RFI submission

March 2023

Salling Group

Sea & Air Strategic Project

We always find a way With respect, quality & commitment

WWW.LEMAN.COM

Introduction to LEMAN

Our understanding of your rationale for change

Building a Salling Group Competency center Roadmap

Introduction to LEMAN

Our understanding of your rationale for change

Building a Salling Group competency center Roadmap

Introduction to LEMAN

Every day, LEMAN helps companies and people all over the world delivering high-quality logistics and transport solutions. We always strive to live up to our values in our approach to customers, colleagues, our surroundings, and the environment.

LEMAN has delivered supply chain and transport solutions since 1900.

We deliver our services in 150+ countries through our own offices and a network of close partners.

Our approach is personalized customer care. We don’t build standard products, but focus on individual needs.

More than 800 dedicated LEMAN colleagues globally, are committed and to delivering high quality solutions.

We are big enough to deliver high quality, global supply chain solution while small enough to care about every single customer of ours.

We always find a way – the LEMAN way.

LEMAN brief

Our approach to Sustainability

“We won't be satisfied with being seen as a foot-dragging follower here. We must be quick to implement solutions that work, and we know have an effect. We must position ourselves right on the heels of the very best, and we will do that.”

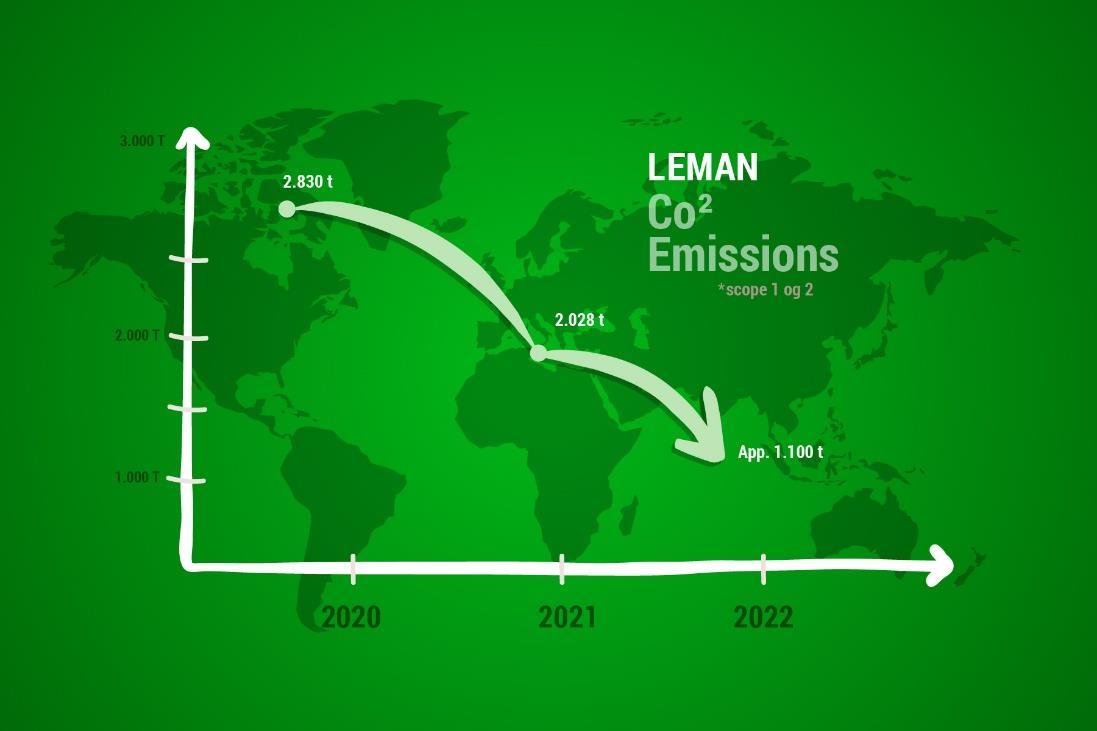

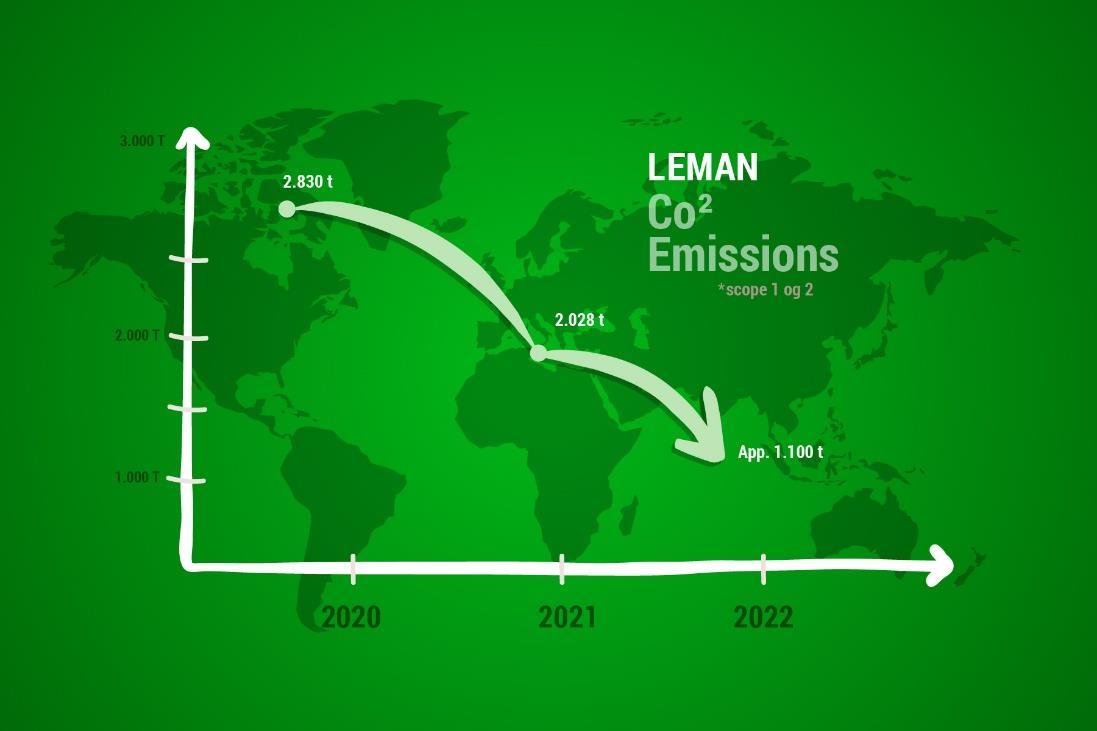

Over recent years, we have halved our own CO2 footprint, and we continue to stretch our ambitions:

• Reduce CO2-emissions from own operations with 60% by 2030 (baseline 2020)

• Reduce CO2-emissions from scope 3 with 30% by 2035 (baseline 2022)

• Install solar panels on all new buildings (owned)

• Offer CO2-compensation to customers

• Reduce climate impact in partnership with customers

Our journey with Salling Group so far

Key value add by LEMAN

LEMAN awarded Spain and Portugal road business. Stabilized performance and improved the quality of delivery and handling.

Awarded Hungary and Czech road business.

Exceptional airfreight in / Covid airfreight.

