The compact and efficient P-profile loader crane with the new Memory Position and Smart Control shows how to turn hard work into smart work − also as electric driven solution!

Reading a quotation about tools the other day got me thinking. Now, hoping to come across as mildly philosophical but clearly at risk of sounding pretentious, here goes. “We become what we behold. We shape our tools and then our tools shape us,” attributed to Canadian philosopher and media expert Marshall McLuhan (or a friend of his).

No, I’m not sure either but let me know what you make of it. Anyway, more than anything else, it called to my mind something rather simpler and more directly accessible – that old tradesman’s adage that goes along the lines of, “Look after your tools and they will look after you.”

To that end, at more like ground level, in my garage at home for many years I have had the same – now moderately unpleasant – pair of old undercrackers, permanently soaked in the contents of a very old can of EP140, thick and sticky gear oil.

I am pleased to say that being in the habit of wiping that oily rag over ferrous metal hand tools before you put them away is really all that’s needed to keep them in good shape. Aside, of course, from those with edges in need of sharpening but that is a whole other ball game for another time.

Anyway, as with most things, that little regular maintenance gives one an enormous sense of well being or, rather, it is better and usually easier than dealing with breakdowns. We all know it is true but a different matter when it comes to carrying it out. We need something to make it happen. Maybe something bang up to date could be brought to bear in this respect.

We see digitisation is beginning to work wonders and we haven’t yet understood or even imagined half of its possibilities. Again, bringing it all down a peg or two, when will it be able to sort out the age old conundrum of “you can lead a horse to water but you can’t make it drink.” New materials may present a solution or perhaps automatic maintenance robots – or a proper disruptor will come along that means old hand tools are done away with entirely – a spanner in the works, you could say. Exciting times indeed.

ALEX DAHM Editor

Correspondence is welcome and should be sent to:

Cranes & Specialized Transport Cranes and Lifting Professionals

The editor, International Cranes and Specialized Transport, Southfields, South View Road, Wadhurst, East Sussex TN5 6TP, UK MEMBER OF

Chile. +56 9 77987493 | cristian.peters@khl.com

CHINA OFFICE

Beijing Representative Office Room 769, Poly Plaza, No.14, South Dong Zhi Men Street, Dong Cheng District, Beijing, PR China 100027. +86 10 6553 6676 | cathy.yao@khl.com

USA/CANADA Matt Burk, Vice president sales +1 312 4963314 | matt.burk@khl.com AUSTRIA, EASTERN EUROPE, GERMANY, IRELAND, RUSSIA, SPAIN, SWITZERLAND & UAE

Mike Posener, International sales manager

+353 (0)86 0431219 | mike.posener@khl.com UK/SCANDINAVIA

John Austin, Marketplace/Classified advertising

+44 (0)1892 786245 | john.austin@khl.com

THE NETHERLANDS/LUXEMBOURG

Arthur Schavemaker

+31 (0)547 275005 | arthur@kenter.nl

FRANCE/BELGIUM Hamilton Pearman

+33 (0)1 45930858 | hpearman@wanadoo.fr

ITALY Fabio Potestà

+39 010 5704948 | info@mediapointsrl.it

KOREA Simon Kelly

+44 (0) 1892 786223 | simon.kelly@khl.com

TURKEY Emre Apa

+90 532 2343616 | emre.apa@apayayincilik.com.tr

CHINA Cathy Yao

+86 (0)10 65536676 | cathy.yao@khl.com

JAPAN Michihiro Kawahara

+81 (0)3 32123671 | kawahara@rayden.jp

USA/CANADA Bev O’Dell

+1 816 8861858 | bev.odell@khl.com

VP GLOBAL SALES Alister Williams

+1 843 637 4127 | alister.williams@khl.com

Chosen as the official magazine of the SC&RA (Specialized Carriers & Rigging Association)

European partner

Approved media partner for:

To subscribe to International Cranes and Specialized Transport or any of the magazines in the KHL portfolio go to: www.khl.com/free-subscription or call +44 (0)1892 784088 for details.

International Cranes and Specialized Transport is a monthly publication with a worldwide circulation. The annual airmail subscription rate is US$301, €258, £215. This issue of International Cranes and Specialized Transport is mailed on 14 February 2024. Material published in International Cranes and Specialized Transport is protected under international copyright law and may not be reproduced without prior permission from the publisher.

International Cranes and Specialized Transport (USPS 017 158) is published monthly by KHL Group and distributed in the US by DSW, 75 Aberdeen Road, Emigsville, PA 17318-0437. Periodicals postage paid at Emigsville, PA. Postmaster: Send address changes to International Cranes and Specialized Transport, c/o PO Box 437, Emigsville, PA 17318-0437.

Tandem lifting with a midair transfer of load. See more details on page 35.

EDITOR & EDITORIAL MANAGER Alex Dahm

alex.dahm@khl.com | +44 (0)1892 786206

DEPUTY EDITOR Niamh Marriott niamh.marriott@khl.com | +44 (0)1892 786208

EDITORIAL DIRECTOR Murray Pollok

NEWS WRITER Leila Steed

GROUP EDITORS Lindsey Anderson, Andy Brown, Mike Hayes, Cristián Peters, D.Ann Shiffler, Leila Steed, Euan Youdale

WORLDWIDE CONTRIBUTORS John Bowman, Australia; Graham Brent, USA; Marco van Daal, Aruba; Heinz-Gert Kessel, Germany; Richard Krabbendam, Netherlands; Tim Maughan, Japan; Brent Stacey, Australia; David Weston, UK

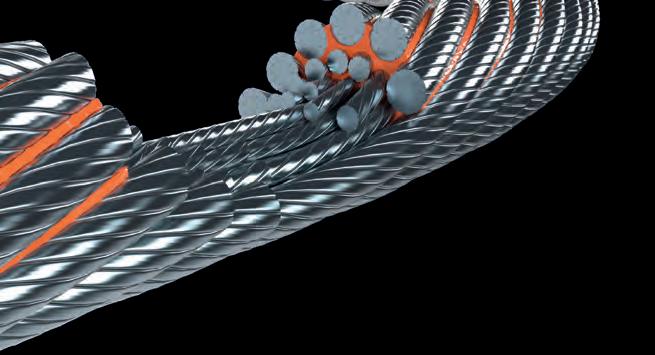

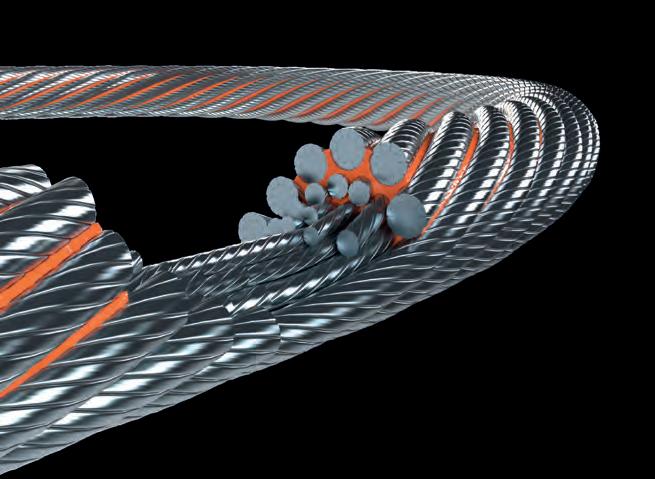

New rope technology gives operators options for lifting

The operations team is a key element at crane manufacturer Jekko, explains operations director Mauro Tonon Alex Dahm reports.

As equipment ages do you keep it running or get shot of it? John Helmink, manager at Mammoet's EMD gave some thoughts on it to Alex Dahm.

Versatility is a key advantage of pick and carry cranes. Niamh Marriott reports.

Check out the highlights of the Association's upcoming main event. D.Ann Shiffler reports.

An unusual rigging arrangement to build a road bridge over a river in Germany. Alex Dahm reports.

SC&RA CORRESPONDENT Mike Chalmers

SALES MANAGER Mike Posener mike.posener@khl.com | +353 (0)86 043 1219

MARKETPLACE SALES John Austin

john.austin@khl.com | +44 (0)1892 786245

GLOBAL MEDIA PRODUCTION MANAGER

Charlotte Kemp | charlotte.kemp@khl.com

MEDIA PRODUCTION ASSISTANTS Ben Fisher | ben.fisher@khl.com

Alex Thomson | alex.thomson@khl.com

GROUP DESIGN MANAGER Jeff Gilbert

GROUP DESIGNER Jade Hudson

CREATIVE DESIGNER Kate Brown

Carriers & Rigging Association

Joel Dandrea, SC&RA chief executive officer.

