Technology Continuous proofers

Recipe Brioche

Reference Artic Bakehouse

Personalities Martin Křižák

Ecology EkoBlok

Marketing Ondra Saida

02 The Kornfeil magazine 02/2022

1/56 !DEA 02_2022 ISSUE CONTENT Foreword News Deodorant ThermoStar Classic The baguette Brioche Artic Bakehouse Continuous proofers BioTherm Technology Technology Recipe Recipe Reference Technology Technology 03 04 02–04 06–08 25–28 29–30 33–36 10–14 10–14

2/56 ISSUE CONTENT The interior of your business says it all Karel Kornfeil What to replace natural gas with Martin Křižák EkoBlok Marketing Personalities Ecology Ecology Personalities 53–56 39–40 47–48 43–44 49–50 Davíð Arnórsson and Gudbjartur Gudbjartsson Personalities 41–42

Although we as a company do not usually comment on political events, this time we must. The war in Ukraine, triggered by the incomprehensible aggression of the Russian Federation, has changed the world we knew and forced us and you bakers, after a never-ending battle with covid, to work more e� iciently and in conditions none of us were prepared for.

And because we perceive a real threat of natural gas shortages, we have put considerable effort into developing and innovating products that help reduce the energy intensity of the production process in bakeries or allow bakeries to be heated completely independently of fossil fuels.

We strive to assist bakers with their long-term plans for the transition of bakery production, which, like all industries, is facing a transformation to fully automated operations with the necessity to minimize the number of workers and the need for digitalization, which contributes to increased quality control and food safety. Investment in this direction is a cornerstone of success in the five-year horizon.

I would also like to thank our colleagues for their unceasing energy and dedication, our new and long-term clients for their trust in Kornfeil products and our suppliers who, despite the reduced availability of materials, ensure a continuous flow of components and enable us to deliver on time.

I believe that in spite of all this, we will retain the much needed energy, optimism and resilience that has driven us forward in the long term and prove once again that together with you bakers, we will face the tough challenges that lie ahead.

MARTINA KORNFEILOVÁ

FOREWORD 3/56 !DEA 02_2022

CEO

We've

easier for bakers for 30 years

In December 2021, Kornfeil celebrated its 30th anniversary, during which it introduced a wide range of products from deck ovens, continuous proofers and energy saving technologies to biomass thermal oil boilers that are now helping bakers survive dramatic increases in gas prices. Kornfeil currently operates in 30 countries and employs 140 people.

Martina Kornfeilová as CEO

Karel Kornfeil, the founder and 100% owner of Kornfeil, has handed over the management of the company to his daughter Martina Kornfeilová, but he continues to actively develop new technologies and innovate existing ones. Martina Kornfeilová has been part of the company for more than 6 years and took over the management of the company with a vision to expand into other foreign markets. Her sister Karolína, who is responsible for HR and compliance, is also in the management team with her.

Marek Zálešák, new Production Director

Since January 2022 Marek Zálešák has been promoted to the position of Production Director. He has been working at Kornfeil as Design Manager for almost 8 years, where he has gained deep knowledge in the field of bakery process automation from A to Z.

New installations

In 2021, Kornfeil achieved the highest turnover in its history, and among the projects implemented we would like to mention at least some successful

projects in Germany – Rönnau, Haferkamp or Lantzsch, in Austria the installation in the Mangold bakery and finally the delivery of a continuous bread proofer for round and oval bread to the Herold bakery, Czech Republic.

Purchase of new technology

As it is not possible to innovate in the production process without investment, Kornfeil invested in the purchase of a new TruLaser laser as well as a TruPunch die-cutting machine from Trumpf.

NEWS 4/56

been making life

Technology Deodorant 7– 9 Continuous proofers 15 –18 BioTherm 19 –20 ThermoStar Classic 11 –12

Deodorant. Steam extraction energy recovery system

The environmental impact of economic production is an issue that can no longer be ignored today. At Kornfeil, we want to be part of the solution, not the problem, and at the same time we try to think about the issue comprehensively. In addition to reducing your carbon footprint, we also strive to keep your energy consumption as low as possible in the future. As an intelligent solution to these factors, we are now introducing the Deodorant device, the benefits of which will be explained in more detail by Martina Kornfeil, CEO of Kornfeil.

7/56 !DEA 02_2022

TECHNOLOGY

8/56 DEODORANT

The baking process generates a lot of waste energy, can the Deodorant system make any use of this energy?

The Deodorant uses the energy of the exhaust steam to the maximum.

Can the Deodorant system be used in smaller bakeries or is it more suitable for large industrial bakeries?

Honestly, the Deodorant is suitable for bakeries that can easily use large amounts of water for example for washing crates or for hygienic purposes.

In the introduction we mentioned the environmental impact of economic production, can Deodorant deal with this problem?

Thanks to the application of Deodorant, the bakery does not pollute the air.

Many bakeries have problems with the characteristic smell that comes from baking. This can cause considerable inconvenience, especially if the bakery is located in a populated area. Can the Deodorant also remove the unpleasant dour that is usually associated with baking?

The deodorant completely eliminates the typical bakery smell, allowing bakers to build production halls, for example, even in urban centers.

Many entrepreneurs are certainly thinking about modernizing their bakery, but complete renovation is very expensive, so is it possible to connect Deodorant to older ovens or is it more suitable for modern baking equipment?

Yes, it can be connected to older ovens, just as it can be connected

to ovens that come from competing companies.

Each bakery is different. They differ in the number of machines and their location in the space. Are you able to provide a tailor-made solution for your customers?

Everything we do is always tailored to the specific needs of the bakery.

Readers will be interested to know how long it will take them to recoup the capital they might have invested in this innovation. So, what about the cost recovery?

This is a very individual matter; everything has to be calculated with the numbers of the specific bakery.

