SOLA-SOLÉ JOSEPH

ARCHITECTURE

WELCOME

CONTENTS

THE PATH, SEGOVIA

A project in which my group mates and I deeply examined a precedent and adapted its materials and form to activate a local site in Segovia, Spain.

2. HONEYCOMB HOME

An exploration into the development of a repeatable housing module which can accommodate Northeastern graduate students.

A summer working at the Northeastern Center for design where I combined with a multidisciplinary team to develop a robotic table that aided in the fileting and sorting of large fish.

CRISP: BIG FISH PROCESSING GREEN RIBBON LIBRARY

5.

HACIN DESIGN INTERNSHIP

An overview of my semester at Hacin Design in Boston’s South End where I worked on construction sites, created graphics for publications and learned the ins and outs of MA Energy Code.

GRAPHIC DESIGN

A project dedicated to the restoration of a library and green space to Chinatown, a community which had been historically stripped of both. 6.

A dive into my experience as a graphic designer, both as head of production for my high school magazine and as a college student.

3. 4.

1.

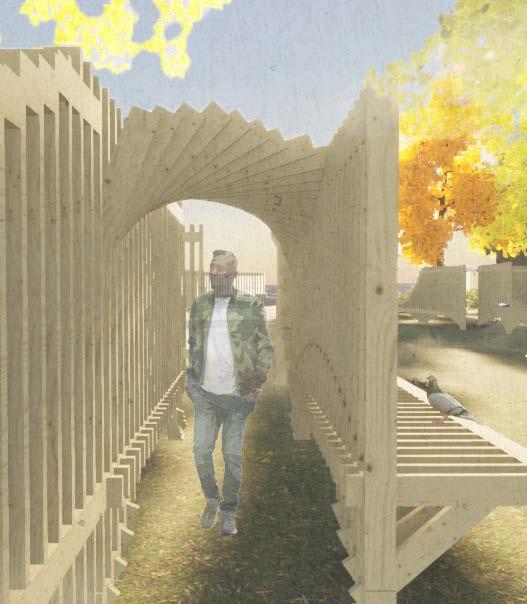

THE PATH

After an in-depth precedent study of an entirely wooden pavilion in a French bog, my three group members and I were tasked with dissecting the precedent and adapting it to a local site in Segovia, our small city of residence outside of Madrid. We spent the semester dedicating ourselves to understanding the complex construction of the original pavilion and learning how we could use its strengths and extract its materials to enhance our own site.

SEGOVIA, SPAIN 1.

