The official magazine for LEEASA (Lifting Equipment Engineering Association of SA) MAR/APR 2023 Construction and engineering insurance

“For

all your Storage Solutions”

The

ACROW, +27 (0) 11 824 1527, info@acrow.co.za, www.acrow.co.za,

Lifting Africa

Managing Editor: Surita Marx

Tel: +27 (0) 87 700 9834

Cell: +27 (0) 83 281 5761

Email: surita@liftingafrica.co.za

Web: www.liftingafrica.co.za

Sales: Lusana Merckel

Email: lusana@liftingafrica.co.za

Cell: +27 (0) 65 704 0003

Sales Assistant: sales@liftingafrica.co.za

Production Manager: Xane Roestroff

Advertisers

Lifting Africa - Mar/Apr 2023 3

ACROW OFC, 4 Big 5 IBC BMG 11 Combilift 15 Condra Cranes 39 Demac 21 Giovenzana OBC Golf day of the year invitation 37 J Express 17 Johnson Crane Hire IFC KZN KITE 29 Liebherr Africa 31 LiftEx 27 LEEASA 6,7 Lifting Placements 19, 46 Phakamisa 43 STM Riduttori SA 35 TVH Parts 13 ACROW 4 From the Chairman’s Table 6 2023 LEEASA Individual Members & Company Members in Good Standing 8

Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers LEEASA. The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication. SPT mini cranes! 10 Unique suspension crane 12 Hiab launches EFFER iQ.1400 HP 14 New electronic platform for Hyva cranes complies with European Standards to assure safety and performance 16 HVO: A step towards zero-emissions 17 Forklifts for farmers 18 Konecranes’ Static Weighing System now with in-cab printer to further reduce wait times in ports 20 Manitou Group chooses Siemens Xcelerator portfolio for the lifecycle management of its products 22 Lifting Africa & Pipes, Pumps And Valves Africa Golf day 2023 23 Check out all different types of Green Pin® Master Links 24 Surge in demand for LTM’s GIS electric chain hoist 26 Advanced Construction Robotics launches the world’s first rebar lifting, carrying, and placing robot 28 Training and service centres for drives distributor 30 Spectacular solar trees 32 Construction and engineering insurance 34 Vita Industrial brings intelligent lifting technology and IoT to CONEXPO 2023 36 PALFINGER makes the showcase for innovative lifting solutions at CONEXPO 38 Tadano invites CONEXPO attendees to take a closer look at the company’s significant advancements 40 How construction drones give contractors a competitive edge 42 BUYERS GUIDE 44

new delivery has arrived at Uplifter in Germany: brand new Uplifter

Cape Town: KwaZulu Natal: Zambia: Italy: Warwick UK: +27 21 905 0500 +27 82 719 1196 +26 79 968 6252 +39 0124 418112 +44 07841 391 421

CHAIRMAN’S

From the Chairman’s Table

It is my pleasure to address you through this article, and I hope that it finds you well. As the ViceChairman of LEEASA, I am humbled by the trust and support that you have placed in our team.

It is my shared responsibility to ensure that we continue to move forward and grow, while staying true to our core values and mission. In the past year, we have faced numerous challenges, both internally and externally.

However, I am excited to share with our members that all the progress we have made in the past year. Our mission has always been to serve our members and make a positive impact on the industry, and I am proud to say that we have continued to uphold this commitment. In addition, we have continued to make progress and achieve our goals. We have launched new initiatives, expanded our reach, and strengthened our partnerships. We have also prioritized our members, and we have taken steps to ensure that we are contributing positively to the industries in which we operate.

We have announced in our previous Chairmans Desk that we have been awarded our service provider status by ECSA and are fully equipped to offer our own CPD Accredited Seminars, courses and training going forward.

As part of upholding our service provider status we are preparing for an audit with ECSA on 26 July 2023, and welcome this as we aim to remain in good standing as an ECSA approved CPD service provider and offering our members the benefits thereof.

Therefor we can offer our member 1-CPD point for attending our conference at the upcoming KITE Show 18-20 July 2023. Be on the lookout for correspondence and communications on more details regarding this. Looking ahead, I am optimistic about LEEASA’s future. We have a talented and dedicated team, a strong standing association, and a clear vision for where we want to go. We will continue to focus on innovation, membership service and responsibility, while maintaining a culture of collaboration, integrity, and excellence. Adding to the association’s success would be the continual support of our members of which I must acknowledge that I have continued to be impressed by their passion and drive and I am honoured to work alongside with our members to uphold the LEEASA visions and missions. As always, I welcome your feedback and suggestions. Your input is critical to our success, and we value your perspectives and ideas. In conclusion, I am confident that LEEASA with its board of directors

will continue to make a positive impact and achieve great things in the coming year. Thank you for your continued support, and I look forward to sharing more updates with you in the future.

Feel free to reach out to the board members if the need requires.

Chairman: Ashley Davis | ashley@leeasa.co.za

Vice Chair: Andries Agenbag | andries@leeasa.co.za

Treasurer: Surita Marx | surita@leeasa.co.za

Ordinary Members: Kyle Graham | kyle@leeasa.co.za

Francois Blignaut | francois@leeasa.co.za

Sandra Hurlimann | sandra@leeasa.co.za

Francois Weideman | francoisw@leeasa.co.za

Administration:

Desiré Davis | admin@leeasa.co.za

Yours in SAFE LIFTING, Andries Agenbag and the rest of the LEEASA team

6 Lifting Africa - Mar/Apr 2023

TABLE

CALL FOR PAPERS The KZN KITE Conference Durban Exhibition Centre, KZN, South Africa 19 July 2023 The Lifting Equipment Engineering Association of SA invites abstracts for the upcoming Lifting Equipment Conference to be held at the Durban Exhibition Centre, on 19 July 2023. Interested participants may submit in Writing to admin@leeasa.co.za before 31 May 2023 All delegates that attends the conference will receive one CPD point! More information: +27 (0) 79 658 5602 | admin@leeasa.co.za | www.leeasa.co.za

Lifting Equipment conference Durban Exhibition Centre 19 July 2023 LEEASA is hosting a Lifting Equipment conference and ECSA members will receive 1 CPD point +27 (0) 79 658 5602 | admin@leeasa.co.za www.leeasa.co.za Invest in your business, visit KwaZulu-Natal’s Premier Trade show

