Master's Thesis Reversible Bauweise Reversible Building Design Supervisors: Prof. Dipl.-Ing. Martin Wollensak Prof. Dr.-Ing. Marcus Hackel Presented by: Lobo, Janice, 369066 Born on: 08.05.1992 Hochschule WismarUniversity of Applied Science, Technology, Business and Design Fakultät Gestaltung Architektur Wismar, 04.07.2022

Declaration of independent work

I hereby declare that I completed this work independently and that I have used no aids other than those referenced.

The parts of the work, which include phrases or points taken from other sources, are clearly marked with the origin of the information. This also applies to diagrams, sketches, visual representations as well as for sources from the Internet.

I also declare that I have not submitted this work in any other testing procedure as an examination paper, nor will I in the future.

The submitted written work corresponds to the electronic version. I agree that an electronic copy may be made and stored to enable verification by anti-plagiarism software.

Janice Frances Lobo

Wismar, 04.07.2022

Abstract

Traditional linear building workflow models have resulted in the construction industry contributing to a significant share of total waste materials produced and greenhouse gas emissions worldwide. To address this issue, circular models are emerging. Barriers to achieving this include the complexity of projects, lack of economic incentives, and lack of awareness. This research analyzes the various frameworks created to aid designers in circular principles and design for disassembly concepts. The key strategies identified are implemented to a case study project set in Berlin, Germany. The design is evaluated using qualitative parameters and quantitatively through simulations and Life Cycle Assessment calculations. Finally, the process is critically analyzed, and suggestions are made to address the challenges encountered.

Abstract (German)

Herkömmliche lineare Bauprozessmodelle haben dazu geführt, dass die Bauindustrie zu einem erheblichen Teil zu den weltweiten Treibhausgasemissionen beiträgt. Um dieses Problem anzugehen, werden zunehmend zirkuläre Modelle entwickelt. Zu den Hindernissen auf dem Weg dorthin gehören die Komplexität der Projekte, fehlende wirtschaftliche Anreize und mangelndes Bewusstsein. Diese Forschungsarbeit analysiert die verschiedenen Rahmenwerke, die zur Unterstützung von Designern bei Kreislaufdesign- und Demontagekonzepten geschaffen wurden, und wendet die Schlüsselstrategien auf ein Fallstudienprojekt in Berlin an. Das Design wird anhand qualitativer Parameter und quantitativ durch Simulationen und Ökobilanzberechnungen bewertet. Abschließend wird der Prozess kritisch analysiert, und es werden Vorschläge zur Bewältigung der aufgetretenen Herausforderungen gemacht.

Acknowledgement

I want to thank my supervisors, Prof. Dipl.-Ing. Wollensak and Prof. Dr.-Ing. Hackel for their guidance and support during the thesis and the course of the Master’s program at Hochschule Wismar. A special thanks to the friends I have made in Germany, from whom I have drawn so much inspiration, joy and support. Finally, I am incredibly grateful to my family and friends for their continuous support and understanding.

Contents 1. Introduction 1.1 Background 7 1.2 Problem statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 1.3 Objectives 8 1.4 Scope of work 8 1.5 Methodology 9 2. State of the art 2.1 Definitions 11 2.2 Strategies for circularity, adaptive design and disassembly 13 2.3 Existing frameworks 16 2.4 German guidelines, policies and challenges 22 2.5 Case studies ....................................................... 25 3. Case study design 3.1 Reversible design strategies .......................................... 33 3.2 Site 34 3.3 Massing 39 3.4 Materials 44 3.5 Final design 60 3.6 Assembly .......................................................... 73 4. Analysis 4.1 Design evaluation .................................................. 82 4.2 Life cycle perspective 87 4.3 Critical analysis 92 4.4 Conclusions 92 5. Resources 5.1 Reference List 94

INTRODUCTION > 1.

