MAXXUM100,MAXXUM110Multicontroller,MAXXUM110,MAXXUM115 Multicontroller,MAXXUM115,MAXXUM120Multicontroller,MAXXUM120, MAXXUM125Multicontroller,MAXXUM125,MAXXUM130Multicontroller, MAXXUM130,MAXXUM140Multicontroller,MAXXUM140

SERVICEMANUAL

Contents INTRODUCTION HYDRAULIC,PNEUMATIC,ELECTRICAL,ELECTRONICSYSTEMSA PRIMARYHYDRAULICPOWERSYSTEM..............................................A.10.A PRIMARYHYDRAULICPOWERSYSTEMClosedcentermechanicalremotevalve...A.10.B PRIMARYHYDRAULICPOWERSYSTEMOpencentermechanicalremotevalve.....A.10.D HYDRAULICCOMMANDSYSTEM......................................................A.14.A ELECTRICALPOWERSYSTEM........................................................A.30.A ELECTRICALPOWERSYSTEM........................................................A.30.A ELECTRONICSYSTEM.................................................................A.50.A FAULTCODES...........................................................................A.50.A ENGINEANDPTOIN...................................................................B ENGINE..................................................................................B.10.A TRANSMISSION,DRIVEANDPTOOUT........................................C POWERCOUPLINGClutch..............................................................C.10.C TRANSMISSIONMechanical............................................................C.20.B TRANSMISSIONPowerShuttle..........................................................C.20.C ADDITIONALREDUCERSCreeper......................................................C.30.C ADDITIONALREDUCERSOverdrive....................................................C.30.D REARPTOHydraulic.....................................................................C.40.C FRONTPTOHydraulic...................................................................C.42.C

REARAXLE..............................................................................D.12.A

STEERINGHydraulic.....................................................................D.20.C

FRAMEANDCAB........................................................................E

ENVIRONMENTCONTROLHeating,ventilationandair-conditioning...................E.40.D

HITCHFronthitch........................................................................H.10.B

HITCHRearhitch.........................................................................H.10.C

HITCHElectronicdraftcontrol............................................................H.10.D

INTRODUCTION 1

Contents INTRODUCTION Foreword........................................................................................3 Safetyrules.....................................................................................9 Torque........................................................................................21 ConsumablesLubricationsandCoolants.....................................................25 Capacities.....................................................................................27 2

Foreword[5195725]

TechnicalInformation

• ofthosecategoriestofindtherightpieceoftechnicalinformationyouneedtoresolvethatcustomersconcernonhis

Thatinformationcouldbe:

• thedescriptionofhowtoremovethecylinderhead

• atableofspecificationsforahydraulicpump

• afaultcode

• atroubleshootingtable

• aspecialtool

INTRODUCTION

Technicalinformationiswrittentosupportthemaintenanceandserviceofthefunctionsorsystemsonacustomers thenewICEcoding,accordingtothefunctionsorsystemsonthatmachine.Onceyouhavelocatedthetechnical havebeenwrittenforthatfunctionorsystem,thetechnicaldata(specifications),thefunctionaldata(howitworks), ByintegratingthisnewICEcodingintotechnicalinformation,youwillbeabletosearchandretrievejusttheright • LOCATION-isthecomponentorfunctiononthemachine,thatthepieceoftechnicalinformationisgoingto

functiononthemachinee.g.CapacitywouldbeatypeofTechnicalDatathatwoulddescribetheamountoffuel

•

3

INTRODUCTION HowtoUsethisManual ThismanualisdividedintoSections.EachSectionisthendividedintoChapters.Contentspagesareincludedatthe EachChapterisdividedintofourInformationtypes: • • • DiagnosticData(faultcodes,electricalandhydraulictroubleshooting)forallthemechanical,electricalorhy• Sections machinethatthemanualiswrittenfor.EachSectionhasaContentspagelistedinalphabetic/numericorder.This SECTION J-ToolsandCouplers PRODUCT Tractors XXXXXXXX Vehicleswithworkingarms:backhoes, XXXXXXXXX XXXXXXXXXX equipment,.... XXXXXXXXX Mountedequipmentandtools,..... XXXX 4

ThisSectioncoversthemainsystemsthatinteractwithmostofthefunctionsoftheproduct.Itincludesthecentral arededicatedtoaspecificfunctionarelistedintheChapterwhereallthetechnicalinformationforthatfunctionis

ThisSectioncoversallthefunctionsrelatedtotheproductionofpowertomovethemachineandtodrivevarious

SECTIONC,POWERTRAIN

ThisSectioncoversallthefunctionsrelatedtothetransmissionofpowerfromtheenginetotheaxlesandtointernal theframe,theshields,theoperator'scabandtheplatform.

SECTIONG,TOOLPOSITIONING

INTRODUCTION Contents INTRODUCTION DISTRIBUTIONSYSTEMS A POWERPRODUCTION B POWERTRAIN C TRAVELLING D BODYANDSTRUCTURE E TOOLPOSITIONING G CROPPROCESSING K

SectionContents

5

Chapters

CONTENTS thatfunctionorsystemonthemachine.

Contents

TECHNICALDATA

CS6050 FUNCTIONALDATA

CS6050 SERVICE

CS6050 DIAGNOSTIC

CS6050

INDEX

Index

CS6050

CS6050

CS6050

CS6050

POWERPRODUCTION

EachChapterisidentifiedbyaletterandnumbercombinatione.g.EngineB.10.AThefirstletterisidenticaltothe

ENGINE-Troubleshooting(B.10.A-G.40.A.10)

ENGINE ENGINE-Dynamicdescription(B.10.A-C.30.A.10)

ENGINE-Generalspecification(B.10.A-D.40.A.10)

TheChapterIndexlistsinalphabeticalorderallthetypesofinformation(calledInformationUnits)thathavebeen

INTRODUCTION

6

•

•

•

•

•

•

Thepageheaderwillcontainthefollowingreferences:

• SectionandChapterdescription

Thepagefooterwillcontainthefollowingreferences:

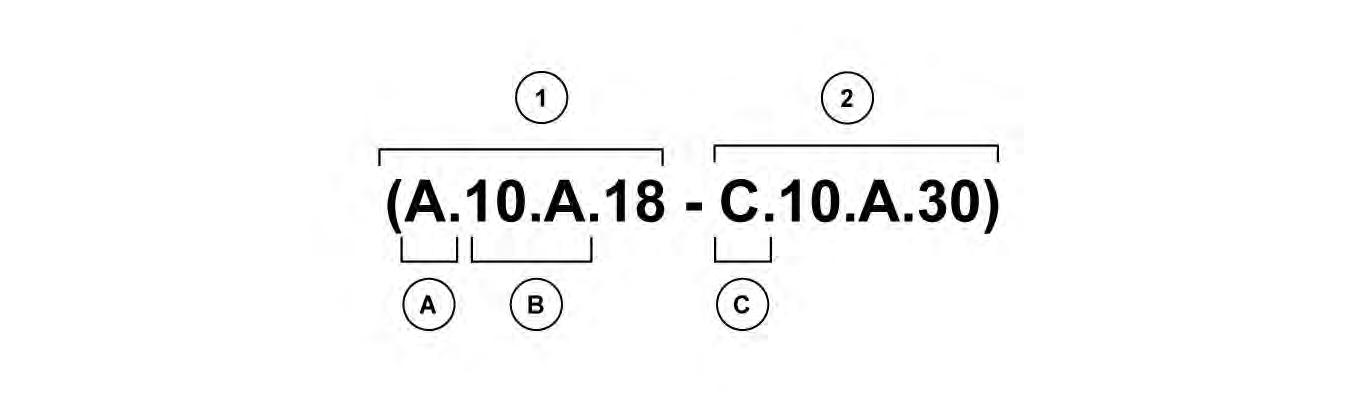

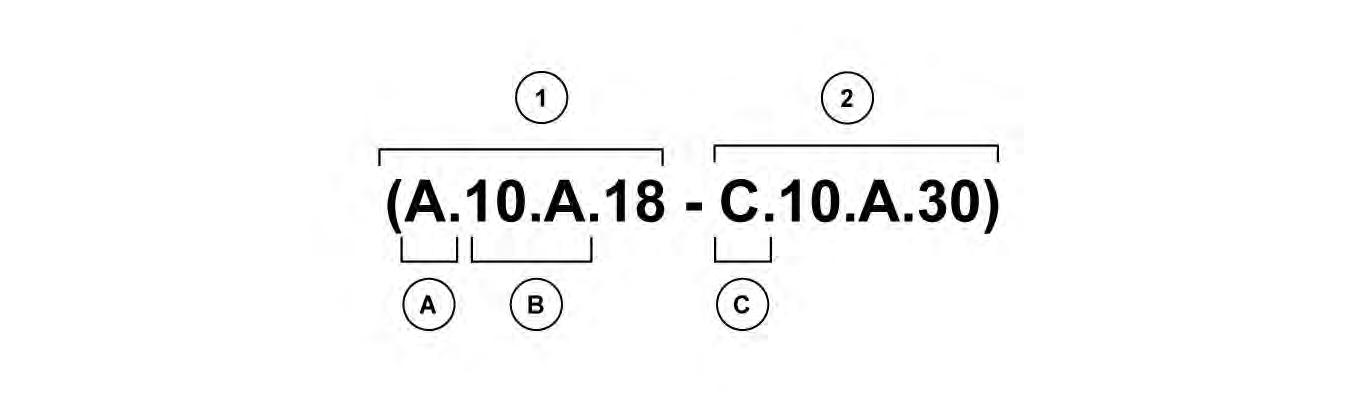

INTRODUCTION InformationUnitsandInformationSearch Eachchapteriscomposedofinformationunits.EachinformationunithastheICEcodeshowninparentheseswhich exampleinformationunit InformationUnitICEcode A C ICEcodeclassification Distribution systems Primary hydraulic power Stackvalve Functional data Sectionalview CRIL03J033E01 1

fromtheICEcode.

Navigatetothecorrectinformationunityouaresearchingforbyidentifyingthefunctionandinformationtype

(1) Functionand (2)

(A)

(B) (C) correspondstothetypeofinformationlistedinthechaptercontents,Technicaldata,FunctionalData,DiagnosticorService. (A) and (B)

•

(A) , (B) and (C)

correspondstothesectionsoftherepairmanual.

•

Byreferringto

PageHeaderandFooter

Publicationdate

7

Importantinformation

AllrepairandmaintenanceworkslistedinthismanualmustbecarriedoutonlybystaffbelongingtotheCaseIH

Anyonewhocarriesouttheaboveoperationswithoutcomplyingwiththeprescriptionsshallberesponsibleforthe

Themanufacturerandalltheorganizationsofitsdistributionchain,including-withoutlimitation-national,regionalor localdealers,rejectanyresponsibilityfordamagesduetotheanomalousbehaviourofpartsand/orcomponentsnot marketedbytheManufacturerincaseofdamagesduetoananomalousbehaviourofpartsand/orcomponentsnot

INTRODUCTION

8

•

Safetyrules[3964943]

IMPORTANTNOTICE

Anyonewhocarriesoutserviceoperationsdescribedwithoutcarefullyobservingtheseinstructionswillbedirectly

NOTESFOREQUIPMENT

Equipmentshowninthismanualis:

• designedexpresslyforuseonthesetractors;

• necessarytomakeareliablerepair;

NOTICES

Thewords“front”,“rear”,“righthand”,and“lefthand”refertothedifferentpartsasseenfromtheoperator’sseat

SAFETYRULES

PAYATTENTIONTOTHISSYMBOL

Thiswarningsymbolpointsoutimportantmessagesinvolvingpersonal

Inthismanualyouwillfindthissymboltogetherwiththefollowing consequencesaffectingtheservicetechnician’spersonalsafety. safetyoftheoperatororotherpersonsdirectlyorindirectlyinvolvedin theoperation.

TOPREVENTACCIDENTS

Awiseandcarefulservicetechnicianisthebestprecautionsagainstaccidents.

DANGER

SAFETYRULES

Generalities •

INTRODUCTION

B013

Nevercarryoutanycleaning,lubricationormaintenanceoperationswhentheengineisrunning.

9

INTRODUCTION • • • • Wearsuitableprotectionsuchasapprovedeyeprotection,helmets,specialclothing,glovesandfootwearwheneverwelding.Allpersonsstandinginthevicinityoftheweldingprocessshouldwearapprovedeyeprotection. • Nevercarryoutanyrepaironthemachineifsomeoneissittingontheoperator’sseat,exceptiftheyarequalified • • Stoptheengineandensurethatallpressureisrelievedfromhydrauliccircuitsbeforeremovingcaps,covers, • • • • Thefuelfillinggunshouldalwaysremainincontactwiththefillerneck.Maintainthiscontactuntilthefuelstops • • • • • TheworkingareashouldbealwayskeptCLEANandDRY.Immediatelycleananyspillageofwateroroil. • • STARTUP

Neverruntheengineinconfinedspaceswhicharenotequippedwithadequateventilationforexhaustgas extraction.

