It’s been a busy and positive start to 2023 at JLG, and speaking to many of our customers in past weeks, it seems that generally there’s a lot of activity and enthusiasm throughout our industry at present.

As a company we’re continuing to work hard to ensure that we’re meeting the demand of our partners, not only in terms of machine availability, but in the manner we’re supporting this equipment by having enhanced service and support mechanisms in place along with footprint and infrastructure.

Regular readers of InSight will know that over the last 24 months our company has invested heavily in our branches across Australia and New Zealand, as well as our manufacturing and technology hub in Port Macquarie, which features several company-first sustainability initiatives for JLG. This focus on infrastructure will continue in 2023 with our Melbourne branch relocating to a new purpose-built in Hallam in the coming months.

It will be a state-of-the-art facility that’s being constructed on an expansive 8000m² site, providing considerably more space than our current location – this will allow added workshop space for major inspections and other maintenance work, and additional areas to house and display equipment. Additionally, the new site will deliver the versatility for JLG to further adapt to meet market and business requirements.

As you read further through this edition, you’ll notice that the topic of sustainability is a strong theme throughout. JLG as a company has had a strong focus on sustainability and the environment for many years; our philosophies extend beyond just the equipment we manufacture and encompass all areas of our operations. And while we’re driving change from the inside, increasingly we’re finding that many of our customers – and indeed their own clients – are of a similar mindset about the importance of minimising our impact on the environment.

I trust that you’ll find our sustainability initiatives of interest and will be reassured by the depth of our commitment. On the product front, JLG is also making strides to ensure that this environmental performance is balanced by the functionality and fit-for-task performance our equipment delivers on the work site. I think that our new JLG equipment such as the DaVinci™ AE1932 Electric Scissor Lift, 630SJ SLC Self-Levelling Boom Lift and SSL-50 Solar Lighting Towers are proof of this.

Before I sign off, I’d like to personally thank everyone who took the time to participate in our customer survey at the end of last year. Programs such as this are vital to gain insights from our business partners, to ensure we continue to meet your expectations as a preferred supplier of access solutions. Our goal is to continue doing what we do well, and to identify those areas where we could perform better – we certainly appreciate the feedback.

Please enjoy this edition of the magazine.

Scott Daly General Manager - Australia & New Zealand

TAKE ADVANTAGE OF 60

& THE ASSET TAX WRITE OFF WITH JLG EOFY DEALS

GREAT DEALS ON ALL STOCK WITH REDUCED INTEREST RATES FROM JLG FINANCIAL. AVAILABLE NOW.

Along with the enhanced efficiency the 670SJ can deliver, there are also other features designed with the operator in mind. The independent control arms absorb bumps and undulations, meaning less bouncing in the platform, resulting in reduced fatigue and distraction from tools shifting and potentially falling from the platform.

Adding to the 670SJ SLC’s appeal is its ability to be driven at a class-leading full platform height of up to 20.36 m (67 feet) with the platform remaining level. Restricted platform capacity is up to 250 kg while unrestricted capacity is 340 kg, to comfortably accommodate operators and their tools.

Operating the new 670SJ SLC is enhanced by its advanced control system. This technology continuously monitors the platform load, the position of the wheels and the level of the machine in real

time, and makes instant automatic adjustments to maximise performance. Operational details are displayed to the user on the platform’s backlit LCD screen. This tablet-sized display offers optimal visibility day or night, reducing eye strain and fatigue.

Power for the unit comes courtesy of a proven Deutz T4i engine that produces healthy output of 67hp / 50kW, and for longer operating times, the machine is equipped with a 117-litre fuel tank.

For optimum uptime for users, 670SJ SLC maintains a high level of parts commonality with other JLG equipment, which increases familiarity during servicing for more efficient maintenance.

The new 670SJ Self-Leveling Boom Lift will be displayed at HIRE23, and will shortly be available from JLG branches across Australia and New Zealand.

Revolutionary self-leveling chassis with independent control arms and drive to all four wheels, which also helps boost stability and traction, and provides the model with impressive 45% gradeability

Introducing the new SSL-50 Solar Lighting Tower from JLG.

Ideal for wherever temporary lighting is required such as work sites, footpaths, events, and equipment storage yards. Designed and manufactured in Australia, the SSL-50 is built with quality components without sacrificing the performance you require.