2023 LEEASA Individual Members in Good Standing

Mr. Aaldrik Graham Kiewiet

Mr. Alan Victor Botha

Mr. Albert Anthony Freeme

Mr. Amogelang Gilbert Mmusi

Mr. Amos Tulela

Mr. Andre van der Merwe

Mr. Andries Aucamp

Mr. Andries Josias Agenbag

Mr. Antoni Frederik Janse van

Niewenhuizen

Mr. Armand du Plessis

Mr. Arnoul Spitsbaard

Mr. Arnoux de Bruin

Mr. Ashley Mark Davis

Mr. Barneywel Chimphondah

Mr. Bartholomeus Jakobus Erasmus

Mr. Brian George Mezieres

Mr. Brian Leonard Meintjies

Mr. Carel Gustavus Potgieter

Mr. Carel Hendrik Ferreira

Mr. Carlos Macuacua

Mr. Challe Andre Bonhamme

Mr. Christiaan Ernst Gerhard Schutte

Mr. Christiaan Hendrik Van Wyk

Mr. Christo Van Eyk

Mr. Christo van Huyssteen

Mr. Christoffel Andries Whitehead

Mr. Coenraad Hendrik Heunis

Mr. Cornelius Frederick van der Nest

Mr. Cyril Raymond Laredo

Mr. Daniel Ntatenyane Mangwegape

Mr. Darren Brian Berndt

Mr. Darrin Ian Cass

Mr. David Dos Santos Cruz

Mr. David Henry Cooks

Mr. Dean Eppel

Mr. Deon Bonthuyzen

Mr. Desmond Errol Lloyd

Mr. Desmond Maurice George

Mr. Diederik Arnoldus Dahms

Mr. Dirk Johannes Christoffel Geldenhuys

Mr. Eben Philip Du Preez

Mr. Edius Topera Mashamba

Mr. Edward Hall

Mr. Edward Kruger

Mr. Emile de Koning

Mr. Enock Mugwede

Mr. Ernest Khanyile

Mr. Ettiene Pollard

Mr. Eugene Terence Redelinghuys

Mr. Ferdinand Pieterse

Mr. Francois Dewald Blignaut

Mr. Francois Frederikus Le Grange

Mr. Frederick Johannes Jacobus Fourie

Mr. Frederik Wilhelm Stonehouse

Mr. Gavin Rayson

Mr. George Cornelius Krafft

Mr. George Khehla Kuhlase

Mr. Gerhardus Jacobus Oosthuizen

Mr. Gert Vos

Mr. Given Nyathi

Mr. Glenton William Rebello

Mr. Graham Roy Twaddle

Mr. Happy Tafara Tati

Mr. Harris Naidoo

Mr. Hendrick Rapule Mahuma

Mr. Hendrik Prinsloo

Mr. Hermanus Barend Dahms

Mr. Ian O’Hara

Mr. Imraan Moolla

Mr. Irvin Charles Murrish

Mr. Isidro Ernesto Fernando

Mr. Israel Mooketsi

Mr. Jacobus (Jacques) Mare

Mr. Jacobus Rudolph Kruger

Mr. Jacobus Stephanus Al Hoffman

Mr. Jaen Pienaar

Mr. James Totman Mark

Mr. Jan Louis Venter

Mr. Janus Jacobus Van Biljon

Mr. Jetro Mzwandile Ngwenya

Mr. Joachim Jacobus Steyn

Mr. Joannes Lugt

Mr. Joao Carlos de Freitas Marques

Mr. Johan Frederick Herselman

Mr. Johan Smith

Mr. Johann du Plessis

Mr. Johannes (Jaco) van Biljon

Mr. Johannes Gideon Kruger

Mr. Johannes Jurgens Marais

Mr. Johannes Mnyameni

Mr. Johannes Roos

Mr. John Carsten Allers

Mr. John George Towsen

Mr. Joseph Johannes van Huyssteen

Mr. Justin Henry Brown

Mr. Karel Johannes Francois Du Toit

Mr. Kebareng Daniel Molausi

Mr. Kesekang Segole

Mr. Kevin Clive Reckas

Mr. Kevin Keith Godfrey

Mr. Khathutshelo John Phalandwa

Mr. Kyle Graham

Mr. Lake Johane Ndhlela

Mr. Leon Johan Snyders

Mr. Leonard Raymond Kelly

Mr. Lesiba Willie Sebothoma

Mr. Linton Moodley

Mr. Lodewickus Robert van de Venter

Mr. Luke Steven West

Mr. Malcolm Ivan Claase

Mr. Malose Kenneth Mabela

Mr. Marius Els

Mr. Marius Marais

Mr. Mark Leonard Munnery

Mr. Mark Leslie O’Connor

Mr. Marthinus Swart

Mr. Matthys Daniel Taljaard

Mr. Matthys Michiel Brink

Mr. Mboshoa Simon Skosana

Mr. Michael Fernandes De Souza

Mr. Michael John Hendry

Mr. Michael Lionel Roberts

Mr. Milton Mhlanga

Mr. Mogakolodi Gregory Thamage

Mr. Mohamed Hoosen Dawood

Mr. Napo Michael Noosi

Mr. Nathaniel Happy Sambo

Mr. Neil Naude

Mr. Nicolaas Benjamin Smit

Mr. Nicolaas Theunissen Wynant

Mr. Nkosinathi Richard Mavimbela

Mr. Noel Nyamukoho

Mr. Octovias Lebakang Mabelane

Mr. Pastor Noosi

Mr. Paulo Jorge de Freitas Marques

Mr. Paulus Stephanus Marais

Mr. Peter Abraham du Toit

Mr. Peter Jacobus Nel

Mr. Petr Kluson

Mr. Petrus Abraham Bester

Mr. Petrus Lafras Fritz

Mr. Phata Simon Mailula

Mr. Philippus Stefanus Kruger

Mr. Phillip Demetrius Kemp

Mr. Pieter Albert Schoeman

Mr. Pieter Andries Engelbrecht

Mr. Pieter Renier Kotze

Mr. Ralph Errol Shamrock

Mr. Richard Donaldson

Mr. Rishi Mungroo

Mr. Robert Du Toit

Mr. Robert Wayne Milne

Mr. Rodney Bassingthwaighte

Mr. Roger Ian Day

Mr. Roland Henry Murray

Mr. Ronald Albert Innes

Mr. Ronald John Laing

Mr. Royden Stewart Turner

Mr. Rudi Lansdell

Mr. Russel Henning Boshoff

Mr. Rutendo Job Sadomba

Mr. Ryno Coetzer

Mr. Samson Kamutasa

Mr. Sarel Petrus Jacobus Dreyer

Mr. Schalk Willem Johannes Burger

Mr. Sello Jacob Sebiloane

Mr. Seth Laredo

Mr. Shadrack Mikel Dlamini

Mr. Shaun Combrink

Mr. Sheldon Grant Pratt

Mr. Shimane Martin Diutlwileng

Mr. Siegfried Schrader

Mr. Simon Lodewyk Sauer

Mr. Stefan Ivanov Babatchev

Mr. Stephen Andrew McGregor

Mr. Steven Duvenage

Mr. Stuart Mark Love

Mr. Timothy Tatenda Zindi

Mr. Victor Manuel Batista Ferreira

Mr. Warren Naude

Mr. Wayne Garnett Shaw

Mr. Weddington Chimbane Moyo

Mr. Werner De Bruyn

Mr. Werner Hermann Schroer

Mr. Werner Snyman

Mr. Willem Johannes Petrus Mostert

Mr. Willem Petrus van den Heever

Mr. William Henry Pepler

Mr. Yogandren (Donny) Soobramoney

Mr. Zaheer Shameer Khan

Mr. Zenzele Siphamandla Ntshakala

Mrs. Ruwaida Mahomed

Mrs. Sandile Wyeth Mzimela

Ms. Lynda Lake

Lifting Africa - Mar/Apr 2023 9 2023 LEEASA Company Members in Good Standing “These records are up to date at the time of going to print” LEEASA: +27 (0) 79 658 5602 | admin@leeasa.co.za www.leeasa.co.za

With over 20 years of experience, Uplifter is the pioneer and specialist in the mini crane sector! With the German premiere in 2022 and the associated exclusive presentation of the Uplifter SPT mini cranes, the company is revolutionising the crane market.

Price-performance ratio, product quality and compact design are convincing. A low dead weight, handy dimensions and a lifting capacity of up to 10 tonnes set standards. The compact mini cranes in Uplifter's corporate colours red and anthracite have already attracted many interested parties, and the demand is enormous. Uplifter knows which requirements the mini crane of today has to meet and which features make the working life of the fitters much easier.

What makes these mini cranes so special?

Currently available are the small cranes Uplifter SPT299, Uplifter SPT499 and Uplifter SPT1009 which are distributed almost all over Europe by Uplifter!

The mini crawler cranes from the Uplifter SPT series have only highquality components from Europe installed, which distinguishes the high quality and durability of these machines.

The slim powerhouse

Unique on the market: Unique on the market: crane operation with the Uplifter SPT299 is possible lower than with comparable mini

Ideal for window glazing on the ground floor and for low ceiling heights in combination with vacuum lifters.

With a massive lifting capacity of 2,950 kg, the Uplifter SPT299 impresses with an ideal power-toweight ratio.

With its slim body and a width of 900 mm, it can be used in areas that are inaccessible to normal cranes.

The Uplifter SPT299 is available particularly quickly: short delivery times - Europe-wide from a single source! Included in the price: extensive features are already built into the standard equipment and do not cause you any hidden additional costs.

Take advantage of the unbeatable prices today without compromising on features and quality. On the contrary: you get more load capacity and equipment than with comparable models - and at a fair and reasonable price.

Due to the low dead weight of only 2.75 t, this mini crawler crane can even be mounted on false ceilings

and is thus ideal for use in facade construction. The practical hybrid drive is already included in the standard version, for even more flexibility when working in industry and trade. The drive is provided by a powerful diesel engine or via a power cable / 380 V 4-phase and is virtually noiseless and emissionfree. All functions can be controlled via a radio remote control, which makes the fitters' work easier. Intuitive, easy operation and little susceptible to errors and therefore predestined as a rental unit.

This spider crane reaches an unbelievable working height of 9.7 m (with jib even over 14.5 m) with a gradeability of 20° or 36 %.

The mini crawler cranes from the Uplifter SPT crane series have only high quality components from Europe installed, which distinguishes the high quality and durability of these machines. This ensures a quick availability of spare parts. With Uplifter you have your competent service partner for mini cranes, mobile cranes, vacuum suction cups and glassworkers directly on site!

The all-rounder for all cases 4,000 kg + 1,000 kg lifting capacity

10 Lifting Africa - Mar/Apr 2023

The new delivery has arrived at Uplifter in Germany: brand new Uplifter SPT mini cranes!

crane models when the arm is fully extended!

MINI CRANES

= 5,000 kg lifting capacity! The Uplifter SPT499 lifts over 1,000 kg more than comparable models in this class! The compact and inexpensive mini crane that can also keep up with the big ones.

The Uplifter SPT499 is a powerful mini crane from the UPC series. With a lifting capacity of an incredible 5,000 kg, you won't find a comparable model in this class. In addition, the Uplifter SPT499 mini crane has a maximum working height of 17.5 m, which can even be increased to 22.0 m with a jib.

The compact design, a small clearance width of 1.4 m, a clearance height of 2.0 m, a very good gradeability of 20° or 36 % and the low dead weight of only 6.2 t are also convincing.

The mini crane Uplifter SPT499 is available particularly quickly: short delivery times - Europe-wide from a single source! Included in the price: extensive features are already built into the standard equipment; 100 % performance, no additional costs. Benefit from the best prices, full equipment and highest quality.

The practical hybrid drive is part of the standard version, for even more flexibility when working in industry and trade.

It is driven by a powerful diesel engine or by a power cable / 380 V 4-phase, with which it operates almost noiselessly and emissionfree. Practical accessories such as hydraulic or manual jib, white chains, jib pads, etc. can be added or retrofitted at any time.

For really heavy tasks

The mini crane Uplifter SPT1009 is the strongest in its class with 10,000 kg lifting capacity. In direct comparison with other brands, the Uplifter SPT1009 lifts around 2 tonnes more!