SC&RA members gather in Mexico to kick off 2024. Mike Chalmers reports.

EVENTS MANAGER Steve Webb

EVENTS DESIGN MANAGER Gary Brinklow

DIRECTOR OF OPERATIONS

Peter Watkinson | peter.watkinson@khl.com

HEAD OF FINANCE & HR Alison Filtness | alison.filtness@khl.com

FINANCE MANAGER

Yasmin Toumi | yasmin.toumi@khl.com

CREDIT CONTROL Carole Couzens carole.couzens@khl.com | +44 (0)1892 786250

AUDIENCE DEVELOPMENT MANAGER Anna Philo

Manufacturer Zoomlion claimed two more world lifting records for its 3,600 tonne capacity lattice boom crawler crane on a project in China.

Between 3 and 8 January the ZCC89000 crawler crane with double lattice booms lifted three giant chemical processing vessels, the heaviest of which weighed more than 3,000 tonnes. Zoomlion claimed two world records, one for the heaviest

single lift and the other for the fastest lifting speed.

Being able to install these reactors in single lifts advanced the construction schedule by two months, the crane maker said, with all the attendant benefits.

The job was to install three slurry bed reactors at Zhejiang Petroleum & Chemical Co., Ltd.’s No.3 new material engineering project in Zhejiang Province, China. The new

vessels were part of a project to construct a slurry bed residue hydrogenation plant with a capacity to turn out 300 million tonnes a year.

Weighing in at 3,037 tonnes and standing 67.57 metres tall, the vessels were claimed as the world’s largest one-piece hydrogenation reactors. To make the lifts the crane manufacturer and the construction contractor upgraded the crane for

Lifting one of the three reactor vessels, weighing 3,000 tonnes, in one piece

required lifting height, load weight, confined space for lifting and roadability.

The 2,000th crane produced at Liebherr in Ehingen in 2023 was an LTM 1070-4.2. Inset, Liebherr sales managing director Christoph Kleiner, left, with production managing director Ulrich Heusel, right, handing over the 2,000th crane to Maik Kanitzky, owner of Maxikraft Group

» SIMS CRANE & EQUIPMENT in Florida, USA, hosted a 65th anniversary event with a day of activities to celebrate its continued expansion and honour its 1,400 employees.

“We were thrilled to show our invaluable staff how much they mean to the Sims Crane family at our 65th anniversary event,” said

Deborah Weber, CEO, Sims Crane. “These are the great people that make this company go, and without their hard work and dedication, we wouldn’t be here celebrating Sims Crane’s 65 years. With their dedication, we’re looking forward to another 65 years and to continued growth and prosperity.”

German crane rental company Maxikraft took delivery of a new Liebherr LTM 1070-4.2 all terrain crane with a twist.

This was the 2,000th crane delivered in 2023 from the Ehingen mobile crane plant in

» Lifting beneath an overhanging roof was a key part of a job for Gräser-Eschbach and its Grove GMK5250XL-1 all terrain crane on a stadium renovation project in Germany.

The lifting services specialist used its 250 tonner on a €130 million project to renovate the MHP Arena football stadium in Stuttgart, home to VfB Stuttgart. It remained open during the renovation which started in 2018.

Using a crane with a telescopic boom was the only way to lift heavy components in below the overhanging stadium roof, according to the crane’s manufacturer.

Germany. It is the most cranes delivered in a year from there.

Around 80 per cent of Maxikraft’s fleet is Liebherr. Since founding the company in 1992, Maik Kanitzky, owner of Maxikraft, has purchased around 800 Liebherrs, investing around US$546 million.

Kanitzky said, “From my point of view, the employees are the company. And great people have to work at Liebherr to achieve this kind of performance.

German crane rental company Anker has taken delivery of a new Tadano HK 4.050 1 truck mounted crane.

Anker will use its new 50 tonner for building roof trusses, and factories.

Hartmut Ballerstädt, Anker ops manager, said, “The new Tadano HK 4.050-1 clearly has what it takes to become the best-running machine in our fleet.”

“With its tridem rear axle, including steered trailing axle and two driven axles, the HK 4.050-1 has an ingenious chassis concept that gives it unparalleled manoeuvrability and makes it suitable for use on even the tightest construction sites," Ballerstädt concluded.

Barnhart Crane and Rigging in the USA acquired two crane rental companies in the first month of 2024.

First was South Carolinabased White Crane. It is the company’s second branch in the state and its fourth acquisition in eight months.

“We are pleased to welcome White Crane to the expanding Barnhart family,” said David Wills, Barnhart regional director for the Mid-Atlantic.

“The company’s customer service is second to none, and their experience in heavy industrial lifts; shutdowns, turnarounds and outages; power generation plants; and the hauling, lifting, and setting of out-of-gauge components makes them a perfect fit for

Gräser-Eschbach using its GMK5250XL-1 at long radius. Lifting a long way in beneath a stadium roof meant a shallow boom angle

us,” Wills continued.

Most recent of the two acquisitions is Baxter Crane and Rigging, of Tupelo, Mississippi.

“Baxter Crane and Rigging has provided crane rental and heavy rigging services in north Mississippi since 2005,” said Shane Bills, district

manager, Barnhart. “The company, which specializes in transporting and setting machinery, millwright work, and lowboys, represents Barnhart’s third field office in the state, complementing services provided by our locations in Columbus and Jackson.”

Italy-based Raimondi-dealer Assistedile has added an eight tonne lifting capacity Raimondi T147 flat top tower crane to its fleet and put it to work on a prestigious project.

This latest addition brings its total fleet to 130 cranes.

A class 110 series crane, the T147 was erected for the first time in the country in October 2023. The crane is at work in Modena, assisting construction of the new technical and administrative offices of car manufacturer Ferrari.

The flat top is 42 metres tall with a 45 metre jib and a 3.58 tonne tip load.

» The first POTAIN MCT 1005 flat top crane in Singapore was put to work on a project for the country’s Housing & Development Board.

It was erected in October and boasts all the capacity to complete the Yishun Central 1 (N9C3) housing development using prefabricated prefinished volumetric

construction (PPVC).

The 50 tonne capacity crane has an 80 metre jib. For added versatility on site there’s also a choice of counter jibs from 15 to 20 metres.

The MCT 1005 at Yishun will reach a final height under hook of 55 metres and has been configured with a jib length of 35 metres,

supported by a 15 metre counter jib.

This will allow it to lift and place all the heavy PPVC sections as the jib can support over 34 tonnes at almost 35 metres in this configuration. Main contractor Debenho has rented the crane from local equipment supplier Manta Equipment.

Ang Guan Hwa, Tiong Woon Corporation executive director and CEO, left, and Paul van Gelder, Mammoet global CEO, signed the memorandum of understanding to work together

Global heavy lifting and specialized transport giant Mammoet has signed up to two new partnerships in Asia and the Middle East.

One is with Belgium-based heavy lifting specialist Aertssen Machinery Services (AMS) to work together in Qatar. The other is with Singapore-based heavy lifting and transport specialist Tiong Woon to partner on turnkey project logistics and heavy lifting services in Asia.

Commenting on the Aertssen agreement Jack van den Brink, Mammoet MEA and APAC managing director, commented, “By combining our capabilities, we are wellpositioned to serve projects

in Qatar, with the aim to bring greater efficiency for all of our customers there.”

The other agreement is between Mammoet Asia Holding and Tiong Woon Corporation Holding and was signed in December. Tiong Woon also bought some heavy lifting and heavy transport equipment from Mammoet.

Ang Guan Hwa, Tiong Woon executive director and CEO, commented, “We are excited about the opportunities this strategic alliance and asset acquisition with Mammoet in Thailand brings to our organisation and our customers. This is yet another chapter in the group’s growth story in the right direction.

As this issue went to press thoughts were turning to crane and transport equipment makers' annual financial results.

Many are likely to post increases. First out of the blocks is Cargotec, owner of crane and materials handling equipment manufacturing brands Hiab, Kalmar and MacGregor. For the whole group, sales in 2023 were up 12 per cent to Euro 4,569 million, from Euro 4,089 million in 2022. Operating profit was Euro 484 million in 2023, as against Euro 106 million in 2022. This was 10.6 % of sales (2.6 % in 2022).

