Cracking open the Crémant

Vineyard Magazine visits the utterly unique Bride Valley Vineyard in Dorset.

INSIDE

From Kent orchards to gold-medal wine

Contract winemaking

Precision in every drop

Vineyard Magazine visits the utterly unique Bride Valley Vineyard in Dorset.

From Kent orchards to gold-medal wine

Contract winemaking

Precision in every drop

Always connected, always ahead

Expert advice, delivered directly — by email, phone & video call.

Proactive seasonal updates & reminders — keeping you ahead of every task.

Actionable feedback from trusted specialists — with decades of experience.

Fast, practical solutions to vineyard challenges — from pests to nutrient issues.

Fast, practical solutions to vineyard challenges — from pests to nutrient issues.

One clear annual fee — consistent support and value throughout the year.

low operating costs consistently High clarity gentle processing preserves aroma minimal wine loss for expert ADVICE ON HOW to

Bucher Vaslin Crossflow Filters, available exclusively in the UK from Core Equipment, deliver high-efficiency clarification while preserving the delicate character of your wines. Bucher Vaslin offers the most versatile crossflow filters on the market, capable of filtering wine, lees, juice, juice lees, and sparkling wine with up to 20 hours of continuous use.

www.vineyardmagazine.co.uk

VINEYARD

Kelsey Media, The Granary, Downs Court Yalding Hill, Yalding, Maidstone, Kent, ME18 6AL 01959 541444

EDITORIAL

Editor: Rebecca Farmer vineyard.ed@kelsey.co.uk

Features: Malcolm Triggs

GRAPHIC DESIGN

Jo Legg Flair Creative Design jo.legg@flair-design.co.uk

ADVERTISING & MARKETING

Jamie McGrorty 01303 233883 jamie.mcgrorty@kelsey.co.uk

PHOTOGRAPHER

Martin Apps www.countrywidephotographic.co.uk

MANAGEMENT

]CHIEF EXECUTIVE OFFICER: Steve Kendall

DIVISIONAL MANAGING DIRECTOR: Fiona Mercer

PUBLISHER: Jamie McGrorty

RETAIL DIRECTOR: Steve Brown

SUBSCRIPTION MARKETING MANAGER: Claire Aspinall

PRINT PRODUCTION MANAGER: Kelly Orriss

DISTRIBUTION

Distribution in Great Britain: Seymour Distribution Limited 2 East Poultry Avenue, London EC1A 9PT Tel: 020 7429 4000 www.seymour.co.uk

Distribution in Northern Ireland and the Republic of Ireland: Newspread Tel: +353 23 886 3850

Kelsey Media 2025 © all rights reserved. Kelsey Media is a trading name of Kelsey Publishing Ltd. Reproduction in whole or in part is forbidden except with permission in writing from the publishers. Note to contributors: articles submitted for consideration by the editor must be the original work of the author and not previously published. Where photographs are included, which are not the property of the contributor, permission to reproduce them must have been obtained from the owner of the copyright. The editor cannot guarantee a personal response to all letters and emails received. The views expressed in the magazine are not necessarily those of the Editor or the Publisher. Kelsey Publishing Ltd accepts no liability for products and services offered by third parties.

Kelsey Media takes your personal data very seriously. For more information on our privacy policy, please visit https://www.kelsey.co.uk/privacy-policy/ If at any point you have any queries regarding Kelsey’s data policy you can email our Data Protection Officer at dpo@kelsey.co.uk

8 The King’s Award for

9 Supporting entry into the wine industry 11 Vagabond opens newest site at Liverpool Street as part of major city development

14 Posing with alchohol

An extraordinary stay at South Lodge and Gusbourne’s Fifty One Degrees North Magnum launch. 16 Matthew Jukes

Building confidence, knowledge, trust and, most importantly, spreading joy. 27 The agronomy diary Reviewing a year to remember. 35 The Vine Post Harvest 2025: What it means for the future. 50 Representing you Celebrating sustainability month. 54 Next generation smart farming solutions

58 Meet Ted 2.0 from Naïo Technologies

Naïo Technologies has established itself as a leader in the field of robotic solutions for viticulture, blending cutting-edge technology with a deep commitment to safety standards.

32 Shaping the future of UK viticulture

This year’s “phenomenal vintage” will help UK winemaking “reset” after a difficult couple of years.

38 More than just a zero number Interest in non-alcoholic alternatives to wine and sparkling wine has increased significantly in recent years.

Front cover image: Bride Valley

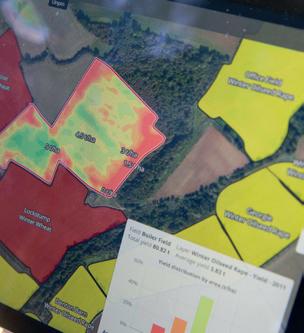

18

30

36

Crack open the Crémant

The story of Bride Valley starts with the soil. The soil in question however was a handful given to some of the greatest viticulturists in Europe.

From Kent orchards to goldmedal wine

We visit J L Baxter & Son in Kent to meet thirdgeneration grower and managing director Clive Baxter and learn more about their award-winning, fruit growing enterprise.

Precision in every drop

Robert Pride looks at how processdriven analysis is transforming winemaking.

43

Contract winemaking

Vineyard spoke to a number of contract winemakers to find out more about the services they offer, what’s new in the trade and how they are giving assurance about the quality of their finished wines.

“There are no strangers here only friends you have not met yet.”

William Butler Yeates

This month a visit to Bride Valley Vineyard (see page 18) made me consider the quote at the top of this column. The warm welcome from the vineyard team meant that the uncooperative weather was hardly noticeable.

In fact the support of the wine community in England and Wales has been a constant companion during the year and as this is the last issue of 2025 it is timely to thank all those who have willingly featured in the magazine throughout the year.

It is common to meet new people willing to go out of their way for others and for the industry as a whole. There is often an instant feeling of inclusion and friendship when meeting for the first time. Camaraderie and a warm atmosphere are evident whenever the community gathers together and is noted by newcomers and observers alike. It is however important to note that no industry will have plain sailing and clear skies all the time.

News reports this month have made clear that there are many businesses that are struggling within the wider agricultural sector and viticulture is by no means immune from this pressure.

The industry needs to harness this abundance of community spirit and grasp tighter to it. Some conversations this month have centred around the idea of the cooperative that is seen in so many successful wine growing regions around the world and how that model could be adapted, personalised and then implemented.

Of course community spirit is not the only thing that has focussed the thoughts this month. Many of the contributors in this edition of the magazine reference the near perfect weather conditions that saw 2025 produce a harvest of outstanding quality. As 2025 comes to a close, on the list of things we would like to order for 2026 is a cold January with lovely clear days for easy pruning and a frost free spring, let’s hope for guaranteed delivery.

Vagabond Wines, the self-pour wine bar group, will open its newest bar in the heart of London, joining British Land’s major transformation at Broadgate. The new site brings Vagabond’s signature tap-and-pour experience to one of the City’s busiest transport and business hubs, with more than 100 wines by the glass, rotating discoveries, and a food menu built for sharing.

Set beside Liverpool Street Station and moments from the Broadgate campus, Spitalfields Market and Shoreditch, the location is perfect for after-work drinks, quick tastings between meetings, and long, curious evenings with friends. With strong weekend traffic from Essex and beyond, Vagabond Liverpool Street is set to become a new social landmark for wine lovers in the City.

Guests can explore at their own pace through Vagabond’s wall of self-pour machines, scan for tasting notes, and build flights with the Vagabond App, including the Find My Style quiz that matches drinkers to wines they’ll love. The opening also coincides with the relaunch of Vagabond’s cult Fondue campaign, which last year captured the screens and attention of Londoners and became a viral hit across the capital.

Christobell Giles, Managing Director of Vagabond Wines, said:

“We’re thrilled to be opening in the heart of the City, surrounded by so many people who already know and love the brand from our Shoreditch and Monument sites. Liverpool Street gives us the chance to reach new audiences right at the centre of London’s energy.”

Liverpool Street follows Vagabond’s new flagship opening at St Paul’s in September and forms part of the brand’s ambitious

expansion under the Majestic Wine Group, with backing from owner Fortress Investment. The group plans to double Vagabond’s footprint over the coming years through selective city openings and partnerships with leading property developers, such as British Land, as it seeks to connect with new audiences across the UK.

As part of that wider growth story, Vagabond will open the UK’s largest urban winery at Canada Water. The 6,000 sq ft site will be able to produce 100,000 bottles over the next five years and will include a bar, shop, and event space for 200 people. Making wine in London allows Vagabond to connect directly with wine drinkers across the capital and beyond, creating an experience that resonates with a new generation who want more from the places they drink. The winery will showcase the full winemaking journey in an urban setting, bringing Londoners closer to the craft, while giving Vagabond-produced wines new homes in its bars and across Majestic Wine Group stores nationwide.

