Cooper & Cooper Group broadens horizons with expanded product line

From the Chairman’s Table

2023 LEEASA Individual Members & Company Members in Good Standing

your match. Power your fleet.

to Condra

Cooper & Cooper Group, +27 (0 11 493 4355, info@coopergroup.co.za, www.coopergroup.co.za

Lifting Africa

Managing Editor: Surita Marx

Tel: +27 (0) 87 700 9834

Email: surita@liftingafrica.co.za

Web: www.liftingafrica.co.za

LEEASA Editor: Kyle Graham

Email: kyle@leeasa.co.za

Editor: Xane Roestroff

Email: adverts@liftingafrica.co.za

Sales: Lusana Merckel

Email: lusana@liftingafrica.co.za

Sales Assistant: sales@liftingafrica.co.za

Disclaimer: Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers LEEASA. The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication.

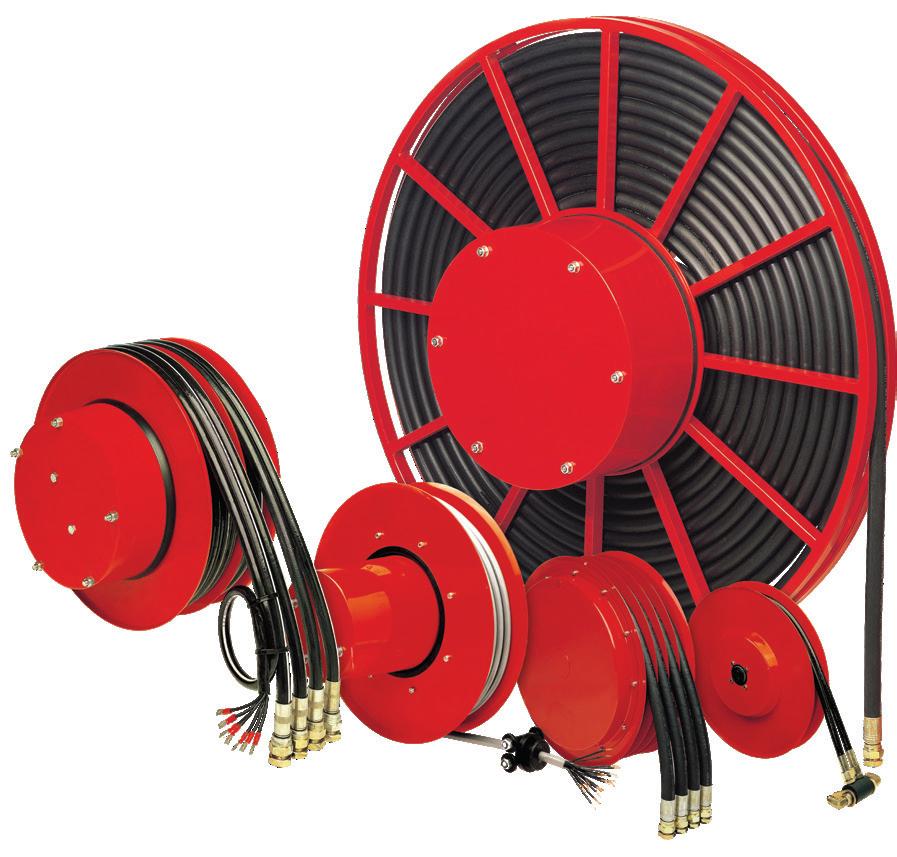

In today’s rapidly evolving business landscape, companies recognise the immense value of diversity. One such business is Cooper & Cooper Group, which recently embarked on a journey to expand its product line. The company is excited to announce the acquisition of exclusive and sole distributorship of DAESAN INOTEC products. Lifting Africa met up with the Cooper & Cooper Group team to learn more about the new developments.

With its 125+ year legacy, Cooper & Cooper Group has built an established reputation for delivering top-ofthe-line products and services to the mining, industrial, construction, OEM and marine industries.

The company’s expansive catalogue is made up of some of the industry’s most trusted lifting and rigging products - with esteemed brands such as Nitchi, Donsa and Tsala.

According to CEO Lorato Mogaki, the company recognised the need to adapt and evolve. “In today’s dynamic business landscape, broadening the scope of supply is crucial to stay competitive and adapt to ever-changing customer demands, technological advancements, and global market trends,” she says, indicating that they set out to diversify their offerings, understanding that it would not only bring a fresh perspective to their business but also allow them to connect with a broader customer base.

Procurement Manager Jacqui Vere says it was no easy undertaking and required meticulous evaluation of

products from a range of suppliers. “Our goal was to broaden our scope of supply within the industry, giving our clients a wider and improved range of options in terms of pricing, but that still met the stringent standards that we comply with.”

Over the past year, the Cooper Group team has considered a range of different brands looking for the ideal products that would meet the balance of superior quality and price, adding value to the existing range within the group.

The company is excited to announce Exclusive and Sole Distributorship of DAESAN INOTEC products for the territory of South Africa and sub-Saharan Africa. The distributorship covers the range of the following products: Electric Chain Hoists, Chain Blocks; Lever Hoists, Trollies as well as Wire Rope Winches. Some exciting and revolutionary features to look forward to include Dual brake systems, Inverter optionality, Synchronised lifting optionality, Weather cover and WiFi application for easy reporting and analysis.

This partnership with DAESAN INOTEC is a major milestone in Cooper’s history and is set to revolutionise the lifting industry in South Africa and sub-Saharan Africa. Katiso Mogaki, Competitive Intelligence Analyst for the group, had this to say about the new range: “With DAESAN’s cutting-edge technology, our customers will enjoy a superior lifting experience that is safe, efficient, and convenient. In addition, the safety features included in these products are second to none, giving customers peace of mind when using them.

The convenience of being able to monitor the lifting process via Wi-Fi is a gamechanger for our customers. We are beyond excited about this new partnership and look forward to seeing how it transforms our industry.”

“While price remains a significant determining factor, compromising safety or quality is not an option, especially in the critical lifting industry. Thus, it becomes imperative for companies like ours to consistently broaden their product range, seeking out valuable offerings that provide our clients with a diverse selection. This approach allows them to access products that offer better prices without compromising on quality or safety standards,” Mogaki adds. Furthermore, commitment to ongoing staff training remains steadfast.

It is imperative that our team possesses extensive knowledge and experience, enabling them to promptly and efficiently assist our clients.” National Sales Manager Leigh-Ann Fernandes emphasises. “Therefore, training holds a paramount position within our strategy. In fact, the team is already undergoing comprehensive training to align with the launch of our new products.”

After occupying the same premises for over a century, it became evident that an upgrade was long overdue. As a testament to its continuous growth, the company recently relocated to new premises in Benrose, Gauteng. “We have been experiencing a remarkable growth trajectory for quite some time, and our previous premises were no longer able to accommodate our expanding operations,” explains Fernandes.

The new premises not only fulfil the current space requirements of the growing business, enabling increased stock capacity, but they also enhance safety measures. Furthermore, the upgraded facility positions the company to sustain its growth trajectory by creating the necessary capacity well in advance of future demands. An exciting development has occurred with the recent appointment of yet another lifting machinery inspector (LMI) within the operational business country wide.

“This appointment opens up new and expanded horizons for the range of services we can provide to our clients. The new scope of work done by our Crane Services division includes the inspection, load testing, repair and examining of lifting tackle, chain blocks and lever hoists, forklifts, overhead and gantry cranes, ariel platforms and vehicle hoists,” elaborates Fernandes. “This expansion not only extends our reach and

with significantly greater value in utilising our services.” Fernandes highlights that equal importance is placed on their after-sales services.

“In addition to our breakdown division, which provides round-the-clock assistance, we are fully dedicated to resolving any issues our customers encounter.”

For Cooper & Cooper Group its comprehensive growth strategy is aimed at offering its clients a complete onestop service, encompassing not only the provision of products but also encompassing repair, inspection, and load testing of their equipment.

“Our ultimate goal is to provide our clients with all the necessary support they require across our products, ensuring their utmost satisfaction and convenience,” said Fernandes indicating that an open day will be held later this year to showcase the new product range.

The Cooper team confirms that the Nitchi Factory in Japan has closed down.

“We want to reassure our customers that we have taken the necessary steps to ensure that the supply of spares remains uninterrupted for as long as possible and we will continue to explore different options in that regard. Our commitment to customer satisfaction remains unwavering; and it is through the launch of DAESAN that we commit to serving our customers with the same level of quality and reliability that they have come to expect from us.” concluded CEO Lorato Mogaki.

Wow, time truly does fly, as we almost reach the end the 3rd quarter of this year. It is with great pleasure that it is my chance to address our valuable readers.

It is with great sadness that we had to say good-bye to Mr. Francois Blignaut, who resigned from the LEEASA Board and are happy to welcome Mr. Kevin Reckas as his replacement. We look forward to working with you.

From the 18 - 20 July 2023 the KwaZulu-Natal Industrial Technology Exhibition (KITE) was heled and we held our conference there. It was well attended and we received great feedback from the attendees as we try and supply each event with interesting topics and presentations.

Should you have any topic suggestions or interests in a specific topic and would like to see it presented at one of our Conferences, please forward them on to us and we will do our best to find a suitable Industry Expert to present on them. We strive to supply our attendees with fresh and new topics all the time.

Last month we received a notification that ECSA (The Engineering Council of South Africa) requested an Audit, which we welcomed. LEEASA was audited based on the ECPD requirements and to the following Standard No: ECPD-01-STA (Standard for Continuing Professional

Development). We are happy to share with you that we had a clean audit.

Feel free to reach out to the board members if the need requires.