By segment, 2023 sales at loader crane maker Hiab were Euro 1,787 million, up 13 % on the Euro 1,578 million of 2022. Offshore crane division MacGregor posted a sales increase of 29 %, up from Euro 569 million to Euro 733 million. Harbour crane and equipment division Kalmar's sales were up a more modest 5 %, to Euro 2,050 million from Euro 1,943 million. Plans are continuing for Kalmar to become a separate standalone company and Cargotec will

"continue to look for a solution for MacGregor."

Cargotec forecasts Hiab's comparable operating margin to be above 12 % in 2024. Let's see how the industry fares in 2024.

Liebherr Transform provides not only the technologies but also the coordination and best solution to find the most suitable and economic answer for your requirements. With our wide range of state-of-the art upgrades, retrofits and overhauls we make your machine even stronger, faster, smarter, greener and...ultimately better!

Liebherr-Werk Nenzing GmbH • 6710 Nenzing, Austria • Phone +43 50809 41-464 info.lwn@liebherr.com • facebook.com/liebherrConstruction • www.liebherr.com

handling reach stackers for heavy handling lifting

– lifting capacity from 85 to 180 tons

From left to right: Bill Grubb, W.O. Grubb owner, Dean Spruill, regional operations manager; Doug Adkins, director of fleet operations; and Kris Becker, crane driver

W.O. Grubb Crane Rental in the USA received a new Grove GMK6400-1 in December 2023 and immediately put the crane to work in high-profile jobs throughout Virginia. The 400 tonne all-terrain proved its worth in tasks such as removing lock gates at the Deep Creek Locks on the Intercoastal Waterway in Chesapeake.

“We were keen on embracing the newest technology and improved roadability without compromising on lifting performance,” said Bill Grubb, owner, W.O. Grubb. “This prompted us to upgrade from our reliable GMK6300L model to the GMK6400-1. With MegaWingLift and luffing capabilities, this marks our first investment in a brand new, large all-terrain crane tailored for the PortsmouthNewport News market.”

China-based manufacturer

XCMG Crane, a subsidiary of XCMG Machinery, reported it had exported 200 mobile cranes to the global market in the last year.

Sun Jianzhong, vice president at XCMG Machinery and general manager of the hoisting machinery division, said, “Over the past year, XCMG Crane has focused on product innovation. The company’s mobile cranes have achieved the highest year-on-year growth in orders and sales in the industry. The optimised

XCMG sees a growth in demand for Chinese manufactured cranes

product mix has led to record sales of large-tonnage cranes. Both wheeled and tracked

models continue to maintain their leading positions in the crane market.”

Lifting and transport specialist Arabian Consolidated Trading in Saudi Arabia will get 18 new mobile cranes from Liebherr.

They will all be in capacities ranging from 100 to 150 tonnes. Three will be the 100 tonne LRT 11002.1 rough terrain. Of the

Left to right: Daniel Tuerkis, Mohammed Hassan Al Naimi, Ajanthas Kumarathas, and Sultan Al Otaibi

» UK-based tower crane and lifting services company Radius Group erected the world’s first Potain MR 229 luffing jib crane in London on a project for housing association L&Q Group. Radius already had four MR 225 A models for the project based on the requirement to lift 2.15 tonnes at full reach. Efficiency pressures led the company to swap one of them for an MR 229 as soon as it became available.

The MR 229 lifts 14 tonnes, offers jibs from 30 to 55 metres and has a 2.7 tonne tip load at full reach. For this job it had a 50 metre jib, 37.5 metre height under hook and a 75HLP35 winch. The three MR 225 As were on fixing angles and with 40 metre jibs.

Teddy Holt, Radius Group operations director, said, “Innovation has always been critical to Radius Group, and this is an exciting milestone for us.”

remaining 15 all terrains seven will be the 120 tonne LTM 11204.1 and eight are the LTM 11505.3, a five axle 150 tonner.

Commenting on this last model Mohammed Hassan Al Naimi, ACT Group CEO, said, “An important factor for us is the longer 66 metre telescopic boom compared to the LTM 1160-5.2. The 150 tonne crane is the perfect addition to our fleet.”

Another three 66 tonne capacity Terex luffing jib tower cranes will join the fleet of UK specialist Select Plant Hire.

The news follows a recent previous order for four units placed less than a year ago in March 2023. On delivery of this latest order Select will have 12 units of the CTL 1600-66. It is more than any other customer in the world, Terex said.

Luffing jib cranes are widely used on urban highrise construction projects. These larger models will handle the growing trend for buildings made using larger

precast concrete elements and modules made offsite.

The 66 tonner is also the largest Terex luffing jib model in the range. Even at full stretch, at the end of its maximum 75 metre jib, it still lifts 16 tonnes. Other features are the T-Torque function to improve slewing control, Terex Power Plus which can boost capacity by 10 per cent, and the Power Match function to reduce energy consumption.

Commenting on the latest order Clare Rodgers, Select Tower Cranes business stream leader, said, “Back in March

The latest additions will consolidate Select Plant Hire’s position as having the largest fleet of Terex CTL 1600-66 cranes in the world

2023 we were placing orders for numbers six and seven of our CTL 1600 fleet. In less than one year this has increased to 12. This is driven by the requirement for heavy lifting tower cranes, which continues to increase, particularly in the energy and data sectors.”

On the overall market for luffing-jib cranes Lee Maynard,

Terex Tower Cranes global sales director, said, “We continue to see significant opportunities in the UK for large cranes, but also globally, most notably Southeast Asia and Middle East. Our established and well-respected range of large luffers is in demand, which makes for an exciting year ahead.”

Your crane should deliver high performance reliably. Then trust CASAR Steel Wire Ropes. Rotation-resistant heavy duty ropes such as the CASAR EUROLIFT, CASAR STARLIFT PLUS and CASAR DOUBLEFIT offer high breaking strength, highest rotation resistance and the best in class multi-layer spooling behavior.

Smart Chart

Expands the customary circular work area to take advantage of the maximum available lifting capacity

Unrivaled Reliability

Unique Quality

Advanced control system with enhanced features

Reduced Fuel Consumption

• Fuel Monitoring

• Eco Mode System

• Automatic Pump Disconnect

Discover how Tadano RT cranes deliver maximum lifting performance with unrivaled reliability.

Tadano RT cranes give your business the next-generation features you need to work safer, faster and more effectively than ever. Tadano View gives your operators a birds-eye view of the crane’s surroundings on a large, multi-function display inside the cab. Reduce fuel consumption with Fuel Monitoring, Eco Mode and Automatic Pump Disconnect. And expand the working area to get the best crane performance in any outrigger extension setup with Smart Chart.

Take a closer look at what Tadano can do for your business. Learn which models are available in your region at tadano.com.

New products lead the biggest trends in the rope market, says a recent Technavio market research report. It says major company innovations and product launches are expected to attract more end users and help companies increase consumer reach.

Furthermore, there is an increasing effort in the market by major players to replace the conventional raw materials used in rope production with modern options that have no negative impact on the environment in the production process.

Rotrex Group has become the biggest provider of 4 tonne winches in the UK after it placed an order with Italian manufacturer OMAC for its UP40 winch.

The company, an exclusive distributor in the UK for OMAC, says the order for the UP40 winch comes off the back of growing popularity in the UK due to its “exceptional capabilities and features.”

It has a maximum pull of 40 kN, maximum speed of 65 metres a minute, a 12 mm maximum rope capacity and steel rope fitted up to 1,300 metres.

Other features include a light composite material canopy, built-in technology, including onboard Wi-Fi for data transmission and data recording technology.

Paccar Winch has added a new TRS synthetic rope to its Braden product line

A feature of Wolffkran’s fibre crane rope is that its cover is an impermeable full sheath

For example, the Euro block VF winch uses Dyneema rope, made using an ultra-lightweight polyethylene fibre that is up to 15 times stronger than steel. These ropes are highly resistant to abrasion, moisture, UV rays, and chemicals. In addition, they also have high energy absorption and very low elongation.

As the rope debate continues – synthetic fibre or steel wire – there are new options coming to the crane market.

Due to properties such as a higher strength-to-weight ratio, synthetic fibre ropes are light and easy to install.

“Fibre ropes, up to seven times lighter than steel ropes and easier to handle, offer significant advantages,” says UK-based industrial equipment supplier Rotrex Winches. “They are compatible with water and corrosive environments, where they can resist rust damage and degradation. Fibre ropes are ideal for offshore projects or marine and port operations.”

“Additionally, fibre ropes are safer than steel ropes, as they do not snap back if broken, reducing the risk of injury for those working nearby. While more flexible than steel ropes, fibre ropes have lower strength and crush resistance.

