20 minute read

Casey Lockrey (Year 12

An experimental investigation of drag and noise reduction properties of sharkskin in a low viscous aerodynamic environment

Casey Lockrey (Year 12) The Illawarra Grammar School, 10/12 Western Avenue, Wollongong, NSW, Australia, 2500

Advertisement

Abstract : In the past decade, research into natural surfaces that outperform those created by man has been on the rise, with potential applications in transportation, military and renewable energy. The surfaces of some organisms, due to the process of natural selection, have evolved due to natural selection pressures in their environment. Sharks, for example, have faced the selection pressure of water density slowing down their movement speed, evolving to possess a unique denticle surface on their skin that reduces drag. This present paper investigates the drag and noise reduction properties of an organic sharkskin denticle coating in a low viscous aerodynamic environment. An evaluation of current literature on the topic is provided along with discussion of the drag reduction mechanism, its effect and an understanding of the developments made in explaining the phenomenon. The drag and noise reduction properties were assessed by measuring the sound and speed of a small DC fan coated in cured organic sharkskin using a microphone and camera. The results indicated a statical difference in noise production (p < 0.05) with a maximum sound reduction of 10 dB seen in the fan with the coating. The rotational velocity remained unchanged due to an unforeseen flaw in the methods design (p > 0.05).

Introduction

In recent times, the utilisation of biomimetic technologies has been explored to address issues with drag and noise (Tian et al. 2021). One promising candidate is sharkskin and its unique denticlestructured surface.