The Uplifter SPT1009 is the most powerful mini crane in the UPC range. With a lifting capacity of an incredible 10,000 kg, it is the undisputed leader among Spider Cranes.

In addition, the Uplifter SPT1009 mini crane has a maximum working height of 20.2 m, which can even

be increased to 25.0 m with a jib. The mini crane Uplifter SPT1009 is available particularly quickly: short delivery times - Europe-wide from a single source!

Extensive features are already built into the standard equipment: Highest performance, no additional costs. Benefit from unbeatable prices with full equipment in the highest quality.

The practical hybrid drive enables even more flexible working in industry and trade. It is driven by a powerful diesel engine or by a power cable / 380 V 4-phase, with which it operates almost silently and emission-free.

Practical accessories such as hydraulic or manual jib, white chains, boom pads, toolbox, etc. can be optionally purchased or

retrofitted at any time.The mini crawler cranes from the Uplifter SPT series have only high-quality components from Europe installed, which distinguishes the high quality and durability of these machines. This ensures a quick availability of spare parts. With Uplifter you have your competent service partner for mini cranes, mobile cranes, vacuum suction cups and glassworkers directly on site!

Feel free to bring brands like MAEDA, UNIC, VALLA, etc. to one of our locations for service, repair and maintenance. We have the expertise and years of know-how to get your machines back in shape for the next job.

Uplifter, matthias.minich@uplifter.com, uplifter.com

BoerSlim is a concept BMG has developed to demonstrate our commitment to providing you with added value products and service.

Through this initiative, BMG’s team of agricultural experts offer farming sustainability solutions that focus on effective food production, the correct use of suitable equipment for the specific task and the efficient application of advanced technologies.

We look forward to showcasing our industry-leading technology through live product demos.

Join us for exciting BoerSlim merchandise and competitions throughout the week.

Lifting Africa - Mar/Apr 2023 11

WE LOOK FORWARD TO WELCOMING YOU 16 - 19 MAY FIND US OUTDOOR AT STAND C21

HARVEST DAY OESDAG

Graan SA/Grain SA

MINI CRANES

Unique suspension crane

contributed to Condra’s winning this order against competition from rival companies in South Africa and abroad. Commenting on the latest contract, a Condra spokesman said that the 15-tonner’s special configuration would make for an inspiring project on the factory floor. “Few companies in Africa, or indeed abroad, have the design and manufacturing skills for a suspension crane of this complexity,” the spokesman said. “It’s a very nice order to get. These are big machines, and the unusual design, welding and finishing specifications will make for interesting manufacture outside the norm.” To minimise chipping and rust, Condra will apply an edge finish, grinding all angular steel to circular section before the application of a customer-specified protective coating.

Condra is to manufacture a 15-ton suspension crane of unusual configuration as one of two overhead cranes ordered for underground use at a Botswana diamond mine. The second machine is of conventional overhead design.

The arrangement of the suspension crane is rarely seen: two I-beams defining its area of movement will be bolted to rock-bolt flanges anchored in the roof of a mine chamber after blasting, excavation and preparation as a service workshop. The I beams will hang from the chamber’s ceiling, whereas they are more usually the topmost side components of a fixed gantry constructed from the ground up. The wheeled 11-metrespan crane girders will then run suspended from the lower flanges of these two long-travel I-beams, with the crane’s crab mounted atop the girders to provide the crosstravel. The whole structure of the crane becomes suspended, running along and across the roof of the chamber.

Condra designed this crane to specifications supplied by the project’s consulting engineers. By suspending the crane, it will deliver the greatest possible lifting height, reducing the volume of rock needing to be blasted and excavated to form the chamber.

After installation, the 11-metre span, 15 ton crane will have a lifting height of 9 metres. Condra has previously manufactured similar suspension cranes for mines in central Africa.

The second crane for the diamond mine will have a 35-ton capacity and 9,2 metre span. Of conventional overhead design, it will work in a larger existing chamber. Lifting height will be 12,7 metres. For both cranes, Condra’s design team had to calculate balance points for individual components, precisely positioning lifting lugs on the sides of component assemblies so that they will hang precisely vertically below the cage that will lower them down the mineshaft. Similarly, lifting lug positions atop the components will ensure balance during crane assembly and installation within the confined spaces of the service chambers. It is thought that competitive pricing, rapid response times during the tender process and a reputation for on-time delivery of completed machines

The cranes will feature flameproofing, stainless steel panels and full weld seams in place of the more usual space-welding along the lengths of steel joints, including the girders. Control of both cranes will be by mobile pendant. The suspension crane will feature a flashing light and siren for safety. The consulting engineers specified brake logic to avoid overuse of the pushbuttons on the mobile pendants. Operators are prone to repeated and rapid use of this control, causing excessive heat and wear on the braking system. With brake logic, as soon as the button is pressed twice in quick succession, a two-second temporary block is activated, overriding the operator and correcting his use of this control. The cranes will be used for service and maintenance applications, the suspension crane being installed in a chamber close to the orebody, where it will work on machinery used for drilling, blasting and ore removal. Such a location will save the time and cost of moving the machines over a greater distance to workshops closer to the shaft.

The cranes are scheduled for delivery in 2024.

Condra (Pty) Ltd, +27 (0) 11 776 6000, sales@condra.co.za, www.condra.co.za

12 Lifting Africa - Mar/Apr 2023 OVERHEAD CRANES

POWERED UP TO SERVE YOU AGAIN. START ORDERING TVH PARTS SOUTH AFRICA (PTY) LTD • HEAD OFFICE JOHANNESBURG 90 Electron Avenue • Isando • Kempton Park 1600 • South Africa • GPS S -26.130318, E 28.214541 T +27 11 281 2700 • F +27 11 392 3599 / +27 11 974 9845 • sales.southafrica@tvh.com • www.tvh.com DURBAN 17 Kyalami Road Westmead Pinetown 3600 T +27 31 100 0760 F +27 31 700 6191 LICHTENBURG Shop 1 103 Scholtz Street Lichtenburg 2740 T +27 18 632 6192/6092 F +27 18 632 6108 PORT ELIZABETH 220 Commercial Road Sidwell Port Elizabeth 6001 T +27 41 453 1404/8 F +27 41 453 1409 RICHARDS BAY Unit 3 Ferro Park 1 Ferro Gang Road • Alton Richards Bay 3900 T +27 35 751 1001 F +27 86 530 3145 CAPE TOWN 4 Buchan Street Stikland Industrial Bellville, Cape Town 7530 T +27 21 988 2432 F +27 21 988 9127 WWW.TVH.COM

Hiab launches EFFER iQ.1400 HP

Hiab, part of Cargotec, launches EFFER iQ.1400 HP, a super heavy loader crane equipped with the advanced control system SPACEevo for improved productivity and safer operations. The size and vertical performance of the new loader crane make it ideal for operations in metropolitan areas.

The EFFER iQ.1400 HP is a 135 tonne metre (tm) crane that combines the V10-Force decagonal boom with the latest control system, SPACEevo.

It has a maximum vertical reach of 39.5 metres and with a JIB of 26 tm, it can deliver materials with an “up and over” of 26 metres. The V10-Force boom, first used in the EFFER 1000, provides increased strength for vertical performance and improved overall precision, further enhanced by the advanced control system.

The high lifting capacity makes it suitable for many applications, but the possible 83° working angle is perfectly suited for operations in metropolitan areas.

14 Lifting Africa - Mar/Apr 2023 LOADER CRANES

Being able to work closer to the buildings, makes it less obtrusive to the surroundings, and the boom profile reduces the side oscillations for high-precision load delivery. The low weight and compact frame size make it possible to install it on smaller trucks than is usual for this lifting category, which lower purchase and operating costs, as well as CO2 emissions.

“Customers will be able to experience a whole new level of heavy load lifting, with a crane that excels in vertical reach of over 39 metres.”

The engineering, combined with a CombiDrive4 remote control from Olsbergs gives operators unprecedented precision even at high heights.

The 135 tm range delivers performances similar to bigger segment cranes.

“The smaller frame makes it suitable for installations on smaller trucks and provides plenty of payload, not normally seen in this

segment,” says Marcel Boxem, Vice President, Sales & Product Management, Loader Cranes Heavy & Super Heavy, Hiab. The precision and safety are enhanced by the SPACEevo control system that provides advanced functions for veteran and novice operators alike.

The Load Stability System for vertical movements (LSS-V) compensates for unintentionally excessive lever movement in vertical operations, while the Variable Stability Logic PLUS (VSL+) feature optimises lifting capacity by monitoring the position and pressure of the stabiliser legs.

The Dynamic Load Chart (DLC-S) reduces setup time by simulating the load capacity before opening the stabilisers.

The EFFER iQ.1400 HP shares parts and controls with the other iQ. and iX range cranes.

This makes it easier for operators to use different size cranes and owners of multiple units can lower their warehouse inventory by

storing common spare parts that can be used across iX and iQ cranes. As the crane is connected, owners can access HiConnect™. It provides access to real-time insights about the condition of the equipment, to further increase productivity and operator safety.