ENGINE

Coolantshouldbetoppeduponlywhentheengineisstopped. •

Neveradjustthefuelinjectionpumpwhenthetractorismoving.

ELECTRICALSYSTEMS

(-)to(-).Avoidshort-circuitingtheterminals.GASRELEASEDFROMBATTERIESISHIGHLYFLAMMABLE.

•

•

•

•

•

•

INTRODUCTION • • HYDRAULICSYSTEMS • medicalattentionmayresultinseriousinfectionsordermatitis. • WHEELSANDTYRES • • • • • Toremovethewheels,blockbothfrontandreartractorwheels.Raisethetractorandinstallsafeandstable • Deflatethetyrebeforeremovinganyobjectcaughtintothetyretread. • REMOVALANDINSTALLATION • HEALTHANDSAFETY CONTENT Section Description Page 4 5 5 5 5 5 BRAKEANDCLUTCHFLUIDS(PolyalkyleneGlycols)-seeFire............. 6 6 6 DO’S........................................................... 6 6 6 7 ELECTRICSHOCK................................................ 7 7 7 7 7 FOAMS-Polyurethane-seeFire........................................ 7 11

INTRODUCTION 8 8 9 9 9 PAINTS-seeSolventsandChemicalMaterials-General...................... SUSPENDEDLOADS.............................................. 11 11 HEALTHANDSAFETYPRECAUTIONS Manyoftheproceduresassociatedwithvehiclemaintenanceandrepairinvolvephysicalhazardsorotherrisksto health.Thissectionlists,alphabetically,someofthesehazardousoperationsandthematerialsandequipmentassohealthandsafetyinmind. ACIDSANDALKALIS seeBatteryacids,e.g.causticsoda,sulphuricacid. Irritantandcorrosivetotheskin,eyes,noseandthroat.Causesburns. ADHESIVESANDSEALERS seeFire Generallyshouldbestoredin“NoSmoking”areas;cleanlinessandtidinessinuseshouldbeobserved,e.g.disposSolventbasedAdhesives/Sealers WaterbasedAdhesives/Sealers Followmanufacturersinstructions. ResinbasedAdhesives/Sealers e.g.epoxideandformaldehyderesinbased. Skincontactwithuncuredresinsandhardenerscanresultinirritation;dermatitisandabsorptionoftoxicorharmful Anaerobic,CyanoacrylateandotherAcrylicAdhesives

Cyanoacrylateadhesives(super-glues)mustnotcontacttheskinoreyes.Ifskinoreyetissueisbondedcoverwitha

Isocyanate(Polyurethane)Adhesives/Sealers seeResinbasedAdhesives.

Individualssufferingfromasthmaorrespiratoryallergiesshouldnotworkwithornearthesematerialsassensitivity

Anysprayingshouldpreferablybecarriedoutinexhaustventilatedboothsremovingvapoursandspraydropletsfrom

ANTIFREEZE

HighlyFlammable,Flammable,Combustible.

ARCWELDING

BATTERYACIDS

Gasesreleasedduringchargingareexplosive.

BRAKEANDCLUTCHFLUIDS(PolyalkyleneGlycols)

Inhalationofvapourhazardsdonotariseatambienttemperaturesbecauseoftheverylowvapourpressure.

BRAZING

seeWelding.

CHEMICALMATERIALS-GENERAL

seeLegalAspects.

Theeffectsofexcessiveexposuretochemicalsmaybeimmediateordelayed;brieflyexperiencedorpermanent;

DO’S

Doremovechemicalmaterialsfromtheskinandclothingassoonaspracticableaftersoiling.Changeheavilysoiled

Docarefullyreadandobservehazardandprecautionwarningsgivenonmaterialcontainers(labels)andinany accompanyingleaflets,posterorotherinstructions.Materialhealthandsafetydatasheetscanbeobtainedfrom

INTRODUCTION

DONOTS

INTRODUCTION Doorganiseworkpracticesandprotectiveclothingtoavoidsoilingoftheskinandeyes;breathingvapours/aerosols/ Dostoreaccordingtonationalandlocalregulations.

DoNotmixchemicalmaterialsexceptunderthemanufacturersinstructions;somechemicalscanformothertoxicor DoNotapplyheatorflametochemicalmaterialsexceptunderthemanufacturers’instructions.Somearehighly DoNotsnifforsmellchemicalmaterials.Briefexposuretohighconcentrationsoffumescanbetoxicorharmful. ClutchFluids seeBrakeandClutchFluids. ClutchLiningsandPads seeBrakeandClutchLiningsandPads. CORROSIONPROTECTIONMATERIALS Cutting De-Waxing DUSTS ELECTRICSHOCK Electricshockscanresultfromtheuseoffaultyelectricalequipmentorfromthemisuseofequipmenteveningood Ensurethatelectricalequipmentismaintainedingoodconditionandfrequentlytested. Nevermisuseelectricalequipmentandneveruseequipmentwhichisinanywayfaulty.Theresultscouldbefatal. Usereducedvoltageequipment( 110volt

• switchoffelectricitybeforeapproachingvictim

•

• commenceresuscitationiftrainedtodoso

• SUMMONMEDICALASSISTANCE

EXHAUSTFUMES

generalventilationandnotinconfinedspaces.

Gasolene(Petrol)Engine

DieselEngine

FIBREINSULATION

Theremaynotbeadequatewarningpropertiesofodourorirritationbeforeimmediateanddelayedtoxicorharmful

Precautionsshouldbetakentoavoidexcessiveskincontactthroughcarefulorganisationofworkpracticesandthe

FIRE

Observestrictfiresafetywhenstoringandhandlingflammablematerialsorsolvents,particularlynearelectricalequipmentorweldingprocesses.

FIRSTAID

Soiledskinshouldbewashedwithsoapandwater.

FOAMS-Polyurethane

INTRODUCTION

Followmanufacturersinstructions.

Vapoursandspraymistsmustnotbebreathed.Thesematerialsmustbeappliedwithadequateventilationandrespiratoryprotection.Donotremoverespiratorimmediatelyafterspraying,waituntilvapour/mistshavecleared.