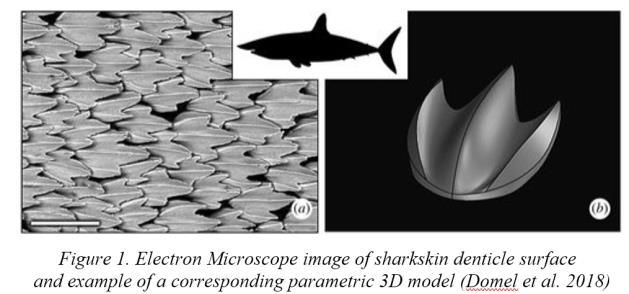

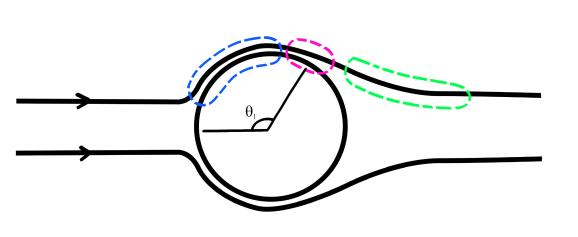

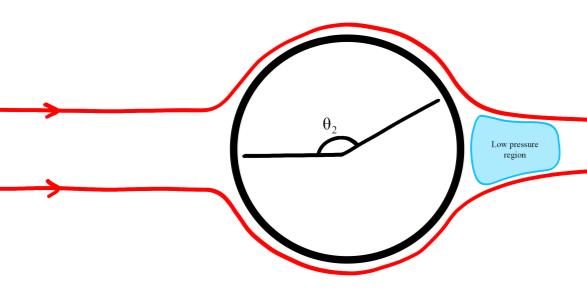

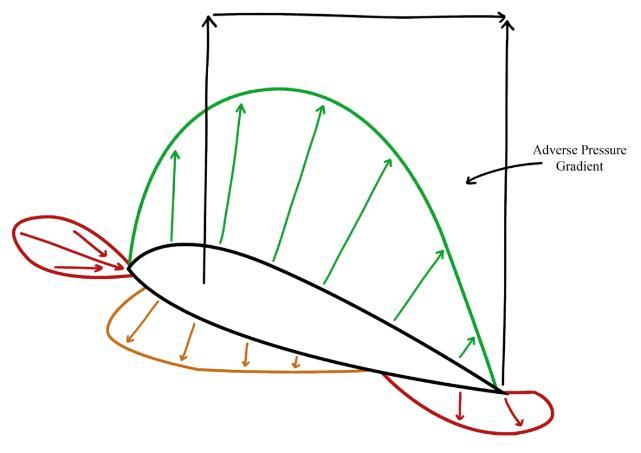

Denticles are tooth-like microstructures that exist on the surface of sharkskin (See (b) in Figure 1), they are the most significant factor contributing to a sharks’ superior movement in the ocean (Society 2020). Just like any other object, when sharks move through a fluid, the fluid exerts a force on the shark. This is known as a hydrodynamic force, or if the object is in air, an aerodynamic force (John David, 2016). The skin of sharks possess tiny rigid scales that effectively delay the occurrence of chaotic fluid movement known as turbulence (green area in Figure 2) by maintaining constant fluid flow known as laminar flow (blue area in Figure 2). This transition from laminar to turbulent flow is called flow separation (pink area in Figure 2) which when delayed (i.e. ��1 <��2 in Figure 2 and 3) reduces pressure drag caused by the lowpressure region near the trailing edge of the object.

Figure 2. A circular object undergoing laminar flow. The blue region indicates the area of laminar flow, the pink area indicates the point of flow separation, and the green area indicates the turbulent flow.

Figure 3 - A circular object undergoing laminar flow with a reduced low-pressure region due to delayed flow separation. The blue region is the low-pressure region.

This low-pressure region is also primarily responsible for sound generation as sound waves are unable to propagate effectively through the region. This causes vibrations that create noise. Initial research into the drag reduction properties of sharkskin was conducted in 1985 when Reif and Dinsklater (1985) discovered that the morphology of sharkskin scales reduce drag in some turbulent conditions via a force balance wind tunnel and an organic sharkskin coating (Reif, 1985) Since then, research has been focused on synthetically replicating this surface with testing results showing that this drag force can be increased and manipulated (Tian et al. 2021).

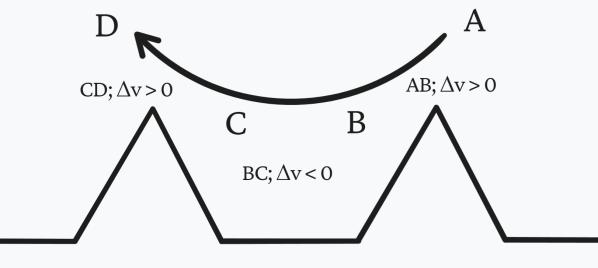

It should be noted that while this flow separation is delayed, that is, the drag reduction mechanism of organic sharkskin, it is not presently understood (Tian et al. 2021). It should be noted that while the concept of flow separation is accepted as common knowledge in literature (John David Anderson 2019), the mechanism of its delay from the organic sharkskin is still not fully understood (Tian et al. 2021). However, there are still a multitude of studies that have provided important conclusions about the properties of sharkskin and its drag reducing effect (Tian et al. 2021). Bechart et al. in 2000 investigated multiple biological surfaces with biomimicry potential. The drag reduction of sharkskin was investigated and experimentally proven, for both organic and synthetic sharkskin, via a direct shear force measurement. (Berchart et al, 2000). Figure 4. Graphical representation of the transfer in momentum (Berchart et al, 2000).

Bechart et al. described this drag reduction via “sweeps” and “ejections”. The strong exchange in momentum as the accelerating high-speed flow decelerates whilst approaching the surface (called a “sweep”, A to B in Figure 4) and then accelerates whilst leaving the surface (called an “ejection”, labelled C to D in Figure 4) (Berchart et al, 2000), reducing skin friction as the force applied to the surface is less. This increases the duration of laminar flow and as a result delays flow separation (Berchart et al, 2000).

In 2012 J. R. Debisschop and F. T. M.

Nieuwastadt conducted a study to investigate the characteristics of the turbulent boundary layer and the effectiveness of riblets for skinfriction reduction using a drag balance (Debisschop & Nieuwstadt 1996).