There is, however, still a case for steel ropes in certain applications, Rotrex says. “Steel or wire cables, typically stronger than fibre ropes, are ideal for winching or lifting heavy equipment. They offer greater crush resistance and a higher nominal strength compared to fibre ropes, but they are not as flexible.

“One advantage of steel rope over synthetic rope is its increased resistance to cutting or melting. Steel ropes can be used in environments over 60 °C (140°F) without losing their lifting capacity, whereas synthetic fibre ropes typically lose capability at around 65 °C (150°F).”

Rotrex has invested in its fibre rope capabilities and now offers an equal choice of steel or fibre ropes.

While Technavio’s report suggests the steel wire segment is estimated to witness significant growth, synthetic options continue to be explored.

“Synthetic rope continues to grow in popularity for utility, trailer and towing, construction, military as well as other applications,” says a spokesperson for USAbased manufacturer Paccar Winch.

“Replacing traditional steel cables can

drastically reduce the overall weight of any towing or utility vehicle, particularly those with multiple winches.

“Abrasion-resistant and easy to inspect, synthetic rope is torque neutral, which means it will not twist and is much easier to handle.”

Paccar Winch added a new TRS synthetic rope to its Braden product line. The rope is engineered and tested to complement its TR series planetary recovery winches, which have rated line pulls up to 13.6 tonnes.

Rope diameters and lengths are suited to specific winch drum sizes and it is an alternative to wire rope. Four times lighter than comparable sizes of steel rope, the synthetic rope helps mitigate the overall weight of equipment transported to site.

As vehicle manufacturers explore battery electric vehicle technology, it will become increasingly important to minimise the weight of accessories to balance the overall gross vehicle weight rating (GVWR).

The Braden TRS range is a UHMPE (ultra-high molecular weight polyethylene) 32-carrier with a polyurethane coated braided sleeve over a Vectran LCP (Liquid

Crystal Polymer) 12-strand load bearing core to make it stronger and more durable. Each rope has two eye splices, one for anchor wedge attachment to the winch drum and the other with a thimble spliced into the eye with a UHMPE protective chafe layer at the throat of the splice.

The rope is non-crushable, abrasion resistant, easy to inspect and torque neutral, which means it will not twist and is much easier to handle than wire, the company adds. The rope is available in rope diameters from 11 to 16 mm and lengths from 24.4 to 64.0 metres.

As previously reported, tower crane manufacturer Wolffkran demonstrated a synthetic fibre hoist rope to replace conventional steel rope at the Bauma Munich construction trade show in 2022.

Its chaRope, developed with rope specialist Trowis, is “the only fibre rope that can replace a steel rope one to one,” Wolffkran says. It was shown on a Wolff 6021 FX flat top tower crane and since being launched to market, has been tested on Wolffkran’s UK rental fleet.

Without fibre ropes, many of today’s deepwater projects would be beyond all but the largest cranes, says Lankhorst Offshore. The weight of steel wire ropes makes wire rope lifting and lowering systems both inefficient and impractical at water depths greater than 2,000 metres. Development of the Lanko Deep AHC fibre rope by Lankhorst Offshore, part of Netherlands-based Lankhorst Ropes, is bringing deepwater projects within the reach of smaller, more cost effective lifting systems and vessels.

LankoDeep is based on Dyneema DM20 XBO optimised for cyclic bending. It is made up of 12 strands where each strand comprises a three-strand rope. This construction, combined with the proprietary yarn coating reduces internal heating and abrasion.

Lanko Deep AHC fibre rope was designed from the outset for deepwater lowering and recovery projects. The company says it offers significant operational and environmental benefits compared with steel wire ropes. Operationally the ropes are easier to handle and allow engineers to lift and deploy the maximum load without the need to factor in the self-weight of steel wire.

“Neutrally buoyant LankoDeep allows operators to maximise the lifting capacity of their crane during deepwater deployment and recovery. With the introduction of the new DNV certified end-to-end splice we’re considerably increasing the utility of LankoDeep, ensuring deployment and recovery operations run smoothly,” says Sergio Leite, Lankhorst Offshore sales director.

WireCo has invested US$30 million in new machines, technology and facility upgrades

The chaRope fibre rope is roughly 80 per cent lighter than a steel rope. This saving in weight not only enables greater lifting capacities but also significantly easier and safer handling during transport, assembly, and rope changing.

In addition to the usual advantages of fibre rope over steel, Wolffkran says, substitution with the new rope can be done without any modification to the crane.

It is not just the choice of material that is impacting the rope market – changes in manufacturing processes and environmental concerns are also priorities.

“Production facilities must have the ability to evolve and adapt as innovations in materials, coatings and manufacturing processes continue to alter the wire rope industry,” Andreas Schmeiss, global crane industry leader at WireCo World Group, comments to ICST sister magazine American Cranes & Transport

In the last two years WireCo has invested US$30 million in machines, technology, facility upgrades and processes, including quality testing. WireCo invested $25 million to expand production in its Sedalia, Missouri, facility in the USA.

This focus on the US market was deliberate, responding to customers’ respect for and recognition of the company’s brands and products.

“We believe strongly in the US market and the infrastructure boom that is happening, both direct and indirect spend,” says Keith White, WireCo CEO. “We know the industry will need ropes as soon as possible, and that operators want to go with brands they trust. By making this investment, we’ve significantly increased our output and capacity and, most importantly, our ability to meet lead times and demand for our most valued partners.” ■

Already before the end of 2023, for the fifth time in a row, Italian crane maker Jekko achieved year-on-year growth. According to the company it is a positive trend of exponential growth driven by the operations division.

Long term planning and the evolution of the operations division is “the real engine of this relentless growth,” Mauro Tonon, Jekko operations director, told ICST. And that growth is impressive. Turnover increased from €20.5 million in 2019 to €31 million in 2021 and €57 million in 2023.

In terms of numbers of cranes built and sold, the total for 2023 will be around 600 units, an increase of 20 % over the 500 cranes of 2022 and 50 % up on 2021’s 400 units. Not only that, “The goal set for 2024 is for a further growth, even if the feelings in our business sector tend to be different. The plan is to be conservative, therefore we estimate a 20 to 30 % growth for the next two years,” forecasts Tonon.

Behind these increases there is a lot of hard work. The company prides itself on consistent high quality and this has to be scalable. “Jekko’s main challenge aimed to preserve its superior standards despite the massive growth of volumes produced. This was only possible by investing time and care in the operations division,” Tonon explains.

“Nowadays operations gathers five crucial activities for our corporate ecosystem: planning, purchasing, supply chain, production welding department, production assembly department.” Of the total 200 employees at Jekko 75 % of them are in operations. It has doubled in recent years due to a major change to the workflow. “The company migrated from work cell production to linear production, which greatly contributed to improve the overall efficiency and quality of the Jekko mini cranes.”

In more detail Tonon goes on to say, “We have standardised the manufacturing process, simplifying the operations following the principles of lean production and Six Sigma. In addition, we have also been working on establishing written guidelines and instructions for the

The operations team is key to the continuous growth at crane manufacturer Jekko, explains MAURO TONON, operations director.

ALEX DAHM reports

different stages of assembly and testing to facilitate our co-workers in their daily tasks. This will also allow us to incorporate new personnel into the production lines more quickly and with a shorter training phase. In parallel to this, numerous intra-production controls and checklists have been implemented in co-operation with the Quality Office.”

Completed cranes out for delivery at the Jekko factory north of Venice in Italy (Inset) Jekko’s operations team, from left to right: Federico De Stefani, purchasing manager; Alessandro Cattai, planning manager; Mauro Tonon, operations director; Andrea Garoffolo, supply chain manager; Alan Rover, steel department plant manager; and Damiano Dal Cin, assembly deptartment plant manager

SPX532 mini crane, the largest option in the single-door range. We’ve had this crane in our catalogue for four years now. However, our expectations are for the SPX328 to draw ahead of SPX532,” Tonon continues.

Operations have also been expanded by extending the company’s headquarters from 10,000 to 30,000 square metres. Further expansion starts in 2024, with the addition of vertical storage warehousing.

Jekko is one of a small number of manufacturers worldwide of so-called mini cranes. It has three product lines: SPX mini cranes; JF articulated crawler cranes; and MPK mini pickers. Largest by turnover are the SPX mini cranes, accounting for 60 % of the total units manufactured. Next is the JF series.

“Single-door cranes, which means up to 3.2 tonnes maximum SWL [safe working load] make up our largest market; cranes with less than 9.5 tonnes capacity account for one quarter of our turnover,” Mauro Tonon explains.

