What was the life of Malcolm: an American pine tree? Well, my life and afterlife is a long story, I grew a lot, I lost many friends along the way, and my corpse is currently being used to structure a house, but now reflecting in the afterlife, I think Iʼve lived a pretty decent life. My life cycle analysis is pretty awesome.

Unlike some others *ahem*, humans, I have done great deeds for the betterment of this earth. Half of my dry weight is attributed to carbon(Allen and Iano 82). Wood tends to be more sustainable and has lower embodied energy than other materials like steel and concrete.

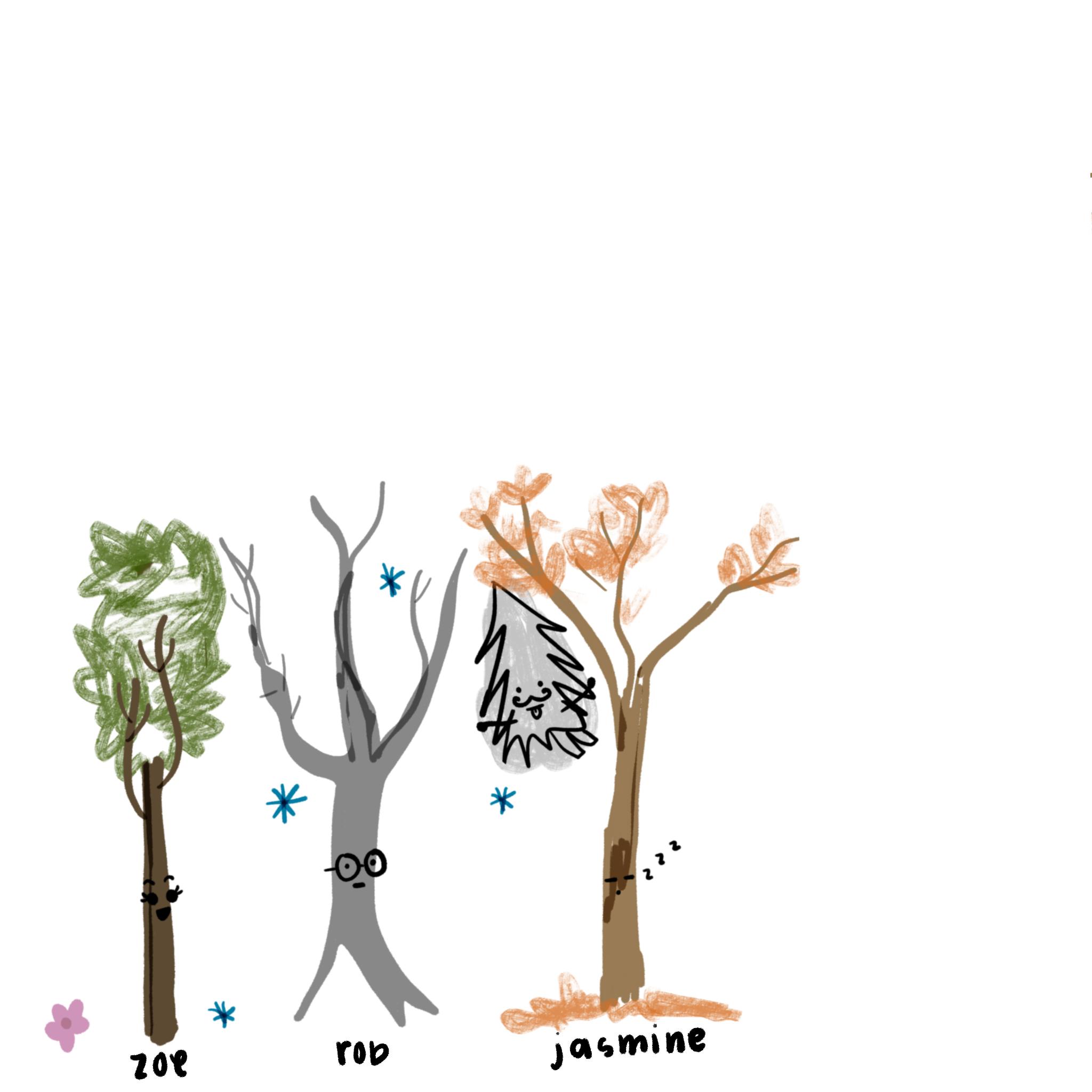

Ahh, the good old days. Itʼs hard to believe that I once was a young sapling but throughout every season I grew. In spring, I felt so happy and full of water and moisture. I grew so much.