Awarded France, Slovakia and Romania road business.

API integration with SAP TMS.

Managed 400% volume increase, Covid lockdown and showed our flexibility to scale and finding solutions. Living ”the LEMAN way”.

Flexibility to support the business needs and finding quality solutions in challenging times.

Demonstrated our network capabilities to handle many small pick ups (France) and handle complex fixed day deliveries.

Supporting Salling Group initiative in building a single version of the truth by investing in API integrations.

Business milestone

2023 YTD Delivery performance 95% Growth in shipments 21/22 37%

2018 2020 2023 2021 2020

LEMAN has been a great partner that understands our needs and walks the extra mile.

- Tina, Head of Road, Salling Group

Introduction to LEMAN

Our understanding of your rationale for change

Building a Salling Group competency center Roadmap

Our understanding of your rationale for change and the market conditions

Multi channel

Covid increased the urgency of multichannel setup, but the post-covid “return” to physical stores has only increased complexity. Managing this, requires a flexible operation, structured use of data, automation and prescriptive analytics.

Regionalisation

As one of the largest markets in Europe, the growth in the Polish retail sector is an opportunity, but also a challenge to ensure that the supply chain can evolve without compromising on quality, cost and sustainability targets.

Disruptions

Exceptional market conditions, energy crisis and a continuous focus on our planetary impact is increasing the need for resilience and agility. It has never before been so important to be flexible to adjust at high speed.

Market trend: Supply chains that in the past has prioritised low cost and “lean” operations has shown a higher risk of failing under adverse events. Today, companies often “procure” resilience over efficiency.

Continuous improvement

Salling Group is known for good supply chain management. But to stay ahead and deliver on the ambitious targets, special attention must be given to continuously and proactively optimize the operations.

Example of an operational performance indicator is inventory turns. Inventory drives up waste, cost and emissions if not managed carefully.