The turbulent boundary layer refers to the layer of fluid in the immediate vicinity of the surface of the object and can be inferred to be related to the delayed flow separation (John David Anderson 2019). The distinctive difference between this study and Berchet et al. is their emphasis on differentiating between the application of riblets in small pressure gradients opposed to medium and large pressure gradients (Debisschop & Nieuwstadt 1996). The pressure gradient essentially refers to the difference between the pressure at the trailing edge and the leading edge. It’s dependent on the position of the flow separation as the flow separation determines the size of the lowpressure region at the trailing edge and the high-

pressure region at the leading edge (John David Anderson 2019).

Figure 5. The green highlighted area indicates the adverse pressure gradient (most effective location for the riblet coating), the orange indicates the medium pressure gradient and the red the low-pressure gradient

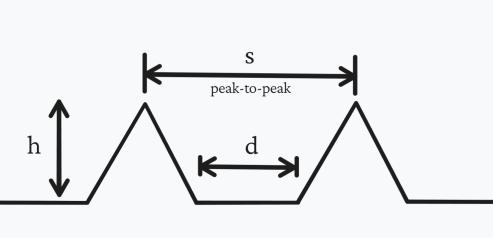

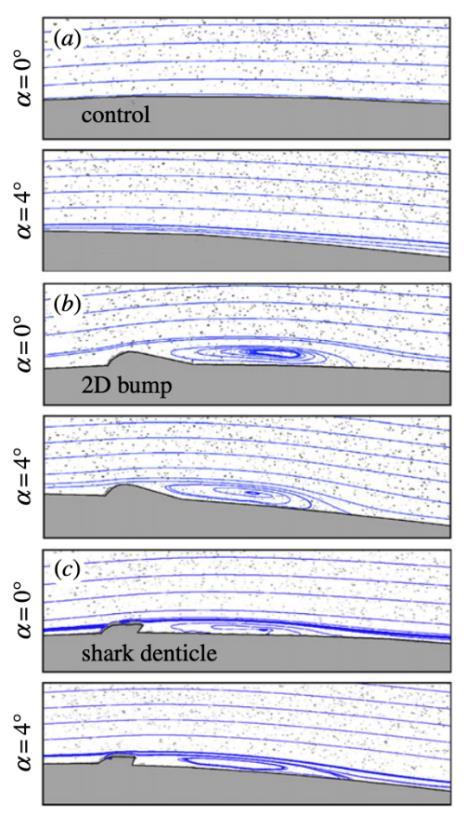

Results from the study indicate that riblet structured surfaces performed better in medium to large (adverse) pressure gradients compared to lower pressure gradients, a maximum drag reduction of 13% being achieved in high pressure gradient regions whereas in lower pressure gradients 6% was achieved (Debisschop & Nieuwstadt 1996). This suggests that in terms of an air foil or wing, the surface experiencing the largest pressure gradient will benefit the most from the addition of the sharkskin denticle structured surface (Green area in Figure 5). In 2012 Leonardo P. Chamorro investigated the drag reduction properties of sharkskin through studies involving a synthetic replica. The skin was manufactured by 3M © and was tested under different conditions, such as, the angle of attack ranging from 0°≤�� ≤10° and different riblet geometries ranging from 100���� to 80���� in height (Chamorro, Arndt & Sotiropoulos 2013). Figure 6. Simplified diagram of the denticle structure that mimics that of sharkskin The drag was measured via a wake survey and sensitive force balance, it was found that a maximum drag reduction of 6% could be achieved with peaks at a height of 100���� in a “V” shape when �� =0 (See Figure 6) (Chamorro, Arndt & Sotiropoulos 2013). This study discovered that the transfer in momentum initially proposed by Bechert et al could be manipulated to maximise the drag reduction by minimising the distance over which the momentum transfer occured (Chamorro, Arndt & Sotiropoulos 2013). In 2018, August G. Domel et al. investigated sharkskin-inspired designs that improved aerodynamic performance in different settings. Additionally, comprehensive CFD simulations and investigations into other surface types were conducted to provide a more comprehensive analysis (Domel et al. 2018). It was determined that the complex denticle structure seen in sharkskin was not integral to increasing lift and reducing drag at low angles of attack. However, at higher angles of attack, the sharkskin denticle structure performed better (Domel et al. 2018). This phenomenon was attributed to a short separation bubble forming behind the denticle enhancing this transfer of momentum mentioned in Berchet et al (See Figure 7), resulting in a more consistent drag reduction across all angles of attack. This provides a more comprehensive explanation compared to Berchet et al. as it was explicit why the transfer of momentum was enhanced, however, in principle both