FEATURES:

160 W Solar Panel with Tilt and Rotate for optimum performance

Lithium Battery

Dusk-til-Dawn Light Switch

100 km/hr Wind Speed Rating

Designed for side-by-side loading up to 20 units on a truck

Motion detection lighting saving power when no motion is sensed by dropping light output to 30%

SPECIFICATIONS:

Mast Elevation Height 5.00 m

Stowed Width 0.70 m

Stowed Length 1.47 m

Stowed Height 2.23 m

Light 1 x 50 W LED

Solar Panel 160 W

Run time 55+ hours

Weight 700 kg

5.00 m

MAST ELEVATION

HEIGHT 160 W SOLAR PANEL

A key area in which JLG achieves its sustainability goals is through the equipment it manufactures.

The machines themselves emit as few emissions as possible, and this has led to JLG reimagining its product portfolio. The company has invested extensively in product electrification since the early 1990s and this is now reflective in the many electric models JLG offers customers.

The fully electric AE1932 Electric Scissor Lift is a prime example of JLG’s innovation, investment and industry leadership – it’s the first machine of this kind available in Australia and showcases advancements in key performance areas including batteries, energy recovery, charging and adoption of common machine components such as motors, controllers and actuators.

For some applications where electrification isn’t yet viable, JLG specifies low emission internal combustion engines. In Australian and New Zealand markets, all engines meet stringent Tier4i emission performance or higher.

JLG applies Environmental and Energy Management Systems to all its manufacturing facilities. The company has attained ISO 14001 certification at the Tianjin, China facility and achieved ‘50001 Ready’ at its facilities in Shippensburg and McConnellsburg, in the United States.

In Australia during 2021, JLG’s Port Macquarie manufacturing facility and technology hub became the first Oshkosh Corporation site to install a solar photovoltaic (PV) system, allowing the location to produce approximately 80% of its electricity requirements. All sites operate a broad recycling program covering batteries, used oil, scrap metal, water and general recycling such as paper, cardboard and pallets. Additionally, facilities operate low draw LED lighting and are well progressed in transitioning to paperless work environments.

In recent years, there’s been an increased interest shown by many companies in minimising the environmental impact of their operations. For some, it’s the requirements put in place by the Paris Agreement that are driving change, but for JLG Industries, this prompting wasn’t needed.

Protecting the environment is a core value at JLG Industries, and as a group there’s been a strong focus on sustainability for considerable time – it’s all part of demonstrating good social responsibility. Parent company Oshkosh Corporation is an industry leader in responsible

On a global scale, JLG Industries has identified responsible water use, energy reduction, recycling and reusing initiatives, and general energy reductions as high focus areas, in order to further increase sustainability outcomes.

A growing number of facilities such as the Leon site in Mexico utilise a water reuse system to wash parts prior to paint. The system treats waste water that’s generated during the equipment manufacturing process and places it through a reverse Osmosis membrane which allows a certain percentage of the waste water to be used on site again. It’s estimated that this water reuse system meets 20 to 30% of the water required for painting operations.

As mentioned earlier, there is has been a shift at JLG facilities towards lower power LED lighting. The transition is well underway and along with consuming less power, other benefits of LED include a brighter white light that more closely resembles daylight which helps improve visibility and employees’ work environment. Compared to older style lights, LEDs are also more reliable and longer lasting.

manufacturing, careful resource management and developing environmentally sound products and services, ensuring sustainability goals for all its companies are promoted at the highest levels.

Oshkosh has been named to the Dow Jones Sustainability World Index (DJSI), for three consecutive years, highlighting a commitment to sustainable business practices, and was also recognised by financial advisory company, Barron’s, as one of the world’s Top 100 Most Sustainable Companies.

Other power reducing efforts have been achieved by upgrading boilers and HVAC systems throughout facilities to more efficient technologies, cutting down considerably on energy use. There’s also been a change in the type of energy used at certain JLG facilities.

In the United States, Oshkosh Corporation partnered with ALLETE Clean Energy in a renewable energy sale agreement to develop a wind energy site in Oklahoma capable of 303-megawatts. This is the first virtual power purchase agreement Oshkosh has made and the first offsite purchase of renewable energy. It supports the group’s strategic sustainability and environmental goals to reduce overall greenhouse gas emissions. The Renewable Energy Credits (RECs) from the project will offset a significant portion of the emissions resulting from the electricity utilised by Oshkosh’s US manufacturing operations which come from non-renewable sources.

At a group level, Oshkosh Corporation is working steadily towards its goal of diverting 90% of waste from landfill by 2024 – that’s good for everyone.

JLG Industries’ Port Macquarie manufacturing facility and technology hub is a vital resource in the company’s local operations, and who better to oversee the site than somebody who intimately knows its workings.