Company

Industry average 10,86

Salling Group 8,88

COOP 9,62

Inventory turns 2021

Tesco >15

Our proposed solution to respond to your future supply chain requirements

We propose a LEMAN Competency center which centralize the operational management of data, documents and secondary goods flows; airfreight and buyers consolidation.

Parameters included in LEMAN’s proposal

Competency Center

We go beyond the industry standard Control Towers, because we think the right solution is not standard. We codevelop Competency centers uniquely to our customers and think this approach would greatly benefit Salling Group as well.

Airfreight

Unscheduled airfreight should be handled as business exceptions. By handling airfreight in our Competency centers we have had great success reducing unscheduled airfreight and drive down cost and emissions.

CFS Consolidation

Managing small shipments is an art of balancing time, cost and resources. By placing that task inside the Competency center, it is possible to optimize asset utilization and reduce transport cost, as well as emissions per CBM.

Key drivers for success

Visibility & Control

Better control will allow for better asset management, optimized capacity utilization and generally reduction in waste, and rush transports.

Integrated view into service, cost and efficiency to ensure that decisionmakers are empowered to make the right decisions.

Partnership for innovation

You want to build a partnership that can foster innovation over time with joint investments into integrations, infrastructure and team competences. Our greatest success stories when building future proof supply chain solutions, comes from co-development.

Introduction to LEMAN

Our understanding of your rationale for change

Building a Salling Group competency center Roadmap

The Competency center

IT’S MORE THAN CONTROL

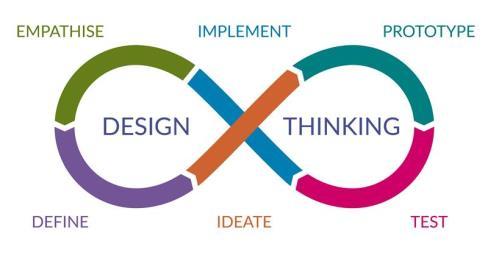

We co-develop

It’s critical to us that our Competency centers are co-developments. We don’t think that generic products fits the future supply chains. So by codeveloping we ensure that we build the right solution for the individual customer. And we ensure alignment on our joint goals.

Start small, dream big

We are craftsmen and our values are in delivering high quality in everything we do. So we start with getting the important foundations in place first: the right team, the right process, system integrations and the right execution competencies.

Unity of people, data and operations

We understand that it is in the intersection between experience, ability to execute and adoption of data that we can create real magic. So in all our Competency centers we ensure that we always prioritise to have all 3 aspects covered in all services that we offer.

“The LEMAN Competency center is always willing to walk that extra mile, whether it for operational performance or investments into new methods and technologies."

- Large Danish Pharmaceutical Company

Our approach to building a Competency center

We start getting the basics in place and then we evolve together over time, adding new layers and codeveloping unique solutions to your needs.

Examples of services included

• Dedicated team

Layer 1

Team and structure

• Integrated with customer

• Key performance metrics

• API/EDI integrations

• PO/order management

Layer 2

Operational Services

• Documentation management

• Airfreight as exception management

• Buyers consolidation programmes

• Business intelligence / one shared truth

Layer 3

Visualisation

• Manage-by-exception

• Automated exception alerts for proactive management

• Integrate with multiple meta-data sources

• What-if scenario planning to support decision making

Layer 4

Advanced analytics

Priority and indicative timelines

Phase 1

Typically established within. 1-6 months based on complexity.

Phase 2

Basic dashboards are typically establish within first 3 months and evolving over time.

• Prescriptive analytics to enable faster and more accurate decision making

• Automation/AI for to reduce reaction time to disruptions

Ongoing co-development initiatives

Layer 1: Team and structure

Our first focus area is building the right team to serve Salling Group, supported by key system and data integrations.

Team design

Senior sponsorship and active involvement ensures fast decisions and ability to make the right investments into the relationship.

We have a dedicated Competency team with a single point of contact. It is a Global team ensuring a uniform process across the world.