Chairman:

Ashley Davis | ashley@leeasa.co.za

Vice Chair:

Andries Agenbag | andries@leeasa.co.za

Treasurer:

Surita Marx | surita@leeasa.co.za

Ordinary Members:

Kyle Graham | kyle@leeasa.co.za

Sandra Hurlimann | sandra@leeasa.co.za

Francois Weideman | francoisw@leeasa.co.za

Administration:

Desiré Davis | admin@leeasa.co.za

Marketing:

Xane Roestroff | production @leeasa.co.za

Yours in SAFE LIFTING, Sandra Hurlimann and the rest of the LEEASA team

Mr. Aaldrik Graham Kiewiet

Mr. Alan Victor Botha

Mr. Albert Anthony Freeme

Mr. Albert Olof Jansen Van Vuuren

Mr. Amogelang Gilbert Mmusi

Mr. Amos Tulela

Mr. Andre van der Merwe

Mr. Andries Aucamp

Mr. Andries Gordon

Mr. Andries Josias Agenbag

Mr. Antoni Frederik Janse van Niewenhuizen

Mr. Hendrik Prinsloo

Mr. Henry Oswald Kerr

Mr. Hermanus Barend Dahms

Mr. Ian O’Hara

Mr. Imraan Moolla

Mr. Irvin Charles Murrish

Mr. Isidro Ernesto Fernando

Mr. Israel Mooketsi

Mr. Jacobus (Jacques) Mare

Mr. Jacobus Rudolph Kruger

Mr. Jacobus Stephanus Al Hoffman

Mr. Neil Van Wyk

Mr. Nelson Chaita Moyane

Mr. Nicolaas Benjamin Smit

Mr. Nicolaas Theunissen Wynant

Mr. Nkosinathi Richard Mavimbela

Mr. Noel Nyamukoho

Mr. Octovias Lebakang Mabelane

Mr. Pastor Noosi

Mr. Paulo Jorge de Freitas Marques

Mr. Paulus Stephanus Marais

Mr. Peter Abraham du Toit

Mr. George Cornelius Krafft

Mr. George Khehla Kuhlase

Mr. Gerhardus Jacobus Oosthuizen

Mr. Gert Vos

Mr. Given Nyathi

Mr. Glenton William Rebello

Mr. Graham Roy Twaddle

Mr. Happy Tafara Tati

Mr. Harris Naidoo

Mr. Hendrick Rapule Mahuma

Mr. Michael John Hendry

Mr. Michael Lionel Roberts

Mr. Milton Mhlanga

Mr. Mogakolodi Gregory Thamage

Mr. Mohamed Hoosen Dawood

Mr. Mthandeni Kunene

Mr. Mzinhle Leonard Sibenya

Mr. Napo Michael Noosi

Mr. Nathaniel Happy Sambo

Mr. Neil Naude

Mr. William Henry Pepler

Mr. Wynand Byleveldt

Mr. Yogandren (Donny) Soobramoney

Mr. Zaheer Shameer Khan

Mr. Zenzele Siphamandla Ntshakala

Mrs. Ruwaida Mahomed

Mrs. Sandile Wyeth Mzimela

Mrs. Surita Marx

Ms. Lynda Lake

“These records are up to date at the time of going to print”

hard, you can achieve anything.

First Employer

Eagle Canyon Spur, Amanzimtoti.

First Salary

As a waitress, I earned R12.80 an hour + tips. Once promoted to Cashier I earned R3500 a month.

Achievements

I pride myself on balancing my work and personal life. My greatest achievement is being a loving wife and raising two precious boys! Moving over from the baking industry was a challenge but I kept my head high and didn’t allow for fear and doubt to take the lead. I am grateful to the industry experts that have helped mould

me, always being a phone call away and ready to answer my silly questions. I’m passionate about safety within the industry and am hungry to keep learning.

The Lifting Industry is currently facing a crisis, one that directly affects businesses today and will without a doubt have a massive impact on the future of the industry. One can spend hours debating on how it got to this stage, but reality is, there is a massive skill shortage in the country. There are only 112 active ECSA registered LMI’s with just over 500 LME’s. Looking at what the law states, these figures shouldn’t be possible, but its reality, which in itself is a major red flag for the industry.

Furthermore, a lack of LMI’s poses the risk of companies having to cut corners, allowing LMI’s to test outside of their scope, sending Crane Technicians or LTI’s to do the actual inspections and having an LMI sign it off – posing tremendous safety risks.

Government, Associations, LMI’s, LME’s and other industry experts – now is the time to join forces, share knowledge and empower the younger generation, the future of the lifting industry depends on it.

You are in charge of your own destiny. Do not let others tell you what you can and cannot achieve, nor wait on them to reach your goals. Follow that fire within you, get up, work hard and reach for the stars.

I have an open-door policy. Having a good relationship with your team is just as important as building lasting customer relationships. Should anyone in the team have suggestions or challenges, I want to hear about it.

Together we can work on a plan to improve, adapt, and overcome. I believe that knowledge should be shared, take what you’ve learnt and carry it over. Our nation’s future depends on empowering the generations to come, and that can only be done by sharing your knowledge. Something fun nobody knows about you

Since entering the industry, I’ve wanted to go up on a tower crane but then my fear of heights kicks in, so I’ll settle for driving a Forklift instead.

Person who has had the biggest influence on your life

The generations of strong warrior women that paved the way before me: my great-grandmother, grandmother and mother. Their love and kindness towards others inspire me to be better and their years of wisdom has taught me so much.

Person who has had the biggest influence on your career

My current Managing Director, Surita Marx. Surita is a strong independent businesswoman, that doesn’t allow anything to stand in the way of her ambition. She is incredibly knowledgeable and uses that to empower others.

Lifting Placements, +27 (0) 87 700 9834, info@liftingplacements.co.za, www.liftingplacements.co.zsa

Leading the national sales team for a material handling company in the industrial sector in South Africa is a position that carries with it great responsibility. As a female, to be accepted as an expert in this field requires strength, determination, and tenacity. Vuyokazi Bangazi, National Sales Manager for Toyota Material Handling, has embraced these qualities and carved a successful 20-year career in this male-dominant industry.

Bangazi is one of many female leaders who are driving change, diversity and inclusiveness in the workplace at CFAO Equipment SA, the partner of choice in the material handling market, offering total solutions and best-in-class brands in new and pre-owned equipment, rental options, and value-added services.

Over the past five years, emphasis has been placed on gender inclusion at CFAO Equipment SA.

Today its management team proudly boasts a 45% contingent of female managers, which is testament to the company’s commitment to investing in, and advancing, women in the industry. A passion to grow the material handling sector is reflected in the entrepreneurial spirit, agility and performance of the

company’s diversely skilled teams, and the worldclass products and services offered through its three dedicated divisions – Toyota Material Handling, 600SA and Heavy Lift.

Bangazi is an example of this committed investment, and her journey from trainee to National Sales Manager. “When I joined the company as a young trainee graduate, I knew very little about forklifts. However, I realised early on there were opportunities open to me if I was willing to learn and grow, and I am forever grateful to CFAO Equipment SA for opening those doors for me. Today, I am passionate about the company, its products, and the industry, and am thankful for the many growth opportunities it has afforded me,” says Bangazi.

Vuyokazi Bangazi

Vuyokazi Bangazi

Jenny Van Dam is a dynamic women who has more Faith than fear. She is the co-owner and Director of Five Successful businesses. Her background as an entrepreneur, mom and life experiences is what makes her the perfect fit for any business.

For far too long, the industrial sector has been predominantly male-dominated, often neglecting the immense potential and contributions that women

bring to the table. However, it is high time that we recognize and embrace the invaluable impact of women in leadership roles within this sector.

The industrial sector, with its vast array of fields such as industrial, manufacturing, engineering, technology, and logistics, has traditionally been associated with male leadership.

However, this perception is outdated and fails to acknowledge the capabilities and skills that women possess. In recent years, we have witnessed a paradigm shift as more and more women have shattered the glass ceiling and risen to influential positions within the industrial sector. Jenny van Dam being one of those women.

So, what makes Mrs van Dam so successful? Firstly, she tends to bring a fresh perspective. Her unique experiences, perspectives, and problem-solving approaches provide a valuable counterbalance to the traditional male-dominated viewpoints. She offers innovative solutions and fosters a culture of inclusivity, collaboration, and diversity within workplaces. By embracing these qualities, industrial organizations can enhance their competitiveness and adaptability in an ever-evolving global market.

Mrs van Dam a wife to Mr Anton van Dam and mom of two exceptional children, has excelled in fostering strong relationships and built effective teams. She possesses exceptional communication skills, empathy,

and emotional intelligence, which is crucial for creating cohesive work environments. By nurturing talent, empowering employees, and actively listening to their concerns, Jenny van Dam as a women leader inspires loyalty and commitment among her teams. She promotes a positive work culture that encourages personal and professional growth, leading to increased productivity and employee satisfaction. Furthermore, Jenny van Dam has been on the front line of driving organizational change. She possesses resilience, determination, and the ability to navigate complex challenges. Her inclusive leadership style encourages diverse voices to be heard, enabling organizations to adapt to rapidly changing market dynamics. By prioritizing sustainability, ethical practices, and social responsibility, Mrs van Dam has contributed to the long-term success and reputation of Delta Crane...

A company she established and grew since 1993 by working side by side with her late father who passed in 2012. This year is Jenny’s 30Th Year in the Construction / Mining Industry.

Jenny van Dam has served as a powerful rolemodel for future generations. By breaking barriers and achieving success in male-dominated sectors, she remains an inspiration to young women to pursue careers in areas previously deemed inaccessible to them, hoping to create a ripple effect, leading to a more diverse and inclusive workforce, and fostering an environment where talent is recognized and nurtured regardless of gender.

Delta Crane & Plant Hire, +27 (0) 16 971 1101, jenny@deltacrane.co.za, www.deltacrane.co.za

Delta Crane & Plant Hire (Pty) Ltd was formed in 2004 in response to the need from several industrial companies for specialized light and medium engineering services.

Hydraulic truck cranes

Telescoping boom lift

Manlift or personnel lift

Articulating boom lift

All terrain cranes

Conventional truck cranes

Rough terrain cranes

Milling machinery

Rigging services

Academic qualifications

• BA Law (Wits)

• Masters Diploma in HRM (RAU)

• MBA (Thames Valley University; Milpark Business School)

• HR Executive Program (Harvard)

• Executive program in Strategy & 0rganisation (Stanford)

Achievements

I worked at Anglo American as an Executive Head in the Platinum

division. I learned a lot from this role and was exposed to the best in class on everything and on thought leadership.

Challenges in Industry as far as lifting is concerned

As a female CEO, I face many unique challenges. The industry is male-dominated and there is a lack of female representation in leadership roles. I however have

made it my goal to learn from these male counterparts and perfect my skills.