And then, summer came around I was much drier, and my growth was denser. It was much harder for me to grow and I did not grow as much during this time. This process is how I earned my rings consisting of springwood and summerwood.

In my forest, we are governed by the FSC, the Forest Stewardship Council, which is LEED recognized and manages and sets standards/rules for my town. I am proud to say that we are all environmentally certified wood in this forest.

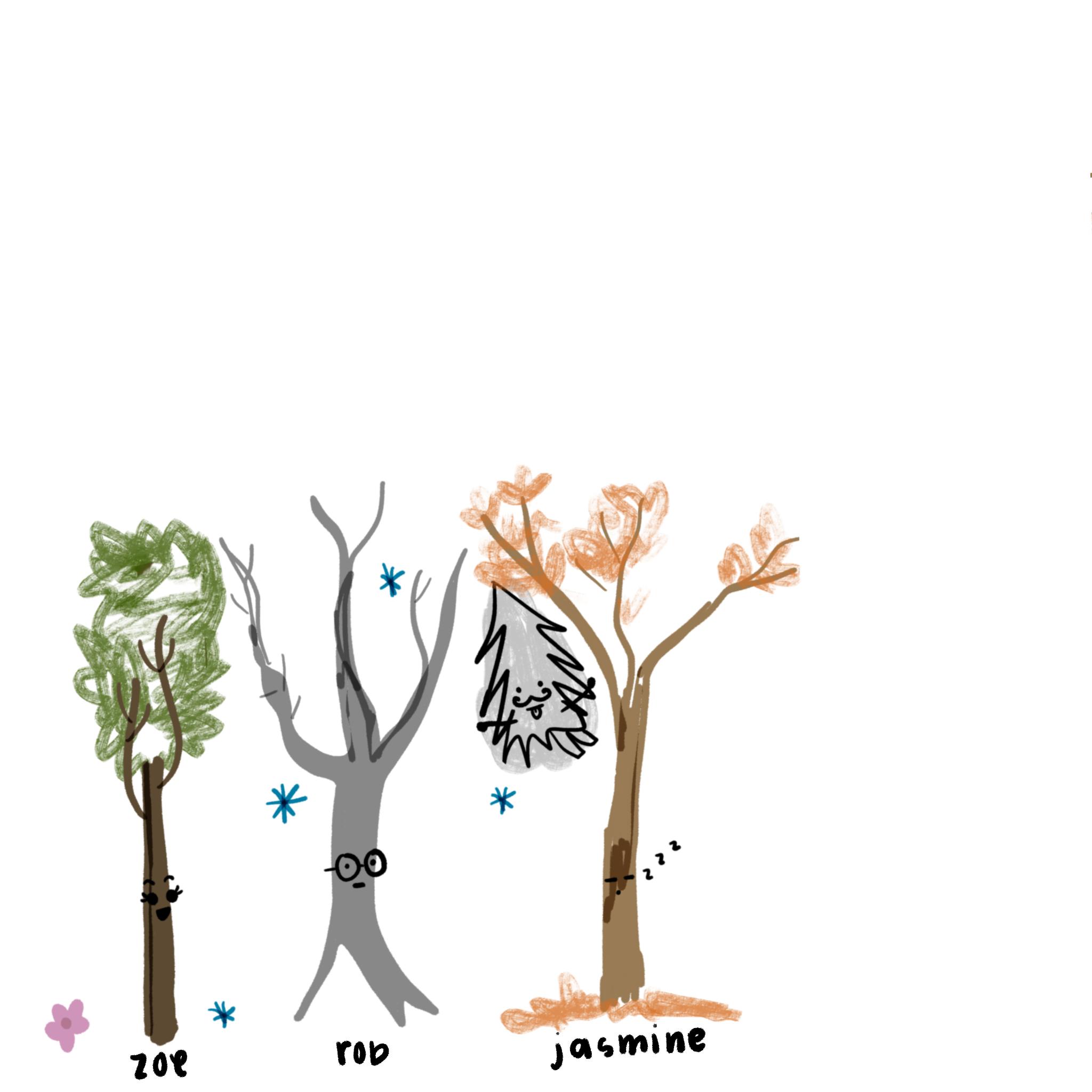

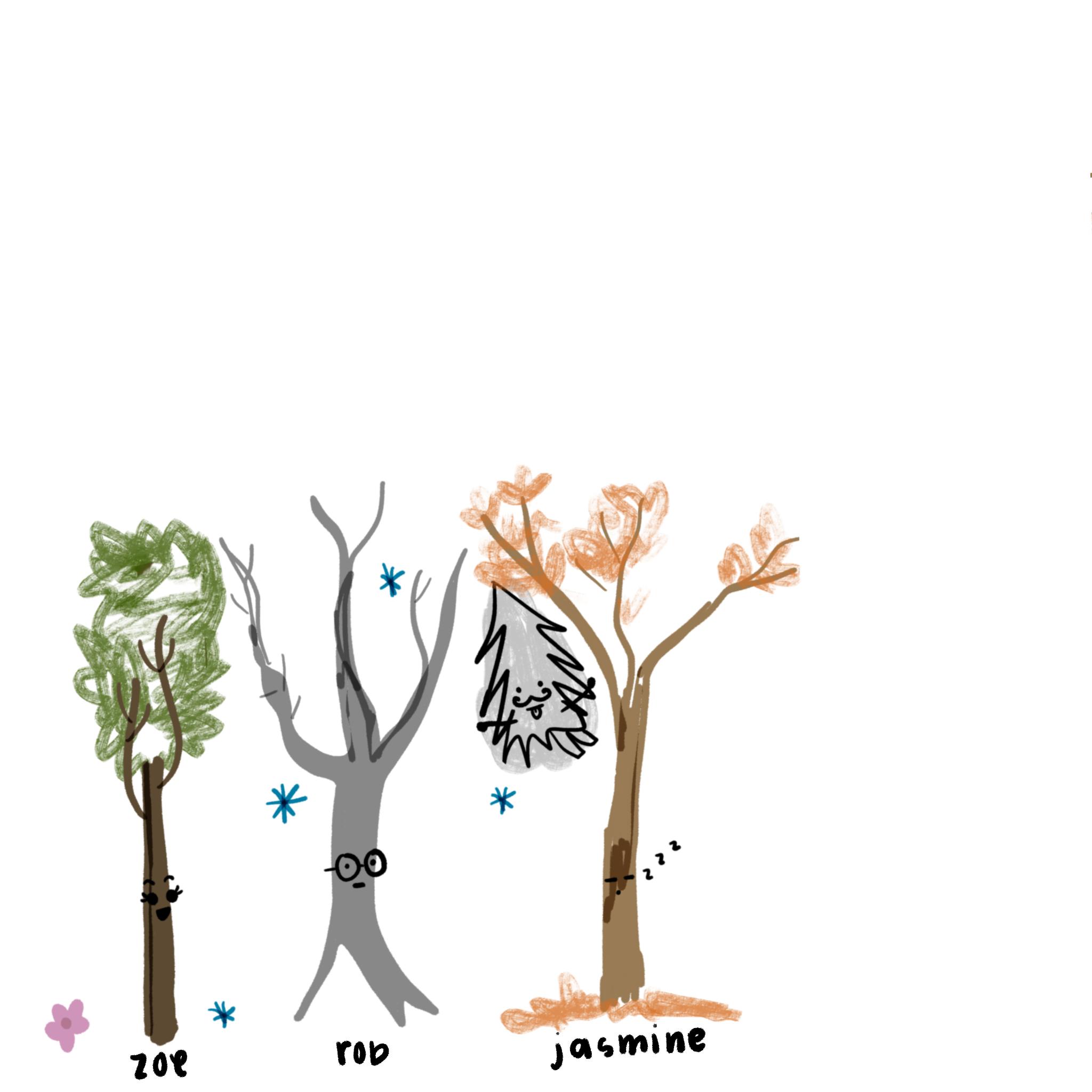

I had lots of friends growing up. Iʼm a softwood, but my hardwood friends are a little more complex. They have more ray cells and they honestly tend to have nicer grain patterns, but donʼt tell them I said that. Trees like me are more common and inexpensive to build with. Softwoods are commonly used as structural elements in buildings.

