The

The

official

magazine for LEEASA (Lifting Equipment Engineering Association of SA)

SEP/OCT 2022

Lifting Africa & LEEASA Forklift Drivers Competition hosted at Electra Mining 2022

Chairman’s Desk

2022 LEEASA Individual Members & Company Members in Good Standing

Building brands for Africa

This year’s EMA welcomed first-time exhibitors CASLAD

Comansa presents the new LCH300 hydraulic luffing jib crane

Two new Grove cranes at bauma 2022

The Crosby Group unveils bauma showcase

Raimondi Cranes announces extensive show plan for bauma 2022

Lifting Africa & Pipes, Pumps And Valves Africa Golf day 2022

Liebherr Transform: unleash the full potential

Lifting Africa & LEEASA Forklift Drivers Competition hosted at Electra Mining 2022

Setting a new standard for crane cable guides on JIB cranes

Magni at the service of Complexe Atlantide

Heavy-duty electric Kito hoists ensure safe and stable operation year after year

JLG’s legacy: a pioneering spirit that drives productive, safe work at height

What is below surface must be above standard

Industrial gear units for lifting drives in mining

business goes from smooth operations to an emptied bank account

is the Cold Chain Logistics still stuck with old technology?

party and

Lifting Africa

Managing Editor: Surita Marx

Cell: +27 (0) 83 281-5761

Email: surita@liftingafrica.co.za Web: www.liftingafrica.co.za Sales: Lusana Merckel

Email: lusana@liftingafrica.co.za Sales Assistant: Christel Bester

Email: sales@liftingafrica.co.za Production Manager: Xane Roestroff

Advertisers

other

by any

contained in this publication.

Lifting Africa - Sep/Oct 2022 3 Contents

Disclaimer:

Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers LEEASA. The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or

proceedings made

third

arising out or in connection with the use of any services and/or products or the reliance on any information

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36 A

38 Why

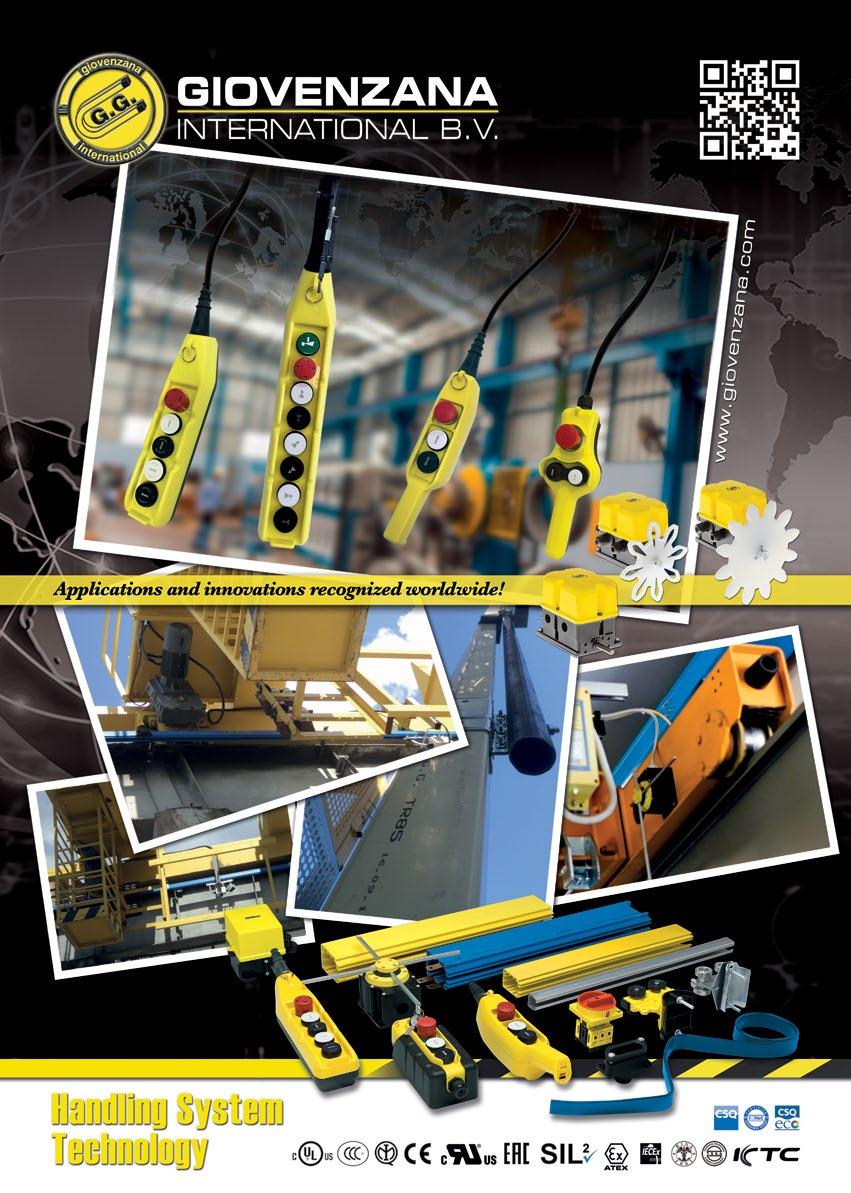

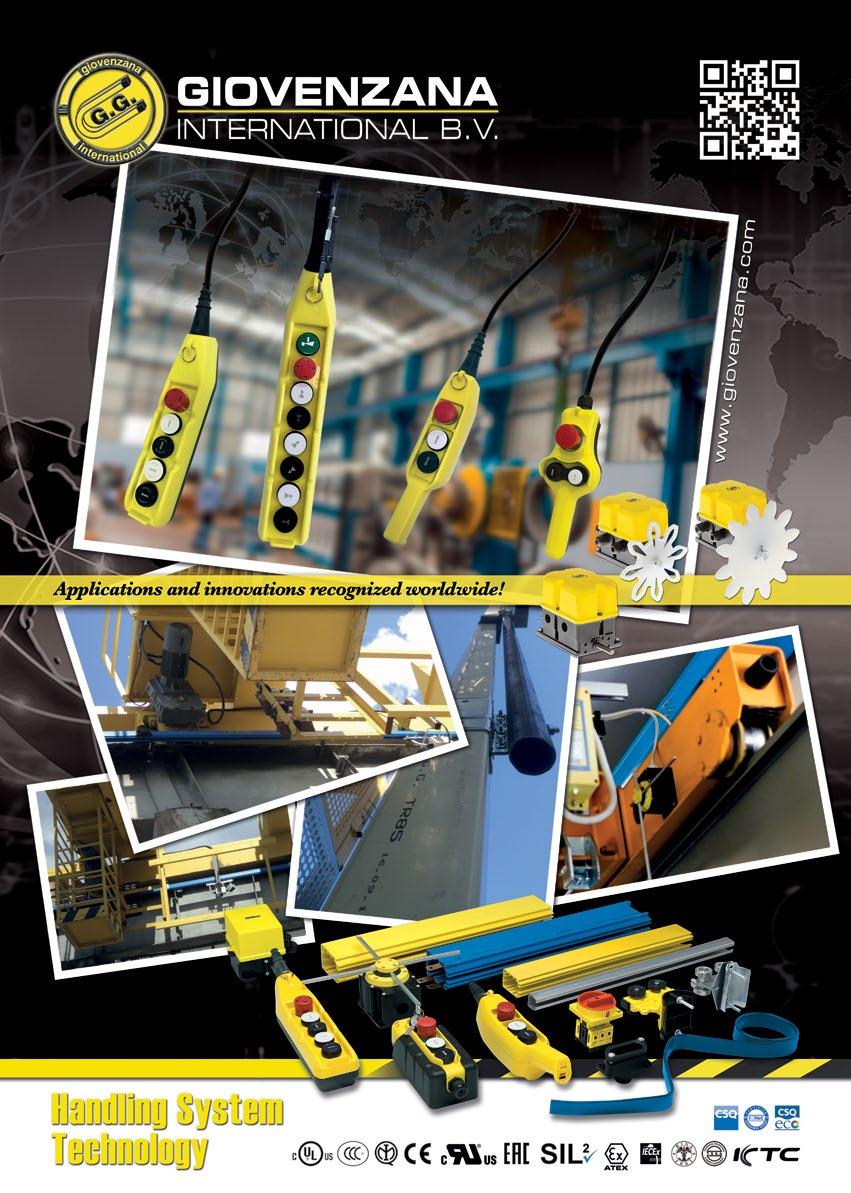

40 BUYERS GUIDE 44 Giants EA Projects +27 (0) 78 471 9901 giantsprojects1@gmail.com www.giantseaprojects.com Alpha Load Testing & Services 17 Bell Equipment 19 Caslad 1 ConExpo IBC CornerStone 39 Demac 33 Econo Flex 29 Giants EA Projects OFC & OBC Giovenzana IFC Igus 21 J Express 31 Johnson Crane Hire 23 Kemach 27 Liebherr Africa 37 Phakamisa 5 Placements 46 Smith Power 13 Talurit 15 Universal Suppliers & Expiditors 35 Van Beest 43

From the Chairman’s Desk

CHAIRMAN’S DESK

It has taken a while to recover from all the activities related to the Electra Mining Show 2022 and the Event was a huge success. Our Lifting Conference was well attended, and some interesting topics were covered. Thank you to everyone that attended and to our guest speakers for sharing their knowledge in their relevant areas of experience.

Topics Covered

Kyle Graham from LEEASA - Vetting Guide for LME’s and LMI’s

Piet Otto from Phakamisa - Trestles

Sandra Hürlimann from WH LiftingVacuum Lifters

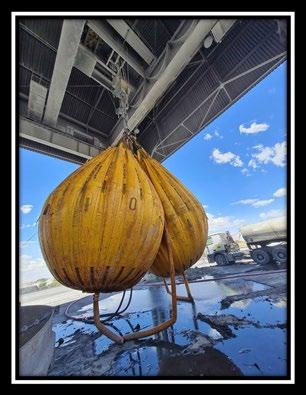

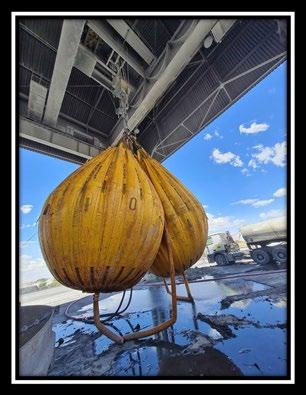

Kyle Graham from WWLT - The Safe Utilisation and Application of Water Weight Load Test Bag

Colin Ford from Lubrication Engineers - Rope Lubrication

Leader Nkala from ACROWRacking Inspection and Safe Rack Loading

Roger Day - SANS 500 – Review

Gert Oosthuizen from SkyJacksHeight Safety

A special thank you to Mr. Roger Day for hosting the day’s activities and Mr. Mohlahola Monyaki from the Department of Employment & Labour for their guest appearance and attendance.

