official magazine for LEEASA (Lifting Equipment Engineering

of SA) NOV/DEC 2022 Automatic cranes characteristics and advantages New Electric Range REDUCE YOUR EMISSIONS, RAISE YOUR STANDARDS.

The

Association

Manitou launches new machines at bauma 2022 4

Chairman’s Desk 6

2022 LEEASA Individual Members & Company Members

in Good Standing 8

Expanding into new terrains 10

XCA 2600, world’s strongest all-terrain crane developed by XCMG, sets new wind power hoisting record 12

Automatic cranes characteristics and advantages 14

Testing the load: Modulift spreader beams perform huge 2420mt load test 16

With pioneering solutions at bauma 2022 18

The new Tadano AC 4.070-2 all terrain crane 20

Raimondi Cranes presents three new products at bauma 2022 22

New legislation pertaining to retirement funds 24

Becker Mining SA launches the new range of Kito RX wire rope hoists 26

Taking a big picture approach to forklift costs 28

World’s most advanced diamond recovery vessel 30 How does a telehandler work? 32

Can a rotating telehandler replace a crane? 34

Danfoss technology powering new fully electric crawler crane 36

5 Ways automated container weighing systems can be integrated into a terminal port? 38

Condra Acquires Itek Drives 40

GEDA celebrates a special anniversary 42

Manitou Group, +27 (0) 10 601 3000, info.msa@manitou-group.com, www.manitou.com

Lifting Africa

Managing Editor: Surita Marx Cell: +27 (0) 83 281-5761 Email: surita@liftingafrica.co.za Web: www.liftingafrica.co.za Sales: Lusana Merckel Email: lusana@liftingafrica.co.za Sales Assistant: Jaen-Dre Saunders Email: sales@liftingafrica.co.za Production Manager: Xane Roestroff Sub-Editor: Wian De Beer

Advertisers

publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication.

Lifting Africa - Nov/Dec 2022 3 Contents

Disclaimer:

Opinions

in

this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers LEEASA. The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the

BUYERS GUIDE 44

Bell Equipment 13 Combilift 11, 29 ConExpo IBC Cooper & Cooper Group 27 Demac 23 Giovenzana IFC J Express 15 Johnson Crane Hire 41 Liebherr Africa 37 Lifting Africa 39 Lifting Placements 46 Manitou OFC, OBC Palfinger 21 Phakamisa Safety & Consultants 7 Van Beest 17 Yale 43

Manitou launches new machines at bauma 2022

The Manitou Group, manufacturers of a range of handling vehicles, aerial lift platforms and earthmoving equipment, used the world’s largest trade event in Munich to showcase and present a record number of new products. Lifting Africa was there.

It was to a fundamentally different world that bauma 2022 welcomed more than 495 000 visitors from over 200 countries in Munich earlier this year. Considered the world’s leading trade fair for the construction, building materials and mining machinery industries, the first bauma post-Covid, however, proved to be as big a drawcard for companies wanting to showcase their new products as ever before thanks to its ability to provide the international industry with a common platform for profitable innovations, cross-border exchange and farreaching perspectives.

With 3200 exhibitors from 60 different countries exhibiting, Manitou Group was one of the companies that stood out thanks to its range of new products available. This included four new aerial work platforms, two rotating telehandlers and a fixed telehandler. The range of mid-height telehandlers also welcomed four new models.

According to Manitou Group, it has made a lot of improvements to its machines. It has also introduced its first electric compact telehandler and first electric highrise rotating telehandler. These many new products said Chief Executive Officer, Michel Denis all reinforce the group in its growth and demonstrate the commitment to the energy transition.

In the third quarter of this year, Manitou Group also announced a 33% increase in revenue compared to the same period in 2021. “This is the result of our ability to accelerate our deliveries in a supply chain context that remains tense and uncertain,” said Denis. “Our teams are fully mobilized to respond to the pressing expectations of customers in markets that show no signs of slowing down. The increase in our order book and inflation are pushing customers to anticipate their orders to secure their future supplies. Given the depth of our order book, the implemented sales price

COVER STORY 4 Lifting Africa - Nov-Dec 2022

increases will have full effect only after 2022.”

Committed to the energy transition

At bauma, Manitou Group took the opportunity to showcase its numerous low-emission products under its OXYGEN label. The group has been committed to offering its users not only more profitable and easy-touse solutions but also machines that are greener and assisting in the energy transition. It was also at bauma that Manitou Group launched its new electric platform range. With four new platform models, the group is accelerating the roll-out of its OXYGEN low emissions range. The 200 ATJe roughterrain platform with a working height of 20 meters was one of the machines on show. Available with a fourwheel steer for greater manoeuvrability and a basket that cannot take 250kg of load, 30kg more than on the twp-wheel drive, it t was the total cost of ownership (TCO) that impressed visitors to the trade show. Manitou has reduced TCO by an almost 50% decrease in maintenance costs compared to the internal combustion version.

The range of rough-terrain electric telehandlers also saw two models, 160 ATJe and 180 ATJe, launched. With a working height of 16 meters and 18 meters respectively, these platforms’ capacity has been increased by 50 kg for a basket that can take a total weight of 250 kg. There is also a second version named 160 ATJ+ e, with a capacity significantly increased to 400 kg. A range extender solution is also presented in the form of a removable generator common to all the machines, allowing for a week of autonomy. The first delivery of these machines is expected in the second quarter of 2023.

Safety first Presenters at bauma showcased the company’s Safety Pack indicating that safety was at the heart of the company’s manufacturing policy. These packs are designed to protect operators and site teams and include several innovations. Fitted with an alert system, operators are, for example, made aware immediately if they are driving over uneven ground or if harnesses are not being worn. Any obstacles around the machine’s chassis are also immediately detected. The system is so advanced that it has an inbuilt escalation process that can even send messages to fleet managers should it detect any high-risk behaviours.

An added benefit is the “lighting pack” that ensures the utmost safety for platform loading and unloading operations thanks to several lights that have been positioned on the platform allowing the operator to not only see but also be seen.

“With all these new products, Manitou Group is the first manufacturer to have a range of 100% electric rough-terrain platforms from 16 meters to 20 meters. The acceleration of our electric development allows us to now offer low-emission solutions across our

platform ranges, as well as on our telehandlers. We will continue to extend this energy to other ranges by the objectives of our CSR roadmap,” said Arnaud Boyer, VP of Marketing & Product Development.

Also on show

Other products launched at bauma included the new version of the 120 AETJ platforms. This model has been entirely redesigned. The MT 625e electric telehandler was also showcased and is Manitou’s first 100% electric compact telehandler. The MT 625e, with a capacity of 2.5tons and a height of 6 meters, guarantees performance as good as the internal combustion version and is the same size. It is fitted with a 25 or 33kWh lithium-ion battery and reduces maintenance by 56%.

The Group also presented an electric version of the rotating telehandler models MRT 2260e and MRT 2660e and launched four new mid-height telehandlers with between 7 meters and 13 meters of lifting height for a lifting capacity of 3.5 tons, namely MT 735, MT 935, MT 1135 and MT 1335. Another offering was the new ultra-compact Ultra Light Manitou telehandler that has a transportable weight of fewer than 3 tons.

Manitou Group, +27 (0) 10 601 3000, info.msa@manitou-group.com, www.manitou.com

COVER STORY Lifting Africa - Nov-Dec 2022 5

From the Chairman’s Desk

Who would have thought that by the time you are reading this that it is already December 2022? Time has flown by, and the current board has officially been in term for two years now and we are pleased with the way the association is headed and in what we have achieved so far. We would like to thank all the members that attended the AGM held on 16th November at ERPM

Golf Club (and online) and that participated in the election of the new board members.

Your commitment to LEEASA is key to its success.

I have been elected as Chairperson for my final consecutive term and in two years’ time I will be handing over the reins to a new Chairperson and be taking a seat as an ordinary

board member.

I would like to congratulate Andries Agenbag being appointed as Vice Chairperson as his second term on the board as well as the other board members on their election.

Below I would like to introduce the talented and united team that aims to make LEEASA the Top Lifting Association in South Africa.

6 Lifting Africa - Nov/Dec 2022

CHAIRMAN’S DESK

In January / February 2023 we will announce the roles and responsibilities of each board member and our strategic initiatives going forwards.

We will also release a yearly planner of all proposed conferences, CPD courses, council meetings etc, as well as other important dates to diarise.

We are also please to announce that we have been awarded our service provide status by ECSA and are now fully equipped to offer our own CPD accredited seminars, courses and training going forwards.

ECSA CPD Service Provider: SP_034/2025 - Expiry 11 October 2025

We do not want to let too much out the bag yet, but in closing we hope you are looking forwards to the exciting new developments and LEEASA’s benefits to come.

