Since its launch 26 years ago, Demolition & Recycling International (D&RI) has been at the forefront when showcasing the very best in our industry.

Along the way, it has benefitted from outstanding editorial leadership (names like Paul Marsden, Steve Ducker and Lindsay Gale come readily to mind).

I am honoured to be the latest custodian of the Editor’s chair, though it comes with a touch of sadness as we bid farewell to my predecessor, Leila Steed.

Her work earned deep respect both within KHL and across the industry, and I know many of you will join me in wishing her every success in the future.

By way of introduction, I have been with KHL for nearly five years, working across all titles, including D&RI, as Content Editor.

More recently, I spent two years as Editor of our sister publication International Rental News. Together, those roles gave me a strong grounding in the industry, and before stepping into this post, Leila also offered me further valuable insights.

She summed up the demolition community in one word: family. She was right. Even in these first few weeks, I’ve seen how collaboration and mutual support define the sector, and I look forward to continuing that tradition with you.

Of course, this comes at an exciting moment, with preparations well underway for the World Demolition Summit in Nashville.

I’m looking forward to seeing many of you there and hearing your perspectives on the challenges and opportunities ahead.

The event also gives us the chance to celebrate all that is good in the industry through the World Demolition Awards. The shortlist for that is now set, and I can't wait to come together to celebrate in November.

For those I’ve not yet met, please feel free to reach out at lewis.tyler@khl.com. I’d be glad to hear from you.

Warm regards, LEWIS TYLER D&Ri Editor

Record-breaking demolition project; Works begin on Tesla site.

Major projects across Australia and New Zealand signal strength, with redevelopment and infrastructure renewal boosting confidence.

D&RI TEAM EDITOR Lewis Tyler lewis.tyler@khl.com

BRAND MANAGER Peter Collinson +44 (0)7957 870982 peter.collinson@khl.com

EVENTS MANAGER Steve Webb | steve.webb@khl.com

GROUP DESIGNER Jade Hudson

CLIENT DELIVERY & SUCCESS MANAGER Charlotte Kemp | charlotte.kemp@khl.com

DATA MANAGER Anna Philo | anna.philo@khl.com

DATA EXECUTIVE Vicki Rummery | vicki.rummery@khl.com

CHIEF

James King

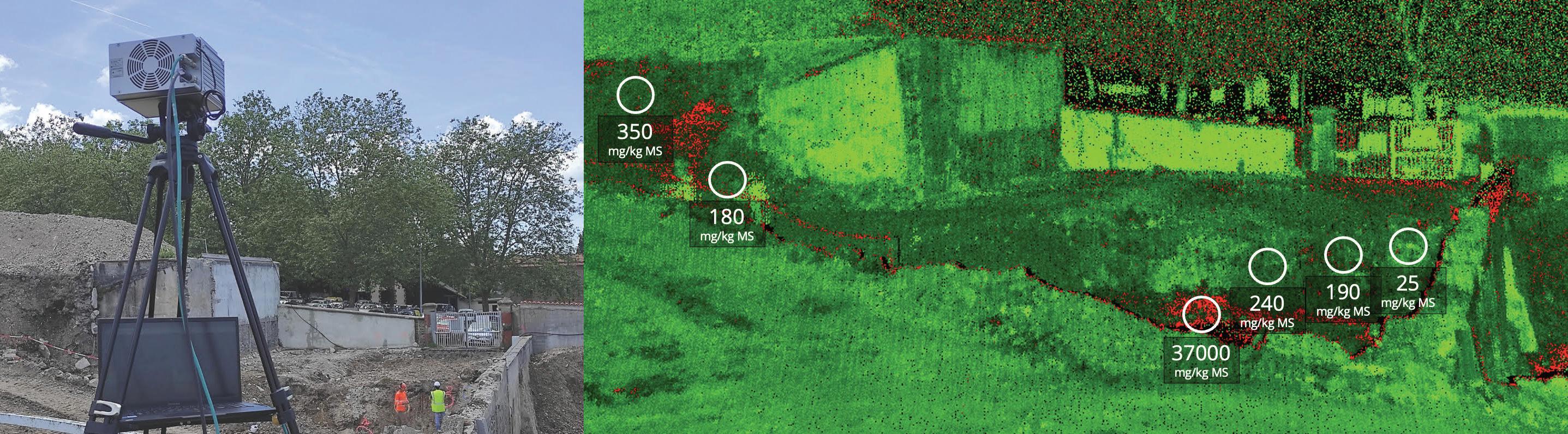

How are the latest advances in site remediation improving sustainability in demolition and waste management for contractors? Lewis Tyler reports.

38

What innovations are changing the way contractors work?

41

Rikki Isgar, Explosive Demolition Manager at Brown & Mason, explains how the company carried out a record-breaking project.

Patrick Frye, the new President of the EDA, shares his vision for the future of the association.

SOUTH AMERICA OFFICE

KHL Group Américas LLC Av. Manquehue Sur 520, of. 205,

OFFICE

KHL Group Americas LLC 14269 N 87th Street, Suite 205 Scottsdale, AZ 85260, USA +1 480 630 0793

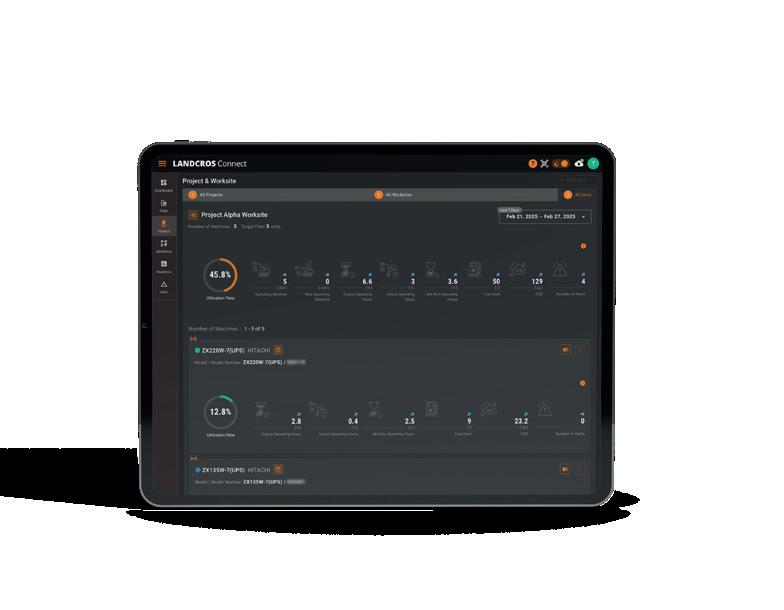

Our user-friendly all-in-one fleet management system gives you instant access to vital performance data on all your equipment. It even collects data from other manufacturers’ machines, giving you a complete overview of your entire fleet. With custom reporting tools focusing on key metrics, and smart geofencing for precise productivity tracking, you’ll have everything you need to boost the efficiency of your machinery and save you valuable time.

Some of the stories currently online at www.demolitionandrecycling.media

United States-based specialists Dykon Demolition, Precision Blasting Services and Academy Blasting have merged to form DetX, a new company focused on providing explosives-related services across North America and beyond.

The photo shows Founder and CEO Dr. Anthony Konya (centre) with Ron Gilbert, VP Blasting Operations (left) and Roland Alford, Managing Director of Alford Technologies and DetX Alford (right). ■

View these stories and more:

Open-S attachments alliance announces three new members

Japanese rental company Nishio Rent All, US-based attachment supplier A&D Equipment (USA) and Netherlands manufacturer Zijtveld Grijpers are the latest companies to join the Open-S Alliance, the initiative to create an industry standard for automatic couplers for excavators.

Contractors named on £93m demolition framework in the UK

Colemans, Lucion Services and Demolition Services Ltd are among the contractors to be named on a new £93.75 million asbestos, demolition and water hygiene services framework. ■

Liberty Industrial has completed the demolition of cyclonedamaged infrastructure at Milner Bay Wharf on Groote Eylandt, using subsea technology to manage the complex marine project. The contract, awarded by McConnell Dowell, followed damage sustained during the 2023–24 cyclone season. The scope included the removal of structurally compromised sections of the wharf to allow reconstruction to proceed.

Sandvik has finalised the acquisition of OSA Demolition Equipment S.r.l., an Italian manufacturer of hydraulic hammers and demolition tools, following the announcement of the deal earlier this year. ■

Skanska US Northeast has signed a contract with the Massachusetts Department of Transportation (MassDOT) for the demolition and replacement of the Rourke Bridge in Lowell, Massachusetts, United States. Skanska’s contract to dismantle and replace the structure is valued at US$347 million (approximately SEK 2.8 billion), with the order set to be included in Skanska’s US order bookings for the second quarter of 2025. ■

The National Demolition Association (NDA) has launched its new Demolition Workforce Development Toolbox, a professional development platform aimed at helping member companies recruit, train and retain talent across the industry.