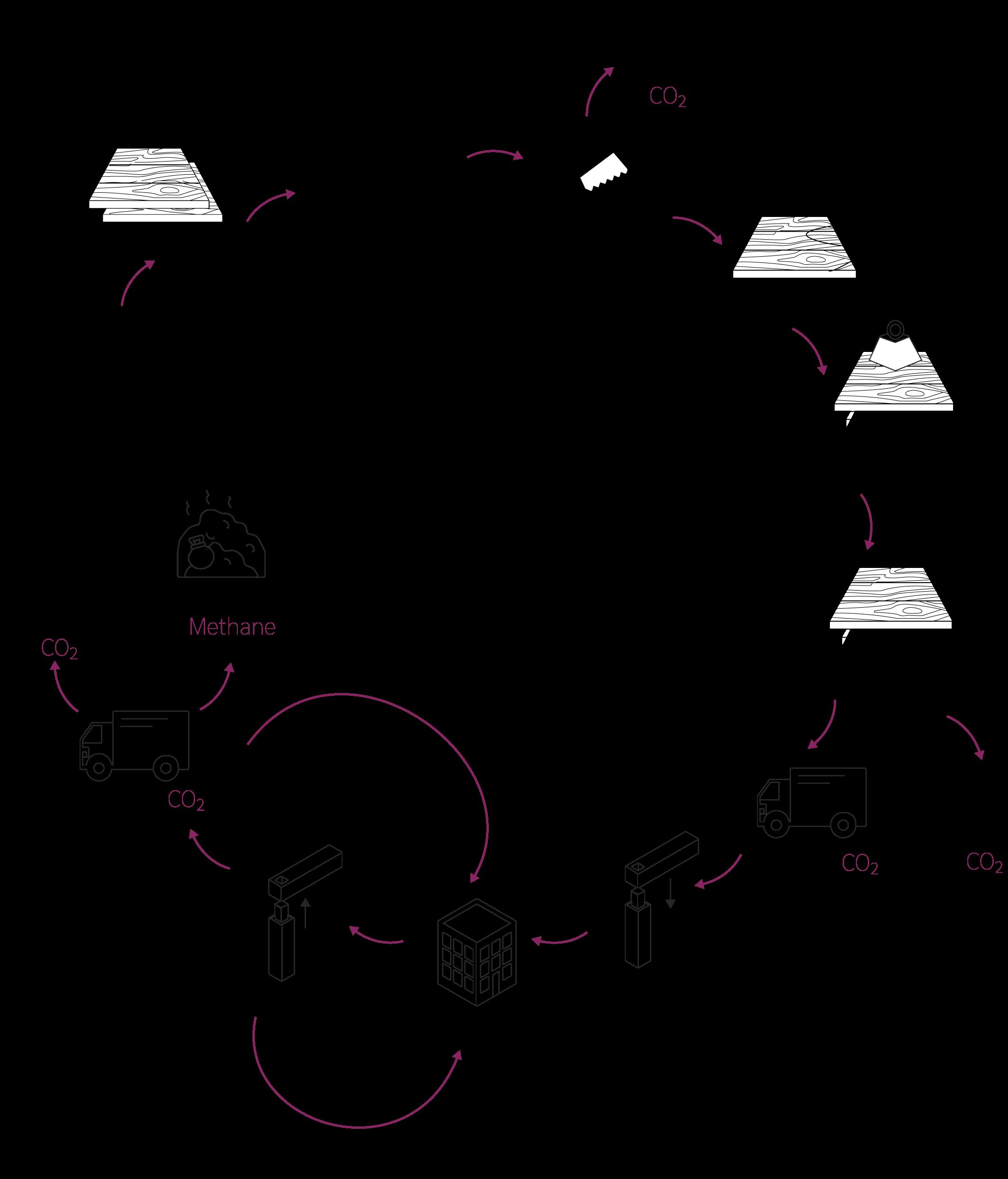

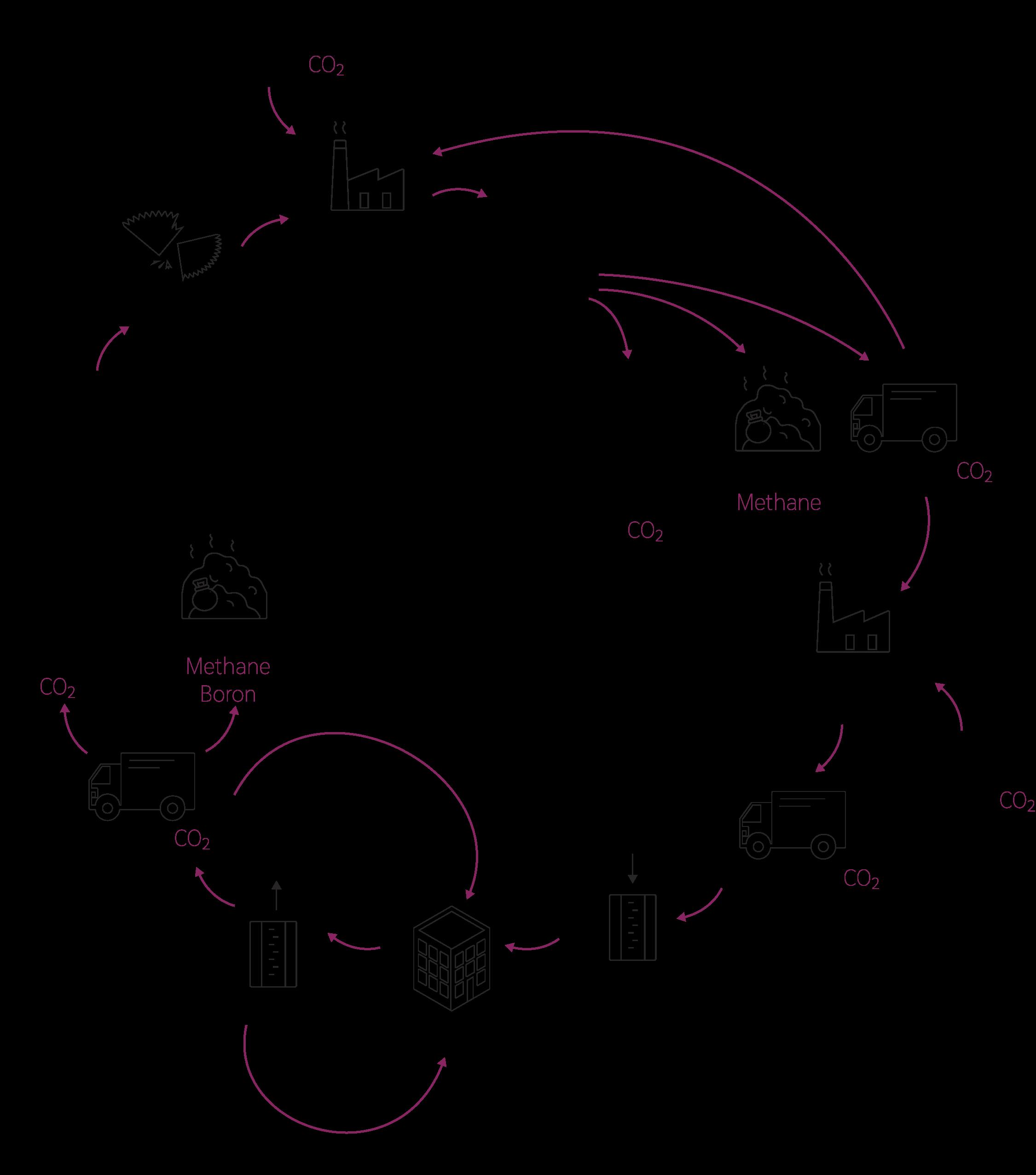

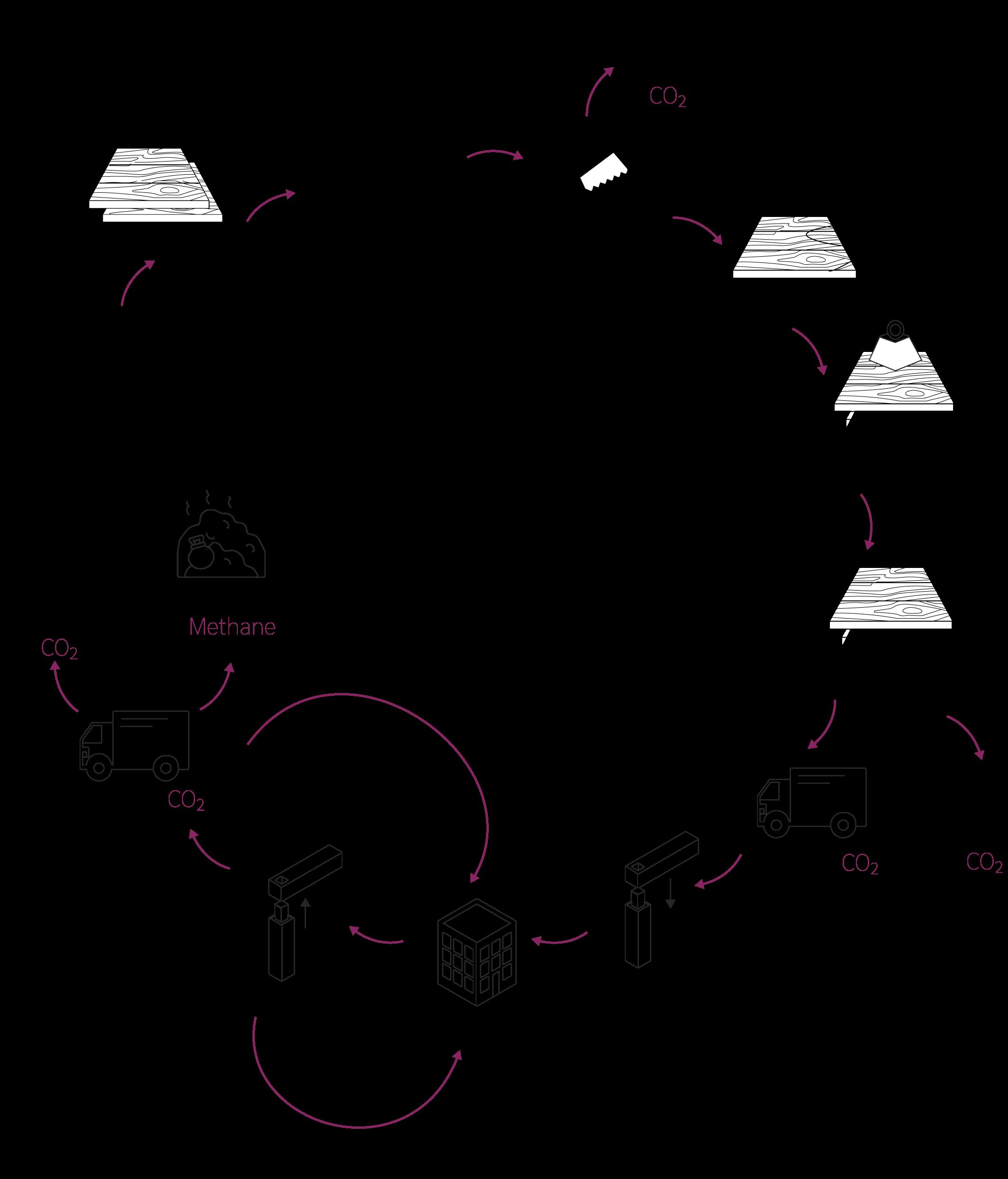

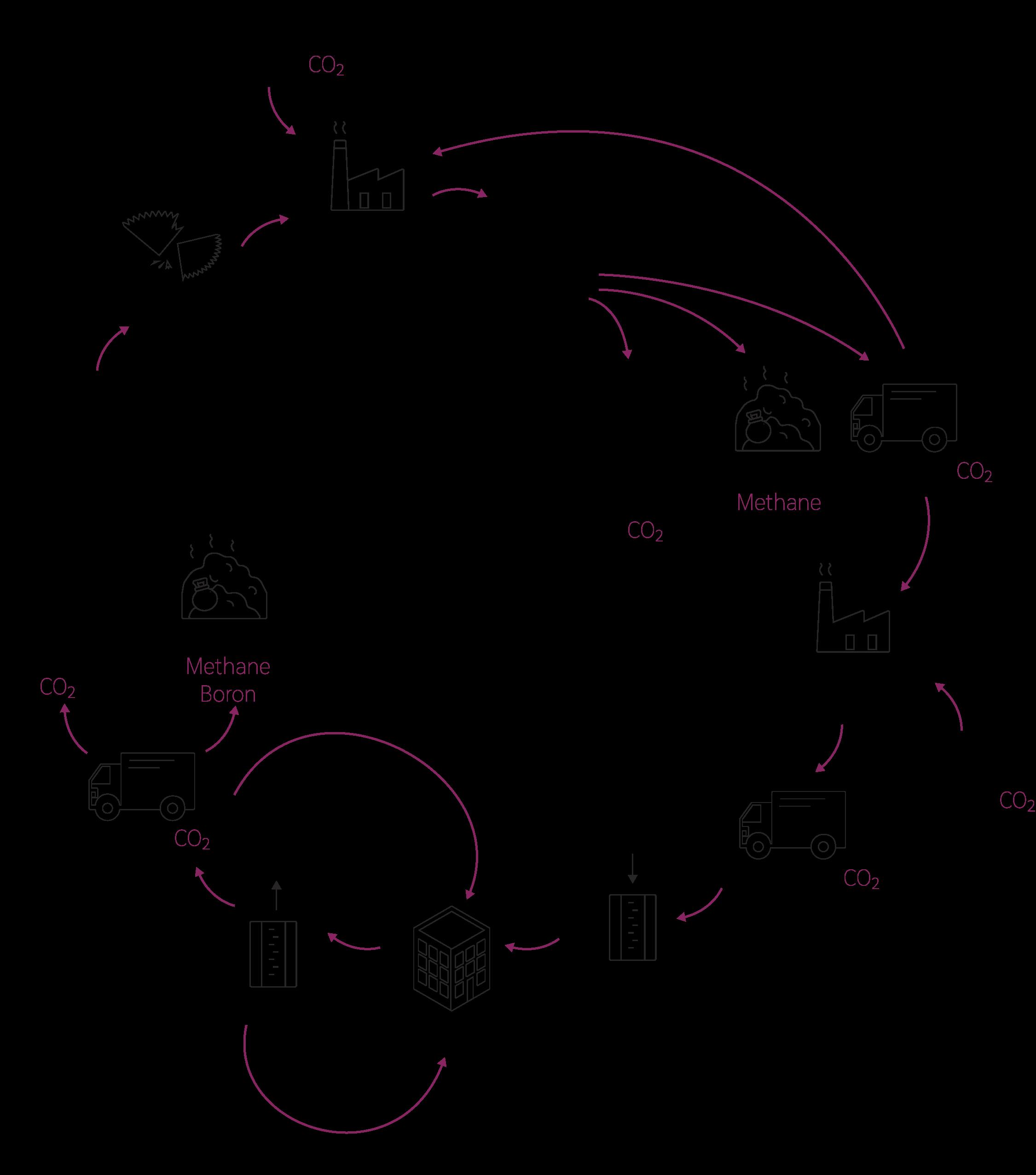

The construction industry contributes significantly to global greenhouse gas production and uses a large number of raw materials without clearly defined end-of-life scenarios. The current workflow for construction is based upon a linear model. Materials are extracted, processed, supplied to the site, used, and then disposed of (Fig. 1). Circular design focuses on adapting this linear flow to bring waste materials from the manufacturing and construction process back into the loop to be upcycled or reused (Fig. 2). It prevents materials still in use from being sent to landfills and avoids excess raw material extraction, which supports economic, cultural, and environmental assets (Durmisevic, 2006). Strategies for sustainable renovations and a new circular way of thinking are required to achieve this. Examples of successful implementation can be seen in other industries such as the technology and automotive sector for inspiration.

Germany’s Climate Action Plan 2050 outlines ambitious goals for a nearly carbon-neutral building stock. The building stock in Germany is old, composed of 49.02% structures built between 1949-1978 and 25.24% built before then (Directorate-General for Energy, 2016). Therefore a lot of them will be due for renovation or demolition and can be considered as sources of materials for new construction, also known as material banks. It is often complex to reuse materials from old projects that have not been adequately planned because the building is not designed to be taken apart and not maintained with this end goal in mind, emphasising the importance of adequate planning in the early design phase.

Introduction > 7

LIFE

MATERIAL SUPPLY PRODUCTION USE ASSEMBLY END OF LIFE DEMOLITION Raw material extraction Landfill

of components and materials MATERIAL SUPPLY PRODUCTION USE ASSEMBLY Raw material extraction CIRCULAR LIFE CYCLE PHASES END OF LIFE Material recycling Design for reconfiguring/ upgrading of components Design for recycling/ upgrading of materials Design for reuse

CYCLE PHASES

Downcycling

Fig. 1, Linear construction model, (adapted from Durmisevic, 2006)

1.1 Background

Fig. 2, Circular construction model, (adapted from Durmisevic, 2006)

Designing for a circular model is complex, and though pilot projects have implemented it, it is still far from being accessible in the mainstream architecture field. Buildings and materials will need to be assessed at different stages and scales. Collaboration is needed from various stakeholders to achieve the climate-related goals set by the Federal Ministry for the Environment, Nature Conservation, Nuclear Safety, and Consumer Protection in agreement with the Paris Climate Agreement. The key players include educators, architects, engineers, product manufacturers, contracting companies, clients, waste management, and policymakers, among others.

Policy and incentivization would help in making circular design a construction norm. Building certification systems such as BREEAM, LEED, and DGNB offer a few guidelines and credit points to promote design for disassembly and circular construction, however in most countries, green building certification is an optional and expensive process.

1.3 Objectives

This research will outline a guideline for circular construction and apply it to a case study design set in the context of Berlin, Germany. It will also aim to analyze circular construction’s potential challenges and limitations and propose strategies to help tackle them. It is estimated that 10% of construction materials are wasted as offcuts or in manufacturing (European Commission, 2022). The project will aim to reduce construction waste through the design of connections and specification of innovative products.

In researching and designing using sustainable principles, the question of the aesthetics of circular architecture will be considered to be an important factor in encouraging the longevity and acceptance of the building within the urban context.

1.4 Scope of work

The research study aims to answer the question of how reversible design concepts can fit into an urban medium-density architectural project. It will analyze and evaluate different construction systems' ability to adapt to circular design principles and the cultural and environmental context.

Potential limiting factors include the availability of transparent data due to the nature of a profitdriven market that does not support open-source information and collaboration. Additionally, pilot projects for reversible design are few and usually focus on temporary or small-scale projects and scaling up solutions might not be successful.

8 < Introduction

1.2 Problem statement

The research project will include a literature review of state-of-the-art articles that outline the principles of circular design, adaptable design, and design for disassembly upon which this thesis will be formed. The research phase will be followed by examining relevant case study projects that document design for adaptability and disassembly and provide insights into challenges faced.

The key strategies and parameters encountered will be combined to form an evaluation tool which will be tested by the design of a case study project set in Berlin, Germany. The life cycle of materials will be researched to understand their related emissions, waste materials, and energy involved at every stage. The design of connections will be explored to understand how a building can be taken apart and reused or adapted. The design will be evaluated using quantitative data from simulations and calculations and qualitative data based on predefined design parameters.

Introduction > 9

1.5 Methodology

STATE OF THE ART > 2.

10 < State of the art

Adaptability

The ability of a space to be modified during its life for uses beyond the one originally designed for.

Adaptive reuse

Redesign and alteration of a building to support a new function it was not originally intended to serve.

Circular economy

An economic model supporting a closed-loop system of material reuse through marketbased means.

Deconstruction

The careful removal of building materials to retain their integrity and value at the end of a building’s service life.

Design for Disassembly

A design practice that focuses on how materials are joined together in a way that can be reversed at the end of life with minimal waste. It is common practice in the automotive and technology industries.

Embodied environmental impacts

A quantitative measurement of the environmental impact of creating a material or product. It includes the greenhouse gases and energy required to extract, transport and manufacture, deliver and dispose of materials.