Cheers to 2022 - Have a safe and joyful festive season, and we hope

to see you all return safely in the new year.

Feel free to reach out to the council members if the need requires.

Chairman: Ashley Davis | ashley@leeasa.co.za

Vice Chair: Andries Agenbag | andries@leeasa. co.za

Treasurer: Surita Marx | surita@leeasa.co.za

Ordinary Members: Kyle Graham | kyle@leeasa.co.za

Francois Blignaut | francois@leeasa.co.za

Sandra Hurlimann | sandra@leeasa.co.za

Francois Weideman | francoisw@leeasa.co.za

Yours in SAFE LIFTING, Ashley Davis and the rest of the LEEASA team

Lifting Africa - Nov/Dec 2022 7

ENGINEERING COUNCIL OF SOUTH AFRICA 11 October 2022 Lifting Equipment Engineering Association of South Africa Primary email address: admin@leeasa.co.za Secondary email address: ashley@leeasa.co.za Dear Sir/Madam, RE: VERIFICATION AS AN ECSA CPD SERVICE PROVIDER With reference to the Lifting Equipment Engineering Association of South Africa application for verification as an ECSA CPD Service Provider. The Engineering Council of South Africa (ECSA) is pleased to inform you that your application to be verified as a Continuing Professional Development (CPD) Service Provider has been successful. The verification of LEEASA as an ECSA CPD Verified CPD Service Provider is in line with the prescribed Rules on Continuing Professional Development (Board Notice 86 of 2017) and the Standard for Continuing Professional Development (ECPD-01STA). As an ECSA CPD Service Provider, the organisation is required to acquaint itself with all the provisions of the enclosed CPD Rules and the Standard for Continuing Professional Development, which will, during the time of the organisation’s verification, be applicable In accordance with the Standard the organisation is entitled to use the title "ECSA CPD Service Provider and should display the verification at its Head Office and/or on its website. Please take note of the organisation’s unique service provider number below. ECSA CPD Service Provide Number: SP_034/2025 The verification is valid for a period of three (3) years as of the date of this communication after which it must be renewed upon the expiry thereof. The renewal process entails a CHAIRMAN’S DESK

2022 LEEASA Individual Members in Good Standing

Aaldrik Graham Kiewiet

Alan Victor Botha

Albert Olof

Albert Anthony Freeme

Albert Olof Jansen Van Vuuren

Amogelang Gilbert Mmusi

Amos Tulelo

Andries Aucamp

Andries Gordon

Andries Josias Agenbag

Angus Hamilton Christie

Anton Oosthuyse

Arnoul Spitsbaard

Ashley Mark Davis

Barneywel Chimphondah

Bartholomeus Jakobus Erasmus

Brian Meintjies

Carel Gustavus Potgieter

Carel Hendrik Ferreira

Carlos Macuacua

Challe Andre Bonhamme

Christiaan Ernst Gerhard Schutte

Christiaan Hendrik van Wyk

Christo van Huyssteen

Christo van Eyk

Christoffel Andries Whitehead

Clarence Fortuin

Cornelius Frederick van der Nest

Cyril Raymond Laredo

Darren Brian Berndt

Darrin Ian Cass

David Henry Cooks

Dean Eppel

Dean Edwin White

Dennis Valentyn Bunge

Desmond Errol Lloyd

Desmond Maurice George

Diederik Arnoldus Dahms

Drean Johannes Kotze

Eben Philip du Preez

Edius Mashamba

Edward Hall

Edward Kruger

Enock Mugwede

Ernest Khanyile

Ernst Cornelius Jansen

Ernst Cornelius Jansen

Ettiene Pollard

Eugene Terence Redelinghuys

Ferdinand Pieterse

Francois Dewald Blignaut

Francois Frederikus Le Grange

Frank Warrick Saayman

Frederek Gerhardus Opperman

Frederick JJ Fourie

Frederick Wilhelm Stonehouse

Gert Vos

Given Nyathi

Glenton Rebello

Graham Roy Twaddle

Happy Tafara Tati

Harris Naidoo

Hermanus Barend Dahms

Ian O’Hara

Ibrahimo Brento Hassane

Imraan Moolla

Isidro Ernesto Fernando

Israel Mooketsi

Jacobus Rudolph Kruger

Jacobus Stephanus Al Hoffman

Jaen Pienaar

James Nicholas Hamilton Wells

Jan Frederick van Niekerk

Jan Louis Venter

Janus Jacobus van Biljon

Jason Brett Mulder

Jetro Ngwenya

Joachim Jacobus Steyn

Nicolaas Wynant Theunissen

Nkosinathi Perfect Mbatha

Nkosinathi Richard Mavimbela

Noel Nyamukoho

Ntatenyane Daniel Mangwegape

Pastor Noosi

Paul Pillay

Paulo Jorge de Freitas Marques

Paulus Stephanus Marais

Michael Bester

Michael Fernandes de Souza

Michael Henry Hassett

Michael John Hendry

Michael Lionel Roberts

Mlungisi Gatyeni

Mogakolopi Gregory Thamage

Mohamed Hoosen Dawood

Mthandeni Kunene

Mzinhle Leonard Sibenya

Napo Michael Noosi

Nathaniel Happy Sambo Neil Naude

Neil Van Wyk

Wayne Shaw

Weddington Chimbani Moyo

Werner De Bruyn

Werner Snyman

Werner Hermann Schoer

Willem Abram Bossie Prinsloo

Willem Petrus Van Den Heever

William Charles Palvie

William Henry Pepler

Wynand Byleveldt

Yogandren Soobramoney

Zaheer Shameer Khan

Zenzele Ntshakala

Lifting Africa - Nov/Dec 2022 9 2022 LEEASA Company Members in Good Standing “These records are up to date at the time of going to print” LEEASA: +27 (0) 79 658 5602, admin@leeasa.co.za, - www.leeasa.co.za

ROUGH TERRAIN CRANES

Expanding into new terrains

Goscor Access Solutions is proud to formally announce that they are an official dealer of Terex® Rough Terrain Cranes in Africa.

It is with great pride that Goscor Access Solutions formally announce their partnership with Terex® Rough Terrain Cranes as they become an official dealer in Africa. The Goscor Access Solutions and Terex® RT Cranes partnership was confirmed

during their visit to Bauma 2022 in Munich, Germany on 24th October 2022. The addition of the Terex® Rough Terrain cranes to the Goscor Access Solutions product offering enhances the diversity of their product range and provides

them with the opportunity to offer both Access Solutions and Lifting Solutions. Africa is a world of its own and it is critical to be forwardthinking and agile to service this ever-growing continent.

Goscor Access Solutions CEO Wayne McCullagh says, “Terex® RT Cranes is a market leader in the global crane industry and partnering with such a quality brand and expert team will no doubt be of significant benefit to our business and our customers. I really believe in the excellence of the Terex® RT product and the team and service that backs this product. Breaking new ground in Africa with such a powerful brand only but elevates our positioning in the Access and Lifting solutions industry across Africa.”

Establishing roots in 1968 in Crespellano, Italy, Terex® RT Cranes form part of the material processing segment at Terex Corporation - a Global manufacturer of aerial work platforms and materials processing machinery. Terex strongly invest in research and development and continually identify new technologies to sustain its rough

10 Lifting Africa - Nov/Dec 2022

terrain cranes range as the market leader.

With +50 years’ experience and knowledge, and a very powerful Global network, Goscor Access Solutions is privileged to have Terex® RT as their business partner. Terex® RT Sales Manager, Guillaume Bertrand says, “We are very excited to embark on this new journey with Goscor Access Solutions (GAS). GAS have established a very strong, trusted relationship with our sister company, Genie, with whom they are top performing.

Goscor Access Solutions has very good knowledge of the lifting industry, a huge footprint in the countries they’re responsible for, and a strong focus on service; all key factors that will fast-track them in becoming a key player in the industry.

Last but not least, sales and marketing efforts have already been implemented to provide our customers the successful service we all want. Let’s expand into new terrains!” Cranes, parts, technical support and servicing &

maintenance will be the core focus to ensure they deliver a superior service to their clients in Africa.

The Terex® Rough Terrain Cranes colleagues were thanked for their trust in Goscor Access Solutions

and they look forward to a very meaningful partnership.

Goscor Access Solutions, +27 (0) 11 393 6437, accesssolutions@goscor.co.za, www.goscoraccesssolutions.co.za

Lifting Africa - Nov/Dec 2022 11

ROUGH TERRAIN CRANES Manage your modular components more safely and more productively using less space with Combilift’s materials handling solutions combilift.com Safety Storage Efficiency • Safer product handling • Optimised production space • Improved storage capacity • Increased productivity & output • Enhanced profits MMC magazine A5 Liz Offsite 1.2.indd 1 18/01/2021 12:19:07

ALL-TERRAIN CRANES

XCA 2600, World’s Strongest AllTerrain Crane Developed by XCMG, Sets New Wind Power Hoisting Record.(PRNewswire)

The XCA2600, the world's first all-terrain crane to have a 10-axle chassis, has a lower crane body that can protect the equipment when it's operating at wind power plants. Because of this, when encountering low-altitude power lines, it can pass through safely. The more compact body, coupled with a wider chassis and independent suspension system, greatly improves the crane's safety and stability.