The demolition of the former Tesla industrial site in Lanškroun, Czech Republic, is currently underway as part of redevelopment plans for a new radio frequency chip production plant. Czech contractor BISA Spol is using a Develon DX380DM-7 demolition excavator to dismantle the four-storey structure’s external walls and chimneys. ■

A major decommissioning project has been completed at the former Sizewell A nuclear power station in Suffolk, United Kingdom, with the demolition of a turbine hall and its adjoining structures. The works were carried out by demolition specialist Erith, on behalf of Nuclear Restoration Services (NRS) and included the removal of more than 17,000 tonnes of concrete and rubble.

Multifunctional and powerful

Three equipment variants: 17 m, 23 m longfront or digging equipment

High load capacities over 360°

Equipment change within minutes thanks to quick-change system

Maximum safety and cost effective transport

Extreme stability (4.5 m support width)

Optimum view due to elevating cab < 3 m transport width

For further informationen sennebogen.com/830-demolition

Sebastian Loibl

SENNEBOGEN

DEMAREC tools proves every day that good tools are literally and figuratively speaking more than half the battle.

In fact, in the end the correct piece of equipment determines the success and outcome of each job.

Therefore, DEMAREC advises its contacts to focus on the piece of equipment and not on the machine, never the other way around!

Thus, it is never ever necessary to surrender any capacity and as a result any (business) performance and profits. In other words, an investment in a DEMAREC tool is much more than a sound investment that is guaranteed to repay itself 100%!

The performance of a concrete or scrap shear is especially important when mounted on a high reach demolition machine.

For this type of machine, the maximum tool weight is defined by the manufacturer. That’s why the 20–25% performance increase offered by DEMAREC’s PremiumLine demolition tools — thanks to the DemaPower system — will make the difference. The job will be completed much faster.

It can determine whether a demolition job is carried out quickly and efficiently, without the need to force or pry with the tool.

A proven innovation from DEMAREC since 2004 for the PremiumLine products.

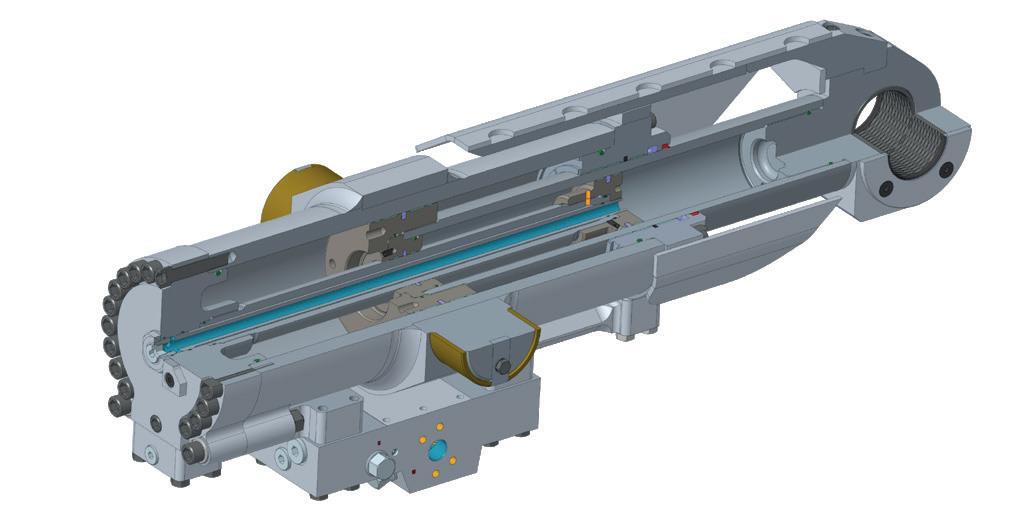

In 2004, DEMAREC introduced the first generation of DemaPower cylinders to the market. Thanks to their immense power and extremely fast cycle times, this cylinder technology has remained a benchmark to this day. It was developed by Ruud de Gier, one of the cofounders of DEMAREC. This cylinder technology is still used in the Multi-Quick Processors, static pulverizers, the Dedicated Demolition Line tand rail cutters.

In 2017, the second generation of DemaPower cylinders, called DemaPower 2.0, was introduced. These cylinders feature eyelets on both the rod side and the cylinder base, enabling them to be integrated into the DCC 2-cylinder concrete shears and DXS mobile scrap shears. Thanks to this special cylinder technology, the DCC and DXS cylinders offer unparalleled high performance.

The key difference between DemaPower cylinders and conventional cylinders with a standard speed valve is that the cycle times of DemaPower cylinders are significantly faster, as the cylinder not only extends quickly (jaw closing) but also retracts quickly (jaw opening).

In practice, this results in a tremendous increase in productivity, as the productivity gain when opening the jaw is always 100%.

In comparison with cylinders that use boosters, the major advantage of the DemaPower cylinder is that it is always under pressure, while a booster cylinder must first build pressure, which takes time.

20 to 25% more power! (due to 20 to 25% more surface area)

Four pressure chambers instead of two, like conventional cylinders

Extremely fast cycle times thanks to a double-acting speed valve

The demolition and C&D waste recycling sectors in Australia and New Zealand are gaining momentum as governments, contractors and technology providers seek to balance booming infrastructure demand with pressing environmental goals.

In Australia, for example, the Dept. of Climate Change, Energy, the Environment and Water found that the construction industry generated around 29 million tons of waste in the most recent reporting year — accounting for roughly 39% of all waste nationwide.

Meanwhile, New Zealand generates an estimated 7 million tonnes of C&D waste annually, with around 40% of landfill inputs linked to construction and demolition, according to government and industry estimates.

James Murphy, Head of Sales - Asia Pacific at CDE, says that while both countries have aggressive targets, much more can be done with soils — the single largest contributor to construction waste. “If there’s an area that really needs development, it’s material standards. Not just locally, but globally, there’s a strong push towards performance-based material standards rather than the traditional, highly localised specifications.”

He adds that in practice, this can be a barrier. “For example, high-quality recycled soils and aggregates meet or exceed engineering performance benchmarks.

"Where performance-based standards have been applied, those same materials have been successfully used in major road and civil projects, proving the quality is there.

“Moving in this direction would unlock far greater use of recycled materials across Australia and help the sector scale much faster.”

Of course, the sector’s growth is closely tied to infrastructure pipelines. In Australia, road, transport and utilities projects remain one of the largest pipelines for recyclers.

A significant boost to companies come in the form of 998 road projects scheduled nationally by 2031, which, according to the Government, will require around 200 million tonnes of conventional materials, of which more than 95% come from just five sources: aggregates, asphalt, rock/bluestone, sand and cement.

However, its estimates suggest that 27% of these could be substituted with recycled alternatives — equivalent to more than 50 million tonnes of materials.

From soil recovery to smart demolition, new technologies are helping the sector in Australasia balance growth with sustainability, while project pipelines underpin confidence.

New Zealand’s outlook is similarly positive. While short-term construction growth has softened, cost pressures are easing and medium- to long-term investment in transport and water projects remains strong.

Council-led urban regeneration in Auckland is also boosting both the volume and quality of recoverable materials.

That circular goal is tied to a larger sustainability demand within the region, with companies being tasked with lowering greenhouse gas emissions which the Government says should “be

considered at all stages of the infrastructure lifecycle.”

With that, Murphy describes demand for low-carbon solutions as “immense”. He says: “In Australia alone the economic value of the construction materials sector is estimated north of $60 billion.

“Demand for low embodied carbon solutions is expected to rise significantly, recent reports estimate it could result in a billion dollar low carbon solutions market in the coming years.”

He adds that with the building and construction sector accounting for around 40% of global emissions, the opportunity to integrate recycled aggregates and soils into major works is significant.

“Ultimately, CDE believes that attitude and legislation must catch up with current technology and innovation to adopt an

application-based approach and enable the re-use of recycled materials to achieve the desired effect on the sustainability of natural resources.

“We’re seeing more mandatory reporting requirements and a stronger push from stakeholders to demonstrate environmental impact.

“Material efficiency, water use and emission data all influence procurement decisions.

"There is a raft of government policy, landfill levies, and procurement frameworks that reward low-carbon or recycled content.”

Meanwhile, Australia’s landfill levies and recycled-content procurement incentives are already creating an enabling framework, though inconsistent planning and permitting between states remain barriers.

In New Zealand, landfill levies and the government’s Waste Strategy are pushing the market in the same direction, although data gaps continue to limit fully targeted policymaking.

New Zealand also has a long way to go with land fill levies in order create a fund to incentivize investment in new technologies which will truly drive landfill diversion.

Interest rate reductions across both countries have improved financing conditions.

In August, the Reserve Bank of Australia cut the cash rate to 3.6%, while in New Zealand, borrowing costs are expected to stabilise in the 3–4% range in the next year.