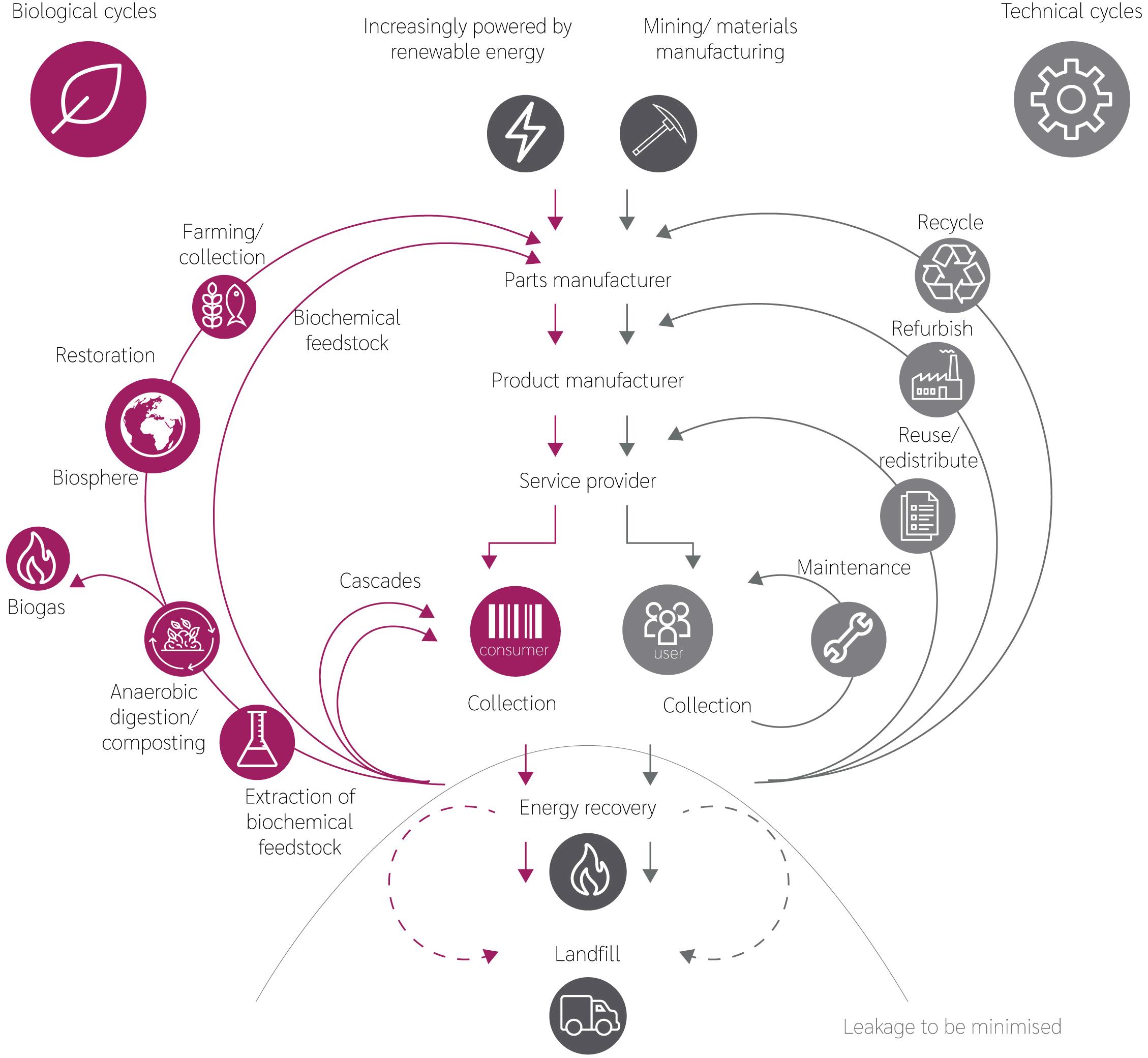

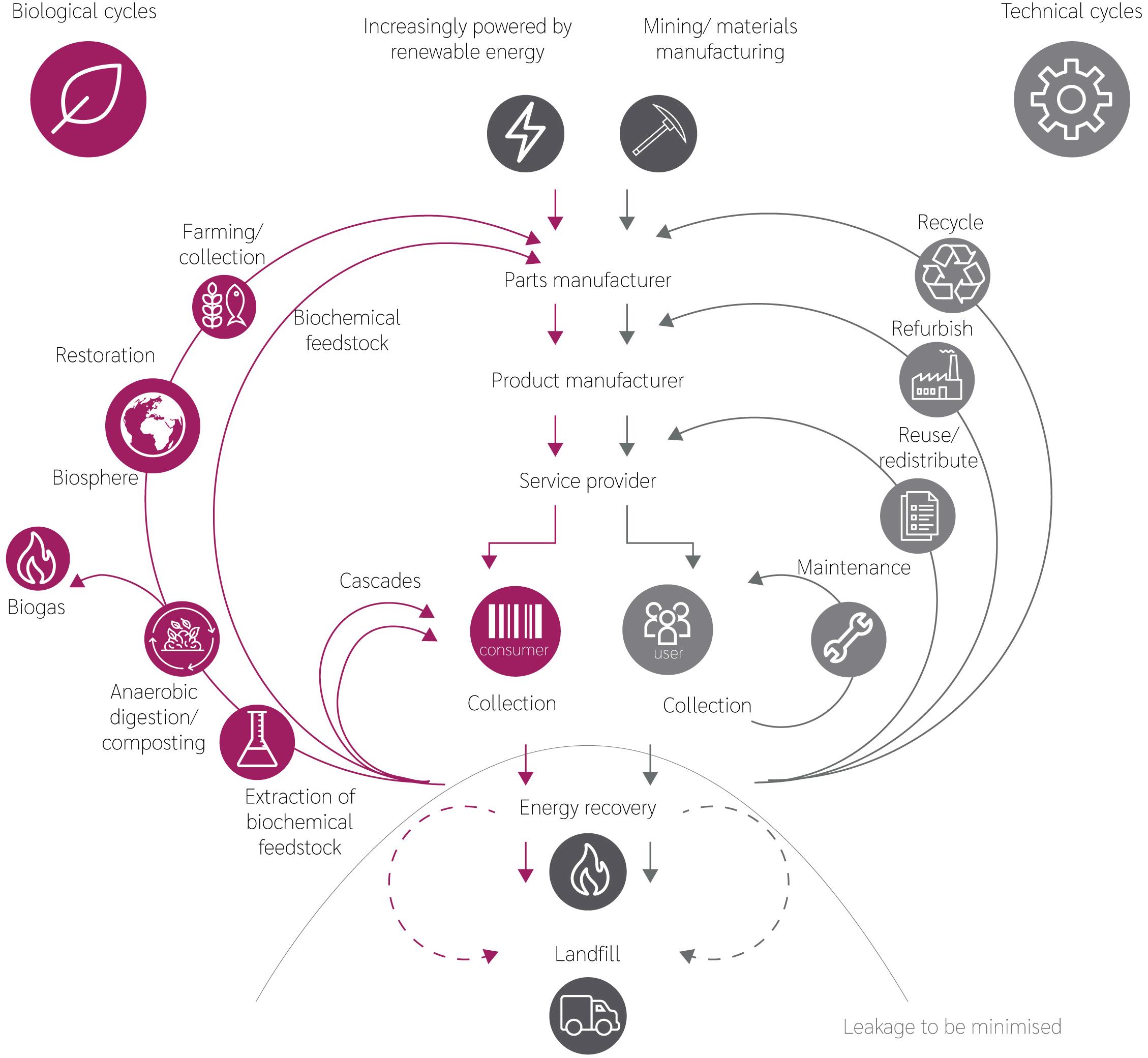

Biological Cycle

Products composed of biodegradable materials that can be returned as nutrients in the biological cycle at end of life.

Technical Cycle

Products composed of materials of human artifice should be designed to circulate within a closed-loop manufacturing process without contaminating the biological life cycle.

(Paula Melton and The American Institute of Architects, n.d.)

State of the art > 11

2.1 Definitions

Cradle to Cradle Design

Cradle to cradle design refers to a set of principles developed in the 1990’s by Prof. Dr. Michael Braungart, William McDonough, and Environmental Protection Encouragement Agency (EPEA) Hamburg. It proposed a model for the safe and infinite circulation of materials and nutrients in cycles (Thibaut. 2018). The butterfly diagram (Fig.3) describes the principles of Cradle to Cradle design. It outlines that materials at the end of their service life be disassembled, sorted, recycled, and returned to the material cycle for further use. The EPEA provides Cradle to Cradle certification for materials and products (EPEA, 2022). Products are assessed based on five categories:

- material health of used ingredients

- recyclability of the product in the technical or biological cycle

- use of renewable energy

- responsible waste management

- compliance with social standards

12 < State of the art

Fig 3. Butterfly diagram (adapted from Ellen MacArthur Foundation, 2019)

2.2 Strategies for circularity, adaptive design and disassembly

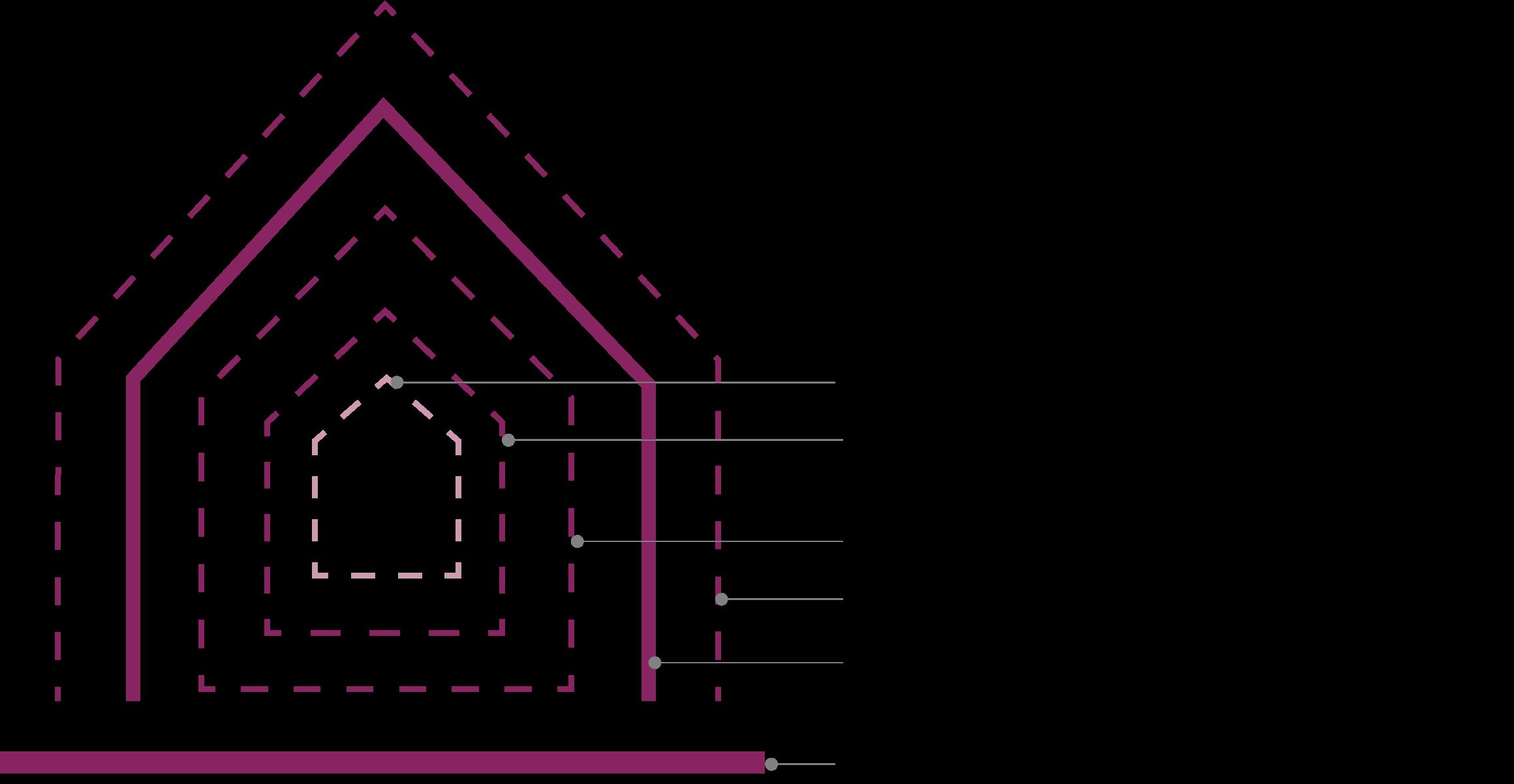

Design for disassembly

Design for disassembly involves thinking of a building in layers where each element has a different life span. This principle is seen in Steward Brand’s ‘Layers of Change’ diagram (Fig. 4), which attached an estimated life span to the six layers (Site, Structure, Skin, Services, Space Plan, and Stuff) of the building. This diagram provides an insight into the complexities of how a building exists through time and justifies the need to design in a way that considers our ability to be able to maintain and replace certain layers without compromising or destroying others. For example, it indicates that a new space plan does not mean the need for a new structural system if the structural system was designed to facilitate adaptability in the first place. Disassembly occurs at the connection points where the layers meet, and careful design of these joining points can avoid the premature obsolescence of the entire building (Durmisevic, 2019).