John Colley, Executive Chairman and CEO of Majestic Wine Group, added: “This opening forms part of a major multi-site expansion plan, with millions being invested to grow Vagabond as a key part of the Majestic Wine Group. It’s about reaching the next generation of wine drinkers; building new experiences and digital connections that make great wine more accessible, social, and fun, and sharing that love of wine across the group.”

Vagabond’s model, part wine bar, part experience, continues to redefine how people discover and enjoy wine. With new sites opening across London, to join their venue in Birmingham, and further expansion planned, the brand’s focus remains on making great wine fun, social, and accessible for all.

Equal Measures is the UK’s leading non-profit dedicated to driving intersectional inclusion in the drinks and hospitality spaces.

Since its formation in 2020, it has supported beneficiaries from marginalised backgrounds who work within the spirits and cocktail spaces, providing fully funded WSET Level 1, 2 and 3 Awards in Spirits, BIIAB Level 2 Personal Licences, mentorships with key figures in the global industry, community days, upskilling and more. Now, it is expanding its reach to support underrepresented people working within the UK wine industry.

As part of its growth into wine, Equal Measures UK will be working alongside the prominent UK wine collector, connector and champion, Queena Wong (Founder of Curious Vines; No. 5 in Drinks Retailing’s Top 100 Most Influential in Drinks). WSET will also continue as Equal Measures’ Education Partner in 2026, expanding the collaboration to support the non-profit’s beneficiaries with WSET Level 1, 2 and 3 Awards in Wine.

Vicky Ilankovan, Executive Director of Equal Measures UK stated: “It has always been important to us to grow in a way that ensures longevity and allows us to support the needs of our industry in the best way possible. Over the last four years, Equal Measures has solidified its reputation as a strong advocate for education, safeguarding, and inclusion in the spirits and cocktail scenes within the industry. Now, as we are entering our fifth year, we believe it is the right time to expand into wine. We are doing so gradually, backed by knowledge, experience, and an award-winning approach made stronger by deep connections within the sector.

“We believe profoundly in the power of collaboration, which is why we will be working with the inimitable Queena Wong to ensure we are stepping into wine with due care, responsibility, and awareness. Queena’s fierce commitment to education and safeguarding mirror ours, making her the perfect partner, and we are thrilled to work with her more. In the same vein, WSET’s continued support allows us to provide underrepresented people with the qualifications, knowledge and confidence to achieve their goals in this industry – invaluable resources to our beneficiaries.”

Queena Wong, Founder of Curious Vines stated: “This is an exciting new chapter as I step into the role of the first Equal Measures UK wine mentor, joining a remarkable group already shaping this successful mentorship programme. With my own Curious Vines project founded on the core pillars of Community and Education, our missions align seamlessly. I look forward to connecting my mentees with the heart of the wine industry – to support, inspire, challenge and walk alongside them. Together, Equal Measures UK and I aim to ensure that individuals from marginalised backgrounds not only enter into the world of wine but are equipped to thrive.”

Equal Measures UK will begin accepting 2026 beneficiary applications from those working in wine who meet the eligibility criteria from 3 November 2025. Those eligible can apply via the application form located on the website: https://bit.ly/em-application-form

Equal Measures UK will also be expanding its mentor pool to include leading global wine industry experts. To apply, please email vicky@equalmeasuresuk.org

Velfrey Vineyard in Pembrokeshire has been selected as the Regional Winner for Wales at the Great British Food Awards 2025.

Founded in 2014, the Awards celebrate the very best artisanal food and drink produce which Great Britain has to offer. The judging panel comprises some of the most acclaimed chefs, food critics and influencers in the country, and each product undergoes a rigorous judging process before the winners are crowned.

Making the announcement, the judges commented: “This year’s Best Regional Winner for Wales is the outstanding Velfrey Vineyard, a shining example of the quiet revolution in Welsh winemaking. Nestled in the rolling hills of Pembrokeshire, Velfrey has swiftly established itself as one of the country’s most exciting producers, crafting wines that are elegant, expressive, and unmistakably rooted in their terroir.

We were particularly impressed by Velfrey’s bold innovation and sustainability credentials, with minimal-intervention winemaking and a clear focus on protecting the land for future generations. In just a few years, this small but ambitious vineyard has set a new benchmark for Welsh wine, proving it can stand proudly alongside the very best in Britain.

Velfrey Vineyard is not only putting Pembrokeshire on the wine map, but also raising the bar for Welsh food and drink as a whole.”

Velfrey Vineyard is situated just outside of Narberth and run by the Mounsey family. Owner Fiona Mounsey commented: “We are quite overwhelmed by the honour of being voted regional winner for Wales and for the judges’ words. We have always aimed not only to produce the best quality wine from the cleanest Welsh grapes, but also to look after this beautiful corner of Pembrokeshire. So, to

see our efforts to be sustainable recognised in such a prestigious competition is incredibly rewarding. Wales has an abundance of outstanding food and drinks producers, and to stand out as a regional winner is way beyond our expectations and makes the hard work and attention to detail worthwhile!”

The vineyard’s traditional method, PGI sparkling wine, Velfrey NV, was also recognised, winning a bronze medal in the awards.

Earlier this year, Denbies Wine Estate received The King’s Award for Enterprise for Sustainable Development, recognising its outstanding commitment to environmental responsibility and innovation.

On 23 October, local dignitaries visited the attraction in Dorking, Surrey to celebrate this prestigious honour.

Denbies is one of only 197 organisations nationwide to receive this year’s award, which continues the legacy of the late Queen Elizabeth II’s Queen’s Awards for Enterprise by celebrating exceptional UK businesses.

The recognition follows a series of recent sustainability milestones for Denbies, including becoming the first UK vineyard and winery to produce certified Net Zero wine and achieving B Corp certification last year. Guests enjoyed a guided tour of the winery – complete with exclusive “from the tank” tastings from this year’s exceptional harvest – before attending the official presentation at Denbies Vineyard Hotel, presented by His Majesty’s Lord Lieutenant of Surrey, with reading of the citation by the Deputy Lieutenant.

Denbies CEO, Chris White, shared recent success stories; vineyard manager, Oliver Whitfield, explained that Denbies had celebrated its earliest harvest in 39 years; winery manager, Marcus Sharp, gave a sneak preview from the 2025 harvest, including what promises to be an exciting new vintage of their Noble Harvest dessert wine; and the Lord-Lieutenant of Surrey, Michael More-Molyneux remarked that the King’s Award for Enterprise has helped to open international markets for businesses.

‘We are honoured and delighted to receive the prestigious King’s Award for Enterprise in recognition for excellence in Sustainable Development. The King’s Award is recognised as the highest level of achievement and consolidates our recent accreditations for sustainability. We continue to invest and advance our commitment and responsibility to the environment.’ commented Chris White, CEO, Denbies Wine Estate Ltd.

For the last 20 years, Christopher White, CEO, has owned and operated the estate. Under his leadership, Denbies has become one of the largest and most successful wineries in England.

Everything included – off-grid tech, sauna, tub, deck, inventory Sustainability first – made in Britain by us. Audited carbon neutral Bookings & support – leave marketing and guest management to us Planning – we exempt sites from planning and solve nutrient neutrality issues

Plumpton College are delighted to have been awarded a £300,000 grant from the Department of Science, Innovation and Technology (DSIT) to lead a groundbreaking 5G Smart project as part of the Growing Sussex 5G Innovation Region initiative led by West Sussex County Council.

The revolutionary project will change practices in sustainable food and drink productivity and will see new technology installed on Plumpton’s South Downs campus across their productive horticulture glasshouses and newly planted 10-hectare Plumpton Estate Centenary Smart Vineyard. Principal & CEO Jeremy Kerswell commented: “We are delighted to be leading this pioneering 5G project, made possible through the Department of Science, Innovation and Technology’s investment. As we enter our Centenary Year, it’s a privilege to use cutting-edge technology to inform the future of sustainable food and drink production, both here at Plumpton and across the wider land-based industries we serve. This project is not only about transforming viticulture and horticulture education and practice through data-driven insight, but also about developing a highly qualified, digitally skilled workforce. By embedding advanced technologies like 5G into our curriculum and operations, we are ensuring our students gain the future-proofed skills that industry needs, and helping to drive demand for innovative connectivity solutions in real-world settings.”

Home to the UK’s centre of excellence in wine education, training and research, this revolutionary agri-tech solution will transform the production and yield of the new Plumpton Estate Centenary Smart Vineyard, due to be planted through 2025 - 2027 by VineWorks. During this time, pioneering data into environmental and

plant monitoring will be recorded proving beneficial for educators, learners and the industry at large.