9/56 !DEA 02_2022

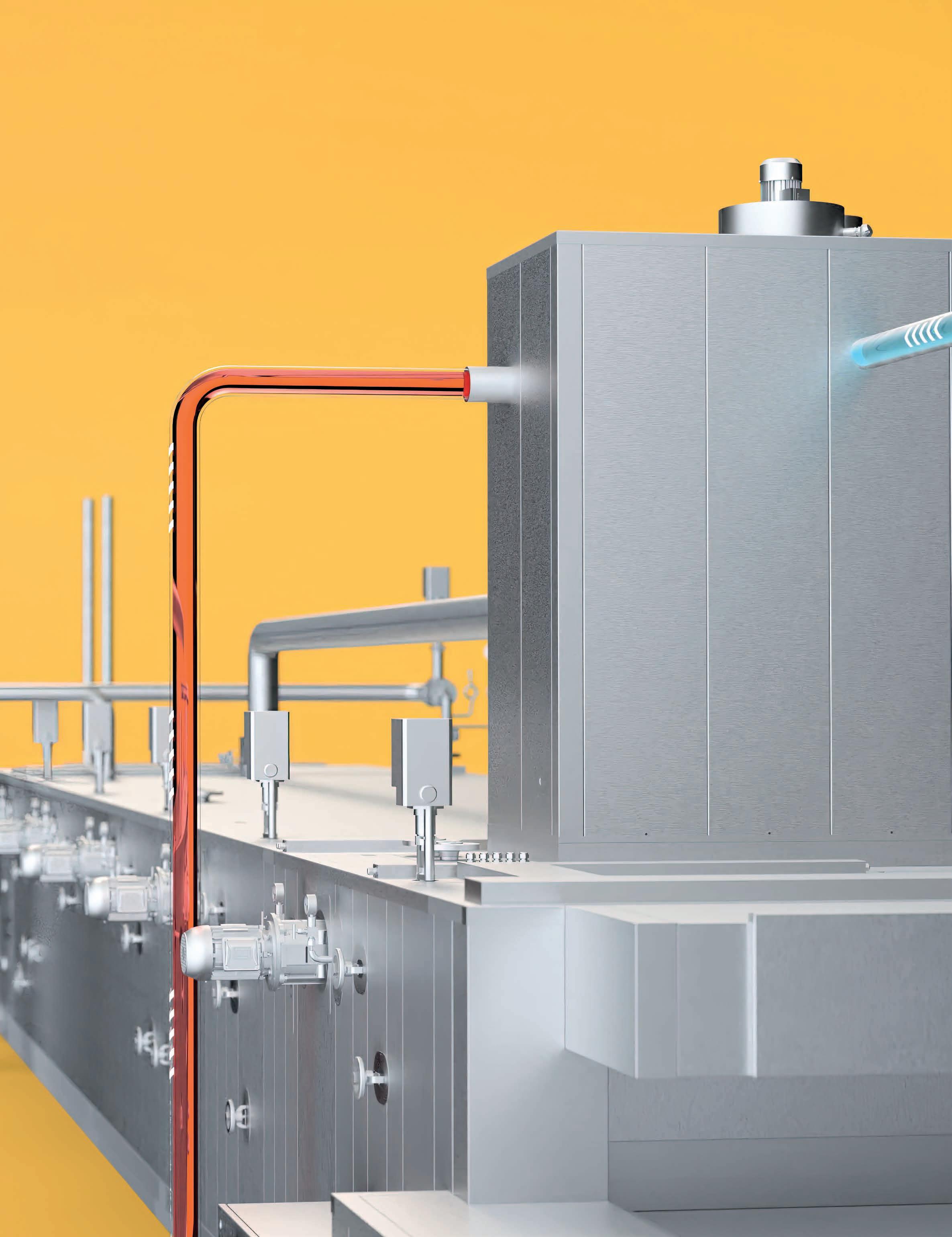

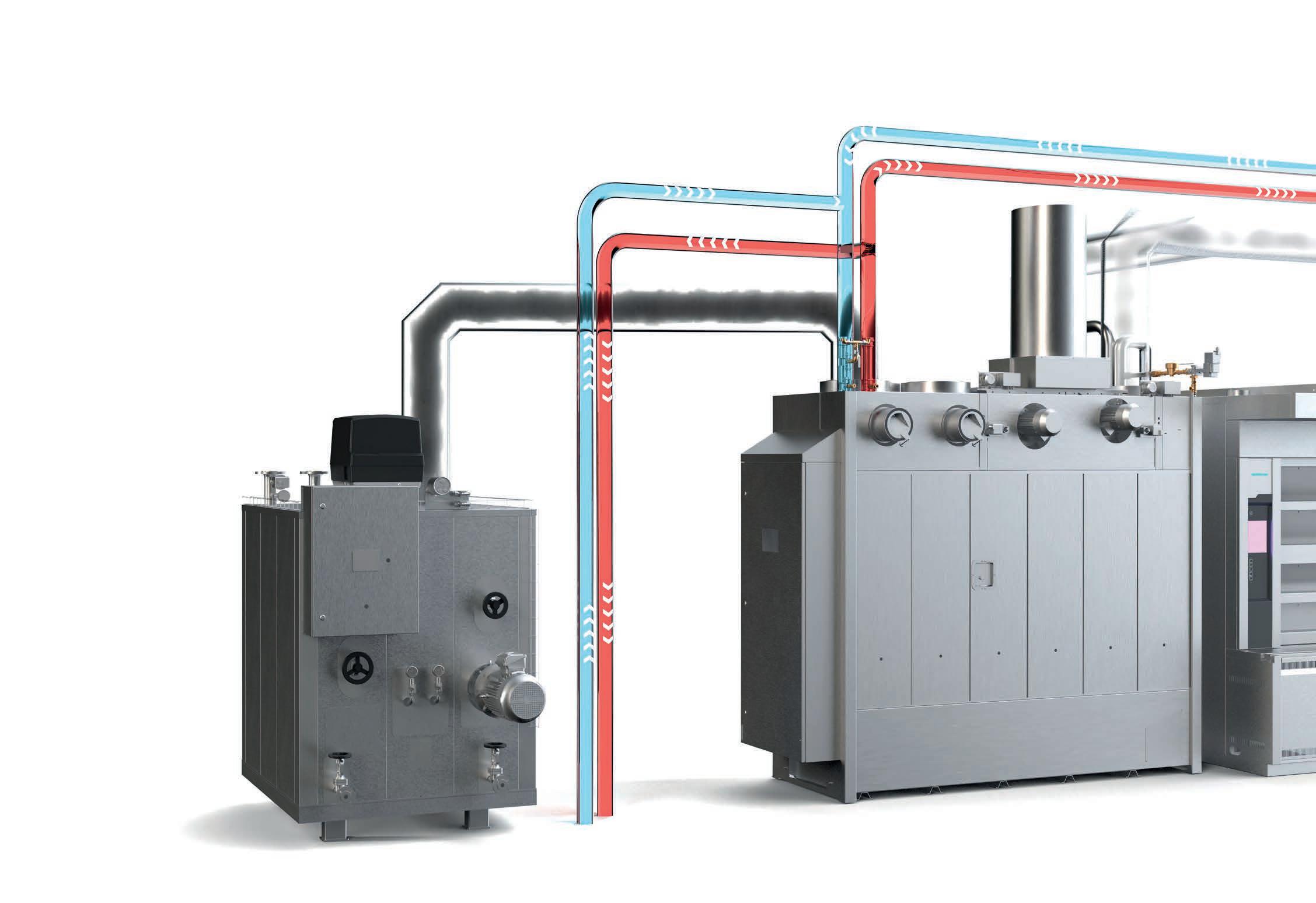

EkoBlok

Accumulation tank for DHW

Deodorant

Thermo-oil boiler

Accumulation tanks for heating

Stream boiler

TECHNOLOGY

Thermail oil conveyor oven Thermo-Line

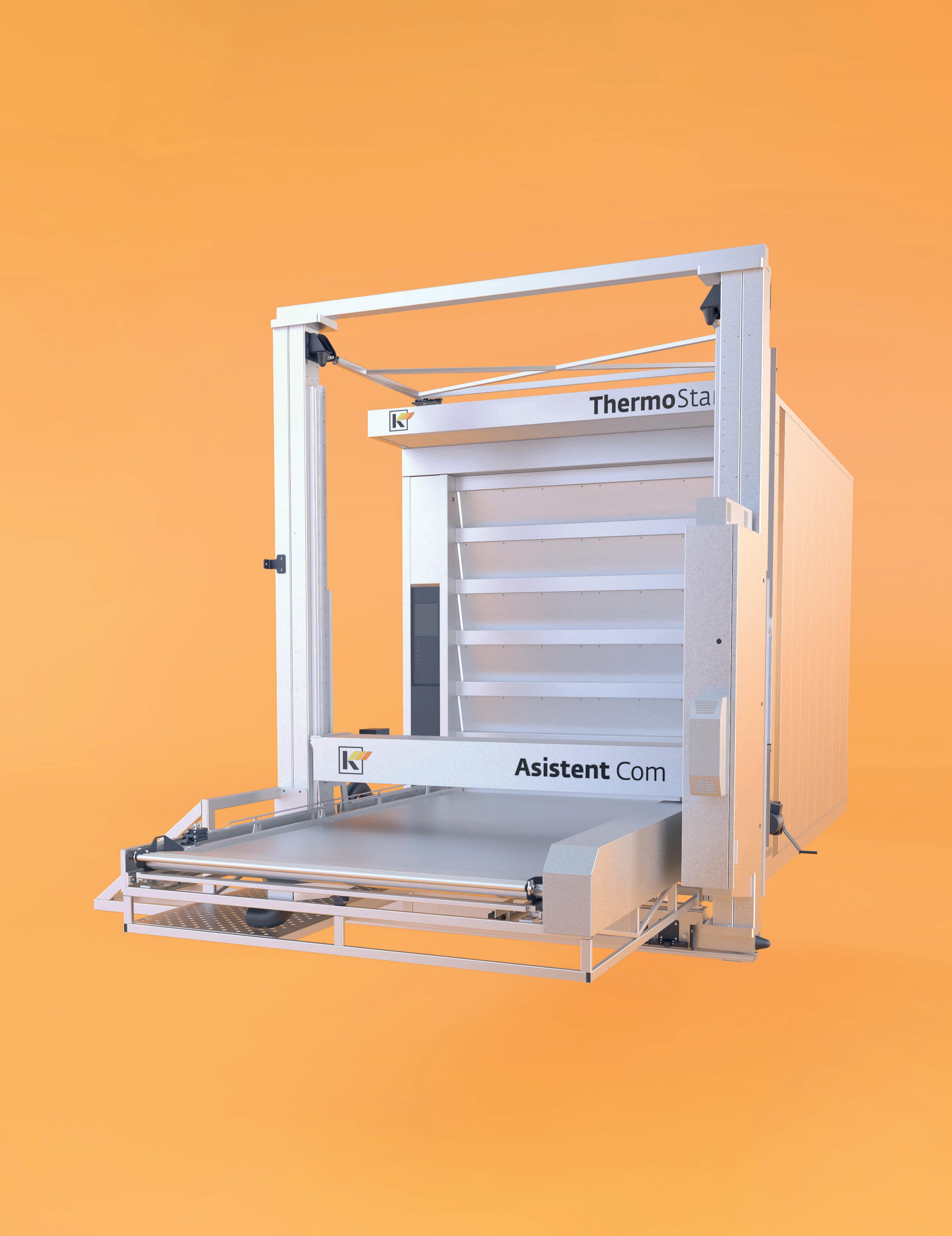

A compact helper for medium-sized bakeries

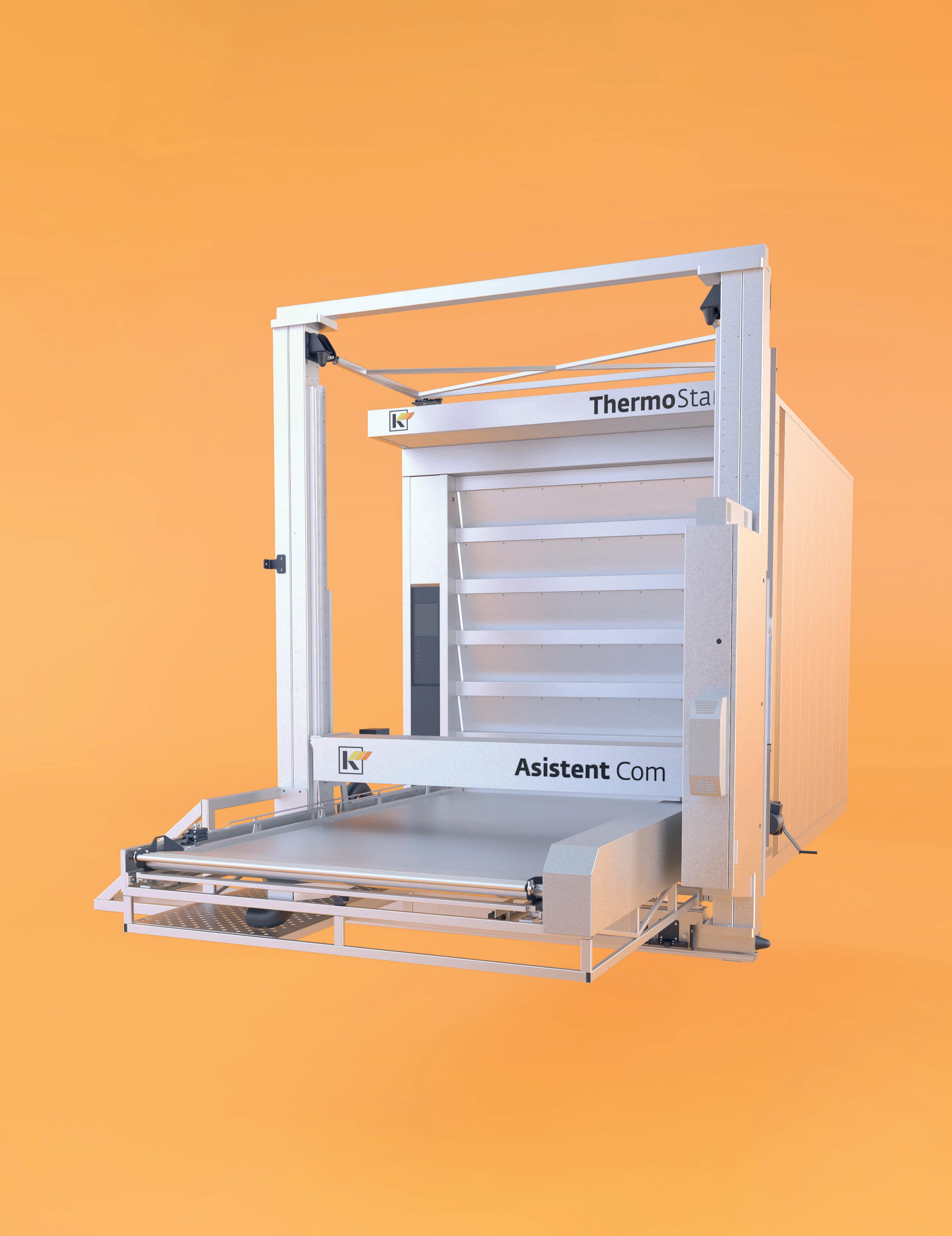

TECHNOLOGY 11/56 !DEA 02_2022

INTERVIEW Artic Bakehouse

Thanks to its compactness and quick installation of ThermoStar Classic, it is one of the most popular products from Kornfeil's multi-deck ovens. But what about the practical experience of customers? Gudbjartur Gudbjartsson from Artic Bakehouse will talk about the issue and present their oven.