State of the art > 13

Fig 4. The “six S’s” diagram of time-related building layers (adapted from Brand, 1994)

Frame Enclosure Partitioning Services Flexible Building 0 20 40 60 80 Years

Fig 5. Building element lifespan (adapted from Durmisevic, 2006)

Elma Durmisevic wrote a vital text relevant to the principles of Design for Disassembly as part of the Buildings as Material Banks 2020 (BAMB) project funded by the European Union’s Horizon 2020 research program (2019). Durmisevic outlines that for a building to be reversible, it needs to meet the design requirements of accessibility, variation, reuse, replaceability and refurbishment, reconfiguration, .and recycling. She states that buildings can be de-constructed in three ways:

1. Functional deconstruction involves separating functions within a building element. For example, a wall component is comprised of cladding, load-bearing structure, and insulation.

2. Technical deconstruction - involves the hierarchical arrangement of building materials and their dependence between material levels. Durmisevic identified six types of arrangements: closed, layered, stuck, table, open, and shared assembly. The simpler the arrangement pattern, the higher the level of de-constructability.

3. Physical deconstruction - involves the design of connections that allow building elements to be taken apart and reused. To facilitate this deconstruction, the aspects that need to be considered are the geometry of product edges, assembly sequences, type of connections, and life-cycle coordination.

A building that can be disassembled can be thought of as a reversible building. Durmisevic categorizes three aspects that should be considered when categorizing a building as reversible. She states that multiple scenarios for the use of a building and its materials should be specified during the design phase to evaluate and prove its reversibility.

1 Reversibility of space

• Volume dimensions

• Position of core

• Load bearing capacity

Design of building core to facilitate transformation from one use to another.

2 Reversibility of structure

• Functional independence through the separation on the building, system and component level.

• Technical independence through minimising relations between different functional modules.

3 Reversibility of material

• Physical interchangeability through the design of de-constructable connections.

14 < State of the art

Fig 6. Conceptualization of the value of recycling and reuse degree (adapted from Eberhardt, Birgisdottir and Birkved, 2019)

Value of recycling and reuse

During the design phase, the parameters for the circularity of the building can be defined. Research by Eberhardt, Birgisdottir and Birkved (Fig, 6) indicates that it is more economically and environmentally beneficial to reuse and recycle on a larger scale, such as the entire building or building modules, rather than to disassemble it and recycle the individual materials (2019).

Each strategy has its pros and cons. For example, with prefabricated modules, transportation is complicated and has high related emissions. Modules sizes are limited by the size of transport vehicles, which leads to smaller spaces and less flexibility. Additionally, prefabricated modules have not received widespread acceptance from the public due to aesthetic reasons and a preconception that it is not possible to personalize the space make them more suitable for short-term use spaces such as emergency shelters or short-term social housing. A case study example of this is the Place, Ladywell Social Housing Block where residents reported feeling stimatized due to the architectural qualitities of the space. (Jessel, 2019).

The design of high-quality prefabricated building components and elements has the potential for multiple reuse cycles and can be sized more flexibly for transportation. To achieve this, however, the system of short-term profits prioritized by manufacturers would need to be revisited and collaboration with policymakers to ensure standardization of elements and quality assurance. Modular panels would need to comply to weight and size regulations for transport by road.

State of the art > 15

Recycling of building materials Reuse of building elements Reuse of building components Reuse of building modules Reuse of entire building Economic value Environmental value increasingcircularity

2.3 Existing frameworks

European Union Level(s) framework

The European Union developed a framework to guide professionals in implementing sustainable design principles. The framework comprises of 6 macro objectives and 16 performance indicators for the construction of sustainable residential and office buildings (Fig 7). User manuals for newcomers to circular construction and professionals have been created to inform designers and clients. They provide step-by-step instructions on applying each indicator to a chosen project. Tools such as excel templates and checklists have been provided to assess the building continuously. The framework was tested in 130 buildings in 21 countries from spring 2018 to 2020, and the results have informed an update of the guidelines and manuals (2022).

Thematic areas Macroobjectives Indicators

1. Greenhouse gas emissions along a building’s life cycle

1.1 Use stage energy performance (kWh/ m2/year)

1.2 Life cycle Global warming potential (CO2 eq./m2/year)

Resource use and environmental performance

2. Resource efficient and circular material life cycles

3. Efficient use of water resources

Health and comfort

2.1 Bill of quantities, materials and lifespans

2.2 Construction and demolition waste

2.3 Design for adaptability and renovation

2.4 Design for deconstruction

3.1 Use stage water consumption

Cost, value and risk

16 < State of the art

6.1 Life

5.2

4. Healthy and comfortable spaces 4.1 Indoor air quality 4.2 Time out of thermal comfort range 4.3 Lighting 4.4 Acoustics 5. Adaption and resilience to climate change 5.1 Life cycle tools; scenarios for projected future climatic conditions 5.2 Increased risk of extreme weather 5.3 Sustainable drainage 6. Optimised life cycle cost and value

cycle costs

Value creation and risk factors

Fig 7. EU Level(s) Framework (adapted from European Commission, 2022)

The specific indicators within the framework analyzed in relevance to the design of this thesis are Level(s) indicator 2 - Resource-efficient and circular material life cycles, however, all indicators contribute to a holistic, sustainable project.

Indicator 2.1 Bill of quantities, materials and lifespans

This indicator involves measuring the mass of construction materials needed to determine quantities and prices. It can be measured at different phases of the project. In the design phase, it informs the choice of the building structure and mass. It assists in designing a building form based on the material efficiency of the structure and provides information to make trade-offs. The durability and maintenance of materials can also be considered at this stage.

Indicator 2.2 Construction and demolition waste

Construction waste accounts for approximately 25-30% of EU waste. Most construction waste materials are inert and can be diverted from landfills and re-entered into the construction material loop. For example, if a material is over-ordered, agreements can be made with the manufacturer to buy it back at a percentage of the total price to avoid wastage. Offcuts from on-site materials can be planned for a particular use on-site or transported offsite to be upcycled for another purpose. Waste management requires multiple players to manage the logistics during the construction and demolition stages . The Level(s) framework provides checklists and excel tools for calculating wastes and related costs to assist designers in streamlining this process. The framework recommends setting goals for waste management, outlining the percentage of materials to be sent to landfill, recycled, reused, or recovered for energy.

The different types of construction and demolition waste are classified as:

01: concrete, bricks, tiles and ceramics.

02: wood, glass and plastics.

03: bituminous mixtures, coal tar and tarred products.

04: metals (including their alloys).

05: soil (including excavated soil from contaminated sites), stones and dredging spoil.

06: insulation materials and asbestos-containing construction materials.

08: gypsum-based construction material.

09: other construction and demolition wastes.

(Donatello, Dodd and Cordella, 2021)

State of the art > 17

Indicator 2.3 Design for adaptability and renovation

Designing in a manner that a building can be adapted to suit a new use or renovated to meet changing requirements or legislation would inherently extend its lifespan. Efficient use of space increases the longevity of the construction elements and improves operational performance, which entails the ability to upgrade the energy technology in the building. A challenge when designing with these methods is that there is a high level of uncertainty as to what the needs of the future would be, and therefore certain aspects of the building, for example, floor-to-ceiling heights, would be less efficient. The framework provides architects with a checklist and a scoring sheet to guide design choices. It allocated more points to wider column spans for more flexible floor layouts, non-loadbearing internal walls and façades, ease of access to technical services, higher ceiling heights, and structural designs sized to support future expansion if needed (Donatello, Dodd and Cordella, 2021).

Indicator 2.4 Design for deconstruction

At the conceptual stage, design principles related to deconstruction have to be adhered to by architects in close collaboration with engineers and manufacturers. At the detail stage, the assessment of the structure, facade, and specifications for deconstruction would be prepared and reviewed. Time scales for deconstruction to be calculated and optimized. Deconstruction potential can be measured by evaluating the ease of recovery, ease of recycling, and ease of reuse. A calculation method proposed by the DGNB on ease of recycling and recovery and the standards outlined in ISO 20887 can be referred to. The standard specifies that the seven design principles for disassembly are ease of access, independence, avoidance of unnecessary treatments and finishes, supporting reuse business models, simplicity, standardization, and safety of disassembly. The guideline recommends that the building elements to be assessed be identified, divided into the categories Structure, Shell and Core, and then a Life Cycle Assessment be carried out as a supporting quantitative measurement (The International Organization for Standardization, 2020).

Existing framework - Ellen Macarthur Foundation circular design tool kit

The Ellen Macarthur Foundation has researched and provided an online tool to aid designers in circular construction. Building upon the EU Levels and EU Taxonomy* frameworks, they have outlined ten main strategies (Fig 8). Each strategy is then evaluated on its impact on Design, Architecture, Structural, Façades, MEP, and Interior (Ellen MacArthur Foundation, n.d.). Each indicator has been subdivided, providing an overlook with example case study projects to learn from and offer insights into potential challenges.

*The EU Taxonomy Regulation established in July 2020, plays an important role in helping the EU scale up sustainable investments with climate change mitigation, adaptation, and transition to a circular economy, amongst others.

18 < State of the art

Build nothing

1. Refuse new construction

Reuse floor area [Total % of total GFA]

2. Increase building utilisation

Total building utilization [h/sqm]

3. Design for longevity EU Levels whole life cycle costs

6. Refuse unnecessary components

Material use intensity per functional unit

Build with the right materials

8. Reduce the use of virgin materials EMF’s material circularity indicator

7. Increase material efficiency

Material use intensity by area

9. Reduce the use of virgin materials Embodied Carbon Intensity

4. Design for adaptability EU Levels adaptability rating

5. Design for disassembly

EU Levels disassembly potential rating

10. Reduce the use of virgin materials

Environmental Impact Cost

The indicator

5. Design for Disassembly has been broken down into three subcategories. Indicator 5.1 Design of reversible connections between super-structure elements

This indicator encourages prefabrication in structural elements and works in collaboration with manufacturers that offer disassembly instructions and exchange or take-back schemes. To enable the ease of Disassembly, universally recognized methods for assembly, disassembly, and reassembly of connections should be utilized. The design of connections should minimize deformations during service life and disassembly.

Indicator 5.2 Allow access to reversible connections between the structure and building services

This indicator suggests the use of access panels to make maintenance and inspection easier and sufficient space around the connection points to disassemble comfortably without damaging the surrounding elements avoiding the use of finishes that block access to technical spaces.

State of the art > 19

Build for long term value

Build efficiently

Fig 8, Circular Toolkit Framework (adapted from Ellen MacArthur Foundation, n.d.)

Indicator 5.3 Develop and issue a Disassembly Manual document for the building

This indicator involves the documentation of the building’s de-constructability. A manual to disassemble components, a detailed 3D BIM model, and material information such as Material Passports should be provided for future stakeholders in the project. (Ellen MacArthur Foundation, n.d.)