“Our best-selling model is definitely the

By far the largest proportion of Jekko’s production goes for export. Thanks to Italian government subsidies 2023 domestic market sales were up, to 18 % of the total, leaving 82 % exported.

“Europe is for us the main market, with Germany being the first country by number of sold units. North America follows [around 100 units] right after and we are now aiming to increase the market share in the Far East,” said Tonon.

Looking ahead, Tonon says, “Ongoing improvement towards operating excellence, sustainable growth and constant innovation: [mean] 2024 promises to be a crucial year for Jekko’s consolidation. The collaboration between the Operations Division and the Quality Control Dept. is going to be increasingly closer. Our future target is to ensure that all products perfectly meet our company’s strict quality standards.” ■

Jekko fabricates in house and uses robotised production

HEAVY HAULAGE HAS A NAME. GOLDHOFER - MADE FOR YOUR MISSION.

flexible, compacted, beautiful

One of two new Cometto MTH45 straddle carriers for Schultze Steel Service at Arcelor Mittal in

This type of handling equipment may be slightly peripheral to ICST’s typical subject matter but it is interesting all the same. A pair of these new highly specialized straddle carriers has joined a fleet in Germany for steel coil handling.

Steel maker Arcelor Mittal stores more than 6,000 steel coils in a 12 hectare storage area at its site in Bremen. Specialist contractor Schultze Steel Service uses a fleet of straddle carriers to

move and manage the stock.

Schultze has just added a pair of new Cometto MTH45 straddle carriers to its fleet. “We have been working together on this challenging project since 2019 and were ultimately able to win the contract in the hard elimination process,”, said Joachim Kolb, Cometto sales manager.

Despite weighing 43 tonnes it manages a top speed of 25 km/h. All up, with a 45 tonne payload and weighing a total of 88 tonnes, it

Express Global Logistics (EXG) in India managed the transport of 30 structural steel deck sections weighing 2,800 tonnes each for the Mumbai Trans Harbour Link Project.

“On 12 January 2024, we stand on the brink of history as Express Global Logistics (EXG) is proud to have played an integral role in the monumental Mumbai Trans Harbour Link Project –officially named the Atal Setu,” said a project spokesperson.

As the lead logistics partner, EXG played a major role in the transportation of the decks that form the floor of the Atal Setu, India’s longest oversea bridge. The bridge was opened by India’s Prime Minister Shri Narendra Modi.

still makes 10 km/h. Not only that, Schultze reported its 500 hp diesel engine also gives a 30 % reduction in fuel consumption over the old equipment. n

Crane rental and logistics company Trex, part of the Peruvian Ferreycorp Group, has taken over sales and service operations of all transport and manoeuvring solutions from TII Scheuerle in Colombia, Ecuador, Peru and Chile.

Trex specializes in the distribution of mobile cranes, equipment for cargo handling in ports and as well as a range of lifting equipment.

TII said the collaboration opens the market for Trex regarding transport for heavy and oversized loads and allows TII to benefit from the growing demand for special vehicles in Latin America. Trex will maintain its own sales offices in the region.

The partnership also includes service

and maintenance, spare parts supply, and training programmes.

“The collaboration offers us the opportunity to open up the market for modular transport solutions especially when it comes to dealing with oversized loads. The quality of Tii Scheuerle’s products gives us the certainty that our product range meets market requirements and furthermore create added value in the market,” explained Gonzalo Salazar Arenas, central business manager at Trex LATAM.

Trex has special know-how in the area of hydraulic systems which is essential for carrying out service and maintenance on TII Scheuerle’s transport solutions. n

UK-based specialized transport company Falcon Freight, part of Falcon Tower Crane Services, has started using Mandata Go for transport management.

Falcon reported an improvement in planning times after migrating from the Stirling transport management system to Mandata Go. “It is definitely saving us time across the team,” said Trevor LawrenceBell, Falcon Freight transport planner.

“It is about 20 per cent quicker in terms of transport planning. It is much easier to use, input information and plan work and gives us much greater visibility of what’s happening throughout the day.”

Go is designed for small and medium hauliers to simplify everything from customer ordering and job planning to real-

Egypt-based logistics and transport company Egytrans and Saudi-based investment firm Links Investment will partner in a new joint venture company in Saudi Arabia.

The new LLC with its capital of US$ 2.6 million sees both partners hold an equal 50 per cent stake. Headquartered in Riyadh, Saudi Arabia, it will offer transport and logistics services, especially in the oil & gas and renewables sectors.

Abir Leheta, Egytrans CEO, said, “We have always sought to expand our business not only in Egypt but also internationally. Our recent acquisition of NOSCO, a major heavy transport player in Egypt, demonstrates our commitment. Our partnership with Links Investment is a strategic move to tap into the Saudi market, which is the largest for logistics providers in the region.”

The new transport management system speeds up planning, Falcon said

time job execution, proof of delivery and invoicing. With it hauliers can control every stage of the haulage process, and planning is made easy with a user-configurable job planner supporting multi-drop and full load operations, using drag and drop functionality and map-based route planning.

“Mandata Go is a much easier system to use, it’s very user-friendly,” said Rachel Gale, transport manager for Falcon Freight.

Falcon Freight specialises in the transport and logistics of tower crane components, self-erecting tower cranes and ballast, including test weights. It also provides transport of rigging mats, containers and cabins. n

As equipment ages how do you decide whether to keep it running or get shot of it? JOHN HELMINK, European manager at Mammoet’s equipment management department, explained some thoughts to ALEX DAHM

Decisions about buying and operating capital equipment can make or break a business in a short time.

Many factors are taken into account when determining whether to keep or replace a machine. In addition to fundamentals like reliability and safety, careful consideration may be given to, for example, the balance between sustainability and the need for, or benefits of, the latest technology and functionality, whole life cost and so on. As an example, is it less damaging to the environment to continue repairing an existing crane instead of replacing it, possibly even for decades?

Repairing and refurbishing can also be cheaper but at what point does the improved lifting performance, reduced environmental impact or other advantages of a new model over an old one shift the balance in favour of replacement?

ICST got some thoughts and answers on these and other questions from John Helmink, Europe manager of the equipment management department at Mammoet, which runs by far the world’s largest fleet of cranes and specialized transport equipment. The Netherlands-headquartered company is also at the forefront in its sector of environmental awareness.

How do you measure and then weigh up the pros and cons of repairing and refurbishing a crane over replacing it with a new (or used) one? This happens based on a few factors. Due to the fact that each and every piece of equipment is unique, this is never a straightforward exercise. In general we can say that the amount of time the equipment has been in our fleet is an important factor in having it replaced or not.

We want each crane to be kept in the optimum condition until we divest it, regardless of whether we’re planning to do that soon or later on. For example, we have the situation going on right now

where we have a crane, which is not ready for operations. We do want to sell it this summer. Yet we give it the repairs needed and we execute maintenance to make sure that we can rely on it like any other crane and when the moment comes then we sell a well-maintained machine to its next owner.

How much does the sustainability element play a part in the decision to repair or replace?

In general, if you maintain your equipment well, you’ve got efficiently operating machines. From an emissions perspective, you do want to run efficiently.

Also, we plan in advance when cranes get their maintenance. Most of the time they are maintained at a workshop close to their home base. Wherever possible, we will not move cranes long distances to be maintained.

It is important that equipment is maintained in a specialist facility. For example, if you have an oil spillage, you need to be prepared to deal with this correctly –so you’ve got the right tools, the right setup for proper maintenance.

How much does lifting performance play a part in the decision to repair or replace a crane?

From day to day, the operator of any piece of equipment is acutely aware of how it is performing, and they certainly let us know if there is any degradation. We can also rely on the equipment specifications we receive from manufacturers.

If for some reason the crane does not perform like it should, then we take action. Next to this, we’re constantly performing routine maintenance, for example checking for degradation of oil.

So in that sense, we kind of monitor from a technical perspective whether there’s an indication that the machine is not operating as it should.

“Safe operations and reliability for our customers are key factors that affect our repair and refurbishment strategy.”

JOHN HELMINK

How much does new safety technology play a part in the decision to repair or replace a crane?

Safety is something we never compromise on at Mammoet. Safety measures are not usually a significant enough investment to factor into replacement decisionmaking, however. Although new models of cranes do in general have better safety measures implemented, cranes we already operate in our fleet can also be equipped with new safety features. For example, we are currently working on having an older crawler crane equipped with a fall prevention system. Also, we installed a 360 degree view camera system and pedestrian alert system on an existing mobile crane.

We also have many workshops capable of manufacturing custom improvements for equipment, should the need arise.