There is a dire need to create more opportunities for women to enter the industry - this means investing in training and development to ensure we have a skilled workforce.

Advice to offer

My advice is short and simple: Take ownership of your journey and be confident in your abilities; Never be afraid to take risks and be boldsuccess doesn't come from playing it safe!

Something fun nobody knows about you

Though I can’t sing, I love to Career history prior to current position

I joined Anglo American in 2005 and held various positions before being appointed as HR Executive.

There, I Led more than 5 big restructuring programs; designed and led the People aspects of three divestments and one Merger &

Acquisition; I Led Culture programs; I led an Organisation Effectiveness program that included people implications for automation, mechanisation and digital transformation and future of work and making sense of the fourth Industrial revolution.

Number of people under your leadership

+/-100 Management style

My management style is that of collaboration and empowerment.

I believe in creating an environment where everyone is respected and valued, an environment where everyone can contribute to the success of the business. I encourage

my team to take ownership of their work and to be creative in their problem-solving.

I also encourage open communication and feedback and work to ensure that everyone is heard and respected.

Personal best achievement

There are many. Amongst these is being a mother to 2 beautiful adult children.

From a young age as a family, we travelled around the world to expose them to different experiences.

Professional best achievement

Being appointed an Executive Head at Anglo American

Person who has had the biggest influence on your life

My mother, father and two grandmothers

Person who has had the biggest influence on your career

Some of my previous bosses who were CEOs and Executives in bluechip companies:

• Khomotso Thoka

• Pinky Moholi

• Abe Thebyane

• Chris Griffith

• Khanyisile Kweyama

• Natascha Viljoen

Cooper & Cooper Group, +27 (0 11 493 4355, info@coopergroup.co.za, www.coopergroup.co.za

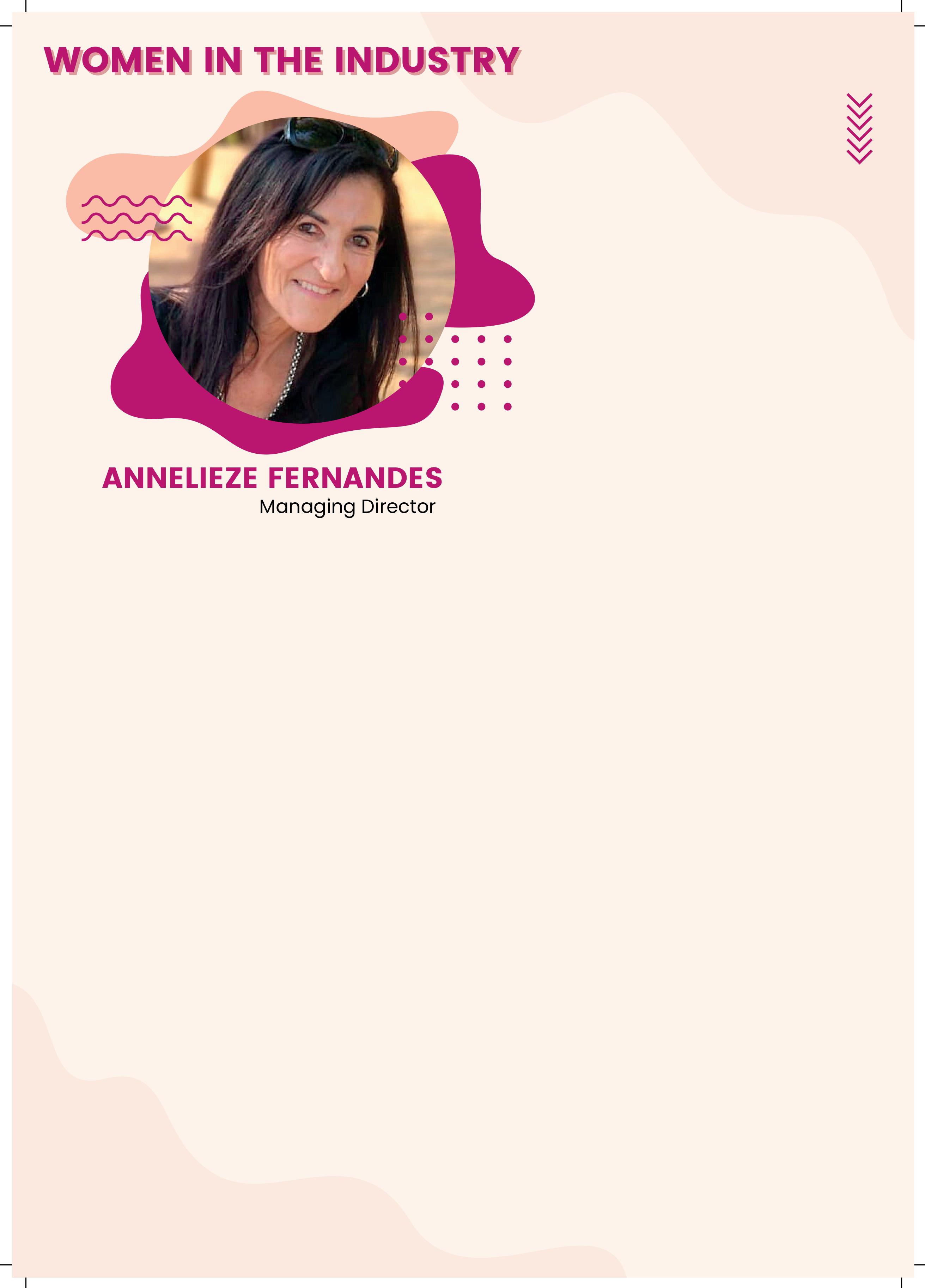

Academic Qualifications:

UNISA – study Business Management, HR and Marketing. We must remember that intelligence is not enough, intelligence plus character – that is the Goal of True Education

First Employer: Volkskas Bank Richards Bay

First Salary:

1987 Volkskas Bank as debtors’ clerk R2550-00pm

Achievements:

My greatest achievement as a mother is the day my daughter was born and today, she has given me 2 beautiful grandkids that I adore.

Changing my career path in the 90’s from the Rail industry to the Lifting and Steel Wire Rope industry was a 360 degrees career change, but no challenge is to big or too small for me, I see myself as a go getter and took the opportunity in my stride.

My support system was amazing, the guidance and expert advice from our engineer’s helped to groom, strengthen and to teach me. I’m very grateful for their support, as it help me grow as a business woman.

I believe I made a difference as a business woman in the man’s world and inspired other women on my Path.

Challenges in Industry as far as lifting is concerned:

Biggest challenge in the lifting industry in is that people are not 100 % dedicated to Safety, (people safety, Load Safety, lifting Equipment or Lifting Machinery safety). Our Government Inspectors (Botswana) do not have equitable training, qualifications and experience as per their South African counterparts (LMI’)

Advice to offer:

Your life is in your own hands, with the right attitude and mindset you can achieve all your goals and dreams

Something fun nobody knows about you:

I like to get my hands dirty, going underground even if I get claustrophobic. In my spare time I love quad bike rides

Career history prior to current position:

• Start my working career

• 1987 Volkskas Bank - Clark

• 1989 – 1996 Transnet

Empangeni – Supervisor / PA

• 25 years in the lifting Industry

• 1997 – 2005 Haggie

Rand Johannesburg – Sales

Representative

• 2005 – 2018 Umholi Steel Wire

Rope – Managing Member

• 2018 to date KL Cranes & Lifting Equipment – Managing Director (Owner)

Number of people under your leadership:

20 employees

Management style:

Very much open-door policy, Strict but fair, always make my employees feel important, open for discussions and suggestions. Very persistent on Customer services and relationship. I believe where I’m today is due to my dedication, passion and support, therefor sharing my knowledge, leadership skills to up lift my team to better themselves When we work, we work hard and focused, but when its time to play we have fun as a team.

Professional best achievement:

• To be a successful woman in a Man World

• I was the first women in South Africa 1991 to successfully complete my Operating Diploma at Olifantsfontein College in the Transnet Group.

• To be a frontrunner as a woman in major projects during my career namely: Bombela Gautrain project, Pipeline project, Medupi Power Station.

• Mostly to be an Owner of a successful Manufacturing, Supplier of Overhead Cranes and Lifting Equipment in Botswana

Person who has had the biggest influence on your life:

My daughter Alicia she is my world. Her love and support through all our years together gave me strength to be best mom for her.

Person who has had the biggest influence on your career:

My good friend Donald Coward is an Engineer in his field, he always has my back with the guidance and advice with no hesitation to share his knowledge and giving advice.

KL Cranes & Lifting Equipment Botswana, +267 397 4853, annelieze@klcranesbot.com, www.klcranesbot.com

Academic Qualifications:

Matric. Remember that career success is not solely determined by educational qualifications but also by personal drive, passion and dedication. Develop a clear vision of your goals, seek opportunities for growth and be pro-active in pursuing them. Your matric can be a starting point for a successful career if you are willing to work hard, continuously learn and seize opportunities along the way.

First Employer: Palmsteel Engineering (1984)

First Salary: R550-00 per month

Challenges in Industry as far as lifting is concerned: The Mobile Crane Hire industry faces several challenges that can impact its operations, growth and profitability.

Safety Concerns: Safety is paramount due to the nature of operating heavy machinery. Skilled operators, strict adherence to safety protocols, and consistent maintenance are crucial. Neglecting safety could lead to accidents, injuries, legal liabilities, and damage to reputation.

Regulatory Compliance: The industry is subject to intricate regulations governing crane operations, maintenance, and operator certifications. While ensuring compliance is time-consuming, it is essential to ensure smooth business operations.

Skilled Workforce Shortage: Finding and retaining skilled crane operators and riggers is difficult. Specialised training, experience, and certification are required, and the shortage of qualified workers can hinder the industry's ability to meet rising demand.

High Equipment Costs and Maintenance: Mobile cranes are costly to purchase, and maintenance and repair expenses can be significant. Regular maintenance,

regulatory inspections, and upgrades are vital to ensure reliable and efficient operations.

Intense Competition: The industry is highly competitive, with numerous companies competing for contracts and projects. Staying competitive involves offering specialised services and maintaining strong customer relationships.