Forklift Competition

The Forklift Competition was well attended with in excess of 50 participants. We would like to congratulate the winners that walked away with some great cash prizes

First Place: Ian Roux

Second Place: Lazarus Mabala

Third Place: Tony Sharp

A big shout out to all of our sponsors and Lifting Africa for making this day a huge success and to our Co-Ordinator Mr. Joe Fourie and all the Judges who kept things running smoothly. We are sure we will see this day again in the calendar soon.

ECSA

LEEASA attended ECSA’s Presidents Forum on Thursday 15 September 2022

“The Forum represented by ECSA`s recognised VA`s that boast engineering membership from the different disciplines, was chaired by ECSA President Refilwe Buthelezi Pr Eng and is aimed at strengthening relations between ECSA and VAs as well as deliberating on critical engineering matters that not only impact the engineering practitioners but the members of the public as well.”

ECSA has been re-approved by SAQUA as a Professional Body and the Re-Registration of Its Professional Designations

“SAQA Approves the Re-Recognition of ECSA as a Professional Body and the Re-Registration of Its Professional Designations

The Professional Bodies Committee (PBC) of the South African Qualifications Authority (SAQA) has approved the Re-Recognition of the Engineering Council of South Africa (ECSA) as a Professional Body and the Re-Registration of the following Professional Designations on the National Qualifications Framework (NQF) valid from 18 August 2022 to 17 August 2027:

• Professional Engineering Technician (Pr Techni Eng)

• Professional Certificated Engineer (Pr Cert)

• Professional Engineering Technologist (Pr Tech Eng)

• Professional Engineer (Pr Eng)

• Registered Lift Inspector

• Registered Lifting Machinery Inspector

• Medical Equipment Maintainer (Reg MEM)”

The Engineering Council of South Africa (ECSA) is pleased to announce the appointment of a new ECSA CEO Mrs. SRM Buthelezi

Pr Eng ECSA president

Verification as an ECSA CPD Service Provider

Since the change of council in 2020

LEEASA has been working hard to ensure the strengthening of our foundation and secure ourselves as the most recognised Voluntary Association for Lifting Machinery Inspectors in South Africa.

We are pleased to announce that we’ve been approved by ECSA as an ECSA CPD Service provider (SP_034/2025) which is valid for a three-year period.

We believe we are the only Lifting VA that is a Registered VA, Licenced Body and CPD Service Provider registered with ECSA, and this now allows us to not only VET External Service providers for CPD but also have our own training material and content VETTED for CPD and offer CPD points for approved material by ECSA

This opens up exciting opportunities for LEEASA so keep watching this space for some announcements soon.

CPD Courses

We are pleased to announce that LEEASA has recently completed the vetting and revalidation of all the below courses for LMI Academy

• Chain Blocks & Lever Hoists

• Lift Trucks – Forklifts

• LMI Ethics & Laws

• Overhead Cranes

The course validations can be seen on the ECSA Website.

We are in the process of validating 6 completely new courses for SkyJacks

• Chain Hoist Training for LMI’s

• Lifting Tackle Training for LMI’s

• Vehicle Hoists Inspection & Load Testing Training

• Electrical Overhead Crane Inspection & Load Testing Training

• Correct Use & Maintenance of Inspection & Test Equipment

• Advanced Crane Rope Inspections

This should be completed by the end of 2022 so there will be some exciting new CPD activities to attend in 2023 for all those LMIs looking to expand their knowledge in Lifting.

4 Lifting Africa - Sep/Oct 2022

AGM

Our annual general meeting will be taking place at ERPM Golf Club on 16 November 2022. On this day we will be announcing the new LEEASA Board of Directors and Chairpersons as well as bringing you up to speed with the future undertakings of the association.

If you would like to run for a seat on the board of directors, please send a motivation letter and cv to admin@leeasa.co.za by 28 October 2022. We will distribute this to our members and vote for the board will take place electronically on the 11 November 2022. The Board will vote for Chairpersons on 14 November 2022 and the new Board announced on 16 November 2022 at the AGM

Timeline

• 28 October 2022 - CVS & Motivation Submitted

• 31 October 2022 - CVS & Motivation Distributed to Members

• 11 November 2022 - Electronic Vote

• 14 November 2022 - Vote for Chairpersons

• 16 November 2022 - AGM @ ERPM Golf Club and Virtual

Membership Cards

We are preparing a second batch of cards to be printed.

If you have not submitted all of the below information, it is not possible to finalise your card so please get in touch with admin@leeasa.co.za and send in your documentation so we can assist you to have it finalised.

• LMI Certificate

• LMI Scope Letter (Very Important)

• ID Copy

• Digital Photo

• Completed Membership Form

Please make a turn at the AGM to pick up your cards during the event.

We have many exciting things planned and would love to have more involvement from our members. If you think you have any value to add please do not hesitate

to contact us and be sure to join our AGM so you can be kept up to date with our future for the association.

Feel free to reach out to the council members if the need requires.

Chairman:

Ashley Davis | ashley@leeasa.co.za

Vice Chair (Treasurer of Finance Committee):

Surita Marx | surita@leeasa.co.za

Ordinary Members:

Andries Agenbag | andries@leeasa. co.za

Francois Blignaut | francois@ leeasa.co.za

Kyle Graham | kyle@leeasa.co.za

Yours in SAFE LIFTING, Ashley Davis and the rest of the LEEASA team

Lifting Africa - Sep/Oct 2022 5

CHAIRMAN’S

DESK

Aaldrik Graham Kiewiet

Alan Victor Botha Albert Olof

Albert Anthony Freeme Albert Olof Jansen Van Vuuren

Amogelang Gilbert Mmusi Amos Tulelo

Andries Aucamp

Andries Gordon

Andries Josias Agenbag

Angus Hamilton Christie Anton Oosthuyse

Arnoul Spitsbaard

Ashley Mark Davis Barneywel Chimphondah Bartholomeus Jakobus Erasmus Brian Meintjies

Carel Gustavus Potgieter

Carel Hendrik Ferreira Carlos Macuacua

Challe Andre Bonhamme

Christiaan Ernst Gerhard Schutte

Christiaan Hendrik van Wyk Christo van Huyssteen Christo van Eyk Christoffel Andries Whitehead Clarence Fortuin

Cornelius Frederick van der Nest Cyril Raymond Laredo Darren Brian Berndt Darrin Ian Cass David Henry Cooks Dean Eppel

Dean Edwin White Dennis Valentyn Bunge Desmond Errol Lloyd Desmond Maurice George Diederik Arnoldus Dahms

Drean Johannes Kotze

Eben Philip du Preez Edius Mashamba Edward Hall Edward Kruger

Enock Mugwede Ernest Khanyile Ernst Cornelius Jansen Ernst Cornelius Jansen Ettiene Pollard

Eugene Terence Redelinghuys Ferdinand Pieterse Francois Dewald Blignaut Francois Frederikus Le Grange Frank Warrick Saayman

Frederek Gerhardus Opperman Frederick JJ Fourie

Frederick Wilhelm Stonehouse Gert Vos

Given Nyathi

Glenton Rebello Graham Roy Twaddle Happy Tafara Tati Harris Naidoo

Hermanus Barend Dahms Ian O’Hara

Ibrahimo Brento Hassane Imraan Moolla

Isidro Ernesto Fernando Israel Mooketsi Jacobus Rudolph Kruger

Individual Members in Good Standing

Jacobus Stephanus Al Hoffman

Jaen Pienaar

James Nicholas Hamilton Wells

Jan Frederick van Niekerk

Jan Louis Venter

Janus Jacobus van Biljon

Jason Brett Mulder

Jetro Ngwenya

Joachim Jacobus Steyn

Nicolaas Wynant Theunissen Nkosinathi Perfect Mbatha

Nkosinathi Richard Mavimbela Noel Nyamukoho

Ntatenyane Daniel Mangwegape Pastor Noosi

Paul Pillay

Paulo Jorge de Freitas Marques Paulus Stephanus Marais

Michael Bester Michael Fernandes de Souza Michael Henry Hassett Michael John Hendry Michael Lionel Roberts Mlungisi Gatyeni Mogakolopi Gregory Thamage Mohamed Hoosen Dawood Mthandeni Kunene Mzinhle Leonard Sibenya Napo Michael Noosi Nathaniel Happy Sambo Neil Naude Neil Van Wyk

Wayne Shaw

Weddington Chimbani Moyo Werner De Bruyn Werner Snyman Werner Hermann Schoer Willem Abram Bossie Prinsloo Willem Petrus Van Den Heever William Charles Palvie William Henry Pepler Wynand Byleveldt Yogandren Soobramoney Zaheer Shameer Khan Zenzele Ntshakala

2022 LEEASA

Lifting Africa - Sep/Oct 2022 7 2022 LEEASA Company Members in Good Standing “These records are up to date at the time of going to print” LEEASA: +27 (0) 79 658 5602, admin@leeasa.co.za, - www.leeasa.co.za

Building brands for Africa

Following the increasing demand for tough and reliable equipment in Africa, Smith Power Equipment has set its sights on expanding its footprint on the continent. Lifting Africa spoke to Eric Schultz, Director of Finance and Operations to find out more.

Reputable Original Equipment Manufacturers (OEMs) are well aware that a brand is only ever as good as its support. They also understand the critical importance of partnerships, especially in Africa.

Smith Power Equipment has built itself a reputation as one of the most reputable distribution partners. With an extensive knowledge of the local equipment market, it is no surprise that many OEMs continue to turn to the company when seeking to establish themselves here.

“OEMs come to us, and we help them build and establish their brands within the relevant markets. If one looks at our business and the type of products we import then it is clear to see that we are all about quality, reliability and affordability. These are the traits we look for in machines,” explains Schultz who describes Smith Power Equipment as the builder of German brands in Africa. “Quality and reliability are also what many German brands are renowned for and many of the OEMs in the country have opted to partner with Smith Power Equipment to be their distribution partner in South Africa.”