Murphy says this could revive previously delayed projects and stimulate recycling demand: “We continue to watch the market closely, interest rates are forecast to hold steady in the 3–4% range over the next year, easing borrowing costs for businesses.

"This stability could revive previously delayed projects and enhance affordability across construction segments.”

In March this year, the state of Victoria unveiled its draft 30-year infrastructure strategy which includes recommended investments of AU$55 billion that is says could provide AU$155 billion worth of benefits over the next decade if actioned.

Infrastructure Victoria named 50 priorities for the state across housing, energy, transport, health, social infrastructure and the environment as part of its draft 30-year infrastructure strategy. The strategy outlines 43 draft recommendations.

“Investing in new infrastructure is one way of building a more productive economy, and more will be needed as Victoria grows,” said Infrastructure Victoria Chief Executive, Jonathan Spear.

“But there is also lots the government can do to make better use of what it already has. The government can prioritise getting better use from its existing assets, improve how it maintains infrastructure so it performs better and lasts longer, and publish long term plans so that other governments, industry and not-for-profit providers can make better informed choices on where and when to invest."

The strategy highlighted how digital technologies can also produce big savings.

Perhaps underpinning project confidence, Liberty Industrial recently completed the demolition of cyclone-damaged infrastructure at Milner Bay Wharf in Australia’s Northern Territory.

The project scope included removal of structurally compromised sections to allow reconstruction works to proceed.

Remotely operated vehicles (ROVs) and daily 3D sonar imaging were deployed to assess submerged structures and guide dismantling in poor underwater visibility. In total, six tonnes of asbestos-containing material were safely removed and disposed of.

Project Manager Mathew Clenton, said: “Our ability to mobilise immediately and apply engineered solutions in such a remote and challenging environment ensured the safe removal of damaged infrastructure, and enabled our client to proceed with reconstruction works without delay.”

Meanwhile,

Follow the QR code to see McMahon’s project in Tasmania.

McMahon Services has been undertaking the controlled demolition of the Bell Bay Power Station in Tasmania.

Working with Hydro Tasmania, the company used 28 kg of explosives in a precisely timed blast to bring down the 24 m-high, 63 m-long structure within a 400 m exclusion zone.

Hazardous materials were managed

under strict controls. The site will make way for ABEL Energy’s green hydrogen and methanol facility, which aims to produce 360,000 tonnes of renewable methanol annually from a 300 MW electrolysis plant and biomass gasifier.

The process will draw exclusively on renewable hydro and wind energy, combined with forestry residues. ■

MAXIMUM PERFORMANCE

LOWEST OPERATIONAL COSTS

HIGHEST RELIABILITY

The World Demolition Summit is returning to North America, with an array of speakers to discuss key industry challenges.

Taking place in Nashville, US, on the 3-5 of November, WDS 2025 promises a powerhouse speaker line-up, with industry leaders tackling demolition’s biggest challenges and opportunities.

From sustainability, regulation and AI to electrification, explosive engineering and contractor-owner dynamics, the programme showcases bold perspectives and practical expertise, making Nashville the place to be for demolition professionals this November.

Sustainability Is Stewardship: How Demolition Contractors Can Lead Beyond the Jobsite

Michele O’Rourke, CEO of O’Rourke Wrecking Company (VIP speaker)

Known for leading high-profile and technically complex projects, Michele is also a passionate advocate for sustainability, workforce development, and community impact.

As one of the few women CEOs in the industry, she brings a bold, purpose-driven perspective to demolition leadership.

Topic to be confirmed

Stephen Farner, International Vice President, LIUNA (VIP speaker)

Currently also serving as Regional Manager for LIUNA’s Ohio Valley and Southern States Region, and as an Executive Director in the Office of the General President, Steve has spent his entire career in construction labour. He joined LIUNA while still in high school and worked on various construction projects while earning a degree in Business Administration from East Tennessee State University.

Steve went on to serve as Business Manager of his Local Union and later of the Tennessee Laborers’ District Council. He was subsequently appointed as an International Representative with responsibility for LIUNA’s multi-state agreements with the Tennessee Valley Authority.

Throughout his career, he has worked with a broad spectrum of stakeholders, including union members, benefit trust funds, utility owners, contractors, regulators, and elected officials. In his current role, he is involved with LIUNA’s Construction, Corporate Affairs and Organizing Departments.

Jose Blanco, European Demolition Association

Blanco has led the EDA since 2010 and also serves as Secretary General of the European Decontamination Institute.

His perspective is rooted in two decades of hands-on experience with European policy, association leadership, and industry practice.

Rick Boyd, Dominion Energy

As Director of Generation Projects, Rick is responsible for capital maintenance works at Dominion’s active generation facilities and for overseeing the decommissioning and demolition of the company’s retired plants.

Since 2019, his team has carried out eight demolition projects — including five that were planned and executed in parallel during a two-year period.

Rick, who has a background in the coal, natural gas and timber industries and who has served at Dominion for almost 25 years, will draw on his experience to share insights on contractor vetting, including the factors that utility firms consider when choosing bidders.

Jason Curtsinger, Tennessee Valley Authority (keynote speaker)

Jason joined TVA in 2019 as Engineering Manager for heavy civil projects and moved into the utility’s Demolition Program in 2023.

Since then, he has played a central role

in the takedown of five coal plants, one gas plant, and multiple ancillary structures across the TVA network.

A civil engineer by training, Jason has also led efforts to foster collaboration within the demolition industry, including the creation of peer networking groups and regular contributions to industry events.

Michael Metzner, Metzner Recycling, and Peter Bauer, Volvo CE

Michael Metzner trained as an Automotive Mechatronics Technician before gaining practical experience as a Truck and Construction Machinery Mechanic.

He then worked as a Construction Manager for five years before advancing his qualifications with a Master’s degree in Road Construction at the Joseph Greising School in Würzburg.

Following his studies, Metzner continued his career as a Construction Manager and later as an Operations Manager.

Since 2006, he has been Chief Executive Officer and Owner of MMRHP – Metzner Recycling GmbH, based in Frensdorf, where he has led the company’s growth and operations for nearly two decades.

At WDS 2025, Michael will present alongside Peter Bauer, Segment Leader for Building & Deconstruction at Volvo Construction Equipment.

After completing professional training as an industrial mechanic at Papier-Mettler Group in Morbach, Bauer performed alternative service in the forestry department before pursuing studies in Mechanical Engineering at the University of Applied Sciences Trier.

During this time, he gained hands-on experience through an internship at Terex Demag Cranes and completed his diploma thesis at Herrenknecht AG, specializing in tunnel drilling machines.

In 2006, Bauer joined Volvo Construction Equipment in Konz as a Special Application Engineer. Four years later, he took on the role of Product Owner for Wheeled Excavators, a position he held for over a decade, leading product development and innovation within the product portfolio.

Since 2022, he has served as Segment Leader for Building & Deconstruction at Volvo CE, where he is responsible for steering strategic growth and customer focused solutions for the industry.

Mahesh Bailakanavar, Thornton Tomasetti

Dr Mahesh Bailakanavar PhD CFEI, Vice President of Applied Science practices at Thornton Tomasetti, is an expert in both mechanical and aerospace engineering with an engineering mechanics doctorate from Columbia University. Mahesh manages a diverse portfolio of projects in the field of engineering risk and safety management.

These include including demolition/ decommissioning of public/private infrastructure, power plants and industrial facilities, forensic investigations, emergency response, and integration of artificial intelligence & machine learning (AI & ML) technologies for engineering applications.

His area of expertise extends from threat, vulnerability and mitigation assessments for critical infrastructure for extreme events, including blast and fire, to hazard assessments for fire and explosions, plume analysis, and the design of active and passive hazard mitigation systems.

During his career at Thorton Tomasetti, Mahesh has led numerous projects involving both mechanical deconstruction and implosion to manage safety and mitigate

3 NOVEMBER

VIP DAY

12:30 – 17:00 Exclusive

VIP networking & sponsor presentations, including keynotes from:

■ Michele O’Rourke, CEO, O’Rourke Wrecking Company – Sustainability is Stewardship: How Demolition Contractors Can Lead Beyond the Jobsite

■ Steve Farner, International Vice President, LIUNA

19:00 – 21:00 VIP Welcome Reception (invitation only)

4 NOVEMBER

07:45 – 12:00 VIP

Guided Tour (including project site visits and Nashville attractions)

■ Morning tour of Nashville

■ Includes demolition projects

■ Includes Nashville’s key tourist sites

Meet: Foyer at Caption by Hyatt Downtown Nashville – The Gulch - 07:45 Return: Music City Center & Foyer Caption by Hyatt – 12:00 12:00 – 13:30 Registration & Networking Lunch

13:30 – 13:40 Opening Welcome & Housekeeping (Conference Chair Connie Clearwater, Priestly Demolition)

13:40 – 13:45 Official welcome from Ben Hayden, President of the NDA

13:45 – 14:15 José Blanco, EDA – European Regulatory Changes and their Impact on Demolition Companies

14:15 – 14:45 Rick Boyd, Dominion Energy –How Owners View Risk on Demolition Projects

14:45 – 15:15 Panel Part 1: Technology &

Sustainability: How technology advancements are transforming machinery and what it means for demolition and recycling companies. From heavy equipment and attachments, to site management and safety, what will the latest advances in electrification, artificial intelligence and robotics mean for onsite workflows and practices?