Advice to offer:

To be successful in this industry there are a few things to consider: Prioritise Safety / Maintain a well-maintained fleet of equipment / Stay Compliant with regulations / Build a skilled workforce / Focus on customer relationships / Embrace Technology.

Career history prior to current position:

Prior to joining one of South Africa’s most successful Crane Hire & Abnormal Transport companies (which shaped me to become who I am today), I was a sales representative for a major Steel Merchant in SA.

Management style:

Open Door Policy: By implementing an open-door policy you can create a collaborative and supportive work environment that encourages communication, trust and employee engagement. This approach can contribute to the overall success and growth of the organisation.

Personal best achievement:

Being a mother (and father) to my two awesome children.

Professional best achievement:

Starting JMB Cranes with the help of my then Business Partner in 2007 & steering this company to the great heights that we have achieved to date.

Person who has had the biggest influence on your career: My ex-business partner (Michael Andrew Naude) who was not only the financial backbone of my business at inception, but his impact undoubtedly played a significant role in shaping my professional journey and contributing to my growth and success. I have immense gratitude for his invaluable guidance, support and mentorship.

Are you using the most efficient power source for each truck in your fleet? Are regulations forcing you to re-evaluate? Which one is most cost efficient? With so many new technologies and improvements to existing options, choosing the right power source for your materials handling fleet may make your head spin. It’s time to ask the experts.

The right power source can make a big impact

• Increase productivity and provide opportunity for higher throughput

• Decrease operational costs

• Improve profit margins

• Comply with emissions regulations and sustainability initiatives

• Reduce labour concerns and costs

• Increase work space utilization and efficiency

Questions to consider

Our Hyster Power Match experts have found that selecting the best forklift power source involves researching and calculating several

variables, some of which include:

1. Fleet size and characteristics

2. Number of shifts

3. Local utility prices and grid stability

4. Space requirements

5. Operator discipline

What are my options?

Hyster offers a wide range of power sources from a variety of providers. This gives us the ability to objectively evaluate your application and recommend the power source that helps give you the best performance for your application.

Streamlined service

The Power Match team has the industry’s broadest power options and the expertise to find the best power solution based on your application and specific needs. Our power solutions are field tested, proven and are currently running successfully in real applications. Your truck and power source are both serviced by Hyster® dealer

service personnel, so it’s fast and easy to address maintenance needs and minimise costly downtime.

Common power myths: busted

MYTH: Lithium-ion batteries are the best option for all electric forklifts.

TRUTH: Though lithium-ion batteries provide consistent power, allow for quicker charging and eliminate the need for a battery room, required operator discipline for charging and robust electrical infrastructure might present

challenges in certain applications.

MYTH: All lead-acid batteries are essentially the same.

TRUTH: In the past decade, designs for lead acid batteries have advanced to keep pace with demanding applications. This has led to a wide array of models, each with its own performance characteristics and requirements.

MYTH: Trucks with internal combustion engines can never be used indoors.

TRUTH: Indoor applications are possible with newer internal combustion engine trucks. However, these applications must be highly-ventilated with frequent air quality monitoring to ensure adequate dilution of pollutants. Strict adherence to equipment maintenance schedules is also required.

BHBW SA, +27 (0) 10 023 8700, info@bhbw.co.za, www.bhbwholdings.co.za

Price should never be allowed to unduly influence the purchase decision. A wrong choice of capital equipment can prove costly not only in downtime and lost production but also in unnecessarily increased expenditure when new equipment must be bought to replace the failed original.

This caveat comes from Marc Kleiner, managing director of crane manufacturer Condra, who says that buyers should exercise caution if they notice tender appraisal paying undue attention to price rather than product capability and overall lifetime cost.

He was commenting on a recent order to manufacture an overhead crane as replacement for a competitor’s machine that failed inspection and load testing.

The rapidly deteriorating crane is now adversely affecting production in the millhouse where it is installed.

The order for the replacement was placed by Natal Cranes, an authorised Condra distributor in KwaZulu-Natal and the firm behind the winning tender to replace the failed machine.

In the same millhouse, Natal Cranes has been servicing a 10-ton Condra maintenance crane installed in 1987 on the same gantry as the rival crane now needing replacement. The 10-tonner is still working reliably after 36 years.

Condra received the order on June 6 and is committed to a delivery date of six weeks from drawing approval.

After installation and commissioning, the failed crane will be scrapped.

The new crane will be a physically large machine of double-girder electric overhead design, spanning 21 metres and equipped with two hoists: a 35-ton main unit and 5 ton auxiliary, both mounted on the same crab and delivering lifting heights of 15 and 16 metres respectively.

Maximum long travel speed will be 31 metres per minute, with 15,4 m/ min on the cross travel. Control will be by mobile pendant.

The crane will feature a full-length walkway, dual-speed controls on all functions, binder brakes, stainless steel panels and IP65 dust and waterproofing for the motors.

Paint finish will be to highspecification anti-corrosion standard.

Commenting on the order, Kleiner said the mill’s need to replace a failed machine was a good illustration of lost production and additional expenditure being the direct result of a buying process where price exerted undue influence. “The old adage that the proof of the pudding is in the eating is relevant even in the market for overhead cranes,” he quipped.

“Condra’s product quite simply has more depth and durability. Our sales pitch might sometimes not be as polished as our rivals, but the mettle of our products is well proven, witness Condra’s 10-tonner on the same gantry as the failed crane, and still working even though it was installed almost forty years ago, years before the failed machine.”

A complete range of spare parts remains readily available, he added. Kleiner explained that Condra’s tender price could in many cases not be the lowest, because the product represented a first-rate, top-quality offering.

“But the longevity of our installations around the world justifies the investment made in them. These are robust, reliable cranes.”

Condra has in recent years captured an increasing share of the lifting equipment market in Africa south of the Sahara, with the company’s success in securing orders against determined competition from European rivals seemingly set to

continue. Company management claims the highest local content of any overhead crane manufacturer in the region. The product range encompasses capacities from 250 kg to 500 tons with a fully automated option offered on all machines. Manufacture is to ISO 9000 standard.

Research and development at the company is ongoing and includes a commitment to environmental improvement.

Design engineers are currently researching the effect of different rotor and rotor winding

configurations – silumin among them – on motor torque and efficiency, the aim being to contribute to environmental improvement by reducing energy input requirements.

The company has additionally installed solar panels at its Germiston and Cape Town factories to provide an estimated 70 percent of electricity requirements.

