are often due to high ambient temperatures. Placement of the system can help in some situations, but the VFD itself can be engineered with a cover on top of the skid to address this directly.

Franklin Electric, +27 (0) 11 723 6500, info@franklin-electric.co.za, www.franklin-electric.com

Pipes, Pumps and Valves Africa - Jan/Feb 2024 23

PUMPS

Empowering pump operations

MARECHAL ELECTRIC has stood as a beacon of innovation in electrical connection systems, revolutionising the pump industry. Originating in 1952, this French family business has blossomed into a global leader, reshaping the pump industry with pioneering solutions.

Central to this transformation is the DECONTACTOR™ power connector, an emblem of MARECHAL ELECTRIC’s dedication to redefining safety, efficiency, and durability in pump and motor applications.

The DECONTACTOR™ stands out as the world’s inaugural Plug and Socket connector capable of being disconnected under load, ensuring both operator and equipment safety.

Spanning a range from 20 A to 1250 A and up to 1000V, the series integrates silver-nickel tipped contacts for exceptional connection quality. With a built-in isolator, visual disconnection indication, and various IP ratings, the DECONTACTOR™ eliminates the need for an electrician, empowering operators to facilitate maintenance and repairs on pumping systems efficiently.

Beyond safety, the DECONTACTOR™ proves to be a gamechanger for efficiency. Pumps / Motors prewired with DECONTACTOR™ connectors result in significant time

and cost savings, cutting downtime costs by up to 50%. The connectors shine in harsh conditions, from outdoor elements to compliance with electrical standards, making them ideal for critical production areas.

MARECHAL ELECTRIC’s product line, ranging from star-delta 7 pole connectors to high-current plugs and socket-outlets, comprehensively addresses diverse pumping needs. With capacities reaching up to 1250 A, it ensures a secure power supply for heavy equipment. The connectors, designed for extended lifespans, minimal energy consumption, and easy maintenance, contribute to a sustainable future for pumping operations. Have a specific solution in mind to discuss or want to experience the DECONTACTOR™ advantage firsthand, MARECHAL ELECTRIC invites you to connect with them.

Request an obligation-free sample to witness the innovation.

PUMPS

THERE IS EFFICIENCY

BEYOND

DECONTACTOR™ - pioneering solutions for the pump industry, revolutionising operational safety, efficiency and performance.

The world’s first plug and socket allowing disconnection under load whilst ensuring complete safety and protection for operators and equipment.

Our technology boasts a range from 5 A to 1250 A, up to 1000 V and up to IP69 Ratings.

Connect with us: ready to elevate your pumping application with the game-changing MARECHAL® solution.

MARECHAL

MARECHAL®’s

CONNECTIONS Try it for free: contact us and experience

advantage first hand!

Telephone: +27 11

7226 marechal.com

ELECTRIC AFRICA Email: j.henriques@marechal.com |

894

Mechanical rotating solutions mobile diesel pumps shows its worth

South African coal mining environments, especially in open-pit scenarios, face the perennial challenge of managing water levels to ensure smooth operations. To address this, companies like Mechanical Rotating Solutions (MRS) have revolutionised dewatering processes with tailored pump solutions.

To this fact, MRS has built and refurbished diesel mobile pump systems explicitly designed for dewatering at coal mines. In 2023 MRS achieved its 20th such mobile diesel pump built or refurbished, showcasing their extensive experience in providing specialised pumping solutions for the local South African coal mining industry. What sets these refurbished pumps apart is the company’s “betterthan-new” philosophy. Each pump undergoes a meticulous refurbishment process, ensuring they exceed original standards. Such attention to detail and commitment to excellence signify their dedication to providing cutting-edge solutions for efficient dewatering in mining environments.