XCMG's pioneering "super crane twin" solution features two 2,600ton mega cranes with different lifting capabilities that can switch freely – crawler base or mobile base. The breakthrough solution pushes hoisting boundaries to empower the overall performance and practicality of the adaptability on diverse construction locations. This progressive approach aims to provide highly efficient solutions for the installation of a super wind turbine and customize operations

for different construction environment and application scenarios. The XCC2600 telescopic crawler crane has excelling loading and driving abilities to carry heavier components (such as six main boom sections, legs, and superlift structure, with the ability to transport with 40-ton counterweight and 457-ton total weight) and pass through severe road conditions. It has a 30 percent climbing ability and a driving speed of 2km/hour.

In the context of "3060 dual carbon" goals, China's wind power sector is developing rapidly and set a new installation record in 2021 with an added onshore wind power installation capacity totaling 41.44 million kilowatts, which was 74.1 percent of the total newly installed capacity. With the sector booming in China, there is a high demand for super cranes to construct wind turbines. As the world record holder for hoisting, XCMG Hoisting Machinery has achieved numerous significant landmarks. In the past decade, XCMG has been delivering super mobile cranes with the

strongest hoisting capability every two years, progressing from the XCA1200, to XCA1600 to XCA1800, to XCA2600.

The XCA2600 owns eight original technologies and has realized full coverage of onshore wind turbine hoisting for generators of 8MW, achieving 173 tons of weightlifting to the hoisting height of 160 meters, which will significantly improving the installation of superlarge onshore wind turbines.

"The rapid development of wind power technologies necessitates hoisting equipment that can lift heavier weights to higher heights while guaranteeing transportation efficiency and safety, and as such XCMG is committed to developing the best super cranes to support the fast development of the global wind power industry and new energy development," said Li Changqing, Technical Expert of XCMG.

XCMG, 0086 135 8547 4543, rsa@xcmg.com, www.xcmg.com

12 Lifting Africa - Nov/Dec 2022

XCA 2600, world's strongest all-terrain crane developed by XCMG, sets new wind power hoisting record

XCA2600, the world's strongest all-terrain crane independently developed by XCMG (SHE: 000425), world top three construction machinery manufacturer, lifted and installed an 8.5MW wind turbine recently in the Changyi Wind Farm in Weifang, Shandong Province, setting the hoisting record of the largest onshore wind power generator and a new milestone for the high-quality development of China's manufacturing industries.

WANTING TO REACH NEW HEIGHTS? Tel: +27 (0)11 928 9700 • E-mail: sales@bellequipment.com • Web: www.bellequipment.com CONSTRUCTION The best features of a mobile crane, wheel loader and a forklift in one efficient package Choice of mast heights, attachments and carriage types so you can adapt the machine to your needs A powerful package loaded with versatile features to set new standards of efficiency and productivity TELEHANDLER ROUGH TERRAIN FORKLIFT SKID STEER BRINGING YOU THE WINNING COMBINATION OF PREMIUM PRODUCTS AND A GREAT DISTRIBUTION NETWORK. Bell1722

AUTOMATIC CRANES

Automatic cranes characteristics and advantages

Cranes are equipment designed to handle heavy loads, lifting and lowering materials. Their automation improves the safety of the installations, offering precision in the movement of the load and efficient performance.

In this post, we are going to talk about automatic cranes. They stand out for their versatility, which allows the operator freedom of configuration, covering complex and repetitive operations thanks to the perfect combination of hardware and software.

Why choose an automatic crane? While it is true that cranes are one of the first devices invented in the world, their evolution to today’s cranes has been abysmal.

Almost all industries have historically used manual cranes to handle heavy parts used in different processes, such as storage, assembly, or moving. This situation has changed over time. Today, much heavier loads need to be moved with precision and safety. Hence, automatic cranes appear as a technological solution that allows different operations, reducing waiting time and saving space.

Regardless of the sector in which your company operates, the level of competition is likely to be high, and labor costs will increase, so having an automatic crane will make it possible to:

• Handle heavy loads efficiently

• Reduce operating costs by requiring less personnel and streamlining operations

• Increase productivity by increasing the efficiency and effectiveness of the work performed

• Improve safety at work by incorporating systems that automate your cranes, especially when working in hazardous areas or with dangerous materials

• Reduce damage when handling objects

• Optimize inventory management

• Configure the movements to be performed

What types of automatic cranes are available on the market?

There are different types of automatic cranes, from overhead cranes, gantry cranes, telescopic cranes, jib cranes, and industrial

14 Lifting Africa - Nov/Dec 2022

cranes. The choice of crane will always depend on the work you want to do.

Depending on your choice, you can hoist loads, make horizontal movements, and balance loads. Remember not to move a load whose weight exceeds the crane’s capacity, as this will affect the crane’s balance.

The people in charge of calculating the weight of the load and the lifting capacity of the cranes are called crane operators or operating engineers, essential personnel when carrying out any work with such delicate equipment.

What is the applicability of automatic cranes?

The scope of action is diverse. Some applications are:

• Handling of paper rolls, steel coils, containers, etc.

• Shipbuilding

• Heavy construction

• Mechanical workshops

• Food production

• For lifting all kinds of loads

What do we offer at Crosby Airpes to automate your cranes?

We can improve and automate your cranes, no matter what type of crane it is.

We will install the systems you need to automate your crane. Among the most innovative are the weighing system and remotely controlled cranes, which we will explain below.

Weighing systems

This system will let the operator know in real time if the weight

loaded by the crane is the right one.

At Crosby Airpes, we have different components that adapt to any crane.

We have extensive experience in the design and manufacture of weighing systems, which follow the quality and safety standards indicated by the European Union.

• Digital crane scales allow you to weigh your load on time

• Weighing hooks are an ideal complement to checking goods in and out of the warehouse

• Weighing blocks allow you to lift and transport a load simultaneously as it is weighed. For this, there is no need to install another scale. With the LED or LCD (backlit panel), you will have precise weight, managing to control almost all the functions remotely. The ATP – 100 models are available for weighing from 2,000 to 250,000 kg.

• The weighing pallet truck performs the same functions as the weighing blocks. It moves the load and weighs it at the same time. The advantage is that you can save time by shortening some processes, such as inspection. In addition, your weighing will be reliable, and if there is an error in the quantities, it will detect it immediately. We also have other complements that will help you in your weighing activities, such as:

• Electronic limiters and mechanical limiters will be the brain of your crane

• Load cells for tanks that will help you to capture the weighing data

• Displays that will allow you to view load data quickly and easily

Remotely controlled cranes

Within the movement of loads, one of the technological advances that have had a positive impact has been the use of remote control in cranes, which is different from the usual procedure of cable systems.

The technology used for remotely controlled cranes can be infrared light or radiofrequency.

The latter is the most widely used due to the range of action it covers and its operability despite environmental conditions or objects in its perimeter.

Therefore, infrared light is less popular due to the high probability of deviation of the light path, either by airborne particles or entities that have a specific size obstructing it.

Implementing this system in your cranes will reduce accidents with the crane or load, increase productivity and modernize processes, making you more competitive in the market.

Crosby Airpes helps you automatize your crane

An automatic crane will be your solution when working at height and moving heavy loads safely, allowing you to facilitate complex and repetitive operations.

Systematize your industrial processes, reduce costs and provide safety to your employees by automating your loader cranes.

Crosby Airpes, airpes@airpes.com, www.airpes.com

AUTOMATIC CRANES

Lifting Africa - Nov/Dec 2022 15

Testing the load: Modulift spreader beams perform huge 2420mt load test

Two Modulift spreader beams were used to perform a 2420MT load test by Modulift Partner Liftek International. Modulift, the market-leading manufacturer of modular spreader beams, was recently involved in an exceptionally heavy load test in Dubai.

Two MOD 1000 spreader beams were used in a crucifix configuration to perform the test, with each beam lifting a load of 990 tonnes, and the remaining load being supported directly by the crane hook. The project was a collaboration between several specialist equipment suppliers

across the world, with 600T & 500T P-6043 Green Pin shackles provided by Royal Van Beest; wireless load links, load pin shackles and T24 electronics from Load Monitoring Systems; and 110MT & 50MT Waterbags, Cable Laid Grommets & Round Slings manufactured by Liftek International.