SITE AND RENDERING EXPLORATION

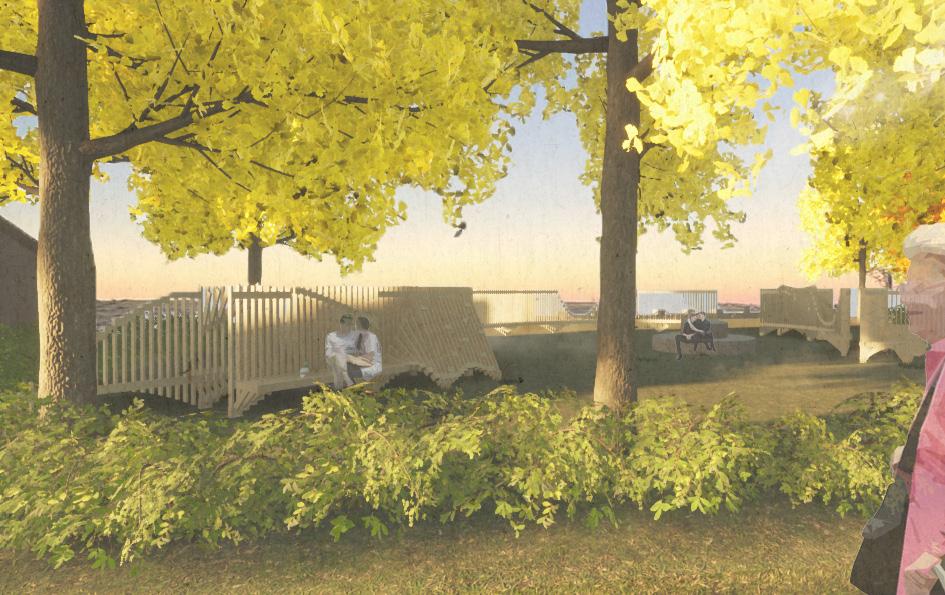

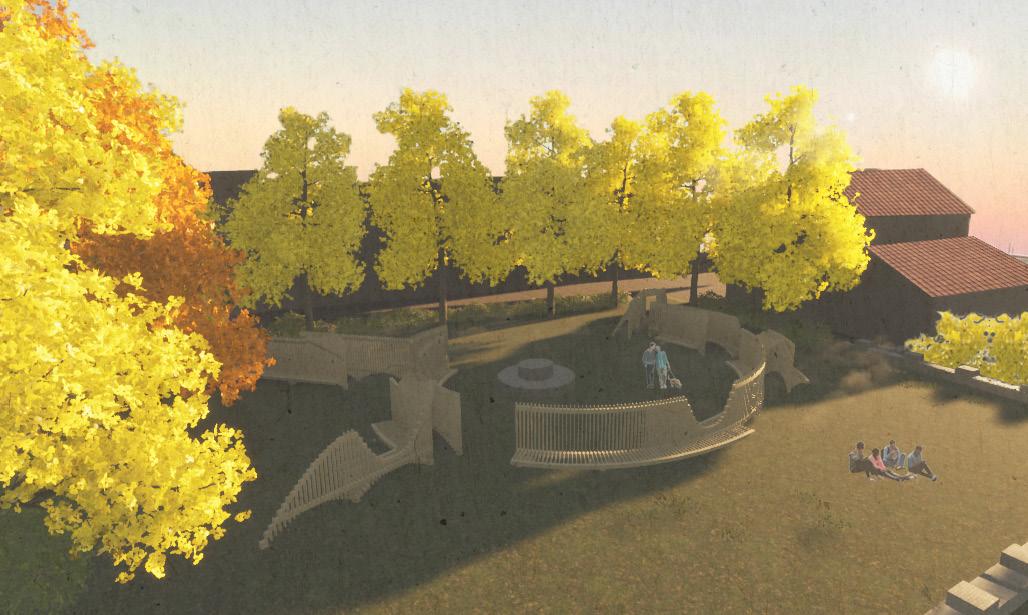

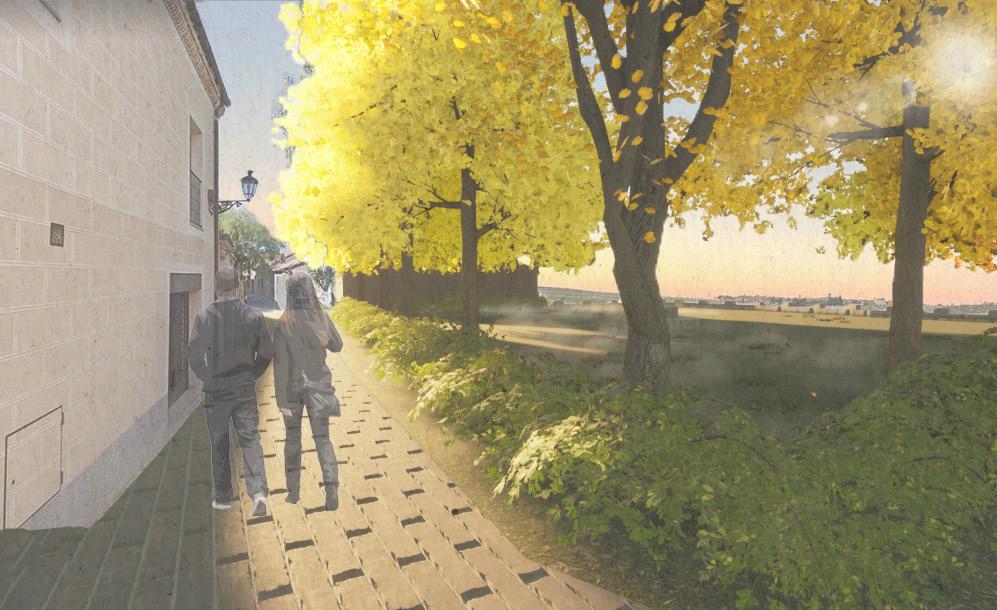

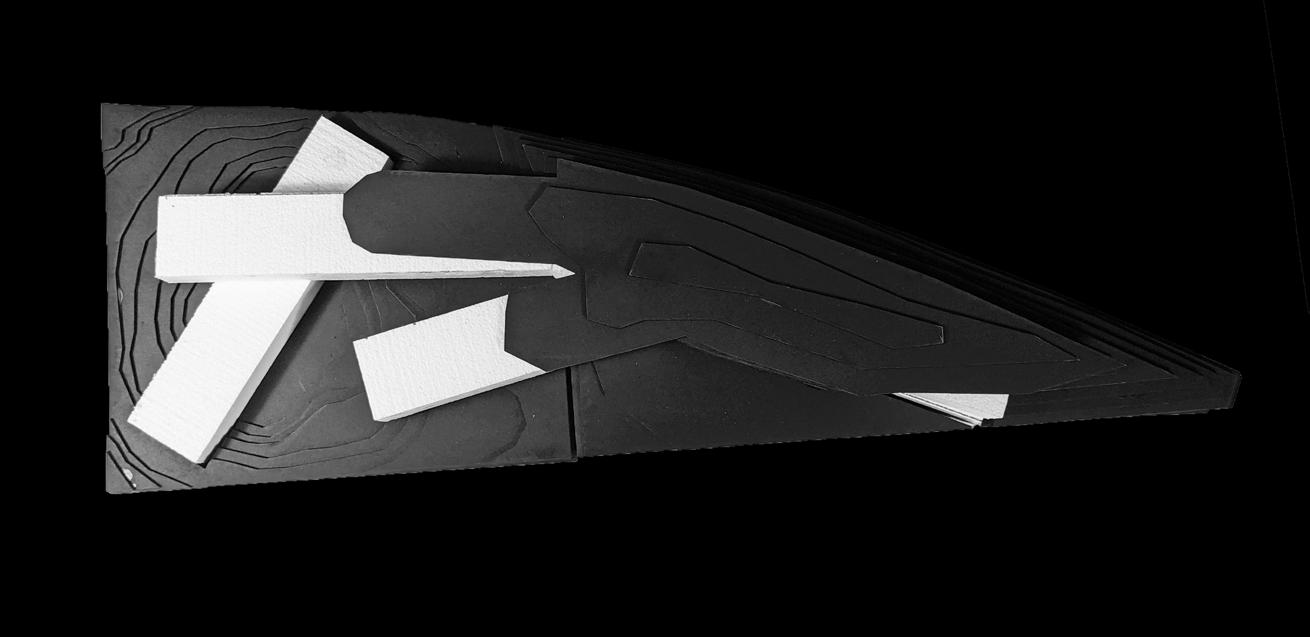

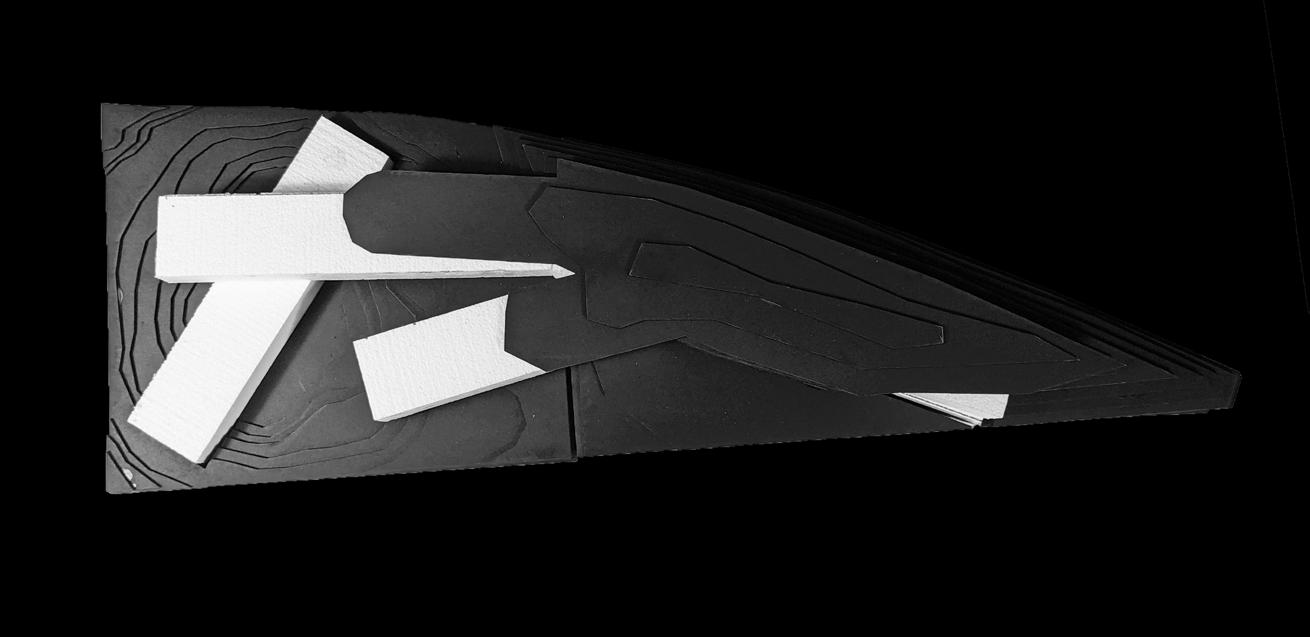

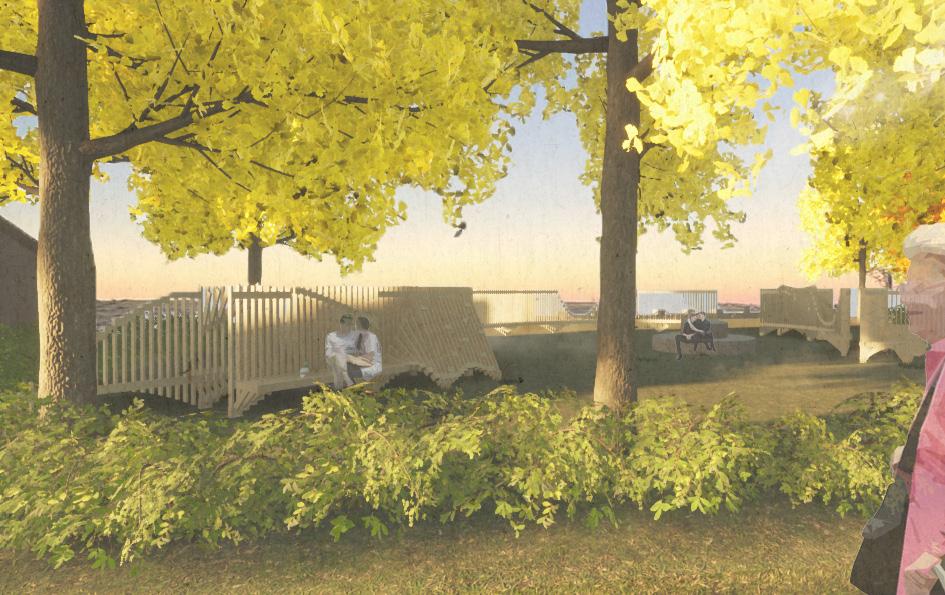

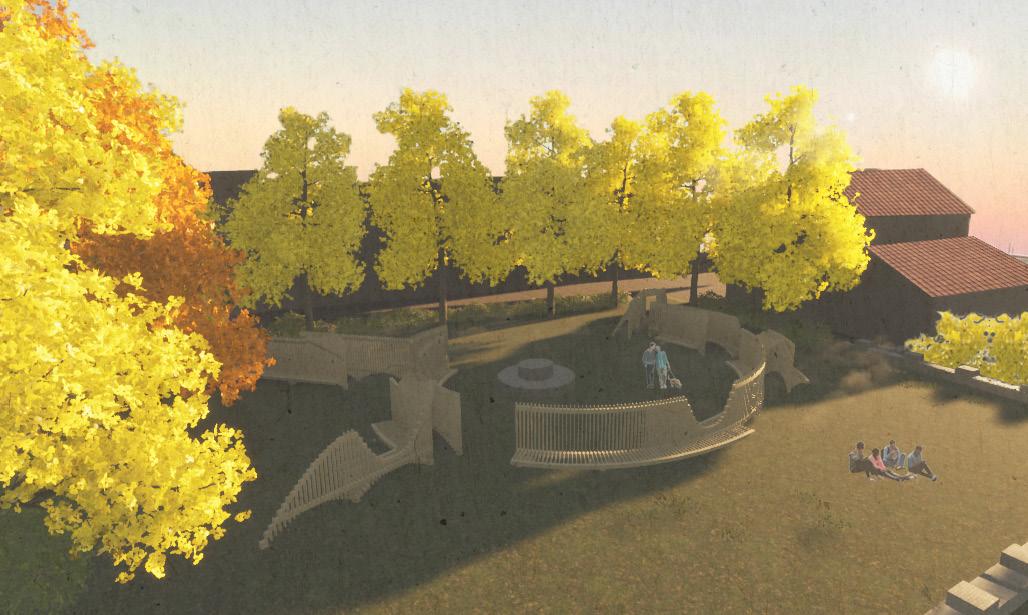

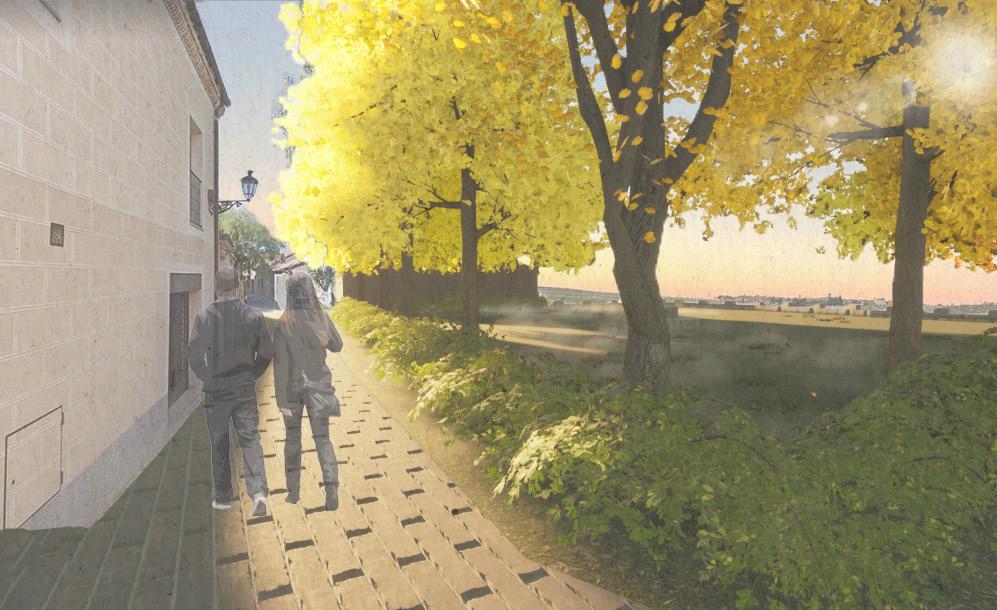

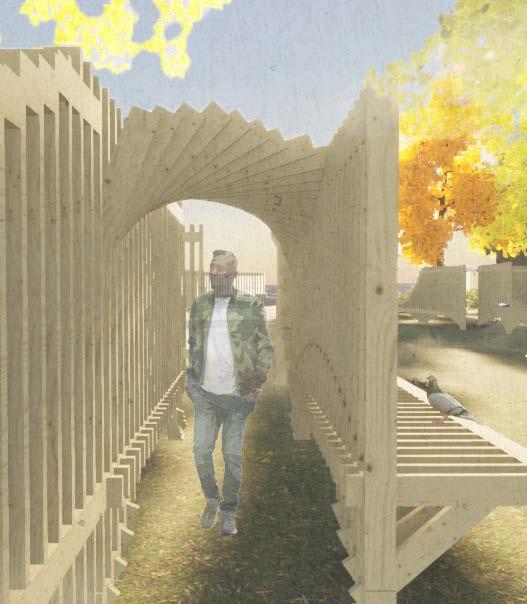

Our designated site was a park which looked out over the valley of Segovia. It stood at the intersection of three small roads on the way between the Roman Aqueduct and the Alcazar Castle, the two tourist attractions in the small city. In our exploration we found the site was poorly designed and failed to do three main things: facilitate traffic, activate its green space and encourage visitors to take in its beautiful view. To represent our site at different stages of our design process I carefully explored my first ever rendering software, Twin Motion.

OUR PRECEDENT

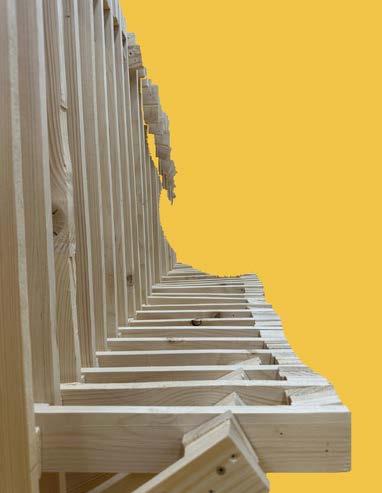

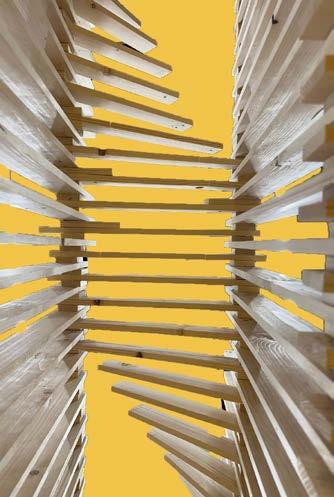

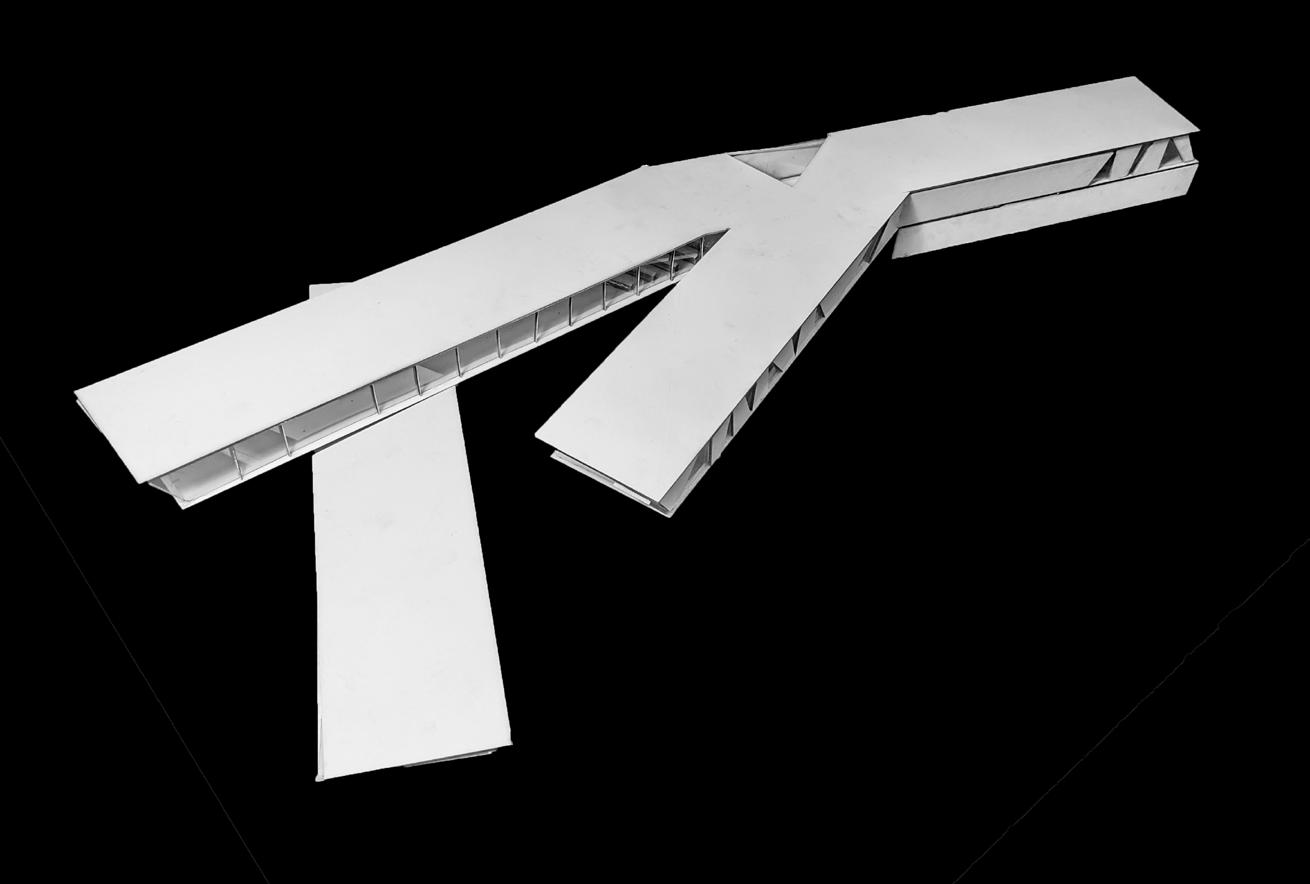

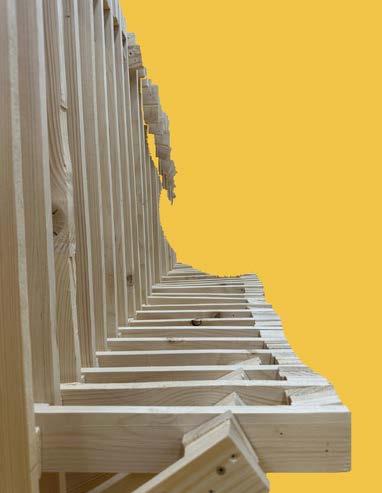

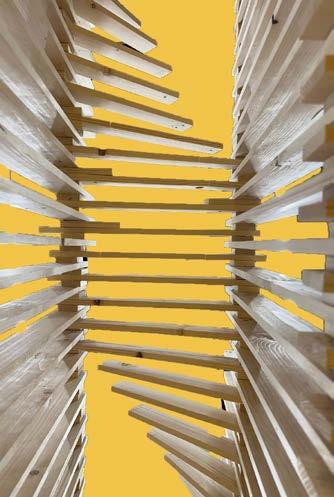

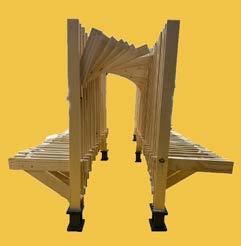

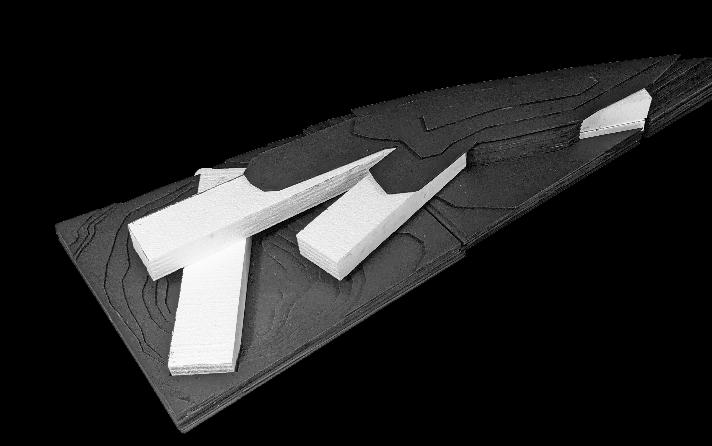

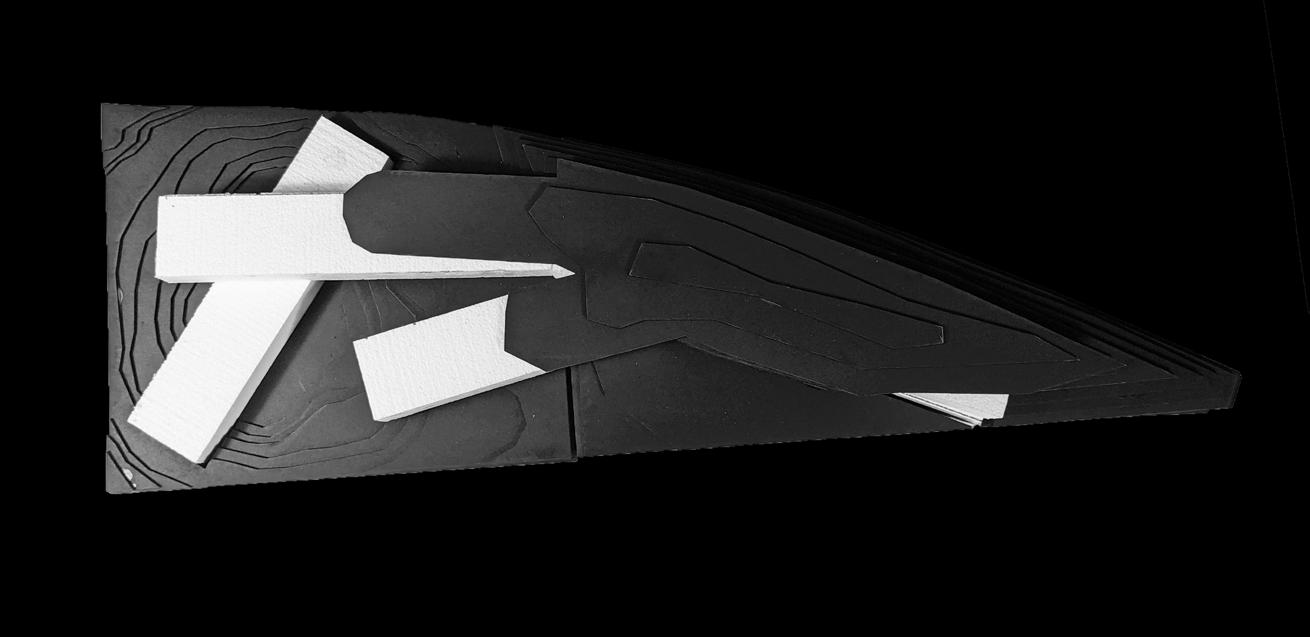

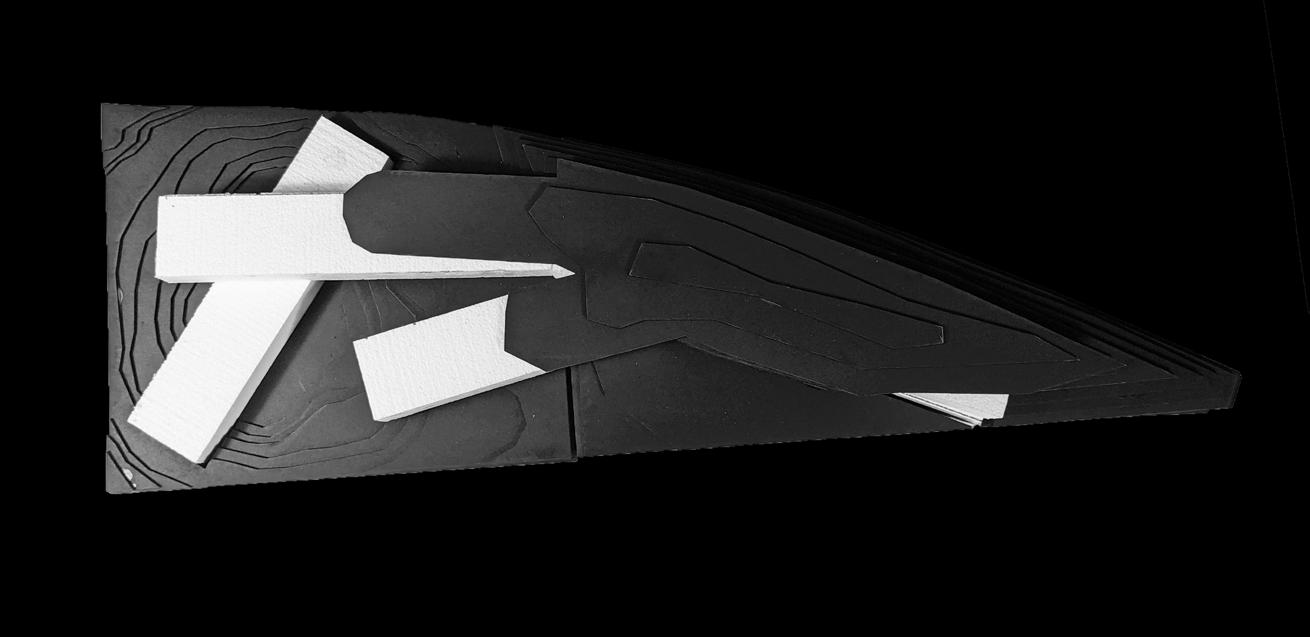

Our assigned precedent seen in this 1/100 model was a complex all wooden pavilion in a French forest. It was built as a gathering place for hikers and nature classes. Its undulating wooden beams are designed in the grasshopper software to mimic the thick forest canopy it sits below while maintaining a thin column shape below for easy visibility in and out.