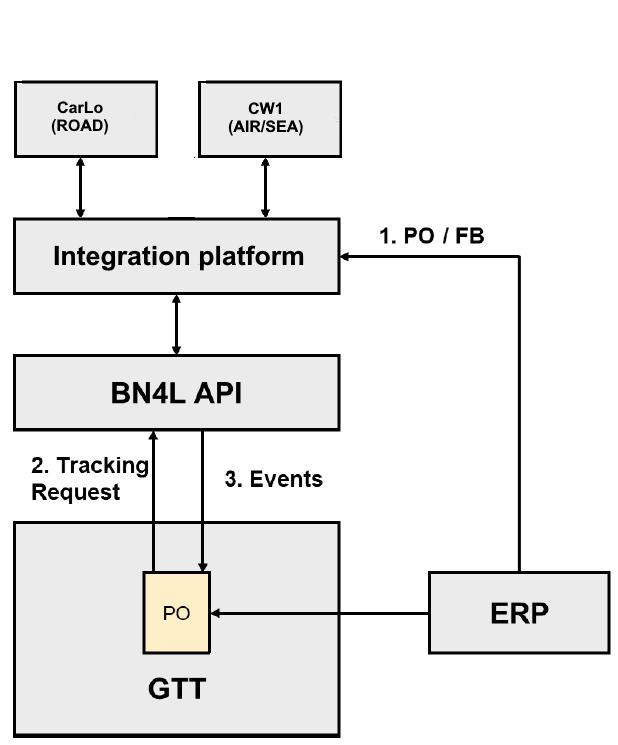

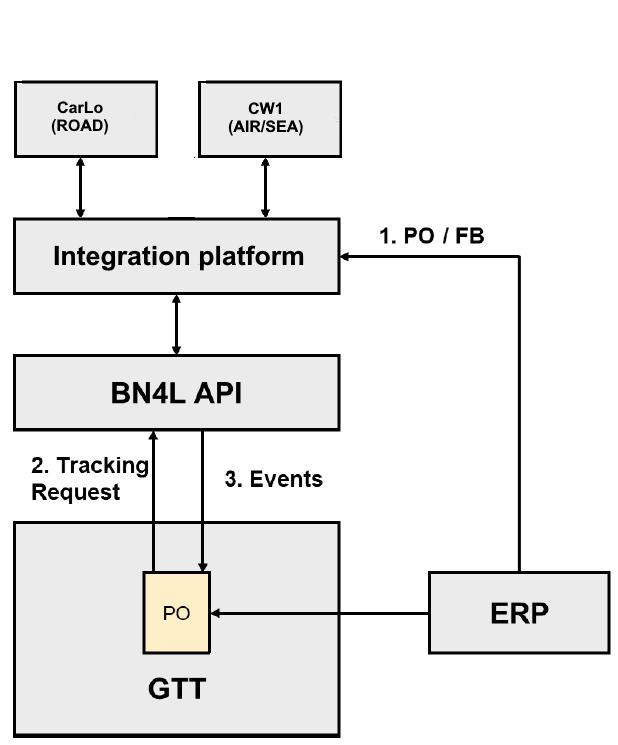

System integration

We are currently suppoprting the development of the SAP BN4L API. Till ready, we rely on EDI integrations. With this integration between SAP and our TMS systems Carlo and CW1, we will be able to transfer PO information, events tracking and receive reqests from Salling Group.

Future integrations may include:

The Account team works closely with our vertical specialist and IT developers to build the right solutions for our customers.

Our Competency team have one or more dedicated supply chain developers.

Dedicated forwarders are responsible for the day to day operations. Local operators report to the Competency center and may or may not be dedicated to the account, depending on the business requirements/needs.

• Implementing a BI layer combining data from Carlo, CW1 and SAP for a single view of data

• 3rd party meta data integrations to combine information from carriers, hauliers, shippers etc.

• Expose API to 3rd parties for customs clearance, warehousing, documentation management, documentation storage etc.

Senior Sponsor Account manager Vertical specialists IT development Dedicated forwardersDedicated forwardersDedicated forwarders Local operator country A Local operator country B Local operator country C Supply chain development

Layer 2: Operational Services

Managing the operation with flexibility, dedication and a mindset for customer value, is key to a successful Competency center

PO Events

PO upload Ready for pick up Gate in, origin Loaded at origin Discharged destination Gate out, destination POD Empty return

• EDI or API integrations. We live up to EDIFACT and X12 standards.

• Electronic check in to capture pick up milestone

• Electronic check in to capture to capture gate-in milestone

• Onboarding of new shippers to familiarise them with Salling Group requirements, SOP and values.

• Proactive follow up on PO to ensure that any delays are captured as early as possible.

• Exception handling for late shipments: alternative route / modes.

• Arrange CFS booking for buyers consolidation

• Booking agent for FCL on Salling Group carrier contracts

• Receive and quality control commercial invoice, packing list and customs documentation.

• Convert document to electronic versions for more effective management.

• Receive or copy of B/L and perform quality control.

• Issuance of FCR for CFS shipments and ensure issued timely and quality assurance.

• Confirm change in modes of transport with Salling Group

• Quality assurance in CFS

• Receive physical shipment in CFS and perform quality control. Issue GR.

• Arrange storage in CFS

• Electronic check in to capture to capture gate-out milestone

• Electronic check in to capture to capture POD milestone

• Proactive follow up on gate out to avoid demurrage fees.