He says the company has opted for an aggressive expansion strategy. Locally it has opted to grow its

footprint in Cape Town extensively so much so that this will become the company’s next headquarters in coming years. The other expansion drive is into Africa.

“We have already started the process of appointing dealers across Africa as we set our sights on growing our footprint. We believe there is a real opportunity in the African market and we are ideally positioned to bring our range of equipment to these markets.”

South Africa, he says, remains the largest capital equipment market on the continent and is still the gateway into Africa for many international companies looking to establish themselves on the continent.

South Africa's trading relationship with countries in Europe such as Germany is also well-established. “In 2017, Germany was ranked as the second-largest trading partner for South Africa and they understand the importance of the country in growing their African markets.” He says the benefit of Smith Power Equipment is that it offers the best of both worlds. With a firm knowledge of local requirements and its strong connection to international OEMs, it can meet Africa’s equipment needs reliably and more importantly, costeffectively.

ADVERTORIAl

Meeting African needs

Affordability, according to Schultz, remains important in Africa. Just as important is the aftermarket service. “These two factors are key parameters when it comes to equipment buying decisions in the capital equipment space. The brands we represent can meet those requirements.”

He says Africa’s potential as a growth market for business cannot be overemphasised. “If we look at the range of products that we have then we are ideally suited to service Africa. We have an extensive range of equipment in the agricultural sector, which is possibly one of Africa’s biggest growth areas.”

Africa’s move to increasing manufacturing will also see Smith Power Equipment boost its material handling equipment in the continent.

“We already have a substantial dealer network in southern Africa and extending this further makes strategic sense. Our brands are doing very well in Africa and continue to see growth.”

One brand in particular that has been very well received has been the Baoli range of machines. According to Schultz, the company partnered with the brand in 2018 and it is still very much in its infancy.

“We are still in the growing phase and our market share is still relatively small in South Africa, but the opportunity to grow and extend this brand in Africa is huge. Our goal is to be one of the serious players in the market.”

He says the machines are ideally suited to the African market thanks to their affordability and robustness. “They are quality machines that are easy to use and easy to maintain.”

Developing trends

Schultz says the rental business continues to go from strength to strength at present. With many companies still recovering from the global pandemic there has been an increased move toward renting equipment rather than purchasing.

“This is another part of our business that we are expanding and both our short to medium-term fleets are being extended to meet the market demands. Many companies also operate with seasonality and so they don’t need a machine for 12 months but only for four or five months of the year.”

He says being able to deliver reliability is still a market trend. “That includes offering a solid after-service.

Having the ability to look after a machine once it has been purchased is important. With this in mind, we invest heavily in our technicians and stockholding to maintain our fleet and ensure that we can reduce client downtimes to a minimum.

This the same approach we are taking in Africa and will ensure our dealers and distribution network can offer the same level of service all the time.”

The move away from diesel machines is a fast-growing

trend in South Africa, says Schultz. “There is a massive drive towards green and reducing carbon footprints. We have seen a definite spike in demand for electric machines.”

Schultz says the sector is not without challenges and the disruptions of the supply chain have been one of the biggest issues to deal with.

“Lead times have increased exponentially as has the cost. Many regions, particularly in the East, are still dealing with Covid lockdowns which has an impact on manufacturing and so planning has become very important to meet deadlines.”

Smith Power Equipment, +27 (0) 11 284 2000, mail@smithpower.co.za, www.smithpower.co.za

ADVERTORIAl Lifting Africa - Sep/Oct 2022 9

Eric Schultz, Finance and Operations Director for Smith Power Equipment.

This year’s EMA welcomed first-time exhibitors CASLAD

Celebrating 50 years this September, Electra Mining Africa is a meeting place and hub for thousands of industry professionals across the mining, electrical, automation, manufacturing, power and transport sectors.

During the five day expo, thousands of innovative products are on display, with a rekindled opportunity for face-to-face interaction and live demonstrations.

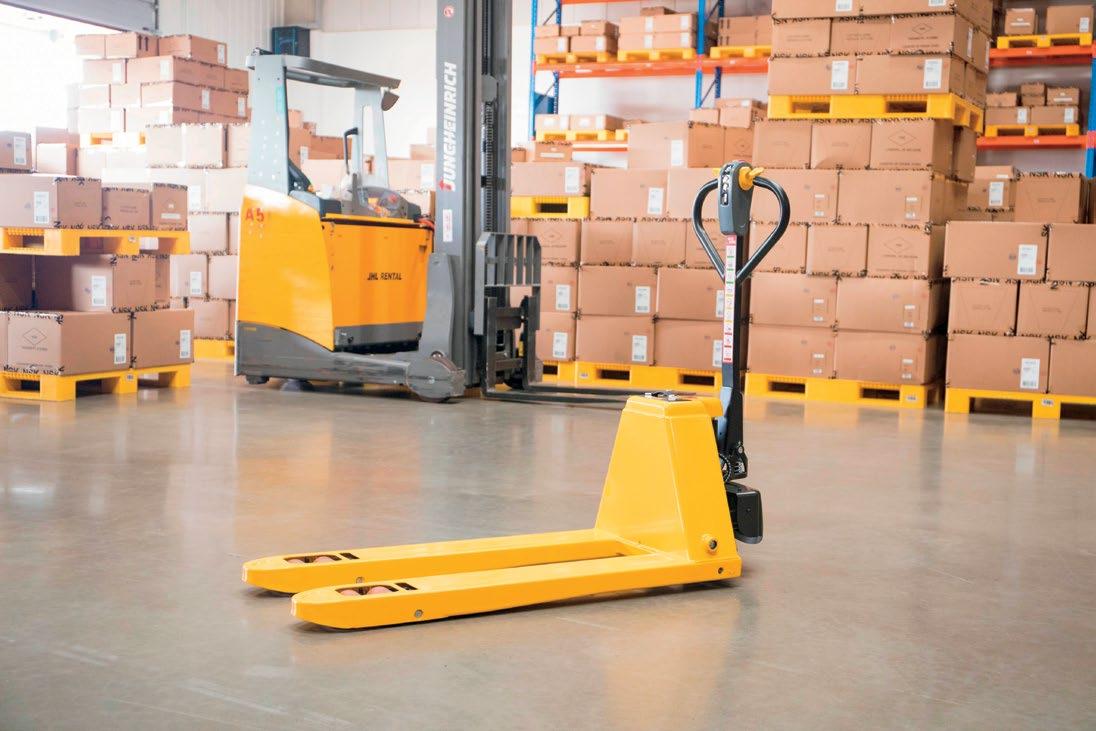

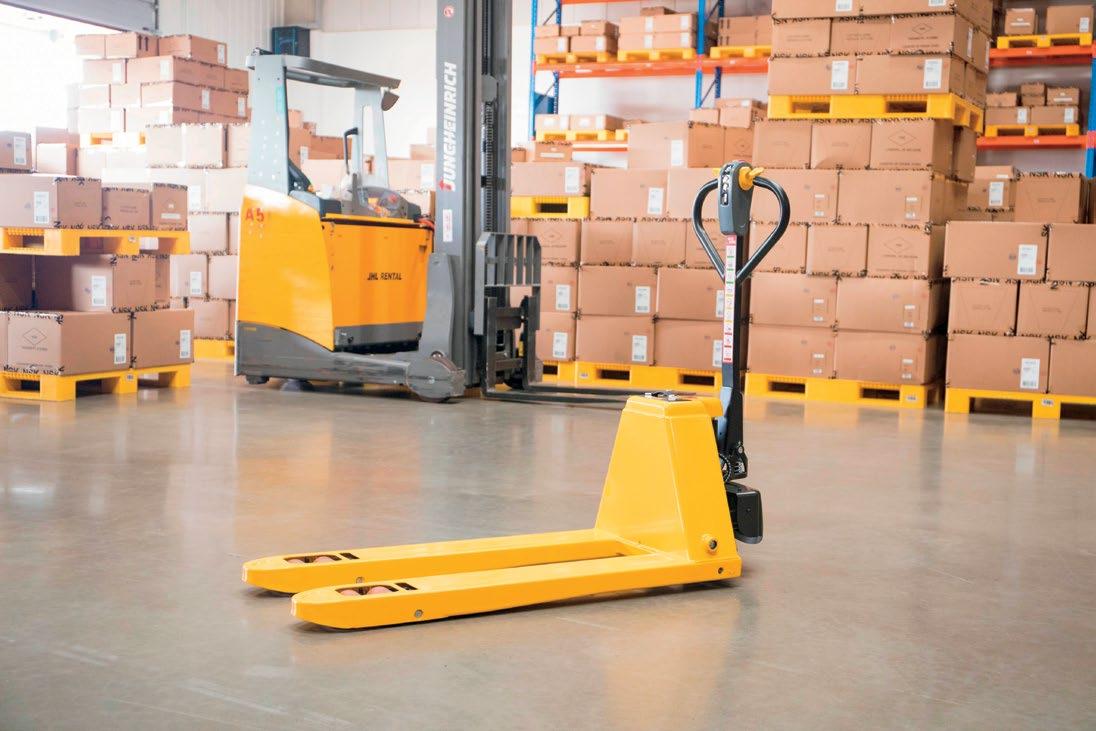

This year’s EMA welcomed firsttime exhibitors CASLAD — a leading industrial warehousing equipment supplier and manufacturer to the floor, and chatted to CEO Clayton Foster about his experience throughout the event.

“We noticed the vast majority of our visitors were existing customers which was a great indication we had come to the right place. Having the opportunity to chat, it soon became clear that many of our customers don’t realize the extent of the products we import and manufacture. The show was a great platform to showcase the full range — from ladders, castors, wheels, trolleys, materials handling equipment, conveyors, scaffolding, shelving and more — making it possible to secure further business from existing clients.” Having already reserved the same stand for next 2024, Clayton went on

to acknowledge the networking possibilities that came with the expo. “EMA gave our sales team the opportunity to connect with key decision-makers and to reconnect with existing clients in person. With industrial products, there is no greater impact than a face-toface demo. This is something not possible via telephone or our online sales mechanisms. All in all it was a great success and we’re excited to

come back in 2024.” One popular debut at this year’s expo was the new 2t Lithium Pallet Truck from STAXX.

Anyone using a manual lifter for weights over 1.5 tons will know that tasks become ergonomically unjustified beyond a certain point, resulting in an uncomfortable and less productive team on your factory floor.

Bridging the gap between manual and full size electric jacks, these lithium battery operated trucks are superior in efficiency, bring enhanced mobility, and offer a 5 year warranty on the chassis — making it particularly advantageous when it comes to the total cost of ownership.

