M325D MH EXCAVATOR

Shutdown SIS

Previous Screen

Product: EXCAVATOR

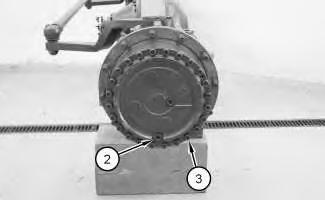

Model: M325D MH EXCAVATOR EDF

Configuration: M325D Material Handler EDF00001-01999 (MACHINE) POWERED BY C-7 Engine

Disassembly and Assembly

M325D Material Handler Power Train

Axle Shaft - Remove - Steering Axle

SMCS - 3259-011; 3278-011; 3282-011-JF

Removal Procedure Table 1

Required Tools

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and mandates.

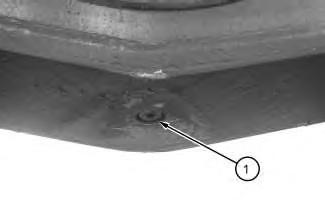

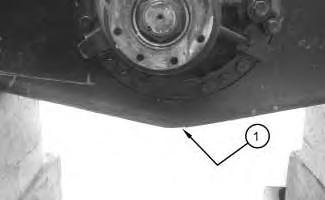

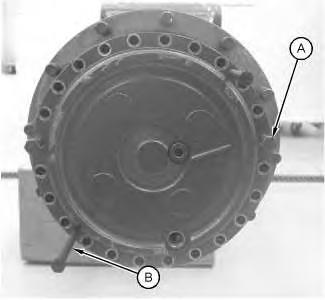

1. Remove plug (1). Drain the oil into a suitable container for storage or for disposal.

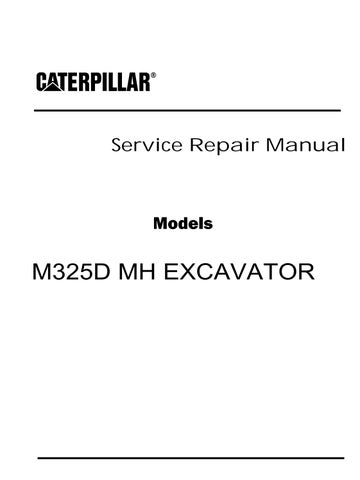

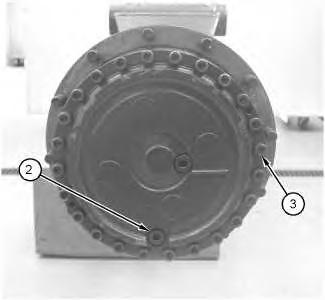

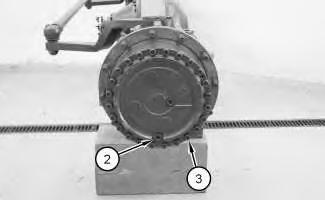

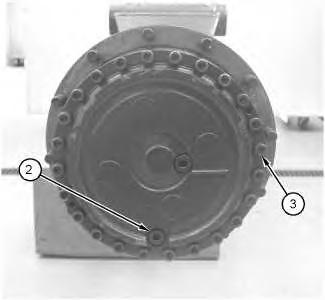

2. Remove plug (2). Drain the oil into a suitable container for storage or for disposal. Remove bolts (3) .

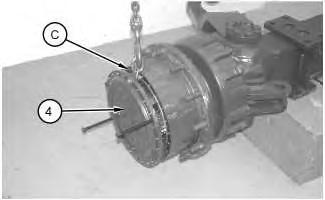

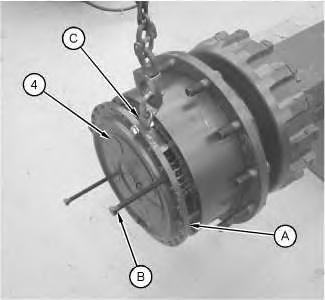

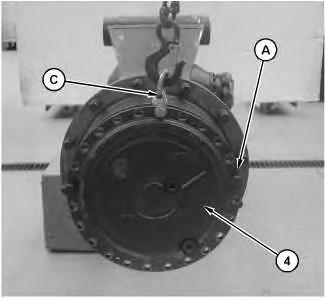

3. Install Tooling (A) and Tooling (B) .

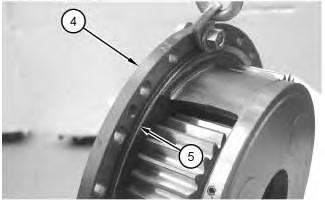

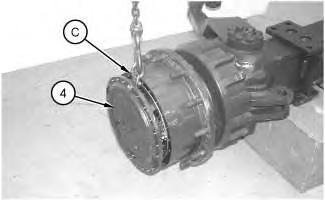

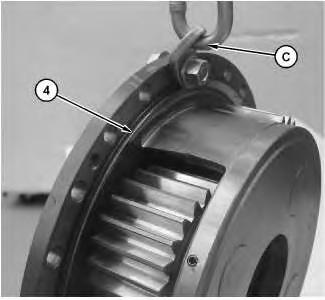

4. Slide final drive (4) outward. Attach Tooling (C) and a suitable lifting device onto final drive (4). The weight of final drive (4) is approximately 52 kg (115 lb). Remove Tooling (A) and Tooling (B) .