Which bakery products do you mainly use the ThermoStar classic oven for?

We mainly use it for sourdough bread, which is one of our main products, and this oven is perfect for this type of bakery product range.

The hallmark of any good bread is a perfect crust, is the ThermoStar classic equal to steam ovens in this respect?

Before we switched to ThermoStar classics, we used steam ovens. We have to say that the ThermoStar is far superior in this respect. The biggest difference compared to steam ovens is that the quality of the bread is much more constant. We have had better days and worse days when baking in steam ovens. With ThermoStar classic, the quality is the same every day.

ThermoStar classic is a very compact and easy to install device thanks to its integrated boiler. Did this factor play any part in you choosing a new oven for your bakery?

Yes, the ease and speed of installation played a big part in our decision and choice of a new oven. The oven is also very compact and fit perfectly into our bakery space.

Approximately how long did it take to assemble this oven?

The whole installation took between four and five days. We believe that for many bakers this is also a big deciding factor as they don't have to stop their operation for long. Fortunately, we didn't have to solve this problem because we placed the new oven in a brand-new space, but we are still very happy that the installation was not complicated. Plus, the oven will arrive to you as a single unit, which adds greatly to the ease of installation.

Is there any range that this oven doesn't suit?

Of course, some bakery products are better baked in other types of ovens. But for us this oven is ideal, we bake sourdough bread in it, for which it is perfect, but for sweet pastries, for example, we prefer to use a different type of oven. But we can still say that the ThermoStar classic is the flagship of our bakery.

Have you noticed a reduction in operating costs after switching to the ThermoStar classic?

In this case it is quite difficult to answer because we have placed the oven in a different location where the energy prices are completely

different. Another reason why it is difficult to answer this question is that we have increased our production significantly and have grown quite a bit by switching to this oven. But we are 100% sure that without this oven our costs would have been much higher. Perhaps in hindsight we will have more accurate figures in this respect but given that we have had this oven for a relatively short period of time, we are unable to say exactly how much this oven has saved us.

Have you thought about investing in an Ekoblok to reduce your costs even further?

We are definitely thinking about it, we talked about it right after the oven was installed. We also want to invest in this technology in the future.

Which bakeries would you recommend this oven to?

Basically, we would recommend it to bakeries like ours, so medium-sized bakeries that bake up to a thousand loaves a day. Smaller bakeries would not make the most of the oven's potential.

THERMOSTAR CLASSIC 12/56

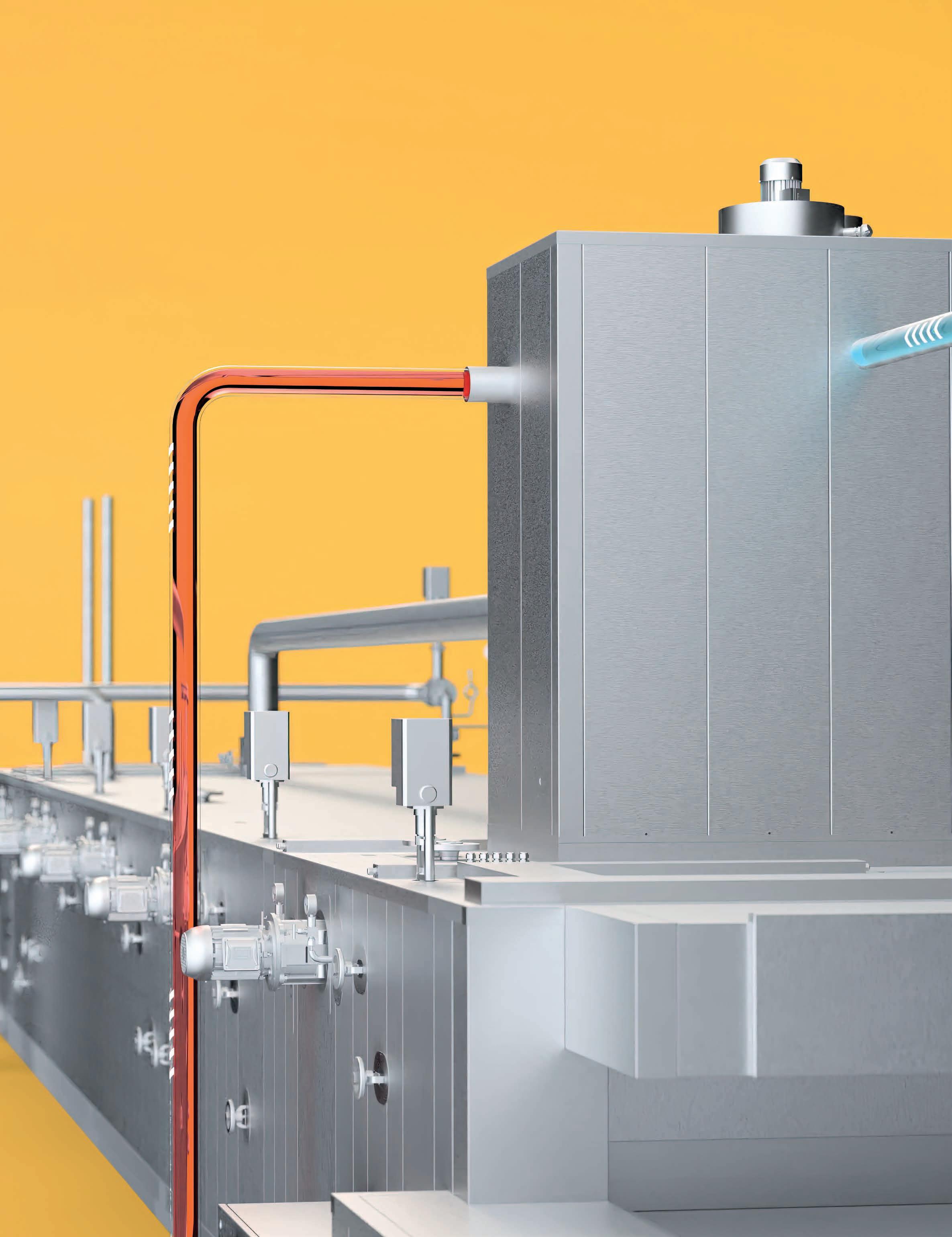

A wide range of products even at high outputs. Continuous Kornfeil proofers.

15/56 !DEA 02_2022

The common denominator of industrial bakeries has always been a narrow product range with high baking outputs, which allow economies of scale but at the same time significantly reduce the attractiveness of the bakery portfolio. It is the alpha and omega of successful product placement in multinational chains, as well as a measure of sales to end customers. With the use of Kornfeil continuous proofers, this success can also be achieved in industrial bakeries.

All Kornfeil continuous proofers are manufactured by the Kornfeil Industry subsidiary. The individual models are thus primarily developed and built to match Kornfeil deck oven assemblies or Kornfeil thermo-oil conveyor ovens. Our proofers are always custom designed to the specific specification of the required output and the breadth of the product range. We offer control of all components of the line, both the ovens and the baking plant, by one control software MultiControl, which can be gradually equipped with additional devices according to the growth and development of the bakery product portfolio.

Several types of proofers have been developed and built based on client requirements. This technology is developed with an emphasis on

the variability of proofing time and temperature. In recent years, for qualitative reasons, there has been a shift away from high temperatures and short rising times to lower temperatures of around 26–28°C and variable rising times of between 90–120 minutes. This means a completely different technical solution in terms of the movement of the hinges or plates and the possibility of humidifying and circulating the internal air. In general, most continuous proofers are heated from the waste heat of the proofer by the Ekoblok. However, ensuring sufficient humidification of the proofer space at lower temperatures offers more options, namely humidification with a fine mist produced by an ultrasonic aggregate. The adiabatic process thus cools the proofer and represents the most cost-effective method of humidification. A similar effect can be achieved by humidification in the form of spraying pressurized water with air, which is also widely used. The most energy-intensive method is low-pressure steam from the central boiler room, which consumes 700W/1 kg of steam and is mainly used at proofing temperatures above 30°C.

And now to the individual models of automatic continuous proofers. These meet the requirements for the production of classic bread in

oval or round shape, loose-leavened products or ciabatta-type products that require rolling, breadsticks and similar products that rise on a baking sheet, and standard proofers for the production of Czech rolls and buns.

Continuous bread proofers

Bread proofers are among the most frequently installed proofers in the Czech Republic and Slovakia, together with lines based on deck ovens, which is due to the primary orientation of Czechoslovak bakeries towards classic consumer bread. Proofers are just as frequently installed together with conveyor ovens. The most comfortable model is hanging bread proofers with baskets, which have been developed for the assemblies of deck ovens with very variable use and are available with one or two types of baskets, oval or round.

The classic continuous bread proofer DUO is equipped with two types of rattan baskets, round for bread weights of 300–800g or oval for bread weights of 300g–1200g. The breads are transferred to the line through two loading devices for both oval and round breads.

The dough tipping is fully program-controlled, so that the dough wedges fall perpendicularly and

16/56 CONTINUOUS PROOFERS

Bakery ovens have remained at the heart of the Kornfeil product portfolio for 30 years, but the extensive product range covers everything from proofing, baking and automation in bakeries of all sizes. In this article, we want to focus on introducing Kornfeil's continuous proofers, which we have devoted our best efforts to develop in order to facilitate the expansion and change of the bakery product range for medium and industrial sized bakeries.

without deformation onto the feed table. We can also adjust the angle of the hinge and the speed of rotation, which fully simulates the manual work of a skilled baker. A properly configured proofer allows us to produce a wide range of breads from pure wheat to breads that have 80% rye. The feed table, on which the wedges are tipped, has a pneumatic lifting system that ensures tipping from the lowest possible height. The proofer can thus be used for proofing very loose doughs.

Like our entire product range, the continuous proofer is controlled by MultiControl software. This connects the individual elements of the line, in layman's terms, everything speaks the same language. The proofer operates fully automatically according to the desired settings and is controlled by a main control panel where the operator can easily check which hinges are filled with dough, thanks to the identification of integrated chips in each of the hanging baskets.

The assortment can be easily rotated, but with good planning of dough preparation and a minimum assortment quantity of 100–500 pieces. For optimum temperature and humidity distribution, air is circulated in the proofer by means of an air handling unit including cooling. Customers appreciate this especially during the summer months, when the rising temperature of conventional bread ovens ranges from 30 to 35°C in 45–55 minutes.

Slab and plate proofers

The assortment can be easily rotated, but with good planning of dough preparation and a minimum assortment quantity of 100–500 pieces.

Even rustic products can be easily produced with the help of molding lines, and the wedges are then automatically loaded on the plates and proofed at cooler temperatures, thus ensuring the suppleness and high quality of the product. We supply proofers mainly to Poland, Romania, Hungary, generally for the free-fermenting wheat markets. However, we see a huge potential for offering free-fermented products in our country as well. A wide range of wheat bakery products does not mean complicated production.