Do you manage a factory or warehouse, or make use of materials handling equipment?

CASLAD welcomes walk-ins at their 4000sqm manufacturing and warehousing facility in Johannesburg, as well as its additional warehouses in Durban and Cape Town.

CASLAD, +27 (0) 11 397 7883, sales@caslad.co.za, www.caslad.co.za

10 Lifting Africa - Sep/Oct 2022

ADVERTORIAL

10 Lifting Africa - Sep/Oct 2022

2T FULL ELECTRIC PALLET JACK Opening Special at R 21 950 ex vat Available while stocks last Capacity Load Centre Overall fork width Fork length Overall length Lowered height of fork Max height of fork Overall height Rear body width Minimum turning radius 2000kg 600mm 550 / 685 mm 1150 / 1220 mm 1552 / 1622mm 82mm 197mm 1276mm 550/685mm 1353/1426mm www.caslad.co.za sales@caslad.co.za +27 (0)11 397 7883 +27 (0)21 271 0119 +27 (0)31 331 0057 48V 10Ah LIMITED OFFER

Comansa presents the new LCH300 hydraulic luffing jib crane

The Spanish tower crane manufacturer will present its innovative model at bauma Munich 2022

Comansa expands its range of luffing jib cranes with the launch of the LCH300, its first hydraulic model, with a maximum load capacity of 16 tonnes and reach of 60 metres. The tower crane manufacturer will officially showcase this innovative model at the Bauma 2022 trade fair. The LCH300/16 t is available in various versions: embedded, supported on bases of 6 or 8 metres, or movable. The crane can be assembled with 2.5 x 2.5m tower sections. Its modular jib has a reach of 25 to 60 metres, with configurations every 5 metres. It has a minimum working radius of 4 metres and a minimum radius of 9 metres when out of service.

It has manual transmission combinations of 1T (direct pulling) and 2T. The maximum load capacity is 8t with the 1T configuration and 16t with the 2T configuration. The maximum load at the jib end is 3,400 and 3,150kg, respectively.

The luffing moves the jib and counter jib jointly by a hydraulic cylinder at the cathead and jib hinge assembly. The hydraulic pump unit is located on a movable platform in one piece.

From the cabin there is direct visibility of the lifting mechanism of between 50kW (standard) and 65kW (optional). Thanks to the Effi-Plus technology, it is possible to increase the speed of the lifting mechanism without affecting consumption, which allows loading cycles to be considerably reduced, thereby improving the productivity of the crane.

The design of this new rotating part - jib, cathead and counter jib - as well as the mechanism, cabin and hydraulic unit platforms, optimises the transport of this model, which may be supplied by 8 trucks or containers.

This new luffing jib crane from Comansa incorporates the awardwinning CUBE Cab (L or XL) with Split type air conditioning. The cabin platform, like the lifting and hydraulic unit platforms, can be transported in a single piece.

Comansa luffing jib tower cranes offer optimal performance where horizontal jib cranes cannot move loads freely due to space limitations. Now, with the incorporation of the LCH300 hydraulic model, the luffing mechanism is optimised to offer even greater performance and an efficient assembly, as well as reduction of the radius when out of service.

Tower Crane Services, +27 (0) 11 865 3202, richardfletcher@towercraneservices.co.za, www.towercraneservices.co.za

BAUMA EXHIBITORS 12 Lifting Africa - Sep/Oct 2022

RELIABLE FORKLIFTS WITHOUT UNNECESSARY EXTRAS.

Engineered to lift your efficiency and profits to new heights.

www.baoli.co.za

Two new Grove cranes at bauma 2022

Manitowoc will be displaying two new five-axle cranes at bauma, the Grove GMK5150XL and Grove GMK5120L. Both cranes set new standards for strength and reach, pushing the envelope of what’s possible for a five-axle all-terrain crane.

Visitors to bauma 2022 will see two new Grove all-terrain cranes in public for the first time. Both the GMK5150XL and Grove GMK5120L are expected to be popular exhibits at the Manitowoc booth. Visitors will be able to view the cranes up close and hear from product experts involved in their design.

“We presented the GMK5150XL and GMK5120L during customer events at our Wilhelmshaven facility in Germany last year. But having them on the booth at bauma will introduce them to a much larger audience,” said Andreas Cremer, vice president of product management for mobile cranes at Manitowoc.

“We are thrilled to present these cranes at the world’s largest construction equipment exhibition and are expecting lots of interest.

In recent years, Grove has led the way in the five-axle all-terrain class and these two new models raise the bar. Their outstanding taxi crane features, strength, and reach redefine what’s possible with a fiveaxle machine in the capacity classes of 120 t and 150 t.” Grove GMK5150XL

The Grove GMK5150XL all-terrain crane provides increased capacity and a boom length that surpasses most 220 t machines. This new

model is redefining the five-axle, 150 t class by offering almost 69 m of main boom. At 68.7 m it can handle 8.1 t; at 66 m it lifts 9.5 t and at almost 60 m it lifts an incredible 13.0 t. These load charts are truly unmatched.

The GMK5150XL’s load charts in taxi configuration are also bestin-class, ensuring easy roadability and transport savings for owners. Counterweight slabs are interchangeable with those from the GMK5120L or any other Grove 150 t crane, further simplifying logistics and handling.

The flexible counterweight configurations enable setup to be tailored to customer needs.

Taxi configurations start from just 1 t of counterweight and for configurations of 12 t per axle, the GMK5150XL can carry up to 10.2 t of counterweight. There is also a heavyweight counterweight configuration of 16.5 t per axle, which makes it possible to drive the crane with an outstanding 30.9 t of counterweight on board.

The new Grove boasts compact dimensions that other five-axle cranes can only dream of.

At just 2.75 m wide, it effortlessly accesses the narrowest of jobsites, and with the MAXbase option for flexible outrigger configuration,

optimizing setup and lifting position is quick and easy.

Grove GMK5120L

The 120 t capacity Grove GMK5120L is equally as impressive as the new 150 t GMK5150XL, offering classleading reach with its extraordinary 66 m main boom.

With this versatile all-terrain crane, Grove expands its range with another outstanding taxi crane that enables customers to benefit from greater flexibility and lower transportation costs.

The crane can easily adapt its onboard counterweight to suit the job – no matter if that’s 10 t, 12 t or 16.5 t per axle.

With compact dimensions of just 14.195 m overall length and 2.75 m width, the GMK5120L offers superb access to jobsites, complemented with great maneuverability from Grove’s MEGATRAK® independent suspension.

New generation carrier cabs

Both the GMK5120L and the GMK5150XL come with the latest generation of Grove carrier cabs, providing increased operator comfort and convenience.

The new cab design seats the operator an additional 235 mm from the centerline, enhancing visibility and maneuverability.

Customers can experience this enhanced operating position themselves when they see the crane at Manitowoc booth number FS1202.

This year’s bauma 2022 is expected to attract more than 600,000 visitors from over 217 countries.

Crane Load Technology, +27 (0) 11 323 9600, sales@craneloadtech.co.za, www.cltcranes.com

14 Lifting Africa - Sep/Oct 2022

14 Lifting Africa - Sep/Oct 2022 BAUMA EXHIBITORS

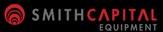

The Crosby Group unveils bauma showcase

The Crosby Group, a leading manufacturer of rigging, lifting, and material handling hardware, will showcase world-class lifting solutions for the future of construction and building at Bauma, which takes place in Munich, Germany, October 24-30, 2022 (Hall / Booth C4.339).

Bauma brings together manufacturers and vendors of construction machinery, building material machines, mining tools, vehicles, and other equipment at Trade Fair Center Messe München (Munich).

It attracts a demographic that relies on The Crosby Group’s lifting and load securement technologies to remain safe and productive in a variety of applications, from industrial manufacturing to highrise construction.

The Crosby Group will show its premier brands, including Crosby, Gunnebo Industries, Crosby Straightpoint, Crosby BlokCam and Crosby IP. Bauma visitors will get a chance to learn more about the new Crosby BlokCam X3L and M3L crane camera systems that extend the legacy of the original X2 and M3 systems.

The X2 is renowned as the industry’s first fully modular system compatible with tower cranes, while the M3 is the first fully modular camera for telescopic and mobile cranes which can be installed in just five minutes. New versions include a new transmitter that can connect to up to two sensors upon request; a repeater that comes with ball joint mount (reducing the ports required); new sensor with integrated audio and video plug; and assembly with an improved Wi-Fi signal. X3L and M3L versions are also available with a state-of-theart lithium-ion battery and charger.

Lifting in the construction industry has always been difficult as there is a lot of variability in the loads. Crosby-branded solutions that will be displayed at Bauma include a range of shackles and CrosbyIP clamps.

The shackle is one of the most powerful, important, irreplaceable pieces of material handling equipment there is.

The company’s range of Gunnebo Industries’ products include the GrabiQ Grade 10 chain sling, an all-inclusive sling system for coupling, shortening, and lifting in the construction industry. GrabiQ gives users the guarantee of correctly sized components for the size of chain, so stockholding for distributors is minimized.

The Midgrab is an inline shortener that allows the rigger to adjust the sling anywhere on the chain, not only at the top assembly, significantly reducing the time needed to adjust a sling.

Also at the heart of The Crosby Group portfolio is its

Crosby Straightpoint range of load monitoring hardware and supporting state-of-the-art software, including its most popular load cell, the Radiolink plus.

The long-range, 2.4GHz version provides an industry-leading wireless range of 3,280 feet to the manufacturer’s SW-HHP handheld or software options. A Bluetooth output version can be connected to any smartphone running its free HHP app on iOS or Android at ranges up to 328 feet.

These products frequently combine below-the-hook of tower and mobile cranes with Crosby shackles. Bauma visitors will also be able to see low headroom load shackles and compression load cells that are commonly utilized for center of gravity testing.

• Visit The Crosby Group at Bauma, Hall / Booth C4.339.

The Crosby Group will showcase world-class lifting solutions for the future of construction and building.See The Crosby Group at Bauma (Hall / Booth C4.339), which takes place in Munich, Germany, October 24-30, 2022.