Forest Shelter at Bertrichamp

Elena, Huzefa, Pilar, Joseph

Forest Shelter at Bertrichamp

Elena, Huzefa, Pilar, Joseph

Plans, Sections, Elevations

IN DEPTH EXPLORATION

The earliest stages of our semester involved a deep dive into the precedent. We were tasked with using only photos to extract a complete list of materials, determine siting, and find the full process used to build the pavilion. As we found more information, I was able to create the four following graphic representations: a materials list, a construction process, an exploded axon, and plans/sections/elevations. Each of these was consistently used to aid our own process as well as help illustrate our parameters during presentations.

Bertrichamp Elevations

Forest Shelter at

Sections Plans Middle Roof Base Joseph Upper Roof Connectors Interior Rafters Interior Supports Center Columns Exterior Supports Exterior Rafters

Joseph 6. 5. 147.2 Foot Connecting Screw Number in Whole Model: 12 VIS ASSY 3.0 5/50 Number in Whole Module: 785 VIS ASSY 3.0 5/80 Number in Whole Project: 1570 Exterior Rafters Number per Module: Wood: Pine cm cm Interior Supports Number per Module: 11 Wood: Pine cm cm 13.3 cm 11. 0.62 m 0.96 m 1.43 m 1.54 m 1.4 m 10. 9. 8. 7. 4. 12. 3. 2. 105 mm Hardware Roof Cap Number in Whole Project: Material: Plastic Upper Roof Number in Whole Project: Material: Corregated Plastic Interior Supports Number per Module: Wood: Fir 2.55 m 2.52 m Exterior Supports Number per Module: 11 Wood: Fir Center Columns Number per Module: 23 Wood: Pine Base Number per Module: Material: Metal Roof Connection Number per Module: 11 Wood: Fir Roof Connection Number per Module: 11 Wood: Fir Roof Connection 3 Number per Module: Wood: Fir Roof Connection cm cm cm cm Rafter Wedges Number per Module: 46 Wood: Fir cm 30 cm 11.7 mm mm Roof Connection Number per Module: 11 Wood: Fir Roofing Structure Lower Roof Number in Whole Project: 2 Material: Corregated Plastic Joseph First lay an outer roof slat on the floor. Followed by the longest center column. Finally lay the first outer support. The outer support is sandwiched on the top end by two 12x12 wood squares. Then lay the second longest center column and the first inner support. The inner support is connected in the same way as the first outer support. Attach a connectors to the edge of the longer rafter piece which will be used to connect to other modules later on. Attach bottom I-beam connector to tallest center columns. This piece is used to put the module into the ground when it is stood upright. On the other side, attach seven roof connectors perpenducular to roof slats. Additionally add one center piece to the edge of the inside. This will be used to connect modules together at the center. Finally attach clear corrugated roofing over roof connectors, and module is complete. Once on site place the module into pre-dug holes with concrete base inside. Place the base on top of concrete and fasten it using screws Repeat this process 11 more times to complete structure Module Construction Process Finish the process by placing a fiberglass corregated roof to the top of the structure. Use the roof connector piece to bridge the gap so that occupants are fully protected from precipitation. 1. 2. 3. 4. 5. 6. 7. 8. 9. Joseph

Exploded Axon

BUILDING AT A (NEAR) HUMAN SCALE

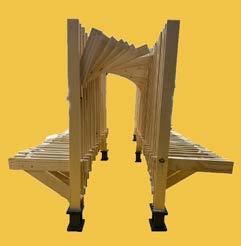

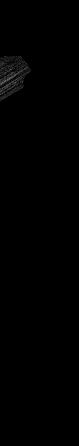

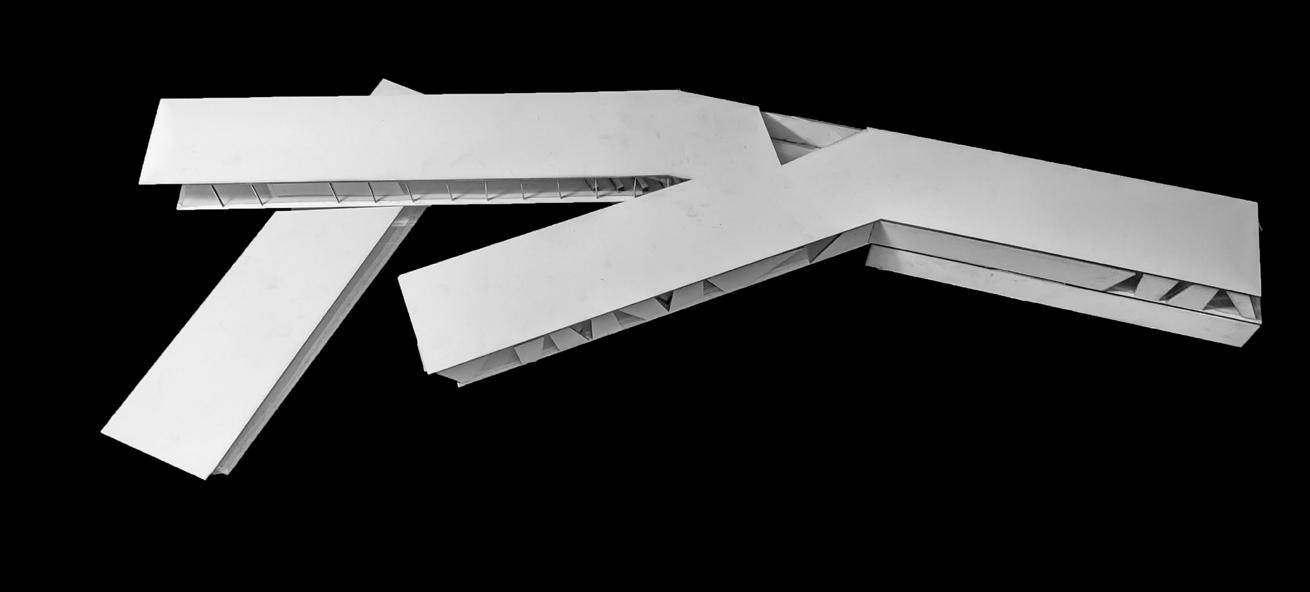

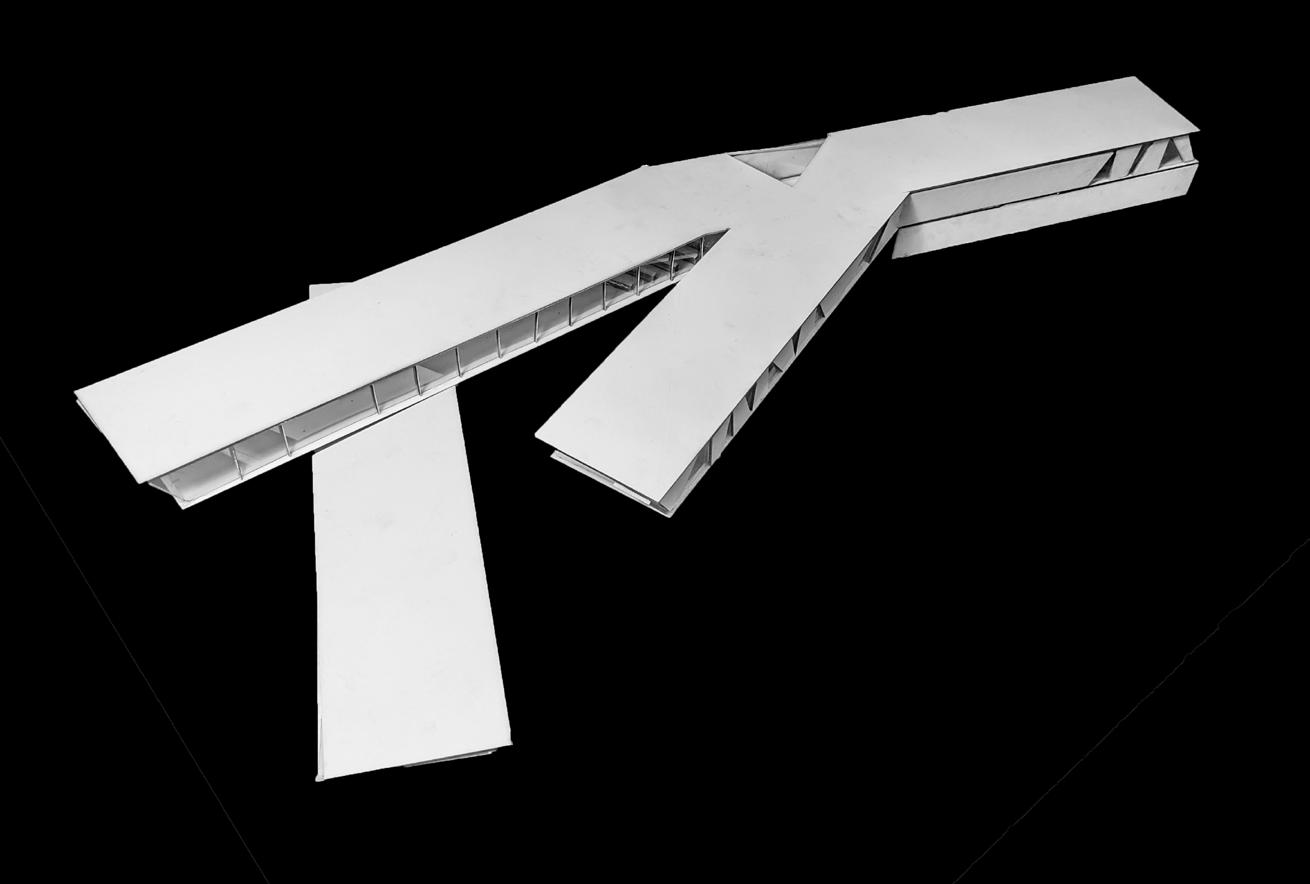

Across the semester we built two models at a whopping 1/2 scale. The first model was a representation of over a third of the original pavilion. For the second model, we were forbidden to buy any new materials, as our professors forced us to reuse exactly the same wood, plastic, and even screws to prove that our new design was in fact a complete repurposing of its former state.

JOSEPH JOSEPH

MODULES

A PROJECT IN PARTS

In our exploration of the original pavilion we found a recurring pattern of “modules” reflected and repeated to make the whole. We took the essence of this and recreated it in our own design. Each of the modules built off the base Wall Module which was built following the same pattern as our precedent.

TOLD THROUGH DIAGRAMS

MODULES

MODULES

As with any project, our main method of communication was the diagram. With this small snippet of the seemingly thousands of diagrams I made, we can see many ideas presented: How our project walls methodically guided site traffic, how we activated different portions of the site, how our benches and windows changed lines of site, how our roofs added impact to views, and finally how we were able to transfer the modules of the original precedent into our own modules while importantly keeping the same materials.

WALLS JOSEPH

MODULES

BENCHES JOSEPH

ENTRANCES JOSEPH

MODULES

ROOF JOSEPH

PLAY AREA 1: CLIMBING JOSEPH

MIRADOR CENTER PRIVACY BENCHES MODULES JOSEPH OUT IN WINDOWS MODULES JOSEPH WALLS WINDOWS ENTRANCE PLAY AREA 1 BENCH PLAY AREA 2 ROOF WALLS WINDOWS ENTRANCE PLAY AREA BENCH PLAY AREA 2 ROOF BUILDING BLOCKS JOSEPH

THE HONEYCOMB HOME

The spring semester of my second year was defined by the more “realistic” project of developing housing for graduate students at northeastern in a current on campus parking lot. We began the semester with a study of our urban landscape and then began experimentation with out own buildings comprised of repeatable and easily replicable modules.

BACK

2.

BAY, BOSTON, MA

MY DESIGN

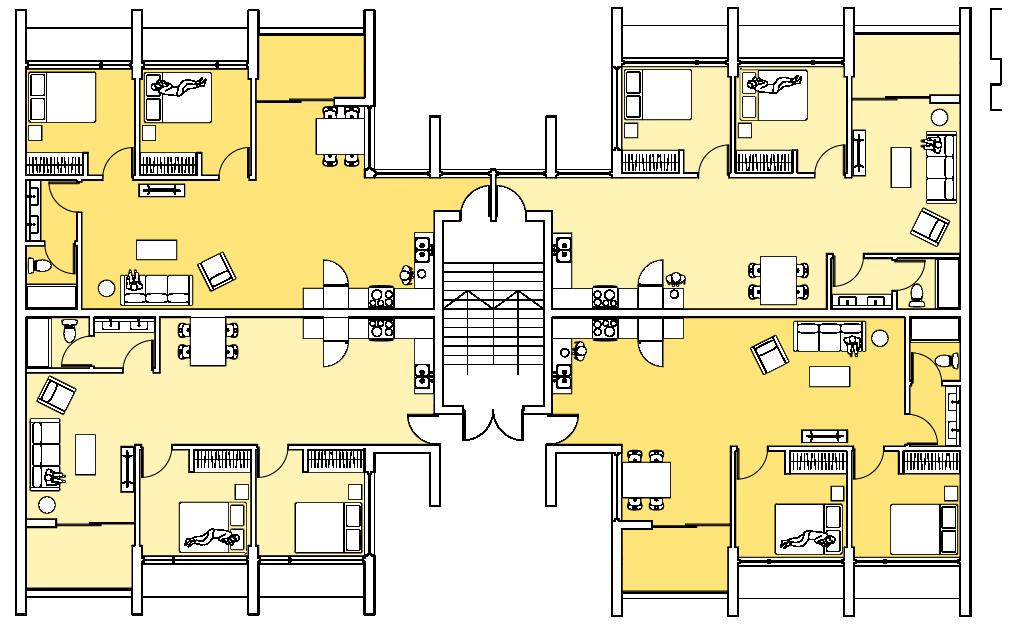

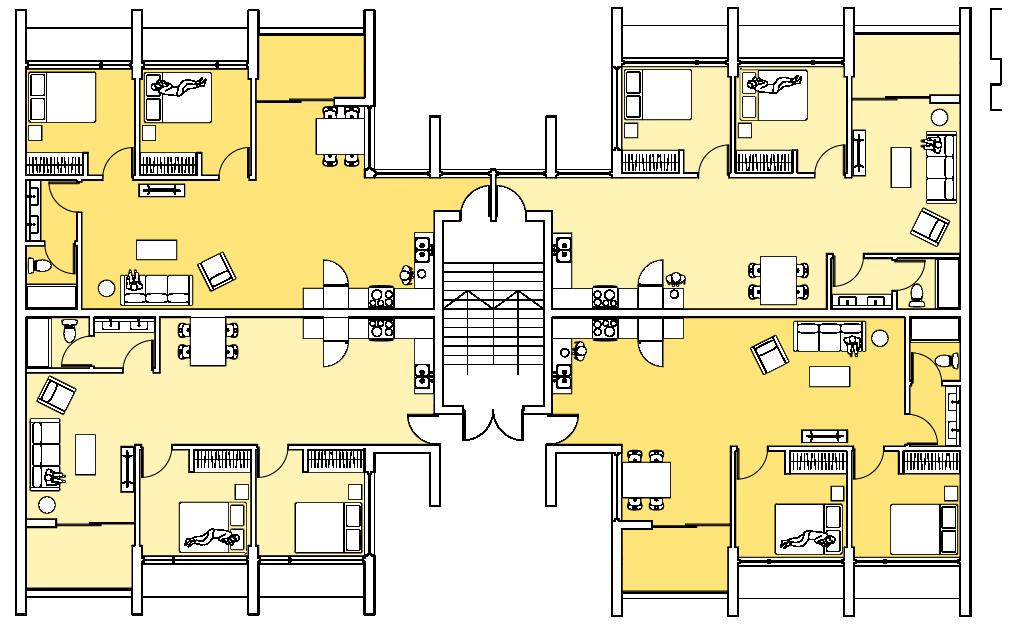

This project required us to develop a repeatable housing module for a site on campus that currently acts as a parking lot. In true modernist fashion, my project focuses its efforts on simplicity. The plan of the building is incredibly simple, and repetitive throughout. The simplicity and repetitivity is to theoretically keep building costs low which is both beneficial to the contractor and the target audience of likely cash strapped grad student. Though it does not match a honeycomb in shape, the building draws inspiration from a honeycomb in the way that the simple form of the facade matches the function of the interior. Each partition indicates a new space on the interior.