explanations are very similar.

Whilst literature exploring and manipulating the drag reduction potential of sharkskin is well established (Tian et al. 2021), it’s sound reduction potential is under-researched and essentially mute in terms of studies conducted in air. However, other studies have been conducted that investigate the sound reduction potential in other settings such as hydrodynamic environments (Dang, Mao & Tian 2019). In 2019 Zhigao Dang et al. utilised CFD simulations to predict the hydrodynamic noise of an air foil (Dang, Mao & Tian 2019). This study determined a maximum noise reduction of 7.28 dB could be achieved and that the noise spectra of the biomimetic hydrofoil lacked the main peaks seen in the air foil void of modification. (Dang, Mao & Tian 2019). The reduction in noise was attributed to the ‘secondary vortex’, or what has previously been described as a short separation bubble, which maintained laminar flow and hindered the process of turbulence. This separation bubble was described as consuming the energy of the flow and weakening the intensity of turbulent burst (also known as flow separation) (Dang, Mao & Tian 2019).

Scientific Research Question

Will the addition of a sharkskin denticle coating aligned with the direction of laminar flow reduce the drag experienced and noise produced by an air foil?

Methodology

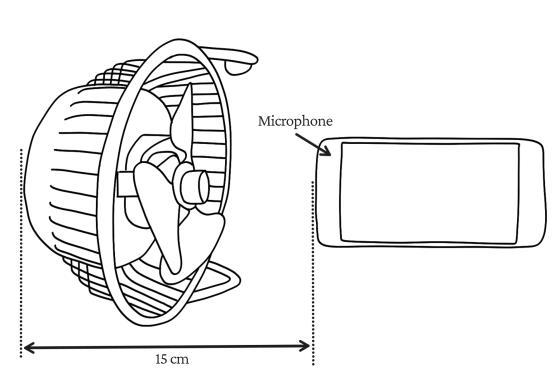

Practical Testing The sound production and speed of the fan void of any sharkskin coating was initially tested as a baseline to compare to the fan with the sharkskin coating. The specifications of the fan include its design speed of 1200 rpm, the individual air foil dimension being 5.5 cm by 3.4 cm, the propellor radius being 9.5 cm and the angle of attack for each propellor being 20±5�� elevation perpendicular to the direction of flow. The sound production was measured in 30 second intervals using an iPhone 13 microphone at 120 Hz, 15 cm from the base fan legs. The ambient noise was reduced by closing doors, windows and turning off devices that were creating noise (air conditioning) with the ambient noise initially being measured to ensure it was stable. The rotational speed of the fan was measured using a 240-fps camera, determined by counting the frames in Adobe Premiere© and calculated using the simple period formula (i.e., �� =

1

Figure 7. Flow trails of fluids passing over different surfaces (Domel et al. 2018).

,

�� where T is the period in seconds and f is the frequency in rotations/second).

Figure 8. Visual diagram indicating the distance between the microphone and the fan.

The position of the recording device was crucial as the sound intensity varied with different positions. The microphone was positioned near the ‘outside rim’ of the fan, which is near the trailing edge of the fan blades, as this has been shown to produce the largest amount of noise (Kohout & Hyhlík 2020).