For the above products, fixed slab and plate with ciabatta dough rolling can be used.

Continuous proofer with plates

The above-mentioned proofers offer two alternatives: with a fixed proofing time, where the plates with the bakery product move horizontally or vertically on a chain track. This is a relatively simpler type of proofer, similar to a hanging proofer.

The second variant, with a variable rising time of e.g., 60–120 minutes, is technically more complex and more costly. The proofing plates move only vertically in separate towers and by omitting the designated towers the proofing time is varied according to technological requirements. The same principle is used by proofers on baking sheets, but instead of plates, the towers are fitted with sheets. This is how the typical French baguettes or salted beer breadsticks are produced.

Continuous proofers for molded bread

The growing popularity of molded breads encouraged the development of a continuous proofer for just

such bread, which is a very interesting export item in foreign industrial bakeries. These are hanger-type proofers with the possibility of variable rising times, where whole cassettes of molds are moved at the proofer inlet to individual hinges. After proofing, they are ejected at the outlet for further sprinkling or slicing, and then primarily conveyor ovens are used for baking. The automatic line for the production of wheat, rye or whole meal mold bread is always equipped with fully automatic technology for the collection of finished bread, returning, cleaning and cooling of molds and other additional equipment according to the final product.

All continuous proofers can be equipped with accessories for sprinkling, slicing and moistening, thus significantly expanding the possibility of assortment production using one type of dough.

For cutting products for high-performance lines, we cooperate with foreign partner companies that offer robotic cutting with rotating discs or the so-called plotter system from the Spanish company Auxpama.

Our experience with the production and installation of continuous proofers to date has convinced us of the significant benefits of continuous proofers in medium and industrial bakeries with a minimum daily production capacity of 5,000 pieces of bread/day. They consistently confirm significant savings on wage costs due to the saving of 3–4 production workers depending on the production volume, easier expansion of the product portfolio with an average economic return of 4–5 years without the use of European subsidies.

17/56 !DEA 02_2022 TECHNOLOGY

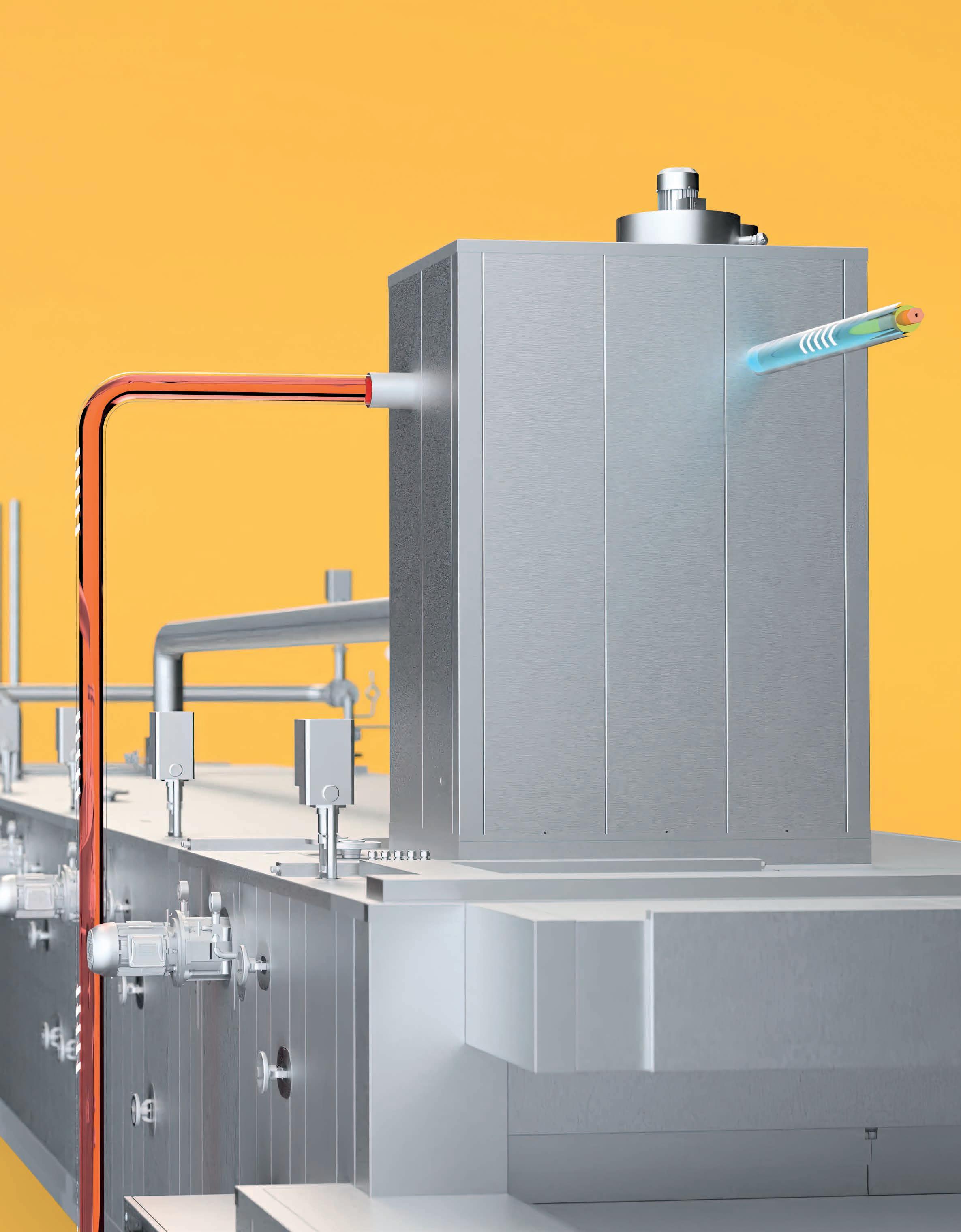

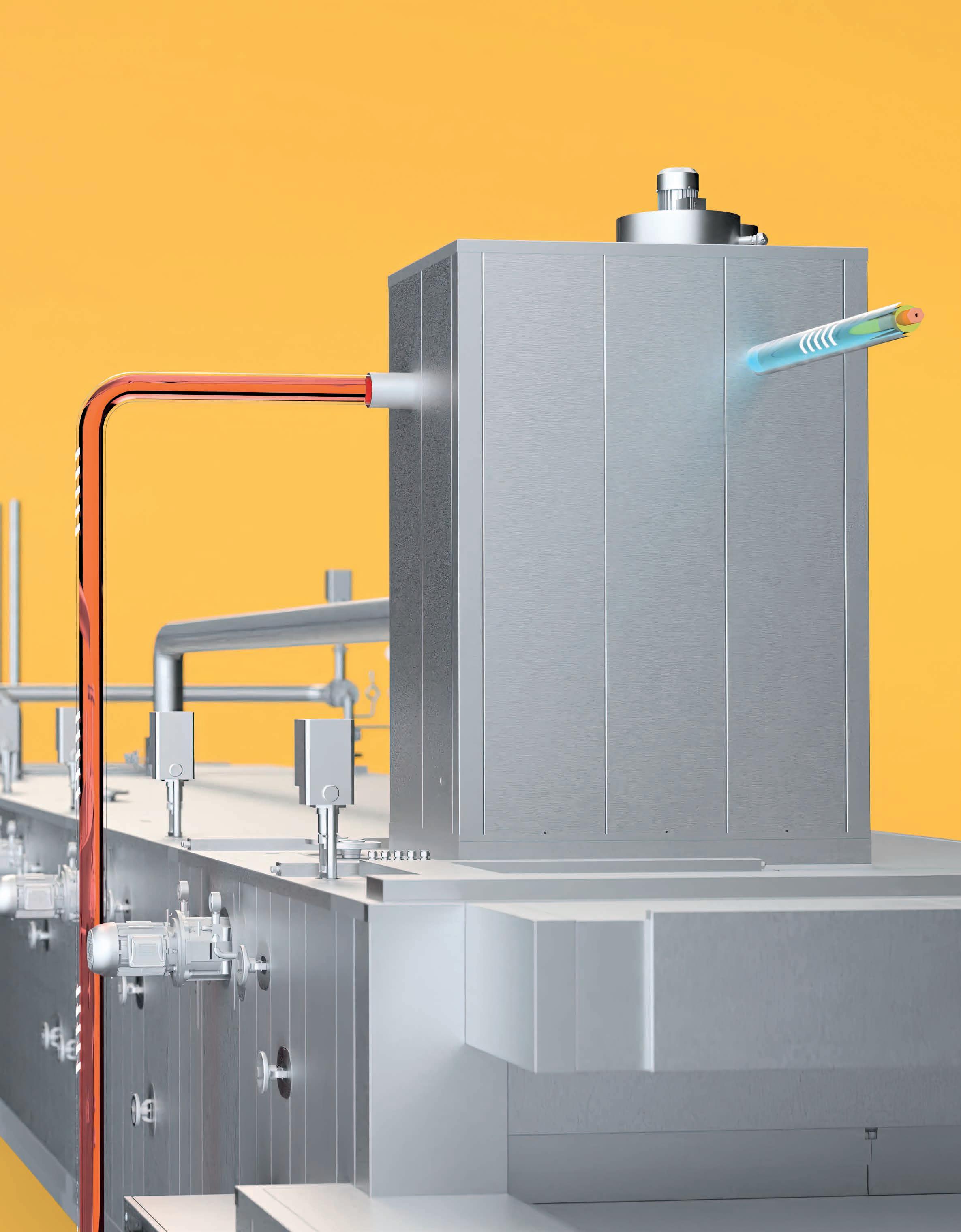

Thermo-oil boiler BioTherm

An ecological alternative to heating bakery ovens

The current economic and geopolitical situation is increasingly forcing us to reflect on our dependence on fossil fuels. Green energy is now becoming a big concept in the baking industry, and we are not standing on the sidelines. Our BioTherm eco-friendly boiler offers a solution. We interviewed Ing. Karel Kornfeil, who will introduce this technology to us in more detail.

Until now, the main energy medium for bakeries has been natural gas or light fuel oil. Biotherm is a thermo-oil boiler, i.e., a source of heat transfer medium for thermo-oil ovens of any design. It is a fully automatic boiler for biomass, wood chips, pellets or briquettes up to 50 mm in size, which meets all European environmental standards and is CO 2 neutral.

The BioTherm boiler does not use fossil fuels for its operation, as we have been used to in the past. So, can you describe what we are able to replace these energy sources with?

The most economically cheapest fuel is wood chips, which have up to 2.8–3.3 kW of energy in 1 kg. Other suitable fuels are wood pellets, agropellets or briquettes made from agricultural waste products or wastepaper and cardboard. There is 4–5 kW of energy in 1 kg, depending on the type of material processed.