F1 F2 F3 F4

CRISP: BIG FISH PROCESSING

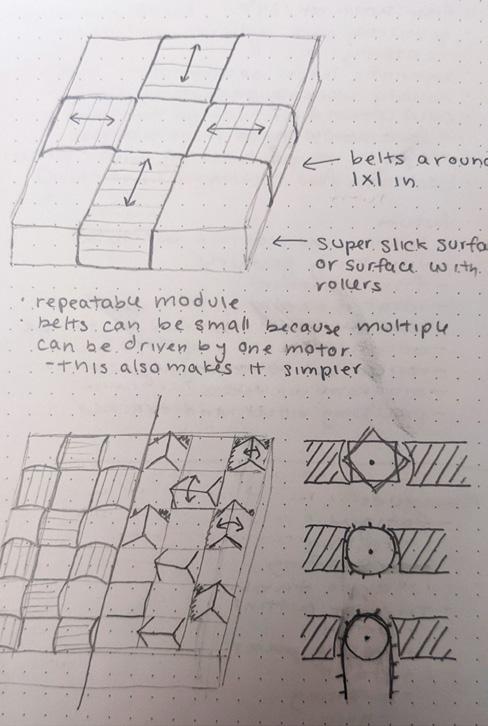

My summer 2022 was spent as a research assistant in the Northeastern Center for Design, an on campus organization led by professors which uses school funds to conduct research with a focus in arts and design. Under the leadership of Professor Kristian Kloeckl, I worked as the design expert in a team of engineers and computer scientists to develop a robotic table which aids the fileting and sorting of large deep sea catches.

NORTHEASTERN CENTER FOR DESIGN 3.

Feedback Systems

Proactive

Quarter Four Cutting Steps North Coast Swordfish Fish Maneuver Trash Maneuver Sort Maneuver First Half Second Half Cut w/ Separation Cut w/o Separation Quarter Three Half Two Quarter Two Quarter One Half One Full Fish Orienting Prep Misc. or Away From Table Direction indicates cut direction One Piece Two Pieces Three Pieces Two Pieces One Piece Two Pieces One Piece Setting up fish Knife Sharpening Remove Fin Remove Ice Remove Other Fin Separate into Halves Remove Spine Remove Trash Remove Trash Remove Trash Cut into Quarters Remove Trash Remove Trash Remove Trash Cut into Pieces Sort Pieces Cut off Piece and Sort Cut off Piece and Sort Remove Trash Sorting Repositioning Remove Trash Remove Trash Remove Trash Remove Trash Remove Trash Cut into Quarters Repositioning Cut off Piece and Sort Remove Trash Sorting Cut off Piece and Sort Cut into Pieces Sort Pieces THOUGHT PROCESS OF A PIECE ON THE TABLE Trash Final Ongoing What type of piece is as indicated by past steps? Does human interfere to change class? Display Classification Yes No Yes Display options and allow them to pick new one Start over Does human interfere to change? Yes Start over Is human working on it? Yes Leave Does it look almost complete? Yes None Called back Changed location Does human interfere to change? No Start over Move to trash Dynamically keep track of probability of different classifications and spots Are new pieces cut off? Remove piece from system End Does human gesture to move it? Yes No Yes No No Display options Yes No Do nothing Start over at Ongoing Reclassify both pieces Does piece class change? Start over at Normal for piece Start over for piece Start over for piece and Do nothing Start over at Ongoing Remove piece from system Display move options Does human gesture to move it? No No Repeat loop until True No Repeat loop until True Yes Move piece and continue to display options Any changes? Move to Front Repeat loop Move piece to set spot No Does human gesture to adjust or move? No Adjust Move Start over at Final Move Piece Display Classification Yes Final Trash Normal Gesture Actions - Display Options (hover) - Move (push) - Adjust (not sure)? - Pull Back (pull) - Change class (swipe) Thoughts - We need to recognize that there are many pieces on the table at a time - Table should have set zones that we know and fish can be moved to - Piece should only move human signals unless it is trash that has been tossed on the back - We need to include types of rolls - We need to set a fine line for when a projection shows up - And if the human needs it otherwise they can hover over it or something and will show up (part of me thinks this should be the only time projection shows up) - Could possibly have a light projection until they want the full one so info is always visible - Minimap would be extremely helpful - We need to be able to tell when the human is working and on what piece either through gesture recognition or knife sensors - If human wants to move by themselves (maybe because its a small piece only moving little) we shouldnt activate rollers -In the case of projections, computer needs to probably recognize somehow what the most important piece is so it can display only one object at time Color Key Computer Action Computer Query End of full loop End of small loop Key Points - Every piece should have a dynamic probability for where it will move at all times so it can be moved easily - This process begins as soon as a new piece is recognized on the table and loops until that piece is removed - It is essentially laid out like a bunch of while loops with if statements - Stars indicate areas of question - Each loop should be a frequent refresh so that human can interfere at any point necesary - We’re assuming that the human can hover and change planned direction at any point Three Classifications - Final - Pieces that are being sorted - Trash - Pieces that are no longer needed and not being sorted - Ongoing - These are full/quarter/half pieces of fish that are still going to be worked on - Types of moves 1. Move away 2. Move around 3. Adjust Display Classification No Is human working on it? Move piece to new set spot Remove piece from system End Remove piece from system End Yirisai Sushi Tuna 250lb Large // 04 02 2022 16 2 Input

Gestures - Can be a mix with wearables - Finger recieved the best feedback in study - Develop a language of 2-4 gestures - Could involve pointing as well - Make use of Microsoft Tech (MRTK) Knife - My favorite option - Knife with electronics in a removable hilt - He never puts his knife down - Options for input Buttons Gestures/Pointing - Vibration feedback Wearables - Can be on finger, wrist, forearm, foot Finger recieved highest feedback But wrist seems most logical here - Buttons to create input - Vibrotactile feedback Touch - Simplest option and my second favorites - Easy to implement with touch projectors Arrow Option - Highlights piece that will be moving - Shows arrows of where the piece is going - Could also be accomplished with just highlighing destination - Assigns numbers to each option - Options in order of most likely option - Only active when piece is about to move Simple Option - Similar to Arrow Option, highlights piece and presents options - Options in order of most likely - Very low profile / not distracting - Only active when piece is about to move “Auto Complete” Option - Low key option - Highlights moving piece - Options are presented at the front of the table where cutter can easily select - constantly updating options below and cutter can choose at any point - might mean projector shines on person or gets in way Screen Option - Projection only happens on bottom right or left - “screen” is a scale replication of the table and indicates fish direction - Cutter can draw out paths or select final destinations by touching it - Best option for Proactive AI in my opinion - Also possible projector interferance AI & Human Relationship - AI is Constantly reacting to human as they work - User is presented with options as they work and can choose to use or ignore any of them - Key is that user has choice and can ignore Continuous C P C C C P - AI decides when to act based on human actions - AI acts entirely on its own and human doesnt have to choose - Key is that user can stop the process and manually adjust, pick another option, or ask AI to repick

Table and Human Interaction

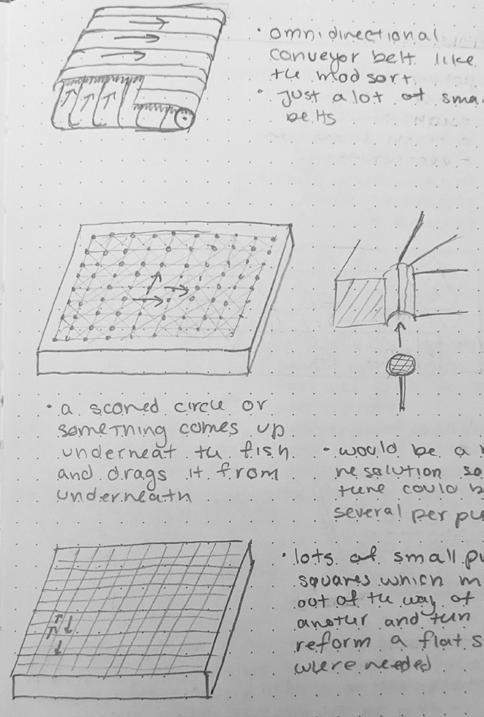

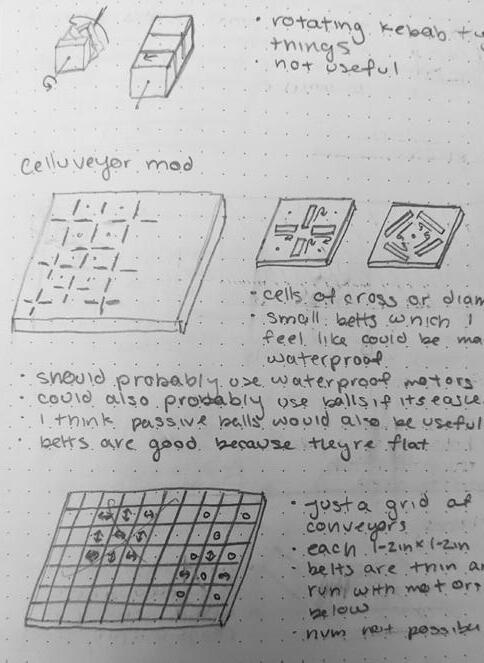

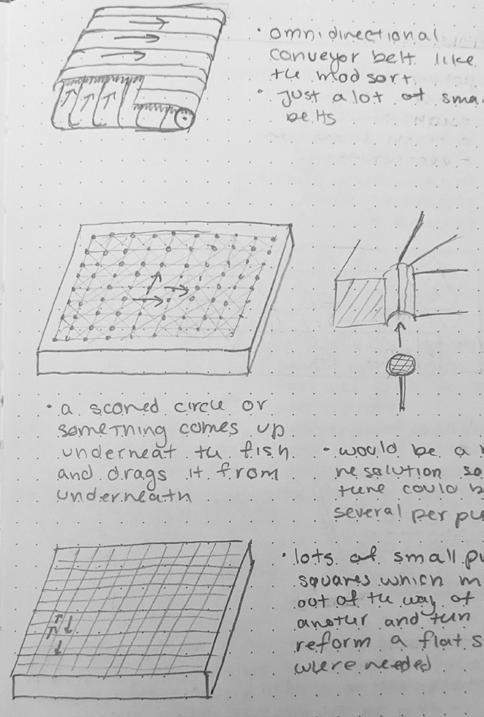

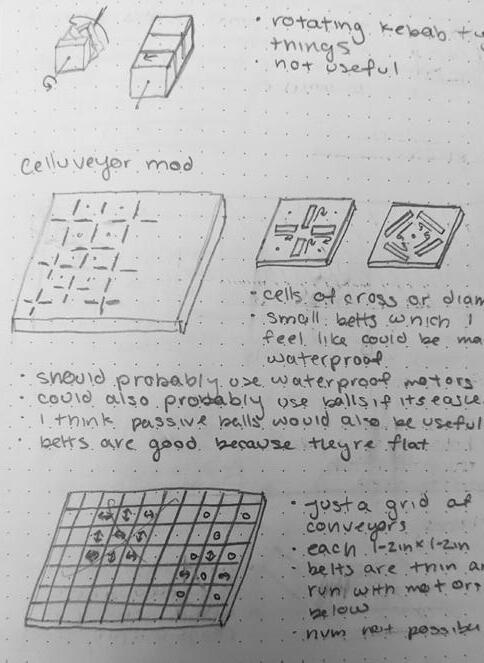

SUMMER OF DESIGN

I worked over the course of the summer with engineers, designers, and computer scientists to develop a robotic table which could recognize and sort pieces of a large fish as a skilled worker fillets. The project required me to draw on my computer, design, and engineering skills to develop the perfect table. I utilized diagrams and sketches to guide my own thoughts and visualize ideas that the group came up with together.

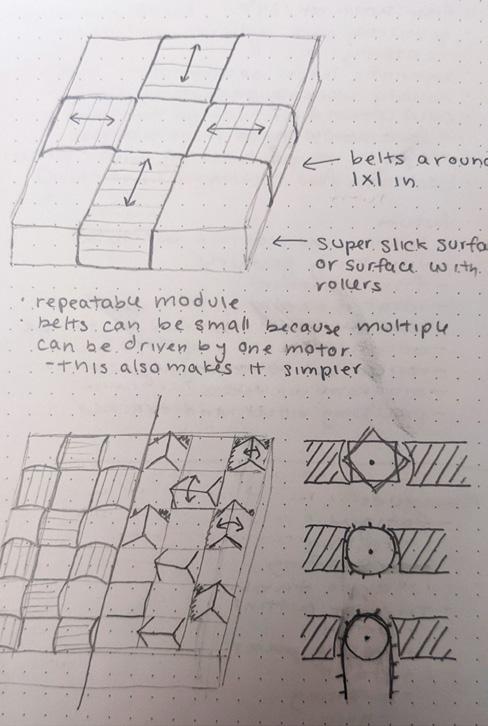

TABLE MECHANISM PROTOTYPE

This is an early prototype of the table mechanism which I helped design. it consists of several rotating squares which lay flat when not needed to create a fully flat work service for the fish cutter. The cubes, while hand turned in this prototype, will be driven by a series of motors, rods, belts, and clutches which a team of mechanical engineers and I worked together to develop after weeks of research and calculations.

4.

CHINATOWN, BOSTON, MA

CHINATOWN, BOSTON, MA

THE GREEN RIBBON LIBRARY

My first ever in-person studio in Fall 2021 revolved around the neighborhood of Chinatown in Boston, an area which has been historically oppressed and diminished by a constant stream of external development taking land from residents and raising cost of living. Because of this, Chinatown lost its library in the mid 20th century, and never had the space to develop another. We were tasked with bringing a library, and all of the essential resources it presents to a community, back to Chinatown on the site of an old parking garage.

