RIGGS REBUILDS

Are you comfortable with your current Cat machine? Keep it! At Riggs Cat, we believe in maximizing the life and performance of your equipment with the help of our dedicated Rebuild Team. Our team of skilled technicians is committed to restoring your trusted machines to their peak condition so you can get the most out of your investment. We take pride in delivering top-notch service and quality, helping you maintain the efficiency and reliability you count on. Thank you for trusting Riggs Cat – your partner in progress and performance.

GEORGE CRESS, CEO

Caterpillar machines prioritize sustainability and are engineered to be reused and remanufactured to extend their lifespan.

Get a 2nd or 3rd life out of your machine

Modernize equipment features & technology

Rebuilds cost significantly less than the price of a new machine

Can be completed in 8 – 12 weeks, typically

Operators don’t have to learn a new machine

Warranty on replaced Cat parts

A CAT® CERTIFIED REBUILD COSTS ABOUT 55-60% OF A NEW MACHINE

Caterpillar engineers equipment & components to perform for multiple lives.

Your rebuilt machine receives a unique identifier, like a Rebuild ID Number or new serial number, helping it retain its value for future resale opportunities.

You don’t have to invest time & effort learning how to operate new equipment when you rebuild. There’s no downtime for training & no adjustment period before operators and technicians can go to work.

Cat machines get more productive, safer to operate and easier to service every year. Having engineering updates introduced after equipment was manufactured means your rebuilt machine may perform better than when it was new.

For example, you can add grade control or payload weighing. Or install a seat belt reminder or a camera system. Make operation safer or more comfortable. You can do all that and more when you upgrade features and tech during a rebuild.

+ You get same-as-new support and services from Riggs. We have the parts, service and expertise to keep your rebuilt equipment on the job.

Your machine is disassembled to the frame, thoroughly inspected, reassembled with every single component being looked over or replaced, and assigned a new rebuild number.

Bring the heart of your machine including radiator, engine, transmission, torque converter, final drive and axle back to new.

Revitalize your machine’s performance by addressing two crucial components, ensuring it operates at optimal efficiency.

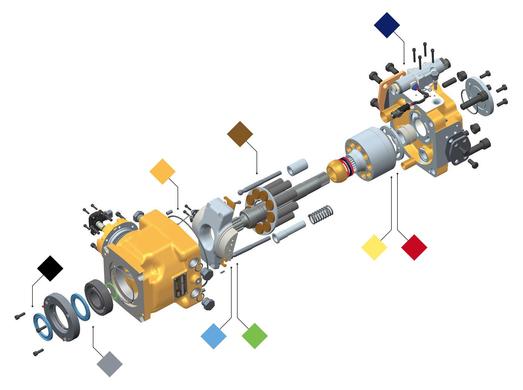

Avoid the cost and downtime of individual repairs by bringing your excavator’s pumps, motors, valves, accumulators, hoses, tubes, tanks, coolers and cylinders back to new.

An “ a la carte” service for hydraulic excavators. Replace a single hydraulic pump or multiple components like the pump and cylinders.

MACHINE

ARRIVES

INSPECTION + EVALUATION

COMPLETE

DISASSEMBLY

RECONDITIONING + CLEANING

ENGINEERING UPDATES

REASSEMBLY + REPAINTING

PERFORMANCE TESTING

FINAL INSPECTION EVALUATION

Approx. 8-12 weeks*

A Cat® Certified Machine Rebuild is a cost-effective alternative that will restore your equipment to like-new condition

60-80% of the price of a new machine

F T E R

INSPECTION/EVALUATION

Perform fluid analysis, visual inspections and review available service history 1

6

COMPLETE DISASSEMBLY

Conduct an extensive inspection of all parts and components 2

RECONDITIONING

Complete work not included in a typical overhaul (e.g., frames, linkage pins, shaft bearings, electronic control modules, software) 3

ENGINEERING UPDATES

Recondition components to include the latest engineering designs 4

REASSEMBLY

Replace approximately 7,000 parts with new or remanufactured Cat parts; maintain all critical torques, clearances and pressure settings; replace all wiring 5

7

PERFORMANCE TESTING

Bench test the engine, fuel system, transmission, torque converter, differential, final drives and radiator; conduct turbocharger boost, stall speed rpm, throttle response, transmission and steering clutch response, and pilot relief valve pressure tests

8

REPAINTING

Paint the machine; apply model identity graphics

9

FINAL INSPECTION

Thoroughly inspect the rebuilt machine and assign a Rebuild Identification Number (RIN), which provides it with a brand new identity

EVALUATION

Ensure satisfaction with performance in the working environment

A Cat® Certified Powertrain Rebuild revitalizes the heart of your Cat machine for a fraction of the cost of buying new.