Sarah Spivey, Managing Director at Modulift, said: “It’s encouraging to see our beams being used as part of such a demanding project, a real testament to the quality of our products.”

“The MOD 1000 is ideal for this type of lift due to its relatively low self-weight.”

“Our spreader beams are specially designed to provide a lightweight solution so that cranes can work at maximum capacity.”

All products within the Modulift Spreader Beam range are compliant with ASME, BS and DNV standards. Capacities range from 6 - 3000t and can be re-used without the need to re-test or re-certify even when dismantled and re-configured, wherever the lift is, anywhere in the world.

Modulift, sales@modulift.com, www.modulift.com

16 Lifting Africa - Nov/Dec 2022

BEAMS

SPREADER

SOME FISH GO MUCH DEEPER.

Some sea creatures are more specialized than others. More fit to the extreme conditions under water. Like our subsea shackles and hooks for ROV-operations. Green Pin® offers an ocean of possibilities with our range of specialized and certified components. Designed and produced with the right subsea mindset. For more control. For more precision. And for more possibilities. So make sure you choose Green Pin®. The great white with the green pin.

GREENPIN.COM/ROV

With pioneering solutions at bauma 2022

At this year's bauma, PALFINGER lifts its products and solutions to the next level with intelligent and connected technologies. In addition to innovative crane models and lifting solutions, the company uses alternative types of drive, as well as smart technologies and assistance systems to open up future-oriented applications for its customers.

Changing conditions need intelligent solutions. They open up new ways of doing things, increase efficiency and are also sustainable and future oriented. It is with this strategy that PALFINGER presents new technologies and solutions at bauma 2022. “In line with our Vision & Strategy 2030, our goal is to offer integrated complete solutions from a single source. The focus is on our customers and their needs. At bauma 2022 we prove that we are already proactively solving the challenges of the current era. We will present developments that continue to make our customers' work more efficient and cost effective in the future,” says PALFINGER CEO Andreas Klauser. “In order to be able to tailor our solutions precisely to the applications of our customers and partners in the future, intensive discussions at bauma are crucial for us. Because the world's leading trade fair is the biggest meeting place for the construction industry.”

On an exhibition space of almost 2,500 m², the world's leading producer and provider of innovative crane and

lifting solutions will demonstrate its comprehensive digitalization competence at bauma. PALFINGER focuses on three key core topics (Smart Solutions, Smart Services and Eco-Efficient Solutions), which are reflected in product innovations and at the same time are part of the Vision & Strategy 2030 — towards becoming a complete solutions provider.

Smart Lifting Solutions: The New TEC Series

Complex challenges at inner-city job sites and lifting tasks that require long reaches continuously present PALFINGER customers with challenges. To meet these requirements, PALFINGER has completely redesigned its core product, the loader crane, ushering in a new era of crane models. It effectively combines the advantages of its predecessors with intelligent technologies, such as the innovative PALTRONIC 180 control system and the ultimate LX-6 control valve. In addition to a new design, all crane models in the new TEC series also feature the innovative Smart Control to control the crane tip and Memory Position crane positioning system, which can

BAUMA

store up to four crane positions. The Levelling Assistant helps to optimally level the cranes. These smart systems enable a faster start to operations as well as more efficient and simpler work processes. The PK 580 TEC will be the first of the new crane models to be seen out on the road.

The true precision expert in the 60-meter-ton large crane segment can be flexibly equipped with PALFINGER TEC assistant and comfort systems. In combination with the mobile hybrid power unit, it becomes an emissionfree solution with a minimum of noise emissions, while the integration of a tilting crane fork on the fly jib creates a high degree of safety for challenging work, such as in narrow spaces. The PK 1050 TEC sees PALFINGER present an absolute highlight in the large crane segment.

Featuring a fly jib and enormous lifting capacity, it stands out in its meter-ton class with an unprecedented reach of 37 meters. With DPS-C, the lifting capacity is continuously maximized in every position, because the intelligent system knows exactly where the crane tip is at any given moment. In addition to the models in the large crane segment, the new PK 250 TEC — currently the smallest P-Profile crane — demonstrates that even a compact crane can deliver impressive performance. It convinces with its hydraulic reach of almost 20 meters and a maximum lifting capacity of 23.5-meter-tons.

Even More Precision with Smart Control and Smart Loading Assist (SLA)

The future of construction is high-tech and interconnected. That is why in addition to hardware product innovations PALFINGER is increasingly using smart solutions that set new standards. The innovative Smart Control to control the crane tip unites the crane with the operator and revolutionizes the work process. Instead of moving up to three different levers, Smart Control only requires one to move the crane tip horizontally or vertically. The operator therefore only needs to specify the direction of the crane tip, while the intelligent technology combines the necessary crane movements to reach the target position exactly. However, precision is required not only for crane control. The work steps involved in loading and unloading containers also require precision down to the last millimeter. Since container handling is one of the biggest challenges in everyday working life, PALFINGER has taken this on and developed an intelligent assistant system — Smart Loading Assist. The latest version of this semi-automatic system will be displayed for the first time at bauma 2022.

The Smart Loading Assist adds a 3D camera system, sensors and a high-performance computing unit to the hooklift. It works in a similar way to optical parking sensors and helps the operator to correctly position the hooklift in relation to the container. The integrated Obstacle Detection solution identifies any obstacles, or people, in the hazardous area and immediately warns the operator. The Smart Loading Assist also provides effective support during the unloading process to protect the surface on the ground, and the container.

The Power of E-mobility

The electrification of applications and processes creates sustainable added value. At bauma 2022, PALFINGER will present a number of electrical solutions, including the innovative eDRIVE technology that enables the energy-efficient and completely emission-free operation of loader cranes. Thanks to eDRIVE, operators can choose between a Li-Ion battery pack, the power grid or the vehicle engine at the press of a button while operating the crane. Depending on requirements, the best drive option can then be selected. In addition, eDRIVE operates almost silently, making it possible to work in noise-sensitive areas and at night. The batteries of this smart system can also be conveniently charged between jobs using the integrated generator. PALFINGER also relies on the power of E-mobility for its access platforms. In addition to retrofittable and mobile power packs, two emission-free access platforms will also be presented at bauma 2022: the P 250 BK and the P 280 CK. PALFINGER also shows pioneering thinking in its proactive cooperation with partners. Together with ZF Friedrichshafen AG and Mercedes-Benz Trucks, they developed the ZF eWorX module, which can power the entire PALFINGER product range. It does this by making energy from the truck available to the mounted equipment so it proactively uses the truck’s electric power source. The principle is simple: The traction battery on the electric truck provides electrical energy through an interface. The ZF eWorX system converts the electrical energy into mechanical energy and handles communication between the PALFINGER lifting solution and the vehicle. At bauma, the module will be displayed on a Mercedes-Benz eActros equipped with the PST 18 skip loader. The bauma 2022 trade fair is all about pioneering and sustainable solutions that increase performance over the entire operating period. With Fleet Monitor, Operator Monitor and Service Cockpit, PALFINGER Connected uses digital networking to combine intelligent applications that avoid unnecessary downtime and create a continuous flow of information between fleet managers, company owners, service partners and the operators of PALFINGER lifting solutions. As a result, PALFINGER ensures efficient and cost-effective use of resources.

Together We are Shaping the Future PALFINGER’s clear goal is to digitalize its divisions and product range, and to contribute to the construction site of the future as an innovation leader. Communication with customers, partners and dealers, which is the focus of the technology and mechanical engineering company at bauma 2022, is essential for this. That is because the know-how and experience of customers make a significant contribution to ensuring that the solutions can be tailored exactly to market requirements. True to PALFINGER’s tagline: “Together we can reach anything.”

Palfinger, +27 (0) 11 608 3670, sales@palfingerafrica.co.za, www.palfinger.co.za

BAUMA Lifting Africa - Nov/Dec 2022 19

The new Tadano AC 4.070-2 all terrain crane

Among the various impressive characteristics, one stands out in particular: The AC 4.070-2 can transport its sizeable maximum counterweight of 11.9 tonnes by itself while staying within an axle load limit of 12 tonnes, and it can still manage an impressive 4.4 tonnes when the axle load is reduced to 10 tonnes instead. Needless to say, this makes the AC 4.070-2 an extremely flexible and versatile taxi crane. And there are also the lifting capacities, which are just as impressive: For example, with a main boom length of 50 meters, the crane can lift a good 7.1 tonnes at a radius of 12 meters, and this goes up to a total of 7.3 tonnes at a radius of 10 meters. “No other crane in its class can reach these lifting capacities,” Sascha Scholler underscores with a glint of pride in his eyes. Among other things, this means that the Tadano AC 4.0702 is the perfect assist crane for erecting large lattice boom crawler cranes, as well as an outstanding crane for residential and functional building construction projects.