Treatment of the Sharkskin Sharkskin was obtained in large strips of 30± 10cm from the scraps of a local fish store and used as the source for an organic sharkskin coating, the width and height were ensured to be larger than what was required as the treatment caused shrinking of 10±5% for both the width and height. The treatment method involved scraping the excess meat off the under-face of the skin using a scalpel followed by curing the skin on a ceramic smooth surface such as a plate for 1.5 to 2 hours in direct sunlight at noon. The skin was dried to a point that made it suitable to handle and rigid before being attached to the fan blades. The rigidity of the sharkskin was crucial to the strength of the adhesion to the surface of the blade, which if not maximised could lead to the sharkskin detaching from the surface during testing. The skin, after treatment, was cut into 7 by 5 cm squares (to fit the blades with minimal off-cut) and ‘re-wetted’ using a standard clothes iron, separated by baking paper to reduce contamination. Figure 9. Sharkskin being ironed in order to increase flexability

The heat and small amount of moisture from the iron provided a temporary amount of flexibility which was required to form the skin to the curved shape of the blade. A thin layer of flexible contact adhesive (Selley’s Kwik Grip ©) was applied to the fan blade and spread evenly using a paddle pop stick. The skin was uniformly pressed onto the blade for 10 minutes, with the abrasive direction (the direction in which you would need to move your finger on the surface of the skin to feel friction) facing the same direction at the rotation and the opposite direction to the flow. The skin was left to dry on the blade for 12 hours before being used for testing. Testing procedures for the fan with sharkskin followed the same protocols as testing the fan without sharkskin.

Statistical Analysis Statistical analysis was conducted after the data was obtained. A two-tailed unpaired student’s t-test of equal variances was undertaken to compare statistically the difference between the noise and speed of both fans. The standard deviation, mean, 95% confidence intervals and F-test were also determined for further analysis. The utilisation of a two-tailed t-test compared to a one-tailed t-test for the noise and speed of both fans is justified due to an absence in literature to

support the initial claim and lack of certainty in whether the addition of the coating would cause an increase or decrease in noise production. The two data sets were compared using an F-test and determined to have similar variances (p < 0.05) and hence it’s also justified to assume equal variances.

Results

Results from the experiment indicate a statistically significant decrease in sound production from the fan covered in the sharkskin and an almost non-existent change in speed.

40

35

Noise produced (dB)

30

25

20

15

10

5

0

0 10 20 30 Time (2 second intervals)

Fan with modification

Fan void of modification

Figure 10. Comparison in the noise produced by the fan with and without sharkskin

As a result, the null hypothesis that the sound would not change or increase can be rejected as the p value was less than 0.05 and the conclusion that there was a decrease in sound can be made. The decrease in sound on average was 10 dB with the 95% confidence interval of this difference being from 8.6 to 11.4 dB. The standard deviation of the fan void of any modification (2.49) was similar to the fan with the sharkskin coating (1.68).

There was however only a slight decrease in the rotational speed of the fan with the sharkskin but was considered not statistically significant as the p value was greater than 0. The mean rpm of the fan without the sharkskin was 1209 rpm and 1196 rpm for the fan with the sharkskin indicating a decrease of 13 rpm. The standard deviation of the speed of the fan with the sharkskin (0.64) and without the sharkskin (0.79) was significantly low indicating that both fans spun consistently at the same speed.