Restoring your power train’s original performance and productivity plus adding engineering updates introduced after it was manufactured—improves machine availability and greatly extends service life.

1

2

INSPECTION/EVALUATION

Perform fluid analysis, visual inspections and up to 200 tests

6

3

COMPLETE DISASSEMBLY

Conduct an extensive inspection of all parts and components

7

PERFORMANCE TESTING

Bench test components and conduct turbocharger boost, throttle response, stall speed rpm, transmission and steering clutch response tests

Paint power train components; apply model identity graphics

4

RECONDITIONING

Complete work not included in a typical overhaul (e.g., electronic control modules, power train wiring harnesses, sensors and switches, hoses, cooling package)

8

ENGINEERING UPDATES

Make improvements introduced after the original manufacture date

5 REASSEMBLY

Replace approximately 3,000 parts with new or remanufactured Cat parts; maintain all critical torques, clearances and pressure settings; replace all engine wiring

9

FINAL INSPECTION

Install power train components and test all supporting systems to ensure proper operation and peak performance (performed by a Certified Cat Dealer Service Technician from our Riggs Rebuild Team)

EVALUATION

Ensure satisfaction with performance in the working environment

A Cat® Certified Machine Component Rebuild is a cost-effective solution for machines only requiring 1-2 repairs.

SPEND UNDER 40% of the price of a new machine

Restoring a key component’s original performance and durability—plus incorporating product enhancements introduced after it was manufactured—improves the reliability of your machine and greatly extends its productive service life.

1

2

INSPECTION / EVALUATION

Inspect the machine to identify worn components, and removes the targeted parts for rebuilding.

3

DISASSEMBLY + CLEANING

The removed components are disassembled, thoroughly cleaned, and inspected to determine if they can be reused or need replacement.

6

PERFORMANCE TESTING

The rebuilt component(s) undergoes bench testing, operational testing in the machine, and additional quality checks to ensure it meets Caterpillar’s standards.

4

RECONDITIONING

Worn parts are reconditioned or replaced with genuine Cat parts, and tested for cracks and fatigue using nondestructive methods.

7

DOCUMENTATION + REPORTING

Detailed records of the rebuild process and testing results are maintained, and a comprehensive report is provided to the customer.

EVALUATION

Ensure satisfaction with performance in the working environment 8

REASSEMBLY

Reconditioned and new parts are reassembled to Cat’s precise specifications, with proper installation of bearings and seals.

9

The machine, with its rebuilt components, is returned to the customer, and ongoing support is provided, including follow-up inspections and maintenance advice.

ONLYSPEND 40-60% of the price of a new machine

1

2

INSPECTION / EVALUATION

Thorough inspection of the hex components is conducted to evaluate their current condition and identify any wear or damage.

COMPLETE DISASSEMBLY + CLEANING

The hex components are carefully disassembled and cleaned to remove all dirt, debris, and residues.

6

3

DETAILED INSPECTION + MEASUREMENT

Each part is inspected and measured using precision tools to assess wear and determine the extent of repair or replacement needed.

7

RECONDITIONING + REPAIR

Worn parts are reconditioned through processes such as machining, welding, or grinding, and severely damaged parts are replaced with genuine Cat parts.

4

5

ENGINEERING UPDATES

Make improvements introduced after the original manufacture date.

WEAR ANALYSIS + REPORTING

A wear analysis is performed to identify patterns and root causes of wear, and a report is generated to outline the findings and recommended actions.

8

UPGRADES + ENHANCEMENTS

Where applicable, upgrades and enhancements are applied to improve the durability and performance of the hex components, using the latest Cat technology and materials.

REASSEMBLY + PRECISION ALIGNMENT

The reconditioned and new parts are reassembled with precision alignment to ensure optimal performance and longevity.

9

TESTING + EVALUATION

The rebuilt hex components undergo rigorous testing, including functional and operational tests, to verify their performance and adherence to Caterpillar’s quality standards.

An “ a la carte” service for Cat Hydraulic Excavators. Replace a single hydraulic pump or multiple components like the pump and cylinders. of the price of a new machine

* Please note: Each project is unique and results may vary based on several factors including the age of the machine, the level of damage, and specific requirements.

1

2

INSPECTION / EVALUATION

Thorough inspection of the hex components is conducted to evaluate their current condition and identify any wear or damage.