Customers can monitor equipment status, plan service and improve operations from whole fleets down to single units. HiConnect is available in two levels: HiConnect Insights and HiConnect Premium. For peace of mind, customers can purchase a ProCare™ service contract to secure original performance with regular preventative maintenance checks and scheduled inspections. Repairs are covered as part of the most extensive package, ProCare Total R&M. Available plans may vary by market. Hiab,

Lifting Africa - Mar/Apr 2023 15 LOADER CRANES

+27 (0) 11 865 1425, sales@hiup.co.za, www.hiup.co.za Manage your steel more safely and more productively using less space with Combilift’s materials handling solutions combilift.com Safety Storage Efficiency • Safer product handling • Optimised production space • Improved storage capacity • Increased productivity & output • Enhanced profits Millennium Steel liz+Colin A5.indd 1 12/04/2021 12:10:34

New electronic platform for Hyva cranes complies with European Standards to assure safety and performance

All Hyva Cranes for CE markets are now fully compliant with European Standards EN12999:2020 and EN 13849* for a higher level of safety and performance in crane controls.

This has been achieved through a completely new electronic platform, which with new ergonomics, precision calculation software, clear displays, controls and top component reliability, delivers higher safety levels for the operator. This new platform underpins all Hyva cranes and the 5-step modular selection creates an environment in which every customer can specify the crane(s) best suited to their needs.

• Step 1 - the selection of the

product line and model with the required lifting capacity, from 1 to 85tm

• Step 2 - the crane control system – to control stability and slewing with a stability logic which computes all stability conditions and enables safe movements

• Step 3 - the human-machine interface – LED panel, intelligent display or smart top monitor – is available as standard or as an option across the ranges. Each gives the operator an excellent overview

of operations.

• Step 4 - the choice of manual or remote controls – single hand (Hetronic), LCD (Hetronic or Scanreco) or graphic (Hetronic).

• Step 5 - the selection of accessories from a wide range of options, including jib, oil cooler, winch and stand up platform.

Performance and safety are also improved through service initiatives such as Connectivity 4.0 (web access to crane data, status, position and analytics) and CUST (a software that can be used on every crane for installation, service, crane calibration, troubleshooting & maintenance).

As we celebrate these improvements, we are not resting, but working on more game changing innovations such as systems for automatic levelling (ALS), automatic stabilizer activation (OAD), and, verified cane lifting capacity based on truck stability (DLD).

Hyva, +27 (0) 11 822 1446, enquiries.sa@hyva.com, www.hyva.com

16 Lifting Africa - Mar/Apr 2023

TRUCK MOUNTED CRANES

HVO: A step towards zero-emissions

HVO is a cleaner fuel that offers up to 90% reduction in CO2 emissions. Helping the transition towards zero-emissions with internal combustion engines (ICE) that offer exceptional durability and consistent power delivery even in the most extreme environments.

Did you know Hyster Big trucks and specified engines in the 2-3.5t range are able to run on HVO100 according EN15940?

What is hvo 100?

HVO 100 is a bio-based, renewable, liquid fuel diesel alternative that meets the standard EN15940 for paraffinic fuels. As a secondgeneration biofuel, HVO 100 is reported to eliminate up to 90% of net greenhouse gas emissions (such as CO2) and reduce nitrogen oxide (NOx) particulate matter (PM) and carbon monoxide (CO) emissions. Produced from renewable materials, such as vegetable oils and animal fats, treated through a hydro treatment process, HVO 100 is almost chemically identical to conventional diesel. The process also removes any esters and contaminants, improving performance. This means that

subject to costs and the availability of a sustainable supply chain, HVO 100 can be used as a diesel alternative in the short term until equipment is replaced with Hyster’s Zero-Emission fleet. To find out if your truck can run on HVO please contact your local Hyster dealer. Benefits of hvo 100 over diesel and biodiesel.

Thanks to the fact that HVO 100’s paraffinic structure makes it almost identical to mineral diesel, it can be used as a drop-in alternative with only a few modifications needed on the equipment.

Both HVO 100 and diesel are similar in density, viscosity, energy content and flash point, meaning HVO 100 is fully miscible with diesel without the need to flush existing diesel from the system or tank before filling up with HVO 100.

Hvo 100 in hyster big trucks

To enable HVO 100 to be used with Hyster Big Trucks, Empty Container Handlers, or ReachStackers, an aftermarket kit has been made available. The solution supports compliance with Tier III, Tier IV, and Stage V emissions regulations and can be easily applied in the field, or factory-fitted for new equipment.

Nitrile Rubber (NBR) seals in the fuel system are replaced with FKM seals, which use fluorinated, carbon-based synthetic rubber with long-term resistance to the effects of ethanol. Current fuel lines and other components used already have good resistance to the longterm effects of HVO.

BHBW SA (Pty) Ltd, +27 (0) 10 023 8700, info@bhbw.co.za, www.bhbwholdings.co.za

Lifting Africa - Mar/Apr 2023 17

FORKLIFTS

Forklifts for farmers

What’s notable about these reliable machines is they can operate efficiently in all weather conditions and also ensure easy handling, cost-efficient operation, low maintenance requirements and stability on site.

TCM forklifts also optimise storage space in warehouses, as they have a high reach, eliminating the need for dangerous, unstable ladders and can easily operate in narrow aisles.

“An essential machine in every farming operation is the forklift truck. Robust TCM iNOMA forklift trucks offer reliable and safe handling of a wide range of materials, come rain or shine. Highperformance forklifts help farmers meet tight delivery deadlines and enhance safety every day,” explains Brenton Kemp, Managing Director of Criterion Equipment – exclusive distributors of TCM forklift trucks. “Instead of handling heavy loads manually - like hay bales, bulk bins and bags of feed or fertilizer - farmers use TCM forklift trucks to efficiently move goods quickly and safely, minimizing injury and freeing up valuable time for other important tasks. “Investing in TCM forklift trucks is a cost-

effective solution, as these versatile machines help reduce labour costs and increase productivity, ultimately leading to higher profits.

TCM iNOMA forklifts, which are reliable, durable and simple to operate, with low maintenance and operational costs, are fitted with tough ISUZU C240 engines, that give farmers the assurance that their machines will never fail them.

TCM’s electric, diesel and gas units are ideal for use in packing houses and warehouses that need to comply with emission legislation for food, processing, and packaging environments.

The company also supplies and supports highly efficient walkbehind and pedestrian trucks for farmers who do not require a forklift but need to move pallets with goods over short distances.

Criterion Equipment offers the highly capable and efficient 1.8 TCM forklift for those who do not need a 2- or 2.5-ton forklift, so customers don’t have to purchase an over-sized and more expensive unit if a 1.8 ton is sufficient. Units with lithium-ion batteries (for quick charging) are also available

for companies that work multiple shifts. Criterion Equipment specialists are on hand to advise farmers about which TCM forklift is best suited for specific agricultural applications. Factors to take into consideration include how much weight the forklift will need to transport and the height the load will be lifted to. Short and longterm rental options are the perfect solutions for seasonal harvesting, as farmers may not have the need for a forklift all year-round.

Different attachments for different farm duties

The versatility of forklift trucks means they can be upgraded or modified at any time to be even more useful on the farm. And with the addition of special attachments, they are able to handle most handling tasks quickly and safely.

Criterion Equipment can source and supply attachments needed, including bin tippers, fork adjusters, rotating clamps, double pallet handlers and scales with printers. By using the correct attachments, a forklift can be used to quickly sweep and clean floors – this method is particularly efficient for cleaning stables and sheds. Other

18 Lifting Africa - Mar/Apr 2023 FORKLIFTS

The Criterion team works closely with local farmers to ensure they benefit from the investment in modern agricultural machinery. TCM forklifts have many advantages for farmers and can be seen hard at work in various agricultural operations across South Africa.

applications include the handling of crates of produce, fence posts and building supplies.

Safe operation requires operator training and certification

Although forklift trucks are a useful tool in farming and agriculture, they can also be dangerous if not used correctly.

Criterion Equipment specialists recommend that operators undergo a comprehensive training programme that covers the safe operation of forklifts, including proper loading and off-loading techniques, maneuvering in tight spaces and quick response in emergency situations.

Operators should also be warned about the hazards and risks associated with operating forklifts in agricultural settings, including the presence of workers and livestock, and challenging outdoor weather conditions.

Forklift operators must be aware of the environmental hazards they may encounter - like uneven terrain, rough surfaces and wet, slippery conditions. To prevent accidents, operators must adjust their driving techniques and slow down on uneven surfaces and avoid steep inclines or declines.

Specialists urge farmers to be especially careful about not overloading the forklift. Operators must be informed of the load capacity of their forklift and ensure that goods are evenly distributed

and secured before moving them. They should always avoid carrying loads that are too heavy or too large for the forklift, which can result in tipping and other accidents.

Good maintenance matters

Taking good care of forklift trucks is important to ensuring optimum performance and extended service life. Every machine requires regular servicing at a reputable specialist and regular load testing should form part of the maintenance programme.

Criterion Equipment’s service includes a national field services facility, which provides assistance during breakdowns, the repair and maintenance of machines and maintenance contracts. The company’s national workshops are also able to completely refurbish an existing machine according to OEM specifications.

Criterion Equipment (Pty) Ltd, +27 (0) 11 966 9700, info@criterion.co.za, www.criterion.co.za

FORKLIFTS

Konecranes’ Static Weighing System

now with in-cab printer to further reduce wait times in ports

As stated by SOLAS, one of the many ways the industry can mitigate any potential risk includes the weighing of containers, where shippers are to provide the verified gross mass of all packed containers, and those that fail to do so, will not have their containers loaded onto a ship.