What about the price and availability of these waste materials? Will this technology be worthwhile even if we are not directly linked to the entities involved in wood production?

It is always logical for any investor to ask how much fuel costs today and what the price will be in the next five years. Or what will be the economic return on the entire investment. In today's turbulent times, when the price of electricity and all fossil fuels is completely out of sustainable reality, it is very difficult to predict future energy price developments. Even the aforementioned alternative fuels are increasing in price today, and the price of pellets is also rising. For this reason, not only companies are stocking up for the winter, but households are also dealing with

the same problem. I believe that the prices of these fuels will gradually be solved by the market itself, because there are many suppliers in our country, and they all want to sell fuels. In view of the energy crisis and the environment, diversification of sources should therefore be a major issue for bakeries.

Is this method of heating the boiler sufficient? To what temperature are we actually able to heat the boiler using wood chips and pellets?

BioTherm thermal oil boilers heat the oil to the required temperature of 300°C, just like gas boilers. BioTherm boilers respond continuously to the required output from 30 to 100% power. We also offer boilers with outputs of 200 and 500 kW, and on customer request we are able to assemble them in tandem according to the required oven output.

How can we get this heat into the baking ovens without significant losses?

The boilers are installed in separate boiler rooms with Ekobloks to

19/56 !DEA 02_2022 TECHNOLOGY

recover the waste energy. The energy can be fed into the plant through insulated pipes over distances of up to 100 m. However, it should be borne in mind that as the distance from the heat source increases, so do the costs of pipework.

Isn't there a possibility that we will run into some design limitations? What ovens can we connect this system to?

It is mainly a question of the size and location of the boiler room, or access to fuel transport. We usually store pellets in steel silos, or we can leave them lying around in the warehouse.

After all, natural materials leave behind more dirt than fossil fuels, so how about the maintenance and cleaning of this type of boiler?

Biotherm boilers in conjunction with Ekoblok meet all EU environmental standards. Thanks to the wet flue gas path in the Ekoblok, dust particles

are also significantly eliminated. The boiler is cleaned automatically, and this process takes place once a week. In terms of maintenance, only an occasional check of the fuel supply is carried out, as well as a weekly check of the combustion chamber and the cleanliness of the cast iron grates from foreign objects.

One of the main factors for getting a BioTherm boiler is definitely energy savings. So, what is the approximate return on this investment?

This is based on realistic biofuel prices. Currently, the price of wood chips is around 0.5 CZK/kW and for pellets in the range of 1–1.3 CZK/kW. However, it is problematic at what price level of gas we calculate the investment.

If we calculate a gas price of 100 €/ mW, the return on investment could be 5 years. However, this is very individual, depending on the operating hours and the load of the technology.

What about the control and setup? Can I change the operating parameters of the boiler in any way?

The entire boiler operation is fully automatic and is controlled programmatically via PC. The operator just selects the fuel type and starts the automatic spiral cleaning after the end of the production at the end of the week.

Do you notice any shortcomings of this boiler?

The operation of such boilers implies the maintenance described above and the responsibility for purchasing and importing fuel.

What types of bakeries would you recommend this thermo-oil heating technology to?

I can recommend it to those bakeries that have thermo-oil ovens or are considering purchasing them regardless of the size of the bakery.

20/56 BIOTHERM

Recipe The Baguette 25 –28 Brioche 29 –30

The baguette

There is probably no bakery product more characteristic of France than the baguette. Whether you buy a baguette tradition, a baguette normale or a baguette à l'ancienne at the bakery, you will always end up with an unmistakable long, narrow bread with longitudinal cuts forming the characteristic ‘ears‘, a soft, moist crumb with large pores and a toasted, crispy crust.

There are countless recipes and processes for making baguettes, perhaps united only by the resulting shape. However, if you want to try a traditional French baguette or li pain de tradition française, the options narrow down slightly. According to Le Décret Pain (or the Bread Law) of 1993, a traditional baguette should be made with only three basic ingredients - wheat bread flour, water and salt. The recipe must not contain any improvers or additives and the final product must not be frozen at any point in the production process.

If you miss yeast in your recipe, the law thinks about this too. Traditional bread can be leavened with either regular baker's yeast (Saccharomyces cerevisiae), natural yeast or a combination of the two. And what do we mean by natural yeast? Wheat or rye yeast, an active leaven, primarily containing lactic acid bacteria and natural yeasts, which are able to sufficiently leaven the dough. A baguette made using only natural leaven is called a baguette au levain. If, for the sake of volume or to speed up the production process, you would like to use a little yeast in such a product, you may do so, but the amount must not exceed 0.2% by weight of the flour used.

RECIPE 25/56 !DEA 02_2022

Basic recipe

Ingredience

100% wheat flour T650

60–62% drinking water

30% wheat yeast (100% hydration)

1,8–2% salt

Flour

What flour is ideal for making baguettes? The standard flour used in France is wheat flour with the designation T650 (W 180–220, P/L 0.7–1).

In our conditions, we can easily use T650 wheat bread flour, or even T512/530 light flours, or various combinations thereof.

Yeast or natural leaven?

That's entirely up to you. Each method brings different flavors, aromas, crumb texture or crust appearance – ultimately, always a different final product. If you have the time and space, try keeping the dough cold for a long time (using yeast or sourdough). You can also achieve great results using preferments – whether you use traditional

French pâte fermentée (‚old‘ or pre-fermented dough from the previous day), polis or a combination of polis and natural leaven. The possibilities are endless.

Recipe

For example, you can try a recipe with a one-day production process using active wheat leaven.

THE BAGUETTE 26/56

Dough preparation

Mix the flour and water on low heat and let the compact mixture stand for about 30 minutes. Then add the wheat leaven and finally the salt. Knead for approximately 4–6 minutes at low speed, approximately 3–4 minutes at high speed. The temperature of the dough after kneading should be between 24–25°C.

Then transfer to an oiled plastic container and close with the lid. Let the dough rise for about 4 hours –by that time it should have risen by about a third and should be smooth and elastic (the pH of the dough at this stage is approx. 4.5). Once the dough has risen, roll it out (one piece should be 400–500g) and gently shape it with a pastry scraper to achieve a smooth loaf. Let it rest on the table for about 15 minutes before

you start the final shaping. The first rise can also be done slowly in the cold. This slow rise at lower temperatures has huge advantages.

Shaping and proofing

How to shape baguettes properly? Undoubtedly, every baker has their own favorite method. With a bit of searching, you can find a number of instructional videos on the internet that walk you through the process in detail. In any case –place the loaf of dough which you had let sit on a floured table, gently stretch it at the corners to form a rectangle and gently fold the dough from top to bottom while closing it tightly to create a roll, which you then roll out into the desired shape And how long should the baguette be? That depends on the weight of the dough. The French standard is

approximately 50 to 60 centimeters, and the baked baguette should be 5–6 centimeters across.

Let the shaped baguettes to rise for about an hour on lightly floured linen sheets or on peel boards if you use this technology. Before baking, cut the baguettes – either the classic 4–5 overlapping longitudinal cuts or one long one in the middle – this way you get a little more volume.

Baking

For ideal results, bake in a deck oven. Bake a 500 gram baguette for about 25–27 minutes at a baking temperature of 260°C; reduce to 245–250°C after five minutes. Steam immediately after loading; steam the baguettes for the first 15 minutes and then open the vents.

RECIPE 27/56 !DEA 02_2022

THE BAGUETTE 28/56

Brioche

“Qu'ils mangent de la brioche!”

“Qu‚ils mangent de la brioche!“ or, in a not quite correct translation, “Let them eat cake!“. A famous phrase, perhaps wrongly attributed to Marie Antoinette, who uttered it after being alerted to the fact that her subjects were suffering from a lack of bread due to crop failure. There is no doubt that brioche has deep roots in the French baking tradition, with its first mention dating back to the 15th century.

What makes brioche so special? First of all, it is made with quality ingredients such as eggs, milk (some recipes do not use it at all, the dough is hydrated exclusively with eggs) and above all butter, which give it its exceptional texture and taste. The traditional recipe doesn't contain too much sugar, so brioche offers a real variety of ways to eat it – or on its own as part of breakfast, like French toast. But it's also great with raisins and candied fruit. It is worth remembering the inseparable combination of brioche and foie gras, which has a firm place in French cuisine.

RECIPE 29/56 !DEA 02_2022

Basic recipe

Flours

We recommend using strong wheat flour for brioche, given the butter content of the recipe (approximate specifications W340–370, P/L 0.55–0.65).

Dough preparation

Mix all ingredients except butter and salt in a spiral mixer on low speed until it forms a compact mass (approx. 4–5 minutes) and let rest for about 15 minutes. Add the salt and mix on low for about 5 to 7 more minutes. The dough should be elastic at this stage and the gluten should be developed enough to form a so–called window. Gradually start adding the softened butter until it is incorporated into the dough. Then switch to high speed and mix the dough for about 4 more minutes to ensure it is completely smooth and does not separate from the sides of the mixer.

Kneading and baking

After kneading, transfer the dough to an oiled plastic container with a lid and leave to rise for approximately one hour, the ambient temperature should not be too high to prevent the butter in the dough from melting. Fold the dough twice during this time. Then remove it from the

Ingredience

100% light wheat flour

50% butter

30% whole eggs

27–30% whole milk

container, squeeze out the gases, wrap it in cling film and refrigerate it for at least four hours, or longer.

Refrigeration is important because of the high butter content of the dough; the butter would melt during shaping and the dough would be too sticky. Similarly, be careful not to let the temperature rise too high when making the final products, as the butter must not melt in the dough –just like in croissants.

Prepare a rectangular mold with higher edges and brush the inside

14% crystal sugar

3% fresh yeast

2% salt

with butter or use a separating spray. Divide the dough into 50–70g clones (depending on the shape and size of the mold), shape into balls and place side by side in the mold. Leave to rise for approximately one hour. Brush with beaten egg before baking. The baking time depends on the size of your tin and the amount of dough. For about 400 grams of dough, bake for about 30–32 minutes at 170–180 degrees. Once baked, remove from the tin immediately and leave to cool on a wire rack.

BRIOCHE 30/56

Reference Artic Bakehouse 33 –36

How to turn pastry into a social media star

Working with social networks is an integral part of marketing these days. Artic Bakehouse knows this, their content on these platforms can be a great inspiration for other businesses. In the following interview, the owners of Prague's Artic Bakehouse bakeries – Davíð Arnórsson and Gudbjartur Gudbjartsson – will share their experiences.

REFERENCE

33/56 !DEA 02_2022

What impact do social networks have on your business?