The Crosby Group, +27 (0) 60 991 5526, martin.long@thecrosbygroup.com, www.thecrosbygroup.com

16 Lifting Africa - Sep/Oct 2022

BAUMA EXHIBITORS 16 Lifting Africa - Sep/Oct 2022

Raimondi Cranes announces extensive show plan for bauma 2022

The Italian manufacturer is set to present two of its newest flattop tower cranes. Raimondi’s exhibit at Bauma will include the first showing of Raimondi’s new machines to the global marketplace alongside its refreshed accessory range and new corporate vision.

the two lineups aim to excite and meet market demand, with further details to be released at a later date. The new models have a range of lifting capacities, from 6t-24t, and boast many technical innovations.

“Our R&D department have been working extensively on developing cranes that respond to market trends and client needs. The new range of machines, designed with fleet rental companies top of mind, will include unique characteristics such as adaptable and lighter jibs, a new seamless crane control system, simplified and compatible components, as well as new tower sections allowing for both internal and external climbing,” said Cristian Badin, Commercial Director, Raimondi Cranes.

All machines will be equipped with the new crane cabin, available in two models, ensuring the highest levels of comfort and safety.

Raimondi Cranes SpA, heritage manufacturer of intelligentlydesigned machinery, will unveil its new visual identity while showcasing two new cranes and a newly-designed cabin onsite at Bauma 2022.

The cranes will be erected at the Raimondi Cranes exhibit situated at FS 1102/2 in the event’s outdoor area at the Messe München Trade Fair Center. Raimondi’s senior management team, together with its full official agent roster, will be welcoming visitors onsite for the duration of the event from October 24-30, 2022.

“The past 14 months have marked an exciting new era for Raimondi with the company working on

several fundamental projects, including the conceptualization and development of a new series of flattops,” said Eng. Diego Borgna, Chief Executive Officer, Raimondi Cranes.

“We will also take the opportunity of the gathering at Bauma, the largest exhibition in the construction industry, to present our new vision and guiding principals to clients, industry stakeholders, and our respected contemporaries in the sector,” he said. Eng. Borgna added that the details around the new 29,000 sq. m. company headquarters will also be shared at the event. The newest range of Raimondi flattops is comprised of two series;

Significant improvements have been made on the structural side with the cabin now featuring a single glass block on the frontal and side windshields, allowing an increase in visibility by 30%. Other major features are the canalized air system to reduce window fogging, an ergonomic seat, and several internal accessories to boost crane operator comfort.

“We are excited to present a new Raimondi that honors our heritage, while heralding in the future of the company,” Badin continued. “We look forward to welcoming clients, visitors, colleagues, and sector stakeholders, at our exhibit during this pivotal time for the company.”

ZLT Cranes, +27 (0) 10 001 0069, info@zlt-cranes.co.za, www.zlt-cranes.co.za

18 Lifting Africa - Sep/Oct 2022

18 Lifting Africa - Sep/Oct 2022

BAUMA EXHIBITORS

Wanting to reach new heights?

STEER

STEER

Bell1650 Tel: +27 (0)11 928 9700 • E-mail: sales@bellequipment.com • Web: www.bellequipment.com Bringing you the winning combination of premium products and a great distribution network.

CONSTRUCTION Choice of mast heights, attachments and carriage types so you can adapt the machine to your needs ROUGH TERRAIN FORKLIFT A powerful package loaded with versatile features to set new standards of efficiency and productivity SKID

The best features of a mobile crane, wheel loader and a forklift in one efficient package TELEHANDLER

Lifting Africa & Pipes, Pumps And Valves Africa Golf day 2022

Lifting Africa - Sep/Oct 2022Lifting Africa - Sep/Oct 2022

Thank you to all our Sponspors:

bauma 2022: Jekko and the new additions to its range between innovation and sustainability

After the success gathered in 2019, Jekko won’t miss out on Bauma 2022, which will take place in Munich on October 24th through 30th.

Our exhibition space (outdoor area FS, booth 903/6) will spread out on a 512-sqm surface that will be set up with 5 containers in line to result into two-floor structure housing offices for meetings, a hospitality zone and a reception-living area where customers and dealers will be greeted. The containers that will be used have been salvaged and refurbished on purpose for this show and will be later installed in our headquarters in Italy and destined to become a new customer training area thus sticking to our corporate sustainability scheme, developed in 2021 and implemented since January 2022.

Jekko’s machines on display at Bauma are designed and developed to be user-friendly, that is easy to use and to understand, suitable to be used by both beginner and skilled operators. The entire Jekko range can always be operated in electric mode as all the machines on display at Bauma will show: the SPX minicrane line is powered by lithium-ion batteries, the MPK minipicker range has acid-lead batteries while the JF articulated crawler cranes are bi-energy machines combining a diesel engine with an electric motor. Bauma 2022 will also be a showcase for the latest

additions in each line of models: the SPX328 in the SPX range that will be officially unveiled on September 20th; the JF235 in the JF line; the MPK10 and MPK20R in the minipicker range.

Jekko will also showcase other models from the above lines:

• Minipickers: MPK06 and MPK10 fitted with their manipulator

• SPX: SPX532 equipped with JVM800, SPX650 set up with tools JIB500GR and SPX1280

• JF: JF545 with 2-man basket and JF990

• Tools: suction cups JVL450 and JVL600 with trolley, manipulator JVM800, JIB500GR and 5-, 10-, 20-ton lifting beams.

For this 33rd edition of the show, Jekko focuses on innovation and progress, two crucial values for the challenges that the company has decided to tackle in the current years in order to strengthen its position as sector leading player.

Jekko, info@jekko.it, www.jekko.it

Lifting Africa - Sep/Oct 2022 21

BAUMA EXHIBITORS

Fast assembly instead of festooning Secure energy supply for slewing cranes up to 10 metres travels. No more cable loops motion plastics® ... improve what moves Tel. +27-113121848 za-sales@igus.net The cable carrier guidelok swing GLO.S increases the safety in the operation of swing cranes. The cost-effective alternative to cable loops reliably protects the cables and thus prevents them from getting tangled and tearing off. The space-saving system thus ensures increased system availability and reduces downtime costs.

Liebherr Transform: unleash the full potential

Liebherr Transform, the new upgrade, modification and overhaul service, has a tailor-made solution for all customer needs. It is available for crawler cranes (up to 400 t), deep foundation equipment, and duty cycle crawler cranes.

The new Liebherr Transform provides tailored solutions that respond to the continuously growing demands on today’s businesses. A range of ingenious upgrades, clever retrofits, machine overhauls and service modifications breathe new life into customers’ existing machines.

Using the latest technology and years of experience, Liebherr brings you a combination of sustainability, smart technologies, maximum productivity and cost-effectiveness in one complete solution.

This allows existing equipment to reach its full potential.

Overhauls, upgrades, retrofits and much more

It is inevitable that equipment becomes outdated over time but that does not mean it has to be replaced. As the name suggests, existing machines are transformed using affordable complete or partial machine overhauls, retrofits and upgrades. This not only saves the increased capital expenditure of investing in new machines, but also reduces the carbon footprint by avoiding the need for new equipment through the extension of the service life.

A number of retrofits and upgrades

are available which increase versatility and performance, or ensure compliance with more stringent regulations, and so open up a wider spectrum of opportunities. At the same time, operators do not have to get used to new machines and can continue to benefit from their vast experience with existing equipment. The Liebherr team of expert engineers takes care of the entire planning and implementation of Transform projects – from consultation, through to installation and technical support and service.

Stronger, faster, smarter, greener Companies are under pressure to increase volume and performance, widen scopes, or reduce emissions and costs, the list is endless.

Liebherr Transform helps to lighten the load through a comprehensive range of structural, electrical, mechanical, ergonomic or digital modifications. Through the application of new technologies and expertise, Liebherr machines are transformed for the workplace of the future. They are stronger, faster, smarter, greener, and ultimately... better.

Liebherr Africa, +27 (0) 11 365 2000, info.laf@liebherr.com, www.liebherr.com

22 Lifting Africa - Sep/Oct 2022 CRAWLER CRANES

Lifting Africa & LEEASA Forklift Drivers Competition hosted at Electra Mining 2022

Lifting Africa - Sep/Oct 2022 25

Thank you for taking out the time for sponsoring our event, your sponsorship has helped us pull it off with great glory

Setting a new standard for crane cable guides on JIB cranes

Manufactured from engineered polymers the energy chains are mechanical machine elements that guide and protect data and power cables needed to operate the crane. Rather than the cables being exposed and hanging from the festoon system, the energy chains secure the cables within the chain and provide the required movement without damaging the cables.

Stahl Cranes and Hoists Sales Manager Marius Ferreira says the latest crane manufactured and supplied to SEW Eurodrive’s Gauteng factory, is supplied with an energy chain system from igus. Its ease of installation on the crane and lack of rotating moving parts makes for a less complicated system with fewer structural attachments, clamps and weld points.

Abrasion resistant

The 3-ton Monorail system is used in the company’s parts wash bay for the cleaning of equipment from its customer sites around the country. The potential for dirt and ingress is therefore significantly higher than usual applications and the use of abrasion resistant polymers ensures that the cable and energy chain do not wear out. Compared to a trolley system on a festoon there are far few moving parts, no lubrication and the energy chain system is less likely to be damaged by accident as is the case with the older method.

“With the introduction of igus energy chains on our cranes, there

is virtually no reason to return to the old festoon systems. Data gathered from our cranes using energy chains suggest they are considerably more reliable, need almost no maintenance, do not use lubricants and most importantly keep the cables out of harms’ way.

“In conjunction with igus’ Chainflex cables which are specially designed to bend and flex there is no reason why the energy chain and cables should not last the lifetime of the crane with just routine maintenance. Growing demand for igus’ energy chains has led to keener pricing and is considered more cost effective throughout its lifespan,” says Marius.

Engineered polymers

igus managing director, Ian Hewat, says the success of its systems lies in the engineered polymer materials on offer which simply cannot be matched globally. igumid G, a high-performance plastic that possesses a variety of traits for a number of different environments can handle strenuous loads and

extreme temperatures. It is also abrasion-resistant and suitable for outdoor use. A host of other materials are available for even extreme or unusual applications.

“We supply our energy chains for applications as diverse as heavy port cranes, mining machines, industrial machines and even 3D printers and robotics.”

Whatever the size or application we are able to produce energy chains that are fit for purpose and able to outlast and outperform just about everything available in the marketplace today.

“With ongoing research and development at the company’s headquarters in Germany and plants across the globe the company continues to innovate and develop solutions and materials for almost any application,” concludes Ian.

igus South Africa, +27 (0) 11 312 1848, ihewat@igus.net, www.igus.co.za

26 Lifting Africa - Sep/Oct 2022

Trend setting crane manufacturer, Stahl Cranes and Hoists in Vereeniging, is shifting its Jib crane cable management systems from the old system of festoons and pulleys to reliable and snag-free energy chain systems from specialist supplier, igus.