It’s not just the 12 plus years that Port Macquarie Operations Manager, Jarrad Smith, has spent at the facility that sees him well placed to undertake his senior leadership role, it’s his hands-on involvement to most aspects of the business over this time that’s also been invaluable.

Beginning at Port Macquarie as a qualified boilermaker and metal fabricator, Jarrad cut his teeth manufacturing lighting towers, including working with engineers to develop parts for prototype equipment.

“I worked closely with the research and engineering team helping them fabricate new components for future machines that JLG was developing at the site,” Jarrad said.

“They were exciting projects to be a part of and this involvement opened my eyes to the opportunities and variety of work I could expect at JLG.”

As part of the upskilling and training available to staff, Jarrad undertook a workplace safety qualification which saw him further transition from shop floor to a white-collar role. After completion, he managed the role out of a new safety management system at the Port Macquarie site, working closely with JLG head office in the United States.

Jarrad then broadened his exposure to other facets of operations at Port Macquarie, spending time in procurement before eventually beginning his role as Operations Manager.

“The exposure to many areas of the business has really helped in my current role. Getting to closely know and work with the broader team and understand the challenges – what works and what doesn’t – has given me valuable insights,” Jarrad explained.

“There are three core areas to my role, looking after the team and making sure we meet delivery targets, ensuring we’re meeting customer expectations while managing the financial aspects of the site, and thirdly, leading the engineering team – this involves looking at new product opportunities, considering enhancements to existing models, while also evaluating and improving manufacturing processes.”

One project that has had Jarred and the broader team excited in recent months is the design and development of JLG’s new SSL50 Solar Lighting Tower – it’s just one of several important new product development programs the team has underway.

“The SSL-50 Solar Lighting Tower along with the other ‘green energy’ projects underway will showcase some of the bigger evolutions that the market has seen in this product category. As a company we’re extremely focused on increasing renewable energy sources and growing the sustainability of our range,” Jarrad said.

“We have an experienced team on site and its fantastic to be able to conceptualise new products such as this, design and develop them and ultimately bring them to life.”

Away from work, Jarrad likes spending time with his young family and confesses to also enjoying getting stuck into projects in the garage. One recent labour of love is his 1979 VB Commodore ‘restomod’ which boasts an enhanced fuel injected 5.0 litre engine, strengthened transmission, upgraded brakes and swish new interior from a much later model VE Commodore. Jarrad even vinyl wrapped the car himself, but given his can-do attitude and willingness to give things a go, that’s not a surprise to anyone.

•

•

•

This type of aerial work platform is ideal for indoor or outdoor construction or maintenance tasks. Choose from electric scissor lifts with longer runtime or engine powered scissor lifts for durability on rough terrain.

Contact JLG to find out more about our range of Scissor Lifts

Earlier this year Onsite Rental Group purchased several JLG Metro-LED Lighting Towers – one was a milestone delivery that marked the 2000th unit produced at JLG’s Port Macquarie manufacturing hub.

As one of Australia’s leading hire companies, Onsite Rental Group, prides itself on the quality and breadth of equipment it offers customers in the mining, oil and gas, construction, industrial, infrastructure and Government sectors.

It’s little surprise then that JLG machines feature prominently in Onsite’s rental fleet, particularly its access equipment and lighting solutions, after all, the company has partnered with JLG now for over two decades.

Among the latest acquisitions was the 2000th JLG Metro-LED Lighting Tower produced at the Port Macquarie site. With its ease of use, bright light output and tough underpinnings, the model is a favourite of hire companies both in Australia and New Zealand, hence the high production numbers.

Onsite Rental Group Regional Asset Manager – Southern, Tracy Friesendorff, said Onsite had been using JLG lighting towers for many years, and that the JLG range was well liked by clients.

“The LED-Metro Lighting Towers offer a versatile all-round lighting solution that’s suitable for many applications, and we also like the fact that they’re Australian-made, this is a big plus,” Tracy explained.

Tracy said there were notable synergies in the way Onsite Rental Group and JLG Industries ran their respective businesses.

“Customer service is extremely important to us at Onsite – it’s a high priority. Along with offering our customers high quality equipment, we provide them with total rental management solutions,” Tracy said.

“We can take control from the outset of a project; from temporary fencing, on-site storage, power generation and excavation equipment through to any other machines that may be needed as the project progresses. For our customers it’s a convenient and streamlined process, you’re dealing with a single company, one point of contact and receiving one invoice – simple.