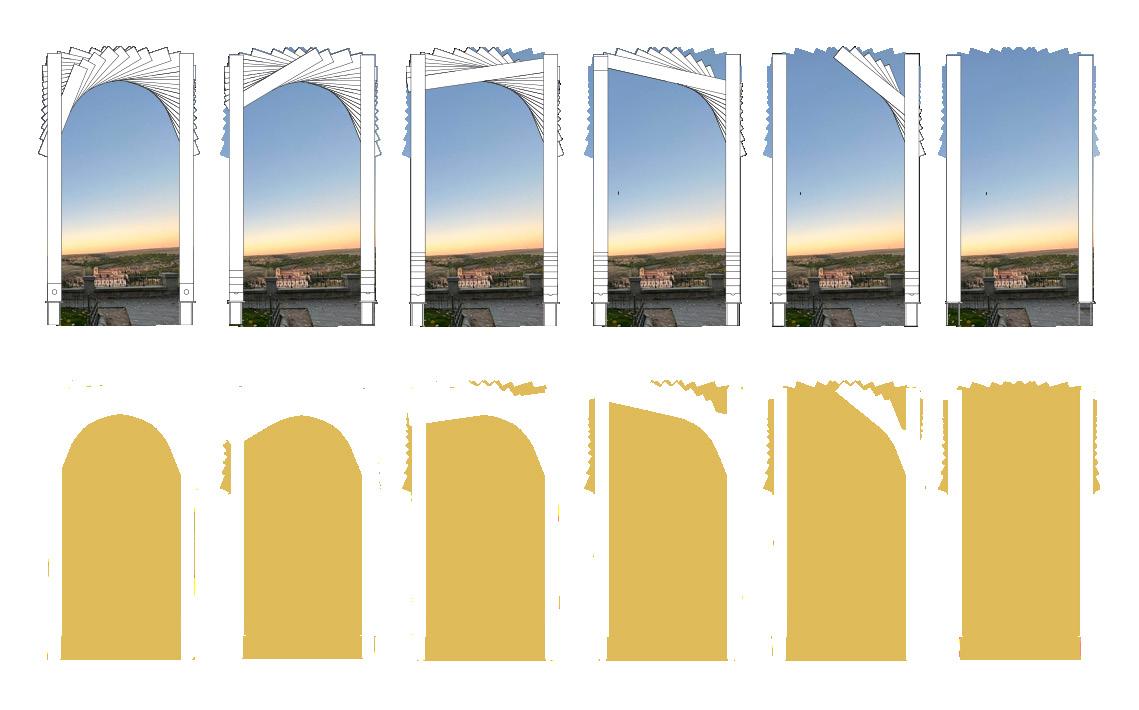

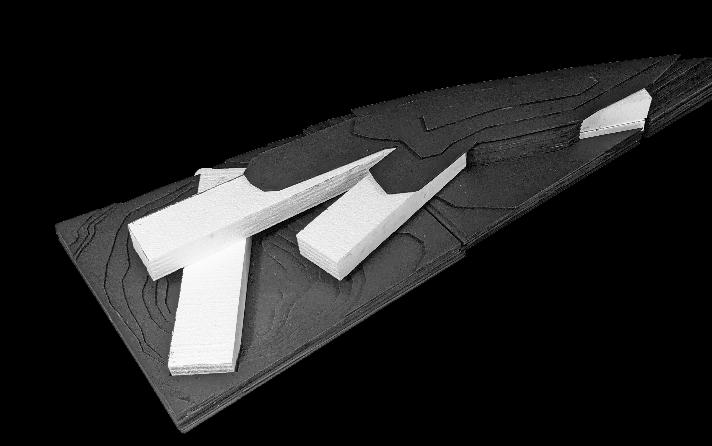

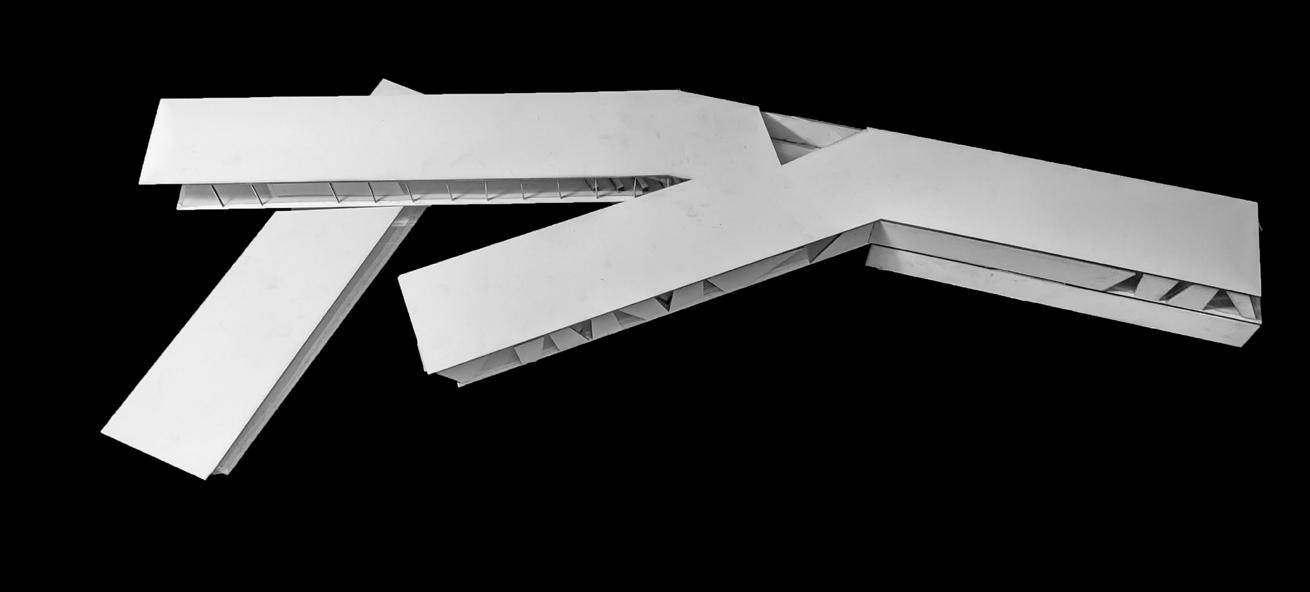

A FORM STUDY

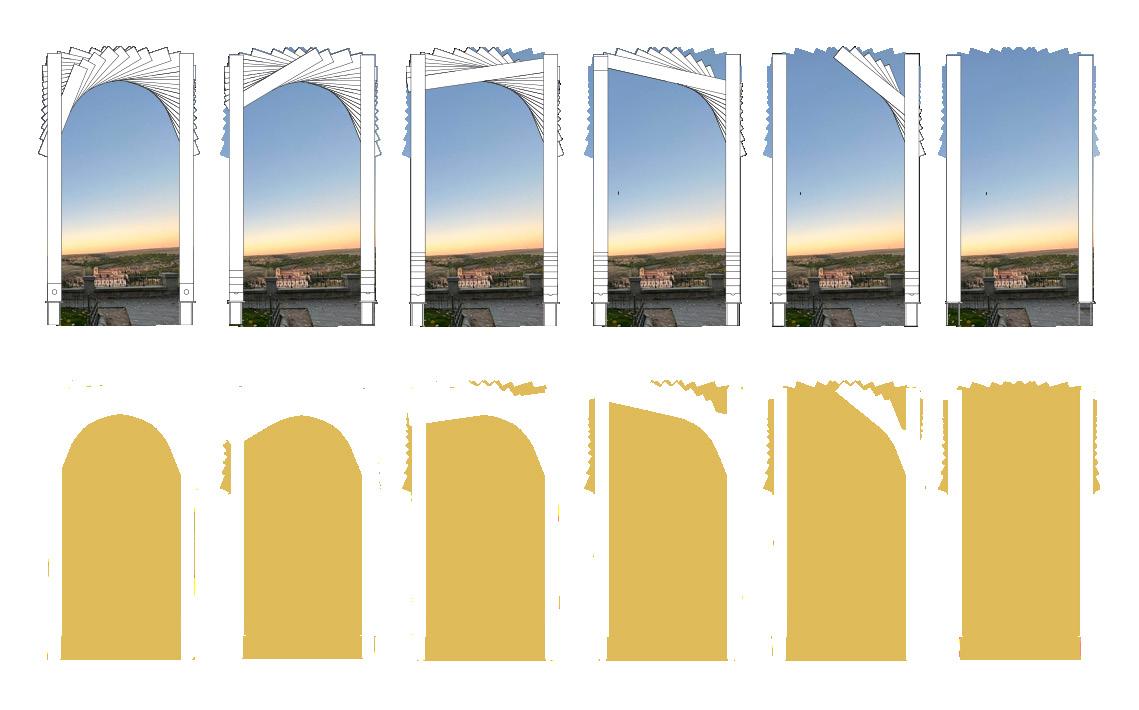

A graphic created to explore possible orientations of an early idea involving 4 masses which eventually evolved into my final form. Each tile examines a possible layout and its view of the street to the right.

FINAL DESIGN

The Green Ribbon library seeks to solve the problem of green space in Chinatown/ the leather district. The greenway, which provides this necessity to so many neighborhoods stops unceremoniously before hitting Chinatown. This design creates a space which facilitates wandering through and getting lost in nature. The rolling hill, like a ribbon around a present, wraps over and then under the building so that one can wander across the whole plot, through the trees. This feeling is brought inside through the controlled views which offer a constant view of the greenery outdoors and natural motifs/ elements which bring the sense of nature into the building.

11

F1 F2

SOUTH END, BOSTON, MA

SOUTH END, BOSTON, MA

HACIN DESIGN INTERNSHIP

My time at Hacin cannot be defined by one single thing. Over my six months there, I punch listed a multifamily apartment building, worked in marketing, coordinated vendor and client meetings, learned key 3D design and rendering softwares, and took a deep dive into Massachusetts Energy Code. The following is a representation of the work I did for the marketing department.

5.

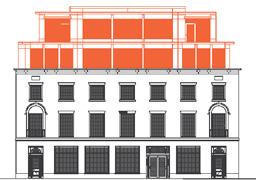

DIAGRAMING ADAPTIVE RE-USE

A group of three diagrams delving behind the scenes of one of Hacin’s marquee services, adaptive reuse. For each of the three diagrams I had in depth conversations with the lead architects and poured through old construction documents to uncover the secrets behind the structure, material, construction techniques and problem solving that made these three projects so unique.

UnderlyingStructure

SectionCut

3 story addition placed on top of the existing roof and new support system. Original cast iron columns were kept in place. Floor Floor Floor Floor Floor Floor Floor Floor Roof Space between existing steel -beams filled with fire retardant grout. New foundation and infill slab doweled into existing foundation. New steel tie-beams and cross bracing attached to new column below existing steel beams. Steel stiffener plates are installed between flanges existing beams to increase support for new load. Column tied into metal rebarring placed throughout the new foundation to reinforce concrete. Lafayette Lofts: The Adaptive Re-use of a 19th Century Mercantile Building and Three Story Addition In the heart of downtown Boston, Lafayette Lofts one of the first, new-construction residential projects to be built in the Midtown Textile District. Located in restored 19th-century mercantile building, the project is comprised of 38 lofts, many of them duplexes with dramatic terraces, housed in a 3-story glass and metal panel penthouse addition overlooking the Rose Kennedy Greenway. Existing -Beams

New steel columns are inserted between existing beams to augment existing structural frame and add capacity for addition. New anchors are screwed into walls underneath each floor provide extra support. New foundations are dug around existing foundations for each new column. Basement Sidewalk Renovations of Existing Warehouse Buildings New Construction 348 Congress Street 354 Congress Street Fire Museum (Outside Project Scope) FP3: An Adjacent Infill and Rooftop Addition Threaded Through Existing Warehouses FP3 includes two fully renovated 19th century warehouse buildings, new adjacent infill building and a terraced 3-story rooftop addition, adding 76 lofts, three restaurants and lobby gallery to the Fort Point arts district of Boston. The modern rooftop addition is supported on new steel superstructure woven through the original heavy timber structure, thus allowing the two existing buildings to be substantially preserved as purposeful pieces of existing urban fabric. Requiring less new material and generating less construction waste, the new internal structure also supports new elevators and stairs and provides seismic stabilization for the entire complex. Within the new infill building, reclaimed lumber from the two original structures shapes the main lobby. New Floor New Top Floor New reinforced concrete ribs between windows from basement roof in existing buildings. Floor beams were tied into masonry where they were originally not. Floors of the old warehouses were supported by wooden columns 15” wide the basement and 1” smaller on each higher floor. New columns were tied into old floor beams on every floor. New columns sit steel and concrete screw-in piles. Old walls and columns sit on wooden piles. Masonry walls are 24” the base and narrow 16” top. Building Cross Section New reinforced concrete columns run through the old floors, supporting the new weight and tying into the existing floor joists for lateral stability. Old columns and roof removed from former top floor, replaced with concrete and steel elements. Sidewalk New Floor Floor Floor Floor Floor Floor Basement New floors step back from the street, giving each floor roof Basement Floor became 10” slab tied the walls for seismic support. The new building cross braced to help support the old buildings. new inner core braced with structural steel runs from basement penthouses. The core houses staircases and elevators. New reinforced concrete floors replace the old roof and basement. Reinforcements CongressStreet Thompson Place New reinforced concrete ribs between windows from basement to roof existing buildings. Section seen above New Reinforced Concrete Columns Big Beams 14” 18” Cross Beams 10” 16” Sidewalk Reinforced concrete shear walls created between windows meet current codes. combination of metal studs and steel deck make up new structure maximize acoustics separation and minimize waste. Openings in floor created to bring light into basement. Openings in existing slab created for new stairs and elevator reinforced with new steel. Addition levels step back from street to create roof decks for top unit and reduce presence on street. Arlington House: A Bay Village Film Industry Warehouse Transformed into Luxury Housing Arlington House boutique, five-unit residential building in Boston’s Bay Village neighborhood. The project includes the renovation of historic building as well as two-story addition. Originally built in 1931 as storage space for neighboring film industry equipment and later used for commercial businesses, offices, and retail storefront, the building’s interior space was carefully adapted to create five distinct, luxury residences, each with its own unique features. The top two floors comprise the penthouse unit and offer grand views of the Bay Village as well as the Back Bay just beyond. The historic, brick façade was preserved, with newly-pointed brick, stonework and Juliet balconies while the contemporary addition symbolizes the 21st-century revitalization of the building. Cuts and Fills New Floor New Floor Floor Floor Floor Basement Existing openings filled to create new rooms. Historic doors and transoms above doors restored to original condition. Newly reinforced masonry elevator core contributes to lateral force resistance system. New opening for car lift Water infiltration system installed below slab. New foundations and micropiles placed for car lift and elevator pit. Street View Elevation Roof Deck Steel and Concrete Metal Stud Raised plenum floor to provide better relationship to window sills Reinforced concrete shear walls between windows on each floor support increased lateral forces. Curated by 450 HARRISON 1 Atsu Gunther Bremelia Casa Candice Couture Ellisha Textiles Giardini Lisa Hillson C-21 C-1 A-17 C-15 C-3 C-16 C-13 460 HARRISON 2 SoWa Studios Michael Studio Alpha Bromfield Chase Gallery Gallery Kim Druker Stockwell Kingston Lanoue Marie Millinery The Open Press Clay Lounge Minni OKW Stitch The Vintage Garden Wyllo Casa Outdoor Giorgetti Molteni&C DADA 200420 410-B 55 27 57 37 308 43 31 1 47 75 71 67 63 61 65 11 19 15 Arch Retail Showrooms Arch Galleries (via Suite

Rojas Design & Spalding Tougias Architects

ZNA Architects

OverUnder Patch NYC

MORE

Jaho

PUBLISHED IN NEW ENGLAND HOME

South End Buttery 314 Shawmut Ave

The Elephant Walk 1415 Washington St

The crowning jewel of my time at Hacin was created in the last couple of weeks on the job. In preparation for the SoWa Design Days Festival, New England Home Magazine commissioned Hacin to create a map of the entire local artistic community. This project fell entirely to me and took me into meetings with magazine editors, local artists and building managers, tested my data collection skills and reminded me of the difficulties of designing under a deadline.

HarrisonAve.ShawmutWashingtonSt. Ave. WalthamSt. E.BerkeleySt.