Anyheatcuttingofcuredfoamsorpartiallycuredfoamsshouldbeconductedwithextractionventilation(seeBody Section44LegalandSafetyAspects).

FUELS

Gasolene(Petrol).

Swallowingcanresultinmouthandthroatirritationandabsorptionfromthestomachcanresultindrowsinessand

Gasolenedriestheskinandcancauseirritationanddermatitisonprolongedorrepeatedcontact.Liquidintheeye ofgasolenevapoursmustbekeptverylow.Highconcentrationswillcauseeye,noseandthroatirritation,nausea, Specialprecautionsapplytocleaningandmaintenanceoperationsongasolenestoragetanks.

Kerosene(Paraffin) maybeslightlyirritating.

keroseneatelevatedtemperaturesshouldbeavoided(mistsmayariseinde-waxing).

Gas-Oil(DieselFuel)

GASCYLINDERS

Grossorprolongedskincontactwithhighboilinggasoilsmayalsocauseseriousskindisordersincludingskincancer.

seeFire.

upto 140bar ( 2000lb/in2 )andgreatcareshouldbetakeninhandlingthesecylinderstoavoidmechanicaldamageto gases(e.g.acetyleneandpropane)shouldnotbestoredincloseproximitytooxygencylinders.

INTRODUCTION

LEGALASPECTS

Manylawsandregulationsmakerequirementsrelatingtohealthandsafetyintheuseofmaterialsandequipmentin

INTRODUCTION

seeGasCylinders. GasShieldedWelding seeWelding. GasWelding seeWelding.

Itisessentialthatalltoolsandequipmentaremaintainedingoodconditionandthecorrectsafetyequipmentused Donotusedamagedordefectivetoolsorequipment,particularlyhighspeedequipmentsuchasgrindingwheels.A

HighPressureAir,LubricationandOilTestEquipmentaccordancewithlocalregulations Alwayskeephighpressureequipmentingoodconditionandregularlymaintained,particularlyatjointsandunions.

Gases

GENERALWORKSHOPTOOLSANDEQUIPMENT

Glues

torateorappropriateauthorityifinanydoubt.

Avoidallprolongedandrepeatedcontactwithmineraloils,especiallyusedoils.Usedoilscontaminatedduringservice Drycleanorlaundersuchclothingatregularintervals.Discardoilsoakedshoes.

LUBRICANTSANDGREASES

NoiseInsulationMaterials

INTRODUCTION

PAINTS

instructionsshouldbefollowedandthesectionofpage5onresinbasedadhesives,isocyanatecontainingAdhesives

Sprayingshouldpreferablybecarriedoutinexhaustedventilatedboothsremovingvapourandspraymistsfromthe breathingzone.Individualsworkinginboothsshouldwearrespiratoryprotection.Thosedoingsmallscalerepairwork

PaintThinners

Petrol

PressurisedEquipment

ResistanceWelding

Sealers

SOLDER used.Oxy-acetyleneflamesshouldnotbeused,astheyaremuchhotterandwillcauseleadfumestobeevolved.

Removalofexcesssoldershouldbeundertakenwithcare,toensurethatfineleaddustisnotproduced,whichcan

Highstandardsofpersonalhygienearenecessaryinordertoavoidindigestionofleadorinhalationofsolderdust

SOLVENTS

Skincontactwilldegreasetheskinandmayresultinirritationanddermatitisfollowingrepeatedorprolongedcontact. Repeatedorprolongedexposurestoexcessivebutlowerconcentrationsofvapoursormists,forwhichtheremight

respiratoryprotectionintheabsenceofadequategeneralventilation.

SoundInsulation

SpotWelding

SUSPENDEDLOADS

Neverimproviseliftingtackle.

Underseal seeCorrosionProtection.

WELDING

seeFire,ElectricShock,GasCylinders.

ResistanceWelding

ArcWelding

Thisprocessemitsahighlevelofultravioletradiationwhichmaycauseeyeandskinburnstothewelderandtoother

Metalspatterwillalsooccurandappropriateeyeandskinprotectionisnecessary.

Theheatoftheweldingarcwillproducefumesandgasesfromthemetalsbeingweldedandfromanyappliedcoatings

GasWelding

extremecaseswhereadequateventilationcannotbeprovided,suppliedairrespiratorsmaybenecessary.

Theprocessitselfproducesfewtoxicfumes,butsuchfumesandgasesmaybeproducedfromcoatingsonthework, rodscontainingcadmiumareused.Inthiseventparticularcaremustbetakentoavoidinhalationoffumesandexpert

INTRODUCTION

INTRODUCTION SPECIALPRECAUTIONSMUSTBETAKENBEFOREANYWELDINGORCUTTINGTAKESPLACEONVESSELS WhiteSpirit ECOLOGYANDTHEENVIRONMENT Thefollowingarerecommendationswhichmaybeofassistance: • • HELPFULHINTS 1.Avoidfillingtanksusingunsuitablecontainersorinappropriatepressurisedfueldeliverysystemswhichmay rechargethesystemanyway. 8.Donotincreasethepressureinapressurisedcircuitasthismayleadtothecomponentsexploding.

Torque[9696959]

Minimumhardwaretighteningtorquesfornormalassemblyapplicationsunlessotherwise stated