“Similarly, for us as a client of JLG we experience great service and support across all areas, which makes life easier and ensures we in turn can provide our clients with the customer service levels they expect and deserve.”

According to Tracy another aspect that makes JLG one of Onsite’s preferred suppliers was its focus on sustainability.

“Recently there’s been a lot more interest from our customers around sustainability and minimising their impact. Some of this thinking is purely from an environmental angle, but many also realise that there are potential longer term cost savings from running more efficient machines,” Tracy said.

“We know that JLG is an innovator in this space and its equipment continues to evolve to meet the changing needs of customers. We look forward to seeing what the future holds for JLG and Onsite Rental Group.”

L-R: Damien Morel – Regional Sales Manager VIC & SA; Ben Peters – Asst Branch Manager (Derrimut VIC); Scott Bernhard – Account Manager (Major Projects); Jonathon Adams – Account Manager (Access).

Damien Morel with JLG’s Daniel Reeve (right).

L-R: Damien Morel – Regional Sales Manager VIC & SA; Ben Peters – Asst Branch Manager (Derrimut VIC); Scott Bernhard – Account Manager (Major Projects); Jonathon Adams – Account Manager (Access).

Damien Morel with JLG’s Daniel Reeve (right).

Another aspect that makes JLG one of Onsite’s preferred suppliers was its focus on sustainability.

THAN

Listening to customer feedback, JLG launches Knowledge Base – an article library to rental companies and service dealers with an account in Online Express, the company’s 24/7 customer portal. Knowledge Base offers technicians the ability to search through a library of more than 400 service-related articles, by Diagnostic Trouble Code (commonly known as fault codes) or symptoms, for troubleshooting machine issues.

With all articles authored by the technical experts within JLG, this library provides our channel partners’ technicians with highly specialised information that they don’t normally have convenient access to. Through Knowledge Base in Online Express, JLG offers valuable, service-related content in a simple, mobile-friendly format to increase efficiencies when troubleshooting common machines issues.

Searching by either codes or keywords, technicians can use Knowledge Base articles to diagnose possible causes, troubleshoot steps needed to resolve the issue, learn more about any special tools or parts that might be required to complete the work and review additional information that could be helpful in getting the equipment back to work.

For annual inspections please ensure every machine has the latest control system software loaded.

JLG is constantly adding new content, including more articles, imagery to show where components are located, detailed parts drawings and schematic clips, to enhance technicians’ experience within the Knowledge Base library. JLG provides links to frequently searched articles and helpful navigation filters to make sure technicians can find the articles they need quickly.

To access Knowledge Base, rental companies and service dealers can sign into their Online Express accounts or go directly to the library by clicking on onlineexpress.jlg.com/knowledge.

To register for an Online Express account, visit: onlineexpress.jlg.com/user-registration

A big geographic state such as Queensland sees JLG’s team there kept extremely busy, but that doesn’t mean some fun isn’t had along the way.

Speaking with JLG Queensland Branch Manager, Martin de Haast, one thing that’s immediately clear is the respect and admiration he has for the people he leads.

“The team we have is best in field, they’re knowledgeable, have world-class technical skills and they’re dedicated – it makes for an excellent working environment,” Martin said.

“We have a lot of fun, but when there’s work to be done, we knuckle down and I know I can count on the team for anything at any time.”

Originally from South Africa, Martin has been at the helm of JLG’s Queensland branch for almost ten years, and is supported by five office staff and a 15-strong team of tradespeople comprising of service personnel and technicians along with three apprentices. Together they look after a broad range of customers across the mining, hire and construction industries.

Operating from a large 7,000m2 premises in Eagle Farm, Brisbane, the site is home to a generous workshop, spray booth and overhead gantry, and is well set-up to undertake repairs, refurbishments and major inspections. The site also boasts large training facilities which are used to run programs for JLG employees and customers, and there’s also an equipment pre-delivery space.

Of the broad spanning JLG range, it’s the large boom lift and scissor lift offering that is the most popular with customers of the QLD branch, and Martin says a lot of progress has been made in recent months towards restoring supply normality after the supply chain challenges posed by COVID.

With some exciting new JLG equipment to shortly arrive in branches, things could soon become even busier for JLG’s Queensland team, as Martin explains.

“We’re excited by the new JLG models that will shortly be available, particularly the 670SJ SLC Self-Leveling Boom Lift. Interest in the model has been very positive and we are receiving regular enquires from clients requesting demonstrations,” Martin said.