15:15 – 15:45 Coffee & Networking Break 15:45 – 16:15 Panel Part 2: Technology & Sustainability: How technology is impacting material identification, sorting, handling and processing, and how it’s shaping the circular economy. From the demolition site to the marketplace, how creating cost-efficient value chains for materials will impact demolition and recycling activities and contribute to sustainable practices.

16:15 – 17:15

KEYNOTE – Jason Curtsinger, Tennessee Valley Authority –Concrete Stack Squatting and an Innovative Felling Technique 17:15 – 17:45 Michael Metzner, Metzner Recycling, and Peter Bauer, Volvo CE - First Full Electric Deconstruction Site Report 17:45 – 17:50 Closing remarks 17:50 – 20:00 Opening & Welcome Drinks Reception 5 NOVEMBER 08:00 – 09:00 Breakfast Networking, 09:00 – 09:15 Welcome – Conference Chair Connie Clearwater, Priestly Demolition 09:15 – 09:45 Mahesh Bailakanavar, Thornton

Tomasetti – Integration of AI and ML Technologies into Demolition to Promote Sustainability, Risk and Safety Management

09:45 – 10:15: Richard Vann, RVA GroupGetting the Scope Right 10.15 – 11.00 Coffee Break & Networking 11.00 –11.30

KEYNOTE – Simon Hébert , Delsan-AIM –Presentation topic to be confirmed

11.30 – 12.00 Cormac McLean, PDC Explosives Engineering - Sustainable Demolition: Can we blast our way to Net Zero? 12.00 – 13.15 Lunch Break & Networking 13.15 – 13.45 Alex Hadden & Alex Ellison (Brown and Mason)Experience & Exuberance: Leveraging Personal & Professional Legacies to Drive the Future of Demolition 13.45 – 14.15 Chris Dowdell, Koch - Why a Contractors’ Culture and Values are Important to Owners 14.15 – 15.00 Coffee Break & Networking 15.00 – 15.30 Kate Bester, Jet DemolitionGrit and Grace: How an Oncology Ward Taught me about Control, Humility and Resilience 15.30 – 16.00 Ryan Priestly (Priestly Demolition Inc) & Andrew Turk (Cameco) - The Deconstruction of the UF6 Building 27 at the Cameco Conversion Facility 16.00 – 16.15

Closing remarks 18.30 – 19.45 Preawards Drinks Reception 19.45 – 22.00: World Demolition Awards & Gala Dinner 22.00 – 23.00: Post-Dinner Drinks

Please note, timings, speakers and topics may be subject to change.

risk by validating the demolition plans against engineering analysis.

Richard Vann, RVA Group

With more than 40 years experience, Richard has led over 1,000 projects worldwide, providing guidance in sectors such as power generation, chemical, petrochemical, pharmaceutical and oil and gas.

Under his leadership, RVA Group has become a leading name in complex decommissioning, working with major global brands including BASF, INEOS, ENGIE, ConocoPhillips, and GSK.

His extensive industry contributions go beyond project execution. A former president of both the Institute of Explosives Engineers and the Institute of Demolition Engineers, Vann is also an Honorary Fellow of the IDE and a respected keynote speaker and awards judge at international events.

Simon Hébert, Delsan-AIM (keynote speaker)

Simon has worked in the demolition industry for more than 20 years, mainly in civils infrastructure dismantling.

He began his career in the sector as a

HEADLINE

Volvo Construction Equipment PLATINUM

Komatsu, Steelwrist GOLD

Caterpillar, Kobelco, OilQuick, LIUNA SILVER

Epiroc, LaBounty, Genesis NETWORKING COCKTAIL RECEPTION

Fortress, by Shearcore AWARDS DRINKS

Demarec

BREAKFAST SPONSOR

Kocurek

POST-DINNER DRINKS RECEPTION

Tiny’s Demolition & Recycling BRONZE

ACDE, KTEG, Okada, Rotar, Sennebogen

LANYARD SPONSOR

Company Wrench

WATER SPONSOR

Delsan-AIM

WINE SPONSOR

FieldFlo

APP SPONSOR

Open S

project manager for a contractor specialising in bridges and highway overpass removal, and in 2015 joined the Delsan-AIM Environmental Services Team to manage its civils department.

Simon played a key role in one of the most celebrated demolition projects of recent years—the dismantling of the original Champlain Bridge in Montreal, Canada.

Sustainable Demolition: Can we blast our way to Net Zero?

Cormac McLean, PDC Explosives Engineering

Born into a demolition family, Cormac has been immersed in the industry his entire life. As the Managing Director of PDC Explosives Engineering, he leads a specialist team that uses explosives to solve complex civil engineering challenges.

His role spans the business’s day-today operations and its expansion into new markets—both in terms of technical capabilities and geographical reach.

Cormac combines a strong foundation from a formal structural engineering education with hands-on training from some of the most experienced professionals in the field.

&

Alex Hadden & Alex Ellison, Brown and Mason

With over two decades of experience and more than 100 explosive demolition events to his name, Alex Hadden brings deep technical knowledge and operational oversight to the event.

Alex Ellison, who joined Brown & Mason in 2024, has a background in digital transformation, policy, and communications.

Prior to joining Brown and Mason, Ellison led the marketing and project management functions of the UK’s National Federation of Demolition Contractors.

Chris Dowdell, Koch Industries Chris is a demolition and decommissioning professional with over 20 years of industry expertise in contracting, consulting, and project management. His career spans business development, project management, and cost estimation for complex demolition projects.

As a Senior Demolition Project Manager at Koch Industries, Chris manages risk, develops project scopes and budgets, and oversees the safe and efficient decommissioning of retired assets. He collaborates with facility stakeholders, contractors, and consultants to align projects with business objectives while maintaining safety and efficiency.

Grit and Grace: How an Oncology Ward Taught me about Control, Humility and Resilience

Kate Bester, Jet Demolition

Kate Bester is a Contracts and Project Manager at Jet Demolition, a specialist in large-scale heavy industrial and commercial demolition. With over 20 years of experience in civil engineering and large-scale heavy industrial demolition, Kate combines technical proficiency with a practical, people-focused approach.

She began her career as a resident engineer with a multinational civil engineering consultancy before joining Jet Demolition 12 years ago.

At Jet, she manages turnkey projects, through bidding to close-out, and leads its marketing initiatives.

Kate has managed complex large-scale demolition and construction projects in a wide range of industries and is committed to continued development of professional standards within the demolition industry.

She also serves as a member of the Jet executive team.

The Deconstruction of the UF6 Building 27 at the Cameco Conversion Facility

Ryan Priestly (Priestly Demolition Inc) & Andrew Turk (Cameco)

Based in Ontario, Canada, Ryan has spent more than 30 years with the family business and now focuses on partnership development, fleet management, and building relationships with key industry stakeholders.

Under his leadership, PDI has taken on many of Canada’s most complex, high-risk demolition projects — including several that have earned both World Demolition and National Demolition Awards.

Meanwhile, a professional electrical engineer, Andrew has previously worked on remote mining and industrial projects and has led Cameco’s Port Hope remediation efforts for the past eight years.

His role has centred on the company’s long-term environmental programme to clean up legacy waste and modernise operations at the Port Hope Conversion Facility in Ontario. ■

From record-breaking blasts to precision engineering feats, the World Demolition Awards is set to showcase the industry at its finest once again.

First held in 2009, the World Demolition Awards recognise and celebrate the innovation, excellence, and dedication of the companies driving the industry forward.

Over the years, the event has grown in scale and reputation, becoming a benchmark of achievement across the global demolition sector.

Winning a category is not only a mark of professional success but also an acknowledgement of the industry’s continuous drive towards safer, smarter, and more sustainable working practices.

Held in conjunction with the World Demolition Summit, the ceremony takes place on the evening of 5 November at the Music City Center in Nashville, Tennessee.

Following two days of conference sessions, technical papers, and networking opportunities, the awards night is the culmination of a week of collaboration, bringing together contractors, OEMs, consultants, and clients to celebrate the very best in the business.

This year’s event is shaping up to be one of the most exciting in recent memory, with 39 companies from 17 countries making the final shortlist.

The judging panel (see box story) once again brings together some of the most respected figures in the field, representing contractors, manufacturers, clients, and trade associations from across the globe.

Their combined expertise ensures a rigorous, balanced assessment of the entries for the following categories in the World Demolition Awards: Civils, Collaboration, Contract of the Year under US$1 million, Contract of the Year over US$1 million, Explosive, Industrial, Manufacturer Innovation: Plant & Equipment, Manufacturer Innovation: Tools & Attachments, Safety and Training, Recycling & Environmental, and Urban.