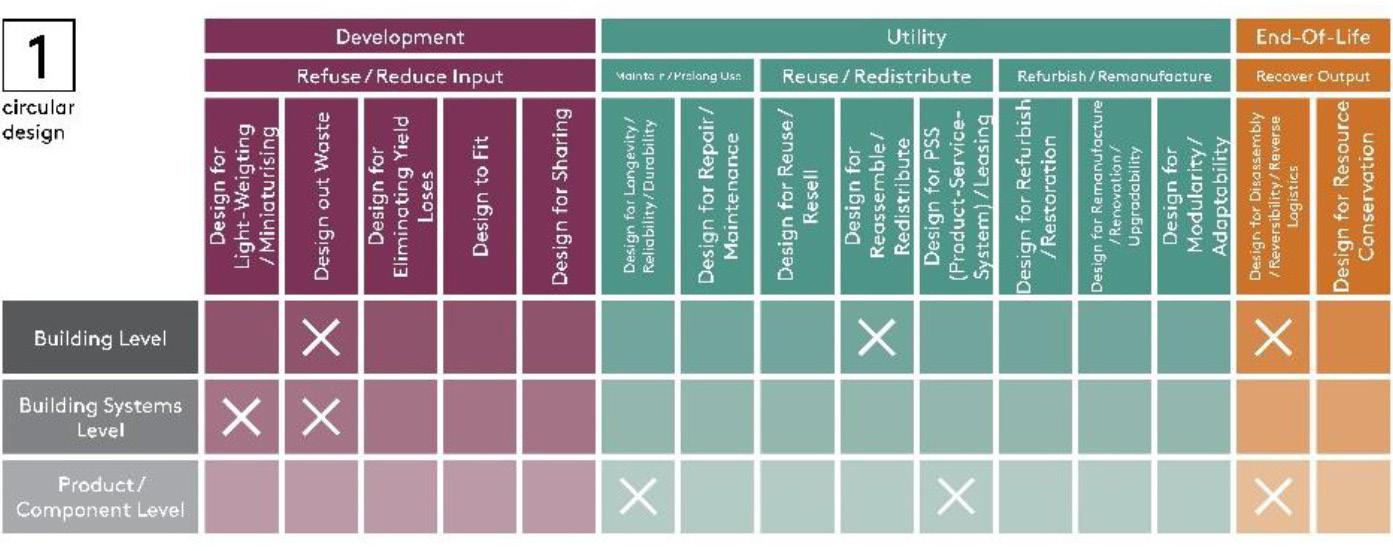

Existing frameworks - A guidance tool for circular building design, TU Delft

The guidance tool developed at TU Delft stipulates and guides designers towards a circular design process. The main aims were to create a tool that comprised of the key principles of circular design, provide strategies that could be applied at different levels and stages in the design process, and address the growing field of circular economy in construction. It was designed to be non-static so that it can evolve as the research in the field grows.

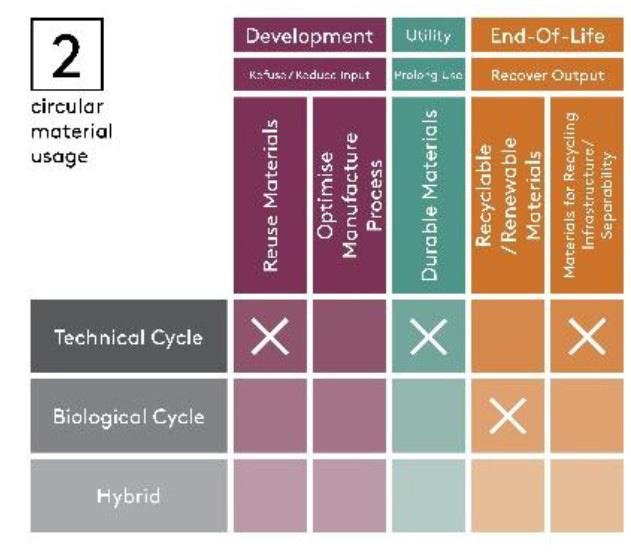

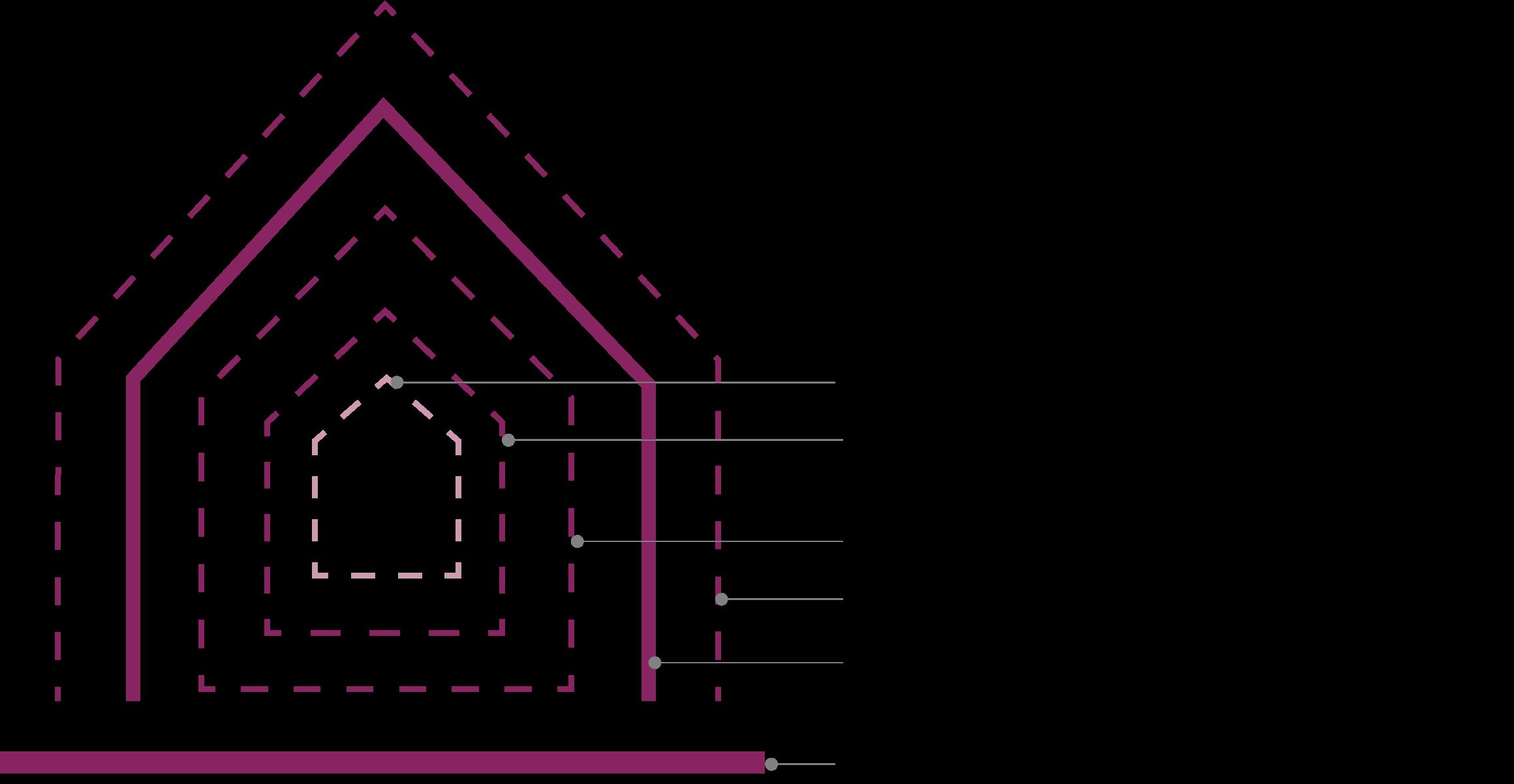

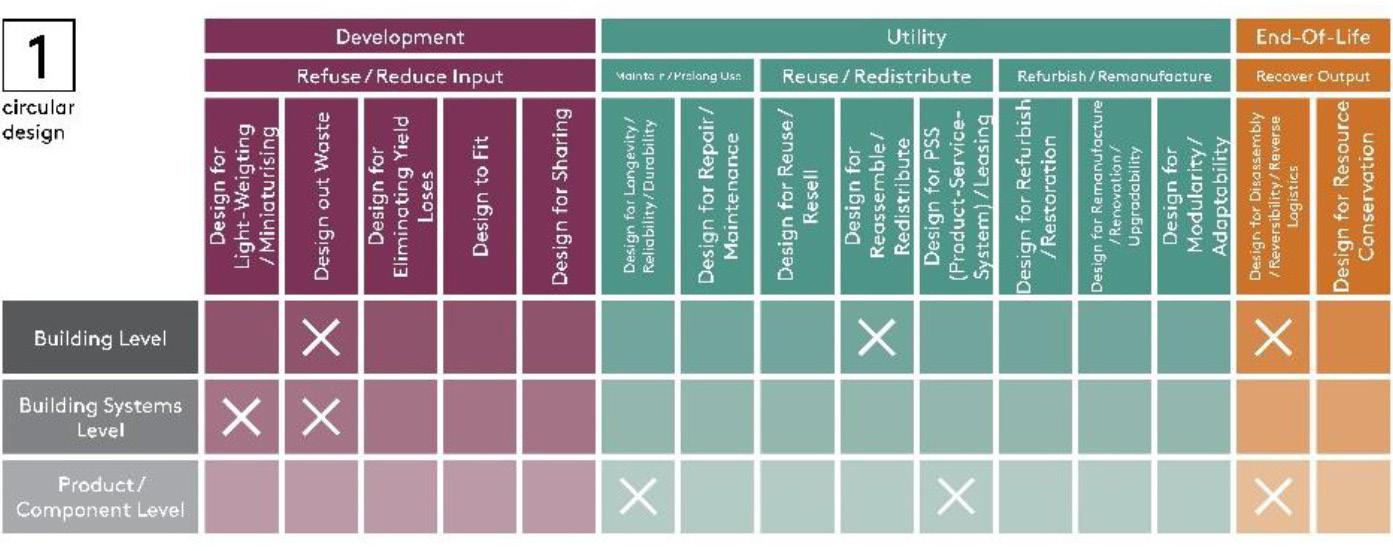

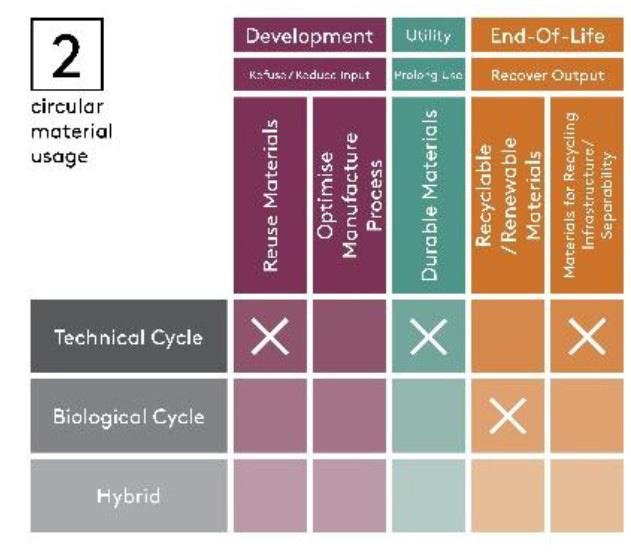

The matrix framework was constructed with the rows following system thinking and columns following life cycle thinking, built upon the cascading cycles of the butterfly diagram (Ellen MacArthur Foundation, 2019). Future updates suggested by the author include energy usage strategies, circular business model strategies, and the elimination of externalities such as pollution and toxicity.

20 < State of the art

Fig 9. A guidance tool for circular building design (Amory, 2019)

Sustainable Building Council (DGNB) Guidelines

The DGNB New building criteria set includes the indicator TEC 1.6 Ease of recovery and recycling, which is relevant to the design of circular buildings in Germany and the rest of Europe. This indicator contributes to 2.5-2.9% of the total score. The guideline proposes an evaluation system to score building elements.

It evaluates the ease of recycling and recovery for each building element. It assesses the planning phase and the reality after construction. The methods proposed are:

- a selection of easy-to-recycle construction materials

- easy-to-recover building structure

- ease of recovery, conversion and recycling in the planning process

The components are allocated points according to the replacement frequency. DGNB allocates bonus points for minimizing resources, using reused materials in the initial construction, and planning for material recovery through take-back guarantees or leasing components from manufacturers (DGNB e.V., 2020).

Material recovery in Germany

In Germany, the construction sector is responsible for 90% of extracted mineral resources and 52% of waste material (Resource Deutschland, 2018). The recycling rate in Germany for construction aggregate waste in 2018 is relatively high at 77.9%. The aggregate breakdown was 4.9% industrial by-products, 38.5% natural stone, 44.1% sand and gravel, and 12.5% recycled aggregates. These aggregates were primarily used for road construction (51.3%), earthworks (22.2%), and asphalt and concrete production (21.6%). However, the amount of construction waste has been increasing, and even though a large proportion is given a second life, it is mainly through downcycling, requiring new materials for construction (Kreislaufwirtschaft Bau, 2021).