I can say that social networks have a really significant impact on our business. Speaking for myself, I have to say that I have never used social networks much. Before we moved to the Czech Republic, I had a company in Iceland and at that time these technologies did not exist or were in their very beginning stages. But here in the Czech Republic, social networks have helped us become a really popular business in the Prague gastronomy field. Nowadays, our Instagram lives a life of its own, thanks to our fans, who constantly supply us with a huge number of great photos. Thanks to our fans, our content is created really naturally, and, above all, we have a constant supply of material for our posts and stories. I still can't believe the numbers myself when I see how many people our posts have reached and how many views we have. So, our posts reach roughly 150,000 users a month. It's amazing that people from all over the world come to see us thanks to social media. And that's just because they found out about us on Instagram or read a travel blog that mentions our bakery. In short, this method of presentation has incredible power. But at the same time, it is important to remember that this way of presentation can help you a lot, but if your product or services are not 100%, it can also destroy you.

Do you use the services of professional photographers, copywriters or marketers?

I have to say that basically we don't use these services much. We have a lady who does Facebook and Instagram for us lightly, but it's not a major marketing job. As for photos, as I mentioned before, most of our content comes directly from our fans.

However, if we need to shoot a product on a white background, we use a small photo booth and we shoot practically everything ourselves on our phone.

Have you worked with other foodie entities? If so, have these foreign entities attracted new fans from their side?

We supply baked goods to various restaurants, but we have never promoted this type of cooperation in an official way. Of course, some of our customers are also restaurant owners and use our bakery products in their restaurants. On their menus you will find a mention that the pastries come from Artic Bakehouse. But as I said, we do not promote these collaborations in any way. Of course, we are happy that these restaurants mention us in their menus and that they like to use our bakery products, knowing that they already have a certain name in the world of Prague gastronomy

Do you have any experience working with influencers? If not, are you thinking about a similar collaboration?

We have never officially collaborated with any influencers. Of course, we have been approached by some, but we have never entered into a paid collaboration with anyone. To be honest, I remember one lady who traveled to the Czech Republic, she told me she was an influencer for a living, but we only offered her to get some of our products for free. But even without paid collaboration, influencers mention us quite often. Just do your craft honestly and these things will come.

You have over 11 thousand followers on Instagram. How long did it take you to build that fan base?

Our fan base has been slowly building for something like three years. Fortunately, in our case, everything happens naturally, and we didn't have to focus so much on reaching out to new fans. The best way we do this is through our loyal customers, who are amazing at this and are constantly tagging and promoting us on Instagram. Our new fans come to us so naturally thanks to the positive reviews and support of our current fan base.

Do you also use paid advertising on Instagram?

We‚ve used this method of promotion two or three times on our Facebook page, but we haven't ventured further into similar paid advertising.

Do you notice that as the number of followers grows, it's getting harder to gain new ones organically?

We know that you can pay for advertising and many other services on social networks. But we don't think that fans gained from advertising are as valuable as those who start following you naturally through their friends or acquaintances. That's why we insist that less is sometimes more. Our fans really care about and value our work. I‚m not entirely sure if it would work this way for users who started following us just based on advertising and had never heard of our work before. We simply really appreciate the fans from the other side of the world, but more importantly for us is the hard-core group who visit us every week and know our work and team personally.

In the future, are you thinking about making any changes to the presentation of your business or even to your presence on other social media sites such as TikTok?

ARTIC BAKEHOUSE 34/56

I think that time will probably come soon, and we will have to hire a person to take care of our social networks professionally. Our reach is constantly increasing and since we are primarily bakers, we have never been completely good about responding to people on our social media. This is largely due to the fact that we are not Czech and find it difficult to reply in Czech. So, in my opinion, the time will soon come when we will have to start addressing this situation and if we hire a professional, they will start addressing our content on other social networks like TikTok.

Are customers from other cities and countries visiting you because of your social networks?

Absolutely, we have customers from all over the world stopping by. I have personally met people from South Africa and Japan, for example, who have come to our bakery because of social media. That's where social media has incredible power. People from the other side of the planet come to us without ever having been to Prague or the Czech Republic at all. At the same time, we are also followed by a large number of people from different parts of the world who have never visited us, but who may visit us one day. :)

Do you have any experience with negative reactions on Instagram? How do you react to them?

Of course, we do. Overall, we have very good reviews, both on Google and Facebook, but there are always some negative ones. We do our best to respond to everything, but it often depends on what the criticism is. If someone doesn't like that our range is a bit more expensive, we have

nothing to say about that. Yes, our products are more expensive than in a traditional bakery, but you still have plenty of bakeries all over Prague to choose from that are cheaper than us. We simply have nothing to say about these objections. But if our customers have a bad experience with the quality of our products or customer service, we always try to track down the problem, find out what went wrong and fix it. After all, not every piece of baked goods will always turn out the same, and our employees are flesh-and-blood people who can make mistakes or simply may not be having their best day.

How do you feel about Instagram competitions? Have you ever used this form of promotion?

We‚ve never tried this form of promotion; in fact we haven't even needed anything like it yet.

Do you have any loyal fans who tag you regularly, re-share your posts and naturally promote your work?

There are a lot of customers like that, and our work on Instagram is built on them. We‚re so happy that these people promote us naturally and out of their own conviction, without us asking them to do so. I‚ve even met a lot of them in person at our store. It's a very nice feeling to meet customers who root for you like that. Anyone running a business should be in a personal connection with their customers. After five years of running our bakery, we have found a lot of great customers who have become good friends. There are also customers who have been shopping with us almost every day for many years, and some of them have been with us since the very beginning. We

are also very happy with customers who are from Brno or Ostrava, for example, but every time they come to Prague, they stop by for something good. One of the nicest things that happened to us from our customers was when one of our loyal customers went on holiday to the seaside with his family and they carved a big heart and the Artic bakehouse sign into the sand.

Are you looking for inspiration from other international bakeries and gastro entities?

Of course, we‚re always trying to soak up inspiration! It's not that we specifically go after other bakeries, but if something appeals to us taste-wise, we‚re happy to try it. It happens to us that some bakers are inspired by us. But I would like to say one important thing, I like it when people inspire each other, and it makes me happy when other bakers are inspired by our work. But what I really don't like is if one doesn't have certain knowledge or experience and tries to make up for these shortcomings by copying recipes and products. Maybe the country we come from has a big influence on us as bakers are really important in Iceland and it takes 6 years to train as a baker here. Our view of baking is more like an art than an industry. We can use this example in this situation as well, if I paint a picture to inspire another painter, I will be very happy, but if another painter copies my picture I probably won't be very happy about it.

In your opinion, do stories or classic feed posts have more influence on your fans?

It's hard to say which type of posts works better on our fans. But we think it's more likely to be our feed photos, which are more constant in nature. As for stories, those are

REFERENCE 35/56 !DEA 02_2022

almost exclusively reposts from our customers.

Are you working with new trends in gastronomy, such as vegan or gluten-free products?

No, you won't find this range in our bakery. We try to go the traditional way, of course it happens that customers come to us and look for this kind of bakery products. As for vegan baked goods, you won't find that in our range. As far as gluten-free baked goods are concerned, thanks to the quality of our ingredients and the fermentation process, our products are really low in gluten. Thus, unless you suffer from a really serious intolerance, our products will not cause you any problems. We have tested this in Iceland, where our customers tried one slice of bread on the first day, two slices on the second day and so on. Above all, we want to bake our products in a way that is close to our hearts and to the best of our ability, and customers who have specific needs in this regard have plenty of options in Prague where to buy these pastries. But at Artic bakehouse, we don't concentrate on all possible assortment, and we don't want to. We believe that we have taken a path that we understand, and it is more important for us to stick to what we know than to try to go against all the new trends.

Do you keep any stats to help you make your Instagram even better?

We don't keep detailed statistics, but in the time we‚ve been using social media to promote ourselves, we already know which products work better than others on our Instagram. But as we‚ve already said, the time is gradually coming when we‚ll need to hire a professional to manage our social networks, and at that point we‚d

certainly like to track that data. So when we find a person who has a similar perspective to ours, we‚ll definitely take those methods into account.

Have you thought about using Czech along with English in your posts?

Of course, we are a Czech company, and we should write our posts in Czech as well. Unfortunately, we are currently not fully capable of writing all our content in Czech and we know that this factor is our weakness. In the future we plan to change this approach and write everything in English as well as in Czech.

Do you also share stories of your employees so that your customers get to know the personalities who work on their favorite pastries?

Yes, we have had a few of these posts in the past, and we would like

to focus more on sharing our employees‘ stories in the future as well.

Do you only use certain filters to keep your posts coherent?

In most cases, we don't use filters at all. Because the light in our stores is very constant, which makes all the photos from this environment have a similar character.

Have you thought about creating custom gifs on Instagram that your fans can use when tagging your account on their stories?

Ha-ha, we have to say that we were very interested in this question, even though we hadn't thought about something like this until today. We think this way of promoting our bakery is a good idea and will definitely consider creating something similar for our fans and customers.

ARTIC BAKEHOUSE 36/56

Personalities Karel Kornfeil 39 –40 Martin Křižák 43 –44 Davíð Arnórsson and Gudbjartur Gudbjartsson 41 –42

How was written the history of Kornfeil

Kornfeil has been in the bakery oven market for more than three decades. What were their beginnings in the field of the baking industry, or how do they compare to other countries? The history will be explained to us by its founder, Karl Kornfeil.

What year was Kornfeil founded?

In 1991. It was not until this year that it was possible to start a free business.

Did you have any experience in the baking industry when you started the company?

In my previous job, I worked on a project for electric baking ovens, but they never made it into production and remained on paper.

What was your job before you dove into baking technology?

I worked as an agricultural production engineer.

How many employees did your company have in the beginning?

In the beginning, we were about ten

co-workers, and compared to today's situation, business was very easy.

A lot of European bakery equipment companies have their roots in the early 20th century, some even earlier. In our country, due to the social situation, free enterprise was not possible until 1989. Was it difficult to fit in with competitors who had been in the industry for many years longer?

Honestly, it's still challenging now. Despite our company not having a long history, because it simply couldn't have such a long history, we are full competitors of all German manufacturers, and we are very pleased about that.

PERSONALITIES 39/56 !DEA 02_2022

Did you immediately set your sights on the foreign market as well, or was your business initially focused only on the Czech Republic?

No, we started in the Czech Republic, then in Slovakia and gradually in the countries of Eastern Europe, but today we sell mainly to the West, to the United States and Australia.

Do you specialize only in industrial bakeries, or do artisan bakeries with smaller production also choose from your range?

Small artisan bakeries looking for quality technology focused on the baking industry can also choose from our range.

To which countries does Kornfeil currently distribute its products?

Our products can be found in 30 countries around the world.

Ecology and environmentally friendly production are a big topic nowadays. Is Kornfeil responding in any way to this pressing issue?