Illustration 3

g01136685

Illustration 4

g01136686

Illustration 3

g01136685

Illustration 4

g01136686

Illustration 5

g01136687

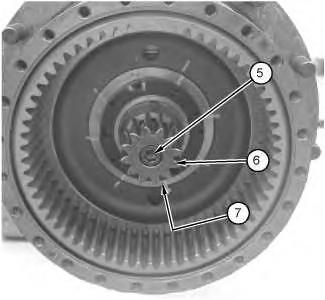

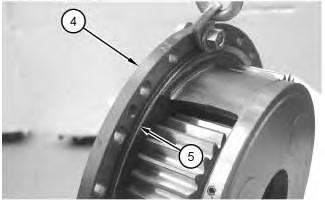

5. Remove final drive (4). Remove O-ring seal (5) .

Illustration 6

g01136688

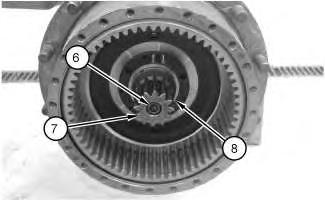

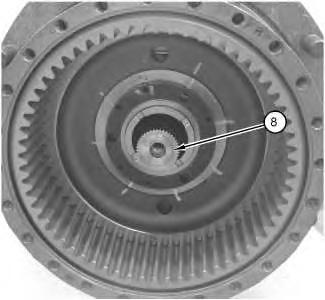

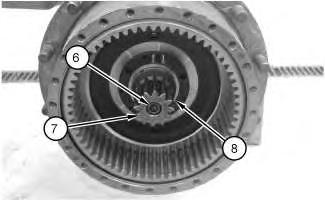

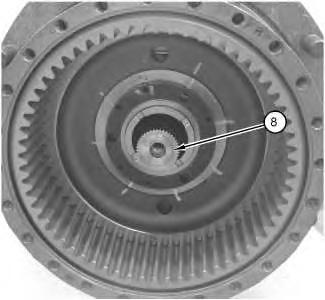

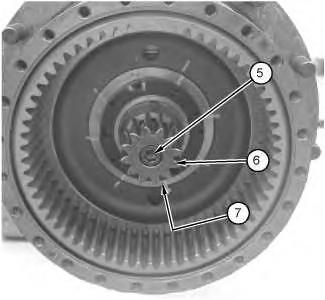

6. Remove bolt (6), sun gear (7), and sleeve (8) .

Illustration 7

g01136690

Illustration 5

g01136687

5. Remove final drive (4). Remove O-ring seal (5) .

Illustration 6

g01136688

6. Remove bolt (6), sun gear (7), and sleeve (8) .

Illustration 7

g01136690

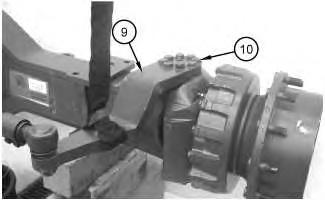

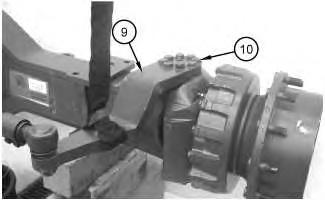

7. Attach a suitable lifting device onto lever (9). Remove bolts (10) and position lever (9) out of the way.

Illustration 8 g01136692

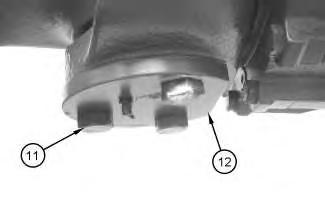

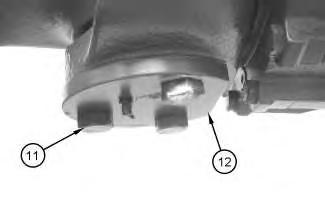