The advantages of using a pump driven by a diesel engine on a mobile trailer for dewatering in open-pit mining are well-documented. This setup offers unparalleled mobility, allowing swift movement of equipment across expansive mine sites. It ensures accessibility to varying water depths, crucial in addressing the ever-changing water levels within open-pit mines. Diesel-driven pumps also provide power independence, a crucial aspect in remote mining locations where stable electrical grids might be lacking. According to MRS Managing Director, Franscois Steenkamp, what distinguishes Mechanical Rotating Solutions’ new and refurbished pumps is their commitment to customisation and efficiency. “To start off with, specifying the right dewatering pump is pivotal in ensuring efficient, costeffective, and safe operations in an open pit mining scenario, impacting everything from productivity to environmental sustainability and worker safety.” Says Steenkamp. “Viewing at our most recent mobile pump projects operating at a specific efficiency point of 100 litres per second at 100 meters head, capable of producing 50cfm (cubic feet per minute), these mobile pumps offer tailored performance optimised for the mine’s specific conditions. This precise operation, as mentioned, ensures maximal effectiveness in removing water from the pit, reducing fuel consumption, and cutting operational costs. While a pump capable of 50cfm can handle dewatering in certain scenarios, especially in smaller operations or where the water volume is moderate and the depth or lift requirements aren’t excessive, MRS can also supply pump sets for larger-scale or faster inflow scenarios which may require pumps with higher capacities or multiple pumps working in coordination to meet the demands efficiently. This is particularly important in situations where the pump needs to quickly and effectively draw in fluids from a source, especially if there are air pockets or the pump is not gravity-fed. “What really sets us apart is our ability to

upgrade the pump seal with the latest technology from our AESSEALTM mechanical seal range whilst further extending the pump’s lifespan by incorporating Belzona engineered coatings. The impeller and casing of slurry disposal pumps on these mobile units mainly fail due to excessive wear and erosion. Having gained extensive experience servicing collieries in the Mpumalanga province, we frequently utilise Belzona Engineered Coatings for the protection and refurbishment of metal surfaces subject to severe erosioncorrosion, as found in coal mines. This ensures that the pumps commissioned by Mechanical Rotating Solutions are true to our better-than-new philosophy”.

The adaptability and reliability of these refurbished pumps shine through their ability to swiftly respond to changing water levels or unexpected flooding. Their mobility, coupled with the optimized performance, ensures versatility in addressing diverse depths and locations within the mine, safeguarding productivity and operational continuity. “Moreover, by operating at their best efficiency point, these pumps exhibit reduced environmental impact, utilizing fuel efficiently, and potentially lowering resource consumption over time. Their reliability under specific conditions, crucial in emergencies, ensures safety and mitigates risks associated with excess water in the mine. The integration of a pump driven by a diesel engine on a mobile trailer, specifically tailored to the specific dewatering needs, stands as a testament to Mechanical Rotating Solutions’ commitment to providing efficient, adaptable, and reliable dewatering solutions for open-pit mining operations.” Adds Steenkamp. While initial investment costs might be perceived as higher, the long-term cost savings derived from these specialised pumps are undeniable. Reduced fuel consumption, minimised downtime, and enhanced operational efficiency significantly contribute to cost-effectiveness and sustainability in water management within the mining operation.

Mechanical Rotating Solutions, +27 (0) 12 809 3935, franscois@mrssa.co.za, www.mrssa.co.za

26 Pipes, Pumps and Valves Africa - Jan/Feb 2024

PUMPS

+27 (0) 31 700 6954 info@aumanat.co.za www.aumanat.co.za Supplier of world leading brands of: - Electric, Pneumatic, Hydraulic and Portable actuators - Valve gearboxes Design and manufacture Installation and commissioning Onsite service and repairs Training

PUMPS

How the IoT superhighway is supporting pump installations at mines

We explore the many benefits of the Internet of Things for pump installations in the mining industry, notably in managing the issue of water curves, which can lead to inefficiencies and significant costs unless correctly handled.