How much does anything else play a part in the decision to repair or replace a crane?

Safe operations and reliability for our customers are key factors that affect our repair and refurbishment strategy. Mammoet is known for having a relatively young fleet, and we maintain this to keep reliability high. This helps to secure delivery of our services to our customers. In parallel we make sure that we invest in preventive maintenance of our existing fleet as both are needed for reliable and safe operations.

Reliability plays an even more important role for some of the equipment which is mobilised to very distant locations. For our customers and also for our colleagues out in the field it is important that it can be relied upon to perform.

How much a part of the equation is the condition or repair or replacement cost of the power unit in deciding whether to refurbish a crane or not? How and how much would it sway your repair or replace decision?

Equipment doesn’t break down often. Also, the heavy lifting phase of projects comes at very specific moments in time. So, before we are involved, there is time to set up and test equipment to perform at the highest level. Between lifts or transports, you need to wait, so again there’s time to test your machine and take preventive measures. »

More generally, we’re talking about equipment that is pretty unlikely to reach its end of life any time soon, and that has been well maintained by our network of expert mechanics. Also, when resold we would like to maintain our reputation for providing quality used equipment to the market.

Do you have a calculation or assessment criteria model for deciding to repair or replace, or is it all done on a case-by-case basis?

Predominantly on a case-by-case basis, but with the above network of checks and balances in place, where operators are

on constant alert, equipment is brought in for predictive maintenance in line with manufacturer standards, and the age of the fleet is kept low.

The location a piece of equipment works at is also a factor. You might want to use an older machine on sites that you know will be dirty and a newer machine where everything is kept really clean.

How much information do you get from crane manufacturers about whole life cost of a crane or other pieces of equipment?

I feel that real world data is most important, regarding this. Real life operations can put

Look after your tools with regular maintenance and they will look after you

equipment in environments that are not exactly unexpected but can cause unusual usage profiles.

We have been talking about cranes really but to provide another example, there’s a lot more to it. We also have the SPMT [self propelled modular transporter) for example. We have SPMT coming in from jobs next to the North Sea. It's not had many hours of operation but being near salt water all the time , it needs maintenance due to the corrosion that has taken place. ■

Where colleagues and competitors collaborate.

• Build relationships with existing clients

• Find new prospects at the Exhibit Center with 90+ booths

• Learn from experts on new trends and the economy

• Network at receptions every night

today at scranet.org/AC2024

Pick and carry cranes are highly manoeuvrable and a real alternative to a forklift or telehandler, says UK-based mini crane and materials handling specialist GGR Group, which offers several small cranes for rental.

Due to their size, they are easier to travel on roads and can access smaller sites with narrow or awkward conditions.

Last year, the company launched its new telescopic boom pick and carry crane with a self-levelling capability.

GGR says its T-Crane 1060 is the first pick and carry mini-crane with self-levelling technology. It has the capacity to lift (to 3.5 metres radius) and transport a maximum load of 990 kg.

Mounted on a crawler tracked platform, the new crane is designed to be adaptable for a wide range of indoor and outdoor applications. It can cope with inclines up to 25 degrees and its self-levelling capability

Danfoss Power Solutions, a global supplier of mobile and industrial hydraulics as well as electric powertrain systems, has partnered with crane manufacturer Terex Franna in Australia to improve the performance of its MAC 25 crane. With the PVG 48 proportional valve at the heart of the work and steering subsystems, Danfoss says it is delivering a reliable, precise, futureproof solution.

Franna is a leading manufacturer of pick and carry cranes. For more than 40 years Franna has been a leader in the Australian market. Its products are at work in more than 30 countries around the world.

GGR T-Crane 1060 in pick and carry operation on a considerable slope

operates on slopes up to 15 degrees, in all directions, to help cope with rough ground.

Maximum lifting height is 7.7 metres (at which it can also carry the load) and its longest working radius is 6.1 metres, where capacity is 450 kg. Fitting a 1,000 kg detachable counterweight allows the overall weight of the crane to be reduced to 2,850 kg for easier transport and to minimise the ground pressure on site.

Power options are either a 300 amphour lithium battery and 4 kW, 48 volt, electric motor, or a 17 hp Yanmar diesel engine to run the hydraulics.

The Danfoss PVG 48 proportional valve installed in the 25 tonne Franna MAC 25

Franna’s MAC 25 mobile articulated crane offers a lifting capacity of 25 tonnes and a maximum boom length of 18.4 metres. It is designed to offer maximum safety, roadability, intuitive operation, and versatility. True to the company’s heritage, the crane’s design has been tested, proven,

and continuously improved over the years.

In 2021 Franna began looking at other options for the MAC 25’s main control valve. The company required a solution that was precise, reliable, and future proof to accommodate increasingly sophisticated electronic control systems. The Danfoss PVG 48 proportional valve,

then in development, emerged as the superior solution.

PVG 48 is a pre-compensated proportional control valve for applications requiring flow rates of up to 180 litres per minute. The latest member of the PVG loadsensing valve family, PVG 48 is ideal for machines such as cranes, aerial lifts and wheeled loaders, where precise flow and controllability are essential.

Danfoss launched the PVG 48 valve to the general market in June 2023 with Franna as a key pilot customer. On the MAC 25, the valve turns operator joystick inputs into quick, accurate boom movement.

“The PVG is extremely precise and reliable. It does what you want it to do repeatedly,” says Adam Murchie, Franna project engineer. “It’s the ideal choice for MAC 25 and likely to end up in other of our

Pick and carry cranes offer attractive capabilities for a range of global projects.

Late last year, Australian pick and carry specialist Franna, a Terex subsidiary, launched its FR17 C into the Africa, UAE and Latin America markets.

A compact pick and carry model with a short turning radius of 6.77 metres, the FR17 C is an entry-level machine for construction, mining and logistics, as well as city, yard and industrial applications where space is limited.

“For over 40 years, Franna has been a name to reckon in Australia for the design and manufacturing of quality pick and carry cranes,” says Danny Black, Terex Franna general manager.

“Bringing our concept to Africa, UAE and Latin America markets with the FR17 C is an

smooth steering flexibility, offering versatility and dependability.

Offering a lifting capacity of 17 tonnes, its compact design enhances manoeuvrability in confined spaces.

Safety features include overload protection, anti-tipping technology and a comprehensive safety monitoring system.

According to Franna, driver fatigue is reduced since there is no clutch pedal to operate, and this along with the full-width, two-person cabin provides better visibility and driving comfort.

The crane is powered by a Cummins diesel engine.

The crane’s “versatility [lends] itself well to road and metro projects and for local hire,” adds Black. ■

cranes, too – not least in future launches where more advanced electronic controls are key. We wanted a future-proof valve. PVG 48 is it.”

The PVG 48 valve integrates easily with electric actuators, sensors, and digital controls, opening a range of possibilities. One of them is to automate certain machine functions so the crane assists –or even takes over from – the operator. Such a function can be advantageous in many situations, particularly when instant reaction is required to ensure safety.

With the change to PVG 48, Franna also switched to Danfoss counterbalance valves. Together with the PVG 48, they ensure smooth and safe activation of the crane’s boom.

“Controllability is smooth and even –very refined,” says Quentin Bourke,

Franna’s FR17C pick & carry crane has a lifting capacity of 17 tonnes

Franna product support technician.

“The initial tiny bounce on the front tyres, which you sometimes see when operators raise or lower the boom, is completely gone. Extension or subtraction of the boom is impressively smooth, too.”

Bourke adds that initial feedback from crane operators using MAC 25 with a PVG 48 and Danfoss counterbalance valves is positive, too. “Together with Danfoss, we’ve managed to create the exact kind of MAC 25 crane feel that we hoped for,” Bourke says.

The Danfoss PVG 48 proportional valve is already at work in more than 100 of Franna’s MAC 25 pick and carry cranes throughout Australia.

Following hot on the heels of January’s Board & Committee meetings and February’s Specialized Transportation Symposium, talk is turning to what is already the third SC&RA event of the year. The 2024 SC&RA Annual Conference is coming up from 15 to 19 April in Texas, USA. The city of Austin is known as the live music capital of the world. This should help set the scene as the perfect balance of entertainment and networking, in addition to the important committee meetings and education sessions.

What follows is our preview outlining just what to expect at this spring event.

One of the most important ways members and attendees can understand and be a part of what’s going on in the industry is to attend SC&RA and SC&RF committee meetings. Attendees will have many opportunities to join the conversation.