As a key collaborator within the UK wine industry and horticulture sector, Plumpton College is well positioned to fully realise the experimental value of this new Smart technology across their viticulture and wine making practices. All findings will be published and available to the industry as a whole, ensuring growth, sustainability and profitability for all stakeholders in UK food and drink production.

Sam Linter, Director of Wine at Plumpton College commented: “By putting education at the centre of our approach we are ensuring that our growers’ workforce is digitally skilled and equipped to use modern technology in their workplace – be it field, farm or vineyard – and generating a cyclical demand within the sectors to invest in it. By training digitally skilled analysts and data managers, we expect to support local job creation in our food and drink sectors and open up employment opportunities to students and workers who might otherwise not consider horticulture, agriculture or viticulture as a career choice for them.

Cool-climate wines are still not as productive as other wine growing regions, and we hope that our research and data insights out of the Centenary Smart Vineyard will help find real solutions and growth for the industry.”

The benefits of this revolutionary project look fruitful for all; research gained will ensure that Plumpton’s wine experts and students can act upon and learn from real-time data – helping to optimise the teaching, management and yield of the Centenary Smart Vineyard whilst staying at the cutting-edge of viticulture education and wine production.

As Steve Waight, West Sussex County Council Cabinet Member with responsibility for Digital Infrastructure highlighted - by fully embracing this 5G Smart tech, Plumpton College position themselves at the forefront of innovation in the UK wine industry and as a key player in delivering the government’s Food Strategy objectives: “Our wider county of Sussex presents fertile ground for growers and education centres to adopt foundational technologies in the sustainable intensification of food and drink products, helping to deliver the government’s Food Strategy objectives.”

For information about studying viticulture and wine-making at Plumpton College, book on to one of their upcoming open mornings or find out more about their courses:

My recent visit to South Lodge, the luxury hotel and spa in Horsham, Sussex, revealed something truly groundbreaking in wine tourism – a destination where vines nurture both wine and wellness.

Arriving at South Lodge’s lakeside Lodges –The Reeds, eight luxury sustainable retreats – I was immediately immersed in the estate’s harvest celebration. The occasion marked the first grape harvest from vineyards planted three years ago in partnership with Ridgeview English Sparkling Wine, but more significantly, it launched an exciting collaboration: the UK’s first circular vinotherapy treatments using ingredients from the estate’s own vines.

My 24-hour experience began in the vineyard with Ridgeview sparkling wine in hand, picking grapes straight from the harvest. The panel conversation, “From Soil to Spa,” brought together voices from South Lodge, Ridgeview, and Pelegrims – the pioneering English skincare brand –revealing the innovative thinking behind

this partnership. What would traditionally be vineyard waste – grape skins, seeds, stems, and vine leaves from spring pruning – has been transformed by Pelegrims into spa-grade skincare rich in antioxidants and rejuvenating properties.

The spa experience itself was revelatory. I became one of the first to try the new Pelegrims Young Vines Wrap treatment, a deeply restorative ritual using antioxidantrich vine leaves blended with botanicals and finished with nourishing body oils. It brought the vineyard’s vitality directly into the treatment room in a way that felt both luxurious and purposeful. Free time in the spa offered the opportunity to try wild swimming – an invigorating complement to the wellness experience.

The day was complete with the harvest feast in the wine cellar, where Botanica’s seasonal menu – from South Lodge’s zerowaste, dairy-free restaurant—was paired to Ridgeview wines. The evening embodied the property’s commitment to sustainability and British innovation.

“This partnership truly captures what South Lodge stands for. Celebrating the best of British innovation, sustainability and luxury,” said David Connell, General Manager at South Lodge. “To see our first harvest come to fruition, and to extend that story through Pelegrims’ beautiful treatments in our spa, is something really special. It’s a full-circle moment that connects our guests to the land in a completely new way.”

What makes this partnership exceptional is its circular approach. Three new treatments launched 1 November – Fresh Leaf Fusion Face & Body Treatment, Vine Leaf & Herbal Infusion Poultice Massage, and Grapevine Face and Body Glow – each connecting guests tangibly to the land. While the estate’s English Sparkling Wine won’t be ready until 2028, the vineyard is already enriching the guest experience in unexpected, beautiful ways.

This is luxury reimagined: where nothing is wasted and every element tells the story of place.

www.exclusive.co.uk/south-lodge

www.ridgeview.co.uk

www.pelegrims.com

An intimate gathering of members of the press at 67 Pall Mall, London, marked a significant milestone for Gusbourne Estate – the launch of their first magnums of Fifty One Degrees North 2016, their prestigious vintage expression. More than just a product launch, it was a masterclass in ageing potential, format influence, and the meticulous terroir-driven winemaking that defines modern English sparkling wine.

The tasting, led by Laura Rhys MS, Gusbourne’s Global Ambassador, showcased the estate’s commitment to both innovation and tradition through carefully curated flights that told the complete story of their winemaking philosophy.

Two new releases demonstrated Gusbourne’s technical range. The Agrafe 2020 marked a return to traditional methods, using agrafe closures rather than crown caps – a first for Gusbourne and English wine as a whole. “Progress isn’t always made by moving forwards. Sometimes we need to circle back to older ways of doing things,” explained AJ Benham, Head of Wine Operations.

The agrafe process, meaning “staple” in French, involves ageing wine on cork from the outset rather than crown cap. It’s incredibly labour-intensive – every step from bottling to disgorgement must be done by hand. “When

Alice Griffiths

you swap crown cap for cork and agrafe staple, you see the benefit of cork ageing in much younger wines,” said AJ. “There is more oxygen interaction, plus you get the flavours and aromatic compounds which come from cork ageing earlier in the process.” The result is more mouthfeel and complexity with lovely savoury notes earlier in the wine’s life, without losing freshness and acidity.

Oak Reserve 2019 presented another exploration of innovation, showcasing Gusbourne’s experiments with oak-aged expressions.

Where Gusbourne really shines is in its single vineyard programme. The flights offered fascinating insight into how terroir expresses itself across Kent and Sussex sites. Selhurst Park 2018 from Sussex epitomized chalk-driven precision with remarkable minerality from high altitude sites. Boot Hill 2018 from Kent contrasted beautifully – more generous mouthfeel and riper fruit demonstrating how lower elevation and clayrich soils create an entirely different style.

The Blanc de Noirs comparison between Downfield 2019 (Sussex) and Heartbreak 2018 (Kent) further illustrated these regional differences.

The comparative tasting of Blanc de Blancs 2016 and 2014 in both standard bottle and magnum format proved revelatory. The

Alice Griffiths is a wine communicator boosting the profile of English and Welsh Wine on social media, under the popular handle of Posing With Alcohol. Alice has worked within the agriculture industry for the past 20 years, spending time as a lecturer and a smallholder before discovering her passion for viticulture, winemaking and wine tasting.

Get in touch to have your events featured: Envelope Posingwithalcohol@gmail.com

INSTAGRAM Alice can be found on social media under @posingwithalcohol on Instagram.

magnum’s slower evolution was immediately apparent, with the 2014 comparison particularly striking – the standard bottle showed prominent oak characteristics while the magnum retained remarkable freshness and complexity.

The centrepiece compared three vintages of Fifty One Degrees North. The 2016 magnum – the star of the show – brought everything into sharper focus. With 92 months on lees and adjusted dosage, the magnum format allowed more graceful evolution, creating arguably a more powerful, more finely tuned expression.

Priced at £395, the Fifty One Degrees North 2016 magnum represents a different trajectory of ageing – one that rewards patience and demonstrates Gusbourne’s commitment to creating wines that can stand alongside the world’s finest.

Building confidence, knowledge, trust and, most importantly, spreading joy.

Do you remember the various collections of ‘If you like this, you’ll like that’ wines crowding the supermarket shelves in the ‘90s? If you like Sauvignon Blanc, you might like this weedy, soulless, hastily thrown-together white from some unknown corner of the globe.

It was a catchy fad that was masquerading as an opportunity to broaden wine drinkers’ horizons to esoteric grape varieties and faraway terroirs when, in fact, it was a cynical ploy to hoodwink punters into drinking sub-standard juice that had been languishing, unsold in tank farms across the world.

However, at its roots, this technique of offering wines of a similar silhouette to one you know you enjoy, without necessarily

running too much of a risk by getting it ‘wrong’, is the core skill of every decent sommelier and wine merchant in the land! The better you are, the more times you get it ‘right’, the more custom you ought to enjoy from your customers.