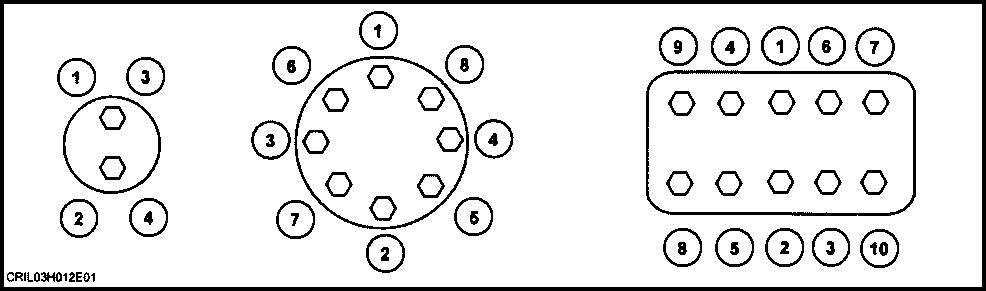

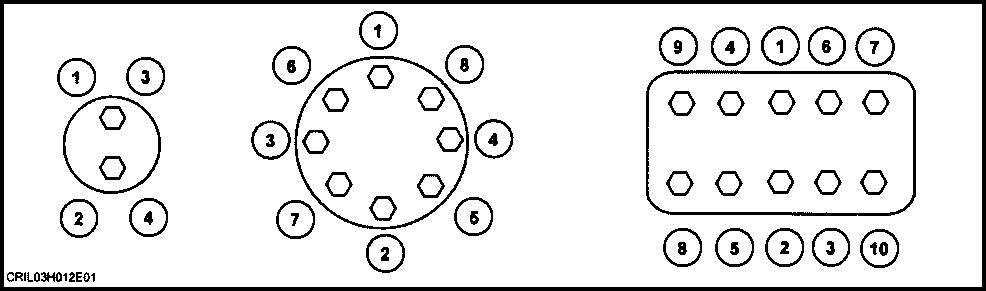

NOTICE: Shownbelowisthesuggestedinitialtorquetighteningsequencesforgeneralapplications,tighteninse-

INTRODUCTION

1 Imperialhardware Nominal Size SAE GRADE2 Unplated orSilver plated SAE GRADE 2plated w/ZnCr GOLD SAE GRADE5 Unplated orSilver plated SAE GRADE 5plated w/ZnCr GOLD SAE GRADE 8Unplated orSilver plated SAE GRADE 8plated w/ZnCr GOLD NUTS GR.B w/GR5 BOLT NUTS GR.B w/GR8 BOLT 1/4 6.2Nm 55lbin 8.1Nm 72lbin 9.7Nm 86lbin 13Nm 112lbin 14Nm 121lbin 18Nm 157lbin 6.9Nm 61lbin 9.8Nm 86lbin 5/16 13Nm 115lbin 17Nm 149lbin 20Nm 178lbin 26Nm 229lbin 28Nm 250lbin 37Nm 324lbin 14Nm 125lbin 20Nm 176lbin 3/8 23Nm 17lbft 30Nm 22lbft 35Nm 26lbft 46Nm 34lbft 50Nm 37lbft 65Nm 48lbft 26Nm 19lbft 35Nm 26lbft 7/16 37Nm 27lbft 47Nm 35lbft 57Nm 42lbft 73Nm 54lbft 80Nm 59lbft 104Nm 77lbft 41Nm 30lbft 57Nm 42lbft 1/2 27Nm 42lbft 73Nm 54lbft 87Nm 64lbft 113Nm 83lbft 123Nm 91lbft 159Nm 117lbft 61Nm 45lbft 88Nm 64lbft 9/16 81Nm 60lbft 104Nm 77lbft 125Nm 92lbft 163Nm 120lbft 176Nm 130lbft 229Nm 169lbft 88Nm 65lbft 125Nm 92lbft 5/8 112Nm 83lbft 145Nm 107lbft 174Nm 128lbft 224Nm 165lbft 244Nm 180lbft 316Nm 233lbft 122Nm 90lbft 172Nm 127lbft 3/4 198Nm 146lbft 256Nm 189lbft 306Nm 226lbft 397Nm 293lbft 432Nm 319lbft 560Nm 413lbft 217Nm 160lbft 305Nm 226lbft 7/8 193Nm 142lbft 248Nm 183lbft 495Nm 365lbft 641Nm 473lbft 698Nm 515lbft 904Nm 667lbft 350Nm 258lbft 494Nm 364lbft 289Nm 213lbft 373Nm 275lbft 742Nm 547lbft 960Nm 708lbft 1048Nm 773lbft 1356Nm 1000lbft 523Nm 386lbft 739Nm 545lbft