Moreover, the crane’s extremely compact design only helps to boost these advantages even further: With a total length of 11.7 meters, a width of 2.55 meters, and a traveling height of 3.8 meters, it is the most compact four-axle unit of its class on the market. The boom solution also plays a crucial role in the AC 4.070-2 crane’s versatility: Tadano offers two extensions for the crane’s 50-meter main boom – a swing-away jib with a length of 6.5 meters and a double folding swing-away jib with a length of 16 meters, making it possible to reach a system length of up to 66 meters. In addition, there is also an optionally available runner.

Comprehensive standard equipment with IC 1 Plus and Flex Base

It goes without saying that the new Tadano AC 4.070-2 would not have been complete without the highly coveted IC 1 Plus control system, which determines the crane’s lifting capacity for every boom position as a function of the superstructure’s slewing angle.

Moreover, the way these computations are carried out directly in the cab means that the lifting capacity for a specific radius is no longer limited to the lowest value for a pre-calculated 360° lifting capacity, but is instead determined in real time. As a result, the AC 4.070-2 is always able to take advantage of the maximum lifting capacity available to it, and the advantages provided by this system literally deliver invaluable support for lifts over the outriggers. And when used together with the Flex Base, an outrigger system that comes as standard and features outriggers that can be extended to any point within their available range, this enables the crane to take care of jobs that would normally be the exclusive purview of larger cranes.

In fact, the Flex Base can be used to extend the outriggers in asymmetrical configurations instead of predefined extension positions, making it possible for crane operators to get the outriggers as close to obstacles as possible

20 Lifting Africa - Nov/Dec 2022

When developing its new AC 4.070-2 all terrain crane, Tadano made sure to pursue some extremely ambitious goals: “To put it simply, we wanted to bring to life a powerful and cutting-edge 70-tonne crane that would deliver the best performance on the market in as many axle load configurations as possible. And to put it plainly, that’s exactly what we did,” explains project manager Sascha Scholler, who was responsible for the development.

BAUMA

and use the maximum possible outrigger spread in any scenario. After this, all the IC 1 Plus has to do is to incorporate every single centimeter of outrigger extension into determining the lifting capacity. In addition to the Flex Base, the innovative Tadano IC-1 Remote telematics solution for locationindependent crane and fleet management is also available for the AC 4.070-2. This cloud solution provides remote access to all relevant crane data from anywhere, enabling online troubleshooting by Tadano Support.

Another highlight behind the new AC 4.070-2 is the one-of-a-kind Tadano Surround View System, which features a separate monitor in the carrier cab that provides 360° visibility and graphically shows the maximum possible extension lengths for the outriggers and the counterweight tailswing radius from a bird’s eye view perspective. Accordingly, Tadano Surround View makes it significantly easier to optimally position the crane at work sites without the need for additional personnel.

The system also provides assistance on the way to the work site by making it easier for crane operators to notice pedestrians and cyclists. For example, the area to the right of the crane, which traditionally does not have the greatest visibility, is highlighted on the monitor when the turn signal is activated.

Featuring an E-Pack prep package

The AC 4.070-2 can also be equipped with another Tadano innovation at the factory: With a special transportation cradle and

the required hydraulic connections, the four-axle unit is optionally prepared for work with the ESTAaward-winning E-Pack. This feature is an electro-hydraulic system that comes with an integrated 32-kW electric motor that makes extremely quiet zero-emission crane operation possible. The E-Pack can be used to carry out all AC 4.070-2 crane functions without any negative impact on the corresponding maximum lifting capacity. Not only that, but other performance characteristics are comparable to those achieved with operation with a diesel engine in many work areas, expanding the range of applications of the AC 4.070-2 to indoor projects and cleanrooms, for example. On top of this, the cost-effective single-engine design allows for climate-friendly crane operation thanks to its compatibility with various alternative diesel fuels, such as HVO. The use of these fuels generates fewer emissions and makes operating the crane more environmentally friendly.

The AC 4.070-2 shares these

advantages with a number of other units, including Tadano models AC 4.080-1 and AC 4.100L-1, which feature a drive train that is virtually identical – this is also part of Tadano’s current shared component strategy, which is intended to provide customers with standardized controls and easier maintenance options.

The bottom line

With the new AC 4.070-2, Tadano is once more introducing the most compact crane of a class while raising the bar in many areas with the best lifting capacities out there. Thanks to comprehensive standard equipment and a flexible range of accessories, the new four-axle machine is a particularly versatile representative of its class, and technical highlights such as the IC 1 Plus, Flex Base, Surround View, and E-Pack prep package are sure to make it an extremely attractive option for many crane service providers.

Tadano, Damien.Bizjak@tadano.com, www.tadanoeurope.com

Lifting Africa - Nov/Dec 2022 21

BAUMA

Raimondi Cranes presents three new products at bauma 2022

Raimondi Cranes presented three new products at Bauma 2022, and welcomed thousands of guests over the course of the event. The two cranes – T187 and T357 – were erected at Raimondi’s outdoor exhibit, and were shown alongside the company’s new extended crane cab, the Raimondi Lumina X.

“We presented the T357 for Bauma, as it demonstrates the superior characteristics of the Class 150, the Raimondi’s new range of six flattop cranes. With a maximum lifting capacity ranging between 12t to 24t, this new class was designed with the Central & Northern Europe, American and Canadian markets in mind,” explained Cristian Badin, Commercial Director at Raimondi Cranes.

The Class 150 range is the second new series announced by Raimondi over the course of the trade show.

With a maximum radius of 77.5m and a maximum tip load of 2.67t in UltraLift, the T357 has the best-inclass specification in terms of jib length and load capacity both at the tip and at intermediate reaches.

“The Raimondi T357 is aptly-suited for construction of medium-to-

high infrastructural jobsites due to its maximum lifting speed of 152 meters per minute using a 75 kW winch, and the drum capacity of 800m,” said Badin.

Similar to the Class 110 series, the full range of Class 150 machines is designed and conceptualized as a whole set of cranes by prioritizing modularity of mechanical and carpentry parts, as well as interchangeability of the jib elements.

The new crane series’ name is drawn from the 1.5m wide jib section.

All of the Class 150 models can be equipped with Lumina X, Raimondi’s extended version of the newlylaunched crane cabin.

“At Bauma, we decided to install the T357 equipped with Lumina, while keeping Lumina X on the ground level to allow everyone to experience its impressive dimensions – at a length of 3.88 meters and a height of 2.14 metersand rich features,” Badin explained.

Market research and feedback

22 Lifting Africa - Nov/Dec 2022

BAUMA

figured heavily into the Lumina’s design planning stage, as the cabin is built around crane operator needs.

The new Cab meets the most rigorous international norms of safety and quality, while catering to the highest level of operator comfort.

“When designing the new Cabin, we wanted to develop a space that satisfied the needs and requests of those who spend significant amounts of time operating the machine itself.”

“We wanted to meet their expectations by raising our standards, and offering them the most comfortable working environment possible,” he stated.

At 2.14 meters high, 2.28 meters long, and 1.50 meters wide, the Lumina is one of the largest and most comfortable cabins in today’s marketplace. Boasting several new benefits such as an integrated refrigerator, multiple drawers, coat hangers, a wireless phone charger station and Bluetooth audio system, Lumina also features a new pneumatic seat made of a 1.50cm

memory foam layer that stabilizes according to operator body weight.

The pneumatic seat alleviates any discomfort during long hauls by preventing fatigue and posture pain, while also allowing for a calming working experience.

“The new Cab sports Raimondi’s fresh branding color scheme and boasts more than 80% of its total surface made of shatterproof glass. We worked to prevent overheating by using athermic glass, and redesigned the AC system to avoid glass tarnish,” Badin stated.

While both versions have the same features, Lumina X has been designed specifically for countries with adverse weather conditions as the electrical cabinet is now part of the cabin, allowing for ease of maintenance.

Class 150 and Class 110 are both equipped with the newly-developed ConCore, a control system that builds on previous model strengths while having the capability to instantly detect and report specific type of errors, malfunctions, and faults. This important integration simplifies maintenance and service

operations, thereby reducing site downtime. Additionally, the control system allows crane operators to fully calibrate the machine directly from the in-cabin station or via remote control.

“We received an exceptional market response for all of the products that we showcased at Bauma.”

Our dealers, potential clients, industry stakeholders, and guests expressed great enthusiasm for all of Raimondi’s launches: Class 110, Class 150, and Lumina.

We are positive that our new models will be seen on several important jobsites globally.

We look forward to delivering our first two T187s in Italy and Belgium,” concluded Badin, thanking his clients for their trust, and congratulating the many customers that have expressed interest in acquiring the new models.