Tuesday 16 April has meetings of the Crane & Rigging Group Safety, Education and Training Committee, the Allied Industries Group Safety Education and Training Committee, the Crane & Rigging Labor Committee, Permit Policy Committee, Tower Crane Committee, Insurance and Risk Management Committee and the SC&RF Educational Assistance Committee.

On Wednesday 17 April the Governing Committee will meet, along with the SC&RF Research Committee and SC&RF

Communications and Development Committee. Attend as many of these committee meetings as possible.

Listen in and engage on the most pressing workforce issues in construction, trucking and manufacturing at the first education session. An Industry Chat: Challenges and Solutions will include discussion about the workforce shortage, labour risk management, decarbonisation, electric vehicles, smart contracts, and how block chain technology can help expedite payment terms. CEO panellist speakers include Chris Spear, American Trucking Associations, Megan Tanel, Association of Equipment Manufacturers and Daniel Groves, CEO, Construction Industry Resources.

As AI captures global attention in the

Ask a panel of experts and get the latest views at first hand

business community, gain firsthand insight from AI, cyber and insurance experts on key considerations and strategies to help prepare and protect your companies. Better understand the realities and implications of AI, and the critical importance of cyber coverage. This is Getting Real: Artificial Intelligence Threats to Your Company will be led by Chris Mikolay, senior VP at National Interstate Insurance Company, Robet Willis, VP security operations at Binary Defense, Ranjit Jaswal, group chief risk officer at DUAL North America and Lawrence Baldino, president – cyber, technology, and professional liability at DUAL North America.

Wednesday’s Link-Belt Breakfast attendees will be entertained by The Bucket List Life Speaker, Kenyon Salo. Known as the James Bond of Speaking, Salo will guide you through three core principles to create more, share more and live more to live the Bucket List Life.

Beyond Coping: A Candid Conversation about Resilience, Connection and Happiness in the Workplace will be led by Johnny Crowder. Leveraging insight from his own decade-long mental health journey, Crowder shows audiences why talking about mental health should be as straightforward as talking about physical health. He’ll share how to build work cultures that support mental health and how to process mental and emotional distress in a way that builds relationships, confidence and happiness.

Well, This Is Awkward: Why People May Not Want to Work for You will spotlight an all-too-persistent truth for many companies. This presentation pulls back the curtain on what perhaps isn’t getting enough attention in the greater workforce conversation: how people are being treated at work, and why it matters. Jason Branciforte, shareholder at Littler Mendelson, Mike Chalmers, principal at WRS Consulting and Kate Lampson, director

of strategic communication at Lampson International, will discuss.

One of the biggest benefits of attending the Annual Conference is the multitude of networking opportunities. If this is your first SC&RA meeting make sure you get to the First-Timer’s Reception. Attendees can network with officers and key leaders in the Association, as well as other first timers and SC&RA staff.

A big draw at the conference is the President’s Reception, hosted by president Scott Bragg. Friday’s International and Board Reception recognises and celebrates members who travelled from afar to attend.

As the event’s grand finale, the Awards and Recognition Reception, Dinner and After Party will be held on the Friday night. The programme includes awards for membership longevity, jobs of the year in eight categories and more.

Participants will be treated to a formal dinner and live entertainment, and plenty of memories to be made with both new and old industry friends.

Another highlight is the sold-out Exhibit Center. Networking is high on the agenda at this immersive, in-person showcase. A wide range of member companies, including

Committee meetings , networking opportunities and the Exhibit Center are among many highlights of the Annual

manufacturers, media, technology, software and insurance groups will be available to demonstrate their latest offerings and answer questions.

The Exhibit Center is one of the best opportunities for immersion in the industry and for familiarisation with the exhibiting companies, their products and services. While many connections are made throughout the week at networking events, there is much to be said for swapping business cards at the Exhibit Center.

All attendees are invited to the Tacos & Tequila Fundraising event. It is designed to pair fun and philanthropy and raise awareness for the SC&RF (Specialized Carriers and Rigging Foundation) mission to support workforce development through scholarships, research, and industry awareness. Attendees will be treated to an unforgettable evening filled with tacos (of course), a live band, raffles, and a great group of friends and colleagues. Tickets are available with registration. ■

You can join and attend for free. Contact Jason Bell: jbell@scranet.org

In the swing of it:

The eighth and last 32 metre long bridge beam is lowered into place using the two cranes together

The two large wheeled mobile telescopic cranes were hooked close together high in the air instead of one at each end of the bridge beams.

Deterioration to the structure of the Hammesberg Wupper river bridge in Wuppertal Heckinghausen, Germany, initially caused implementation of temporary restrictions. Only vehicles below 30 tonnes travelling at no more than 30 km/h could cross the bridge. This couldn’t continue for long which meant the old bridge, built in 1965, had to be replaced.

Traffic disruption caused by the bridge being out of action had to be kept to a minimum. Installing a new one as quickly as possible meant making it out of precast concrete elements. Additional preparatory work

»

An unusual rigging arrangement was used in tandem lifts to install a new road bridge in Germany. Alex Dahm reports

The 700 tonne crane, left, hands over some of the load to the 450 tonner on the other bank of the river. The second crane’s hook was manually attached at height

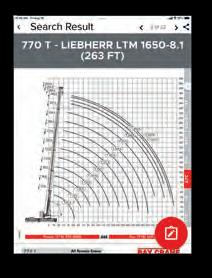

One of those simple but effective ideas. The gross load of the reinforced concrete girders, including hook blocks and triangular beam, was 95 tonnes. Depending on the radius, the LTM 1650-8.1 lifted 60 to 95 tonnes, while the LTM 1450-8.1 lifted 24 to 57 tonnes

prior to the old bridge’s demolition included completion of new bored piles and installation of new power lines across the river.

With the old bridge now dismantled it was time for its replacement. Available space was insufficient for one large heavy crane to build the new bridge. Instead, a pair of large wheeled mobile cranes, lifting in tandem, was used for the job. A 700 tonne capacity Liebherr LTM 1650-8.1 was brought in from Autokrane Schares and a 450 tonne LTM 1450-8.1 was deployed from Dornseiff Autokrane and Schwertransporte.

The cranes were erected one on each bank of the River Wupper, lined up centrally just outside the bridge’s abutments. From there they shared the lifting of eight precast concrete elements each weighing 85 tonnes. On delivery of the concrete elements the larger of the two cranes, the LTM 16508.1, lifted them from the low loader trailers as far across the river as it could manage. At that point the LTM 1450-8.1 on the other side of the river lent a hand. Following an

With both cranes now hooked on the first of the new reinforced concrete bridge beams heads towards its final position to be placed on the bridge abutments

unconventional approach working high above the ground out of a safety cage suspended from a third crane, technicians attached the hook of the 450 tonne crane to a special triangular cross beam rigging arrangement.

Eric Reichmann, Schares project manager, explained the size and capacity issue, “Even the 800 tonne LTM 1750-9.1 wouldn’t have been able to install the girders on its own. Furthermore, the transport vehicle would not have been able to drive alongside the crane. There was simply not enough space. So we had to use both banks of the river.”

The tandem lift solution required a 160 tonne capacity triangular cross beam and an additional mobile crane with a safety cage. “For this, we utilised our LTM 11004.1 with emergency take down system. When attaching the hook on the lifting gear below the triangular cross beam, different cable lengths were used to achieve a slight inclination of the concrete beams for installation on the slightly divergent abutment heights,” Reichmann continued. Each load’s total weight came in at 95 tonnes, comprising the 85 tonne bridge beam, hook blocks and the triangular cross beam lifting frame. This was split according to radius between 60 and 95 tonnes on the larger crane and 24 to 57 tonnes on the smaller one.

Over a period of two days the two cranes lifted and placed eight reinforced concrete bridge beams, each 32 metres long, across the river.

The new bridge is due to be opened by the end of March 2024, allowing all users of the L420 road to avoid having to make a 3 km detour.

■ Sales & production data

■ Annual reviews and monthly market updates

■ Detailed research reports

■ Conferences & webinars

■ Analyst calls and bespoke briefings ■ Private client research capabilities

elling a construction business is a complex undertaking that requires careful planning, strategic thinking and a thorough understanding of the industry. The sale represents not just a financial transaction but a crucial step in ensuring the legacy and sustainability of the enterprise.

One of the fundamental aspects of selling your enterprise is financial preparation. Central to this process is the ability to meticulously organise and optimise your financial records to present a clear picture of your company’s performance. Clean and transparent financial statements not only instil confidence in potential buyers but also contribute to a smoother due diligence process. If you have independently audited financials, even better.