The Internet of Things (IoT) is revolutionising the mining industry by impacting every stage of the mining value chain, from prospecting to reclamation – with many advantages for pumping operations. Connected sensors and actuators can monitor and help control the environment, assets, machinery, and people within mining operations. The technology enables mining companies to automate workflows, improve efficiency, and reduce costs, while also enhancing safety and ESG credentials.

The spread of IoT into mining has been encouraged by reduced latency, increased computing power, and the falling price of sensors, which have led to a faster ROI. Additionally, a growing number of IoT products and services now incorporate AI technology into their capabilities, especially for predictive maintenance.

For pump installations specifically, IoT has much to offer. With the correct applications, IoT can remotely monitor wear and tear on equipment, nose clearance, vibrations, temperature and load conditions, movement of materials and water in tailings. IoT tech can also manage water curves – all vital for reducing inefficiencies and saving costs.

Potential problems with slurry pumps

Low pump efficiency and flow rates are potentially major problems for slurry pumps. Water curves indicate a slurry pump’s performance at various speeds, with curves changing depending on what slurry is going through the pump.

As such, water curves are an effective way to calculate performance. However, being unable to read and adjust a pump’s water curves for the presence of solids can adversely affect production – by increasing the likelihood of subsequent line blockages, and even possibly resulting in shutdowns.

By providing operational visibility, IoT sensors and cameras installed in mining pump installations can monitor and gather data about the movement of materials and water in tailings. With IoT sensors in place, remote monitoring of water curves can take place, allowing rapid and accurate adjustments. “GIW’s IoT offerings allow customers to monitor and accurately control their nose gaps, which can lead to upwards of 6% gains in hydraulic efficiency, according to tests performed on an 84in impeller in the GIW Hydraulic Lab,” explains Aaron Cutright, manager of engineering IT systems at GIW Industries.

Digital processes to transform pump operations at mines KSB Group is a leader in digital transformation and is using technological solutions to enhance customer ownership through monitoring, analytics, and IoT – all to ensure optimal pump performance. KSB offers four mining IoT intelligent applications that allow for effective monitoring of both slurry and non-slurry pumps, making a significant contribution to operations efficiency.

These solutions can be installed as single units, or as a combination depending on the application. KSB Guard is a non-slurry pump monitoring system that allows

28 Pipes, Pumps and Valves Africa - Jan/Feb 2024

remote monitoring of pump performance data, optimising maintenance and reducing downtime, increasing efficiency. Consisting of four components, the smart pump monitoring system contains a sensor unit, a transmission and battery unit, a gateway, and a web portal and app.

Current dynamic data can be viewed at any time as a complete overview and in detail. For example, vibrations and temperature, load conditions or even warnings and alarms. GIW® SLYSEL is KSB’s proprietary software program for slurry pump performance calculations and pump selection, helping mining operators identify the best slurry pump for their needs by analysing key data points.

As well as calculating the minimum pipeline velocity to avoid sanding, it also predicts a range of recommended flow rates and supports the pump selection process for the specified pipeline system. It can also simulate large pipelines with dozens of pumps and can be used to plan startup sequencing. GIW® SLYsight is a pump wear analytics tool, which measures the actual wear rate of pump parts, including the nose gap, by collecting realtime data from custom sensors. The motivation behind SLYsight is to continuously monitor the thickness in different locations and to visualise that wear over time. This can extend maintenance cycles and because operators can see how long their parts are lasting, it also means fewer unnecessary downtime events, which can lead to significant improvements in operational efficiency.

GIW® RAMSL improves maintenance procedures by remotely adjusting the nose gap of a pump, enhancing operational safety and efficiency, and increasing adjustment accuracy. In slurry pump operations, units are

expected to run continuously 24/7, and there is critical maintenance activity involved with maintaining a tight, continually adjusted nose clearance between the impeller and the suction liner. Historically completed during manual maintenance, with most or all of the equipment shut down, this can lead to a loss of productivity. Remotely adjusted mechanical suction liner (RAMSL) offers the ability to do nose clearance adjustments down to around a quarter of a millimetre. In addition, the technology can be adapted to existing equipment with minimal impact.