COMPLETE DISASSEMBLY + CLEANING

The hex components are carefully disassembled and cleaned to remove all dirt, debris, and residues.

6

3

DETAILED INSPECTION + MEASUREMENT

Each part is inspected and measured using precision tools to assess wear and determine the extent of repair or replacement needed.

7

RECONDITIONING + REPAIR

Worn parts are reconditioned through processes such as machining, welding, or grinding, and severely damaged parts are replaced with genuine Cat parts.

4

5

ENGINEERING UPDATES

Make improvements introduced after the original manufacture date.

WEAR ANALYSIS + REPORTING

A wear analysis is performed to identify patterns and root causes of wear, and a report is generated to outline the findings and recommended actions.

8

UPGRADES + ENHANCEMENTS

Where applicable, upgrades and enhancements are applied to improve the durability and performance of the hex components, using the latest Cat technology and materials.

REASSEMBLY + PRECISION ALIGNMENT

The reconditioned and new parts are reassembled with precision alignment to ensure optimal performance and longevity.

9

TESTING + EVALUATION

The rebuilt hex components undergo rigorous testing, including functional and operational tests, to verify their performance and adherence to Caterpillar’s quality standards.

TRACK-TYPE TRACTORS

D6H, D6M, D6R, D7G, D7H, D7R, D8K, D8L, D8N, D8R, D8T, D9H, D9L, D9N, D9R, D9T, D10T, D10N, D11N, D11T

TRACK-TYPE LOADERS

953, 953B, 953C, 963, 963C, 973, 97L

WHEEL LOADERS

938G, 950B, 950E, 950F, 950G, 962G, 966C, 966D, 966E, 966F, 966G, 970F, 972G, 980C, 980F, 980G, 988B, 988F, 988G, 988H, 990, 992B, 992C, 992D, 992G, 994, 994D

MOTOR GRADERS

12G, 12H, 14G, 14H, 16G, 16H, 24H, 120G, 140G, 140H, 160H

WHEEL TRACTOR-SCRAPERS

615C, 621E, 621F, 621G, 623F, 627E, 631D, 631E, 633D, 637D, 637E, 637G, 657E

OFF-HIGHWAY TRUCKS AND TRACTORS

768C, 769C, 769D, 771C, 771D, 772B, 773B, 773D, 773E, 775B, 775D, 775E, 776, 776B, 777, 777B, 777C, 777D, 777F, 785B, 785C, 789B, 789C, 793B, 793C, 793D, 797

CAT UNDERGROUND

AD30, AD45, AD55, R1300, R1300G, R1600, R1600G, R1700G, R2900, R2900G

320, 330, 330B*, 345B, 365B, 375, 385B PIPELAYERS

572G, 578, 583K, 589, 594H

SKIDDERS

525B, 535B, 527, 545

Our Riggs Rebuild centers are conveniently located in 6 locations across the state of Arkansas:

Even the best-built machines eventually need repairs.

Get repairs done right by certified Cat dealer technicians

Convert a variable cost (unplanned repairs) into a budgeted item

Lock in costs for parts and labor now Choose coverage that fits your needs and budgets Finance EPP with your equipment loan / lease or pay with your Cat Card

Extended Protection Program options by Cat

EPP programs for Cat

Certified Rebuild Equipment

Cat Certified Machine Rebuild

Cat Certified Powertrain Rebuild

Cat Certified Machine Component Rebuild

Cat Certified Hydraulic Rebuilds (for Excavators only)

EPP programs for Cat Certified Rebuilt Parts

Powertrain:

Powertrain: Coverage for certain components that produce, transmit, or control engine horsepower

Powertrain + Hydraulics:

Powertrain + Hydraulics: Coverage for the powertrain elements previously described, as well as certain components associated with steering and implement control

Components:

Components: Coverage for certain major components such as engine, transmission/torque converter, drive axles, differentials, and final drives.

Hydraulics (Excavators Only):

Hydraulics (Excavators Only) Coverage for certain components associated with steering and implement control.

A traditional loan may be the right option for you. Choose from flexible payment plans including skip payments on monthly schedules for qualified customers.

Ask one of our Rebuild Reps about our current Cat Card financing offers.

The Cat Card is the fast, easy way to pay wherever the job takes you. When you use your Cat Card during a rebuild, you often get access to special offers.

Eligible account holders earn Cat Card Rewards on all qualifying purchases. You can use those rewards to pay for parts, attachments, services, rentals, future rebuilds and more at your Cat dealer.

Very satisfied with my rebuild. The fuel economy and hydraulics run like it’s a new machine.

BART WILLIAMS Montgomery County Judge