Condra, +27 (0) 11 776 6000, sales@condra.co.za, www.condra.co.za

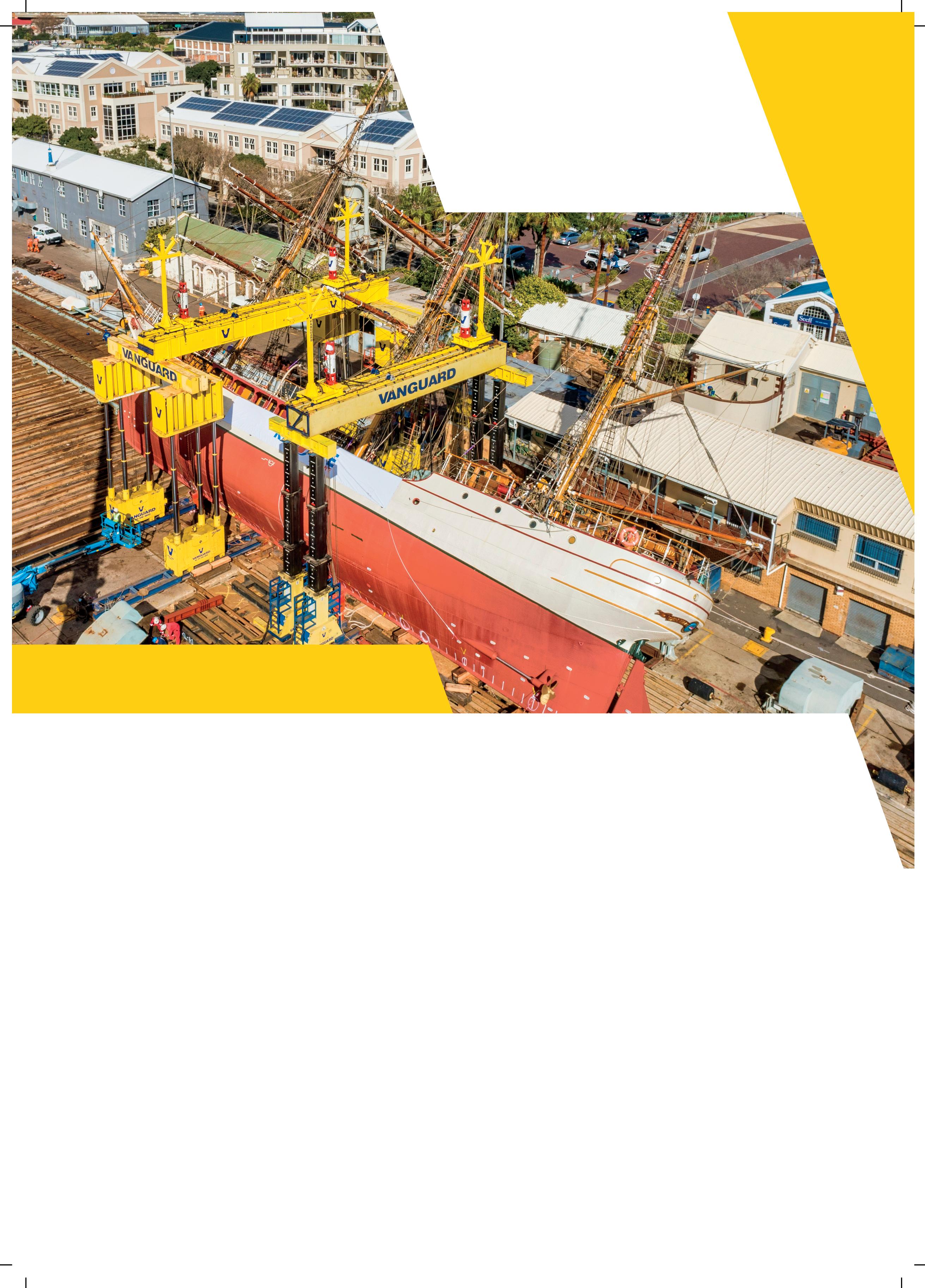

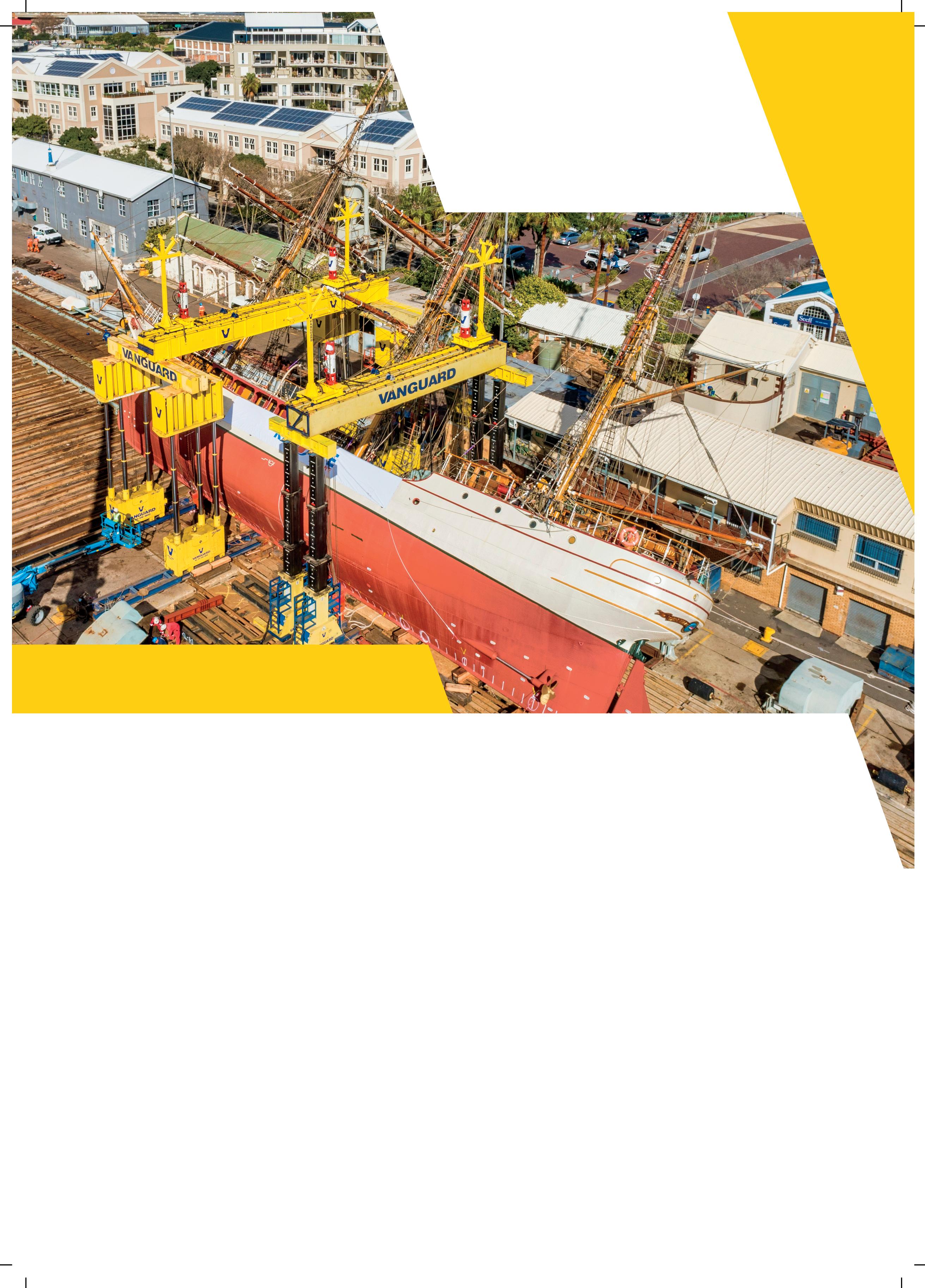

Vanguard have successfully completed a complex lifting operation to upright a barque rigged sailing vessel, named the EUROPA, at Victoria and Alfred Waterfront Yard, Cape Town.

Vanguard have successfully completed a complex lifting operation to upright a barque rigged sailing vessel, named the EUROPA, at Victoria and Alfred Waterfront Yard, Cape Town.

The vessel, which weighs 650t and measures 44.5m in length, recently slipped from its keel supports and rolled onto its starboard side during relaunching operations.

Vanguard were contracted to engineer and perform an uprighting operation to realign the vessel with the centre line of the track system. A crane lift was not

Vanguard team to lift and upright the vessel in a controlled and precise manner.

Once the vertical lift had been completed, Vanguard completed a transverse skidding operation to realign the vessel with the track system.

“Vanguard were delighted to work for Resolve Marine and alongside Trinity Marine Architects on this unique project. The extensive planning and engineering work that was involved is evident in the precision of the execution,” commented Bryan Hodgkinson, Director at Vanguard.

“It was a true team effort and the success of the project is testament to the knowledge and experience within the business”.

Vanguard, +27 (0) 11 616 1800, info@vanguard.co.za, www.vanguardheavylift.com

possible, due to the restricted workable space surrounding the vessel, therefore Vanguard’s engineering team designed a bespoke lifting solution.

The solution comprised of two hydraulic gantry systems, which were positioned over the vessel and between the masts to minimise further impact to the masts and rigging.

Once the 400t and 600t capacity systems were in place, header beams were positioned and four 186t capacity strand jacks were installed.

The strand jack system, which was rigged to keel brackets that had been custom fabricated for the operation, provided a high degree of accuracy and enabled the

Equipment selection is a major consideration in the movement of items in various processes and throughout the supply chain and has the potential to make or break an operation’s effectiveness.

According to Devan Govender of Smith Power Equipment, the authorised distributor of Baoli materials handling equipment in South Africa, there are many

considerations when choosing a forklift or reach truck that go far beyond the price and current application of the equipment. Factors such as future growth,

product expansion, underfoot conditions and production hours can play a significant role in machine selection. Furthermore, weather and climatic conditions may play havoc with the best plans where temperature can affect charging times or traction of machines among other factors.

That is also the reason why Devan recommends working with companies that have the expertise and product range to ensure the right equipment for the job.

"Proper planning in the selection of material handling solutions is the most important part of the process for businesses.

"It contributes to the optimisation of operational efficiency and productivity in a business. If the handling division can maintain high levels of operating efficiency, then it should be able to generate greater profits per project with the same resources.

“It all starts with current and future plans and the compilation

of a comprehensive site survey document per application. This takes all the factors mentioned previously into account and looks at the height that loads need to be lifted, weight, available space, energy requirements such as battery, diesel or LP Gas etc and any other requirement such as floor surfaces, outside terrain including gradients and other factors.

“To make it even more challenging, we recommend gaining insight into the operation’s future plans with consideration to possible changes of premises, energy efficiency and other considerations. Proper health and safety planning also needs to be done as does understanding hour usage and site application to get the best results,” says Devan.

He explains that the last and most important requirement is to choose an equipment partner with the expertise and product range to meet the unique needs of each site. Rather than just focussing on price, it is important to deal with a company like Smith Power Solutions with the infrastructure

and nationwide dealer network to be able to provide parts and services wherever the customer needs them.

Its unique customer-centric approach extends to Baoli South Africa and promotes the building of longstanding relationships with customers and ensures personalised service from the point of sale to aftersales service, support and ongoing advice and assistance throughout an operation’s lifespan. Its strong product line-up means that there are machines available to meet customers’ requirements.

Depending on the application Baoli has a range of equipment designed to meet the diverse needs of businesses across various industries. These include diesel forklift trucks from 1,8T to 5T, LP gas driven forklifts from 2,5T to 3,5T and new generation battery-driven forklift trucks ranging from 1,8T to 2,5T. a 2T reach truck with a mast height of up to 11m as well as a choice of 1,2T, 1,5T or 1,6T power pallet trucks are also available. The stackers complete the line-up with 1T, 1,5T or 1,6T options available

with lifting heights of between 1,6m to 3,5m.

There are various options available for machines with different terrains, mast heights, and attachments.

Customers can also request industry-specific modifications for cleanrooms, cold storage, and certain mining applications. In addition, there are numerous options available for common applications in logistics, warehousing, manufacturing and retail.

Baoli equipment is a part of Europe's market-leading Kion Group and has gained a strong reputation for its effectiveness in an increasing number of applications in South Africa since first being distributed by Smith Power in 2018. The durability and manoeuvrability of these machines have made them popular among fleet owners and operators ever since.

Smith Capital Equipment, +27 (0) 11 873 9830, mail@smithcapital.co.za, www.smithcapital.co.za

Last years the use of high performance synthetic slings is gaining popularity. One of the properties to this product is its very low elasticity. Will the design factors that were developed for steel rigging hold for the new generation lifting material?

In this white we will zoom into the case, determine the problems and give recommendations to designers and engineers to avoid potential unsafe situations.

Background

Current sling tension calculations are typically considering exact sling lengths. Due to manufacturing

tolerances however, in real life one should take into account a certain mismatch in this length. Especially in lifts with 4 slings to 1 lifting point, different sling lengths will result in different load in each sling.

Obviously the shortest sling will hold a larger load than the longest. Elasticity in material will

compensate for this effect as the shortest sling will stretch and distribute more of its load towards the other 3 slings in the rigging, but in material with low elasticity this effect is limited.

In order to deal with this uncertainty, suppliers are requested to manufacture their slings in so called ‘matched pairs’. This term has multiple possible definitions but mostly it refers to an item-to-tem length difference of max 0,5 times the sling diameter.

This way the tolerance is somehow controllable, but the bigger the loads (and so the bigger the sling diameter), the larger the allowable length difference may be. To compensate for this difference in length engineers multiply the minimal required breaking load with a safety factor of typical 1.25, this is called the Skew-load-factor (SKL). This factor is totally arbitrary and nowadays implemented the same way for every kind of material, no matter if it is polyester, HMPE or steel.

When lifting a box on 4 equal lifting points. Assuming a CoG that lays exactly in the center of the box. In ideal situation all 4 slings will take an equal load. But imagine 4 slings all out of the same production batch, matched pair ad so all within 0,5x the diameter from each other.