A 12th award, the Best of the Best World Demolition Award, will also be handed out to one of the above category winners in recognition of its standout features.

This accolade is regarded as the pinnacle of the programme and is reserved for an entry that goes above and beyond in terms of ambition, execution, and impact.

With Nashville set to host this year’s World Demolition Awards, anticipation is building for what is set to be a memorable gathering that will not only honour individual excellence but also showcase demolition at its most innovative and dynamic.

D&RI wishes to thank the judges for their valuable time and input throughout the course of the judging process.

■ Henrik Bonnesen – Cowi, Denmark

■ Leonard Cherry - Cerise Family - USA

■ Francisco Cobo – European Demolition Association

■ LaJuan Counts – City of Detroit, USA

■ Dan Collins – Kobelco

■ Dan Costello – Costello Dismantling, USA

■ Tony den Hoed – Volvo Construction Equipment

■ Clinton Dick - Liberty Industrial, Australia

■ Patrick Frye – Cardem, France

■ Karel Glaaser – ACDE Europe

■ Jim Graham – Winter Environmental, USA

■ Gordon Hambach – Epiroc

■ Ben Hayden – President, National Demolition Association

■ Bill Moore – Former President of the National Demolition Association

■ Michele O’Rourke - O’Rourke Wrecking, USA

■ Walter Reeves – Steelwrist

■ David Sinclair – Safedem, USA

After taking place in Stockholm, Sweden, last year, the World Demolition Awards returns to North America in 2025. PHOTOS: D&RI/KHL

PC390HRD-11 and PC490HRD-11

The K100 system allows the configuration of your Komatsu high reach demolition machine to be changed within minutes, from the safety of your cab without any outside help. Use the most effective attachment at any stage of the project for a new level of demolition efficiency, whether you choose the PC390HRD-11 or PC490HRD-11.

COUNTRY Germany

PROJECT Reinbrucke Demolition

CLIENT Hochtief Infrastruktur GmbH

The Rheinbrücke Neuenkamp had exceeded its technical lifespan. Tens of thousands of repairs were needed to keep it safe and operational.

To handle increasing traffic, a new bridge was built. In March 2024, the dismantling of the original bridge began— a project led by Hochtief and DDM. The demolition was carried out in reverse order of construction, requiring precise planning and accuracy.

One of the biggest challenges was developing a working method that met

COUNTRY Italy

PROJECT Ex Centro Direzionale Alitalia

CLIENT Freccia Alata

In a changing urban context, the regeneration of the neighbourhood was being hindered by a large, abandoned building complex. Due to its location between inhabited buildings and busy streets, its demolition required an extremely careful approach to ensure safety, quietness and an absence of vibrations.

The objective was to work unobtrusively, respecting time, people and the environment. Every step was precisely planned, beginning with a detailed Operational Safety Plan.

The area was protected by barriers and electronic controls, and a real-time environmental monitoring system ensured compliance with regulatory limits. JUMBO, Europe’s largest excavator and a converted CAT 6015, was the star of the operation.

strict safety and environmental protection requirements. The safety of river traffic had to be continuously ensured.

No materials were allowed to fall into the water, and no work could be performed from the river itself. These restrictions demanded an innovative approach.

A critical element was removing the existing stay cables without the bridge collapsing under its own weight. To achieve this, DDM installed a 25 ton pylon cap at 50 m height to redirect the forces from temporary support cables and strand jacks.

The new bridge remained operational and river traffic uninterrupted. Despite challenges, the project was completed on schedule within 20 months. ■

Weighing 351 tons and equipped with an 8.1 m³ bucket, it could dig to a depth of 7.9 m and deliver 556 kW of power. This allowed the use of heavy equipment while maintaining a safe distance.

Its structure is made of low-strength carbon steels to detect abnormal deformations. Supported by other large excavators, the team worked to hit deadlines and keep dialogue with the community. ■

COUNTRY Germany

PROJECT Construction of crossover

A3/A67 Mönchhof-Dreieck

CLIENT Die Autobahn GmbH des Bundes Bridge demolition during traffic was the challenge for Max Wild during the demolition work of the connecting ramp above the highways A3 and A67.

To ensure this process was carried out efficiently and safely while the highways were in use, the bridge superstructure had to be lifted 5.20 m first, and then a 130-m-long and 1,200 ton heavy supporting structure was inserted. Max Wild dismantled the existing bridge, without traffic interruption. 6,000 tons of concrete was demolished and fully recycled. Prior to the demolition, a supporting framework was inserted.

The supporting framework provided protection for the highways below during the demolition works. For the supporting framework to be inserted, the 104-m-long and approximately 3,200 ton heavy bridge superstructure was lifted 5.20 m.

Max Wild ‘stacked’ the bridge superstructure upwards using (20) hydraulic jacks. The jacking operation was controlled with a synchronized lifting system developed by Max Wild specifically for this project.

Max Wild was responsible for the complete services including project management, design, and the execution of all deconstruction works, and has completed the project ahead of schedule. ■

COUNTRY Philipines

PROJECT DDM Asia Philippines –

EPRD Refinery Demolition project

CLIENT Oil company in the Philipines DDM undertook the task of transforming a refinery into a World-Class Tank Terminal. The projects defining challenge? Executing a safe, large-scale demolition using 75% local workforce, many of whom had limited experience in industrial decommissioning.

To succeed, DDM built a team combining European technical experts and Filipino employees. Through team-building sessions, hands-on mentoring, and HSSE planning, DDM fostered mutual trust, skillsharing, and a culture of joint responsibility.

Dismantling work included the removal and sustainable recycling of process installations, gasspheres, crude oil tanks, and site buildings. Despite working within a live facility, the team achieved zero safety incidents and a 99% recycling rate.

The project delivered lasting social value. Local workers gained transferable skills and several progressed into leadership roles. ■

COUNTRY Australia

PROJECT Chifley South Tower Demolition

CLIENT Built Pty Ltd

The Chifley South Tower project showcased collaboration amid complexity. Mann carried out the demolition of the South Tower whilst the adjacent 43-storey Chifley North Tower remained fully operational, despite thousands of services running through the demolition zone.

The project required extensive unity, with Mann leading the development of a staged program, facilitating daily interface meetings and workshops to ensure every move was aligned with all involved.

A major challenge was the hand stripout of 18,000 m² of office fit out due to limited service disconnections. This enabled service trades to follow behind, identifying, isolating, and rerouting live systems without disrupting North Tower operations.

An evolving scope on the retention system became a collaborative highlight. Initially a temporary measure, it served as the client’s permanent retention solution. ■

COUNTRY Argentina

PROJECT Calidra San Juan

CLIENT Calidra

Grupo Mitre partnered with steel producer ArcelorMittal Acindar and lime manufacturer Calidra to transform the Calidra San Juan project into a benchmark of circular collaboration. The intervention spanned four industrial plants located in the mountain regions of San Juan province, all within continuously operating production environments.

The challenge involved dismantling steel and concrete structures using flame cutting at height, precision lifting, and specialized equipment including 200 ton cranes, demolition robots, and access platforms reaching up to 40 m. A platform was developed to allow a demolition robot to enter the kilns and extract refractory bricks.

It is being executed under ISO integrated certification, with strict safety protocols in place to address extreme temperatures and exposure to lime, with zero incidents to date. Thanks to the collaboration, over 5,000 tons of scrap metal are being recovered and recycled, aligning it with circular economy principles. Scheduled for six months, it will be completed in four. ■

COUNTRY Scotland

PROJECT Wyndford Demolition

CLIENT Wheatley Group

No longer is it just the technical aspects that demolition professionals are faced with. External factors, political activists, building conservationists, environmental concerns, embodied carbon, and nearby residents who are “anti-demolition” are all challenges.

At Wyndford in Glasgow, Wheately and Safedem faced challenges that replaced the client-contractor contractual approach with a collaborative partnership that drew upon 24 organisations to support and deliver a safe and successful project. ■

COUNTRY Vanuatu

PROJECT Resurrecting Earthquake

Damaged Vanuatu

CLIENT Port Villa City

Ward Brunet Ltd, a collaboration between Ward Demolition and Pierre Brunet Enterprises, was formed to re open Port City following an earthquake, with 15 out of 20 damaged structures demolished thus far.

Challenges included having to adapt the equipment available on an island with limited resources, while improved safety equipment and procedures to combat a relaxed safety culture meant zero incidents.

The project has not only been essential and beneficial to both companies, but also to the city. ■

COUNTRY US

PROJECT West Valley

Demonstration Project

CLIENT CH2M Hill BWXT West Valley American DND was part of the original teaming organization contracted to perform decommissioning and facility dispositioning at the West Valley Disposal Project.

The company supported planning and development of demolition and decommissioning plans, work sequencing, scheduling, and coordination.