Raimondi Cranes, media@raimondi.co, www.raimondi.co

Lifting Africa - Nov/Dec 2022 23

BAUMA DEMAC S.R.L. | MAGENTA (MI) - ITALY | +39 02 9784488 | INFO@DEMAC.IT | WWW.DEMAC.IT Management system certified in accordance with the requirements of ISO 9001 - ISO 14001 - OHSAS 18001 WAKE UP! GET BACK TO REALITY Dreams are not reel, it can be real.

New legislation pertaining to retirement funds

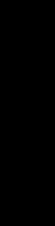

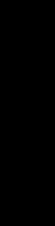

A set of proposed tax bills with significant changes to retirement reform and additional steps toward a so-called “two-pot system” for retirement savings were published by the National Treasury in the middle of 2022.

Introducing the two-pot system

In the event of an emergency, the two-pot system would enable retirement fund participants to withdraw one-third of their pension assets once a year while keeping the remaining two-thirds for retirement. This is regarded as a better alternative to people resigning from their jobs to access their pensions or provident funds.

According to Treasury, this system will allow South Africans to save for non-retirement objectives (e.g. emergencies) via their retirement funds while maintaining more of their assets for retirement.

The basic workings of the two-pot system

Terminology – the pots

Vested pot: This is the member’s accumulated retirement savings in the fund before the implementation date and comprises both the current vested rights and non-vested rights (introduced from 1 March 2021).

Savings pot: This is one-third of retirement savings in the fund that the member can withdraw/access without termination of their employment or leaving the fund.

Retirement pot: The two-thirds of contributions that can only be paid upon the member’s retirement (even if the member’s employment is terminated).

Summary of the fundamentals of the two-pot system

1. Existing fund members do not need to re-enrol to access the two-pot system because existing funds will be modified to do so. To do this, each fund will need to revise its regulations.

2. Up to the aforementioned caps, contributions are still tax-deductible; however, any contributions that exceed R350 000 annually or 27.5% of your taxable income must go into your retirement pot.

3. The vested pot refers to all contributions and growth made before March 1, 2023, and it must be valued at the time of implementation for rights to vest. There will be no changes to the restrictions that were put on such contributions.

4. The savings pot and retirement pot will only build up from contributions to the fund made after 1 March 2023.

5. Any withdrawals out of the savings account will be taxed at the appropriate marginal rate and added to

INDUSTRY NEWS

the member’s taxable income for that tax year.

6. Only one withdrawal from the savings pot is permitted a year; it must be at least R2,000. You may withdraw all or a portion of the money that has accumulated in your savings pot as of the annual withdrawal date.

7. When the member reaches retirement age, he or she has two options: either add the savings pot to the retirement pot to buy an annuity or withdraw the entire amount as cash, which will be taxed in accordance with the retirement lump sum tables. The lump sum tables have more favourable tax rates (maximum of 36%) relative to the marginal rate tables that apply to annual withdrawals preretirement from the savings pot (maximum of 45%).

8. The entire retirement pot must be used to purchase an annuity when you retire. The minimum amount that can be used to purchase an annuity is R165 000, amounts less than R165 000 in the retirement pot can be withdrawn as a lump sum.

9. A member may still take money out of the vested pot before retirement, and this withdrawal will be taxed in accordance with the retirement lump sum tables.

10. Although no amounts can be transferred out of the retirement pot, transfers can be made into it from other pots (vesting, savings or retirement). No transfers can be made into the savings pot, unless from other savings pots. The retirement pot and the savings pot must be held in the same retirement fund – for example, you cannot hold the savings pot in your old employer’s fund and the retirement pot in your new employer’s fund.

Importance of a financial plan

Retirement planning is a proactive activity that affects people’s quality of life both now and in the future.

Additionally, retirement planning involves more than just being a member of a pension, provident, and/or retirement annuity fund.

To maintain your quality of life after retirement, you must properly plan your finances and estimate your financial retirement needs well in advance before retiring.

We at Cornerstone, cannot stress enough the importance of having a solid financial plan. It guarantees that your financial goals have been achieved and that could positively impact your savings.

Because of this, retirement planning is an intricate continuing process that must be started years before the actual retirement date and needs to be reviewed annually.

Whether you’re just starting, buying a first home and getting married, or gearing up for retirement, priming your investments and paving the way for succession, we’ll help you to visualise a future that works for you, and plan for it accordingly.

At Cornerstone, we’ll make sure that your financial plans are perfectly aligned to make the most out of life, no matter which chapter of your story you’re in.

Cornerstone Financial Services Group, marketing@cornerstonefsg.co.za, www.cornerstonefsg.co.za

INDUSTRY NEWS

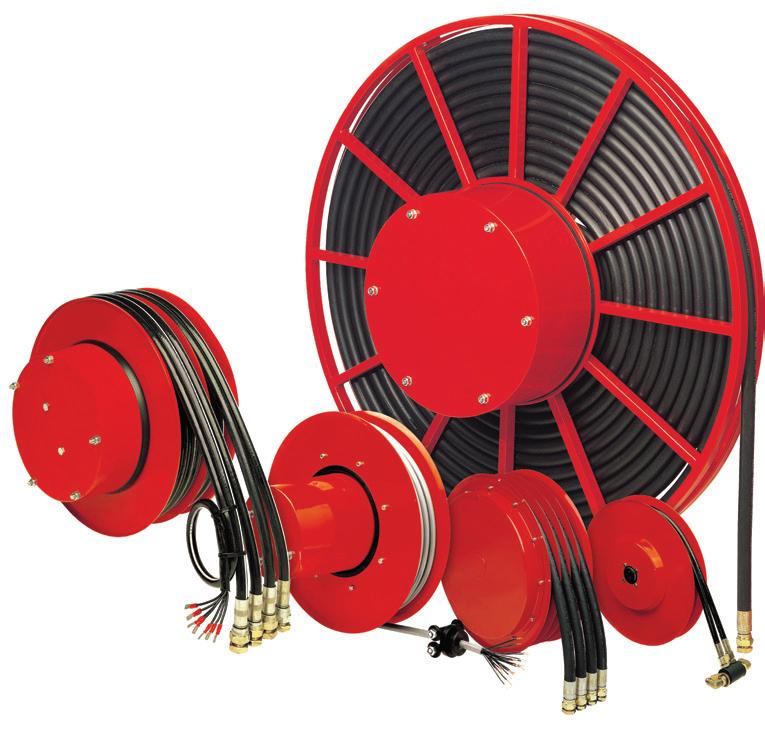

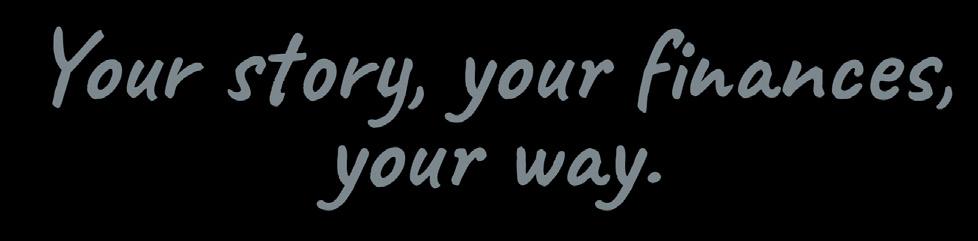

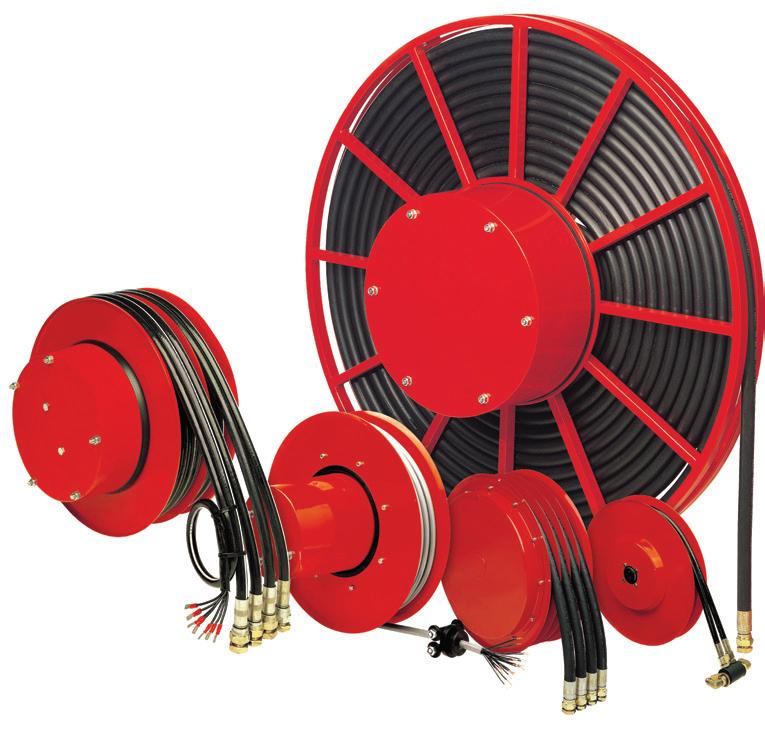

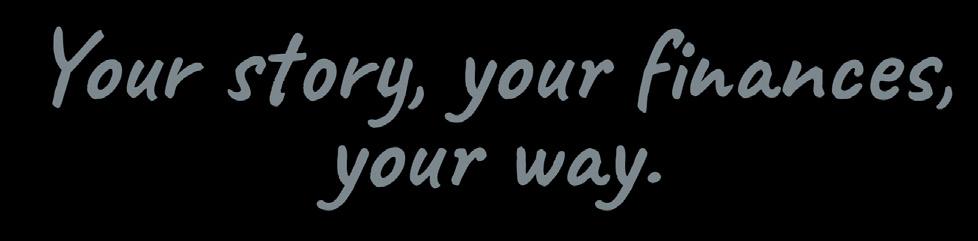

Becker Mining SA launches the new range of Kito RX wire rope hoists

(Pty)