Remote monitoring with IoT

Through the targeted use of IoT, water and slurry pumps can be monitored more accurately, making the pumps more efficient, and reducing costs and potential downtime.

Although KSB and GIW have had software controls for their pumps for some time, the new consolidated offering of products can help miners monitor their equipment remotely.

Additionally, these solutions are available with real-time technical support, 365 days a year and 24/7 from anywhere in the world. According to Cutright: “Customers that have installed SLYsight on their equipment in the field have been impressed by the insights it has provided into wear development, which is novel data that has allowed them to extend maintenance cycles further than ever before.”

KSB, +27 11 876 5600, support.za@ksb.com, www.ksb.com

Pipes, Pumps and Valves Africa - Jan/Feb 2024 29

PUMPS

Tsurumi’s commitment to safety in pump design

Engineers who design industrial plants, lift stations, rail loading stations and similar facilities bear equal responsibility for safety and design functionality. As the safety-first design philosophy becomes more prevalent, hazardous location rating requirements appear more frequently in project specifications.

To meet these parameters, Tsurumi offers the AVANT Series of FM-approved submersible pumps and mixers, which ensure safety through their quality in construction, manufacturing and performance.

A pump must undergo a series of tests to determine if its design meets construction requirements. These tests are conducted by FM Approvals or another nationally recognized testing lab for hazardous location product certification.

Tests such as the cord pull and impact tests ensure that potential wear and tear will not compromise the pump’s ability to prevent or retain an explosion. Locked rotor and running overload tests intentionally raise the motor’s temperature to establish its compliance with the hazardous rating’s temperature class (T-Code).

Finally, flame propagation tests verify the flame path effectively prevents the explosion from escaping the pump into the surrounding atmosphere. In these tests, the pumps are surrounded by a specified hazardous gas and intentionally ignited.

Once testing and evaluation are complete, the pump model will be certified for use in the tested hazardous location and within temperature limits established by the T-Code. However, pump manufacturers must consider additional

requirements, including properly marking the pump and affixing permanent, visible nameplates containing manufacturer information, serial numbers, hazardous location ratings and several warning statements related to hazardous location operation.

The manufacturer will additionally be quarterly audited to ensure the previously certified pump’s quality is being maintained and a quality control program is in place. This program entails pump assembly, record keeping, documentation control, etc.

While this article is not intended to be a comprehensive guideline, we consider it important to have a basic understanding of the hazardous location certification process.

Certification for Tsurumi’s AVANT Series is secured through demonstrated quality in construction, manufacturing and performance. Similar to the engineers designing plants and lift stations, Tsurumi prioritizes the safety of our equipment as much as we emphasize its performance.

Tsurumi Pumps SA, +27 (0) 82 404 4743, enquiries@tsurumipumpsafrica.com, www.tsurumipumpsafrica.com

PUMPS 30 Pipes, Pumps and Valves Africa - Jan/Feb 2024

We offer valves for precision processes - and demanding applications.

Our valves fulfill the highest of standards and are designed for many years of safe and reliable operation. Our service specialists regularly check, monitor and maintain all relevant system components - depending on what has been agreed. Our modular framework agreements offer you individual service and spare parts concepts. And we even go one step further. We additionally check systems for efficiency in order to reduce operating costs and increase productivity. For example, with the SES System Efficiency Service.

ZTS GATE VALVE GATE VALVE AKG - A/AKGS - A NORI 500 BOA - H Contact our dedicated Valves Sales Engineers for all your Valve requirements Tel: 011 - 876 - 5600 • E mai l: info - za@ksb.com KSB Pumps and Valves (Pty) Ltd www.ksb.com/en-za Your Level 1 B-BBEE Partner

STAALWEDGE GATE VALVE AKDS/AKD