SoWa Artist Studios Grassi Design Group Hark+Osborne Interior Design Oudens Ello Architecture

2A

108 C-100 Ctyd

Designed by J K L M N O P Q R S T U V

ART + DESIGN DISTRICT DIRECTORY

Coffee & Tea 1651 Washington St JJ Foley’s 117 East Berkley St Myers + Chang 1145 Washington St Oishii 1166 Washington St

Artefact Home | Garden 1317 Washington St

Christopher Peacock 520 Harrison Ave Hudson Interior Design 12 Union Park St Lekker Home 38 Wareham St

Modern Relik 485 Harrison Ave

Venegas and Company 477 Harrison Ave New England Home 530 Harrison Ave

Gallery

Gallery A Street Frames Addicted Fashions Boston Fiber Company Bang & Olufsen Clei Icon Group J.D. Staron Boston The Vision Group 29 A-16 C-18 B-7 C-2 B-6 B-16 C-19 B-17 C-8A C-24 C-8 C-17 C-12, C-14 C-14 B-5 A-14 A-4 B-15 B-1 1A A-4 Chatham Interiors Hacin Isgenuity LDa Architecture & Interiors Marathon Construction Ailanthus on Harrison Charles Spada Showroom 3R-A 4F 5F 3F 4R-B 2F 101103 Blanc Slate Institute for Human Centered Design LeBlanc Design Machado Silvetti Shawmut Design and Construction Marseille 405 401402 407 301 B4 B1 Eck MacNeely Architects EMBARC Sea-Dar Construction 3N 2W 4W 100302 3A 206 4A MJ Berries Design 562 Tremont St Nicole Hogarty Designs 530 Harrison Ave Beacon Gallery 524 Harrison Ave Boston Sculptors Gallery 486 Harrison Ave Dahlia Gallery 524 Harrison Ave South End Frames 105 E Berkeley St Atlántico 600 Harrison Ave Burro Bar 1357 Washington St Cathedral Station 1222 Washington St A B C D E F G H I HARRISON AVE 560 HARRISON AVE 500 HARRISON AVE 580 HARRISON AVE 46 WALTHAM ST PLACES 3 4 5 6 Gunther Bremelia Design Living Candice Wu Couture Ellisha Alexina Textiles Giardini di Sole Hillson Interiors HARRISON AVE SoWa Artist Studios Michael Barnum Gallery Bromfield Gallery Young Gallery Gallery Kayafas Druker Stockwell Studio Kingston Gallery Lanoue Gallery Galvin Millinery Open Studios Lounge Fashion and Tickle Vintage Garden Design Outdoor Giorgetti Boston Molteni&C and & Design Showrooms & Design Galleries Showrooms Retail Arch & Design Showrooms Dell Anno Boston First Rugs Officine Gullo TSP Smart Spaces Paris Ceramics PID Floors Melinda Home 105 107 102 108 435 106 3R Arch & Design Restaurants Arch & Design Arch & Design Retail Galleries Arch & Design Galleries Retail Restaurants Showrooms Other (via Thayer St.) Retail K F L I C H P O N Q A R M 6 4 5 2 1 3 E B V D G S T U J

Abigail Ogilvy Gallery Anderson Yezerski Gallery Claire Carino Contemporary Christopher Peter Art Fountain Street Galatea Fine Art Gurari Collections International Poster

Kevin Day Photography LaiSun Keane M Fine Arts Galerie MassArt X Sowa Ran Photography Samuel Owen

17

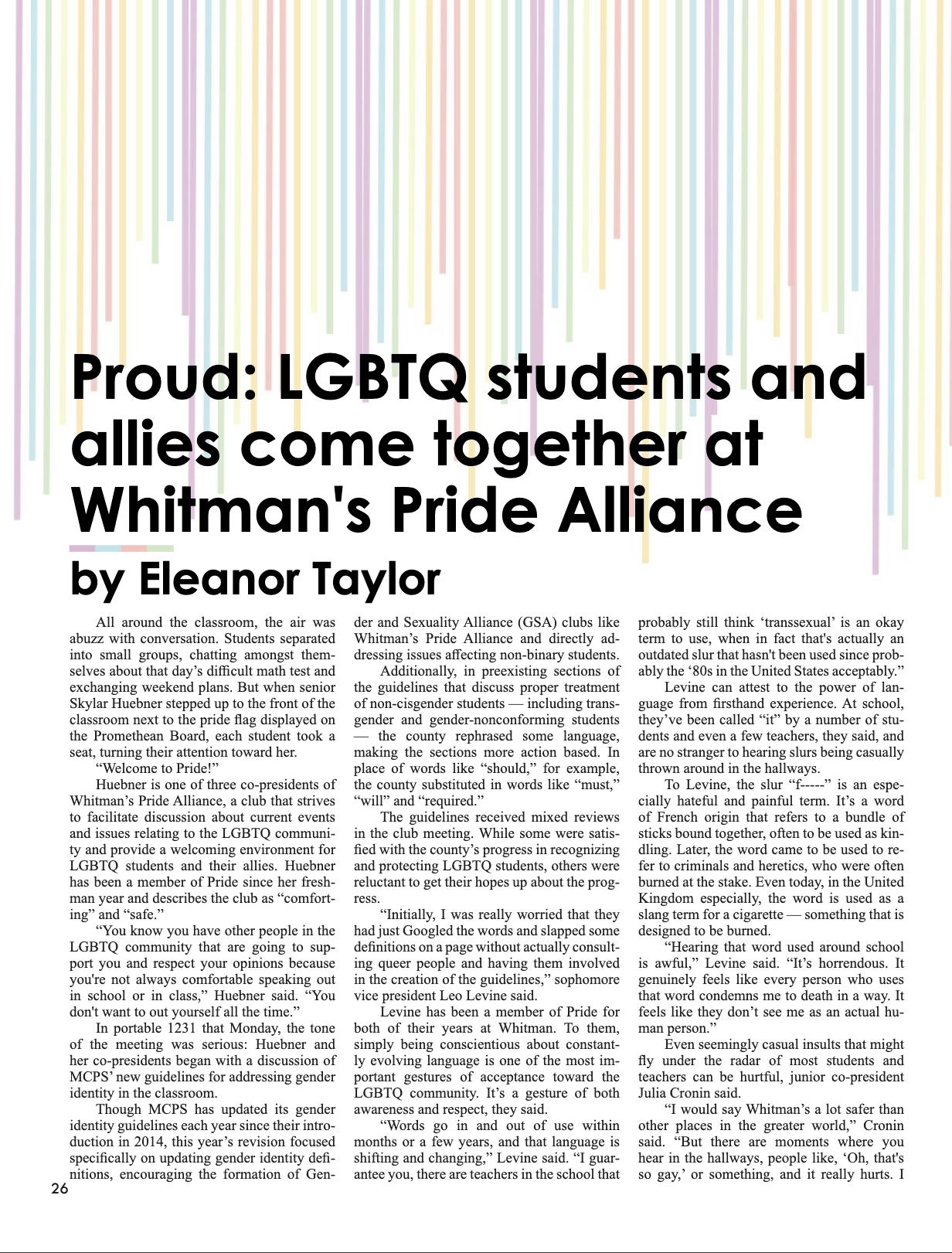

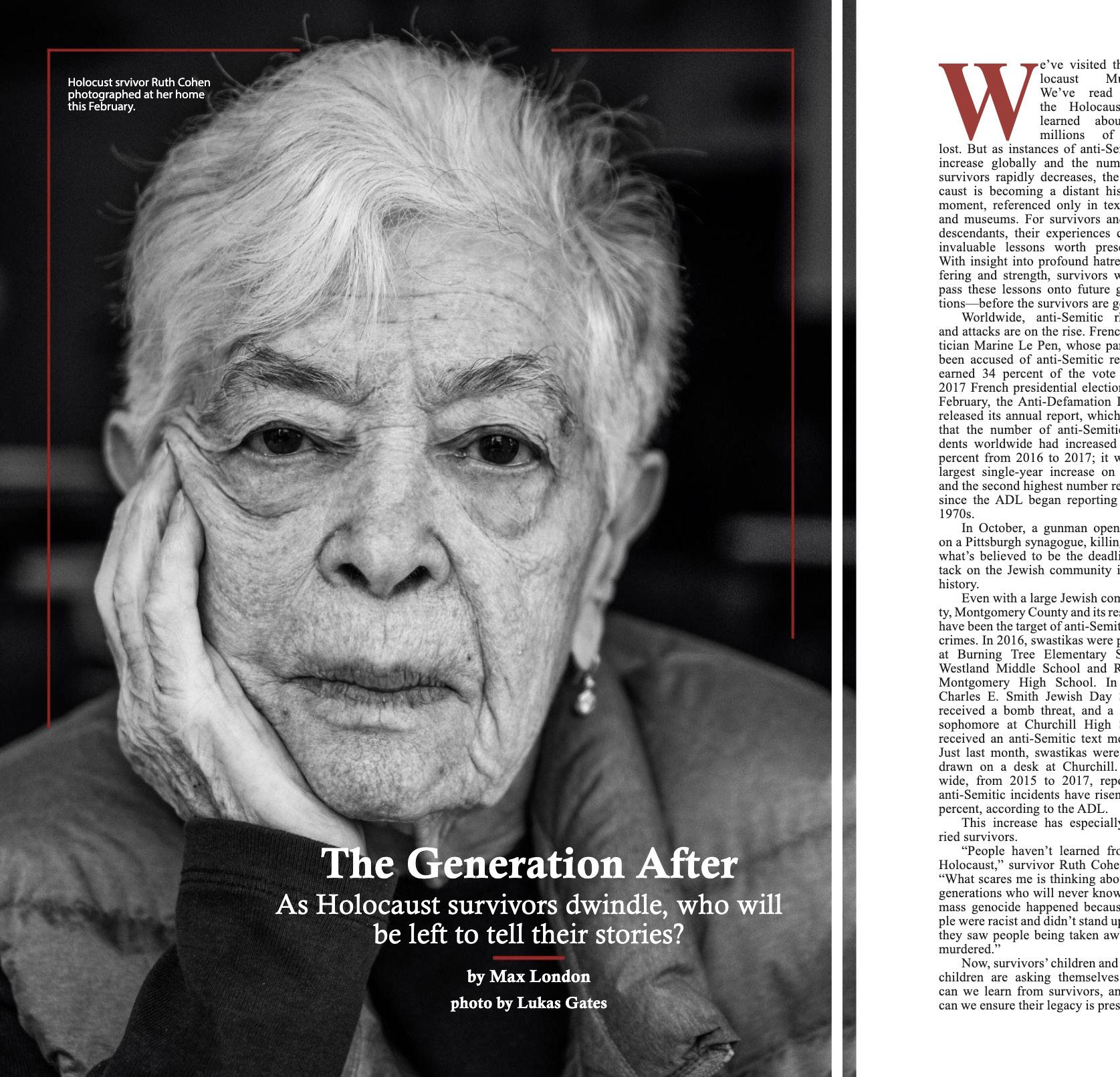

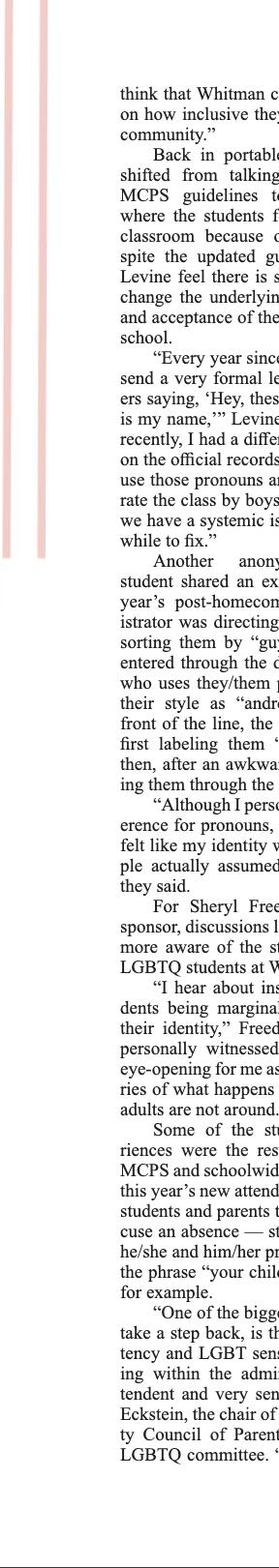

GRAPHIC DESIGN

My graphic design career began in high school when I was accepted onto the design team of my high school newspaper/ magazine. The next three years, my afternoons were dedicated to the development of a nationally recognized magazine, winning multiple scholastic gold crown awards as assistant and director of design. I’ve taken this skill into college with my presentations and diagrams which are found throughout my portfolio.

HIGH

COLLEGE 6.