“This 10 Ton 525V with 25m lift Kito RX wire rope hoist will be supplied by Tech North - our distributor in the Rustenburg region, to a processing plant in the platinum area, for use in maintenance procedures and the installation of new equipment in the plant,” explains Rick Jacobs, Senior General Manager (SGM) for consumables,

Becker Mining South Africa. “The addition of wire rope hoists is an important addition to our extensive range of Kito lifting equipment, which includes manual and electric chain hoists and lever hoists.

“Our new Kito RX wire rope hoists have been developed with a robust design and advanced technology, for dependable operation and

extended service life in tough conditions. These flexible hoists are adaptable for use in conjunction with existing cranes and machinery and all components are easily accessible for ease of maintenance.

“RX wire rope hoists are suitable for the use in many industrial applications, including production plants, plant engineering, production lines and workshops, as well as ship building and maintenance.”

The Kito RX range, with lifting capacities between 1 000 kg and 50 000 kg, is available in units with two or four rope strands, reeving 2/1, 4/1 and 4/2. These hoists have lifting speeds from 1.5 m/min to 12m/min, with the option of singlespeed, two-speed, and frequencycontrol.

Features include 380 - 440V / 5060Hz / 3 phases, Insulation Class: IP 55 (standard) or IP 66 (optional) and a control voltage of 42 V, 110 V, 24 V, 48 V or 230 V (optional). These hoists are powered by a three-phase asynchronous motor or the option of a sliding anchor motor. A planetary gearbox ensures

26 Lifting Africa - Nov/Dec 2022 HOISTS

Becker Mining South Africa

Ltd has recently launched the new range of Kito RX wire rope hoists in Southern and Sub-Saharan Africa and has sold its first unit to a processing plant in Rustenburg area.

optimum power transmission between the hoist motor and rope drum.

For enhanced safety, an electromagnetic disc brake acts directly on the rotor shaft for effective braking force. Electronic overload protection, with two adjustable levels, offers protection to the hoist and all its components from overloading (Performance Level C). There is also integrated overheating protection for the motor.

A notable design feature includes the rope guide that consists of two parts - the guide ring and tension spring. The tension spring ensures that the rope lies correctly in the drum groove, whilst the guide ring always maintains the rope in the correct position, preventing it from coming off the drum groove. By moving the guide ring along the drum, limit switches are activated for the highest and lowest hook positions.

The double-girder trolley is equipped with double-flange wheels, all with high quality ball bearings. This construction, where driven wheels are connected directly to the self-braking gear motor, ensures efficient power transmission between the running wheels and the trolley rail. This design also ensures extended service life, reduced wear and low maintenance requirements.

Trolley construction comprises a standard headroom monorail design that enables the hoist to operate directly under and parallel with, the crane or runway beam.

The hoist is directly connected to the trolley and all components are easily accessible for ease of maintenance.

Hoists available in this range include a foot mounted hoist without a trolley, designed for lifting capacities from 1 000 kg to 50 000 kg and a hoist with a standard headroom monorail trolley, for capacities from 1,000 kg to 32,000 kg. Double girder trolleys are suitable for capacities from 1,000 kg up to 32,000 kg, either supported or suspended, version S2-S4.

Units are available only in supported execution, for capacities from 20,000 kg up to 25,000 kg two rope falls, and for capacities from 40 000 kg to 50 000 kg, four rope falls. Units are also supplied as a double hoist, with capacities up to 100 000 kg. The low headroom monorail hoist trolley is designed for capacities from 1 000 kg to 16 000 kg. There are many options available to suit specific application

requirements. These include radio remote control, customised painting and festoon cable systems. User can also choose load spectrum monitoring and synchronisation, load display, summation and measurement, as well as anti-sway control.

Becker Mining also supplies a full range of Kito accessories, designed to enhance performance of Kito hoists. These components include universal trolleys, available in plain or hand-geared configurations, to provide smooth, precise and easy traversing and positioning.

Becker Mining South Africa offers a technical advisory, repair, test and back-up service for the Kito range throughout Southern and SubSaharan Africa.

Becker Mining SA, +27 (0) 11 617 6300, info@za.becker-mining.com, www.za-becker-mining.com

Head

Johannesburg: 27 Colyn road, Village deep, Johannesburg P. O. Box 57042, Springfield, 2137 Tel: 011 493 4355 info@coopergroup.co.za www.engineeringsupplies.co.za

Rustenburg Tel: 011 493 4355 Email: rustenburg@coopergroup.co.za

Lifting Africa - Nov/Dec 2022 27

HOISTS

Marine Equipment Supplies: 57 Salt River rd Salt River Cape Town, South Africa

office:

P.O. Box 476 Salt River 7925 Tel: 021 464 4100 infomes@coopergroup.co.za

Trichardt Tel: 010 141 1993 Email: essecunda@coopergroup.co.za Welkom Tel: 057 355 4172 Email: welkom@coopergroup.co.za Witbank Tel: 013 650 1591 Email: witbank@coopergroup.co.za

Taking a big picture approach to forklift costs

Across industries, South Africa is grappling with increasingly difficult economic conditions as the cost of doing business soars. According to Masslift Africa, a long-term view and “bigger picture” perspective is best when managing – and mitigating – material handling costs to ease pressure on the bottom line.

Material handling and warehousing activities that drive key economic sectors such as retail are costing companies more and more. The three main factors driving cost include increasing fuel prices, interest rate hikes and a global rise in cost due to lack of supply over the past two years.

These factors have all had a knockon effect on the cost of material handling equipment. Costs from factory to shipping and the supply crisis in electronics manufacturing have resulted in higher prices to purchase new forklifts. For example, freight costs alone have doubled since 2020 and in most cases,

manufacturers have no choice but to pass this cost on to the customer. Compounding what is happening on a global scale, local market conditions have also increased the running costs for forklifts. Technicians call out, labour fees, and the cost of spare parts have all increased because of the global factors mentioned but locally, the rise in fuel prices have also made forklifts more expensive to run. The Rand’s rate of exchange has also affected the cost of spare parts. This all points to higher maintenance costs.

These factors make it more important than ever for South

African businesses that rely on material handling as a key part of their operations to be operationally resilient says Masslift Africa CEO, Marco Caverni. Caverni states that all these costs can be managed –and to some extent mitigated – but that this will require a long-term view and a look at the full picture.

“The best way to save on material handling costs now is to start looking at the bigger picture and the long-term. We need to say ‘ok, how much is this forklift going to cost me in total over the next 5 years?’ Especially if you’re going to take a conservative approach and assume that market conditions are only going to get worse. Start looking at your 2025 costs and figure out what you can do today to manage what lies ahead,” Caverni advises.

So, what can companies change or implement to manage rising material handling costs? “Start by making sure that your business is structured to look at the full picture over the course of the forklift’s lifespan. The Procurement teams (who purchase forklifts on a finite capital budget) and the Operations teams (who run the forklifts within

28 Lifting Africa - Nov/Dec 2022

FORKLIFTS

a pre-determined maintenance budget) don’t align when they should be speaking to each other,” explains Caverni.

Running costs depend on what forklift you are buying and who you are buying it from. If these two departments can better align on making decisions when buying material handling equipment, the business benefits. It's not tough to imagine the impact of considering long-term cost factors such as the forklift’s energy consumption, maintenance requirements, and warranty at the purchasing stage. A lot of these features differ from supplier to supplier, therefore who you buy from will play a huge part in that big picture. “Quality, to a degree, has been equalised in the market, so there’s no such thing as a ‘bad forklift’ anymore. Therefore, we are urging customers to consider a different perspective and turn their focus to the aftersales services made available to them by their preferred supplier and the long-term value that both the supplier and the OEM can provide.” To illustrate this point, Caverni

lists off the numerous ways in which Masslift Africa curbs costs for their clients – starting with their value proposition. “Simply put, we are selling an internal combustion product that meets the industry’s best quality standards at a price point that is 10 to 25% cheaper on average than our main competitors.”