This project included the first open-air demolition of a Department of Energy site vitrification facility, done so using a real-time radiological monitoring system providing instantaneous readings, control over demolition operations, and mitigation of potential spread of contamination.

Over its tenure of more than 330,000 hours worked over, American DND demolished 100,000-plus sqft of above- and below-ground contaminated and potentially contaminated facilities, structures, and foundations without any safety incident.

Demolitions required equipment with specialty attachments to demolish heavily reinforced containment structures of up to six-ft-thick concrete and to achieve belowgrade excavations down to 25 ft. It also performed contaminated soil remediation and site restoration to advance site closure.

Its crews used specialty, custom American DND–designed dust-suppression equipment and techniques, to mitigate worker risk and reduce exposure. ■

COUNTRY US

PROJECT Ford - DIG Powerhouse Demolition

CLIENT Ford - Devon Industrial Group

Brandenburg and Devon Industrial Group performed the abatement and demolition of the Ford Rouge Power Plant and towering eight boilers.

With exposure to the elements since its closure, an environmental clean up and abatement effort was undertaken to prepare the power plant for demolition. With active utilities near the demolition zone, both below and above grade, meticulous planning and protections were put in place to proceed with the demolition work.

A combination of conventional methods and mechanical methods were used on the East and West boilers. Over 20,000 tons of steel was recovered for recycling. ■

COUNTRY England

PROJECT University of OxfordScience Area Campus

CLIENT University of Oxford Colemans was appointed to plan, coordinate and complete the de-build, demolition, stripping and associated alteration works on two of the Science Area buildings, Le Gors Clark and Sherrington.

This included traditional stripping of all deleterious materials in Le Gros Clarke and the sensitive deconstruction, dismantling and stilling of isolated areas of Sherrington.

To enable it to remain open, a bespoke temporary roof was designed and installed.

During its period on site, the Colemans team removed 2,800 tons of waste from the site whilst maintaining a recycling / reuse rate of 99.62 %. ■

COUNTRY US

COUNTRY Australia

PROJECT Kalamia Sugar Mill Stacks Demolition

CLIENT EDMS / Wilmar Sugar Demex was contracted to demolish two boiler stacks reaching 74 and 65 m at Kalamia Mill in North Queensland.

Works commenced with inhouse engineering design and fabrication of a work platform for the 2.1 ton Brokk demolition robot to be suspended over the stack by a 150 and 180 ton crawler crane.

Working to bring both stacks to ground required carefully synchronised communication between crane and robot operators, a challenge complicated by the inability to sense pressure, vibration, and depth. Any miscommunication could have risked safety and project delivery. ■

PROJECT Demolition of the Frank Erwin Center

CLIENT SpawGlass Constructors, Inc.

Due to its surroundings, an implosion of the Frank Erwin Center was not possible for Lindamood. Strict engineering controls meant only compact equipment could be used for all interior and elevated demolition. Exterior and ground-level work relied on high-efficiency excavators, material handlers, and carefully managed sequencing. Over 69,000 tons of debris were removed—86% recycled via off-site processing, with digital tracking ensuring full documentation for UT’s “living laboratory” sustainability study. All work was completed ahead of schedule and under budget and with zero safety incidents. ■

COUNTRY Canada

PROJECT Dismantlement of 12 kV

Atwater Substation

CLIENT Hydro Quebec

Delsan completed the deconstruction of Hydro-Quebec’s 12 kV Operations Building at the Atwater Substation in Montreal.

This turnkey project demanded expertise in hazardous materials abatement, structural stabilization, environmental remediation, and live infrastructure protection. The site was constrained by a 1.5-m diameter high-pressure water main located less than 3 m from the demolition zone, and a critical scope change required the protection and relocation of live high-voltage cables running through the basement.

Key challenges included: negative pressure containment systems for asbestos removal and real-time vibration monitoring. Despite scope changes, zero safety incidents occurred. The project was delivered on time, within budget, and with full regulatory compliance. ■

COUNTRY Canada

PROJECT Allen Square Re-purposing180 King St S, Waterloo

CLIENT Jackman Construction

This project was the Romeo's most complex and technically demanding job to date.

The objective was to return a six-storey office building with basement and parking garage to its base concrete structure—slabs and columns only. The scope included hazardous asbestos abatement, full interior strip-outs, selective and structural demolition, complete façade and rooftop removals, and the intricate takedown of a precast parking structure.

Challenges included managing multiple scopes simultaneously, navigating engineering constraints, and executing work with precision in a dense urban setting. Work was completed ahead of schedule, and with zero incidents or disruptions to surrounding buildings. ■

COUNTRY England

PROJECT Heaps Rice Mill

CLIENT Legacie Contracts

Appointed as Bespoke Demolition Enabling Solutions Partner, the task for Total Controlled Demolition Services was to remove the internal structure of the building while preserving the entire external façade and roof. With limited access, unstable internal floors, and strict conservation status, traditional methods were ruled out.

The company deployed its in-house Brokk robotic excavators to dismantle from within, ensuring no operatives were at risk and the building’s shell remained untouched.

The company worked sensitively, safely, and collaboratively. Noise, dust, and vibration were managed; residents and local stakeholders were fully informed; and all works were completed ahead of programme and within budget – with zero incidents. ■

COUNTRY US

PROJECT CLT Air Traffic Control Tower

CLIENT Walsh Group

COUNTRY Wales

PROJECT Brackla1 Car Park, Bridgend

CLIENT Bridgend County Borough Council

Appointed by Bridgend County Borough Council, Haywood was tasked with the deconstruction of a deteriorated five-storey concrete structure, constructed using the rarely seen lift slab method, an inherently unstable and interconnected system.

Surrounded by two major supermarkets and a live railway line just 2 m away, the project demanded intricate planning and coordination. Haywood’s engineering-led approach incorporated over 400 steel props and column bracing to ensure structural stability throughout the process.

Drawing lessons from past structural failures, the company collaborated closely with structural engineers, Network Rail, and local stakeholders to devise and approve a demolition methodology that prioritised safety, continuity, and precision.

Despite the complexity and high-risk environment, the company delivered the project on time and within budget.

The site was operated under a bespoke safety regime, which included real-time air quality monitoring, dust and noise control, and night works to protect live infrastructure. The result: zero incidents, uninterrupted rail operations, and full client satisfaction. ■

For this abatement and full demolition project, Trifecta first had to understand how it was built in order to deconstruct it safely. The team identified structural connection points between large concrete blocks and prepared them for removal by grinding and burning through embedded reinforcements. A 550 ton crane was then used to lift the tower sections down for processing and recycling.

A Volvo 380 excavator was then used to complete the remaining demolition. Trifecta delivered the project on schedule, with no safety incidents, and with a 65% recycling and salvage rate. to-workp ■

C ompact equipment engineered to boost machine productivity and versatility.

Extensive range of integrable solutions crafted to simplify your work.

Designed to withstand even the most demanding conditions – Experience it yourself.

COUNTRY UK

PROJECT Cottam Power Station Chimney

CLIENT EDF Energy

The 200 m chimney at EDF’s decommissioned Cottam Power Station in Nottinghamshire was brought down with unprecedented precision using a pioneering explosive method.

Situated among live infrastructure, including a gas main, absorbers, and electricity substation, and in close proximity to residential properties, the complex operation required a meticulous level of control.

Rather than toppling the chimney in traditional fashion, the team employed a “telescoping” collapse technique, causing the structure to implode vertically.

The result: vibrations reduced by 75%, debris confined to a 35m radius, and zero damage to surrounding assets. A Comparative Risk Assessment found this method safer than alternative approaches, including piecemeal demolition, by option of extended high-risk work at height. ■

COUNTRY US

PROJECT Tropicana Las Vegas

Hotel - Paradise Tower and Club Tower

CLIENT GGG Demolition

CDI performed the design and implosion of the two 23 storey Tropicana Hotel and Casino towers using over 1,421 lbs of dynamite.

Vibration monitoring was conducted at numerous locations. Peak particle velocity and air overpressure readings were a fraction of limits allowed by local, State and federal regulations. CDI iaised with various local departments, including Clark County Police and Fire & Public Works Departments.

It also met with adjacent property owners of casinos, hotels and condominiums on how to mitigate the impact of the implosion and street closures on their property.

From the structural complexity of the two towers, to the coordination and timing required for the pyrotechnic show thereafter, this was one of the most complex projects CDI has ever undertaken.

COUNTRY England

PROJECT Sizewell A - Turbine Blocks

CLIENT Erith Group

The decommissioning of the Sizewell “A” nuclear power station involved demolishing the redundant turbine hall and removing its reinforced concrete turbine bases.

The blocks, measuring 92 m by 19.8 m by 10.4 m, needed to be removed to clear the land and advance decommissioning. Due to the proximity of the operational Sizewell “B” (SZW B( reactor, the project had to comply with strict nuclear regulations and minimise disruption.