Discussion

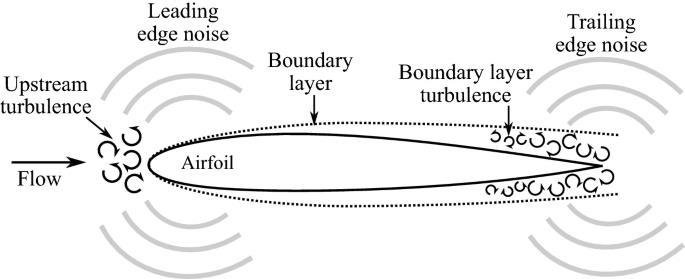

Upon initial inspection the results from this investigation clash, as there is a reduction in noise from the addition of the coating but an unchanged rotational speed. This was simply due to a flaw in the experimental design of measuring the speed of the fan. The essentially unaffected speed can be attributed to the design specifications of the fan, limiting the speed at which the fan can operate, which is an unforeseen limitation of this investigation. The reduction in drag, as described previously, can be attributed to the denticle structured coating maintaining laminar flow and thus delaying flow separation. As a result, the extent to which the low-pressure region can interfere with surrounding air molecules is reduced and hence less noise is generated. This is also described as interactions with the turbulent boundary layer and is found to occur at the trailing edge of an object (Kohout & Hyhlík 2020).

Figure 11. Graphical representation of air foil and areas of noise production (Doolan & Moreau 2022)

In the case of sharkskin, it is important to identify what type of drag is being reduced because there are countless unavoidable sources of drag such as those seen in viscous energy losses (John David Anderson 2019).

The denticle structure of sharkskin is primarily responsible for minimising pressure drag by delaying the flow separation. It does this by forming a small separation bubble that consists of vortices. When the fluid collides with these vortices there is a transfer in momentum that favours the movement of the object, this is because the collision is highly elastic as the kinetic energy of the particle approaching the vortice is close to that of the kinetic energy of the particle leaving the vortice (John David Anderson 2019). The small separation bubble is formed from the unique curvature of the denticle structure, which when undergoing laminar flow is observed to create these vortices (Bhatia et al. 2021). The sharkskin, as mentioned in the methodology, was only located on the upper surface of the air foil in support of Debisschop & Nieuwstadt’s conclusion that the sharkskin coating performed better in adverse pressure gradients. A limitation of this study was the lack of resources to produce a 3rd fan model with a coating on both the top and the bottom of the air foil to test Debisschop & Nieuwstadt’s conclusion. This would have provided greater insight into the properties of the surface and contributed to the accuracy of this design decision (Debisschop & Nieuwstadt 1996). The method used, however, was able to validly indicate whether noise was produced (as indicated by the results), being enhanced (in terms of validity) by the microphones positioning which was supported by literature (Kohout & Hyhlík 2020). As a further area of study, the use of CFD simulations using software (such as ANYS FLUID©) could allow the comparison of the experimental results to the theoretical results. This comparison would ensure that the results were accurate and in-line with baseline data computed previously. The extent to which sound reduction occurred at varying distances from the fan was left unexplored due to limited time. This would have provided a better indication on if the observations were in line with other studies such as Dang, Mao & Tian in 2019 which described the noise reduction as weakening with distance (Dang, Mao & Tian 2019). This investigation did not intend to experimentally prove that the lining of the blades with real sharkskin is a feasible commercial solution to reducing sound production in everyday life, however the findings presented in this paper do suggest that a synthetic denticle coating has the potential to reduce noise production. Further research could involve synthetically replicating the sharkskin in a manner that is more suitable for an aerodynamic setting such as that experienced by a plane wing or helicopter blade. The results from this paper thus act as a preliminary indication of this sound reduction for further research to use. This synthetic replication has been seen in a multitude of research papers such as Leonardo P. Chamorro and J. R. Debisschop who both synthetically replicated the denticle structure seen in sharkskin using polymer-based materials (Debisschop & Nieuwstadt 1996).

Conclusion

The results from this study indicate that the sharkskin denticle structure seen in sharks has

the potential to reduce the noise produced by an object undergoing laminar flow. This is in-line theoretically with current literature as a drag reduction tends to lead to a reduction in noise production (John David Anderson 2019), however, lacks direct verification from other studies due to the absence of research into the phenomenon. The methodology employed was flawed in its ability to measure the drag reduction due to the design specifications of the fan, however the measurement of noise was valid as it was able to differentiate and effectively compare the noise levels of the two fans. In comparison to other studies this paper lacked accuracy, however with the resources available it was successful in scientifically proving that sharkskin can reduce noise production. This paper acts as a basis for further study into the use of synthetic denticle coatings to reduce noise production.