Beyond the upfront cost, the real value in Masslift’s offering is how they lower running costs over time for their customers. This is thanks to the incredible fuel efficiency of the Mitsubishi Forklift as the fuel savings come in at approx. 0,5 to 1,3 litres per hour which translates to approx. R1500 saved per forklift per month (based on the R25 per litre fuel price).

In terms of maintenance, these forklifts require servicing at 500 hours instead of the 250 hours required by other manufacturers. This halves the downtime required to service the forklift and increases the customers uptime. This is backed by Masslift’s world leading powertrain warranty of 8 years / 12 000 hours.

“The overall product design also affects maintenance. These forklifts are robust and have fewer electronic components and we have found that keeping it simple is better for the South African market given what we all pay for electronic parts. This together with the fuel efficiency makes it the perfect forklift for Africa,” says Caverni.

As proof of its robust and reliable operation, Caverni disclosed that Masslift had less than 30 warranty claims on the first 1000 Mitsubishi Ninja Forklifts sold.

“Let’s not forget that we also offer a 50% buyback after 5 years or 5000 hours, whichever occurs first. This technically halves the total cost of ownership,” he adds.

“We’ve piled on the long-term value and proven, with our business and pricing model, that we’re here to support our customers and to weather any storm with them.”

Masslift Africa, +27 (0) 11 786 8524, sales@mlift.co.za, www.mitsubishiforklifts.co.za

Lifting Africa - Nov/Dec 2022 29

FORKLIFTS Manage your steel more safely and more productively using less space with Combilift’s materials handling solutions combilift.com Safety Storage Efficiency • Safer product handling • Optimised production space • Improved storage capacity • Increased productivity & output • Enhanced profits Millennium Steel liz+Colin A5.indd 1 12/04/2021 12:10:34

World’s most advanced diamond recovery vessel

Much has been said of Debmarine Namibia’s (a 50/50 joint venture between the De Beers Group and the government of the Republic of Namibia) brand-new purpose-built ship, the MV Benguela Gem. The product of international collaboration, the ship was designed in Norway and Poland, built in Romania and fitted out by De Beers Marine South Africa. The vessel, which took two years to construct, is the most technically advanced diamond recovery vessel in the world, underpinned by high standards of sustainability and safety performance.

The Benguela Gem is unique in Africa, being able to carry out the entire under-sea diamond dredging and treatment process. It arrived in South Africa in September 2021 with an empty deck, says Andre du Toit of PBA Projects, designers of the treatment plant on board the vessel. “PBA Projects was responsible for

all elements of the processing plant, from the actual process design to mechanical equipment selection, electrical design, instrumentation selection, structural design, and shop detailing,” says Andre. “The structural design components covered the design of structures to withstand ships motions, vibratory equipment and reverse loading for the rigging of the fully fitted out structures onto the vessel.” The project was so impressive that it walked away as the overall winner at this year’s South African Institute of Steel Construction (SAISC) Annual Awards.

According to SAISC CEO Amanuel Gebremeskel, a number of high-quality, truly excellent projects were showcased at the awards. “While there was tremendous merit across all of our entrants, as well as all our category winners,” enthuses Gebremeskel, “The SAISC

Building a treatment plant on a custom-built diamond recovery vessel was never going to be the easiest of undertakings. Doing it in an award-winning fashion, however, is something to be proud of. Lifting Africa finds out more.

CASE

STUDY

Annual Awards judges were unanimous in their praise of our overall winner - which was also the winner of the Western Cape and Mining categories - the Treatment Plant, on board the ‘Benguela Gem’, the world’s most advanced diamond recovery vessel.” The exceptional design, fabrication and installation of the 3000-ton diamond treatment plant on the vessel was carried out ahead of schedule by a team of local engineers and fabricators in the midst of Covid-19 pandemic restrictions. Says Gebremeskel, “This project stood out in a number of different ways, and presented a first in the history of the Steel Awards: it operates off-shore and is floating rather than being stationary and anchored - a truly distinctive applicant within the Awards categories. As a sea-faring structure, it is furthermore subject to unusual engineering loads from a naval engineering perspective.”

Building the plant

The Treatment Plant is on board the central section of the ship that is 177m long and 27m wide. According to Emma Loubser of PBA, the Mammoet FOCUS30 was used to lift the structures onto the vessel. “This crane has a 2500t lifting capacity and an incredibly small footprint. The crane can operate in very constricted spaces which were perfectly suited to this application as space on the quayside between the structures was very limited.” Working in such close confines the entire project required close collaboration between all the role-players. “The mass of the overall treatment plant components, combined, weighed in at just under 3000 tons. Each structural lift weighed between 50 and 428 tons,” says Emma.

It was important that the plant be designed so that its structures could withstand reverse loading during lifting as well as all the custom lifting attachments to the treatment plant modules. “PBA also designed the lifting frames that were used to reduce loading in the structures during lifting,” says Emma. “The planning of the lifts was done in close collaboration with Mammoet and De Beers Marine.”

Dealing with the challenges

One of the biggest challenges facing the team was the space constraints on land. Lifting onto the vessel was not easy requiring a lot of careful planning.

“Everything from where the modules were constructed on the quayside to accommodate the crane reach, to needing to lift over or around other structures, as well as considering the floating vessel and its orientation while structures were loaded had to be taken into account the entire time,” says Andre. “There were extremely small tolerances lifting onto the vessel for alignment to the correct landing locations, and as more and more structures were loaded the space on the vessel became increasingly smaller. The last structural

lift onto the Benguela Gem was required to fit between 3 other structures with clearances of as little as 20mm, and thanks to the brilliant Mammoet team, and careful planning, it was executed perfectly.” Another big challenge was time. “The FOCUS30 crane is one of a kind in the world. The crane had been shipped to South Africa from Europe specifically for this job and had a strict end date to leave for North America for its next assignment.” In an effort to deal with these challenges, the team returned to the drawing board. “Where there were previously 16 smaller structural modules that had been designed to be lifted individually onto the vessel, these were revised to 9 super lifts,” explains Emma.

Also, the lifting design aspects needed to be reexamined and special lifting frames designed to help reduce loading in the structures due to the revised super lift methodology. “Because of the super lifts and high loads, special rigging equipment needed to be sourced from around the world to make the lifts possible. These included 25t turnbuckles, 55t high strength shackles and 80t slings.”

Thanks to the FOCUS30 and the structural re-design from a lifting perspective, the vessel sailed out of Cape Town only three months after it arrived in December 2021 with a fully operational mine onboard.

Celebrating excellence

The SAISC award, says Andre, has shed light on an exceptional area of extreme world-class engineering that is happening right here in South Africa. “The PBA Projects team is used to working in such a unique environment, but it is not necessarily common knowledge that such a level of design is happening here in Cape Town all the time, and the SAISC award has made this more accessible and given greater awareness to the broader engineering communities in South Africa and worldwide by showcasing this one-of-a-kind Project,” concludes Andre.

Lifting Africa - Nov/Dec 2022 PBA Projects | +27 (0) 21 948 8502 | andredt@pbaprojects.co.za | www.pbaafrica.co.za

How does a telehandler work?

The telehandler has a range of capabilities, making it suitable for various work environments, such as construction, agriculture and waste and recycling. The equipment features a telescopic boom, and you can add various attachments to this, for different lifting functions, suspending loads etc.

Consequently, the telehandler is suitable for working across a diverse selection of sites, environments and terrains. The functions that the telehandlers perform can replicate the work of a forklift, crane, by adding the appropriate attachment. Changing these attachments is a quick process, due to the design of the telehandler, which makes the equipment all the more useful and versatile.

This quick hitch design feature means that the telehandler operator can switch functions on demand, minimising the time and effort involved in carrying out tasks and transporting heavy loads, which would otherwise involve using more than one type of machine.

What is a telehandler used for?

Telehandlers are useful in a variety of different environments but are most often used in construction and agricultural industries. Whilst telescopic handlers can be used both inside and outdoors, they are large pieces of machinery, so unless the indoor area is very

spacious, they are best suited to working outdoors. Primarily, telehandlers are used to lift and move large or heavy loads from one area to another. If the load is only being moved a short distance, then the telehandler may be able to complete the task by extending and retracting its telescopic arm, without needing to move its base. A telehandler can be fitted with a variety of different lifting attachments and equipment, allowing it to lift and transport a huge range of different loads.