JIB CRANES

EQUIPMENT THAT DOES IT ALL | GROUND-BREAKING | | EXCAVATING | | COMPACTING | | CRUSHING | | SCREENING | | LIFTING | | HANDLING | sales@kemach.co.za Head Office: 011 826 6710 Contact us: www.kemach.co.za

Magni at the service of Complexe Atlantide

Complexe Atlantide is a water park that opened in 2013 in SaintCalixte, Quebec. The owners, Tommy Gagnon and Alain Turcotte, wanted to create a family oriented site of fun and entertainment with attractions and shows. Complexe Atlantide’s mission is to offer quality recreational experiences, relying on a family atmosphere, respect for customers and diversity, quality of services and a highly passionate and professional team.

Over the years, the owners have invested heavily in increasing the number of activities available. To date, the site includes wave pools, water slides, zoos, animal refuge,

magic castles, labyrinth, gyms and nature trails. As a 2022 novelty, a new swimming pool and a structure consisting of two slides were added, one for the bravest and one for the youngest.

Offering a lifting height of 35 metres and a capacity of 6 tonnes, an RTH 6.35 was used to assemble the whole structure. This model was crucial to the realisation of the project.

Besides building the load-bearing structure, it allowed to handle and positioning of the slides and tubes.

The RTH 6.35 was supplied by our local authorised dealer Cropac

Equipment Inc. Covering the highest number of provinces, the company is the largest dealer of Magni in Canada. They offer a wide range of solutions for the sale and rental of lifting equipment, including Magni’s ranges of rotating and fixed telehandlers. Cropac Equipment Inc deal in transportation, forestry, steel processing, rigging, heavy materials movement and marina storage. With highly qualified staff, sales and technical support teams, the company listens to its customers’ needs and satisfies them in the best possible way. They also provide specialised technical assistance and spare parts service.

The 6 tons winch was the key attachment for this specific type of job. Consisting of a swivelling type-approved hook equipped with a rope pressure roller and hydraulic limit switch system for rope raising/ lowering, it allows handling heavy loads with the utmost precision.

We wish to thank the park owners for choosing us as their lifting partner and Cropac Equipment Inc for supplying the machine to the customer.

Magni SA, +27 (0) 11 383 2227, info@magnisa.co.za, www.magnisa.co.za

28 Lifting Africa - Sep/Oct 2022 HEAVY LOAD

As a 2022 novelty Complexe Atlantide has decided to build an impressive new water slide. The park chose Magni to handle and assemble the structure.

• Econo Flex was Established in 1993 • We started out as a hose and fittings company which grew to repairs and maintenance on all hydraulic and pneumatic equipment, as well as specialised tools. • We are also an authorised Enerpac Importer and Repair Centre • In 2001 our staff went on their first lifting tackle course with the OEM’s. • We received our LME number in March 2010 • In 2018 we went into a joint venture with a motor rewinding company, which has since then been a large part of our business. • Currently we have 5 lifting maintenance and repair contracts which includes the entire lifting scope, as well as 4 tool supply contracts which includes everything from pliers to pumps Head Office : Vanderbijlpark Shop D3, Turbo Industrial Park, Cnr of Golden Highway and Rautenbach Str. Vdb Middelburg: 6 Tandjiesberg Street, Aerorand Secunda: 2127 Erasmus Street, Secunda - Hartebeespoort: 40 Baldwin Street, Schoemansville Somerset West: 22 Kirkia Street, Heldervue - George: 1 Iris Ave, George Pretoria: 185 Van Eden Crescent, Rosslyn - Lephalale: Plaas Uiterste LG 475, Lephalale Tel: +27 (0) 16 933 5705 | Email: econoflex@econoflex.co.za | Web: www.econoflex.co.za

Heavy-duty electric Kito hoists ensure safe and stable operation year after year

“This robust hoist replaced an existing hoist that continued to break down. The Kito hoist offers

reliable service during the change out of skips and cages which operate in this shaft,” explains Rick Jacobs, Senior General Manager (SGM) for Consumables, Becker Mining South Africa. “Adherence to the strictest safety standards is critical in every aspect of a mining operation, which is why the investment in dependable, industryapproved equipment is essential. This durable lifting equipment has exceeded our customer’s expectations in terms of durability, performance, cost of ownership and reliability.”

Kito ER electric hoists boast important design and performance features, including an ED duty rating of 60 % - the highest in its class of equipment – a compact Aluminium die-cast body that is structurally strong and an IP 55 rated enclosure that offers protection against dust and water.

A double safety mechanism, consisting of a friction clutch and an upper-lower limit switch, enhances safety and prevents hoist damage.

The electromagnetic brake delivers strong braking power, while holding the load securely.For reliable and safe operation, a standard thermal protector prevents the motor from burning out due to excessive usage. An emergency stop button is standard to allow the motor power to be disconnected in an emergency, without disrupting the main power supply. The dual speed inverter of Kito ER electric chain hoists improves efficiency and ensures easy operation, precise positioning and minimal downtime during installation and maintenance procedures. “

“This design also reduces load swing and ensures smoother movement than a conventional pole change motor. The high to low-speed ratio can be adjusted for even starts, improved low speed stops and accurate positioning.”

Also in Becker Mining’s Kito range are manual chain hoists with a solid construction for durability and ball bearings that increase mechanical efficiency and ensure minimal effort

30 Lifting Africa - Sep/Oct 2022 HOISTS

Becker Mining South Africa’s heavy-duty 10 T Kito electric hoist, which was installed in the head frame of a shaft at a platinum mine in 2014, continues to offer safe and dependable operation in harsh conditions, seven years later.

is required for smooth and safe operation. High strength, nickel plated load chain for all Kito hoists increases resistance to wear and corrosion. Top and bottom hooks are equipped with a hook latch and the bottom hook swivels 360 degrees to prevent kinking and twisting of the load chain.

Kito trolleys are available as motorised, plain and geared, to provide smooth, precise and easy traversing and positioning.

The extensive range of Kito electric chain and manual hoists, which meets stringent quality and safety specifications, is available exclusively in southern Africa from Becker Mining SA and a network of carefully selected distributors.

These hoists have been designed for dependable use in materials handling applications in diverse industries, including mining, construction, shipbuilding, food, beverage and pharmaceutical processing, manufacturing and general industry, as well as in chemical and petrochemical plants and the wind power sector.

To ensure hoists are in pristine condition and operate safely and efficiently, it is critical they are tested regularly at Becker Mining SA’s workshops, or at any certified repair centre. The company offers a technical advisory and support service throughout the country.

Becker Mining SA,

www.za-becker-mining.com

Lifting Africa - Sep/Oct 2022 31 HOISTS

+27 (0) 11 617 6300, info@za.becker-mining.com,

JLG’s legacy: a pioneering spirit that drives productive, safe work at height

Through customer-inspired innovation and the exploration of new technologies, our innovation strategy is advancing the access industry on job sites around the world.

And we do it all with people in mind, creating solutions that protect, elevate and empower our customers to do their jobs.

Here’s a little bit more about how we continue to build on our founder’s legacy — one that’s centered around a constant desire to keep people safe.

Safety from the beginning

JLG’s attitude toward safety goes back to its roots when the company’s founder, John L. Grove, witnessed human tragedy during the building of the Hoover Dam and thought, “There has to be a better way.” That tragic incident led to many sketches until Grove came up with the boom lift concept.

Over the years, we expanded the original single model boom lift into a full line of articulating and straight-mast (i.e. telescopic) boom lifts and added scissor lifts and telehandlers to our product portfolio. While these are not our only product lines, they are our core product lines.

The innovative spirit of John L.

Grove is alive and strong today across the company. We still focus on finding a better way.

This focus has three key areas in terms of innovation:

1. We look at safety; 2. We look at productivity; 3. And, we look at technology.

Those three things help us continue to elevate the access industry and bring products to market that give customers tangible benefits on the job site.

How do we do that? Our engineers visit a lot of job sites, and we do a lot of observation and say, “That looks like it’s difficult for that person to do. How could we do that better? How could we integrate something into our product to make that job easier for them?”

We call it customer-inspired innovation.

Customer-centric mindset

JLG can offer that by its extensive use of customer feedback.

When we’re developing a product,

we take prototypes out into the field and ask customers for feedback — What do you like about it? What do you not like about it? What would make this have greater value? Is this something that would be of value to your business?

We take that feedback and then we modify and do rapid prototyping throughout the product development life cycle.

50 Years and counting

JLG celebrated its 50th anniversary in January 2019, marking a halfcentury since Grove spearheaded the access industry with the introduction of the JLG 1 — the world’s first boom lift.

With this innovation, Grove not only started a company but an entire industry. This is a key point of differentiation for the JLG brand: We continue to build on this legacy through the continuous development of products, services and technology that advance safety for work at height.

Since it introduced the first commercially produced aerial work

32 Lifting Africa - Sep/Oct 2022

TELESCOPIC HANDLERS

platform, JLG has claimed many access industry firsts, including:

• Oscillating axles for boom and scissor lifts in 1981

• The only fuel-cell powered boom lift in 1999

• The first environmentally-friendly 60-ft electric boom lift in 2000

• The first straight boom lift to reach 150-ft in 2011

• The company surpassed its record in 2014 with the introduction of the 185-ft model 1850SJ, the world’s tallest self-propelled boom lift

• In the same year, JLG introduced the first true hybrid diesel/electric boom lift, the H340AJ

John L. Grove was a skilled inventor, a savvy businessman, and an extremely hard-working individual who was driven by the pursuit of perfection in the products that bear his initials.

A former employee once said, ‘You could show John L. Grove anything, even a fountain pen, and he could immediately tell you how to improve it.’ Grove formed JLG with three investing partners, and

in a few short years, the company had developed a product that filled a huge void in the construction industry.

Today, JLG is represented across five continents with manufacturing facilities in the United States, France, the U.K., Australia and China. As the world’s leading designer and manufacturer of access equipment, JLG products and personnel can be found all over the world, going above and beyond to support customers. We deliver

the powerful, versatile equipment they need, along with unsurpassed training and service, because we have a responsibility to be more than a manufacturing company. We’re a partner in our customers’ success, reaching out worldwide to enable performance, boost productivity, ensure uptime and support forward progress.