8. Remove bolts (11). Remove cover (12) .

Illustration 9 g01136693

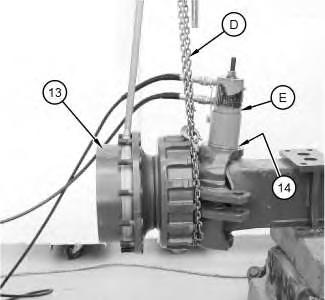

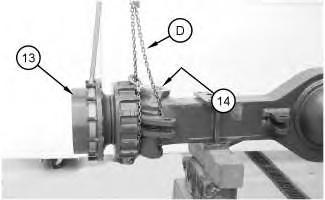

9. Attach Tooling (D) and a suitable lifting device onto hub assembly (13). The weight of hub assembly (13) is approximately 246 kg (542 lb). Attach Tooling (E) in order to remove pin (14). Do not exceed 44126 kPa (6400 psi). Remove pin (14). Repeat for the other side.

Illustration 10 g01136716

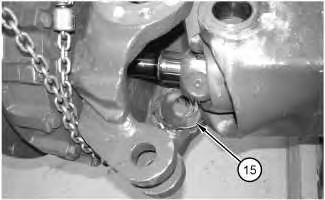

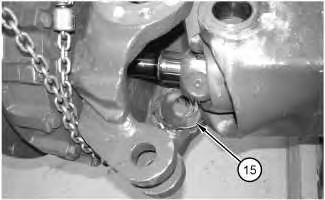

10. Note the location of shim (15) .

Illustration 11 g01136720

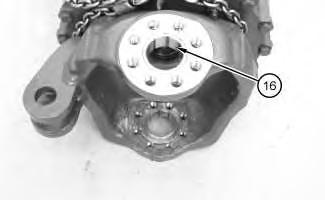

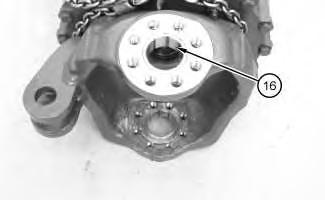

11. Remove bushing (16) .

Illustration 12 g01136735

Illustration 10 g01136716

10. Note the location of shim (15) .

Illustration 11 g01136720

11. Remove bushing (16) .

Illustration 12 g01136735

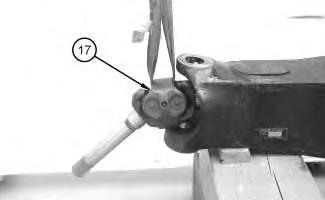

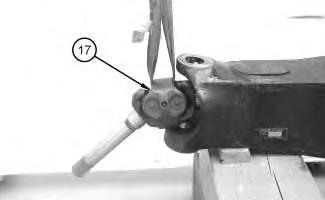

12. Attach a suitable lifting device onto axle shaft (17). The weight of axle shaft (17) is approximately 34 kg (75 lb). Remove axle shaft (17) .