Under the SOLAS amendments, there are two permissible methods for weighing. Method one requires the weighing of the container after it has been packed, and method two, which requires weighing all the cargo and contents of the container and adding those weights to the container’s tare weight as indicated

on the door end of the container. According to Lenny Naidoo, Acting National Operations Manager at CFAO Equipment SA’s Heavy Lift division, the container weighing process in port operations is a lengthy process, often leading to inefficiencies and poor productivity.

“It is for this reason that Konecranes, a leading international manufacturer of cranes and lifting equipment for use in port operations, developed its Static Weighing System. As an industry first, the Static Weighing System has seen great success since its recent launch, where reach stackers can now hydraulically measure the weight of lifted containers before they are loaded onto a ship, with 1% full-scale accuracy achieved and verified in less than five seconds. This is a dramatic improvement compared to conventional weighing methods where containers are loaded onto weighbridges, with the process taking more than five minutes at the least,” explains Naidoo.

20 Lifting Africa - Mar/Apr 2023 FORKLIFTS

The need to bolster safety, productivity and efficiency in the port environment has come under the spotlight in recent times. This is as amendments to the Safety of Life at Sea (SOLAS) have become more stringent to reduce any potential maritime risk.

Recent updates to the system include an in-cab printing system that not only provides the port and operator with a printed verified weight, but automatically transfers and stores the data on the YourKonecranes cloud-based service. This allows for seamless integration between the weighing systems and users’ Terminal Operating System (TOS), Transport Management System (TMS) or Enterprise Resource Planning (ERP) systems.

The Static Weighing System is easy to operate, with the operator initiating the weighing process from a multi-touch 7-inch control display inside the cabin once the container is lifted into its transport position, and provided with an automated Verified Gross Mass (VGM) declaration using the data gathered. The automated VGM declaration contains detailed information such as gross container mass, exact container ID, time and date stamps on each container, operator details and even lift truck data. Furthermore, the system detects the GPS coordinates of

the container, making for easier container picking and loading.

“The updates to the Konecranes Static Weighing System will make it not only easier for customers to comply with SOLAS regulations but will bolster their productivity and overall efficiency. The system will also provide them with the agility

and performance required to do more in less time, which will lead to increased operational profitability and elevated levels of safety in port operations,” concludes Naidoo.

CFAO Equipment SA, +27 (0) 11 395 0600, info@cfaoequipment.co.za, www.cfaoequipment.co.za

Lifting Africa - Mar/Apr 2023 21 FORKLIFTS

Piacenza

5-7 Ottobre 2023

Las Vegas, NV

14-18 Marzo 2023

Bologna

DEMAC S.R.L. | MAGENTA (MI) - ITALY | +39 02 9784488 | INFO@DEMAC.IT | WWW.DEMAC.IT

29-31 Marzo 2023

Manitou Group chooses Siemens Xcelerator portfolio for the lifecycle management of its products

Manitou Group, a world reference in the handling, aerial work platform and earth moving sectors, has teamed up with Siemens Digital Industries Software to develop a global solution for managing the lifecycle of its products.

As part of the Group’s digital transformation, the implementation of this tool aims to standardize its design processes.

Manitou Group has chosen Teamcenter® software for Product Lifecycle Management (PLM) from the Siemens Xcelerator portfolio of software and services.

Dedicated in particular to the management of the machine database, the elements linked to the various components and their nomenclature, Teamcenter will be implemented to streamline and simplify product design on all of the Group’s 10 production sites in the United States, India, Italy and France.

In addition to this innovative tool, Siemens’ NX™ software for product engineering has been chosen as the CAD (Computer-Aided Design) tool. This sizeable project is fully in line with the Group’s desire to make its digital transformation one of the pillars of its strategic roadmap.

Julien Waechter, Vice President

R&D at Manitou Group, explains: “This major investment will allow us to

modernize our tools, particularly through virtual reality, to enhance our performance and to achieve the same design across several sites without having to rework the data. In practice, we will have unique data for each product for all Group employees. The advantage of the Siemens solution is also its ability to connect to our existing tools, including our ERP. Siemens’ reputation and the expertise of the support teams convinced us that we were making the right decision.”

By implementing this global solution, the Group will be able to optimize the time spent on its product development, while working on a single tool that allows the entire product life cycle to be centralized. 1,600 users will be impacted by this change.

They primarily work in the design and R&D offices, in the methods, technical documentation and after-sales departments, and in the marketing teams, and will be given training within the Group over the next three years.

The first stage of this implementation, up to 2024, concerns definition of the core

model and preparation for deployment. The Group’s goal is to implement the solution in the United States by the end of 2024, with roll-out in Europe and India estimated for 2025.

To help the project run smoothly, the team from Siemens is working closely with the Manitou Group project team.

“We are delighted that Manitou Group has selected the open and interoperable Siemens Xcelerator portfolio of software and services and we are fully committed to supporting Manitou during its journey to achieving its digital transformation goals,” said Jean Marie Saint-Paul, CEO Siemens Digital Industries Software France.

“It’s another great example of how industry pioneers are choosing our solutions to help them build the products of the future and we look forward to helping Manitou Group across the globe.”

Manitou Group, +27 (0) 10 601 3000, info.msa@manitou-group.com, www.manitou.com

22 Lifting Africa - Mar/Apr 2023 FORKLIFTS

Lifting Africa & Pipes, Pumps And Valves Africa

Golf day 2023

Thank you to all our Sponspors:

23 Lifting Africa - Sep/Oct 2022

Check out all different types of Green Pin® Master Links

The Green Pin® assortment includes a variety of master links and master link assemblies. All these master link(s) assembly (ies) have different specifications and can be used in different environments. Check out the variety of the Green Pin® Master Link assortment below.

Green Pin® Master Link EN1677-4

Grade 8 master link EN1677-4

The Green Pin® Master Link EN1677-4 is a single grade 8 master link according to European standard for components for sling EN 1677-4.

This welded master single link is designed for a 1 or 2 leg sling. The flat on the eye enables the assembly with an omega link or on a thimble. The Green Pin® Master Link EN1677-4 is available in a range with a working load limit from 1.6 t. up to 125 t.

• Reliable Green Pin® quality and support

• Superior stock availability of 99%

Green Pin® Master Link

Grade 10 master link

The Green Pin® Master Link is a grade 10 single master link. This welded single master link is designed for a 1 or 2 leg sling. The flat on the eye enables the assembly with an omega link or on a thimble. The Green Pin® Master Link is available in a range with a working load limit from 2 t. up to 27.6 t.

• Reliable Green Pin® quality and support

• Superior stock availability of 99%

Green Pin® Wider Master Link GR 10

Grade 10 wider master link

The Green Pin® Wider Single Master Link is a grade 10 single master link with larger inside dimensions. This welded single master link is designed for 1 or 2 leg slings.

This range is complementary to the existing range UMS and UMTS. The extended width enables you to connect the link to a connection point, which is wider than usual or to fit in a large crane hook. A flat part on the link enables assembly with an omega link or with a thimble. The Green Pin® Wider Master Link is available in a range with a working load limit from 4.1 t. up to 64 t.

• Larger inside dimensions: fits on large crane hooks

• Easy assembly with omega link/thimble due to flat part

• Specially designed for 1- or 2-leg slings

• Superior stock availability of 99%

Green Pin® Master Link NS9415 GR8

Grade 8 master link acc. to NS 9415

The Green Pin® Master Link NS9415 GR8, is a grade 8 master link. The Master Link is certified according to DNV NS 9415 and has a large opening to accommodate larger connecting links.

The hot dipped galvanization ensures long-term durability even under severe environmental conditions, as required by the NS 9415 standard. This master link is designed for a one- or two-leg sling. The master links are available in a range with a minimum breaking load from 32.8 to 112.4 t.

• Ideal for aquaculture: DNV-certified to NS 9415

• Hot dip galvanization assures long-term durability

• Larger inside dimensions: fits on large crane hooks

• Part of Green Pin® aquaculture system

• Reliable Green Pin® quality and support

Green Pin® DNV Master Link

Grade 8 master link

The Green Pin® DNV Master Link is perfect for offshore use. The Master Link is DNV-certified and has a large opening to accommodate larger lifting points and crane hooks. Moreover, the coating of the DNV Master Link ensures long-term durability, even under severe environmental conditions. The DNV Master Link is available in a range with a working load limit from 4.1 up to 100 ton.

• Extra large opening to accommodate larger lifting points

• Ideal for offshore use (DNV certification)

• Coating assures long-term durability

• Superior stock availability of 99%

Green Pin® DNV Master Link Assembly

Grade 8 master link assembly

The Green Pin® DNV Master Link Assembly is perfect for offshore use. The Master Link Assembly is DNV-certified and has a large opening to accommodate larger lifting points. Moreover, the coating of the DNV Master Link Assembly ensures long-term durability, even under severe environmental conditions. The DNV Master Link Assembly is available in a range with a working load limit from 4.1 up to 100 ton.

24 Lifting Africa - Mar/Apr 2023

Master Links or Master Link Assemblies are the starting point of each sling assembly. They are directly connected to the crane hook and therefore this component is an important link in the whole assembly.

• Extra large opening to accommodate larger lifting points

• Ideal for offshore use (DNV certification)

• Coating assures long-term durability

• Superior stock availability of 99%

Green Pin® Master Link Assembly

Grade 10 master link assembly

The Green Pin® Master Link Assembly is a grade 10 master link assembly. This welded master link assembly is designed for 3 or 4 leg sling.