Eazi Access, +27 (0) 87 086 4900, info@eazi.co.za, www.eazi.co.za

Lifting Africa - Sep/Oct 2022 33

TELESCOPIC HANDLERS DEMAC S.R.L. | MAGENTA (MI) - ITALY | +39 02 9784488 | INFO@DEMAC.IT | WWW.DEMAC.IT Management system certified in accordance with the requirements of ISO 9001 - ISO 14001 - OHSAS 18001 WAKE UP! GET BACK TO REALITY Dreams are not reel, it can be real. Pad A3 - Stand 509 24-30 Ottobre 2022 Pad 15 Stand C35 9-13 Novembre 2022

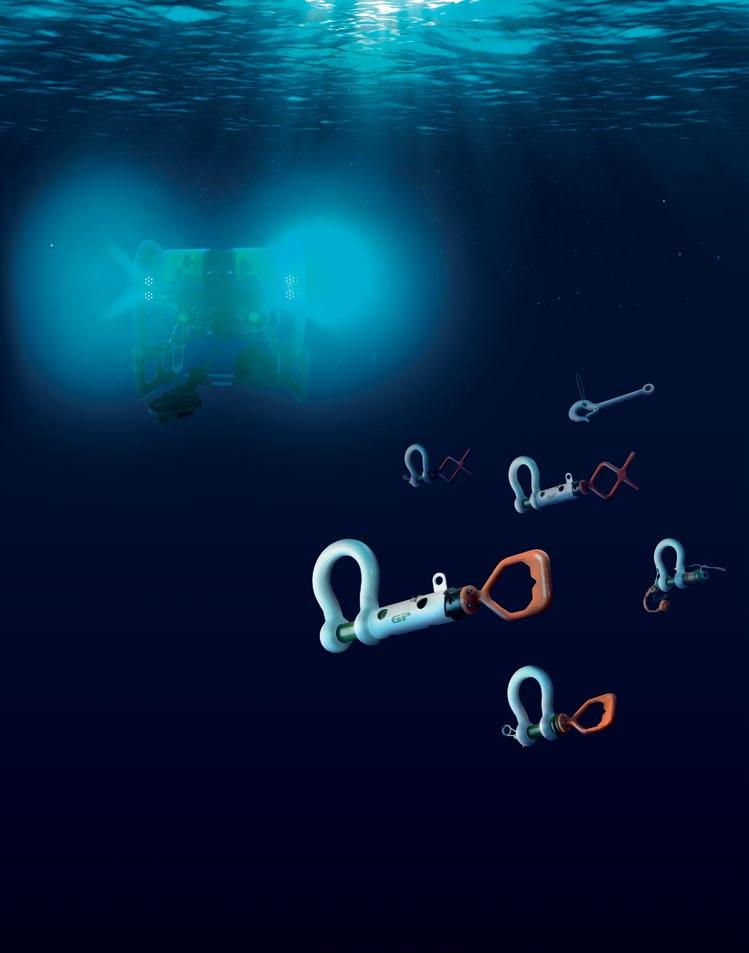

What is below surface must be above standard

If ever durable products were required, it is probably most visible in the fishing and aquaculture industries. Equipment is constantly exposed to water, salt and different temperatures.

For aquaculture, cages need to be secured under water reliably for longer periods of time to safeguard large investments. Your underwater cages and mooring systems therefore need shackles, bolts and other mooring accessories that are below surface, but above standard. That is why the Green Pin® aquaculture products are the top choice for fish farmers.

Green Pin® Mooring Bow Shackle NS9415 BN

Grade 8 mooring bow shackle with safety bolt and sunken bolt head

The Green Pin® Mooring Bow Shackle NS9415 BN is a bow shackle with a safety bolt and a sunken bolt head that has been designed for mooring applications.

The shackle offers a double safety (safety bolt and synthetic cotter pin) which prevents accidental unscrewing of the pin. The sunken

bolt prevents rotation of the bolt, making it much easier to assemble. It also minimizes the risk of damage to the cage net or mooring line.

The wider shackle mouth enables you to connect the shackle to a mooring or connecting plate which is wider than usual. The shackle offers best-in-class quality, guaranteeing absolute security for your mooring system. The hot dipped galvanization ensures long-term durability even under severe environmental conditions, as required by the NS 9415 standard and in compliance with NYTEKregulation (as certified by DNV).

The Mooring Bow Shackle NS9415 BN is suitable for both one-leg and multi-leg systems and is available in a range of minimum breaking load from 30 up to 150 t.

Highlights

• Ideal for aquaculture: DNV-

certified to NS 9415

• Fast and easy (dis)assembly due to the sunken bolt

• Wide shackle mouth: perfect for wide connecting points

• Hot dip galvanization assures long-term durability

• Part of Green Pin® aquaculture system

Green Pin® Bow Shackle NS9415

BN

Standard bow shackle with safety bolt acc. to NS 9415

The Green Pin® Bow Shackle BN is a bow shackle with a safety bolt. The shackle offers a double safety (split pin and safety bolt) which prevents accidental unscrewing of the pin. The shackle's hot dipped galvanization ensures long-term durability as required by the NS 9415 standard, in compliance with NYTEK regulation.

Green Pin® Bow Shackle NS9415

BN is suitable for both one-leg and multi-leg systems and is available in a range with a working load limit from 2 up to 25 t.

Highlights

• Ideal for aquaculture: DNVcertified to NS 9415

• Hot dip galvanization assures long-term durability

• Double safety (cotter pin & safety bolt)

• Suitable for both one-leg and multi-leg systems

• Part of Green Pin® aquaculture

34 Lifting Africa - Sep/Oct 2022

PRODUCTS & SERVICES

system

Green Pin® Master Link NS9415 GR8

Grade 8 master link acc. to NS 9415

The Green Pin® Master Link NS9415 GR8, is a grade 8 master link. The Master Link is certified according to DNV NS 9415 and has a large opening to accommodate larger connecting links. The hot dipped galvanization ensures long-term durability even under severe environmental conditions, as required by the NS 9415 standard. This master link is designed for a one- or two-leg sling. The master links are available in a range with a minimum breaking load from 32.8 to 112.4 t.

Highlights

• Ideal for aquaculture: DNVcertified to NS 9415

• Hot dip galvanization assures long-term durability

• Large opening to fit larger connecting links

• Part of Green Pin® aquaculture system

• Reliable Green Pin® quality and support

Green Pin® Mooring Bolt NS9415 T Bolt with T-shaped end-fitting

The Green Pin® Mooring Bolt NS9415 T is a grade 8 mooring bolt with a T-shaped end fitting that provides best-in-class quality, guaranteeing absolute security for

your mooring system. The mooring bolt's hot dipped galvanization ensures long-term durability as required by the NS 9415 standard. The mounting depth is indicated by the green colour, which makes the installation of the product much easier and the special type of thread will result in a better fixation of the bolt.

What's more, the mooring bolt NS9415 is certified by DNV in compliance with NYTEK regulation and NS 9415.

It is available in a range of minimum breaking load from 40 up to 170 tons.

Highlights

• DNV-certified to NS 9415

• Hot dip galvanization assures long-term durability

• Better fixation due to special type of thread

• Part of Green Pin® aquaculture system

Green Pin® Dee Shackle NS9415 FP

Dee shackle with square sunken hole screw pin (flush) and double safety plug

The Green Pin® Dee Shackle NS9415 FP is a dee shackle with a square sunken hole screw pin (flush pin) which provides best-in-class quality, guaranteeing absolute security for your mooring system. The Green Pin® Dee Shackle NS9415 FP is an exemplary shackle in this product

line. Its square, sunken hole screw pin combined with a safety plug makes it a double safety product that is easy to assemble and disassemble with the Green Pin® Sunken Hole Key. The shackle's hot dipped galvanization ensures longterm durability as required by the NS 9415 standard.

Testifying to its superior record when it comes to mooring safety, the 40.000 cycle fatigue rating is twice that required by NS 9415 and unparalleled in the market. What is more, the safety factor leads the industry with an MBL of seven times the WLL. The The Green Pin® Dee Shackle NS9415 FP is certified by DNV on compliancy with NYTEK regulation and NS 9415. It is suitable for one-leg mooring systems only, and is available in a range of working load limits from 2 up to 8.5 ton.

Highlights

• Double safety according to NS 9415

• Industry-leading safety factor of 7 x WLL

• Superior mooring security: 40.000 cycle fatigue rating

• Hot dip galvanization assures long-term durability

• Fast and easy (dis)assembly

Green Pin, sales@greenpin.com, www.greenpin.com

Lifting Africa - Sep/Oct 2022 35

PRODUCTS & SERVICES ISO 9001/2015 Accredited Company Hydraulics: Design, manufacture and repair of cylinders, power packs and systems. Suppliers of pumps, valves, accessories, hoses and fi�ngs. Arc furnace equipment: Design, manufacture and repair of clay guns, furnace drills, clay/drill combo, skimmer hoists, electrode clamping systems and rod gates. Design, manufacture and repair of Opencast charging trucks and underground charging units. Site services: Pipe installa�ons, hydraulic installa�ons, lubrica�on installa�ons, general mechanical installa�ons, electric / electronic installa�ons. Electric / Electronic: PLC integra�on, Scadadevelopment, panel design and building. Engineering: Boiler making, machining, gearbox repairs, water pump repairs and general mechanical repair. Load Test: Truck mounted cranes etc. Registered LME: 294

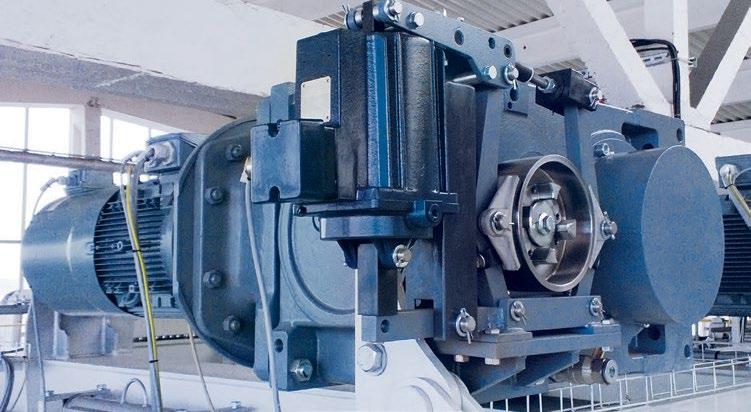

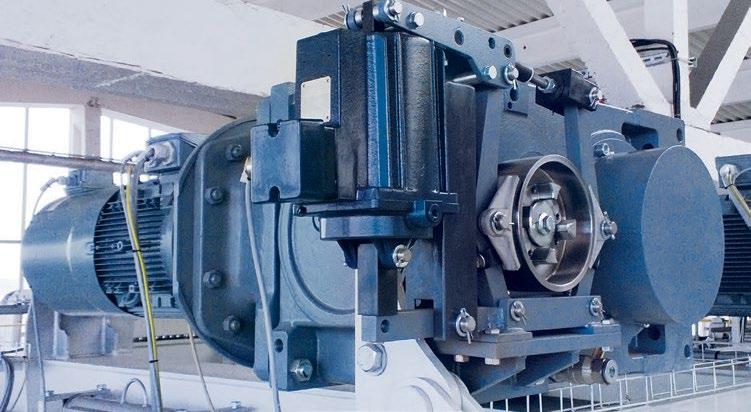

Industrial gear units for lifting drives in mining

“Lifting applications place great demands on limited installation space for drives. NORD MAXXDRIVE® XD industrial gear units have been designed by NORD DRIVESYSTEMS, with an increased centre distance that is ideally suited to the U-shaped configuration of the drive, motor and cable drum, used in lifting equipment in all kinds of cranes,” states Deon Crous, National Sales Manager – Gears, for BMG’s Electromechanical division. “With the launch of these new industrial gearboxes, BMG is able to offer the mining sector a complete package of running gear and lifting gear drives for cranes from a single source.