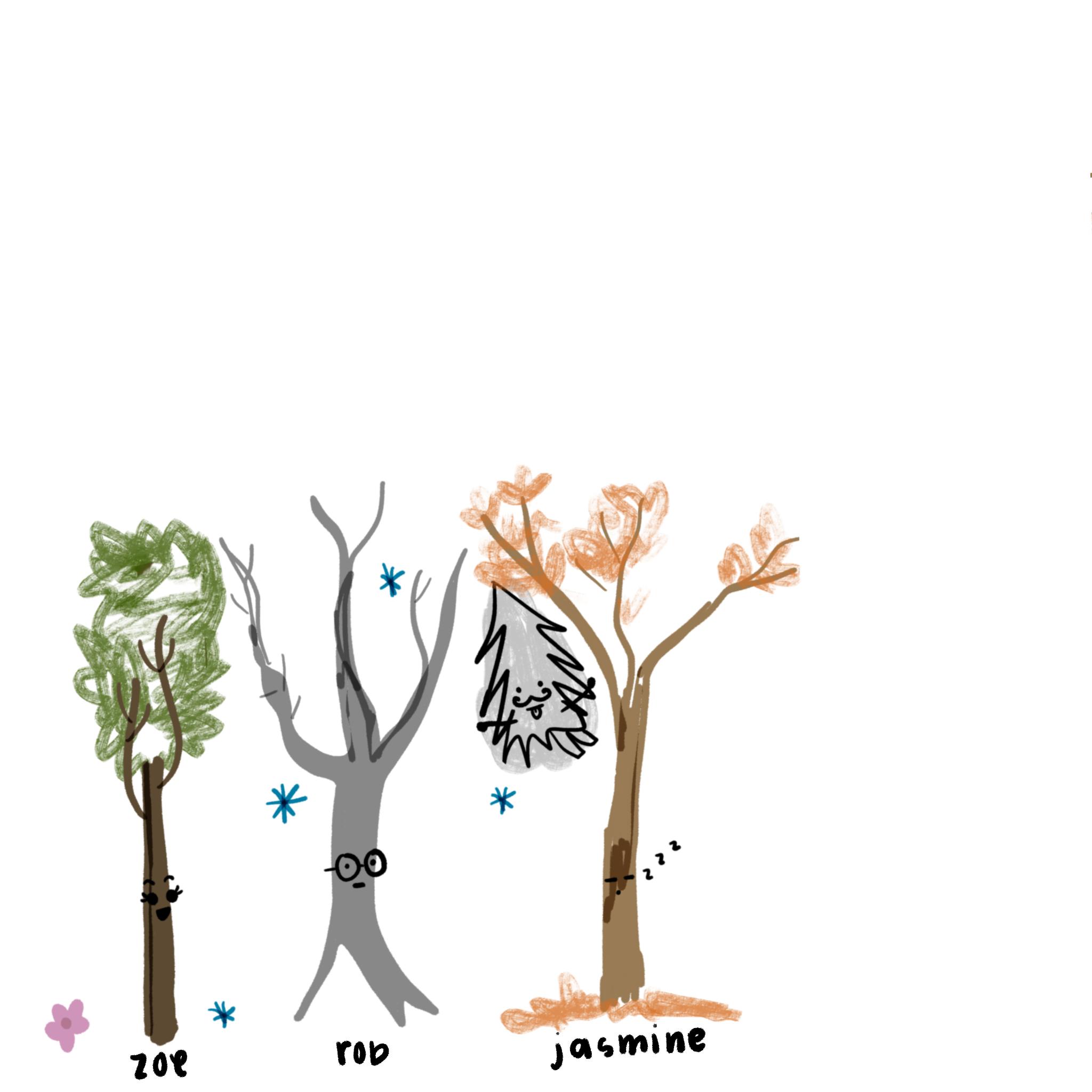

One morning, while I was enjoying a casual chat with my bird residents, I suddenly was chopped down and I began my afterlife. Then, I was transported to a sawmill and was sawn into lumber. I had the option to be either plainsawn or quartersawn.

I was plainsawn which requires the least repositioning and maximum yield of useful pieces. This made me have a broad and irregular grain figure. If I was quartersawn, my growth rings would likely be aligned at 45º creating a more consistent vertical grain. I would be more expensive that way.

After I was cut the water left my body and I was seasoned meaning dried to reduce my moisture content. How each of me and my friends was cut determined how we distorted as we dried. Due to shrinkage stresses, sometimes splits and checks occurred. All lumber has their unique quirks and idiosyncrasies. For instance, some have lots of knots and knotholes.

At the end of this process, I finally was structurally graded. Wood is anisotropic and can handle more compressive stress parallel to the grain.

For instance, my friend Douglas Fir has a great structural grade, but their strength of wood decreases as their moisture content increases.

As lumber, we trees have two enemies: Water and Fire. Moisture and Water make us vulnerable to expansion and splits. It also can encourage environments for decay and rot. Fungal growth can be minimized by using preservative treatments to give wood toxic properties to biological organisms. FRTs use pressure to impregnate wood with chemical salts, but is also expensive.