The flat on the eye enables the assembly with an omega link or on a thimble. The Green Pin® Master Link Assembly is available in a range with a working load limit from 3.65 t. up to 41.6 t.

• Reliable Green Pin® quality and support

• Superior stock availability of 99%

Green Pin® Master Link Assembly EN1677-4

Grade 8 master link assembly EN1677-4

The Green Pin® Master Link Assembly EN1677-4 is a grade 8 master link assembly according to European standard for components for sling EN 1677-4.

This welded master link assembly is designed for 3 or 4 leg sling. The flat on the eye enables the assembly with an omega link or on a thimble. The Green Pin® Master Link Assembly EN1677-4 is available in a range with a working load limit from 2.5 t. up to 100 t.

• Reliable Green Pin® quality and support

• Superior stock availability of 99%

Green Pin® Wider Master Link Assembly

Grade 10 wider master link assembly

The Green Pin® Wider Master Link Assembly is a grade 10 master link assembly with larger inside dimensions. This welded master link assembly is designed for 3 or 4 leg slings. This range is complementary to the existing range UMS and UMTS. The extended width of the main link enables you to connect the link to a connection point, which is wider than usual or to fit in a large crane hook. A flat part on the link enables assembly with an omega link or with a thimble.

The Green Pin® Wider Master Link Assembly is available in a range with a working load limit from 4.3 t up to 75 t.

• Larger inside dimensions: fits on large crane hooks

• Easy assembly with omega link/thimble due to flat part

• Specially designed for 3- or 4-leg slings

• Reliable Green Pin® quality and support

• Superior stock availability of 99%

Green Pin® Heavy Duty Master Link

Weldless Heavy Duty Master Link (grade 8)

The Green Pin® Heavy Duty Master link is a grade 8 master link for heavy duty applications. By using a unique innovative production method, the master links are fully forged as a single piece, without any welding whatsoever.

As a result, the master links meet the most stringent safety- and performance requirements and will keep working reliably in even the harshest environments. The master links are painted silver with a green mark indicating a maximum lifting angle of 120 degrees, making it easy for riggers to spot potentially unsafe operations.

The exceptionally smooth surface reduces wear on counter components such as slings and shackles. To rule out cracks, each Master link is submitted to several non-destructive tests before shipping. The consistent Charpy-V Value of at least 42 Joule throughout the entire Master link, makes it compliant with offshore certification requirements. All products are available from stock and ready for fast delivery. The master links are available in a range with a working load limit from 131 to 400 ton.

• Extremely safe: fully forged & completely weldless

• Smooth surface: less wear to slings

• 120 degrees lifting angle indicator

• Conforms to offshore certification requirements

• Available from stock, fast delivery

Green Pin, sales@greenpin.com, www.greenpin.com

Surge in demand for LTM’s GIS electric chain hoist

GIS-owned Lift Turn Move Ltd.’s (LTM) single-phase electric chain hoist series is being widely utilised, with construction a primary market.

GIS-owned Lift Turn Move Ltd.’s (LTM) single-phase electric chain hoist series is being widely utilised, with construction a primary market.

The GIS GP single-phase series includes the GP250/500 and GP1000 models, which have a lifting capacity range of 125Kg to 2000Kg and are available in both 110V and 220V options.

With a higher duty rating than the previous GCH series, the GP series is also IP65 standard which is dust proof and protected against water jets and can be combined with the GIS GPR (Corrosion Resistant/Food

Grade) series, which has the added benefit of stainless-steel load chain and hook assembly.

This combination makes it extremely suitable for not just harsh environments such as offshore or by the sea but food and pharmaceutical clean room applications also.

When asked why single-phase 110V is often favoured in construction compared to 400V three-phase.

Robert Price, general manager, LTM explained: “In construction 110V is generally accepted as being inherently safer as it's a lower

voltage that reduces the risk of harm if a cable is accidentally cut or damaged”.

Price said since its acquisition by GIS in 2018, LTM is focusing on selling the core range of GIS electric chain hoists and trolleys.

“Prior to the acquisition, traditionally LTM had always been one of the go-to manufactures for lifting jacking, winching equipment, offering a vast range of products. The focus on selling our core products has allowed us to stock more of items our customers expect from us with a positive impact on sales as a result,” he said.

“The 110V GIS hoist is a great example of this focus on GIS products; we’ve got the stock, the expertise and the hoist speaks for itself as it’s a great product.”

• LTM, located in Bromborough on the Wirral, was founded in 2004 and is a full member of the Lifting Equipment Engineers Association (LEEA).

26 Lifting Africa - Mar/Apr 2023

Lift Turn Move, sales@liftturnmove.co.uk, www.liftturnmove.co.uk CHAIN HOIST

Sponsors and Partners: Hosted by:

Live Demos Innovation Discussion Training

The networking exhibition for the lifting equipment industry

liftex.org #liftex2023

Packed show floor of lifting equipment and services

21-22 November Exhibition Centre Liverpool

FREE TO ATTEND FOR USERS AND BUYERS OF LIFTING EQUIPMENT ACROSS MULTIPLE MARKETS

Advanced Construction Robotics launches

the world’s first rebar lifting, carrying, and placing robot

Advanced Construction Robotics (ACR) is launced its second product, IronBOT®, during ConExpo, IronBOT augments construction crews by lifting, carrying, and placing up to 5,000-pound bundles of rebar in a transverse or longitudinal orientation without the need for heavy lifting from crewmembers.

When IronBOT is combined with TyBOT®, our rebar-tying robot, this powerful BOT Bundle can typically provide 50% schedule savings during rebar installation.

“We are confident the combination of TyBOT and IronBOT generates a disruptive technology, meaning the time and cost savings are so significant on a job that it will disrupt the way our industry installs reinforcing steel,” said Stephen Muck, Founder and Executive Chairman of Advanced Construction Robotics.

IronBOT successfully completed its inaugural project in February on the Port St. Lucie West Boulevard Bridge in Port St. Lucie, FL alongside Shelby Erectors, Inc. The originally estimated duration of the rebar installation was 14 days. By augmenting Shelby’s crew with the BOT Bundle, the same amount of work was completed in only seven days. During the pilot, IronBOT placed 147,032 LB of rebar while TyBOT completed 58,068 ties over 6.5 production shifts. Shelby Erectors, ACR’s Integration Partner, has already been boosting crew productivity with TyBOT for over two years. "We were excited to be

able to have IronBOT and TyBOT work together alongside our crews on this project. We were impressed that we could slash our rebar installation schedule in half. We are actively looking for new projects to incorporate the BOT Bundle in our operations," said Jack Nix, COO of Shelby Erectors, Inc.

"I am so excited to see our initial prediction of cutting schedules by at least 50% come to fruition on IronBOT’s maiden voyage. This was a perfect example of how field teams, working alongside our technology, can form a “modern crew” to unleash disruptive productivity levels," said Danielle Proctor, CEO of Advanced Construction Robotics. "This robotic revolution provides innovative construction firms the ability to become game-changers by adopting and putting their ‘modern crew’ to work.”

ACR is also excited to announce Brayman Construction and Advantage Steel & Construction are currently the only contractors certified to provide the BOT Bundle solution as part of its newly launched Certified Innovator Program. Certified Innovators have

dedicated crews that have gone through hands-on training on how to optimize operations alongside the BOT Bundle and incorporate the technology in their installation pricing. "We are excited to work together to show the construction industry how this adoption of robotics at an organizational and cultural level can lead to overall results that are impossible to ignore," said Zach Rosswog, General Manager of Advantage Steel and Construction.

"Technology is changing the way we approach construction. It helps contractors like us cope with shrinking labor forces and growing demand. We become more productive, efficient, and safer when we pair this technology with an innovative mindset," said Tim Taylor, Vice President – Heavy Civil of Brayman Construction Corporation. "That's why we are proud to be the first Certified Innovator and will continue to work with ACR to weave technology into our company identity."

Advanced Construction Robotics, info@acrbots.com, www.constructionrobots.com

28 Lifting Africa - Mar/Apr 2023 ROBOTICS

Training and service centres for drives distributor

iTek Drives, the Germiston-based variable frequency drives distributor, is to open a training centre for transferring and improving knowledge of Optidrive product installation, programming and repair.

The training centre will open in May of this year.

Variable frequency drives (VFDs), also known as an inverters, are electronic controllers that change electric motor speeds by adjusting the frequencies and voltages of current supplied.

They are most commonly fitted to fans, pumps and compressors, but are also found in lifting equipment and other applications where fully adjustable speeds during start, stop and machine acceleration are advantageous.

Optidrive products are manufactured in the UK by Invertek Drives. In South Africa, iTek Drives has built upon the brand’s solid reputation for quality by supporting it with pricing up to 25 percent lower than competitors.

The result has been significant local competitive advantage.

Besides increased sales, iTek’s

training centre is needed for an expanding geographic footprint. The company recently announced an export order for 20 drives for mining machinery in Zimbabwe.

Sales director Ryan Bisnath says that, besides the training centre, the company has plans to establish a separate service centre for product maintenance, repair and refurbishment, removing this responsibility from Invertek in the UK.

“We will focus on the service centre as a secondary objective after our expanded training programmes are running,” Bisnath said.