“The housing of the MAXXDRIVE XD gear units has been specially designed for lifting applications and optimised for downward loads. The elongated arrangement of gear stages also enables a mechanical tailor-made dimensioning of the gear unit with sufficient centre distance – thereby avoiding an overdimensioning.”

BMG offers this range in five sizes, with centre distances between 509 and 963 millimetres and in versions with three or four gear stages that have identical housing dimensions and centre distances. This feature enables customers to standardise and reduce versions for the construction of cranes. In addition, the MAXXDRIVE XD covers a wide speed range, with a maximum nominal gear ratio of i = 355. The constant torque across the whole speed ratio guarantees high efficiency while in use.

Standard components from BMG’s NORD range of industrial gear units are compatible with MAXXDRIVE XD. This ensures customers have a wide choice of options and are guaranteed a short delivery time. The grey cast iron (GJL) or nodular cast iron (GJS) housing is available with an inspection cover, enabling a visual check of internal components, without having to remove the gear

unit. Apart from use in the mining sector, MAXXDRIVE XD industrial gear units are suitable for ports, logistics and shipyards, in metal, chemical and paper facilities and for bulk goods trans-shipment.

Getriebebau NORD – a leading global manufacturer of drive technology for mechanical and electronic solutions - is represented exclusively in southern Africa, by BMG.

BMG’s electromechanical teamwhich is committed to ensuring every mine and plant operates efficiently and safely - works in close partnership with NORD DRIVESYSTEMS, to offer ongoing supply and support of a wide range of engineering components.

BMG’s team of technicians supports the NORD range with a technical advisory and support service, which is tailored to meet the precise specifications of contractors, designers and the end-user.

Local assembly at BMG World in Johannesburg, enables prompt delivery of drive systems and the quick availability of spare parts.

BMG’s Electromechanical division, +27 (0) 21 493 3250, deonc@bmgworld.net, www.bmgworld.net

36 Lifting Africa - Sep/Oct 2022

PRODUCTS & SERVICES

BMG has launched a new range of NORD

MAXXDRIVE®-XD

industrial gear units, designed to enhance the efficiency of lifting gear used in many industries, including the mining sector.

The maximum on eight axles.

The LTM 1650-8.1

A

lifting capacity of 700 tonnes with either a 54 or 80 metre telescopic boom. Global mobility and convenience thanks to Hillstart Aid, ECOmode, ECOdrive, VarioBase and hydraulic VarioBallast. Nothing more is possible on eight axles. www.liebherr.com

Mobile and crawler cranes

A business goes from smooth operations to an emptied bank account

SARS reviews old VAT returns, rejects all input VAT and demands millions. The business is on the brink of collapse when Cornerstone comes to the rescue.

In 2017 an enterprising young business was formed and quickly found growth and success within its community over the subsequent years. Common to young businesses the owner – and manager – did not have any familiarity with SARS, tax, or general principles.

Through a recommendation from a mutual friend, the owner found a company that offered to handle all the administrative and tedious requirements of tax compliance for the business.

As the business was still young and growing at the time, this third party negotiated to handle the tax compliance in exchange for a percentage of any VAT refunds that the company received as a result of its efforts.

As a result of unfortunate negligence, the business owner agreed to the negotiation, thus allowing the third party to load their contact details with SARS as if they were the business.

This way, any notifications or correspondence from SARS would go directly to the third party without the appropriate business owner being alerted.

With this arrangement in place, the business continued with its operations and trusted the third party to

handle all tax-related matters. The business had consistent growth, money was coming in, and life appeared to be good and bountiful.

The truth of the matter was that tax compliance was not actually going well. The third party had negotiated to be paid a percentage of all refunds, and as such, they were heavily incentivised to maximise refunds whenever possible.

Eventually, SARS noticed something strange going on with this growing business. SARS conducted an investigation and concluded that this growing business had a suspicious pattern of refunds, and that their VAT submissions of their years were littered with fraudulent errors.

As a result, SARS raised additional assessments on almost all the returns submitted in the past, denied all the input VAT, and demanded immediate payment for all the output VAT.

With all correspondence set up to go directly to the hired third party, the relevant business owner did not know the demands made by SARS.

The business owner was only alerted after the fraudulent third party failed to resolve the matter themselves. These alerts came a little too late, as the

38 Lifting Africa - Sep/Oct 2022 INDUSTRY NEWS

business owner was unable to timeously respond to the additional assessments raised by SARS.

SARS, becoming impatient with the business that seemed to be ignoring demand after demand, saw that the bank account of the business seemed to be slowly declining over time.

While this ebb and flow of the bank balance is a regular occurrence in business, SARS assumed the worst and decided to take what money they could before it disappeared. With an instruction to the bank, the business bank account was forcibly emptied and all funds were deposited to SARS.

The owner of the business, fortunately, had additional capital set aside and used this to seek out the services of a more reputable tax practitioner to help find a way forward. The newly appointed tax practitioner for the business was of course Cornerstone Tax and Accounting Services.

Using bank statements, slips, and various contacts Cornerstone has been able to arrange a more amicable situation with SARS, allowing the correction of the old VAT returns and the denied input VAT.

The business does still owe money to SARS as they were, strictly speaking, never supposed to receive any refunds. The money owed to SARS has however at least been reduced by an order of magnitude.

While the owner is not exactly happy that they will not be getting back the money that SARS emptied from their business account – in addition to the money still owed to SARS – they have at least learned the importance of having some involvement in their tax affairs and having a reputable practitioner guiding them along the way. How can Cornerstone help you?

Cornerstone Financial Services Group, marketing@cornerstonefsg.co.za, www.cornerstonefsg.co.za

Cornerstone Financial Services Group, marketing@cornerstonefsg.co.za, www.cornerstonefsg.co.za

INDUSTRY NEWS

Why is the cold chain logistics still stuck with old technology?

Savings to increase the bottom line, which everyone is desperate for these days, are all around us. The simplest way to find them is to evaluate a facility – starting with their operations which is a particular point we see at many sites that have the potential for improvement.

As my first column in Cold Link Africa, I thought it would be appropriate to start off by addressing this subject that is highly relevant as the sector is in a strong growth phase but to top that, a lot of storage stock systems have reached their end of life term and it’s time for system replacements and upgrades.

There are certainly several reasons for the mindset of facility owners and managers in regard to ‘Evasion of Technology Adoption’, and If I had to talk honestly, the majority of businesses in the local environment have this view. I like to think about it that we don’t need to continue to ‘Trade like a Third World Country’ because we already have access to great advances made in Europe here and available now to all Facilities in Africa.

One of the major factors that we see in logistics and storage solution designs is the fact that decision makers are just not aware or familiar with what is actually available as a solution, and what is already adopted widespread in other countries around the world. They may have seen a Video or heard about the Technology, but have not actively embraced the thought of investigating the Technology and understanding how these advanced Systems in Cold Storage Technology will set them

apart from their Competitors. In many cases, it is due to the fact that they may be very focused on the day to day, and no one has provided them with the understanding of how this will change their business short, medium and long term.

Coupled to that lack of knowledge for a roll out of technology in this country is the disadvantage that there are very few companies that can design and deliver any specialised and integrated handling and storage systems. Limited experience or exposure to international trends and technology of course means an equal result in the solutions that engineers can provide - even if they can conceptualise a great idea – there are a lot of intricacies involved other than just the storage of goods.

So, the typical situation for local projects is that because of these two factors there is a total disconnect between clients and service providers, and the proposal process is turned on its head. The various pitches from suppliers cater to their individual thoughts on a solution rather than the client specifying exactly what they want, and then each supplier proposing appropriate technology related to their ability what they can offer as their company scope and offering, omitting the true Client Centricity approach.

If it is a Logistics Consultant, and not an Expert Storage System Engineering Firm, or Storage Solutions Engineering Expert, and the reality is that in many cases, the DCs all look like the same Cookie Press Solution of a Competitor they have done, which Add no Value to the Customer seeking advancement in Technology.

In my follow up Columns and Contribution, I will explain this resistance to change by Logistics Consultants, Customers in a larger context to ensure the mould can be broken, and SA can gain greater efficiency in Warehouse and Cold Chain Storage Technology, and not play leapfrog to their Competitors. The major reason is that the Consultants in many cases play it “save”, and design what they themselves are familiar with due to them attempting and in some cases rightfully protecting their own Reputation, but regretfully and without a doubt, this means they are not giving the Customer and User the advantaged of Technological Advancements made in the Intralogistics Equipment Sector made daily, which they need to be more efficient, safer, faster, and have a better OPEX than any of their Competitors.

When this happens, the inevitable is that the client doesn’t get what they

40 Lifting Africa - Sep/Oct 2022

PRODUCTS & SERVICES

want - or indeed need as they are now informed about what they need - and automation and technology get a ‘bad name’ as we have seen, even within our borders as many white elephants are installed that the designer and supplier just supplied what they had, impressing Customers and End-Users with that what they have available, and at the time of the Roll Out, Customer’s true needs and true bottom-line savings are not understood and addressed.