Acknowledgements

I acknowledge the resources provided by the TIGS science faculty and am grateful to all those who I have had the pleasure of collaborating with on this project. I was especially like to thanks Dr J. Gollan, my teacher, and C. Harvey, for insight into aerodynamic equipment and methods.

References

Ankhelyi, MV, Wainwright, DK & Lauder, GV 2018, ‘Diversity of dermal denticle structure in sharks: Skin surface roughness and three-dimensional morphology’, Journal of Morphology, vol. 279, no. 8, pp. 1132–1154. Bhatia, D, Zhao, Y, Yadav, D & Wang, J 2021, ‘Drag reduction using biomimetic sharkskin denticles’, Engineering, Technology and Applied Science Research, vol. 11, no. 5, pp. 7665–7672. Chamorro, LP, Arndt, REA & Sotiropoulos, F 2013, ‘Drag reduction of large wind turbine blades through riblets: Evaluation of riblet geometry and application strategies’, Renewable Energy, vol. 50, pp. 1095–1105. Dang, Z, Mao, Z & Tian, W 2019, ‘Reduction of Hydrodynamic Noise of 3D Hydrofoil with Spanwise Microgrooved Surfaces Inspired by Sharkskin’, Journal of Marine Science and Engineering, vol. 7, no. 5, p. 136. Debisschop, JR & Nieuwstadt, FTM 1996, ‘Turbulent boundary layer in an adverse pressure gradient - Effectiveness of riblets’, AIAA Journal, vol. 34, no. 5, pp. 932–937. Domel, AG, Domel, G, Weaver, JC, Saadat, M, Bertoldi, K & Lauder, GV 2018a, ‘Hydrodynamic properties of biomimetic shark skin: effect of denticle size and swimming speed’, Bioinspiration & Biomimetics, vol. 13, no. 5, p. 056014. Domel, AG, Saadat, M, Weaver, JC, Haj-Hariri, H, Bertoldi, K & Lauder, GV 2018b, ‘Shark skin-inspired designs that improve aerodynamic performance’, Journal of The Royal Society Interface, vol. 15, no. 139, p. 20170828. ― 2018c, ‘Shark skin-inspired designs that improve aerodynamic performance’, Journal of The Royal Society Interface, vol. 15, no. 139, p. 20170828. Doolan, C & Moreau, D 2022, Airfoil Noise Mechanisms and Control, Flow Noise, Lecture Notes in Mechanical Engineering, pp. 139–171. Ibrahim, MD, Amran, SNA, Yunos, YS, Rahman, MRA, Mohtar, MZ, Wong, LK & Zulkharnain, A 2018, ‘The Study of Drag Reduction on Ships Inspired by Simplified Shark Skin Imitation’, Applied Bionics and Biomechanics, vol. 2018, pp. 1–11. John David Anderson 2019, Fundamentals of aerodynamics, Mcgraw-Hill, [20]04, Boston. Kohout, D & Hyhlík, T 2020, ‘Influence of the shroud leading edge shape on the axialfan noise’, in Proceedings of the 6th World Congress on Mechanical, Chemical, and Material Engineering. Krauss, C 2022, ‘Falling Oil Prices Defy Predictions. But What About the Next Chapter?’, The New York Times, 15 August.

Moore, M 2022, With wind farm decision expected Friday, Port au Port residents are divided, CBC. Society, NG 2020, Marine Food Chain, National Geographic Society. Tian, G, Fan, D, Feng, X & Zhou, H 2021a, ‘Thriving artificial underwater dragreduction materials inspired from aquatic animals: progresses and challenges’, RSC Advances, vol. 11, no. 6, pp. 3399–3428. ― 2021b, ‘Thriving artificial underwater dragreduction materials inspired from aquatic animals: progresses and challenges’, RSC Advances, vol. 11, no. 6, pp. 3399–3428.