Worst case scenario two opposite corners have the slings with a short length on the lower end of the tolerance. And the two other slings have a tolerance on upper end of the tolerance. The SLF of 1.25 now compensate for a difference in load of max 125% per sling. So if in ideal situation both pairs take 50% of the load, worst case 62,5%/37,5% is still allowed.Now if we take this theory in real case, and use 4 HMPE soft sling of 10.000mm with a diameter of 200mm. The max allowable length tolerance according to the matched pair definition is 100mm. Without going becoming too technical we can assume that a sling will stretch 0,5% during normal use and 1% on 2 times the Working load limit (WLL). If in this case the 2 opposite slings are both

short (9.900mm) and the others are 10.000mm. Two slings will pick up all load while the other 2 barely touch the hardware. A SKL-factor of 2 should be applicable instead of 1.25.

Increasing the safety factors can be seen as treating symptoms. In fact solving the underlying problem might be far more effective. This will be decreasing allowable length differences, but at least detaching

it from the diameter of the sling, as the length of the sling is a far more efficient parameter to work with. Besides that, be aware that in fact SKL-factors can better be determined per project/rigging instead of following the standard regulated factor of 1.25, taking into account the length of the actual hardware used.

Enduro

When it comes to rigging applications involving steel chains or wire ropes, Green Pin® is your reliable source of high-quality swivels. The extensive Green Pin® swivel range is designed to meet the demands of various industries, including construction, subsea, aquaculture, and general lifting.

Swivels play a crucial role in preventing the effects of rigging-induced spinning. When you encounter an object that lacks rotational capability, Green Pin® swivels step in to enable smooth rotation and precise load positioning.

The range of Green Pin® Swivels

Each Green Pin® swivel has different specifications and

can be used differently. Check out the specifications of the Green Pin® swivel range below.

Green Pin® Needle Bearing Swivel EE GR8

Grade 8 needle bearing eye-eye swivel

The Green Pin® Needle Bearing Swivel EE is a grade 8 needle bearing eye-eye swivel. Needle bearing swivels are used to prevent any transfer of the normal twisting

motion from the load to the chain. These swivels are fitted with a needle roller thrust bearing on both eyes. This enables smooth, easy rotation under load.

The Green Pin® Needle Bearing Swivel EE is available in a range to suit 5/6 mm up to 18/20 mm grade 8 chain.

Green Pin® Needle Bearing Swivel EE GR10

Grade 10 needle bearing eye-eye swivel

The Green Pin® Needle Bearing Swivel EE is a grade 10 needle bearing eye-eye swivel.

Needle bearing swivels are used to prevent any transfer of the normal twisting motion from the load to the chain.

These swivels are fitted with a needle roller thrust bearing on both eyes. This enables smooth, easy rotation under load.

The Green Pin® Needle Bearing Swivel EE is available in a range to suit 6 mm up to 20 mm grade 10 chain.

Green Pin® EE Swivel

Swivel with eye-eye end-fittings

The Green Pin® EE Swivel is a swivel with eye-eye endfittings. The swivel is made from high tensile steel and can be used under water. Galvanization of the Green Pin® EE Swivel ensures its long-term durability. The swivel is available in a range with a working load limit from 0.4 up to 20.5 ton.

Green Pin® JE Swivel CP

Swivel with jaw-eye end-fittings

The Green Pin® JE Swivel CP is a swivel with jaw-eye end-fittings and a split pin.

The swivel is made from high tensile steel and can be used under water. Galvanization of the Green Pin® JE Swivel CP ensures its long-term durability.

It is available in a range with a working load limit from 0.39 up to 20.5 ton.

The Green Pin® Thrust Bearing EE Swivel is a swivel with eye-eye end-fittings and thrust bearings. The Green Pin® Thrust Bearing EE Swivel can rotate under load thanks to its bearing. The swivel's long-term durability is assured because of its long-lasting coating. The product is available in a range with a working load limit from 1 up to 40 ton.

Green Pin® JE Swivel BN

Swivel with jaw-eye end fitting and safety bolt

The Green Pin® JE Swivel BN is a swivel with jaw-eye end-fittings and a safety bolt. The swivel is made from high tensile steel and can be used underwater. Galvanization of the Green Pin® JE Swivel BN ensures its long-term durability. It is available in a range with a working load limit from 0.6 up to 5.7 t.

Royal Van Beest Group, sales@greenpin.com, www.greenpin.com

The company now offers a pool of over 24 000 items, including cranes ranging from 5 to 400 tons, trailers, tractors, welding machines, generators, rigging, grinding, and drilling equipment.

The Middelburg depot serves clients in the power generation, petrochemical, chemical, mining, renewable energy, pulp and paper, construction, and general industrial sectors. To date, the depot has handled plant projects in Sasolburg, Rustenburg, Newcastle, Richards Bay, and Eskom power stations in Mpumalanga.

“We are committed to providing our clients with the best possible service and ensuring that their high standards are upheld. With our hire solutions, clients can get their projects up and running quicker while mitigating equipment ownership costs,” said Mpho Muvhango, Corporate Communications Specialist at Steinmüller Africa.

The company has simplified its equipment hire process. Muvhango pointed out that its equipment hire agreements are tailor-made to each client’s requirements and are

subject to availability. All equipment complies with nationally recognised safety standards and is issued with safety certificates. The company additionally has a devoted Lifting Machine Inspector, ensuring the utmost quality for clients.

Muvhango added that the company also offers expert advice to their clients on equipment selection: Our team assesses our clients’ projects and provides them with a comprehensive and optimised solution,” she said.

Steinmüller Africa is a manufacturer and provider of comprehensive solutions, products and services throughout the lifecycle of plants in the power and process industries. In addition to the planning, maintenance and repair of complete power generation plants, the company also designs and manufactures power plant components, at its workshop in Pretoria.

Steinmüller Africa, +27 (0) 11 806 3321, mpho.muvhango@bilfinger.com, www.steinmuller.bilfinger.com

The mobile anchor devices of the ALPHA ANCHOR series from SpanSet enable safe working on fall edges and can be adapted to the respective situation. All ALHPA ANCHOR systems are easy to use and therefore require little training for new users.

The basis is the mobile anchor device ALPHA ANCHOR-B. A free-standing system that can be used immediately as a fall arrest system or restraint system without anchoring to the structure. In addition, the ALPHA ANCHOR-B mobile anchorage device can also be used as a rescue system, thus simplifying the creation of the prescribed rescue concept.

The systems can be easily moved using a hand pallet truck or a crane with suitable lifting equipment. The modular design of all ALPHA ANCHOR systems also simplifies transport and storage. ALPHA ANCHOR systems also impress with their low costs during the annual mandatory inspection, as all components with the exception of the lanyards can be inspected by

visual inspection. Further additional components are already planned to offer the existing systems even greater flexibility in order to meet future challenges.

The mobile anchor device type ALPHA-ANCHOR-D was developed as a fall arrest system for use on conventional slab formwork with the aim of using it at a potential fall height of 2 m. Together with edgetested fall arresters and harnesses, ALPHA-ANCHOR-D is an easy-touse mobile anchorage device that contributes to a safe workplace.

The AlphaAnchor fall arrest system, tested according to EN 795:2012, Type E and CEN/TS 16415:2013 Type E, is approved for a maximum of two persons. The system consists of a basic anchor point in which a 360° swivelling davit arm is inserted. 1 fall arrester is attached to each of these booms, to which the user can secure himself by means of a harness.

SpanSet, info@spanset.ch, www.spanset.com

Economical. Efficient. Sustainable. Reliable. Safe.

CMAK Crane Systems is expanding its NXS Series range of electric wire rope hoists in 2023. With lifting capacities ranging from 2.0t to 160t as standard, the initial models were introduced to customers in 2021. The latest additions to this lineup are currently being launched and are scheduled to be completed for the entire series by the end of 2023.

"Our team at CMAK designed the NXS series electric wire rope hoists by meticulously considering the gathered client feedback and incorporating all the design advantages of CMAK's previously designed hoists," stated Orcun Cakmak, General Manager of CMAK.

The NXS series hoists come equipped with either pole-changing or stepless inverter-controlled AC induction squirrel-cage hoisting motors. All cross-travel or longitudinal motions are driven by inverters. Thanks to preset acceleration and deceleration ramps, CMAK asserts that the cross-travel mechanism experiences minimal wear, leading to extended service life and smooth operation.

NXS series electric wire rope hoists have modular casted chassis and direct-driven forged wheels, providing exceptional durability and productivity. Additionally, the robust and compact design focuses on maximizing workspace utilization.

Furthermore, the company also says that the NXS hoists have a large-diameter rope drum and a compact pulley system, enabling them to have the “maximum

number of reeving for easily reaching high lifting heights without increasing the hoist size.” Lifting and lowering, the company adds, “are done with minimal hook drift, similar to absolute vertical lifting systems”.

"This ongoing 7-year development aims to create hoists that embody next-generation speed variation, increased durability, reduced vibration, cost savings, higher lift height, and more."added Orcun.

These hoists adhere to ISO, FEM, and CE standards and employ hightensile strength wire ropes with a grade of 2,160N/mm². The design ensures tight rolling of the wire rope onto the drum, minimizing breakage due to improper use. Moreover, the hoists feature a special high-performance polymer rope guide, enhancing chemical resistance and extending service life.

The NXS series hoist can be easily disassembled for efficient maintenance and part replacement, following the "plug/remove" principle in both mechanical and electrical aspects. Also, equipped with PTC, Termic, Phase SafeGuard, Emergency Systems, Top and Bottom Limiters, and overload

limiters to ensure reliable and safe operation.

Like all CMAK’s hoists, NXS series electric wire rope hoists are equipped with overload limiter in standard.

An electro-mechanical overload device can be easily adjusted to ensure safe operation. With preset values, in case of lifting heavier loads than the nominal load, the lifting operation is stopped immediately to avoid damage to the machinery, system and most importantly the building.

NXS wire rope hoists are compatible with the CMAK's advanced electronic system, HoistSense+, which keeps track of usage, load, and critical incidents; further increasing efficiency and decreasing downtime.

Digital intelligence extends even further with Industry 4.0 application HoistSense+. This advanced technology effectively assigns the entire crane to a virtual supervisor, monitoring it around the clock and providing reports in real-time.