“Local enquiry flows are strong, so the aim now is to become a distribution hub for the Optidrive range across sub-Saharan Africa. We have begun exploratory negotiations with potential agencies in Zambia and Namibia to expand our network beyond the ten we have here in South Africa.”

In addition to the 20 VFDs for Zimbabwe, there have been significant orders within South Africa’s borders: 20 drives for lifting equipment, and another for 17 VFDs for a local steel mill.

These orders include eight large units of 55kW, 70kW and 75kW.

Bisnath noted that iTek Drives has seen a significant increase in the number of enquiries from potential customers not yet on the company books.

“We did suffer from the impact of global supply shortages, but these difficulties are behind us now. We are looking forward to becoming central and southern Africa’s onestop automation solution company for drives, motors, gears and control panels,” he said.

Itek Drives, +27 (0) 62 301 0478, ryan.bisnath@itekdrives.com, www.itekdrives.com

30 Lifting Africa - Mar/Apr 2023

PRODUCTS & SERVICES

Tower Cranes & Mining A continuing success story Economical. Efficient. Reliable. Safe. www.liebherr.com Tower Cranes

Spectacular solar trees

At first glance, the massive tree structures at the Eastgate Shopping Centre in Bedfordview, Johannesburg, look like impressive pieces of art, but visit the centre at night and you will find them transformed into awe-inspiring lights. Lifting Africa decided to find out more about these solar trees and their journey to the shopping centre’s rooftop piazza.

Inspired by a visit to Baines’ Baobabs in the Botswana Nxai Pan National Park, the solar trees at the Eastgate Shopping Centre are probably one of the most iconic steel structures in the country at present. There is no doubt that if a baobab tree was made of steel, this is what it would look like.

For Andrew Kirkland, Director of Anchor Enginuity the main contractor of the project, it is work that he and his team are exceptionally proud of. “Anchor is known as architectural steel specialists. When we heard of this project, we knew that this was exactly the type of work that we

pride ourselves on and wanted to be involved with.”

Commissioned by Liberty Two Degrees (L2D), a retail center real estate investment trust (REIT) and owners of the Eastgate complex, Anchor was involved in the project from the early stages.

“We did a lot of the upfront research and development with the team to refine the design to meet aesthetic needs. The design also needed to be in such a way for the structure to be installed in a live shopping centre on top of a roof slab,” explains Kirkland.

For L2D the trees needed to serve several purposes; the first and foremost being the provision of light to the area at night. The decision to go solar was strongly aligned with the company’s 2030 net-zero targets. With its patrons in mind, L2D are continuously seeking to enhance visits to its properties with human-centric designs. With a strategy in place to activate rooftop spaces as part of its vision to create

32 Lifting Africa - Mar/Apr 2023

INDUSTRY NEWS

smart and interactive spaces for shoppers, several options were presented for the Eastgate Piazza space.

The solar trees were immediately preferred as they were not only sculptural but also functional and sustainable, providing an architecturally enriched identity to the centre.

For the architect, the three trees in Botswana that represent a meeting point for the local community, it made sense to recreate this at Eastgate. The three trees represent a father, mother and child in their respective sizes.

Weighing a whopping 18,8 tons combined, the three structures are all symmetrical within themselves with the scale varying for each one to overall compliment the aesthetic picture.

The biggest of the three trees weighs 10,5 tons on its own. It is 13,5 meters high by 14 wide. The second tree is 10,5 metres high by 10 wide and the smallest of the trees, representing a child, measures 9 metres high by 9 wide. Accuracy and wrap-around infill members needed to be rolled perfectly to keep the perfect symmetry of each of the structures. The infill slices had to all be jigged per tree in three dimensions in order for all locating bolts to fit perfectly.

Rooftop construction

Moving the structures onto the site was an exceptionally difficult task, says Kirkland who explains that for constructability the trees were broken into three components – the trunk, the arms and the infill slices.

According to Steven Hasselbach, Eazi Access General Manager: Gauteng, who was contracted for the lifting work, an in-depth site inspection based on the customers enquiry was essential to fully understand the scope of the application and to ensure that the correct equipment was used.

“For this specific project, moving structures was an extremely sensitive task and safety needed to be a key focus from many different aspects,” he said. “A Maeda

MC305 mini crane that spesialises in working in confined spaces was used. It offers a very compact dimension with high lifting capacity, with exceptionally low noise and it is designed to work both indoor and outdoor. It plays a significant role in safety with four supportive outriggers.”

Hasselbach says the JLG X20 Compact Crawler was used for lifting people to height to perform the work needed.

“This machine has a smart design low weight accessibility and operates in a weight restricted area which was a requirement for this project. It is equipped with track drive for easy manoeuvrability in sensitive environments and minimal emissions and noise pollution.”

According to Kirkland, because the Eastgate piazza had a slab load limit of 2KN/m2, the piazza was some way away from where they could access.

“We offloaded the various components with a crane onto the roof slab. We then placed this material directly onto fabricated trolleys on the roof slab and manually rolled this to our laydown area. We then used spider cranes to handle the material.”

With the shopping centre fully operational every day with hundreds of shoppers, only night work was permitted. “Each evening the relevant component was trollied into position and hoisted up,” says Kirkland. “The biggest tree component was the tree trunk weighing in at 7.5 tons. We needed to do a tandem lift with two spider cranes. While lifting, we had to

be mindful of load distribution on the cranes out riggers at all times. The big tree’s final infill was also a challenge as the height versus reach of the spider crane we were using was tested.”

Also, he says, this structure was overlapping with the main building. Whilst the project was not without challenges – including the outbreak of Covid-19 and a global lockdown – the three trees are today, undoubtedly, a proud beacon of what the South African building industry is capable of.

“It is always rewarding seeing the final output of a project like this, especially a project around renewable energy. The Solar Trees are not only functional in design but truly are a beautiful, architectural design,” says Hasselbach.

Award-winning structure

The workmanship was recognised in 2022 by the South African Institute of Steel Construction (SAISC) with the project getting the sculptural/ architectural award.

“Not only are the trees aesthetically pleasing but it also cleverly reflects a renewable energy focus.”

“The project was delivered under challenging circumstances as access to the site during the construction phase was limited, making for a complicated and challenging installation process,” says Amanuel Gebremeskel, SAISC CEO.

Lifting Africa - Mar/Apr 2023 33

Anchor Enginuity, +27 (0) 72 386 7969, info@anchoreng.co.za, www.anchoreng.co.za INDUSTRY NEWS