• Proactive follow up on empty return to avoid detention fees.

• Arrange deconsolidation if required

• Palletize, add slipsheets and other destination VAS

• Container loading for consolidation shipments. Issue GI.

• Issue packing lists for consolidated shipments

• Booking of empty return

• Delivery and capture POD

• Arrange delivery of part loads / deconsolidated shipments

Selected services

provided

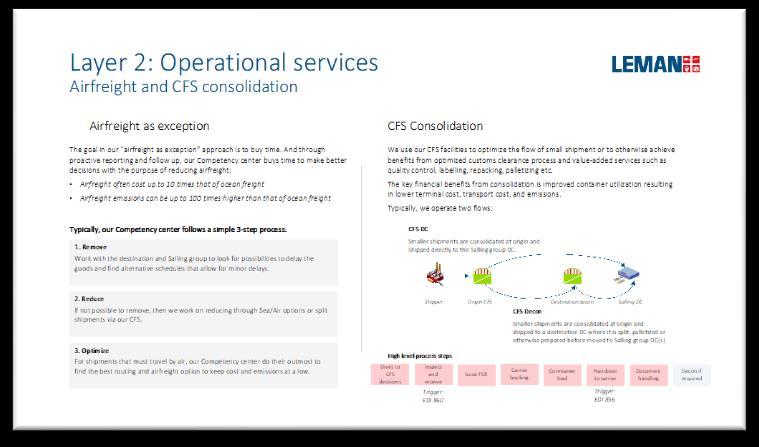

Layer 2: Operational services

CFS Consolidation Airfreight as exception

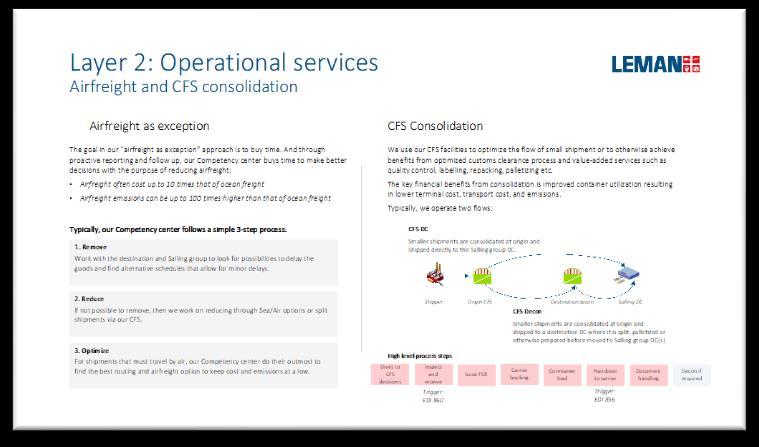

The goal in our “airfreight as exception” approach is to buy time. And through proactive reporting and follow up, our Competency center buys time to enable better decision making, with the purpose of reducing airfreight:

• Airfreight often cost up to 10 times that of ocean freight

• Airfreight emissions can be up to 100 times higher than that of ocean freight

• We will use the Salling Group agreed rate structure for invoicing supplier

Typically, our Competency center follows a simple 3-step process:

1. Remove

Work with the destination and Salling Group to look for possibilities to delay the goods and find alternative schedules that allow for minor delays without compromising service delivery.

2. Reduce

If not possible to remove, then we work on reducing through Sea/Air options or split shipments via our CFS. This way we may be able to limit the amount of goods that ends up on airfreight.

3. Optimize

For shipments that must travel by air, our Competency center do their outmost to find the best routing and airfreight option to keep cost and emissions at the lowest possible level.

We use our CFS facilities to optimize the flow of small shipment or to otherwise achieve benefits from optimized customs clearance process, port rationalization and valueadded services such as quality control, labelling, repacking, palletizing etc.

The key financial benefits from consolidation is improved container utilization resulting in lower terminal/port cost, transport cost, and emissions.

Typically, we operate two flows:

CFS-DC

Smaller shipments are consolidated at origin and shipped directly to the Salling Group DC.

High level process steps

CFS-Decon

Smaller shipments are consolidated at origin and shipped to a destination DC where it is split, palletized or otherwise prepared before moved to Salling Group DC(s)

The Competency center helps optimizing the “secondary flows” and is a key to drive down cost and emissions.

Origin CFS Destination decon Salling DC Shipper

Divirt to CFS decisions Inspect and receive FCR Issuance Document handling Trigger EDI 860 Handover to carrier Conntainer load Carrier booking Trigger EDI 856 Decon if required

Layer 3: Visualization

Phase 1: Performance reporting Phase 2: Interactive Dashboard

• Definition of joint key performance indicators

• Reactive KPI reporting, using historical data

• Weekly and monthly reports shared through email or simple dashboard.