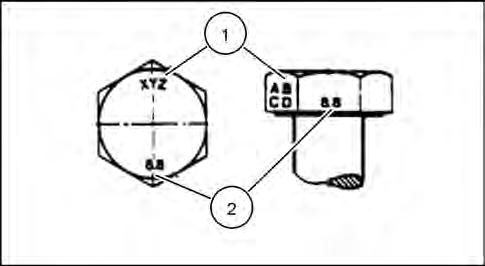

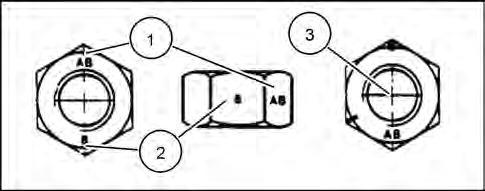

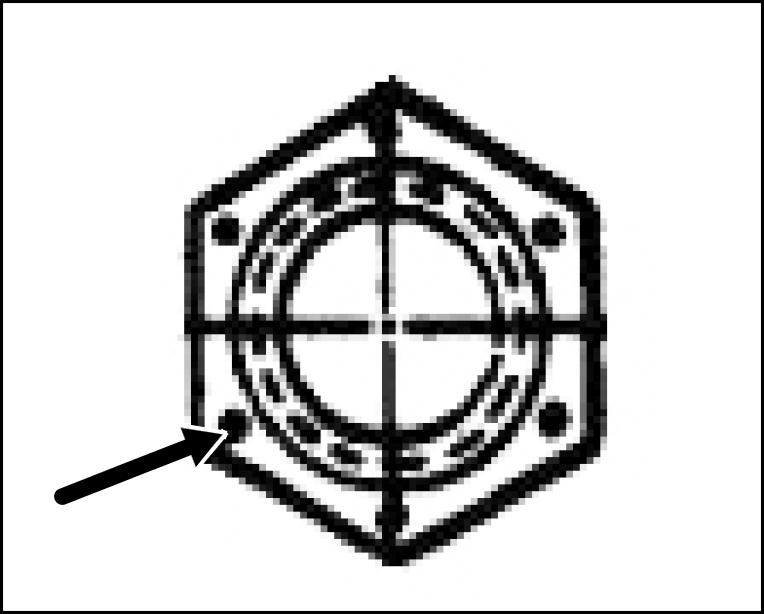

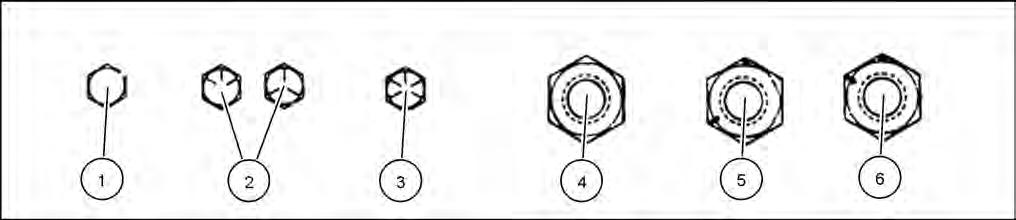

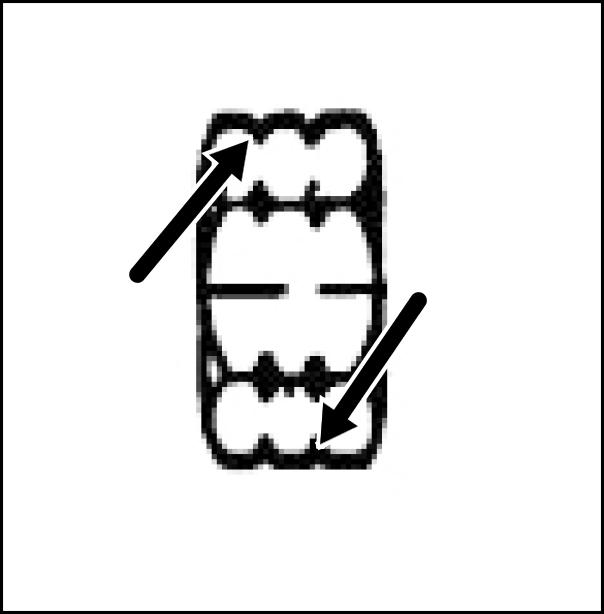

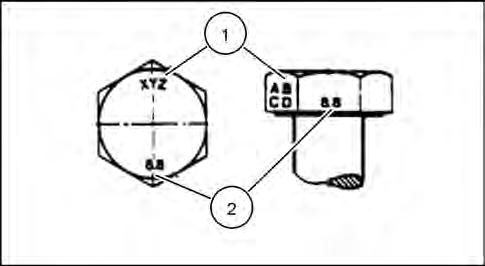

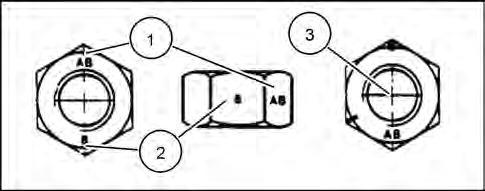

Metrichardware Nominal Size UNPLATED UNPLATED UNPLATED UNPLATED UNPLATED UNPLATED LOCKNUT CL.8 w/CL8.8 BOLT 1.7Nm 15lbin 2.2Nm 19lbin 2.6Nm 23lbin 3.4Nm 30lbin 3.7Nm 33lbin 4.8Nm 42lbin 1.8Nm 16lbin 5.8Nm 51lbin 7.6Nm 67lbin 8.9Nm 79lbin 12Nm 102lbin 13Nm 115lbin 17Nm 150lbin 6.3Nm 56lbin 14Nm 124lbin 18Nm 159lbin 22Nm 195lbin 28Nm 248lbin 31Nm 274lbin 40Nm 354lbin 15Nm 133lbin M10 28Nm 21lbft 36Nm 27lbft 43Nm 32lbft 56Nm 41lbft 61Nm 45lbft 79Nm 58lbft 30Nm 22lbft M12 49Nm 36lbft 63Nm 46lbft 75Nm 55lbft 97Nm 72lbft 107Nm 79lbft 138Nm 102lbft 53Nm 39lbft M16 121Nm 89lbft 158Nm 117lbft 186Nm 137lbft 240Nm 177lbft 266Nm 196lbft 344Nm 254lbft 131Nm 97lbft M20 237Nm 175lbft 307Nm 107lbft 375Nm 277lbft 485Nm 358lbft 519Nm 383lbft 671Nm 495lbft 265Nm 195lbft M24 411Nm 303lbft 531Nm 392lbft 648Nm 478lbft 839Nm 619lbft 897Nm 662lbft 1160Nm 855lbft 458Nm 338lbft 20083680 2 20083681 3 Identification-Hexagonalnutsandlocknutsclasses05onwards