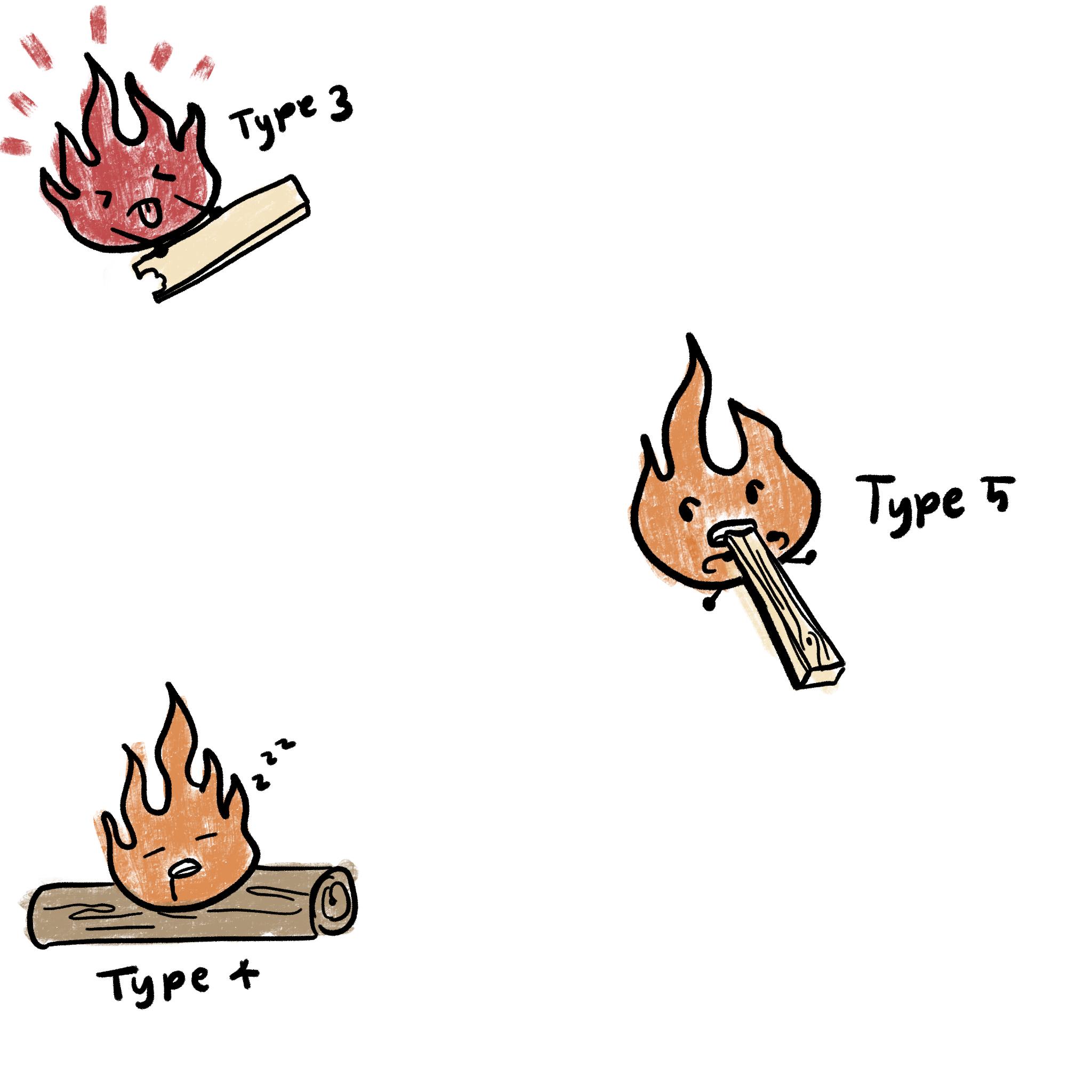

Fire

is scary because we are pretty combustible. In building code like IBC, we encompass Types 3, 4, and 5. Type 3 is FR wood, Type 4 is heavy timber, and Type 5 is 2ʼ x construction. Type 5B buildings can burn down in as little as 20 minutes greatly limiting the number of stories to only two.

Not to brag, but wood is flexible, can be inexpensive, relatively lightweight, and better for the environment than most building materials. We have been used in construction and architecture all over the world, like the Setas de Sevilla, Todaji in Japan, and many buildings in the United States where wood is readily available.

If you live in Berkeley, most construction is wood. With technology such as CLT, in the coming years you will see us as skyscrapers so watch out! My question for you is what will wood building look like in the near future?

The

End. (4 hours)