To accelerate the process, PDC implemented a preweakening technique using controlled explosives, reducing the mechanical demolition timeframe from six to two months and limiting noise, vibration, and disturbance to workers and the community.

The method used the most significant single deployment of electronic detonators and NG cartridge explosives on an operational UK-licensed nuclear site. The work adhered to strict standards, ensuring that risks were minimised as far as reasonably practicable.

Collaboration ensured safe and efficient execution. The project enabled the processing of 4,980 tons of concrete, a 4-month program reduction and a carbon savings of 78.4 tons. ■

COUNTRY Scotland

PROJECT Caledonia Road, Glasgow

CLIENT New Gorbals Housing Association

Detailed planning and co-ordination laid the foundations for this project. The two 24 storey tower blocks collapsed as predicted into a confined site, safely away from a child care facility and high-pressure gas main.

Structural analysis and modelling predicted the demolition collapse mechanism and supported the design of protection levels installed by Dem-Master.

An explosive delay sequence with over 2,200 charges controlled the rate and direction of the structures.

COUNTRY Scotland

PROJECT Avon Lake Power Plant

CLIENT ALERG

This project saw Trifecta bring down four boiler units, two 600-ft stacks, and one heavily reinforced precipitator.

The project’s first implosion safely felled Boiler Units 9 and 10. Precipitator 8 was postponed due to fall trajectory concerns and handled in the second phase alongside Boiler Units 11 and 12 and Stacks 8 and 9.

To cut through six-inch flanges on Precipitator 8, Trifecta and Dykon sourced 5,000-grain shape charges from overseas and custom-assembled them with C-4.

Advanced safety monitoring was deployed, ensuring no incidents and recycling of over 80,000 tons of steel. ■

COUNTRY Cyprus

PROJECT Demobilization of the Centralized Workshop

CLIENT EAC - Electricity Authority of Cyprus

This project involved the demolition of six 30 MW oil-fired steam units and auxiliary equipment in the EAC power plant.

The work took place over a large and complex area, including asbestos abatement, closure of turbine cooling ducts and covering of contaminated areas.

Asbestos removal was one of the first activities, carried out in parallel with the demolition of external structures.

After the certified clean-up of certain areas, the main demolitions began: first the administration building, then the ducts, the boilers and the boiler itself.

This allowed excavators access to the turbine hall. A major challenge was the closure of the channels below sea level, which required solutions to manage the tidal water and analysis to identify the connections between the channels.

Once turbine demolition was completed, the controlled demolition of six 40-m-high metal chimneys proceeded, monitoring vibrations to protect nearby turbogas plants.

Finally, four 17,000-litre tanks were demolished with a special shear designed by Despe. All activities were completed without incident, meeting safety and environmental standards.

COUNTRY Brazil

PROJECT Demobilization of the Centralized Workshop

CLIENT Vale - Metal Salobo

The objective of this project in Marabá was the complete dismantling of the facility.

The scope included the demolition of the Central Workshop, including reinforced concrete structures, foundations, and buildings. Additionally, demolition services were performed on the bus station flooring, uncovered yard, and other flooring areas.

All activities were conducted in compliance with technical, environmental, and safety requirements, ensuring proper segregation, packaging, transportation, and disposal of generated waste, according to applicable standards and the client’s guidelines. ■

COUNTRY Chile

PROJECT Dismantling and Demolition of Dry Area – Quebrada Blanca, Iquique

CLIENT EAC - Teck Quebrada Blanca

Mining Company S.A.

The main objective for this dismantling and demolition project focused on existing facilities.

The Allis Chalmers 54”x74” primary gyratory crusher includes concrete wall and slab structures, with a reinforced concrete perimeter wall. The receiving hopper, crusher discharge chute, and compensation hopper are all made of concrete and lined with metal plates.

Conveyor belts No. 1 to No. 8 are 42 inches wide and extend over 1,500 meters in total length. Each is equipped with a dust collection system including bag filters, fans, hoods, and ducts.

The Secondary and Tertiary Crusher Building is an open steel structure with no roof and includes a 170-ton capacity steel secondary crushing hopper. ■

COUNTRY US

PROJECT Historic DTE Trenton Channel Power Plant

CLIENT DTE Electric

The retirement of DTE Electric’s century-old Trenton Channel Power Plant demanded the safe removal of two 600 ft stacks, twin boiler houses and a 650 ft turbine hall while a live 120 kV substation operated only 25 ft away. Independence Demolition delivered

COUNTRY US

PROJECT NewRange Copper Nickel Concentrator

Plant Demolition

CLIENT NewRange Copper Nickel

Veit led one of the most significant dismantling and recycling efforts in Minnesota state history. The 384,000 sqft facility required meticulous planning to safely remove legacy process equipment and infrastructure.

Veit removed major process equipment, including 67 rod and ball mills, 270 magnetic separators and 3 thickeners, along with steel structures, concrete foundations and floors. Recycling was a priority, with 32,000 tons of steel salvaged, 72,000 tons of ore repurposed, and 65,500 tons of concrete crushed for reuse. ■

Michigan’s most complex industrial demolition in 22 months—finishing on schedule.

Zero OSHA-recordable injuries were achieved across more than 400,000 manhours, involving explosives, asbestos, PCB soils, and dredging.

The team executed precision felling of 45,000-ton boiler houses and 600-ft stacks, with peak vibrations measuring just 0.55 in/s—well below utility thresholds.

Material diversion reached 98.6%, with 49,000 GT of scrap successfully recycled. ■ >29

Avant e series is the new fully electric generation of Avant loaders. Ideal for demanding professional use, the new Avant e727 and e747 loaders guarantee unprecedented heavy work indoors and outdoors, in hot and cold conditions. Avant e747 is the world’s first compact loader in its size class with a 47 kWh battery.

Battery

Lift

Zero emission – Safe battery technology

Excellent power-to-weight ratio

Top-notch GT cab for superior comfort

Work full day with one charge

PRODUCT Turbine High Lift Dust Suppression System

The purpose-built turbine high-lift (THL) dust suppression system is tailored specifically for radiological demolition and environmental remediation.

Key designs include: Use of a turbine atomizer with dispersion head and large-diameter supply hose; Overhead atomized spray to draw clean air from above rather than contaminated air from below; Extension capabilities and height allowing turbine head to be placed over tools performing work without blocking the operator’s view; Remote wireless or tethered operation reduces worker hazards and exposure by keeping them and the equipment out of contamination areas. ■

The 330 UHD is a lighter more nimble machine that allows for precise work where a larger straight boom machine may not reach.

Suitable for 5–6 storey projects, it is light enough in many configurations to move without special permits or trailers.

Key aspects are: Heavier than standard counterweight and variable gauge undercarriage for 360-degree stability with larger tools; Optional fixed gauge undercarriage to reduce overall weight; Demolition-ready with FOGs, P5A glass, full track guarding, bucket cylinder guard, and auxiliary hydraulic circuits; Stability monitor and boom coupler system; Standard ease-of-use features including E-fence, Payload for buckets, thumbs, and grapples, Hammer auto-stop, 2D Cat Grade and joystick steering. ■

PRODUCT SETTANTA

Launched as part of Laurini's 70th anniversary, the SETTANTA demolition machine has a base weight of 35 tons and delivers performance comparable to 45 ton machines.

Its high-pressure hydraulic system powers multiple tool configurations with precision, while a quick-change boom system with HQCS couplings allows

PRODUCT Beilite BLTB-280-5-W-AC15

Engineered for 100–350 ton excavators the BEILITE BLTB-280-5-W-AC15 comes with a patent-pending 300 MPa working pressure, delivering the world’s highest impact energy for processing of large volumes of material.

Designed for mining, tunnelling, and infrastructure, it features selectable piston configurations, flangeless wear bushings with indicators, a return oil accumulator to protect carrier hydraulics, and a reinforced 20CrNiMo cylinder body. Other benefits include side-entry oil ports with a rotating joint, rectangular damping system, and standard anti-blank firing with BI-B Lube high-capacity lubrication. ■

PRODUCT TS-WD2800V

The TS-WD2800V is equipped with a steel body, powerful dual-cylinder performance, 2800 mm jaw opening, and low-maintenance friendly design.

Key aspects are: Full casting one-piece body design for superior strength and reliability with no welding weak points; Big bore dual cylinders and onepiece piston for a total shorter body length which can generate exceptional crushing power and structural stability; Hollow arm structure to reduce weight while maintaining high rigidity for smooth and efficient operation; Every TS Series unit is built under a unique cell production system where one craftsman is responsible for building one unit from start to finish. ■

rapid switch between high- and low-reach demolition booms, digging booms, or a lattice lifting boom.

Thanks to its quick-change boom system, connection of all hydraulic and electrical lines is done within the cabin.

The operator’s cabin is FOPS-certified, tiltable by 30°, and features integrated safety systems and real-time machine monitoring. ■

PRODUCT

Steelwrist SQ40

The Steelwrist SQ40 brings fully automatic quick coupler technology to compact excavators in the 2–7 ton class and enables high-flow hydraulic work tool changes from inside the cab.