INTRODUCTION

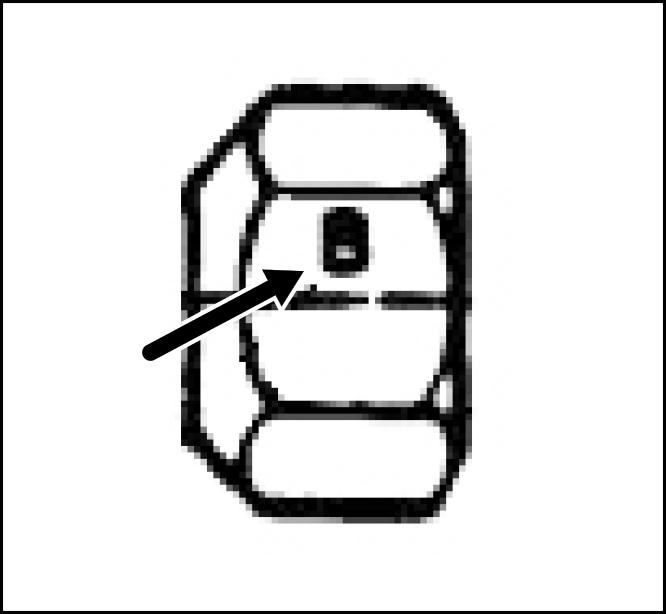

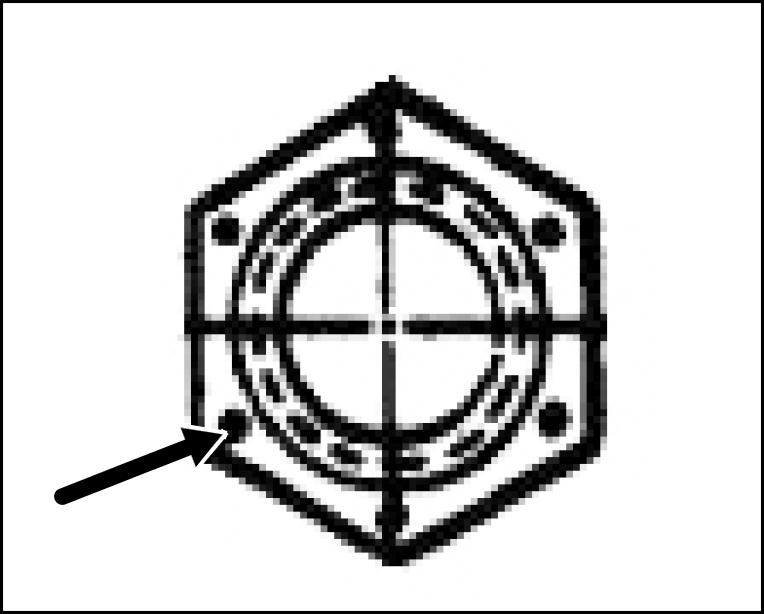

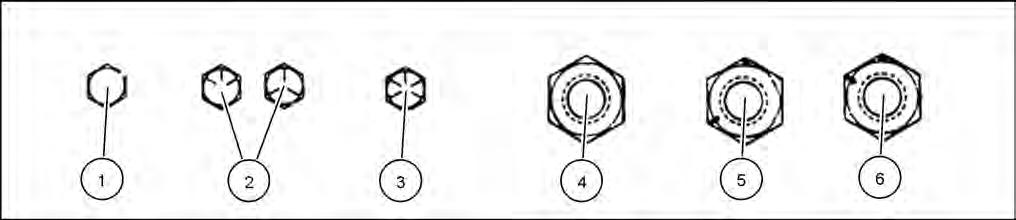

GradeA:nonotches

GradeC:twocircumferentialnotches 20083684 6

Locknuts-gradeidentification

GradeA:nomarks

GradeC:sixmarks

GradeB:onecircumferentialnotch

GradeB:threemarks

INTRODUCTION

20083682 4 20083683 5

INTRODUCTION 20083685 7 Locknuts-gradeidentification GradeA:nomarks GradeB:letterB GradeC:letterC

ConsumablesLubricationsandCoolants[11922313]