• Root cause analysis and operational improvement initiatives

• Interactive dashboard with information on-demand

• Perform what-if analysis with instant impact assessment

• Aggregated performance reports for different business units, business functions, geographies etc.

Phase 3: Proactive reporting

• Dynamic and real-time insights to support decision making

• Automated alerting when risk of operational failure

• Automatically suggested actions for instant approval/implementation (prescriptive analytics).

Centralized meta data

• Initially, data integration between Salling Group and LEMAN using EDI and eventually the SAP BN4L API

• Later this interface can be exposed to other meta data surces like carriers and other 3PL’s

• Centralizing the data warehouse will provide single source of truth, flexibility and faster integrations

Visualization is to gain centralized control and insights, but also a key in enabling proactive decision making.

Layer 3: Visualization

Integrated quality assurance in our operational processes helps to ensure we capture the critical milestones to support quality decision making.

Description Approach

Happy flow

The happy flow follow the designed SOP and all suppliers adhere to agreements.

Goal: move as many shipments into the happy flow as possible.

Integrate QA into the process so that the process itself supports a happy flow. Examples we have in place:

• Incentivize hauliers to deliver in designated window by providing unload time guarantee

• Using check-in system at CFS to remove doubt about transfer of responsibilities.

• Proactive/automated milestone follow up prior an expected event

• Automatic payment release based on met milestones

Unhappy flow

The unhappy flow are shipments that does not follow the standard process. Late deliveries, damaged items, missing documents, wrong information, missing data etc.

Goal: Minimize business impact and solve root cause.

Manual follow up on exception to ensure business impact is limited while disclosing the root cause:

• Solve business requirements/operational issue first

• Document communication with implied parties

• Ensure all milestones are kept for record

• Register the non-compliance event in log

• Post-mortem follow up with implied parties

• Implement permanent solution where possible

• Claim compensation where necessary

We understand the nature of Salling Groups business with constant changes to the supplier base. To make this a success it is therefore also crucial that our co-developing and partnership mindset extends to all parties in the supply chain:

• Proper onboarding process for new suppliers

• Co-develop the right technical solutions

• Share KPI’s vertically in the supply chain

• Incentivize the right behaviour

– together we most often find mutual benefits in collaboration.

Layer 4: Advanced analytics

Building a Competency center

Alert generation and prioritization support

Start small –dream big!

We are not afraid to dream bigand deliver on our dreams! But experience has tought us to get the basics in place first. So typically, layer 4 is defined, designed and developed together with our customers - and only once layer 1-3 are operational.

Automatically distill the special cases for follow-up by business owners. It allows you to focus your time on the most important things. This is implemented with rulebased analytics that can identify an exception and trigger the suitable warning.

Predictive analytics

Pro-actively identify what might be happening and define followup actions. We use data modelling similar to that of demand forecasting to predict patterns and react before an event occurs.

Scenario modeling

Determine the impact of decisions prior to executing. We often work with simple ”what-if” scenarios that allow the operator to reach faster and more accurate to an event.

Machine Learning based prescriptive analytics

Prescriptive analytics is the most important step in data science because it translate insights into action; how to react to an unplanned event. With this logic we can use machine learning algorithms to automate decisions.

Typical services that we co-develop with our customers

Introduction to LEMAN

Our understanding of your rationale for change

Building a Salling Group competency center Roadmap

Summary of our proposal

Airfreight and CFS consolidation Competency center

We believe that the LEMAN Competency center is the right approach for Salling Group in order to future proof your supply chain:

• Our dedicated team operate with a large degree of flexibility and agility to be able to adopt to your needs. This is a critical component to build more resilient Salling Group supply chains

• Integration to your SAP TMS platform and possible other meta data sources will ensure that you get a single version of the truth.

• Where other logistics providers deliver standard solutions, we In LEMAN focus on customized solutions benefitting from our agile organisation and flexible people.

• The current Road business that LEMAN handles for Salling Group would be included in the Competency center benefitting from the setup and synergies.

Managing airfreight as exceptions and CFS consolidation inside the Competency center, is a more agile and proactive way of managing these non-standard flows. The benefits to Salling Group would be:

• Positive contribution to reduced emissions and supply chain cost from a reduction in airfreight transports.

• More effective management of smaller shipments resulting in lower transport cost and faster turn around times.

• Flexible CFS and decon setup which provides new opportunities for Salling Group at origin and destination to perform a variety of value adding services.