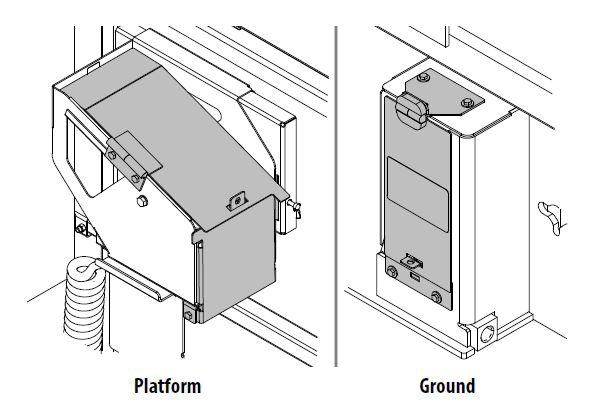

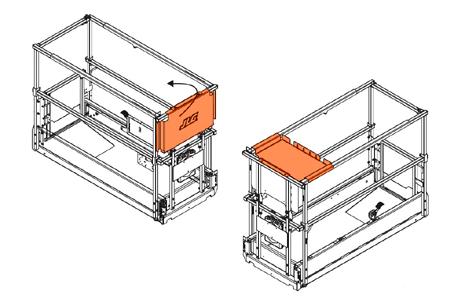

Suitable for indoor construction applications

DESIGNED WITH YOUR TASKS IN MIND

• Point & Go® steering with single-handed joystick control for easy navigation of busy work environments

• Enhanced ease of entry and exit from platform, with coiled control cable to keep area tidy

QUICK-CHANGE PLATFORMS

• Choose from 5 platform options to fit the job

• No tools necessary for changing

GREATER DURABILITY

• Anodized aluminum mast with covers that reduce potential for debris to accumulate and hinder operation

• Simplified single cable and improved sheaves for optimized uptime

LIGHTWEIGHT & MANOEUVRABLE

The new E18 Mobile Maintenance Lift (18MML) and Mobile Construction Lift (18MCL) line up features familiar controls and a machine weight less than 900 kg.

SPECIFICATIONS:

Steer System

Machine Weight 885 kg 885 kg

• Under 885kg machine weight and 30–in width, allowing for use on a variety of sensitive surfaces

• Zero turning radius with electric drive motors and caster wheels for peak efficiency

ENHANCED GROUND CONTROL PANEL

• Onboard Multi-Display Indicator provides real-time DTC codes and errors

• On-site troubleshooting with JLG Analyzer capability

indoor or outdoor applications

DESIGNED WITH THE OPERATOR IN MIND

General indoor-only maintenance applications

• Platform control box commonality with scissors for increased familiarity

• Enhanced ease of entry and exit from platform, with coiled control cable to keep area tidy

QUICK-CHANGE PLATFORMS

• Choose from 5 platform options to fit the job

• No tools necessary for changing

GREATER DURABILITY

• Anodized aluminum mast with covers that reduce potential for debris to accumulate and hinder operation

• Simplified single cable and improved sheaves for optimised uptime

LIGHTWEIGHT & MANOEUVRABLE

• Under 885kg machine weight and 30–in width, allowing for use on a variety of job sites and sensitive surfaces

• Zero turning radius with electric drive motors for peak efficiency

ENHANCED GROUND CONTROL PANEL

• Onboard Multi-Display Indicator provides real-time DTC codes and errors

• On-site troubleshooting with JLG Analyzer capability

EASE OF SERVICEABILITY

• Toolless access to key components

• Increased parts commonality with scissors

LONGER-RUNNING BATTERIES

• 2x more duty cycles over the leading competitor

• Located in base of the machine for increased stability

EASE OF SERVICEABILITY

• Toolless access to key components

• Increased parts commonality with scissors

LONGER-RUNNING BATTERIES

• 2x more duty cycles over the leading competitor

• Located in base of the machine for increased stability

SCISSOR STEERING

• Provides precise operation with increased control through tight spaces and doorways

• Features solid, nonmarking tires for maximised traction on most types of flooring

WHERE:

WHEN:

SSL-50 SOLAR LIGHTING TOWER

670SJ SELF LEVELLING BOOM LIFT

SEE THESE MACHINES ON STAND 12 AT HIRE23

Used

Used

...TRADE-IN AND TRADE-UP ON YOUR USED MACHINE

Used

TURN YOUR IDLE ASSETS INTO CASH

ALL USED EWP AND TELEHANDLER MODELS CONSIDERED

THERE’S NEVER BEEN A BETTER TIME TO REACH OUT AND BUY A NEW JLG...