These manoeuvres build confidence, knowledge, trust and, most importantly, they spread joy. The winery, the wholesaler and the eventual retailer or restaurant ought to benefit accordingly along the way if the final drinker is satiated and content with their purchase. So, for one month only, I have decided to resurrect ‘If you like this…’, and I can assure you my three recommended wines are absolutely off the charts.

I tasted Ben Walgate’s 2022 Chardonnay at the WineGB event in September, and it was a stupendous, unhurried, impeccably balanced and juicily resonant experience.

It was the first wine in the booklet and on his table, and my personal perceptual and sensory foibles mean I must follow the book at all costs!

His wines were laid out: Chardonnay, Pinot Blanc, Pinot Meunier, Pinot Noir, Cuvée M (a complex aromatic blend), and sparkling 2020 Blanc de Blancs last. Every other table had Chardonnay placed at the end of the whites, not first, given its expected girth.

So how would Ben’s Pinot Blanc fare, seconds after writing an enthusiastic note about his impressive Chardonnay? The answer is that it corresponds perfectly to the theme of this week’s column.

If you like epic Chardonnay, you will fall head over heels for this sensational Pinot Blanc. It reminds me of the first time I came across the wines from Cantina Terlan and fell immediately under their spell. These elite Italian whites are my favourite in all of Italy, and their top wines are based on Pinot Blanc. And so, it follows that Walgate Pinot Blanc is layered, super-classy and complex, and is blessed with a mixture of formats of oak and steel, with six months on gross lees and further ageing on fine lees.

There are no tricks employed here – just incredible Crouch Valley fruit coupled with mindblowing composure and confidence. Only 1,522 bottles were made, and you ought to do everything you can to track them down.

2023 Simpsons, Rabbit Hole Pinot Noir, Kent

£32.00

www.simpsonswine.com www.corkk.co.uk

www.noblegreenwines.co.uk www.grapebritannia.co.uk

£25.00

www.thewinesociety.com

Simpsons is a winery whose gradual augmentation in momentum, impact, and wine quality is as metronomic as its wines are becoming increasingly delicious.

I recently fell at the feet of both NV Chalklands Classic Cuvée and 2024 Gravel Castle Chardonnay. These are wines that have always been attractive but now have genuine character and flair that elevate them to a new and fascinating echelon of distinction. And for the first time, 2023 The Roman Road Chardonnay joins its cousins with impressive structure, traction and presence.

But this perennial white wine specialist has been working as hard with its Pinots, and this month’s recommendation has vaulted to the top strata of my Pinot hit-list with a croquante, superbly perfumed and sleek-fruited wine. There are legions of dynamic red Burgundies who would kill for the freshness and vivacity found here.

Mornington Peninsula, Waipara and Hemelen-Aarde make wines with these ravishing dimensions, but none are thirty quid. So, if you like balletic, resonant and refreshing Pinot Noir, you will find it down this rabbit hole.

www.artelium.com

www.thecheesehutshop.co.uk

I recently spent an illuminating couple of hours with Sue Hodder, the chief winemaker at Wynns Coonawarra Estate. She is one of the world’s most respected and knowledgeable wine luminaries, and for countless vintages she has crafted Cabernets and Shirazes with twelve-point-something-degree-alcohol levels. Her wines are hypnotic, exhilarating, delicious and seamless on the palate. You want to drink two of her wines to one bottle that weighs in with a 14+ percentage. And while Coonawarra has its unique proximity to the Southern Ocean tempering the climate and permitting grapes to ripen fully with keen alcohol levels, this is not a newfound fad here… They have been doing it for a century.

We have naturally low alcohols in our wines, too, and Artelium’s cunning Artefact #9 is crammed with exuberant black fruit and spice, and yet it tips the scales at a mere 12%! It casts an identical shadow on the palate as Sue’s wines and countless elegant clarets from the ‘40s, ‘50s and ‘60s! It is the shape of yesteryear and also the shape of the future. It is the style of red wine that we all (including those pesky millennials) love to drink, and so this beautiful wine ought to be celebrated far and wide for its bravery, acumen and individuality.

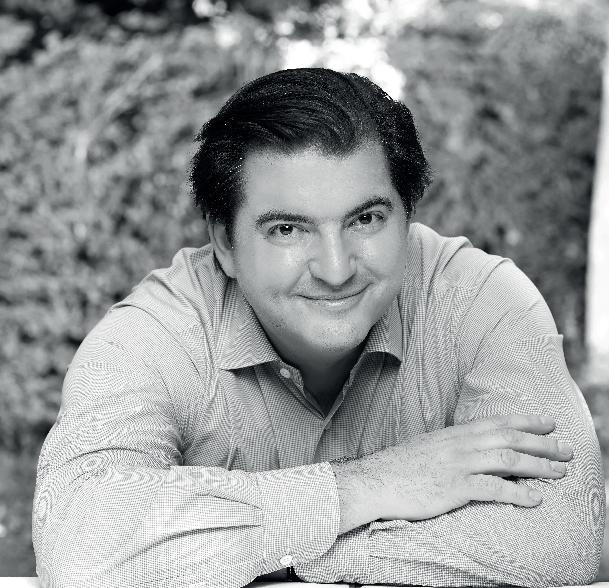

The story of Bride Valley starts like most vineyards with the soil. The soil in question however was a handful given to some of the greatest viticulturists in Europe.

A small sample of soil from Dorset was given by Stephen Spurrier to a group of experts who after an inspection all universally declared it must be… from Champagne. Stephen who famously held the 1976 blind tasting which is now known as the ‘Judgement of Paris’ had once again provided a revelation. Look beyond the traditional and exceptional is within reach.

Bride Valley was planted in 2009 by Stephen and Bella Spurrier on a beautiful site at Litton

Cheney about 20 miles from Lyme Regis. The vineyard is located in a secluded spot but is well signposted from the main A35. This easy to reach location is perfect for the vineyard to highlight the wonders of the English wine scene to the many visitors who come every year to visit the beautiful Jurassic Coast.

Alasdair Warren, current owner of Bride Valley, planted 1.5 hectares of vines on a site near to Bride Valley in 2018. This was a fulfilment of a promise to his grandfather, who

had started an award winning cider business almost 100 years before, to bring cider and other fruit growing back to the farm. “There are parallels in that there is just one shot to get both cider and wine right. My Grandfather said that the secret to award winning cider is great fruit and cleanliness and the same is also true for wine,” said Alasdair.

“Steven and Bella were my neighbours,” continued Alasdair who had been involved in local businesses including a wine shop and

pubs as well as the preservation of a local art deco era cinema and events venue. “From 2019 onwards Steven and Bella were not only regular visitors to my pubs and wine shop but we also started to discuss the business of wine and all the ups and downs that come with that,” said Alasdair with warmth. It is easy to see why Bella trusted Alasdair with Bride Valley Vineyard after the sad death of Steven in 2021. “I was aware that the commercial production of grapes required a certain size of production and Bride Valley was a perfect fit. I feel that 75,000 vines is the right number for a single estate boutique vineyard, once a vineyard goes beyond 100,000 vines the ethos of the business has to change,” he said. Bride Valley Vineyard is planted in a chalk bowl and when first arriving at the vineyard the sight of vines rising up on the gentle slopes in every direction is quite breath taking. The dramatic Iron Age site gives a sensation of Alice in Wonderland as if you have shrunk and the vineyard has become the entire world. (Considering the A35 is only a few minutes away this is an impressive achievement.)

Alasdair Warren and Anna Timone were married at the vineyard in July 2025

“I feel that 75,000 vines is the right number for a single estate boutique vineyard”

<< The vineyard is planted with Chardonnay, Pinot Noir and Pinot Meunier with Chardonnay by far the largest part of the planting at around 60% of the entire vineyard. “The soil here is the distinguishing feature and as you would expect Steven chose rootstocks and clones that were well suited to the soil and he planted heavily with Chardonnay in order to produce Blanc de Blancs along with the wine unique to Bride Valley, the Dorset Crémant,” said Alasdair.

“Bride Valley have a unique certificate allowing the production and sale of Dorset Crémant, the only such product of its kind grown in the UK,” explained Bride Valley Event and Tours Manager Anna Carey who has been with Bride Valley for two years.

Steven Spurrier was so well known amongst the international wine community that it was possible for him to achieve the seemingly impossible feat of procuring permission for the use of the term Crémant for a wine with grapes grown in this amazing chalk bowl only a few miles from the coast in the county of Dorset. Drawing comparisons to the unique nature of this situation is extremely difficult so much so that such permission is unlikely to ever be granted again.

The Crémant is bottled at a lower pressure than other traditional method sparkling wines therefore creating an entirely different mouthfeel and drinking experience. The Dorset Crémant was

The soil here is the distinguishing feature and as you would expect Steven chose rootstocks and clones that were well suited to the soil and he planted heavily with Chardonnay

launched as a way to introduce high quality traditional method wine available at an affordable price and with a price point of £32 it remains faithful to its ethos.