Road map – joint journey ahead

• Kick off and scope

• Detailed implementation plan

• Mobilize team

• Integration requirements

• Initial EDI integration

• Global SOP / process

• Implement documentation management

• Implement data quality management

• BI platform / one version of truth

• Dedicated LEMAN team in place

• KPI definitions

• Establish baseline performance

• Data modelling

• Dashboard / reporting on historical data

• Ability to execute

• Common goals to ensure we work as a team

• Shared definition of success

• Implementation of airfreight process

• Launch airfreight as an exception

• Launch CFS consolidation and deconsolidation

• Reduce documentation handling time

• Reduce customs clearance time and ease process

• Build high quality data foundation for future advanced development

• Gain visibility to inform better decisions

• Uniform execution to improve performance

• Drive reduction in transport cost from better process control

• Meta data from multiple sources

• Track and trace at origin / QR readers

• Live track and trace of all key milestones

• Exception management

• Automated alerts

•

• Share best practice

• Define the future vision and capabilities

• Define Layer 4 initial scope

• Mobilize team and resources

• Centralize data warehouse

• Reduce Air emissions

• Reduce Air cost

• Reduce freight cost of small shipments

• Proactive alerting

• Shorter response time

• Higher delivery performance

• Centralized data management

• Automated data cleansing and quality assurance

Month 1 2 3 4 5 6 7 8 Activities Layer

1

We will build on already established knowledge of your business to fast scale the Competency center capabilities.

Layer

Layer 2 Layer 3 Layer 4

Value add / Synergies

Integration using SAP BN4L API

Our experience from similar setups

CASE: Large pharmaceutical company

LEMAN Competency center was chosen to manage the company’s very important clinical trials business, where delivery performance is critical. In collaboration with our client, LEMAN has developed the right tools, infrastructure, physical hardware and processes to manage the business successfully.

Key achievements:

• Delivery performance of 99,3%

• Co-development of new security standards

• Reduced airfreight by finding alternative modes without compromising quality.

CASE: Global technology company

LEMAN has been instrumental in designing solutions for exceptional cases. Where there larger 3PLs struggled with flexibility and agility, LEMAN has been able to tailor solutions around Covid challenges, new transport modes, customs processes and CO2 reporting.

Key achievements:

• Customized CO2 dashboard

• Solution for urgent and creative expansion of warehouse capacity

• Designed and implemented NCR system (nonconformity reports)

CASE: Global consumer product company

Our customer has experienced close to 1000% growth in the past 4 years. The LEMAN Competency center has been able to grow with the client and continue to find innovative and customized solutions, ensuring their supply chain is future proof and can support the continuing growth.

Key achievements:

• Designed and implemented large scale CFS consolidation program in China.

• Urgent sourcing of 9 new warehouse sites to cope with increased volumes

• Consolidation hub to enable entry to EU markets

• Named booking agent for all carrier contracts

Your LEMAN team

Salling Supply chain lead

Salling Integration lead

Salling IT lead

Christoffer

Key Account Manager

Jesper Group COO, Road

Rikke Group CCO

Lars VP, Air & Sea

Morten Group CIO

Christoffer

Key Account Manager

Jesper Group COO, Road

Rikke Group CCO

Lars VP, Air & Sea

Morten Group CIO

Appendix

Our Values -

The LEMAN way Our Sustainability program

At LEMAN, we value and respect people and are committed to building an inclusive environment where you can balance personal commitments and interests with a successful career. We believe we will deliver the best customer care and quality service if we work well together as a team and if we all as individuals maintain a solid life balance.

At LEMAN, we are in a fun and exciting development at the moment. We are in the process of changing to become climate neutral, and we continuously engage in social or human causes that help others besides ourselves, and that make sense and remind us that we are more than just a business.

At LEMAN, we don’t just work for someone – we work for something. We are driven by values, we have fun and have fun together, and we want to make a difference for both our customers and our colleagues.

In total, we are 800 people in more than 29 offices worldwide, but even if they speak American, Swedish or Chinese over dinner, they are just like you. They are also part of the LEMAN family, and they go to work every day with the desire to make a difference to our customers.

At LEMAN we live our values – every day – always!

Respect

Have you ever heard the saying "Treat others the way you want to be treated"? Well, that's exactly what our core value of RESPECT is all about.

To us, RESPECT means listening to each other, accepting others for who they are, and understanding that we all come from different cultures and backgrounds. It means acknowledging both our colleagues and customers for what they do and being patient with one another as we strive for a good collaboration.

And let's not forget about taking a personal interest in our colleagues - it's about trying every day to make an effort to talk to people we may not interact with regularly. This not only fosters great relationships but also helps us get a better understanding of different perspectives and ideas.