Delivering 70 l/min flow—40% higher than standard couplers—it is ideal for demanding demolition tools.

Available as a stand-alone unit or with the X07 tiltrotator, the SQ40 supports a wide range of powered tools and, through Open-S Alliance standards, gives contractors the freedom to combine products across manufacturers without compromise. ■

COUNTRY Canada

PROJECT Environmental remediation works of the former Solutia chemical plant

CLIENT Englobe / City of Montreal

Contractor Englobe partnered with DelsanAIM to execute the site works—including demolition, excavation, and soil treatment.

Among the project’s most impactful innovations was Englobe’s shift from thermal to on-site biotreatment of phthalatecontaminated soils.

Delsan-AIM supported its field implementation, achieving contaminant reductions of up to 96%, while avoiding high-emission, off-site alternatives.

Additional challenges included managing mercury and asbestos, seasonal ecosystem restrictions, and steep terrain. Controlled containment zones and advanced PPE also ensured worker protection throughout.

Recycled asphalt, concrete, and woodchips were reused on-site, and over 1,240 truckloads of material were avoided. ■

COUNTRY Denmark

PROJECT Tscherninghuset

CLIENT Soren Tscherning

This project combines elements from multiple in-house demolition sites into a single, architecturally ambitious structure.

Nearly every part of the building has a past life. Rather than demolishing with disposal in mind, Tscherning dismantled structures strategically, harvesting highquality components for reuse.

These included concrete elements from industrial sites and steel from a demolished hostel.

New construction materials were selected only when necessary. One of the project’s key achievements was proving that reused

COUNTRY Australia

PROJECT Acacia Ridge Business Park

Redevelopment (Stage 2)

CLIENT ESR

Demex completed an enabling works program of hazardous materials removal, demolition, and associated civil works.

A second package is a contaminated site on the Queensland State Government’s Environmental Management Register.

The site was characterised by high levels of asbestos. Stringent regulatory requirements and ESR’s requirement to meet 6 Star Green Star rating standards in construction prompted innovative thinking.

Demex recycled 95% of salvageable materials, processing and reusing 100% of 40,000 m2 of demolished concrete onsite.

Reduced timeframe for removal of hardstand reflected benefits in reduced fuel consumption, fewer emissions, and water use. The 350 m retaining wall protected against soil erosion. ■

COUNTRY Germany

PROJECT Siemens Industrial Campus

CLIENT Portosole C.N.I.S. S.R.L.

Metzner Recycling, Siemens and Volvo, carried out the world’s first electric deconstruction site.

COUNTRY Italy

PROJECT Demolition of the Hotel E

Autorimessa

CLIENT Portosole

This San Remo port project required a specialised approach, as the lightweight concrete building contained polystyrene that could pollute the marine environment.

The project was submitted for approval to the Ministry of Ecological Transition, which imposed five conditions: preparation of an environmental report, continuous monitoring of dust and noise, verification of the absence of hazardous materials, control of the marine biocenosis, and logistical management of the site.

The first phase involved securing the site, with the installation of a 9 m high perimeter scaffold, covered with dust sheets.

Drains were sealed to prevent marine contamination. Demolition was controlled, starting from the interior areas, and a misting system to abate dust and dedicated operators to collect the polystyrene. ■

The project integrated decontamination, dismantling, structural deconstruction, recycling, and logistics. Key challenges included establishing a reliable power supply and ensuring safety while operating high-voltage equipment. The company implemented a dedicated transformer solution and buried the power supply wires underground. Comprehensive training for all staff on electric machinery and emergency protocols further enhanced safety.

structural elements can meet modern engineering standards.

Through close collaboration between demolition teams, engineers, and architects, the project delivered a safe, beautiful, and resource-efficient building.

Tscherninghuset is more than a headquarters; it’s a living case study in circular demolition. It challenges the notion that demolition is the end of a building’s life. Instead, it positions demolition as

the starting point of intelligent reuse— maximising environmental benefits, reducing costs, and inspiring a new generation of sustainable construction. ■

COUNTRY Italy

PROJECT Dismantling and associated works at Motor Oil Hellas Corinth Refineries

The decommissioning and dismantling project of the U-1100 unit at the Motor Oil Hellas refinery in Corinth was a highly technically complex operation, carried out in an active and highly constrained operational environment.

The objective: to remove obsolete and damaged structures, ensuring the integrity of adjacent facilities and the absolute safety of personnel.

The intervention area included pipe-racks, process columns, air coolers compromised by fire and metal structures, with operations at height and in an ATEX environment.

The team, consisting of 20-25 specialised Despe operators, working in continuous shifts, under constant coordination with MOH technicians.

The critical issues addressed by Despe included the presence of active lines, risk of product residues, structural instability and environmental constraints.

Each phase was preceded by targeted training, operational simulations and daily briefings. Advanced technologies such as the Fly Demolition System and hydrocutting robots allowed remote operation, reducing risks.

Demolition took place in a selective and controlled manner, with progressive removal from top to bottom. The project ended without incident, with the complete separation of the U-1100 unit, the recovery of the required components and the absence of environmental impacts.

An operation that has combined innovation, rigour and safety, becoming a reference model for refinery decommissioning. ■

COUNTRY Chile

PROJECT West Valley Demonstration

Project Phase 1 A DecommissioningFacilities Dispositioning

This project involved the partial demolition of a turkey processing facility, carried out as part of its industrial conversion into a chicken processing plant.

The primary objective was to free up space for expansion, allowing a significant increase in production capacity—without compromising operational safety at any stage.

The demolition scope included the removal of 4,800 m² of non-friable asbestos roofing, dismantling of insulated partitions, 38-meter-span steel trusses (11 m high), metal ducting frameworks, and reinforced concrete structures.

These tasks were performed adjacent to active food production zones and live ammonia (NH₃) pipelines, making safety the project’s top priority.

A comprehensive safety strategy was implemented, including real-time remote video monitoring of demolition zones, ammonia gas detection systems on all machinery, and strict access control protocols.

Workers received specialized training in ammonia hazard management, respirator use, and emergency response procedures.

Daily safety briefings and coordination meetings with the client ensured full alignment and rapid response to any emerging risks.

The demolition was executed in three phases, with staged handovers to the new construction team. Zero health or safety incidents were recorded during the entire project— despite the high-risk environment.

All waste was managed responsibly: over 1.2 million kg of ferrous scrap were recycled through AZA, and mixed debris was processed at Revaloriza using advanced sorting systems. ■

COUNTRY US

PROJECT BWM 52 Hall

Trifecta Services Company was selected to perform demolition work within BMW Manufacturing’s eight-million-sqft active automotive production campus.

The Hall 52 project spanned over two years and required careful coordination with Turner Construction and BMW to complete work safely and efficiently inside an operational plant.

The scope included selective demolition of concrete, façade, and structural steel, as well as utility identification and removal. In total, Trifecta removed 497 loads totalling 3,900 tons of concrete and 153 loads totalling 1,090 tons of scrap, all without incident.

From the start, the team emphasized planning, training, and safety culture. Every task began with a detailed Pre-Task Plan involving field crews, safety professionals, and supervision.

Site-specific hazard controls included negative air machines, floor-to-ceiling barriers, specialized utility detection tools, and a rigorous layout verification process. Trifecta logged more than 38,000 labor hours on the project without a single lost time or restricted duty injury.

New hires were integrated into the team through a structured short-service mentoring program and received hands-on equipment training specific to the machines used onsite.

Weekly toolbox talks kept crews informed of the latest safe work practices, drawing from ANSI, ASSE, and other industry leaders.

COUNTRY Australia

PROJECT Adelaide Festival Plaza Tower 2 enabling works

CLIENT Walker Group

Tasked with deconstructing a carpark and building new foundations for a skyscraper, Delta Group deconstructed a 1,000 m² plaza footprint across five levels of a live, high-end carpark. The team delivered outstanding results under some of the most challenging conditions in the industry.

Operating 11 shifts weekly with a peak workforce of 100, the team employed advanced saw-cutting techniques, customengineered machinery, and modular temporary works to navigate restricted 2.2 m headroom, groundwater challenges, and high-security environments.

Over 4,000 m² of suspended slab was removed, supported by 2,000 props and 30 tons of structural steel, all while maintaining full carpark operations for stakeholders.

Innovations included bespoke low clearance drilling rigs, custom air ventilation system to manage silica and emissions, and the installation of 150 ground anchors in some of Australia’s toughest soil conditions.

Despite logistical and urban constraints, no truck access, limited air flow, and a live urban setting—the project was delivered on time, on budget, and with zero lost time injuries. Custom ventilation systems ensured optimal air quality in confined spaces. ■

COUNTRY Italy

PROJECT TDW deconstruction

of Largo Treves Tower

CLIENT STELLA R.E. S.r.l.