Illustration 13 g01136723

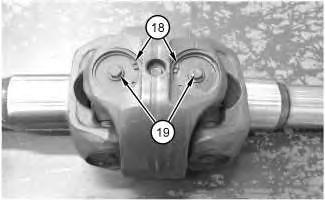

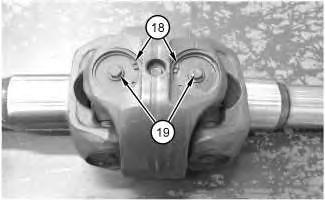

13. Use Tooling (F) in order to remove retaining rings (18). Remove plugs (19) .

Illustration 14 g01136749

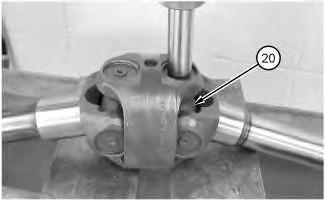

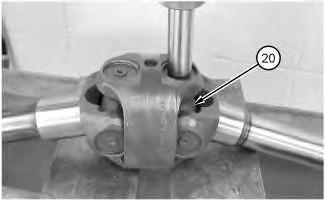

14. Use a suitable press and remove U-joints (20) .

15. Use Tooling (G) and Tooling (H) in order to remove seal (21) and bushing (22). Repeat for the seal and the bushing in hub assembly (13). Hub assembly (13) is not shown.

Copyright 1993 - 2020 Caterpillar Inc. All Rights Reserved. Private

Previous Screen

Product: EXCAVATOR

Model: M325D MH EXCAVATOR EDF

Configuration: M325D Material Handler EDF00001-01999 (MACHINE) POWERED BY C-7 Engine

Disassembly and Assembly

M325D Material Handler Power Train

Axle Shaft - Remove - Fixed Axle

SMCS - 3259-011; 3278-011; 3282-011-JF

Removal Procedure Table 1

Required Tools

Start By:

A. Remove the tire and rim. Refer to Disassembly and Assembly, "Tire and Rim - Remove".

NOTICE

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and mandates.

1. Remove plug (1) and drain the oil into a suitable container for storage or disposal.

Illustration 1

g01133286

Illustration 2

g01133289

Illustration 1

g01133286

Illustration 2

g01133289

Illustration 3

g01057338

2. Remove plug (2) and drain the oil into a suitable container for storage or disposal. Remove bolts (3) .

Illustration 4

3. Install Tooling (A) and Tooling (B) .

g01057339

Illustration 5 g01057340

4. Slide final drive (4) slightly outward. Attach Tooling (C) and a suitable lifting device onto final drive (4). The weight of final drive (4) is approximately 52 kg (115 lb). Remove Tooling (A) and Tooling (B). Remove final drive (4) .

Illustration 6 g01057341

5. Remove bolt (5). Remove sun gear (6) and sleeve (7) .

Illustration 7

6. Remove axle shaft (8) .

g01057342

7. Repeat this procedure for the opposite side.

Copyright 1993 - 2020 Caterpillar Inc.

All Rights Reserved. Private Network For SIS Licensees.

Shutdown SIS

Previous Screen

Product: EXCAVATOR

Model: M325D MH EXCAVATOR EDF

Configuration: M325D Material Handler EDF00001-01999 (MACHINE) POWERED BY C-7 Engine

Disassembly and Assembly

M325D Material Handler Power Train

Axle Shaft - Install - Steering Axle

SMCS - 3259-012; 3278-012; 3282-012-JF

Installation Procedure Table 1

Required Tools

1. Lower the temperature of bushing (22) . Use Tooling (J) in order to install bushing (22) . Use Tooling (J) in order to install seal (21) . Repeat for the seal and the bushing in hub assembly (13) . Hub assembly (13) is not shown.

2. Use a suitable press and install U-joints (20) .

3. Install plugs (19) . Use Tooling (F) in order to install retaining rings (18) .

Illustration 1 g01136750

Illustration 2 g01136749

Illustration 3 g01136723

Illustration 1 g01136750

Illustration 2 g01136749

Illustration 3 g01136723

4. Attach a suitable lifting device onto axle shaft (17) . The weight of axle shaft (17) is approximately 34 kg (75 lb). Install axle shaft (17) .