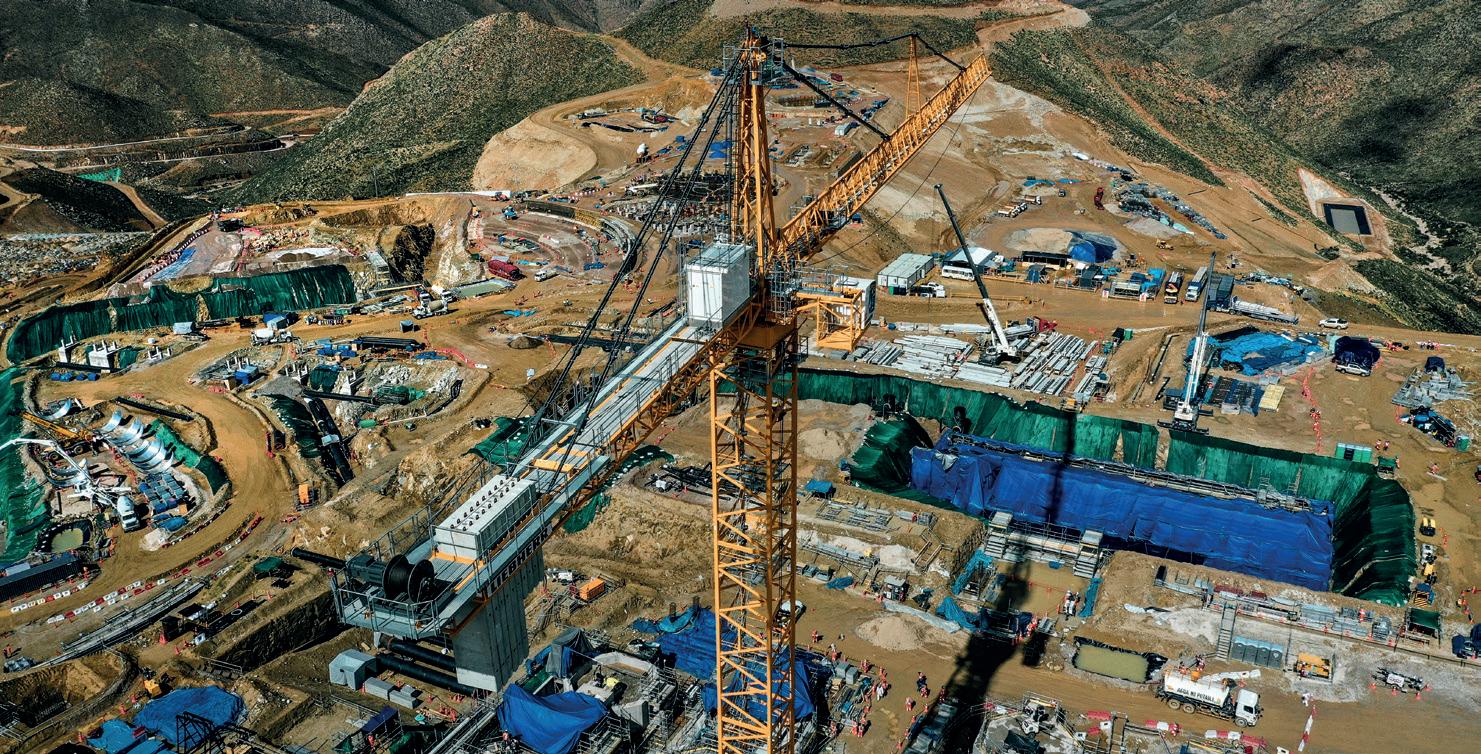

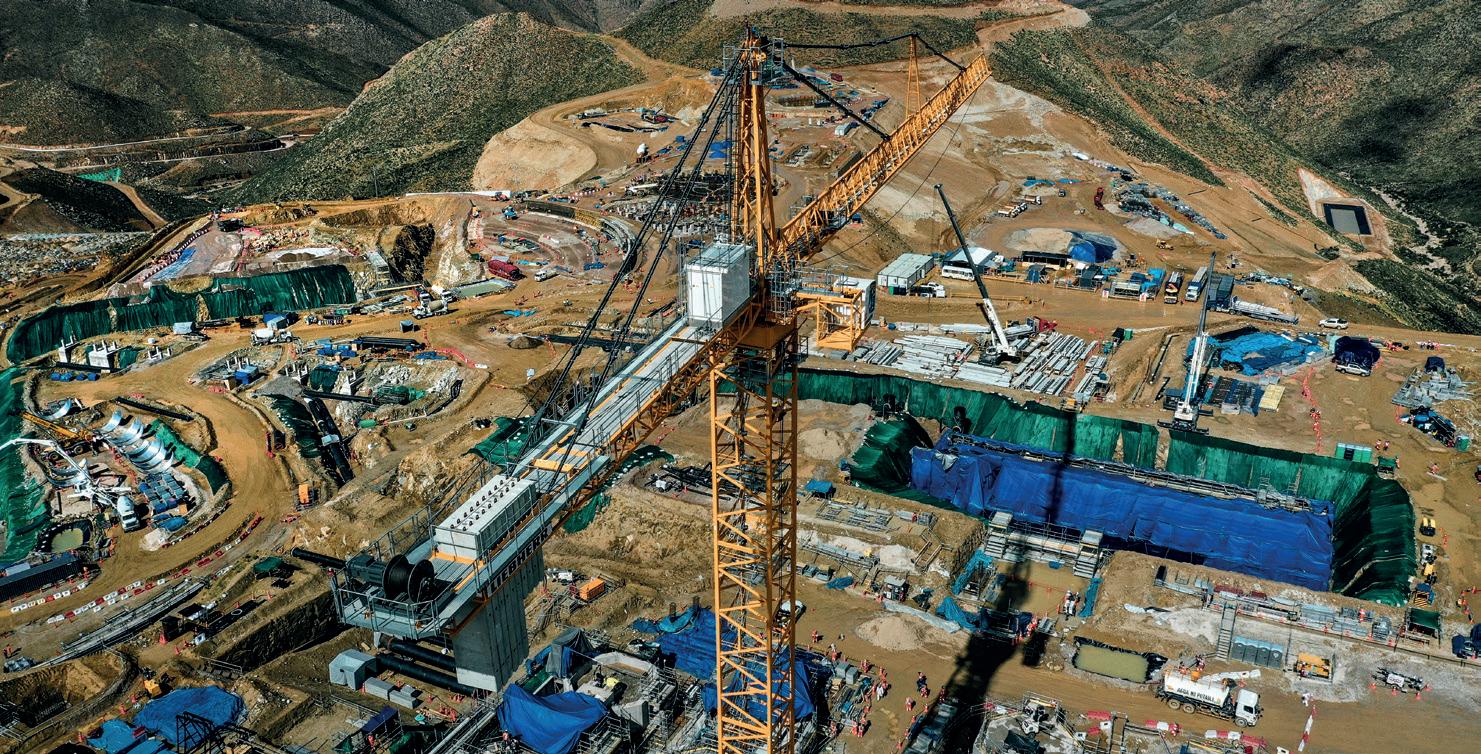

Construction and engineering insurance

Major construction projects are more likely to be undertaken by clients with a global footprint, attracting investors to local economic development projects.

And while there is currently a strong focus on smaller commercial projects such as office blocks or manufacturing facilities, the investment is welcomed in an industry that remains under pressure. According to the latest StatsSA findings, the construction industry remains 23.1% smaller than it was before the pandemic, with 2022 marking construction’s sixth consecutive year of decline.

“When planning a construction

project of any size, insurance and risk management are crucial components that need to be factored into the planning stages of a project, as these costs need to be included in the construction budget,” says Santesh Pillay from Aon South Africa’s Construction & Engineering team.

“A construction project usually comprises of three distinct disciplines which is engineering, procurement and the actual

construction of the project. The spectrum of cover required across these disciplines can be vast, ranging from core lines such as property, general liability, marine, business interruption and directors and officers insurance; through to specialty lines such as cyber, environmental liability and stand-alone riot, strikes and civil commotion cover,” Santesh explains. Santesh highlights the importance of having adequate cover in place. “We know that insurance is viewed as a grudge purchase, but in an industry where a loss can amount to millions if not billions of Rands, it is imperative to do your research thoroughly and to make sure that your sums insured are correct for all your identified risks.”

Aon unpacks salient risks to consider in the making of a well-rounded construction and engineering insurance schedule:

• Construction materials procured for a construction project are subject to the risk of theft, with materials such as copper wire and other high-value items frequently

34 Lifting Africa - Mar/Apr 2023 INDUSTRY NEWS

targeted. Many insurance policies are specific on how items need to be stored in addition to having 247-365 security personnel on site.

• The risk posed by Strikes, Riots and Civil Commotion (SRCC) needs to be considered. From a South African perspective, Sasria SOC Ltd offers insurance against such risks in terms of various Sasria products in accordance with the Public Finance Management Act No 1 of 1999. It is important to speak to your broker about including Sasria SOC Ltd cover relating to property damage, business interruption, money, goods in transit, motor and construction risks.

• Adverse weather affects 45% of construction projects globally, a 2021 report from the Air Force Institute of Technology found, resulting in billions of Rands of additional expenses and lost revenue related to project delays, supply chain shortages and even impacting worker safety on site. The adoption of a robust Business Continuity Management (BCM) plan is key in addressing the issue and finding workarounds.

• Defect in design from an engineering perspective is usually tied to costly legal liabilities and can severely damage the reputation of the engineer(s) and/or construction companies involved. An example is a bridge that is not adequately designed to span a river or is

not sufficiently enforced to carry the weight. Many construction companies are paying closer attention to contractual wording related to engineering contracts and are including liability clauses for defect of design, which in turn highlights the need for Professional Indemnity cover for professionals in the field.

• Specialised plant or machinery refers to ‘yellow metal equipment’ which are designed and built for specific tasks or functions such as excavators, bulldozers and cranes. These types of equipment are often costly to manufacture and purchase, and they require specialised knowledge and training to operate. Needless to say, cover for these items often needs to be very specific and bespoke taking into account the replacement value of the item; especially in instances where a piece of equipment was designed to fulfil a specific need and cannot be easily replaced.

Renewed focus on renewable energy projects:

With energy disruptions being front and centre, there is healthy interest in the construction of renewable energy projects. The sheer scale and urgency of these projects bring significant and complex risks into play that span across financial requirements, right through to contractual liabilities. “Renewable

energy insurance products cover the main lines of insurance such as property, engineering, marine and liability while additional special types of insurance can be made available such as credit insurance, political and weather risks, Errors & Omissions, and Directors & Officers cover,” Santesh explains. “While the cover is similar to construction, it also addresses the specialised needs that come with a renewable energy project and the liabilities it entails, that looks at specific extensions, limits and endorsements that we can negotiate on behalf of clients,” he adds.

Any construction project needs to be undertaken with a clear understanding of the risks that the project may be faced with. “Ensure that you are adequately covered so that any mishap along the way does not put you or your business under any financial strain. It is crucial to engage the services of a broker who has a deep understanding of the construction, engineering and renewable energy landscape, so that the only thing you need to worry about is finishing your construction project,” Santesh concludes.

Aon South Africa, +27 (0) 86 010 0404, info@aon.co.za, www.aon.co.za

www.nerimotori.co.za

Lifting Africa - Mar/Apr 2023

INDUSTRY NEWS

Vita Industrial brings intelligent lifting technology and IoT to CONEXPO 2023

Throughout CONEXPO, Vita Industrial had live demonstrations of its Vita Load Navigator (VLN) which uses a powerful system of sensors and air thrusters to automatically stabilize loads and prevent them from spinning.

The demonstrations showed how the VLN can increase safety, efficiency, precision, and therefore, profitability when managing loads compared to the use of taglines.

“Vita Industrial is thrilled to be a part of the largest construction tradeshow in North America for the first time,” said Caleb Carr, chairman and CEO of Vita Inclinata.

“Construction companies and equipment suppliers in the U.S. and around the world are quickly learning how load stabilization can dramatically improve their lifting operations. The VLN can speed up construction schedules and improve jobsite safety. We can’t wait to show off the technology live in Las Vegas.”