Lubrications

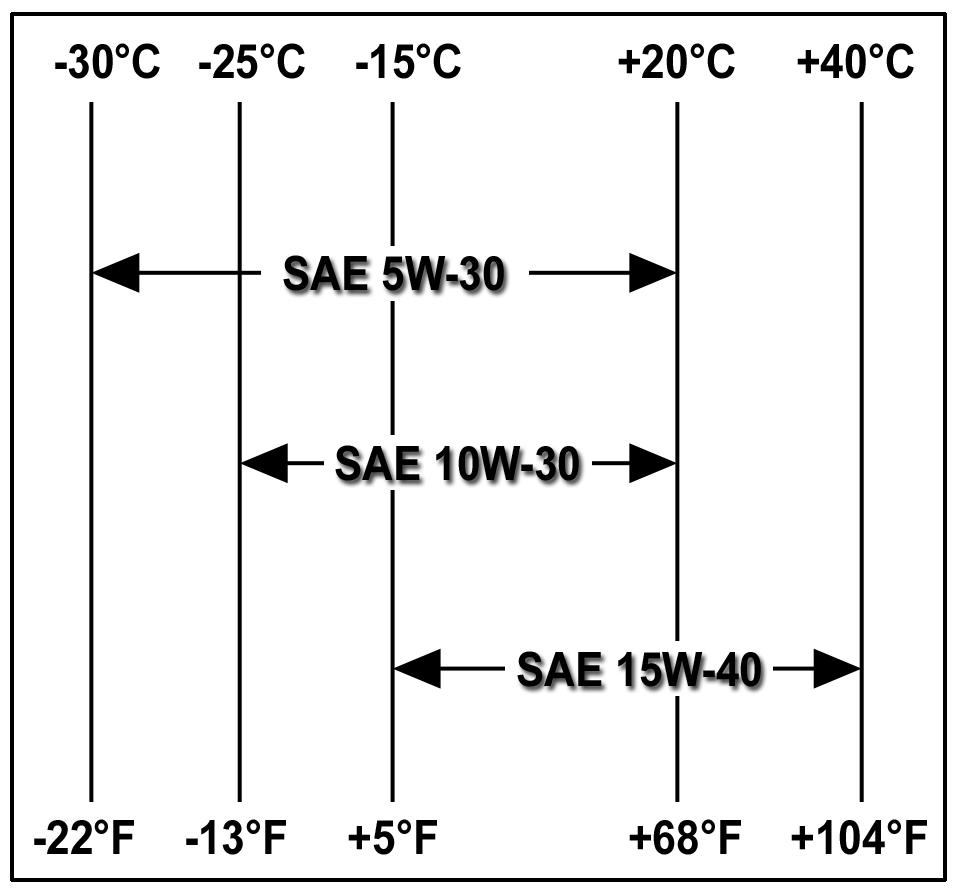

SS09J076 1

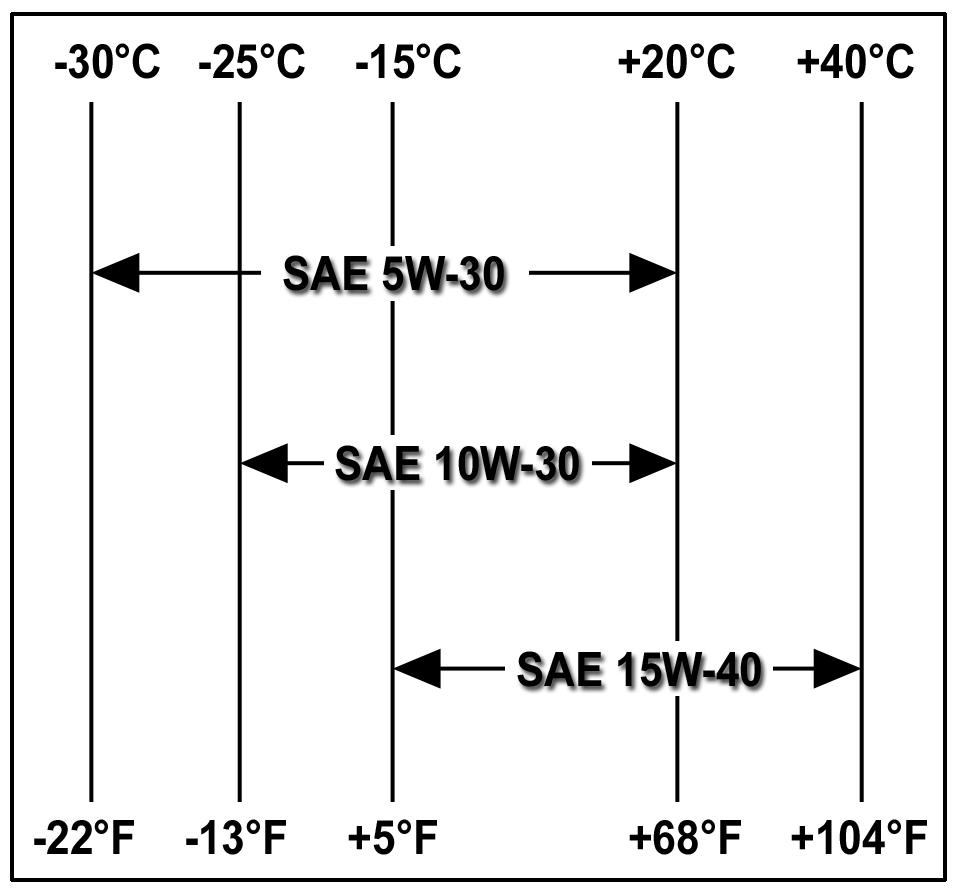

NOTE: acceptable;suchastheuseofSAE5W-30inextremelowtemperaturesorSAE50inextremehightemperatures.

2.Stoptheengineandimmediatelydraintheoil.

4.Addthebiodegradableoiltothecorrectlevelandrunthetractortocirculatetheoil.

SulphurinFuel shouldbeadjustedasfollows:

NOTE:

INTRODUCTION

60°C

BiodegradableTransmissionandHydraulicOil oilwithbiodegradablelubricant.

( 140°F

SulphurContent% OilChangePeriod

Below0.5 Normal From0.5-1.0 Halfthenormal

Above1.0 Onequarternormal

INTRODUCTION Coolants Toreducetheamountofdepositsandcorrosion,thewaterusedinthecoolingsystemmustcomplywiththefollowing TotalHardness Chloride Sulphate 300partspermillion 100partspermillion 100partspermillion UsingPlainwater CAUTION Inhibitorsolutionisirritatingtoeyesandskin.Itcontainsbufferedpotassiumhydroxide. B084 • Avoidcontactwitheyesorprolongedorrepeatedskincontact. • • • • LubricationsandCoolantSpecifications RECOMMENDEDFLUIDSANDAPPLICATIONS CIH SPECIFICATION INTERNATIONAL SPECIFICATION ENGINEOIL MS1121 APICI-4, ACEAE7 SYSTEMOIL AKCELANEXPLORE FRONTAXLE(AxleandHubs) AKCELANEXPLORE AKCELANEXPLORE MAT3525 M2C134D ENGINERADIATORCOOLANT AKCELAPREMIUMANTI-FREEZE (mixedwith50%ofwater) MS1710 EthyleneGlycol BRAKEOIL AKCELALHMFLUID n/a ISO7308 AIRCONDITIONINGCOMPRESSOROIL LowViscosityOilSP10 n/a PAG-E13,ISO100Viscosity GREASEFITTINGSANDBEARINGS AKCELAMULTI-PURPOSEGREASE251HEP 251HEP NLGI2,Li-Ca Capacities()

INTRODUCTION

Capacities[16227161]

MAXXUM/MAXXUMMulticontroller UNIT 100110120130115125140 FUELTANK 176l (46.5USgal) 250l (66USgal) COOLINGSYSTEM(withcab) *)onlyforNorthAmerica *23l(6.1USgal) COOLINGSYSTEM(lesscab) 21l n/a 21l gal) 23l gal) n/a ENGINE(includingfilter) TRANSMISSION/REARAXLE (with12x12,LightDutyaxle) 58l n/a 58l n/a 65l n/a 65l n/a n/a n/a n/a n/a n/a 62l DIFFERENTIAL 9l 4WDFRONTHUBS(Class3 4WDFRONTHUBS(Class3 3l (0.79USgal) 4WDFRONTHUBS(Class4 (0.95USgal) 4WDFRONTHUBS(Class4 4l

HYDRAULIC,PNEUMATIC,ELECTRICAL,ELECTRONICSYSTEMS

MAXXUM100,MAXXUM110Multicontroller,MAXXUM110,MAXXUM115

Multicontroller,MAXXUM115,MAXXUM120Multicontroller,MAXXUM120, MAXXUM125Multicontroller,MAXXUM125,MAXXUM130Multicontroller, MAXXUM130,MAXXUM140Multicontroller,MAXXUM140

SERVICEMANUAL

A

Contents HYDRAULIC,PNEUMATIC,ELECTRICAL, ELECTRONICSYSTEMS-A PRIMARYHYDRAULICPOWERSYSTEMElectro-hydraulicremotevalve...............A.10.C PRIMARYHYDRAULICPOWERSYSTEMOpencentermechanicalremotevalve.......A.10.D SECONDARYHYDRAULICPOWERSYSTEM............................................A.12.A HYDRAULICCOMMANDSYSTEM........................................................A.14.A ELECTRICALPOWERSYSTEM..........................................................A.30.A ELECTRONICSYSTEM...................................................................A.50.A A

A

HYDRAULIC,PNEUMATIC,ELECTRICAL, ELECTRONICSYSTEMS-A MAXXUM100,MAXXUM110Multicontroller,MAXXUM110,MAXXUM115 Multicontroller,MAXXUM115,MAXXUM120Multicontroller,MAXXUM120, MAXXUM125Multicontroller,MAXXUM125,MAXXUM130Multicontroller, MAXXUM130,MAXXUM140Multicontroller,MAXXUM140 A.10.A/1

Suggest:

If the above button click is invalid.

Please download this document first, and then click the above link to download the complete manual.

Thank you so much for reading

Contents HYDRAULIC,PNEUMATIC,ELECTRICAL,ELECTRONIC SYSTEMS-A TECHNICALDATA PRIMARYHYDRAULICPOWERSYSTEM Torque....................................................................................4 Hydraulicpump Fixeddisplacementpump-Generalspecification...............................................6 Fixeddisplacementpump-Torque...........................................................6 Variabledisplacementpump-Generalspecification............................................7 Chargepump FUNCTIONALDATA PRIMARYHYDRAULICPOWERSYSTEM Overview-VariableDisplacementPumpHighPressureHydraulicCircuit24x24Models...........37 Hydraulicpump Fixeddisplacementpump-Staticdescription.................................................57 Variabledisplacementpump-Dynamicdescription(SystemdescriptionCCLS)...................66 Chargepump A.10.A/2