5. Lower the temperature of bushing (16) . Use Tooling (J) and install bushing (16) .

Illustration 4 g01136735

Illustration 5

g01136720

Illustration 6

g01136716

Illustration 4 g01136735

Illustration 5

g01136720

Illustration 6

g01136716

6. Position shim (15) .

7. Attach Tooling (D) and a suitable lifting device onto hub assembly (13) . The weight of hub assembly (13) is approximately 246 kg (542 lb). Install hub assembly (13) . Lower the temperature of pins (14) . Install pins (14) .

8. Apply Tooling (K) to the contact surface of cover (12) . Install cover (12) . Apply Tooling (L) to the threads of bolts (11) . Install bolts (11) . Tighten bolts (11) to a torque of 310 N·m (229 lb ft).

Illustration 7

g01136846

Illustration 8

g01136692

Illustration 7

g01136846

Illustration 8

g01136692

9. Attach a suitable lifting device onto lever (9) . Position lever (9) and install bolts (10) .

10. Install sleeve (8) and sun gear (7) . Apply Tooling (L) to the threads of bolt (6) . Install bolt (6) . Tighten bolt (6) to a torque of 310 N·m (229 lb ft).

Illustration 9

g01136690

Illustration 10

g01136688

Illustration 11

g01136687

Illustration 9

g01136690

Illustration 10

g01136688

Illustration 11

g01136687

Note: Check the O-ring seal for wear or for damage. If necessary, replace the O-ring seal.

11. Install O-ring seal (5) onto final drive (4) . Attach Tooling (C) and a suitable lifting device onto final drive (4) . The weight of final drive (4) is approximately 52 kg (115 lb).

Illustration 12 g01136863

12. Install final drive (4) .

Illustration 13 g01136680

13. Apply Tooling (L) to the threads of bolts (3) . Install bolts (3) . Tighten bolts (3) to a torque of 72 N·m (53 lb ft). Install plug (2) .

g01136679

14. Install plug (1) .

15. Fill the axle and the final drive with oil. Refer to Operation and Maintenance Manual, "Axle Oil - Change"and Operation and Maintenance Manual, "Final Drive Oil - Change". Refer to Operation and Maintenance Manual, "Capacities (Refill)".

Copyright 1993 - 2020 Caterpillar Inc.

All Rights Reserved. Private Network For SIS Licensees.

Thu Nov 26 13:44:53 UTC+0800 2020

Shutdown SIS

Previous Screen

Product: EXCAVATOR

Model: M325D MH EXCAVATOR EDF

Configuration: M325D Material Handler EDF00001-01999 (MACHINE) POWERED BY C-7 Engine

Disassembly and Assembly

M325D Material Handler Power Train

Axle Shaft - Install - Fixed Axle

SMCS - 3259-012; 3278-012; 3282-012-JF

Installation Procedure Table 1

Required Tools

1. Install axle shaft (8) .

2. Install sleeve (7) and sun gear (6). Apply Tooling (D) to the threads of bolt (5). Install bolt (5) and tighten bolt (5) to a torque of 310 N·m (229 ft).

Illustration 1 g01057342

Illustration 2 g01057341

Illustration 3 g01057508

Illustration 1 g01057342

Illustration 2 g01057341

Illustration 3 g01057508

Suggest:

If the above button click is invalid.

Please download this document first, and then click the above link to download the complete manual.

Thank you so much for reading

3. Attach Tooling (C) and a suitable lifting device onto final drive (4). The weight of final drive (4) is approximately 52 kg (115 lb).

Illustration 4

g01057509

4. Position final drive (4) on the axle. Install Tooling (A). Remove Tooling (C). Slide final drive (4) in all the way. Remove Tooling (A) .

Illustration 5

g01057338

5. Apply Tooling (D) to the threads of bolts (3). Install bolts (3). Tighten bolts (3) to a torque of 200 N·m (148 lb ft). Install plug (2) .