CMAK Crane Systems, sales@cmak.com, www.cmak.com

That includes the lifting and rigging industry, where worker safety is of utmost importance.

“We should have known when the load was being lifted. We could have prevented this incident. Our workers would have been okay if we took more steps to enforce safety.”

If you’ve ever heard these phrases on a jobsite, or even uttered them yourself after workers suffered injuries or worse because they weren’t aware a lift was being conducted, there are ways to prevent them from being said again. As part of the BlokCam line, The Crosby Group has created the BlokAlert System. It’s designed to warn you when a lift is being conducted.

The BlokAlert is a wireless, audiovisual warning system that can be deployed quickly to the hook block of a crane.

When activated by the lifting crew, the BlokAlert receiver gives out a recognizable audio-visual warning

signal. The distinct alarm system can be seen and heard by site personnel in proximity to the hook block or load.

This forewarns the workforce to the position and movements of the hook block. Additionally, it increases awareness and reduces the risk of being struck by the crane’s hook block, lifting accessories, or load.

Why would you use the BlokAlert system?

In doing their research for the BlokAlert project, The Crosby Group found traditionally, the distance between the horn, often located near the operator’s cab, and the load, is inconsistent and does not efficiently warn site personnel to the position of the hook block or load.

The same could be said for airhorns or whistles when used by riggers. In both scenarios, the attention of the work force is diverted to where the sound is coming from, as opposed to the hazard.

Crosby created a solution to fit a warning system to the hook block.

When activated, the consistent proximity between the hook block and load enhances the efficiency of the warning system and draws attention to the hazard, not away from it.

The BlokAlert System is compatible with a variety of cranes.

What is included in a BlokAlert system order?

When you order a BlokAlert system, you will get the following:

• Receiver

• Fob

The BlokAlert Receiver (BA-R1) features an LED beacon and is capable of producing up to 528 unique audible warnings. This audio-visual warning system combines functionality and performance with design. Excluding the antenna, the BlokAlert Receiver is:

• 6.82” (173 mm) in height

• 8.27” (210 mm) wide

• Features a depth of 3.39” (86 mm)

What is BlokAlert, and how does it make lifts safer?

“Shoulda, coulda, and woulda won’t get it done.”Legendary basketball coach and executive Pat Riley’s words hold meaning not only in the sports world, but also, other industries.

• Weighs 7.5 lbs. (3,400 grams)

BlokAlert Fob

The BlokAlert Fob (60009) is a fourbutton remote that allows riggers to operate multiple BlokAlert systems across your jobsite.

You will receive two four-button fobs per system. Each comes with a rugged design and a neck lanyard. Note that eight- and 16-button fobs are available upon request.

BlokAlert Accessories

Along with the receiver and fob, the BlokAlert can be purchased with the following accessories:

• BlokAlert Transmitter (BA-T2)

• BlokAlert Footswitch (FS1)

BlokAlert Transmitter (BA-T2)

Through the use of a footswitch, the BlokAlert Transmitter gives the crane operator hands-free operation of the BlokAlert System.

BlokAlert Footswitch (FS1)

The BlokAlert Footswitch provides the hands-free operation of the BlokAlert Transmitter. It offers endusers quick and easy installation.

How does the BlokAlert system work?

If activated by the lifting crew or a rigger, the signal is transmitted from the fob to the receiver on the crane’s hook block. If the crane operator is controlling BlokAlert via a Footswitch, the Transmitter is activated from the crane cab. When operated, the signal is transmitted to the Receiver on the hook block of the crane. Regardless of where the signal comes from, once the signal is transmitted, the Receiver is activated. This alerts the workforce

to the proximity of the hook block. What are the design elements of the BlokAlert system?

The BlokAlert System comes with the following design elements:

• High-powered neodymium magnets

• Equipment that is easy to install, remove and charge

• Two hand-held transmitters per system

• Easy-to-use, multifunction operation

• Two 78-107 decibel electronic sounders

• 180° LED beacon

• Choice of four beacon colors

• Blue

• Orange

• Red

• Green

• Pair your transceivers with the push of a button

• Built-in lithium-ion battery with 124-hour battery life

• Built-in, fold-away carry handles

• Long-range transmitter and receiver

• Purpose-built aluminum housing

• Built-in lanyard anchors

• Safety lanyard that provides secondary security tethering

• LED power indicator

• 86mm low-profile design

• Durable all-weather design manufactured to an IP67 rating*

• -10°C to 50°C (14°F to 122°F) operating temperature

• Easy-access fuse

• High-quality industrial charge connector

• Optional cab transmitter

• CE and FCC approved

*By being IP67 rated, the BlokAlert System is completely protected from dust contact and protected against water submersion up to 1m.

The Crosby Group, +27 (0) 60 991 5526, martin@long@thecrosbygroup.com, www.thecrosbygroup.com

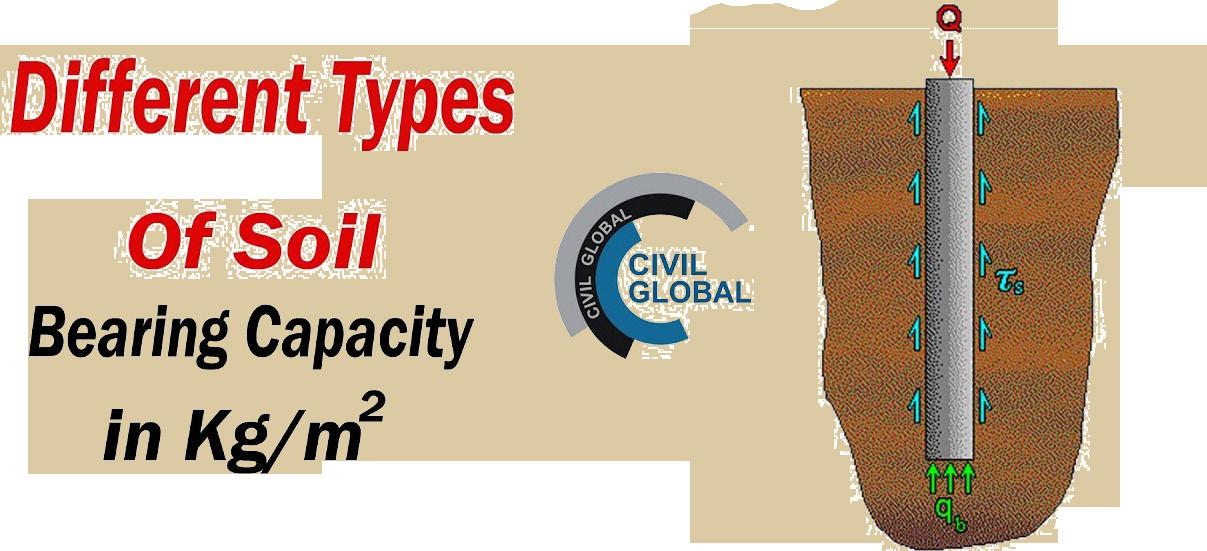

Before setting up a crane or other equipment with outriggers it’s essential to know the ground conditions to keep equipment upright. Knowing the strength of the ground helps operators plan for and determine the pad area needed to reduce bearing pressures to levels the ground can withstand.

As an outrigger and crane pad manufacturer, DICA works with operators in various industries using heavy equipment to determine which pad or mat would best fit their needs.

When evaluating ground conditions, these are important terms to know:

Ultimate ground bearing capacity

The maximum amount of vertical pressure that can be applied to the ground surface, at which point failure develops in the supporting soil.

This number is typically determined by a civil engineer, or someone who is trained and experienced in the science of determining the strength and stiffness of the ground.

Allowable ground bearing pressure (AGBP) may be specified by the controlling entity to help ensure pressures imposed on the ground will stay below levels the ground is believed to be able to support. Typically, the AGBP is calculated by dividing the Ultimate Ground Bearing Capacity, by a factor of safety. The generally accepted factor of safety for temporary loading is two.

Example Calculation

• The Ultimate GBP = 5,000 psf

• The AGBP = 2,500 psf (5,000 psf /

2 = 2,500 psf)

• This approach helps mitigate ground failure issues due to overloading.

Soil bearing capacity chart

Best practices to determine soil bearing capacity

Assessing the ground conditions should be done by a qualified individual because so many factors— such as water, excavations, underground utilities or hazards— need to be considered.

Before starting a project the operator must evaluate the jobsite to determine the best location to set up and to assess the ground.

Several methods exist to identify and understand the soil bearing capacity, such as:

• Documented Information

• Physical Observation

• Visual Investigation

• Field or Laboratory Testing

• Physical Testing (Plate Testing or Roll Testing)

The result of this investigation will:

1. Help the operator determine if the ground needs to be improved and/or if additional pads, matting, dunnage or cribbing is needed.

2. Provide a key piece of information needed to determine the minimum bearing area, which will determine the minimum pad

(supporting materials) size and area. Equipment specific planning

As noted above, determining a planned AGBP is essential to determining the minimum pad (supporting surface) area when selecting “everyday” crane pads, mats, dunnage or cribbing to a specific piece of equipment.

An “everyday” pad is selected for a specific piece of equipment based on it’s area, strength and stiffness. Typical “everyday” pads are sufficient for use with the equipment based on a specific plan that includes an assumed maximum load and an AGBP.

Lift specific planning

Lift specific planning is generally done by a Lift Planner, or engineer. This is someone who has the experience and skill to account for all of the factors that go into planning a lift.

In many cases lift planners will be given an AGBP by the controlling entity.

In other situations they will have to use the methods identified above to help ensure the ground is properly accounted for.

DICA, sales@dicausa.com, www.dicausa.com

Condra cranes and hoists are without equal in their quality, performance, reliability and overall lifetime cost. Operating data and the experience gathered from installations around the globe are today incorporated in all Condra products, the endurance of which has been proven in highly corrosive and abrasive environments, and under wide extremes of temperature, humidity and altitude. Technical support, service and spare parts delivery are guaranteed worldwide.

When two renowned companies like Uplifter and Kassecker Stahl und Metallbau want to turn an innovation into reality, the result is something great, something unprecedented: the Uplifter Glassworker 2.0, a 2-in-1 combination device for production and construction site.