But RESPECT isn't just about the good stuff - it's also about avoiding gossip, rough speaking, and not letting each other down. So let's remember to always be mindful of how we treat each other and strive to create a workplace culture where everyone feels valued and respected.

So, next time you're communicating with a colleague or customer, just remember to give them the same RESPECT that you would want in return. After all, we're all part of the same team here at LEMAN and together, we can make it a truly amazing place to work.

Quality

We all want to feel proud of the work we do, right? And that's exactly what our core value of QUALITY is all about.

We're all about putting each other first and making sure we create the best possible experience for our colleagues and customers. But it's not just about the end result, it's also about the journey. We want to make sure we have a great work environment, good communication, and reliable processes. And don't forget safety! We always want to make sure everyone is safe.

and make sure we're communicating effectively and clear. We want to create strong relationships based on mutual trust and respect.

But QUALITY isn't just about what we're doing, it's also about how we're doing it. That's why we aim to create a modern and quality workplace where everyone can thrive. We want to work together and take things to the next level, by providing more information and making sure we have the right tools and systems in place.

So, let's make sure we're not settling for average, and always strive to go above and something, don't keep them to yourself - let's work together to make things even better!

Commitment

At LEMAN, we live and breathe COMMITMENT! It's not just a word, it's a lifestyle. We give it our all in everything we do, from serving customers with a smile to collaborating in a meaningful way with our colleagues.

We believe in spreading joy and positivity in the workplace, which only fuels our commitment. And, we understand that commitment is always a two-way street!

Feeling appreciated and having the resources to do our jobs to the best of our ability, pumps up our commitment levels. We take ownership of our actions and strive to make a difference in all we do.

Better communication, training, and investing in our people and systems will help us stay true to our values and goals. Our commitment extends to our colleagues, suppliers, customers, and most importantly, to ourselves. We strive to create a thriving environment where everyone can reach their full potential.

At LEMAN, our values are non-negotiable and serve as the cornerstone of our commitment. Even on the toughest days, we stay committed to making LEMAN a top-notch and modern workplace where everyone can flourish!

Appendix

Our Values –

The LEMAN way Our Sustainability program

Our new SUSTAINABILITY strategy

For most of 2022, we have, together with external experts, worked on developing a new and updated sustainability strategy that both sets the direction for our focus on the environment and climate and on CSR. Initially, here we launch our results and goals in the ‘green’ area, and later we will present the second half, which consists of the future focus points in the CSR area.

For us, the main point is that we now have a unified strategy for this entire area, where we have determined our level of ambition and have determined specific goals, priorities, and initiatives that we can work with over the coming years. Having a coherent strategy and clear objectives will help us to prioritize efforts over the coming years and will also show customers and partners that we take this area very seriously.

sustainability on LEMAN.com

SUSTAINABILITY

We see ourselves as a 'Fast Follower', and both of those two words are important. We do not have an ambition for 'industry leadership' when it comes to sustainability – we leave that to the giants in the industry who have the resources to experiment with new, cutting-edge solutions. But we also won't be satisfied with being seen as a foot-dragging follower here. We must be quick to implement solutions that work, and we know have an effect. We must position ourselves right on the heels of the very best, and we will do that. Over recent years, we have halved our own CO2 footprint, and with our new strategy we have now set new, clear, and ambitious goals for how we can move forward further. Here you can see our specific objectives:

• Reduce CO2-emissions from own operations with 60% by 2030 (baseline 2020)

• Reduce CO2-emissions from scope 3 with 30% by 2035 (baseline 2022)

• Install solar panels on all new buildings (owned)

• Offer CO2-compensation to customers

• Reduce climate impact in partnership with customers

These specific objectives naturally place strict demands on our transformation, but we are ready to pursue this throughout the business, and we will communicate more about the individual elements in the strategy and our implementation of these elements on this page over coming months.

CO2 EMMSION DATA

As a responsible company that strives to reduce the climate impact of our operations, we measure our own carbon footprint, and support our customers’ environmental ambitions by allowing our customers to see CO2 emissions per shipment free of charge.

The data is provided by EcoTransIT – one of the leading emission reporting systems, compliant with GHG protocol, GLEC Framework and EN16258.

https://en.leman.com/co2

https://www.ecotransit.org/en/

/

With respect, quality & commitment

We always find a way

WWW.LEMAN.COM

Thank you!

Christoffer

Key Account Manager

Jesper Group COO, Road

Rikke Group CCO

Lars VP, Air & Sea

Morten Group CIO

Christoffer

Key Account Manager

Jesper Group COO, Road

Rikke Group CCO

Lars VP, Air & Sea

Morten Group CIO