You’ll also want to focus on enhancing profitability. This involves optimising operational efficiency, managing costs effectively and

SPECIALIZED CARRIERS & RIGGING ASSOCIATION

CHAIRMAN

Ed Bernard

Precision Specialized, Ontario, Canada

PRESIDENT

Scott Bragg

Bragg Companies, Long Beach, California, USA

VICE PRESIDENT

J Rozum

MSA Delivery Service, Canton, Michigan, USA

TREASURER

Michael Vlaming

Vlaming & Associates, Vallejo, California, USA

ASSISTANT TREASURER

Jim Sever

PSC Crane & Rigging, Piqua, Ohio, USA

ALLIED INDUSTRIES GROUP

Tonya Fry

Harry Fry & Associates, West Newbury, Massachusetts, USA

CRANE & RIGGING GROUP

Jeremy Landry

Deep South Crane & Rigging, Baton Rouge, Louisiana, USA

TRANSPORTATION GROUP

Louis Juneau

NOVA Permits & Pilot Cars, Quebec City, Quebec, Canada

PRESIDENT

Jennifer Gabel

JK Crane, Kenvil, New Jersey, USA

VICE PRESIDENT

Kate Landry

Deep South Crane & Rigging, Baton Rouge, Louisiana, USA

TREASURER

Brent Hutton

TruckStop.com, New Plymouth, Idaho, USA

showcasing a history of consistent, increasing revenue.

Diversifying revenue streams is another strategic move that can increase the appeal of your business. It not only mitigates risks associated with dependency on a single market segment but also positions the business as versatile and adaptable – factors that potential buyers often consider.

A business is only as strong as its skilled workforce, and potential buyers recognise the value of experienced and reliable employees. With that in mind, as part of the strategic preparation for sale, showcase your workers – highlighting their expertise. A committed and capable workforce is an asset that can ease the transition for the new owner. If you have an impressive employee retention rate, make it known in the sales process and help buyers understand the quantifiable value of retention.

Moving forward through your checklist, effective project management is integral to the construction industry. Demonstrating a track record of delivering projects on time and within budget only adds to the overall value. In addition, a construction business that prioritises safety and consistently delivers high-quality work stands out in a competitive market.

Along the way, legal and regulatory compliance is nonnegotiable. Business owners must ensure the company adheres to all relevant laws and regulations. To that end, addressing any potential legal issues or liabilities before the sale not only minimises risks for the buyer but also demonstrates your commitment to ethical business practices.

And of course, timing is key. You’re wise to assess market conditions and aim to sell the business during a period of economic strength or when demand for construction services is high. This is where advisors come in. Business brokers and legal experts bring valuable expertise to the table, helping to guide you through negotiations and structure a deal that aligns with your goals.

All this will eventually lead to identifying potential buyers. Whether competitors, investors or employees, it’s important that you assess the best fit for the future of the business.

Ultimately, this process will involve a lot of hard work and might take years but, if done well, these steps are fully capable of rewarding you appropriately for the time and effort you’ve put in. ■

SC&RA members gather in Mexico to kick off 2024.

Members of SC&RA from around the world met up in Cabo San Lucas, Mexico, from January 7 to 10 for the annual January Board and Committee Meetings (JBCM). There they set priorities on a wide range of issues that will impact and influence the crane, rigging and specialized transport industries in 2024 and beyond.

The Crane and Rigging Safety Education and Training Committee opened its meeting by examining crane operations in bad weather – with a comprehensive focus on operating protocols during lightning, snow and ice, rain and related visibility events and high wind.

Fire suppression systems in tower cranes was also a point of discussion, due to incidents in New York City in 2023.

Boom dollies were also discussed,

SC&RA’s Permit Policy Committee will debut its “Best Practices for Specialized Motor Carriers in Qualifying, Selecting and Utilizing Pilot and Escort Vehicle Operator Services” guide this month at the Specialized Transportation Symposium in Texas, USA, 20 to 22 February

particularly the Association’s soon-tobe released Boom Dolly Best Practices e-learning module. SC&RA senior vice president, crane and rigging, Beth O’Quinn updated the committee by explaining that the task force was recently reseated and plans to work with member company Industrial Training International (ITI) on the development of the module.

To that end, the group also discussed the new Outrigger Mat Resource Guide, which the committee was expecting to release by the end of the month.

In addition, O’Quinn reviewed SC&RA’s ongoing membership with CISC (the Construction Industry Safety Coalition), which monitors and responds to changes within OSHA (US Occupational Safety and Health Administration) rules. She

SC&RA’s 2024 meeting programme kicked off in Cabo San Lucas, Mexico, early January

highlighted how the Association was recently signatory to formal comments submitted to OSHA on several issues, including the use of leading indicators for companies’ safety programmes, clarification of employer representatives during inspections and heat injury and illness prevention. The comments urged OSHA to recognise the impact on small businesses and to develop and-or create tools to be applied across industry regardless of jobsite size and different construction sectors.

With that in mind, OSHA’s regulatory agenda includes a wealth of proposed rule changes in 2024. O’Quinn assured the committee SC&RA would be monitoring applicable changes and keep SC&RA members aware accordingly.

Also noteworthy, attendees were informed that the American Society of Mechanical Engineers (ASME) is looking to work with crane companies operating electric cranes – noting that such equipment currently isn’t captured under its B30 safety standard. This topic would be of particular interest to European crane manufacturers who sell product in the US, where electric cranes will almost certainly require B30 compliance in the near future.

SC&RA’s Tower Crane Committee described a new workforce development initiative in conjunction with the Specialized Carriers & Rigging Foundation (SC&RF) – designed to focus on towercrane-specific career pathways

Out of the Transportation Group Safety Education and Training Committee came an update on the Permit Policy Committee’s forthcoming pilot car best practices guide – aptly titled Best Practices for Specialized Motor Carriers in Qualifying, Selecting, and Utilizing Pilot/Escort Vehicle Operator Services. Chris Smith, SC&RA vice president, transportation, said the guide will be available for members as a free resource, debuting at the Specialized Transportation Symposium in Houston, Texas, USA, 20 to 22 February.

Conversations within the meeting moved towards continued difficulty for the industry to work in the US state of California due to a lack of regulatory uniformity and harmonisation beyond permits that threatens to expand elsewhere. Challenges connected to the California Air Resources Board’s (CARB) expected limitations on emissions were also considered, as well as the classification of independently contracted drivers in California as full-time employees eligible with the same benefits, rights and workers’ compensation, as other employees.

Smith also used parts of the discussion to note that “…because real and perceived concerns regarding poor safety performance by bad carriers leads to bad permit policy for all carriers, we have an obligation to advocate SC&RA members’ exemplary safety performance as a powerful advocacy tool moving forward.”

Many members in attendance agreed, and also pointed to challenges co-ordinating with utilities across North America concerning crossings during specialized load movements. Smith added that SC&RA is looking at working with utility associations in 2024 to help members achieve more efficient OS/OW moves throughout the USA and Canada.

On the tower crane side, it was brought to the attention of committee and audience members during the Crane & Rigging Group Tower Crane Committee meeting that the buzzword around the globe in tower cranes is “normal.” Association members from New York City did, however, deviate from that thinking – expressing that, due to skyrocketing costs, too much available office space and a lack of planned commercial construction, the “age of the high rise” is over in the Big Apple.

Moving on to new business, the Tower Crane Committee described a new workforce development initiative designed to focus on tower-crane-specific career pathways. They will work with the Specialized Carriers & Rigging Foundation (SC&RF) on this effort.

The Committee also informed audience members that the final draft of the new Tower Crane Best Practices Procedures document will be completed by the end of the month.

Looking ahead, the Committee reminded those in attendance that, following a very successful International Tower Cranes event last June in Barcelona, Tower Cranes North America 2024 is set for 11 and 12 June,

Committee members on both the crane and rigging and transportation sides of SC&RA discussed the emerging legalisation of marijuana in the USA and Canada, with an eye towards putting the topic on agendas at SC&RA’s Annual Conference in April

in Nashville, Tennessee – representing another wonderful chance for international companies to learn more about business opportunities in North America.

Drug testing was another topic of interest for members at the JBCM – particularly, what has fast been labelled “cannabis confusion.” In the Crane & Rigging Group Labor Committee, multiple discussions evolved around which US states and Canadian provinces have legalised marijuana, employer and employee rights, testing limits, privacy issues, the mental health component and ongoing legal ramifications connected to all of the above. The committee made a point to examine the topic more thoroughly and put it on the agenda for the next meeting at the SC&RA Annual Conference in Austin, Texas, USA, 15 to 19 April.