The industry has never seen such a fully functional and universally applicable development!

In this project, the development and construction departments of both companies worked hand in hand, worked out various ideas, optimised them and finally a frame solution was constructed for the Uplifter Glassworker, with the help of which, for the first time, elements without glazing can now also be lifted and transported safely. But that is by no means all.

The requirement:

Lift and transport window and door elements and frames without glazing.

The basis:

A fully equipped Uplifter Glassworker GW625 with a vacuum cross and a load capacity of up to 625 kg.

The construction:

A specially designed frame solution with a max. load capacity of up to 400 kg

for maneuvering elements up to 4 m (width) x 3.5 m (height).

The 2-in-1 combination unit:

The Uplifter Glassworker 2.0 can be used to its full extent and with all its advantages both on the construction site during window installation and, in combination with the specially designed frame device, make production processes much easier for employees. A device that can be used in many different ways. Valuable time is saved not only in the assembly and production processes themselves but also already in the training phase since the production and assembly employees have to familiarise themselves with the operation of only one device. The manipulator at the head of the glassworker enables rotation, lateral movement, tilting and swivelling. Damage-free assemblies, even with sensitive surfaces, are thus no problem.

The result:

The Glassworker 2.0 is a highly

innovative assembly lifter that facilitates work in the production halls for window and door elements with heavy loads, simplifies assembly processes and ensures reduced personnel deployment during assembly. This unit can alternatively be used as GW625 with load hook or vacuum technology. ALL FUNCTIONS on the GW625, such as turning, tilting and swivelling, are retained. Let this 2-in-1 combination device convince you and optimise your production and assembly processes sustainably and always at the cutting edge of technology. Uplifter is your competent partner in special machine construction. We develop innovations on customer request, exactly the devices and updates you need to facilitate the work of your employees and to remain competitive in the market or to be always the decisive and innovative step ahead of the competition.

Uplifter, matthias.minich@uplifter.com, www.uplifter.com

Glassworker 2.0 - from idea to groundbreaking innovation!

9-13 October 2023 CTICC2, Cape Town,

Africa’s leading upstream event returns on 9-13 October in Cape Town. As the global platform for driving collaboration, reputable deals, and transactions between the public and private sector, Africa Oil Week brings government representatives, energy policymakers, financiers, and dealmakers together to shape the future of the African Upstream.

Download the 2023 Agenda to discover exciting sessions and key topics that will be discussed such as Exploration, Gas, Finance, Technology, and Country Spotlights.

KEY SPEAKERS INCLUDE:

DOWNLOAD THE 2023 AGENDA

Phuthuma Nhleko Chairman Tullow

Taiwo Okwor Vice President Africa Finance Corporation

Rahul Dhir Chief Executive Officer Tullow

Eberechukwu Oji CEO ND-Western

Nina Koch SVP Equinor

Pascal Nicodeme CFO Africa Oil Corp

Luca Vignati Upstream Director ENI

Dennis Zekveld Country Chairman Shell Namibia

Roger Brown CEO Seplat Energy

Dr. Ainojie ‘Alex’ Irune COO Oando Energy Resources

Phuthuma Nhleko Chairman Tullow

Taiwo Okwor Vice President Africa Finance Corporation

Rahul Dhir Chief Executive Officer Tullow

Eberechukwu Oji CEO ND-Western

Nina Koch SVP Equinor

Pascal Nicodeme CFO Africa Oil Corp

Luca Vignati Upstream Director ENI

Dennis Zekveld Country Chairman Shell Namibia

Roger Brown CEO Seplat Energy

Dr. Ainojie ‘Alex’ Irune COO Oando Energy Resources

Umholi

T: +27 (0) 11 914 2210/11

F: +27 (0) 11 914 2209

E: umholi@umholi.co.za

W: www.umholi.co.za

Kempston Controls

T: +27 (0) 140 776 2888

E: holyhead@kempstoncontrols.co.uk

W: www.kempstoncontrols.co.uk

CHAIN BLOCKS

Condra Cranes

T: +27 (0) 11 776 6000

E: sales@condra.co.za

W: www.condra.co.za

Cooper & Cooper Group

T: +27 (0) 11 493 4355

E: info@coopergroup.co.za

W: www.coopergroup.co.za

Bell Equipment Southern Africa

T: +27 (0) 11 928 9846

E: susanmy@bell.co.za

W: www.bellequipment.com

Forklift Network

T: +27 (0) 10 023 1912

E: nicky@forkliftnetwork.co.za

W: www.forkliftnetwork.co.za

Jungheinrich

T: +27 (0) 10 596 8460

E: info@jungheinrich.co.za

W: www.jungheinrich.co.za

Kemach Forklifts

T: +27 (0) 11 826 6710

E: info@kemachjcb.co.za

W: www.kemachjcb.co.za

Kempston Controls

T: +27 (0) 140 776 2888

E: holyhead@kempstoncontrols.co.uk

W: www.kempstoncontrols.co.uk

Palfinger Africa

T: +27 (0) 11 608 3670/1/2/3/4

E: sales@palfingerafrica.co.za

W: www.palfinger.co.za

CRANE HIRE Morris Material Handling SA

T: +27 (0) 11 748 1000

F: +27 (0) 11 748 1093

E: sales@morris.co.za

W: www.morris.co.za

Johnson Crane Hire

T: +27 (0) 11 455 9222

E: PeterY@jch.co.za

W: www.jch.co.za

Liebherr Africa

T: +27 (0) 11 365 2000

E: info.laf@liebherr.com

W: www.liebherr.com

Yale Lifting Solutions

T: +27 (0) 11 794 2910

F: +27 (0) 11 794 3560

E: crm@yalelift.co.za

W: www.yale.co.za

Yale Lifting Solutions

T: +27 (0) 11 794 2910

F: +27 (0) 11 794 3560

E: crm@yalelift.co.za

W: www.yale.co.za

DEMAC SRL

T: +39 (0)2 9784488

F: +39 (0)2 97003509

E: info@demac.it

W: www.demac.it

Econo Flex

T: +27 (0) 16 933 5705

E: econoflex@econoflex.co.za

W: www.econoflex.co.za

CB Lifting

T: +27 (0) 22 719 1437

E: info@cblifting.co.za

W: www.cblifting.co.za

GregBev Enterprise

C: +27 (0) 82 854 5143

C: +27 (0) 72 395 4342

T: +27 (0) 53 285 0842

E: admin@gregbev.co.za

W: www.gregbev.co.za

LOAD TESTING

IY Safety & Inspections

T: +27 (0) 82 773 7019

C: +27 (0) 82 956 3176

E: bianca@iysafetyinspection.co.za

W: www.iysafetyinspection.com

Morris Material Handling SA

T: +27 (0) 11 748 1000

F: +27 (0) 11 748 1093

E: sales@morris.co.za

W: www.morris.co.za

3 60 5 Services

T: +27 (0) 72 207 7443

T: +27 (0) 64 687 7270

E: sales@3605services.co.za

W: www.3605services.co.za

Econo Flex

T: +27 (0) 16 933 5705

E: econoflex@econoflex.co.za

W: www.econoflex.co.za

GregBev Enterprise

C: +27 (0) 82 854 5143

Rhino Lifting Maintenance

T: +27 (0) 16 971 2348/49

E: sales@rhinolm.co.za

W: www.rhinolm.co.za

C: +27 (0) 72 395 4342

T: +27 (0) 53 285 0842

E: admin@gregbev.co.za

W: www.gregbev.co.za

GregBev Enterprise

C: +27 (0) 82 854 5143

C: +27 (0) 72 395 4342

T: +27 (0) 53 285 0842

E: admin@gregbev.co.za

W: www.gregbev.co.za

Econo Flex

T: +27 (0) 16 933 5705

E: econoflex@econoflex.co.za

W: www.econoflex.co.za

Integrate Lifting Specialist Africa

T: +27 (0) 12 141 3615

T: +27 (0) 86 571 4387

E: info@integrateliftingsa.com

W: www.integrateliftingsa.com

IY Safety & Inspections

T: +27 (0) 82 773 7019

C: +27 (0) 82 956 3176

E: bianca@iysafetyinspection.co.za

W: www.iysafetyinspection.com

J Express Crane Services

T: +27 (0) 11 864 8402

M: +27 (0) 83 425 5535

F: +27 (0) 11 864 8408

E: jexpress@telkomsa.net

Kempston Controls

T: +27 (0) 140 776 2888

E: holyhead@kempstoncontrols.co.uk

W: www.kempstoncontrols.co.uk

Levi’s Trio Engineering

T: +27 (0) 11 907 9258

F: +27 (0) 86 742 9410

E: admin@levistrio.co.za

W: www.levistrio.co.za

Rhino Lifting Maintenance

T: +27 (0) 16 971 2348/49

E: sales@rhinolm.co.za

W: www.rhinolm.co.za

Shosholoza Consulting

T: +27 (0) 14 495 1994

C: +27 (0) 79 391 2990

E: info@shosholoza.africa

W: www.shosholoza.africa

Yale Lifting Solutions

T: +27 (0) 11 794 2910

F: +27 (0) 11 794 3560

E: crm@yalelift.co.za

W: www.yale.co.za

3 60 5 Services

T: +27 (0) 72 207 7443

T: +27 (0) 64 687 7270

E: sales@3605services.co.za

W: www.3605services.co.za

Cooper & Cooper Group

T: +27 (0) 11 493 4355

E: info@coopergroup.co.za

W: www.coopergroup.co.za

Morris Material Handling SA

T: +27 (0) 11 748 1000

F: +27 (0) 11 748 1093

E: sales@morris.co.za

W: www.morris.co.za

MOBILE CRANES

Liebherr Africa

T: +27 (0) 11 365 2000

E: info.laf@liebherr.com

W: www.liebherr.com

Chimaera

T: +27 (0) 84 506 1209

E: ndt@chimaera.co.za

W: www.chimaera.co.za

By Carpel SRL - Italy

T: + 39 (0) 39 532 0952

F: + 39 (0) 39 532 0825

E: info@bycarpel.it

W: www.bycarpel.it

Condra Cranes

T: +27 (0) 11 776 6000

E: sales@condra.co.za

W: www.condra.co.za

Econo Flex