Other sparkling wines at Bride Valley include the Blanc de Blancs, Bella Sparkling Rosé and the Brut Reserve 2018 which received a Gold medal at the IWSC and was one of those wines selected for the WineGB Golden Fifty for 2025. Still wines come in the form of Dorset Chardonnay and Dorset Pinot Noir both currently reflecting the excellent 2022 harvest. “Awards are critical,” said Alasdair. Across the entire range the wines have won numerous awards from various competitions. “The truth is most consumers buy wine based on their perception of quality and awards help not only by providing some context for consumers but also help to ensure that world leading wine experts write about the wines,” added Alasdair.

The Dorset Crémant was launched as a way to introduce high quality traditional method wine available at an affordable price

Nikki Gallagher, Commercial Director at Bride Valley explained that the 2018 Brut Reserve had a little extra lees aging than might normally be expected and the resulting wine is extremely special. The 65% Pinot Noir, 35% Chardonnay wine was made possible by an excellent vintage in 2018 “we made life harder for ourselves by producing this wine but it is so precious and we are delighted that it is winning awards,” Nikki said.

The tasting notes for the Brut Reserve highlight a subtle but important ethos that is shared by everyone connected to Bride Valley. The food pairing recommendations include local caught seafood or asparagus galette and every opportunity is taken to incorporate the wines into the local area. Dorset has much local produce to savour from traditional cider making and cheese to the rusk like Dorset Knob biscuits and Bride Valley is actively working to make sure that local produce is showcased and championed at every opportunity. “Eat Dorset, Drink Dorset,” is the message Alasdair wants to convey.

This ethos was on display in July 2025 when Alasdair married Anna Timone on the eighth anniversary of their very first meeting. “We only offered our own wines and we were able to pair them with our own produce, nothing gives greater pride than cracking open a bottle of wine and your friends and family saying, wow,” said Alasdair with a smile.

The harvest for 2025 was the first at the vineyard for Mark Wilson, the Vineyard Manager at Bride Valley. Having come from a vineyard in Kent after making a career change from the finance sector Mark is clearly passionate about working with the vines. “I love the cycle of the vines, because it is different every year whilst also being the same,” he said with emotion in his voice. In line with this appreciation of the life cycle of a vineyard Mark highlighted pruning as his favourite vineyard task.

The vineyard at Bride Valley utilises the Simonit pruning method. Alasdair drew comparisons between the south west of England and other climates such as South Island of New Zealand and northern coastal parts of the Sonoma Valley. “We make wine in a marginal climate and that means there are things that are out of our control, so you have to identify the things that you can control and work hard on those,” he said. The vineyard team at Bride Valley are all really passionate about what they do and have received training from Marco Simonit and Tito Sordi from Simonit&Sirch to master the sympathetic pruning method. “There is so much logic in the method,” said Mark who has a team of six that undertake the vineyard tasks in house.

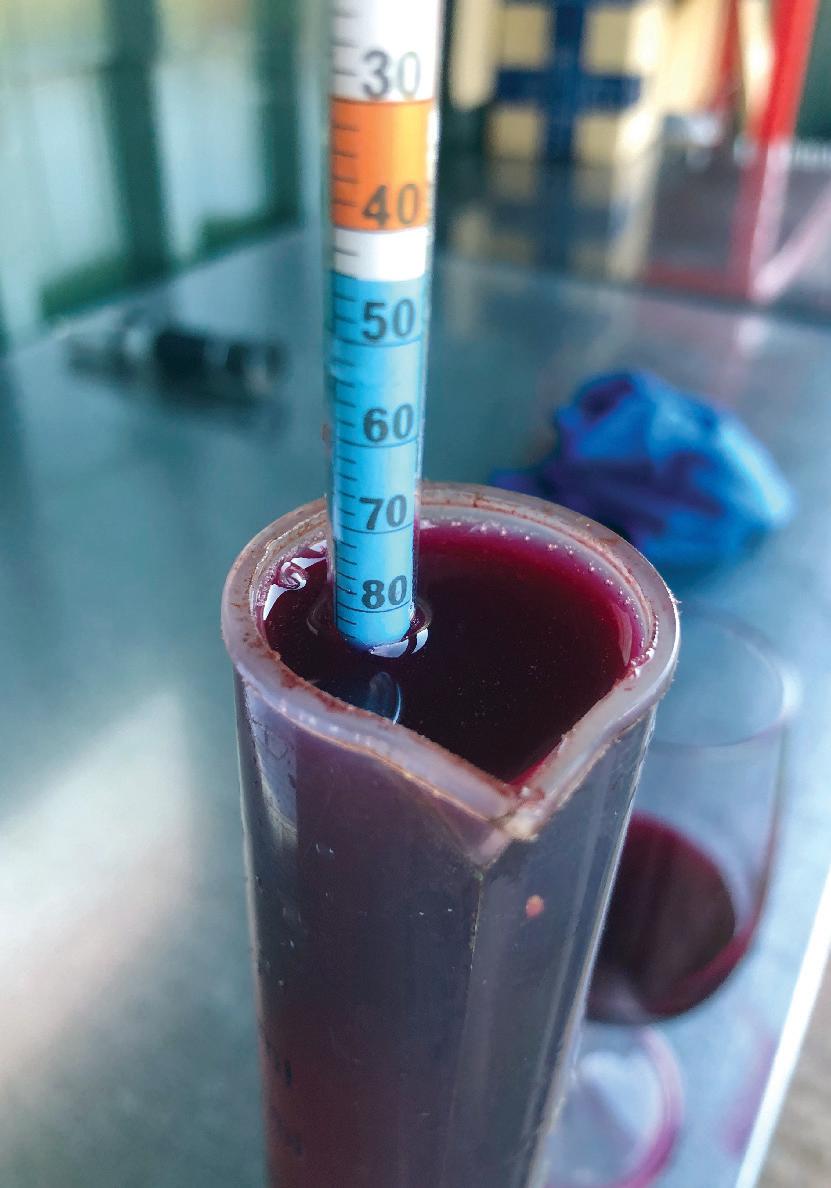

Discussing harvest 2025 Mark explained that the total harvest figures were 33 tonnes, which is more than double the 16 tonnes harvested in 2024 but still far below the record breaking 80 tonnes in 2018. “The Pinot Noir and the Pinot Meunier performed well in 2025 and the weather was perfect all through the season.” To illustrate the point Mark produced rainfall figures from the weather app used by the vineyard. From 1 June - 17 October 2025 the rainfall was 259.6mm, compared to the 448.1mm of rain for the same period in 2024 “In 2025 the rain arrived three weeks before harvest which was great timing,” said Mark. The chardonnay has also performed well in 2025.

The vineyard usually aims for oechsle measurement in the mid 70’s but this year have achieved an exceptional 85 oechsle. For the first time Bride Valley will make a single block wine from an impressive Chardonnay block that has outperformed the rest of the vineyard.

Discussing harvest 2025 Mark explained that the total harvest figures were 33 tonnes, which is more than double the 16 tonnes harvested in 2024

As sugars increase this can put pressure on the vineyard to ensure that the acidity levels do not drop out of balance and the care taken at Bride Valley has ensured that balance was well maintained right through to harvest. “The clonal varieties are Burgundian clones such as 76 and 95 and the acidity was fine,” said Mark. The rootstocks are a mixture of 41B and Fercal and so the vineyard is focussed on the management of vigour. The site with its bowl shape can be prone to humidity, “low cloud can sit over the vineyard,” said Mark and the main defence against the associated issues this can cause is canopy management so leaf stripping in the fruiting zone is a continuous process throughout the season.

Non-detectable TCA

Supercritical technology

Full flavour protection

Ideal for fruity, aromatic wines

Without microspheres

Negative carbon footprint* -34.8 g

amorimcorkstoppers

amorimcork.com

<<

At the end of the season just before pruning was scheduled to begin Mark said: “Flowering 2025 was excellent and the basis is there for an excellent 2026 so there is every reason for quiet confidence.”

There are still the vagaries of the English climate to contend with and the well documented issues of chalky soils making iron difficult for the vines to access but Mark has this covered by implementing a spring schedule to cover the whole vineyard on a block by block basis checking and rectifying any iron deficiencies that might be found.

The vines are at the centre of everything at Bride Valley and tastings are held in a designated area in a covered marquee only a few feet away from the vines themselves. There is nothing in the setup that encroaches on the wonderful feeling of harmony that captivates the visitor holding them suspended from reality throughout the entire experience. “We want the tours and tastings to be all about the vines and we are off grid which is important to the ethos of what we do,” said Nikki. The tours are conducted by Anna Carey who trained as a winemaker at Plumpton College “I really enjoy the interaction that happens when I take the tours,” said Anna and it is clear that she is passionate about wine education.