SCHOOL AND

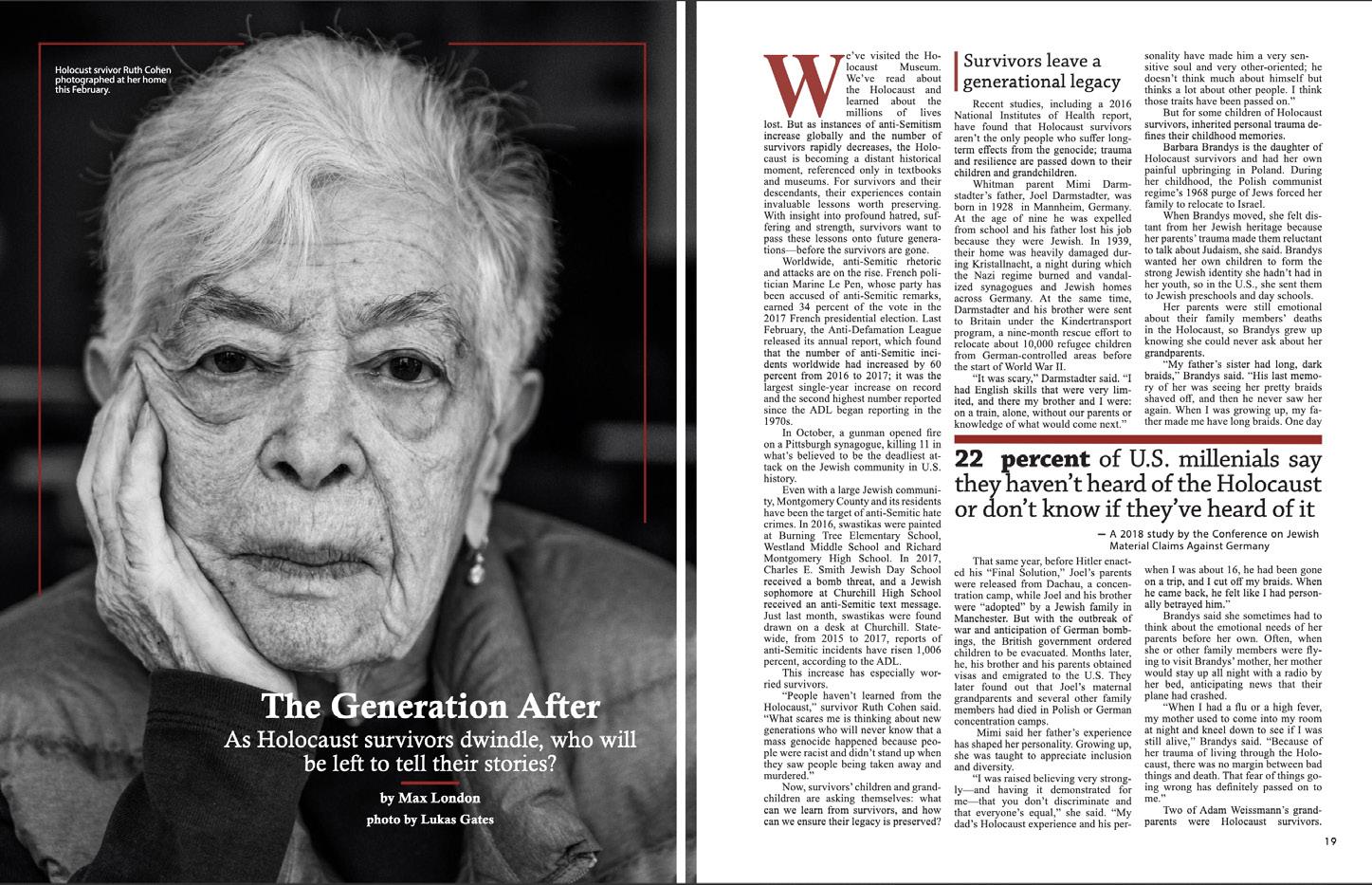

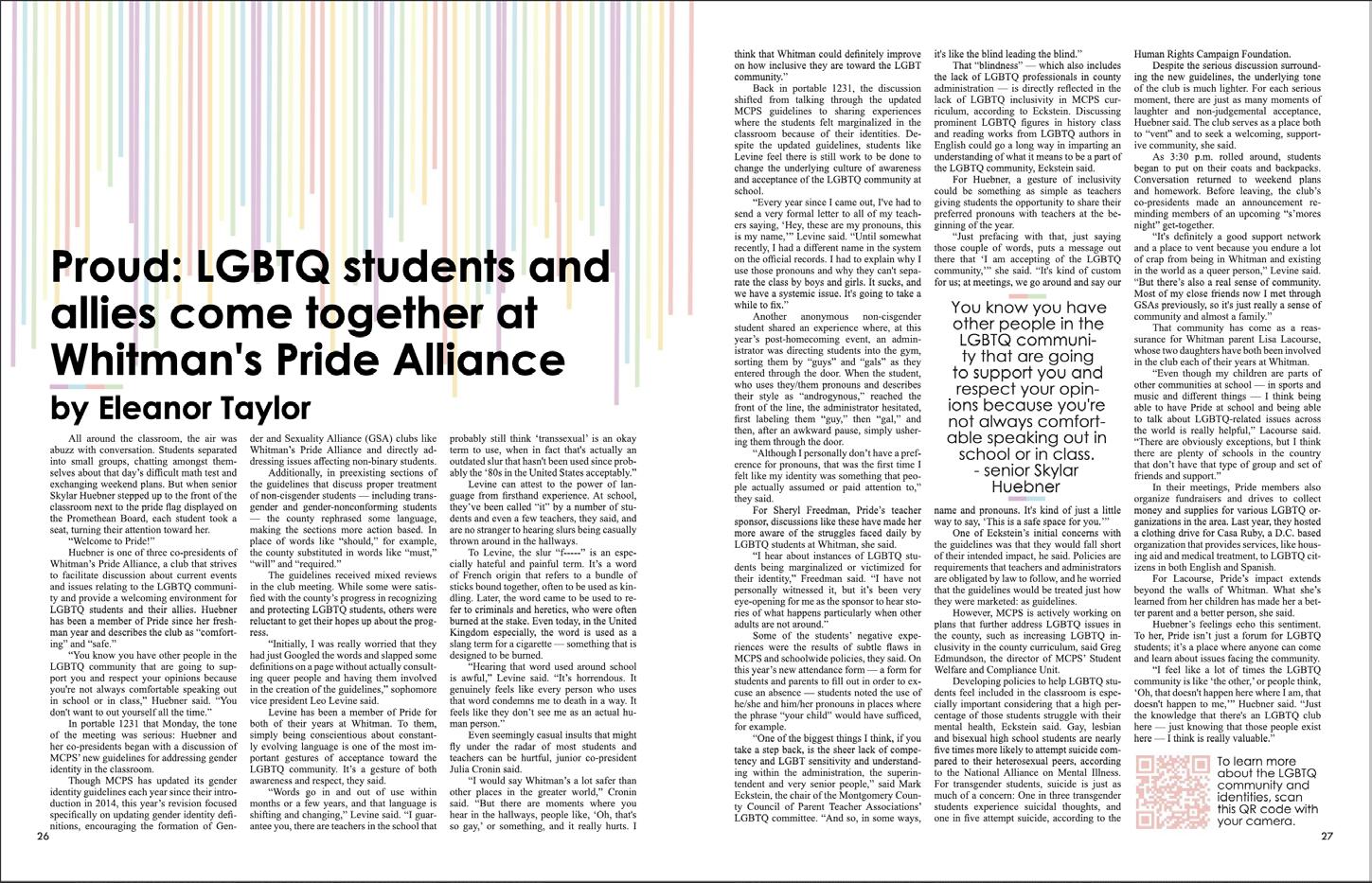

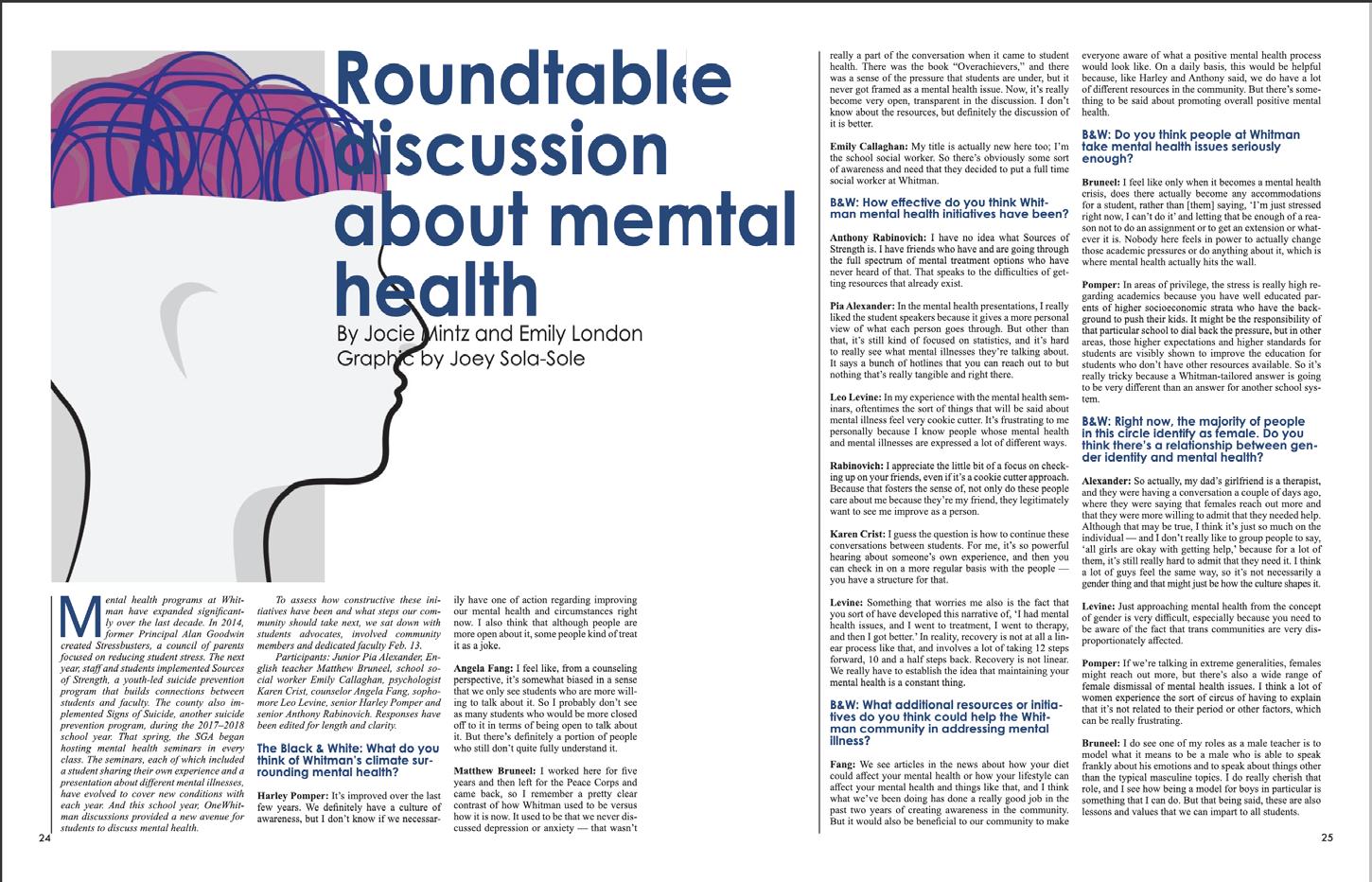

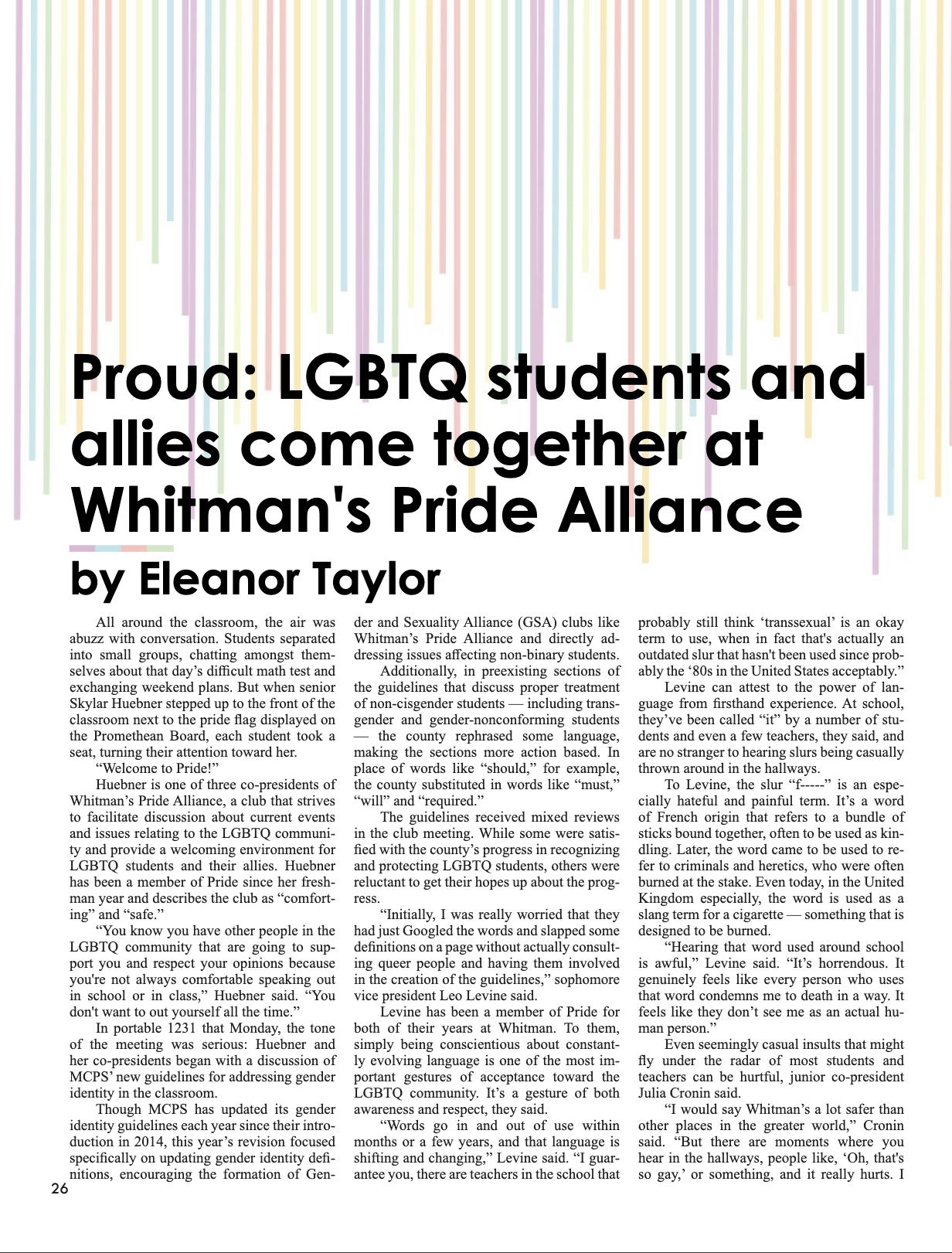

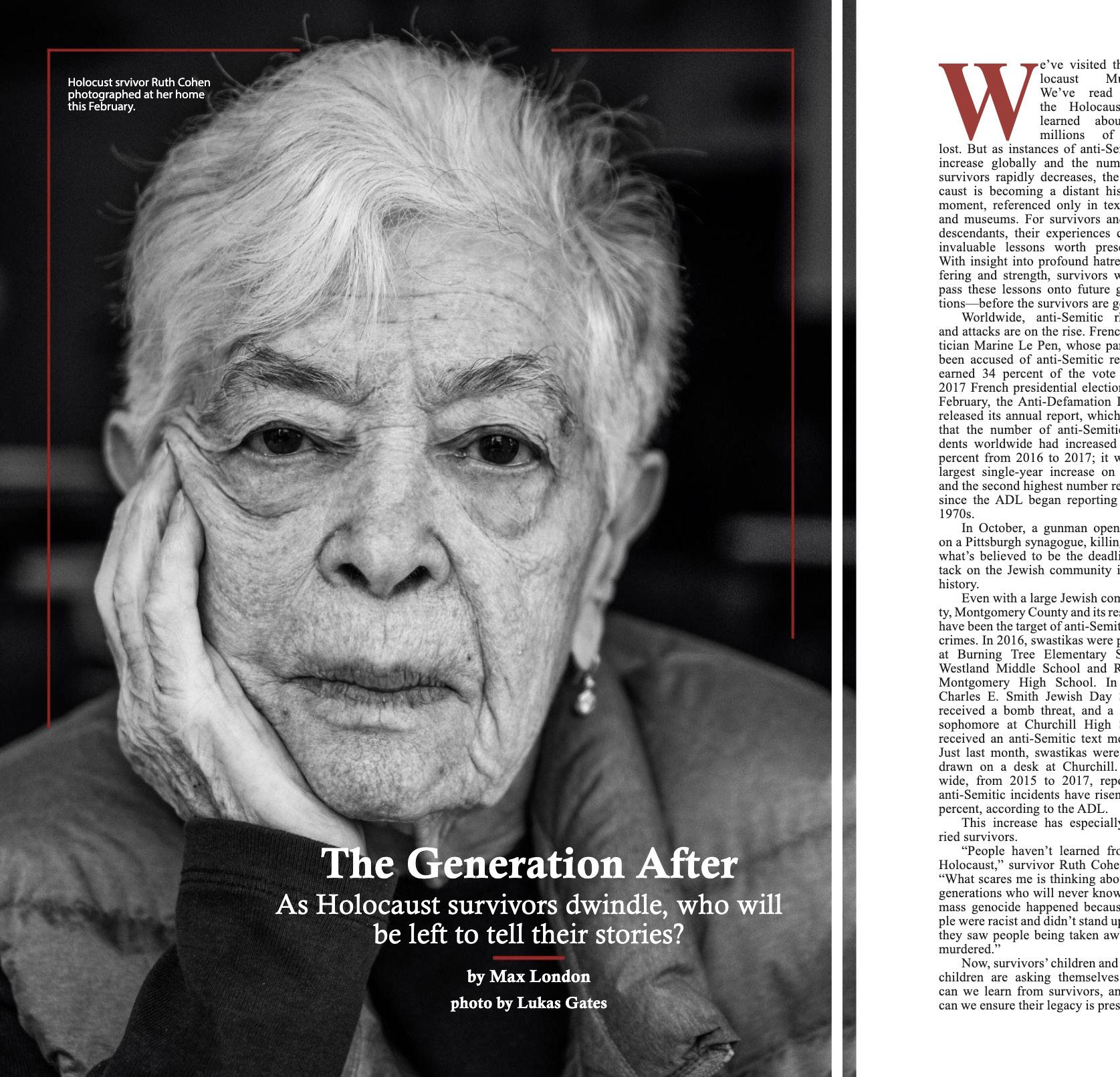

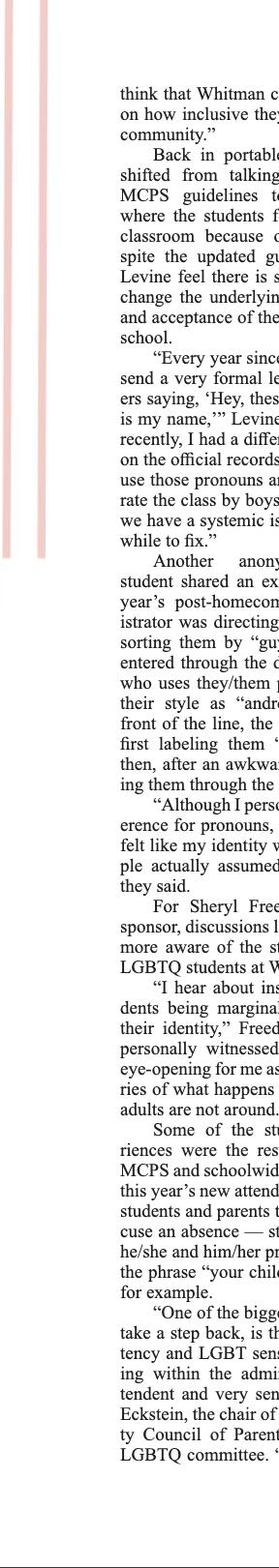

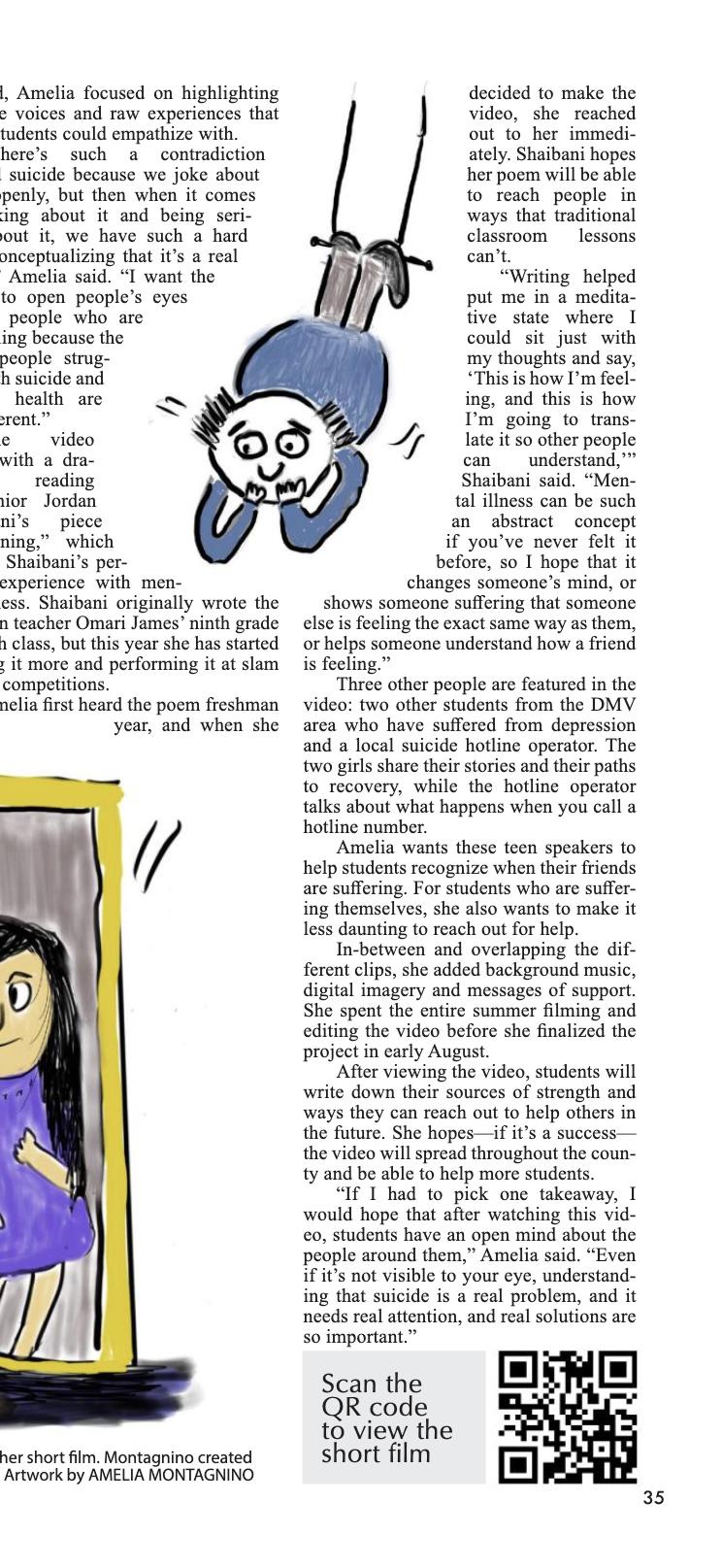

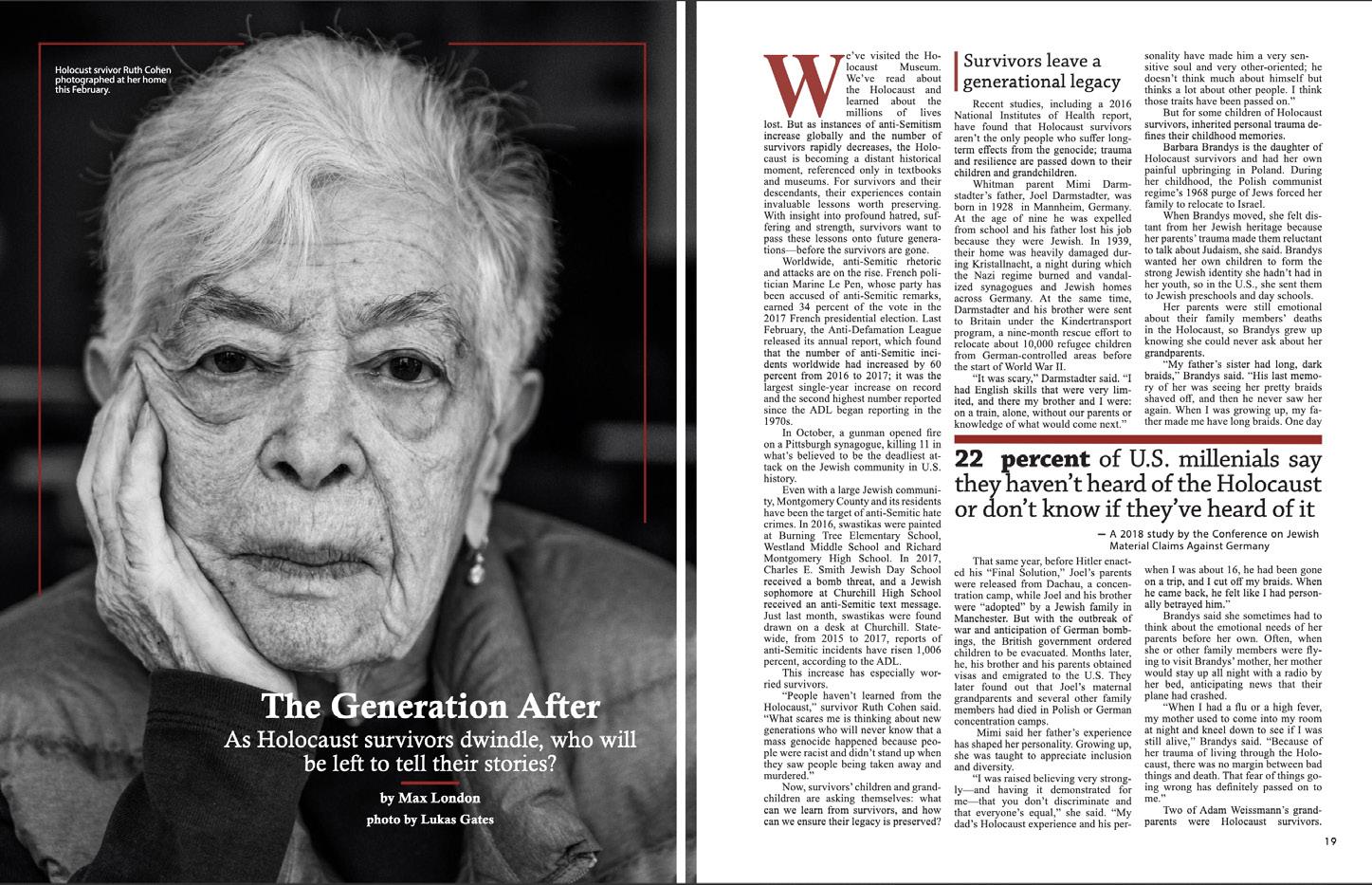

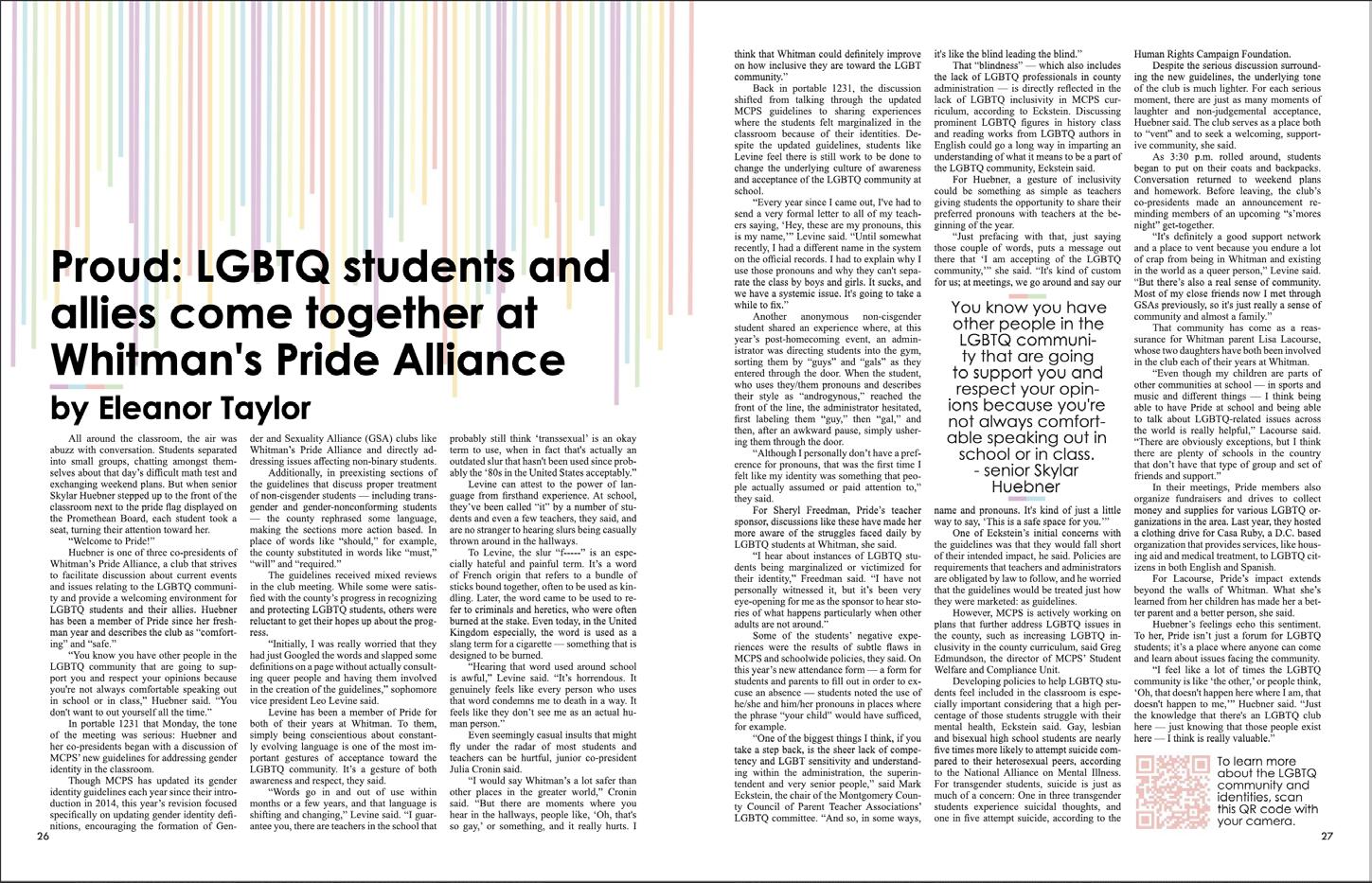

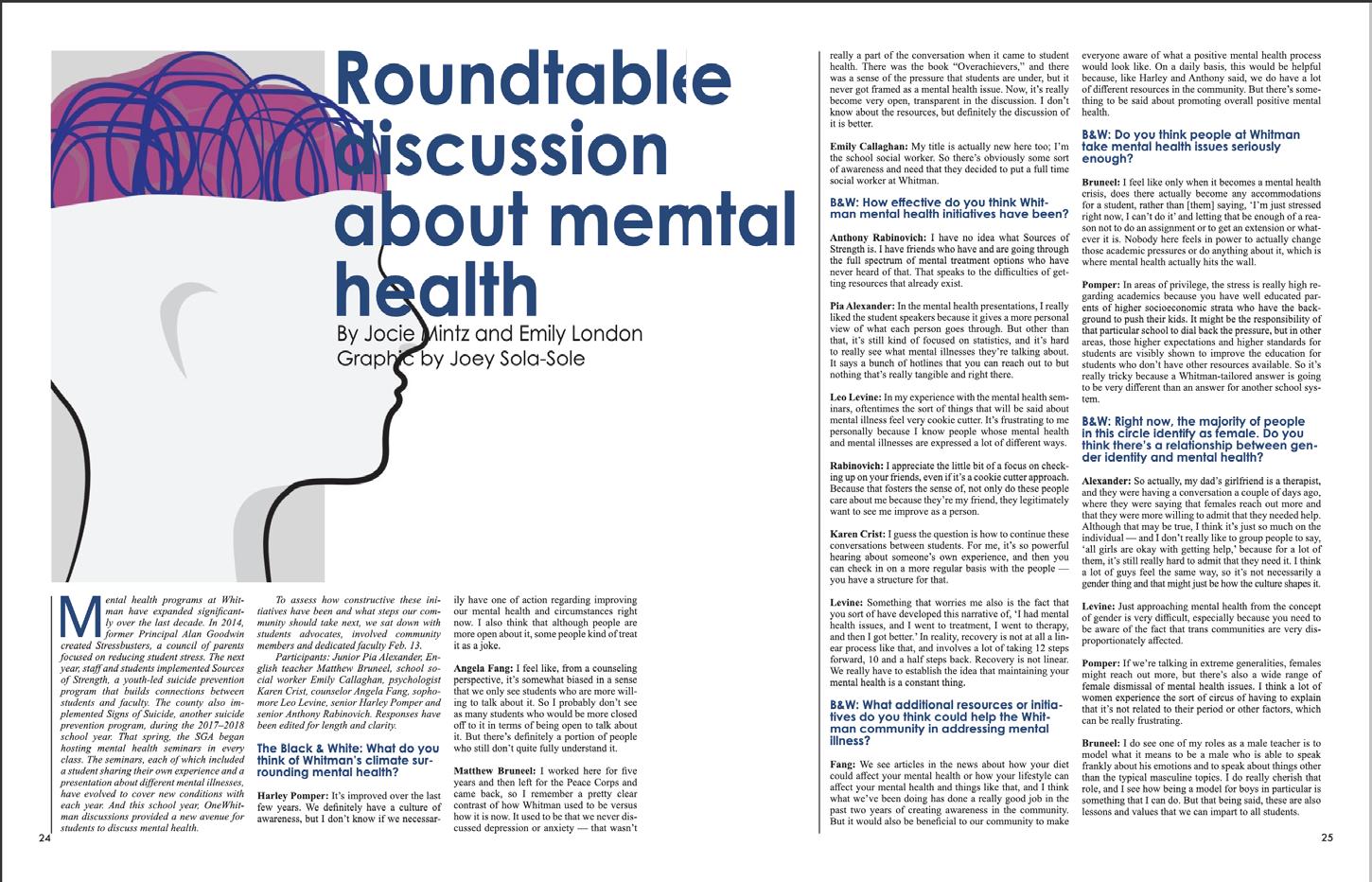

For three years of high school I worked on my school’s magazine, The Black and White. While on the design staff the publication won multiple National Scholastic Gold Crowns for design. Here is some of my work over those three years.

HIGH SCHOOL MAGAZINE 19

1 min Northeastern Sign A Walk Around Huntington Cars People Train Wind Trucks Misc.

MODELING A STREET CORNER THROUGH SOUND

In a simple one week assignment we were given the task to “diagram an intersection” on campus, and nothing more. I diagrammed the sound of the intersection by recording a full circle walk visiting each corner before returning to my original spot. Afterwards I broke the sound down by the cause of the noise and the volume of each part. This is the resulting sound wave featuring time and corner labels.

2 min 3 min 4 min 5 min 6 min 7 min

Cabot Marino Center Qdoba Forsyth Forsyth Huntington Huntington

Huntington

and Forsyth

JOSEPH SOLA-SOLÉ

301-247-9965 • BOSTON, MA • sola-sole.j@northeastern.edu

THANK YOU GOODBYE

Forest Shelter at Bertrichamp

Elena, Huzefa, Pilar, Joseph

Forest Shelter at Bertrichamp

Elena, Huzefa, Pilar, Joseph

CHINATOWN, BOSTON, MA

CHINATOWN, BOSTON, MA

SOUTH END, BOSTON, MA

SOUTH END, BOSTON, MA