Kornfeil was the first to introduce the EkoBlok product, which enables the use of waste energy from ovens. Thanks to this product, we can save bakers up to 40% of the input energy, while we have long experience with BioTherm thermo-oil boilers. To heat them, bakeries do not need fossil energy sources and can become a so-called green bakery. Last year we introduced the Deodorant, a unique device for harnessing the energy

of exhaust steam, but you can read more about that in the following pages.

Do you manufacture your product range entirely in the Czech Republic?

Yes, and we are proud of that.

In recent years, the situation has not been favorable for anyone and for entrepreneurs in particular, has the covid pandemic affected the baking industry in any way?

Yes, the situation has not been easy for anyone, but in any crisis, investment and a proactive approach is the only cure.

How do you think the Czech bakery industry is doing compared to other countries?

Czech bakers have long been struggling with traditionally low bread and pastry prices, hopefully they will manage to change this situation, but

the current energy crisis is unfortunately not helping with this.

What are Kornfeil's plans for the future, can you tell us some of them?

To make life easier for bakers and to find an easier way to produce quality bakery products together with them.

Thank you very much for the interview and I will finish by asking you what is your favorite bakery product? Bread, of course.

HOW WAS WRITTEN THE HISTORY OF KORNFEIL 40/56

Bakery yesterday and today

The baking industry has experienced unprecedented growth in recent years thanks to modern technology development. How the industry has changed over the past few years into the form we know it today will be presented by Křižák Bakery and Artic Bakehouse. What do they think about the current evolution of their craft, is the industry still burdened by tradition and what trends are they following?

41/56 !DEA 02_2022

PERSONALITIES

DAVÍÐ ARNÓRSSON AND GUDBJARTUR GUDBJARTSSON

How long have you been in the baking industry?

Almost 30 years, I started in this industry when I was only 13 years old. So, I‚ve been between the flour and the oven pretty much all my life. I never wanted to do anything else, baking is simply my life.

What are the most significant changes compared to your beginnings in this field?

This is going to sound strange, but the most significant change is that we are trying to go back to our roots. A lot of bakeries are trying to make their jobs easier, freezing their products and so on. We don't do any of those things, instead we try to go the most frugal way possible and make our products the traditional way.

Has your product range changed with the times?

We cannot say that we are changing our product range radically. All the changes we are making are really gradual. We don't want to take anything out of our range too much, as all our products sell very well and have loyal customers who we don't want to take away their favorite bakery products. But of course, the range has changed slightly since we started.

our employees‘ jobs much easier. At the same time, these ovens allow us to stick to our traditional recipes and we don't have to adapt them to some automated programs or the like. To be clear, we do use new technology and automatic ovens, but to the extent that it does not affect our approach, which is based on traditional baking. We simply still like to get our hands dirty with honest baking work.

Is this craft still burdened by tradition or are younger bakers also coming to the fore?

In our case, we try to work more with young bakers. We have a lot of young people coming in, but baking is hard work and not every young person can stick with it. But we do try to work with young people, but sometimes we run into a lack of experience. In Iceland, it takes 6 years to become a baker. Here in the Czech Republic, it takes only three years and at the same time the baking education here is not as good as it is in Iceland, which is noticeable for young bakers. The education system here tends to produce bakers

for the large industrial bakeries, not for the artisanal ones. That is why we choose young people who do not have the necessary experience but have a passion for the baking craft and enjoy further education and improvement in this direction.

Are baking trends from abroad gradually coming to us?

Absolutely, we are part of it ourselves. We are very happy when we get new recipes from different countries around the world. Although in our case we tend to concentrate on bread. We try to make our bread as healthy as possible and low in gluten. In the Czech Republic, this is a big problem and bakers do not address the gluten content too much. But we want to go a different way. This is the legacy of our bakery; we try to make delicious bread that at the same time does not put too much strain on your body.

We also like to bring inspiration from our holidays. It often happens that we taste something and try these new flavors as soon as we arrive.

Is there any technology that has radically changed your industry during

your career?

Absolutely! A big change for us was switching to the ThermoStar Classic oven from Kornfeil. Our products have a much more consistent quality with this oven. Another huge advantage is the automation and control of these ovens, which makes

42/56

Martin Křižák from the Křižák bakery

What are the most significant changes compared to your beginnings in this field?

First and foremost, it's experience, but one of the most significant changes from my early days in the baking industry is overemployment. I perceive that there is a shortage of skilled and hard-working people in the labor market at the moment. However, this problem is nationwide and not just in our industry. A lot of people are running their own businesses, and at the same time there are a lot of foreign companies operating in our area. This is largely due to the logistical position of the Czech Republic, which is almost the center of Europe, making it very interesting for the aforementioned foreign companies.

Has your product range changed with the times?

In our early days, we focused on

classic commercial baked goods such as rolls, breads and Christmas cakes. Over time, our product range has evolved in a completely different direction. We process ingredients in a completely different way, whether it is flour or other cereal products. We have resisted supplying our products to supermarket chains, which means that we have started to target a completely different market. These are, for example, gastro-pubs, health food stores, farm shops, in short, stores that offer food with a different added value. This is where I see the way forward for smaller bakeries, which is still one of our focuses. At the same time, we also have our own stores, but this segment is quite unstable. There are periods when these stores do very well, but then there can be a downturn and people start saving more. It's not that customers have stopped visiting these stores, but they are buying less. Our goal is to have our stores

operate as independent entities that are not dependent on the bakery. Unfortunately, in a recession, this model may not work very well.

Is there any technology that has radically changed your industry during your career?

One thing is a more responsible and environmentally friendly approach to production. I‚m thinking of heating ovens with biomass. These technologies have quite a promising future, not only in our industry. Another technology that is undoubtedly having a big impact on the baking trade is thermooil. It has had a significant impact on the quality of baked goods. This is mainly due to atmospheric pressure, which does not have such an impact on the quality of baking when using thermo-oil, whereas it can have a really significant impact when baking with conventional

PERSONALITIES 43/56 !DEA 02_2022

I started baking thirty years ago. At that time, I was my own first employee, and to date we have about 120 employees.

burners. There are other factors that make this method of baking easier and the quality of the baked goods better. Using a thermo-oiler makes the baking process faster, which means the bread retains more water and is much juicier. We can also see the development of mixing technologies. The new machines knead the dough to perfection in a really short time, and it doesn't heat up unnecessarily. I would also like to mention the cooling machines and their advantage when working with long maturing doughs. If we look at large automated industrial lines, here the machines do not so much affect quality as efficiency. On the contrary, I would say that in these cases it is quality that takes a back seat to efficiency.

Is this craft still burdened by tradition, or are younger bakers coming into their own?

From this point of view, baking is still a traditional craft, but of course there is also a generational change in the industry. The descendants of older bakers and the younger generation of bakers are also getting involved. But I don't think this has affected the tradition or the range of bakery products in any significant way. In my opinion, young people are bringing more emphasis on marketing or new technology to the industry. But as far as the craft itself is concerned, there is not much to change. Bread has been baked for several thousand years and the process of making it is still the same. We‚re still working with live material, which you can't change much. If I see someone trying to do that, it's usually to the detriment of the pastry. Any improvement product will not improve your bakery products, but rather make your work easier and more efficient.

Are baking trends from abroad gradually coming to us?

Definitely, the main boom in this respect was in the 90's, when preparations came from Germany and other Western countries. That period was the most important from my point of view. But nowadays I would say it is rather the opposite. The Czech Republic is at a high level in terms of the range of baked goods. The Czech baker has products on

the counter that you will not find elsewhere in the world. I try to go abroad as often as possible, but there is little that inspires me or throws me for a loop anymore. We prefer to find ways to go back to our roots. When we are in France, for example, we try to find an old baker who bakes baguettes the old-fashioned way. That's the way that inspires us the most.

MARTIN KŘIŽÁK, THE KŘIŽÁK BAKERY 44/56

34/56 PEKÁRNACROISSANTTARTINE Ecology What to replace natural gas with 47–48 EkoBlok 49 – 50

What to replace natural gas with

Although the need to move away from fossil fuels, especially with regard to the environment, has been talked about for several years, it was only the energy crisis caused by the war in Ukraine, with the threat of an absolute suspension of the supply of the always available gas and unpredictable price rises, that made us think seriously about alternative energy sources, with the need for an immediate response.

Nature offers us the opportunity to use, for example, the potential of biomass and solar energy, and together with the flexibility of thermo-oil technology, bakery ovens and bakeries can be heated completely without the use of traditional energy sources. The dramatic rise in gas and electricity prices has turned the bakery's normal cash flow into a nightmare from which we unfortunately cannot wake up but must learn to live in temporarily. Although the situation in black scenarios seems currently unsolvable, it is necessary to change the way of thinking about traditional bakery production methods, as well as on the maximum possible use of waste energy in bakeries, which Kornfeil has long experience with.

The variety of oven technologies across bakeries is very wide, their sizes and technological processes vary widely, so it is impossible to provide a simple guide to solving the energy and economic crisis.

However, the common denominator is the need to reduce energy costs with the possibility of full independence from natural gas or the comprehensive use of waste energy in bakeries, which will bring savings in natural gas consumption.

Below I would like to present the possibilities of alternative energy sources in baking, the use of which in production is significantly supported by European Union subsidy programs, which can include the renovation of baking ovens, photovoltaic power plants and biomass combustion.

Thermo-oil flexibility

Thermo-oil as a heat transfer medium offers the flexibility to use other energy sources, the installation of which usually takes place outside the production area of the bakery and does not disrupt the production itself for a longer period of time. Although the most important factor when looking for alternative heating is the quick economic return, by moving away from fossil fuels to biomass combustion or the use of solar energy, along with maximizing the use of waste energy, you will make a significant contribution to much needed environmental protection. You will also ensure complete or partial independence from the currently politically exposed natural gas

BioTherm – the thermo-oil boiler that saves your costs and nature

The BioTherm thermo-oil boiler uses wood chips and pellets as its heat energy source. Compared to natural gas, this fuel is a more economical and environmentally friendly source of energy. It is a fully automatic boiler which, in combination with the Ekoblok, meets all applicable EU environmental standards. The BioTherm thermo-oil boiler connects to an existing thermo-oil boiler system, but it is necessary to build a fuel storage tank, whether it is wood chips in bulk or in silos as well as pellets.

Wood chips – the cheapest fuel for baking

Wood chips are the cheapest fuel for heating thermo-oil boilers, with prices around 450 CZK/1 MW. Chips in 1 kg contain 2.8 kW of energy at up to 30% moisture to achieve full boiler output but are more difficult to handle and store compared to pellets.

Pellets – a convenient energy source for BioTherm

Pellets are a more comfortable and convenient fuel in terms of storage and transport. In 1 kg of pellets we can find 4,8–5 kW of energy, but the price is currently increasing and ranges from 1,100–1,500 CZK / 1 MW.