Bride Valley relies heavily on a direct to consumer model with locals being able to take advantage of free delivery and Dorset itself offers many wonderful food festivals and events which also allow the team to interact directly with their consumers. The tours are also a major part of this model and with a 10% discount as an incentive Anna explained that a tour party of 14 people have been known to spend over £1,000 on wine.

Taking a tour with Anna it would be impossible not to be engaged, her extensive knowledge is coupled with a commitment to make wine accessible simplifying the language around wine and demystifying the atmosphere. “I often have a visitor who may have received the tour as a gift and they are not really engaged at the beginning but by the end of the tour they are asking questions and having a really great time.”

The vineyard tours start with a welcome drink (so that people are not waiting for that part of the experience) and then finish with a four wine tasting experience. “The Dorset Pinot Noir is often a revelation to many big red wine drinkers offering notes of raspberry, vanilla and peppercorn,” said Anna with pride.

The tours cost £25 and take place every Saturday from April to September. The reasonable price point has ensured the tours have become extremely popular not just with visitors from the UK but also those from wine producing countries such as France and New Zealand as well. The world renowned fossils of the Jurassic Coast attract many visitors to the area and the vineyard is perfectly situated to showcase the fantastic work of English viticulturists. The vineyard does not neglect the locals. “Since Covid-19 more people want to know what is located on their doorstep and we also hold a picnic in the vineyard – this family friendly event helps to keep us connected with local people,” added Anna. The vineyard also allows the local community of Litton Cheney to walk through the vineyard and Bella Spurrier is often spotted walking her dog through the vines.

In the future there may well be new varieties introduced to Bride Valley, with Alasdair expressing an interest in PIWI varieties.

“The really interesting thing about English and Welsh wine is that there are no constraints and so many winemakers are willing to experiment. A perception that a wine is unknown brings the freedom to create something new,” said Alasdair with enthusiasm in his voice.

One thing is certain, whatever vines are planted, whatever wines are made the team at Bride Valley are determined that every single bottle produced will be the very best reflection of everything that has gone before so with this ethos the future looks very positive indeed. Instead of feeling the pressure of the history and heritage of Bride Valley Vineyard Alasdair and the team, Nikki, Mark and Anna, have an air of infectious enthusiasm. Whilst the history of the vineyard has made Bride Valley unique, its future will be equally exciting. A deep connection to the area is an intrinsic feature of Bride Valley to the point that you want to linger just a little longer soaking in the atmosphere. A visit to Bride Valley is just as refreshing as a glass or two of their excellent award winning wines.

“The really interesting thing about English and Welsh wine is that there are no constraints and so many winemakers are willing to experiment.”

CropAid’s biostimulant range CropAid AntiFrost and CropAid AntiHeat helps growers improve yield and quality when temperatures swing to damaging extremes. CropAid products prime the vine’s natural stress-response pathways, improving cell membrane stability, osmotic balance and antioxidant capacity; buds, flowers, and young clusters ride out cold snaps and heat spikes with less or no damage.

CropAid AntiFrost, independently evaluated by ADAS in the UK, induces the vines to produce their own antifreeze proteins protecting the vines and providing further vitality throughout the entire growing period right up until harvest. Growers report stronger bud survival, reduced shoot necrosis, and more even fruit set. Protection lasts up to 14 days per spray, giving cover across multi-night frost windows and cutting operational costs. CropAid reports increases in cold tolerance up to 7°C below some crop’s natural levels.

CropAid AntiHeat supports vines during heat waves helping maintain stomatal function and canopy integrity. Growers have observed steadier photosynthesis, better bunch protection, and improved colour and flavour development under stressful conditions with less sunburn and shrivel.

Both products have been approved by the Soil Association for organic use, giving viticulturists assurance on both performance and compliance. For vineyard managers focused on quality, yield and cost control, CropAid offers a quiet, clean and scalable programme: spray ahead of forecast stress, then maintain coverage through the risk period and beyond. Fewer logistics, predictable per-hectare costs, and protection that lasts.

There are many trial results on the website, here are what some UK vineyards have to say:

“Good for the vines and good for the grower” - Andrew Barnes, Hungerhill Vineyard, Bedfordshire

“I have been using it for three years and I noticed an increase in buds and quality of buds. This is a low-cost solution that every grower should have,” said Martyn Pollock, Nine Oaks Vineyard, Kent.

Andrew Beamish, Mallard Point Vineyard, Lincolnshire said: “We’ve never seen leaf health so abundant. I am a firm believer. It’s 100% obvious!”

“We have been using CropAid AntiFrost for a number of years as part of our frost fighting armoury. Following the instructions and applying it regularly through the frost season has provided seemingly good protection although the frosts have not been so severe in recent years. We will definitely continue to use it going forward. It is worth adding that the support from the team at CropAid is first class,”said Mark Darley, All Angels Vineyard, Berkshire.

“We first used CropAid as a frost protection in May this year, we were forecast a -1°C frost, so were quite concerned. We applied it 24 to 48 hours before, our thermometer recorded -0.8°C during the frost, we had no issues at all. We decided we would add it as a monthly addition, and we feel it really helped with the health of the vines and improved the yield and quality at harvest,” said Tim Spakouskas, Yorkshire Heart Vineyard, Yorkshire.

While 2025 was something of a vintage year for UK grape growing, it was not without its challenges, both commercial and agronomic. Hutchinsons agronomists Rob Saunders and Will Robinson review some key talking points, and look forward to next season.

Conditions for growing grapes in the UK do not come much better than 2025, with yields and quality largely reflecting this. Indeed, anyone targeting top quality generally achieved it, and with lower disease pressure, input costs were below previous years. On the face of it then, 2025 was an excellent season, and for many it undoubtedly was. However, it would be remiss not to acknowledge the commercial challenges that have also come to the fore, with some wineries and vineyards facing tough financial decisions, and those without contracts sometimes struggling to find a home for grapes, at reduced prices in a ‘buyers’ market’.

Whether this is just a temporary correction of a sector that has grown exponentially in the past decade remains to be seen, however it may well prompt some future tightening of purse strings. Indeed, this year we have seen more mechanical operations taking place, notably harvesting and pre-pruning, in a bid to address issues with the cost and availability of labour. Many are sharing equipment with neighbouring growers to keep overhead costs down. Going forward, we may well see more mechanisation within vineyards, but agronomy-wise the focus needs to remain on maximising yield consistency and quality, with precisely targeted inputs. Being realistic about what your site can deliver in any one season, and taking note of lessons from previous years, will help achieve this.

Although overall disease pressure was lower this year, one issue that did appear -

quite rapidly in many cases – was powdery mildew. The main hotspots were typically in areas that have experienced issues in previous seasons, such as hollows in the ground, or sheltered areas near trees and hedges, where humidity tends to be higher. Excess canopy growth is another major contributing factor, reducing airflow and increasing humidity.

It is worth mapping, or at least making a note of these ‘hotspots’ for extra attention in future, and ensure any affected material is pruned out and disposed of to reduce risk of carryover into next season.

Once powdery mildew is in the crown though, it cannot be pruned out, and with no real curative fungicide options, a preventative strategy of uprated cultural and chemical controls is essential.

Alongside good canopy management, sulphur post-harvest and again in spring at woolly bud stage and bud burst is very effective, although it is something some growers skipped this year given the perceived low risk in dry, warm conditions at the time. On some sites. this may well have contributed to an increase in disease later in the summer.

Another issue, which thrived in the more Mediterranean conditions, was spotted wing drosophila (SWD), which arrived with vengeance during September on some sites. Again, issues were particularly evident where airflow was restricted in some way. Interestingly, SWD were often concentrated at the bottom of bunches, out of obvious sight, highlighting the need for careful monitoring and vigilance.

Recognise too, that in many cases, by

the time you see SWD on grapes in any number, damage is already being done, so consider integrated options to help manage risk throughout the season. SWD tends to remain quite localised, overwintering in hedges and woodlands, so a collaborative effort to manage the pest across neighbouring sites may well be worthwhile.

Finally, it is worth touching on the topic of water, or the lack of, during the growing season. While established vines are generally pretty robust in dry conditions, we saw some distinct benefits from irrigating at key times on some sites, notably where soil structural issues were restricting deeper rooting.

Often during very dry, hot conditions, vines will shut down the apical shoots, first apparent as tendrils which become brittle and fall off. In extreme cases, this is followed by berry abortion. But this year, we found that applying additional water – in one case, for an hour a day for three days on the most at-risk areas – did a great job of keeping vines going and avoiding any severe impact.