Timber construction waste in Germany is forbidden to be sent to landfill and is usually sent to combined heat and power (CHP) plants to be incinerated as fuel. This releases the embodied carbon in the wood back into the atmosphere. Used timber is put into four categories in Germany. A-I wood has been treated mechanically, A-II wood has been glued, painted, coated, or varnished, A III wood can contain halogenated organic compounds, and A-IV wood is intended for outdoor use and is treated with preservatives. Waste wood classified as A-III and A-IV are considered polluted and are not allowed to be reused. These elements contain traces of PVC, lead-based paints, or hazardous substances. Waste wood categories A-I and A-II are considered safe for reuse (Brockmann Recycling GmbH, 2017).

State of the art > 21

2.4 German

guidelines, policies and challenges

Urban Context

Achieving circularity in a project goes beyond the confines of the architecture of the building. It requires holistic thinking across various areas of expertise, including architecture, urban design technology, engineering, social sciences, and politics. The city of Berlin, in recent years, has implemented regulations and investments into projects that help reduce our impact on an urban scale.

Storm water management

Climate change has increased the potential for unpredictable natural events such as rising sea levels and flash floods. The effects of this are felt stronger in urban environments due to high impervious areas that create a phenomenon called soil sealing. Increased runoffs are causing the hydraulic system in Berlin to be overloaded and space to install storage tanks is limited (Berliner Regenwasseragentur, 2018). The Berlin House of Representatives promoted decentralizing rainwater management in 2017 and set a goal to reduce rainwater discharge into the sewage system by 1% annually. The Senate Administration for the environment, transport, and climate protection § 29 Para. 1 Building Code (BauGB) informs construction projects that rainwater discharge should be avoided or equal to the level that would occur in the natural environment (Senatsverwaltung für Umwelt, Mobilität, Verbraucher- und Klimaschutz, 2021).

The water management systems in Berlin are transforming to adopt a more resilient system to climate change through a concept called ‘Sponge City’. The stormwater management design in Rummelsburg, Berlin, was spearheaded by landscape architect Carlo Becker and urban hydrologist Heiko Sieker. The area is void of conventional pipe stormwater systems. Instead, rainwater is absorbed by green roofs and courtyard gardens, and runoff is directed to swales which are wet depressions in the ground. This strategy helps manage stormwater on-site and has the added benefit of keeping the neighborhood cooler by lessening the urban heat island effect (Gloria Kurnik, 2017).

District heating

Berlin is testing a corporation between Vattenhallen and Siemens to implement a combined heating and cooling system. A combined heat and power (CHP) plant located in Berlin Marzahn provides district heating to the eastern Berlin area. The plant uses a gas-fired Klingenberg CHP together with a gas turbine manufactured locally at the Siemens Energy workshop in the Berlin Moabit area. Research and testing at the Siemens Clean Energy Center are ongoing to phase the plant towards using hydrogen and natural gas mixers (Siemens Energy, 2021).

22 < State of the art

Challenges

There is an awareness among individuals in the construction industry about the concept of circular economy thinking in construction. However, little research has been conducted on an industry-wide scale from a systems perspective and how new business models are required to make it a reality. A survey conducted by Loughborough University revealed that the absence of training and incentives for clients, designers, and subcontractors is one of the key issues. To encourage implementation throughout the supply chain, a clear business model and economic and regulatory support would be beneficial (Adams et al., 2017).

The Circular Economy Initiative Deutschland (CEID) was formed to provide a framework to guide and configure the system to transition towards a circular, resource-efficient model. The organization has identified barriers to achieving circularity that has been categorized into regulatory, financial, technical, organizational, consumer, and value chain. Their model suggests that the relationship between providers, users, and the product leads to challenges requiring integrated solutions. Digital technologies provide opportunities to overcome these barriers and enable the organization of circular material and product flows, smart maintenance, repair, reuse, and recycling strategies. The framework also outlines challenges in maintaining, upgrading, and repairing buildings and materials. These include:

- the potential for the repair cost to be similar to or higher than a new build or product

- complexity to have the same manufacturers and designers involved in the project in the subsequent lives of the building

- an economic devaluation of products

- lack of access to spare parts

- low maintenance knowledge.

The organization has proposed solutions to deal with the identified challenges. They propose integrating user responsibilities into service contracts and creating service hybrids such as renting building components to promote better maintenance and care for building materials. They encourage forming a national intersectional repair alliance to help tackle the issue of maintenance and accessibility to spare parts and propose adding digital technologies to facilitate condition management. Additionally, they provide support to stakeholders in Germany to foster knowledge sharing and transparency (Circular Economy Initiative Deutschland and SYSTEMIQ, 2021).

State of the art > 23

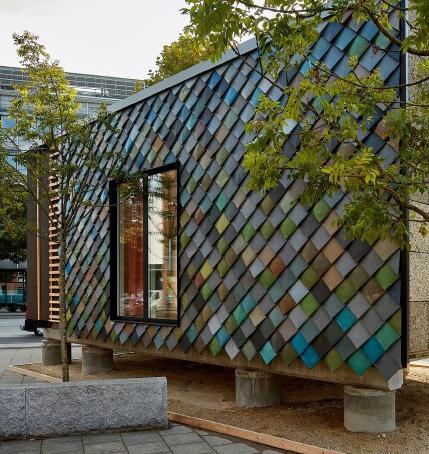

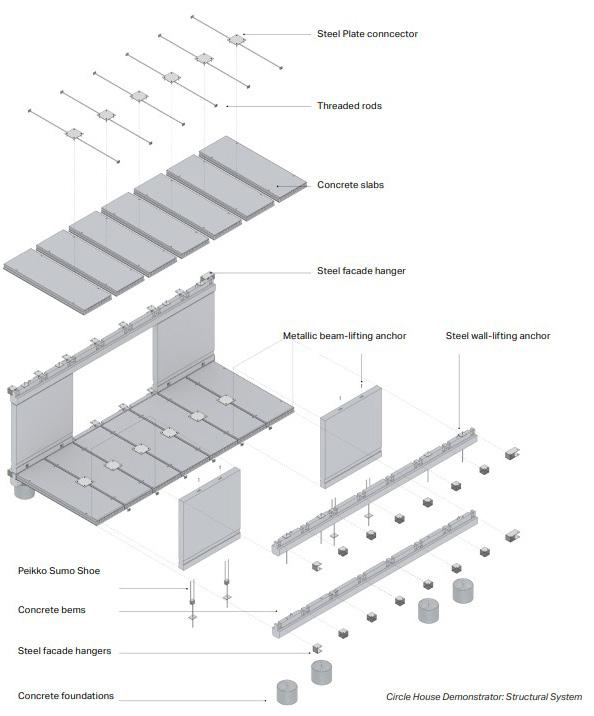

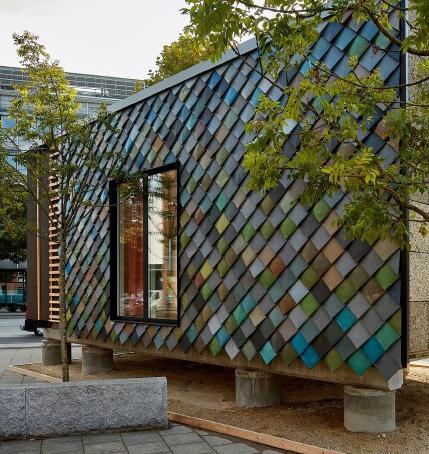

Case study : Circular house, 3xn

Building type: Residential

Location: Aarhus, Denmark

Area: 5500 m2

Architect: 3XN/GXN, Lendager and Vandkunsten Architects

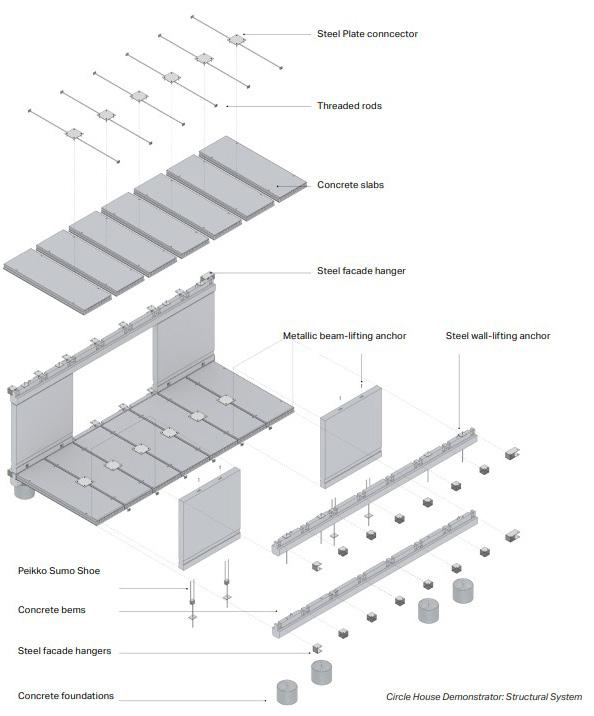

The Circular House located in Lisbjerg Bakke district will consist of 60 social housing units designed and built with the principles of circular economy. The objective is to reuse 90% of the building materials at the end of life. The project will be completed in 2023 but a demonstrator 1:1 mock up and exhibition space has been constructed and is open for viewing and inspiration. The project uses materials that have been produced through a recycling process and considers the end of life scenarios for each element.

The architects have done extensive research into circular construction strategies and have prepared a guideline. It outlines the 15 key factors considered when designing the project and goes into the details of each material and the construction process.

The project specifies high quality materials with low environmental impact and potential for future use and the design of adhesive free, de-constructable connections. The layout of the building is designed so that the technical systems and plumbing run through the main circulation stairwells to allow easy access for maintenance (GXN and Responsible Assests, 2018).

24 < State of the art

2.5 Case studies

Fig. 10, 11, 12, Circle House Demonstrator facade (Jersø., GXN and Responsible Assests, 2018)

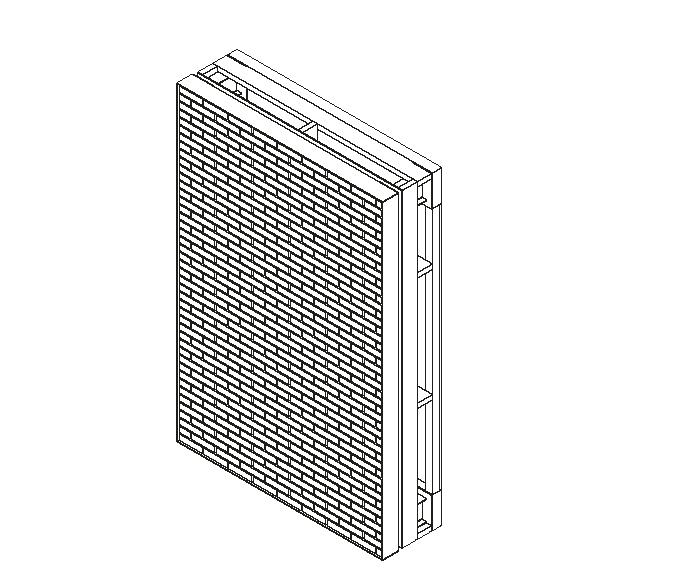

The facade system selected is a lightweight facade mounted with screws to the exterior of the structure to preserve it for future reuse. The focus was place on the design and sizing of the system, with the option to implement various materials options allowing personalisation, and potential for future adjustment. The floor structure is a wood laminate system manufactured by Tarkett that clicks in place without the use of adhesives to allow for maximum flexibility.

State of the art > 25

Fig. 13, Circle House Demonstrator Structural System (GXN and Responsible Assests, 2018)

Case study : Resource Rows, Lendager

Building type: Residential

Location: Oerestad, Copenhagen, Denmark

Area: 9000 m2

Year: 2020

Architect: Lendager

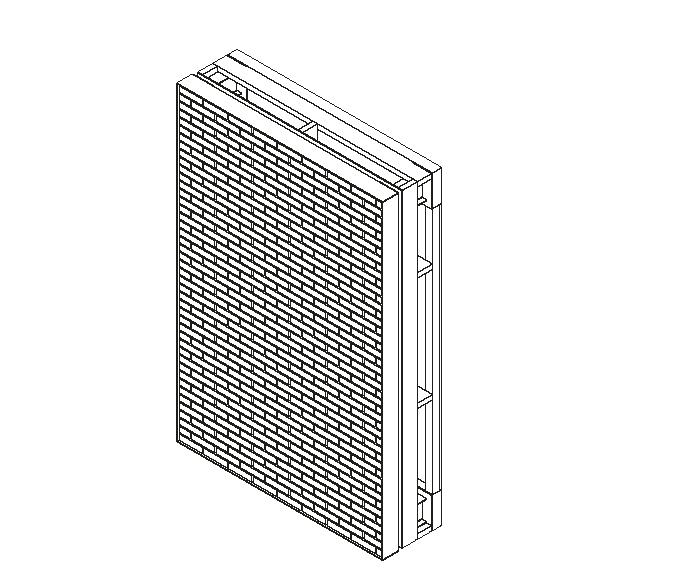

The project uses upcycled bricks, waste wood, recycled concrete beams, old windows and waste wood rooftop community gardens. The facade is designed with prefabricated concrete elements with reused brick cladding. The energy concept includes solar panels and water-to-air heat pumps to further reduce the environmental impact. The result of this project is an aesthetically pleasing building that balances lowering environmental impact and adding value to the urban environment (Lendager, 2020).