47/56 !DEA 02_2022 ECOLOGY

Solar energy in bakeries

The use of solar energy makes sense for any size of bakery, electricity cannot be replaced. The energy obtained from photovoltaic panels can also be used for baking, but it must be said that the solutions presented below have their limitations and rules.

Again, solar energy can only be used in bakeries with thermo-oil ovens or, logically, electric ovens. It is necessary to fit a thermo-oil electric boiler with the appropriate capacity into the boiler room system and at the moment of its selection it is necessary to know what type of ovens it will be used for and, above all, when. Here we come across the traditional, i.e., night-time, method of baking already mentioned. Worldwide, however, we can see that, because of the use of solar energy, it is possible to plan production so that the greatest possible volume of production takes place during the day, i.e., at a time when energy is free. Daily production offers the possibility of distributing fresh bread several times a day, which is an interesting topic to consider in a situation of ever higher consumer demands.

In the case of a combination of a PV power station and a thermo-oil electric boiler, a conventional natural gas boiler remains in reserve for the winter period and when the sun is not shining.

Approximately 400 kW of heat output is required to produce 1,000 kg bread/hour, which includes energy consumption for rising and baking. However, the accumulation of energy in the oil during the daytime for overnight baking is problematic due to the large amount of energy required for baking. This problem can be solved by storing it in battery storage, which is an additional costly investment, but we expect that this

will soon be supported by national or European subsidies. The installation of a PV power station brings the possibility of selling surplus energy back to the grid on a spot basis, which may have an interesting impact on the economic return on the whole investment.

It must be said that the alternatives described above represent financially and organizationally demanding investments. However, each change brings both negatives and positives, here representing the burden of independence from natural gas or long-term reduction of energy costs.

If you use cyclo-thermal or rotary ovens in your bakery, the only option is to change the burners to other fuels.

Weishaupt, whose products we have been installing in our ovens for a long time, offers combined natural gas and LTO burners for situations where the natural gas supply is interrupted or stopped. There are also LPG, LNG or biogas burners available, but for most of these fuels the price will probably follow the price of natural gas, which is currently changing dramatically.

Use of waste energy

Another topic to reduce energy costs is to maximize the use of waste energy from baking oven flue gases and steam extraction energy. Kornfeil has been involved in energy projects, including the installation of the well-known Ekobloks, for more than 20 years. During this time, we have gained a lot of experience and we can handle projects of a smaller but also larger nature. This year, we have introduced two new products that are used to recover waste energy. These make a fundamental improvement in the use of the condensation heat of the exhaust steam that exists

in all bakeries, and that exists every day, every hour of baking. The steam is 10–12% of the so-called “waste steam”. In every kg of steam, we find practically 0.5 kW of energy.

To give a simple idea, this means that 100 kg of extraction steam can heat 1,000 l of hot water to a temperature of up to 60°C per hour. The energy obtained can be used to heat hot water for social purposes, feed water for steam boilers or crate washers. We have innovated the ExtraSteam and ExtraClean Ekoblok model ranges with the steam energy recovery technology, where there are two waste energy outputs: the first in the form of 60/80°C heating water as before and the second in the form of hot water heated in the range of 60–90°C according to the design requirements.

Similarly with the new product Deodorant, where the energy-deprived steam is no longer exhausted out of the bakery at all, the steam is cleaned of so-called “odors“, hence the chosen name Deodorant. The outlet humid air slightly humidifies the bakery environment, which contributes to a more pleasant environment and at the same time does not create a problematic vacuum in the bakery – a known negative phenomenon in winter, which is associated with cracking bread.

New products for processing waste heat from bakery ovens mean that the input energy for baking can be recovered up to 95%. Also, these products come with significant energy saving benefits in bakery operations. For more information, please visit www.kornfeildeo.com.

If you are interested in the described issues, please contact us. We are ready to help you implement a sustainable energy concept for your bakery.

48/56 WHAT TO REPLACE NATURAL GAS WITH

EkoBlok

The way to sustainable production in the bakery industry

49/56 !DEA 02_2022 ECOLOGY

EkoBlok

Petr Marek, Sázava Bakery

Nowadays we are trying to eliminate the negative impact of our production on the environment as much as possible, how can EkoBlok help us?

The most important factor is the use of waste heat that we would normally throw out the window. EkoBlok can process this heat and further utilize it.

Waste heat is a great source of energy and it's a shame to just throw it away. Can we use EkoBlok to transform this heat and put it to further use?

This heat energy is transferred via heat exchangers to the water and the heated water has a wide range of uses in the bakery. It can be used as utility water, while also being a very useful medium for heating air systems.

Is it also possible to use the waste heat for cooling purposes with the Ekoblok?

In this case it is absorption cooling. The water has to be heated to a

How to deal with waste heat? This question has certainly been asked by many entrepreneurs in the food industry, and the bakery sector is no exception. Our exceptional EkoBlok product helps to reduce waste heat and its impact on the environment, while also saving you money. This is on account that it can further make use of this energy in the operation of your bakery. We will introduce this technology in more detail in the text below.

temperature of at least 80–90°C and with an apparatus similar to the one we have in the refrigerator, for example, we can convert this hot water into the energy needed for cooling. However, we do not use this method of cooling because we do not heat the boiler to such a high temperature, and we would have to heat the water with gas. However, in other plants it is possible to use the EkoBlok in this way as well.

What about the control of this technology? A Is there any way to monitor or even archive the operational indicators? Absolutely, we have a visualization system where all processes related to the EkoBlok are visually outlined. Thus, we know what the temperature is at the inlet and outlet, what the power is, we can see for example the fault message. Of course, we also archive this data, and you can also display everything graphically, for example in a graph.

What about the special requirements of the bakery?

Has Kornfeil created a specific solution for your bakery so that the dimensions of the Ekoblok fit your production ecosystem?

Yes, the Ekoblok in our bakery has been sized to accommodate all the equipment we need. Some of the products that are connected to the Ekoblok are new, others are older products from our original bakery. This is where Kornfeil's approach is really individual, and they have catered to our needs.

Do we need to do any complicated construction work to install the EkoBlok?

Basically, if there are any complicated construction interventions, we only had to deal with the wastewater drainage. Everything else we were able to connect to existing facilities, so as far as construction interventions in your bakery are concerned, EkoBlok is not very demanding.

50/56 THE WAY TO SUSTAINABLE PRODUCTION

Marketing The interior of your business says it all 53 –56

of your business says it all

53/56 !DEA 02_2022 MARKETING

TEXT Ondra Saida, architect

Get to know your surroundings and your future customers.

Researching your surroundings, competitors and future customers is one of the most important processes in interior design. Your goal is to differentiate yourself as much as possible from the gastro entities in the area, but it is also important to fit in with the local color and appeal to local customers who will visit your café or bakery regularly. So always try to adapt your business to a concept that is missing in the area. Should you decide to use professionals for the design, it is definitely worth considering architects from the city or neighborhood where your business will be located. This will ensure that the architect or designer you use can fully empathies with the local area and your future customers. If you decide to approach an architect who comes from another city or location, it is very important to focus more on personal consultations that will help the professional get to know your space and neighborhood better and adapt the design based on the knowledge gained.

You can't do that today without a good concept.

Getting the concept of a business right is the alpha and omega of its success these days, especially

in larger cities where the level of competition is much greater. In cafés and design bakeries, customers are looking for a pleasant place to sit and relax. The interior design of your business can therefore often play a much bigger role than the product range itself. In the age of social media, many customers are eager to show off where they‚re enjoying their coffee or where they‚ve just been served an honest piece of artisan pastry. We need to remember that the interior design and identity of a business is linked to its pricing. Simply put, design-led gastro entities can command a little more money for their services. Increasingly, we are seeing businesses using smaller details, such as customized tiles or engraved wooden elements, to emphasis their identity. The functional means of your concept can also be the accompanying identity, where your logo does not speak for you primarily, but rather some functional element, often associated with the motto of the company. A beautiful example of an accompanying identity can be the neon sign “love“ in the 4 Pokoje in Brno. This sign is so distinctive that it can be seen in almost all the photos taken by customers in this establishment. It is definitely worth pushing your branding into materials that have a certain relationship to your concept.

So, if you are working with a branded paterno, you can press it into perforated sheet metal, but also glass or wood. But you need to be careful that this way of branding does not look cheap. Therefore, in most cases, the less the better. Nowadays, however, we can notice that the logo tends to be neglected behind the overall identity, which plays a primary role, can distinguish you from the competition at first glance and attract attention on a wider scale.

Scandinavian minimalism or colorful playfulness?

Minimalist design based on Scandinavia is of course timeless and will probably never get old for many of us. These spaces always have a clean, airy feel and their simplicity will appeal to most of your potential customers. However, we can also see that trends from completely different parts of Europe are starting to make their way into interiors. Many architects and designers today are inspired by Southern playfulness and hotness. More and more often we can find interiors influenced by Italy and Spanish Art Deco. The playfulness of color and the bold contrasts associated with it are once again making their way into modern trends. You don't have to be afraid of garish colors, which are making a comeback in architecture as well

54/56 THE INTERIOR OF YOUR BUSINESS SAYS IT ALL

The interior of a restaurant is quite often one of the most important criteria for success. Only thanks to it can a business be novel and easily recognizable from the competition. Through the interior, we can imprint a concept on our business that we further develop through our products and services and that has an absolutely crucial influence on how our brand is perceived by our customers. In the following article, we'll take a slightly closer look at this topic through the eyes of an architect who already has extensive experience in interior design for the catering industry.

as in fashion. Upcycling is also a big concept in modern interiors. The use of various discarded materials, for example to produce lights and interior accessories, is experiencing a really big boom. The demand for sustainable materials and the current attitude towards waste are to some extent responsible for this.

What about the choice of furniture?

Of course, budget is always a factor when choosing furniture and accessories, but even with a smaller budget you can furnish your space in a stylish yet novel way. You don't even have to worry about big retail chains like IKEA. Here, too, you‚ll sometimes find a range of design pieces that beautifully enhance the overall impression of your interior. Of course, if your budget allows, investing in brands that aren't as commercially known and tend to gravitate towards more thoughtful design is a much better choice. Today, interiors in which every piece of furniture is completely different are definitely drawing attention to themselves. This option is one of the cheaper ones, but at the same time it is a very interesting way of choosing equipment. However, it's not easy to create a coherent style and you have to prepare for a really complicated search for all the pieces to match each other. Of course, the best option is furniture that is made to measure. With these pieces, you can work on a whole other level in terms of branding. You are thus able to imprint your identity directly on chairs, tables and counters, i.e., on the equipment of the business with which your customers come into contact most often. You can thus match the furniture to the overall concept of your café or bakery.

Light that you will love to come back to.