If seasons such as 2025 become more common, irrigation may be something more growers need to consider, especially if there are underlying soil issues affecting rooting.

Expert insight, state-of-the-art machinery and a partnership approach ensures the maximum possible return for landowners who work with South East Forestry to manage their woodland.

South East Forestry’s in-house sawmill allows the business to extract maximum value from the trees the team harvests, which in turn allows the company to pay premium rates for forestry work.

And it’s not just the machinery that contributes to a healthy payment for the landowner. Jon Davies, who runs South East Forestry with business partner Dave Holmes, is a skilled and experienced woodsman who can expertly

assess the value of timber and ensure that every bit of it is used appropriately.

Turning trees into woodchip is a last resort, with as much timber as possible used in construction, for furniture or for fencing, which not only increases its value but locks up the carbon while supporting rural jobs.

Even larger diameter sweet chestnut trees, which generally have minimal value once they are too big for fencing, are put to good use by South East Forestry, a use that is again reflected in the price the company will pay for standing timber.

While moving with the times in many respects, farmers like doing business with a handshake, and South East Forestry co-owner Jon Davies respects that approach.

“We don’t tie landowners up in knots with long-winded contracts and we don’t add a management charge when we are invited to thin, improve or manage woodland,” he explained.

“We will discuss the project with the owner, use our experience to work out the value of the wood, agree a price and get on with the job. It’s also worth remembering that income from the sale of standing timber is tax free, another bonus for the farmer or landowner – and the initial site appraisal is free.”

Overstood, dense, neglected woodland does the trees, and nature in general, no favours. Competition for light leaves trees stunted, with the better trees unable to achieve their potential, while the diversity of plant and animal life within the woodland is crowded out by volunteer saplings and invasive species.

Harvesting the poorer trees allows the better specimens to fill the resulting space, while allowing more light to reach the woodland floor encourages new plant life, insects and butterflies, all of which can thrive in the lighter, warmer and more spacious environment.

“What we really enjoy is returning to a site a year or two later and seeing new wildlife where once there was just a tangled mass of poor-quality trees and scrub,” commented Dave Holmes.

When South East Forestry bought a sawmill for the company’s home at Hawkhurst in 2012, the idea was for it to be mainly used to put lower grade timber to the best possible use.

Over the past few years, though, customer demand has seen the sawmill increasingly used to create bespoke English oak planks, beams, frames and posts for use in and around homes and gardens.

“It’s got to the point where we need a steady stream of English oak to feed the ever-hungry saw mill to satisfy the demand for timber frames, pergolas, gate posts, high end furniture, planks, sleepers and the many other uses to which this amazing wood can be put,” explained Jon.

“While we are keen to talk to landowners about harvesting all kinds of timber from overstood woodland, we are particularly interested in oak and sweet chestnut – and that increases the amount we are happy to pay for it.”

A final word

South East Forestry has a good relationship with the Forestry Commission and will organise all the necessary felling licences. “We handle all the paperwork after carrying out the free site survey and agreeing the felling or thinning plan with the landowner,” Jon said. “We also have full public liability insurance, a comprehensive health and safety policy and all necessary documentation and accreditations.”

As well as well-maintained, state-of-the-art, felling and forwarding machinery, South East Forestry operates its own Class 1 HGV road transport to remove timber from the site to the sawmill and yard at Hawkhurst.

“We keep everything in house as that just makes the job easier and more efficient,” said Dave. “That makes life easier for both us and the landowner.” The South East Forestry team will also put in any infrastructure needed to get the felled trees from the woodland to the roadside.

“All British woodland benefits from being managed, and working with South East Forestry ensures that the landowner obtains the maximum value from the management process while leaving the woodland healthier and more vibrant.” Jon Davies.

Nigel Akehurst visits J L Baxter & Son in Kent to meet third-generation grower and managing director Clive Baxter and learn more about their award-winning, fruit growing enterprise.

In 2019, Kent fruit grower Clive Baxter decided to plant vines. After decades of growing apples and pears at J L Baxter & Son, the idea of producing wine on the family’s gently south-facing slopes near Maidstone offered both a challenge and an opportunity.

“I could see the fruit industry was under pressure,” he explained. “Labour costs, market consolidation – it made sense to diversify. When Balfour Winery approached us about planting vines, I thought, ‘why not?’”

Five years later, the Baxters’ wine label, Four Daughters, named after Clive and his wife Carol’s four girls, has already made its mark, winning gold for its debut Albariño at the 2022 Independent English Wine Awards.

The first vines, mainly Chardonnay, Pinot Noir and Pinot Meunier, followed by Albariño, went into the ground in 2019, with the first crop harvested in 2022. Most grapes are still sold under contract to Balfour, but a small batch is vinified separately by Defined Wine in Canterbury.

“I made 20 litres myself one year,” said Clive with a grin. “Same grapes,

same yeast. My wife said it was only fit for cooking. The winemakers at Defined turned the same fruit into gold-medal wine. They’re magicians.”

He’s quick to credit the professionals. “Making great wine is 90% about the winemaker. Growing good grapes is the starting point, but what happens next is alchemy.”

On the vineyard side, the Baxters work closely with local contractors VineWorks, who have carried out vine planting and provide regular advice and guidance through their Viti-Scout package.

The vineyard now spans around 45 acres, and Clive takes a cautious, long-term approach. “We’ve seen people plant without a business plan. It’s not just about romance. You need a clear route to market.”

All four of his daughters play an active role in the business, from managing social media accounts (@fourdaughters.wine on instagram and tiktok) to running vineyard tours and tastings. “It’s added a lovely social side,” said Clive. “People enjoy hearing the story; it’s a working farm, not a manicured estate.”

While the vines are flourishing, top fruit remains the backbone of the business. “Apples still pay the bills,” Clive smiled. “The vineyard complements what we do; it doesn’t replace it.”

With most of the grapes under contract, the enterprise provides both income stability and scope for creativity. “We’ve just broken even on the initial capital investment,” he said. “Now it’s onwards and upwards, though we’ve planted more, so perhaps sideways, too.”

The next phase may include expanding their own-label wines and developing a small cellar-door experience at Amsbury Farm. “We’ve visited wineries all over the world,” said Clive. “The best advice we heard was: grow the grapes, make small batches, learn the craft and take your time.”

Four Daughters has already achieved what many new entrants only dream of; a medal-winning English wine rooted in genuine farming heritage. As Clive puts it: “I still love growing things, whether it’s apples or vines. Work’s never felt like a chore. When it’s your passion, it’s just life.”

This year’s “phenomenal vintage” will help UK winemaking “reset” after a difficult couple of years, viticultural expert James Dodson, founder and CEO of the UK's leading vineyard services company VineWorks, has predicted.

James Dodson, who set the company up in 2006 and has since overseen the establishment of more than 300 vineyards containing more than five million vines, believes 2025 will prove to be a historic year for grape quality.

He is also confident that UK wine will continue on its upward trajectory despite the over-production that led to “a few tears” for some growers over the past two years. “It’s happened all over the world at some point,” James said. “We just have to get back to sensible levels of production, and that means maintaining yields at seven to nine tonnes a hectare by pruning and crop management, which will maintain quality and keep the price of fruit sustainable.”

With yields up 35% to 40% in 2023, James said growers faced increased costs turning the fruit into wine, leading to a “cash crunch”. In 2024 many tried to sell fruit to recoup some of that cost, but with more sellers than buyers the price collapsed.

But while VineWorks’ own brokering activities noted a drop in business and many growers struggled to find a home for their grapes, James insisted that it was “not a crisis, just an opportunity for an industry reset in terms of direction of travel”.

Stressing “the growth in UK wine continues”, he added that with the biggest cost pressure coming from vine husbandry, VineWorks continued to look at ways of reducing costs for its clients.

While UK growers have enjoyed a few frost-free years recently, James’ message is clear: “Don’t relax.”

One environmental innovation is VineWorks’ Viti-Till, a strip tilling implement designed with German manufacturer Wagner to meet the regenerative agriculture demands of reducing cultivation by clearing a 50cm wide strip of land ready for planting. “Viti-Till also reduces ground preparation costs and is better for the soil and the environment as it only removes the grass or cover crop from the area to be planted,” explained James. “That reduces carbon and moisture loss and preserves the soil structure.”

Viti-Till was the brainchild of head of establishment Will Mower and uses GPS to sync with the vine planting machine. It has already proved successful on several sites, including at Plumpton College, where it was used in the establishment of the new vineyard in 2025.