26 < State of the art

Fig. 14, 15, 16

Resource Rows brick assembly (Rasmus Hjortshõj and Lendager Group, 2020)

Fig. 17, Resource Rows (Rasmus Hjortshõj and Lendager Group, 2020)

The diagram shows the assembly of the facade panels made from recycled bricks and hung from load bearing T-profile brackets. The modules can be produced with different materials or in different sizes using the same system.

panels hung from load-bearing T profile brackets

Fitted with brackets panels attached to internal wall and insulation

Masonary elements can be produced in varying sizes according to the same principles

State of the art > 27

Fig. 18, Recycled brick facade assembly (Lendager Group, 2019)

recycled brickwork initial assembly

Case study : Brummen Town Hall, RAU Architects

Building type: Public

Location: Brummen, Netherlands

Area: 3000 m2

Architect: Rau Architects

Brummen Town Hall constructed a temporary housing facility extension design for a 20 years use phase The architects worked with Turntoo, which focuses on circular business models, and developed agreements with manufacturers to take back materials for reuse at the end of life. This was achieved by designing components that could be disassembled at the end of life with mechanical joints. The manufacturers retain ownership of the materials and bear the cost of operation, installation, and maintenance.

The supporting structure, facade, and floors are made from prefabricated timber components with minimal concrete elements. Phillips designed and supplied the lighting design. The client paid for a certain lux level rather than the products and fittings. This strategy motivates manufacturers to use better quality products (Rau BV, 2022).

28 < State of the art

Fig. 19, 20, 22,. Brummen Town Hall (Appelhof, 2013)

Fig 22. Brummen Town Hall (Appelhof, 2013.)

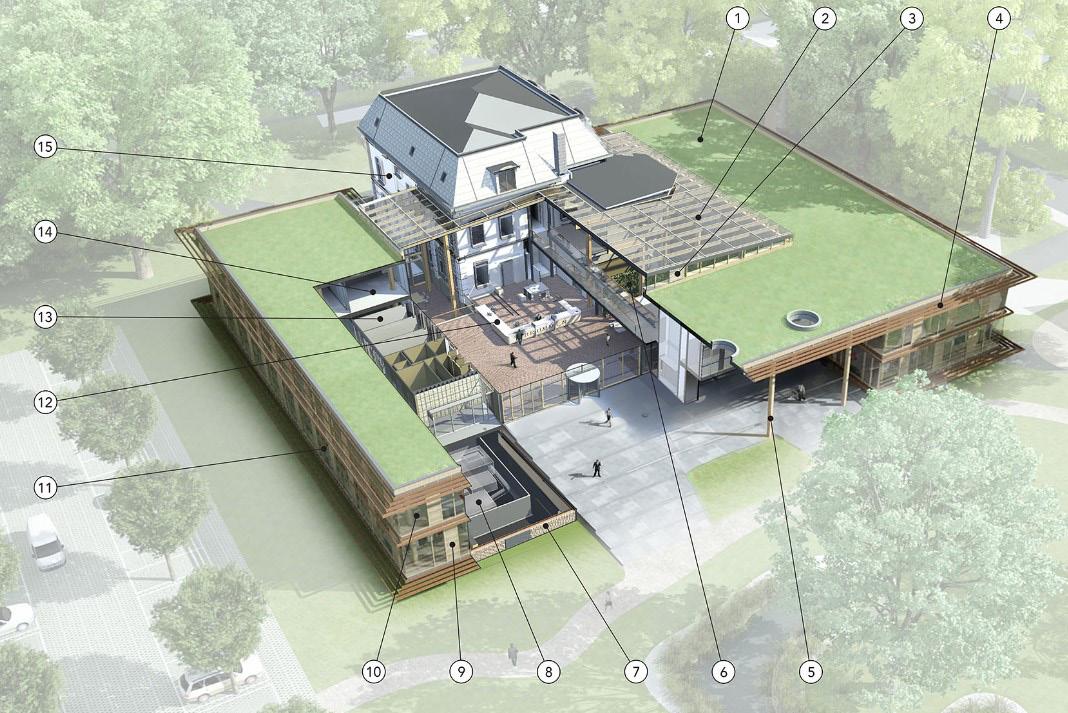

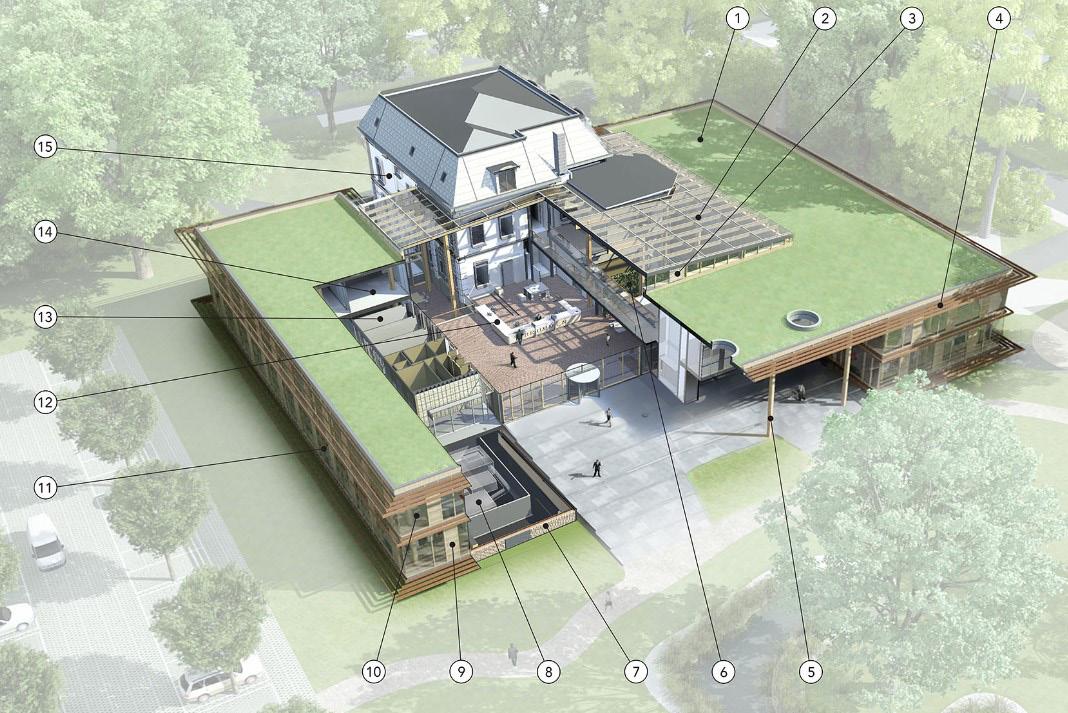

Rau architects implemented several strategies to achieve a circular, aesthetically pleasing, and energy-efficient renovation. Passive strategies are seen in Fig 23. such as natural ventilation, green roofs, and Cradle to Cradle certified material selection helped attain their final result. They avoided the use of concrete and favored high-quality prefabricated timber elements. The modular prefabricated elements also helped in significantly reducing the construction time and minimizing waste on-site. Thomas Rau aimed to have the building function as a material bank, and the project has material passports from Madaster to enable future reuse of the elements (Ellen MacArthur Foundation, n.d.).

1 moss green roof

2 maximum daylight

3 natural ventilation

4 passive blinds

5 demountable wooden construction

6 green wall

7 gabions with stone from old building

8 installations under the building

9 c2c facade panels

10 triple layer glass

11 presence sensor lighting

12 cardboard counter

13 flexible room layout

14 c2c carpet/ bamboo floor

15 re-purposed monumental villa

State of the art > 29

Fig. 23, Brummen Town Hall (Rau, 2013.)

CASE STUDY DESIGN > 3.