The East Sussex-based company is also working on an exciting research project which is grafting UK budwood onto rootstocks imported from France to create vines for future expansion. “It’s a complex process but will allow existing vineyards to buy vines for infilling using their own budwood or plant expansion projects, reducing the issues with importing vines from Europe,” said James. “We are excited about the potential of the project, which is in the later stage of development. We are working on grafting orders for 2027 for bespoke vines so are keen to talk to growers who are interested in British vines that originate from their vineyards.”

“We are seeing continued interest in vineyard establishment, but we are also keen to make sure new entrants to the industry have a clear understanding of the market,” James said. “We try to ensure new vineyards have a properly developed business plan. We don’t want to see vineyards for vineyards’ sake; growers need to have thought carefully about the marketing and selling aspects of their business.”

The company is seeing considerable growth in demand for its management services packages, with vineyards, estates and farms outsourcing their husbandry in order to streamline operations and reduce costs. VineWorks’ management services are led by Tom Reid, who returned to VineWorks after a year in New Zealand as head of vineyard services at the end of 2024.

Another new member of the team is George O’Leary-Quinn, who joined VineWorks to deliver tractor-based and mechanical operations. George is responsible for VineWorks’ new quad-based herbicide service which allows herbicide and liquid nutrition to be delivered more effectively to smaller areas.

The company’s Gregoire GL7 machine harvester was in increasing demand in 2025, picking four times the quantity of grapes for clients as in 2024. The Gregoire is the only one of its kind in the UK. The grapes are collected in a trailer that is specially adapted to separate and contain the free-run juice from the berries, minimising

waste and allowing the winemaker to use both components in the winemaking process.

While UK growers have enjoyed a few frost-free years recently, James’ message is clear: “Don’t relax.” As the UK distributor for the infrared-based Frolight Frost Systems, the company will be demonstrating the technology at the Vineyard & Winery Show on 19 November at the Kent Showground and is planning a number of demonstration days in the new year.

The VineWorks online shop continues to offer a comprehensive range of supplies, from vine plants and wire to stakes, guards, shears and everything in between, with the team taking pride in turning orders around as swiftly as possible.

VineWorks also made 1,600 bottles of its own ‘garagiste’ style Chardonnay from grapes harvested in 2023. Barrel-fermented, the wine, named Unit 20 after the warehouse in which it is stored, will be launched at the Vineyard & Winery Show. Senior viticulturist Charles Martin played a lead role in its creation, having previously owned his own vineyard in France for many years.

VineWorks is also planning to make more wine from this season’s “historic vintage in terms of quality and essentially disease-free grapes”, in James’ words. “This will be remembered as one of the great vintages for the UK,” he added.

The Red Cabin showcases how vineyard owners can diversify income through premium, design-led accommodation. The company’s off-grid cabins provide private saunas, plunge pools, and hot tubs, crafted from timber-rich, sustainable materials and built in Britain with carbon-conscious practices.

The Red Cabin model is simple: the team designs, builds, and fully manages each cabin, while landowners contribute only a small proportion of the installation cost and receive the majority of the revenue generated from each stay. This creates a low-risk, high-value opportunity to attract premium guests and enhance income without the burden of full ownership or management.

Beyond revenue, the cabins elevate the visitor experience, giving guests an immersive, design-led stay that strengthens the connection to the vineyard, the wines, and the brand. They offer a memorable way for vineyards to engage high-value visitors while reflecting a commitment to sustainability and quality.

The Red Cabin team is seeking a select number of vineyard partners who share the ethos of thoughtful design, environmental care, and exceptional hospitality. The model can transform vineyards into destinations that delight guests while generating meaningful revenue, turning vineyards into more than just a place to visit.

Envelope host@theredcabin.co.uk

• Steel frame buildings for: farming, industry,

• Site clearance and demolition

• Full groundwork

• Covering Sussex, Surrey, Kent and Hampshire

Finding balance after years of extremes.

After two turbulent seasons, the 2025 vintage has offered the UK wine industry a welcome sense of relief – and real excitement.

Conditions across much of the country were close to ideal: a warm, dry summer followed by timely late-season rainfall allowed for healthy canopy development, balanced ripening, and fruit of excellent flavour and structure.

Yields were comfortably above 2024’s depressed figures without tipping into the excesses seen in 2023. More importantly, the fruit was clean, consistent, and ripe, making for smooth harvest logistics and strong quality in the winery. Sugar and acid levels were well-balanced, and winemakers are already talking about the potential for elegant, expressive wines across both still and sparkling categories.

This was a year that reminded everyone of what UK viticulture can achieve when conditions align – a true “reset” vintage. Picking was efficient, winery intakes were steady, and the industry enjoyed a sense of momentum not felt in recent years. Of course, it will be many months before we can taste the finished results, but early signs suggest 2025 could stand alongside 2018 as a benchmark harvest.

Taken together, the 2023-2025 run has provided a crash course in business resilience. Each season told a different story – and together, they underline just how volatile agricultural production can be. In 2023, the industry faced a bumper crop. Many vineyards enjoyed record yields, but that abundance quickly created logistical and economic headaches. Wineries struggled to find tank space, fruit prices fell, and some grapes went unpicked. While quality was good, the market was left with

an overstock of wine, limited consumer growth, and financial pressure.

Then came 2024, a year defined by poor weather, disease pressure, and widespread crop losses. Some producers lost more than half their fruit; others saw none reach full ripeness. With far lower volumes, cash flow tightened dramatically. Fruit sales collapsed, contracts faltered, and many businesses were left exposed. For smaller growers especially, the lack of income after 2023’s oversupply created real instability.

Now, in 2025, we’ve finally had balance: manageable yields, excellent quality, and renewed optimism. Yet if these three seasons have taught us anything, it’s that agriculture is predictably unpredictable. We can safely assume that within every decade there will be at least one terrible harvest and one bumper one – and business planning must reflect that reality.

Our biggest takeaway is the need for better alignment between production, processing, and demand. Yield contracts are no longer optional – they’re essential. Controlling both the quantity and quality of fruit ensures that supply matches market needs, protecting pricing, reputation, and long-term financial health.

The 2023 glut proved the risk of oversupply; the 2024 crash proved the danger of under-capacity and over-reliance on a single good year. A sustainable future for UK wine depends on levelling out these swings. That means forward planning for winery space, stronger agreements between growers and producers, and an honest assessment of market appetite.

We also need to think long-term about cash resilience. Harvests like 2024 show that a single bad year can expose weaknesses in

finance and operations. Building reserves, diversifying sales channels, and investing in adaptable infrastructure will help businesses withstand the next downturn – because there will always be one.

As a CEO, I believe the role of companies like VineWorks is to help our clients balance optimism with realism. We work hard to keep up-to-date on the latest innovations and research to make sure that grape growing is the most economically viable it can be. We use our extensive contacts to help our clients understand the market to help them avoid the boom-and-bust pattern that has defined recent years.

If 2023 was a warning and 2024 a reckoning, then 2025 is a reminder of what’s possible when balance returns. The fruit this year is outstanding, but the true measure of success will be how we use it to build a stable, sustainable, and confident future for UK viticulture. At VineWorks, that future starts where it always has: by supporting our growers, strengthening our industry, and building sustainability – one vine at a time.

Robert Pride looks at how process-driven analysis is transforming winemaking – robert.pride@campdenbri.co.uk

In today’s competitive wine industry, consistency and stability are built not only on experience, instinct and craftsmanship but on data, precision, and process. Process-driven analysis brings a proactive, science-based approach to winemaking –empowering producers to make informed decisions at every stage.

At Campden Wine Services, we work with wineries of all sizes to apply this method, helping them produce better wine, minimise risk, cut costs, and protect their brands.

Process-driven analysis is a structured system of monitoring and testing wine throughout production - not just at bottling. It combines laboratory testing, sensory evaluation, and real-time process monitoring to improve quality, safety, and efficiency.

Unlike traditional quality control, which reacts to faults after they occur, this method prevents problems before they develop by monitoring and responding to chemical, microbiological, and physical parameters from grape to bottle.

From the vineyard to the bottling line, process-driven analysis applies targeted testing and control strategies at each production step:

◆ Grape maturity/quality: Brix, pH, titratable acidity, phenolics, yeast assimilable nitrogen (YAN), disease status

◆ Fermentation kinetics: Sugar drop, temperature, yeast health, volatile acidity, organoleptic assessment

◆ Post-fermentation: Malolactic fermentation (MLF) tracking, sulphur dioxide (SO₂) levels, microbial stability

◆ Pre-bottling: Tartrate, protein, colour and microbial stability assessments. Antioxidants and preservatives within permitted ranges. Density measurements for accurate fill volumes.

◆ Packaging: Dissolved oxygen (DO) and carbon dioxide (CO2) levels, closure integrity, fill volume

◆ Post-bottling: Product meets regulatory, labelling, safety and quality requirements.