30 < Case study design

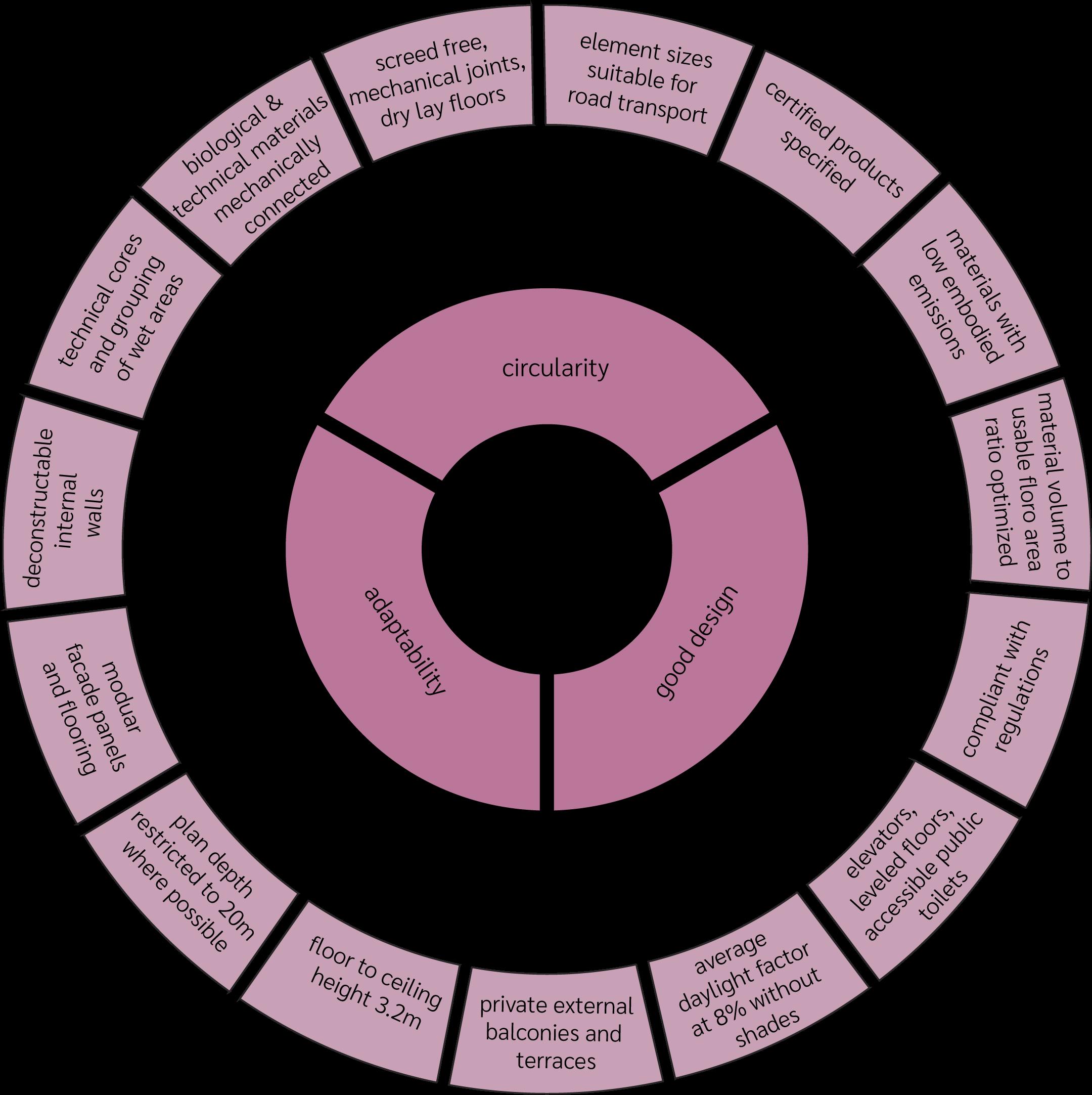

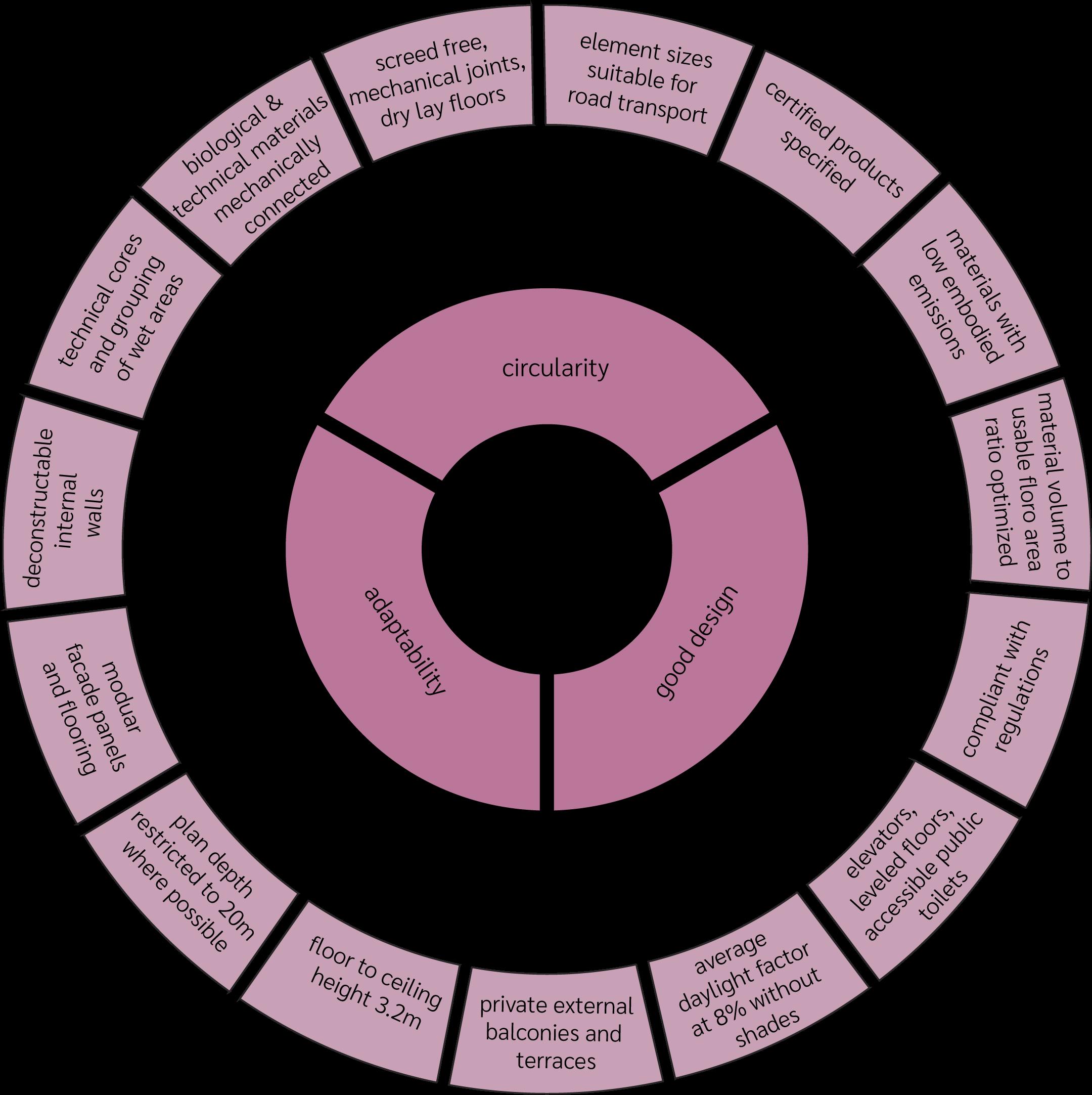

3.1 Reversible design strategies

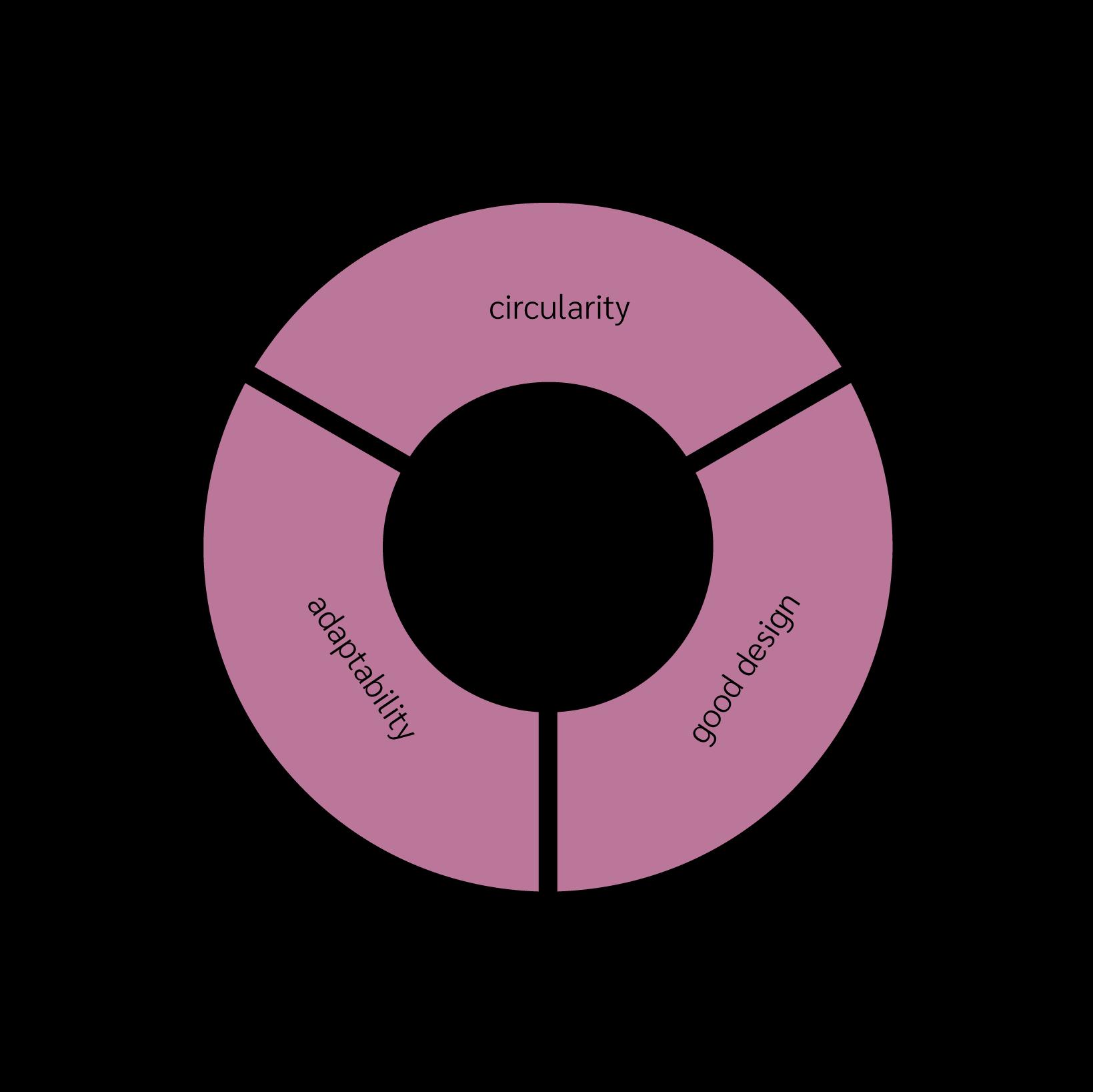

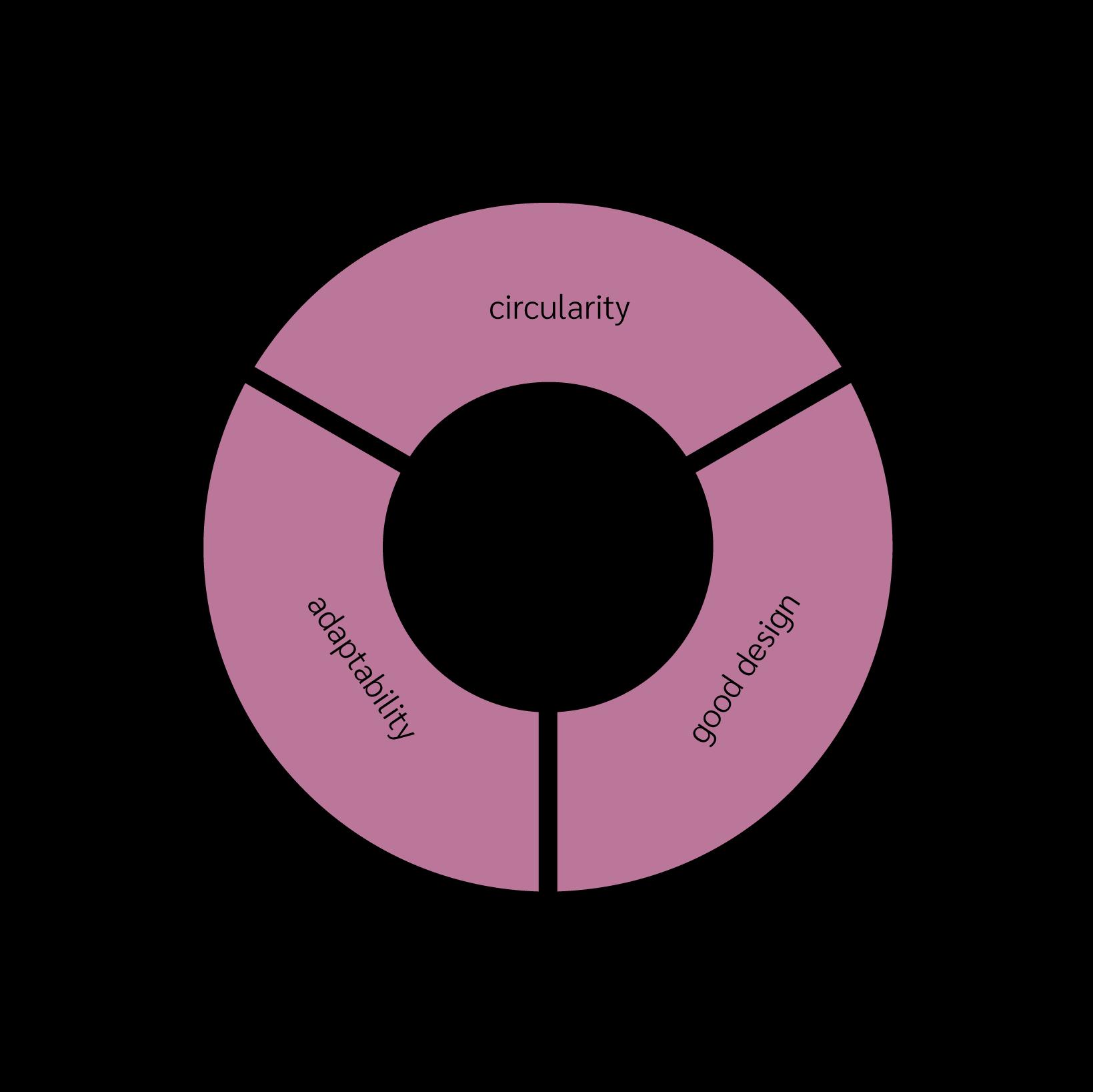

Analysis of the frameworks and guidelines have highlighted keywords related to the design of circular buildings. These qualities can be linked to this design project’s three main goals: circularity, adaptability, and good design. In this context, good design refers to a holistic design from a sustainable, social and cultural perspective. The implementation of these qualities in the design will be continuously assessed and optimized during the case study design phase, and be used as a tool to evaluate the end result.

Case study design > 31

Fig. 24, Strategy

Diagram

(adapted from Stoyanova, 2018)

in order from top to bottom, left to right:

Fig. 25, Rummelsburg Map (TUBS and Wikipedia Commons, 2010)

Fig. 26, Rummelsburg Bay (dpa, 2019)

Fig. 27, Rummelsburg (Pieper, n.d.)

Fig. 28, Rummelsburg (Delenk, 2019)

Fig 29,30, View of ufer (Google, 2022)

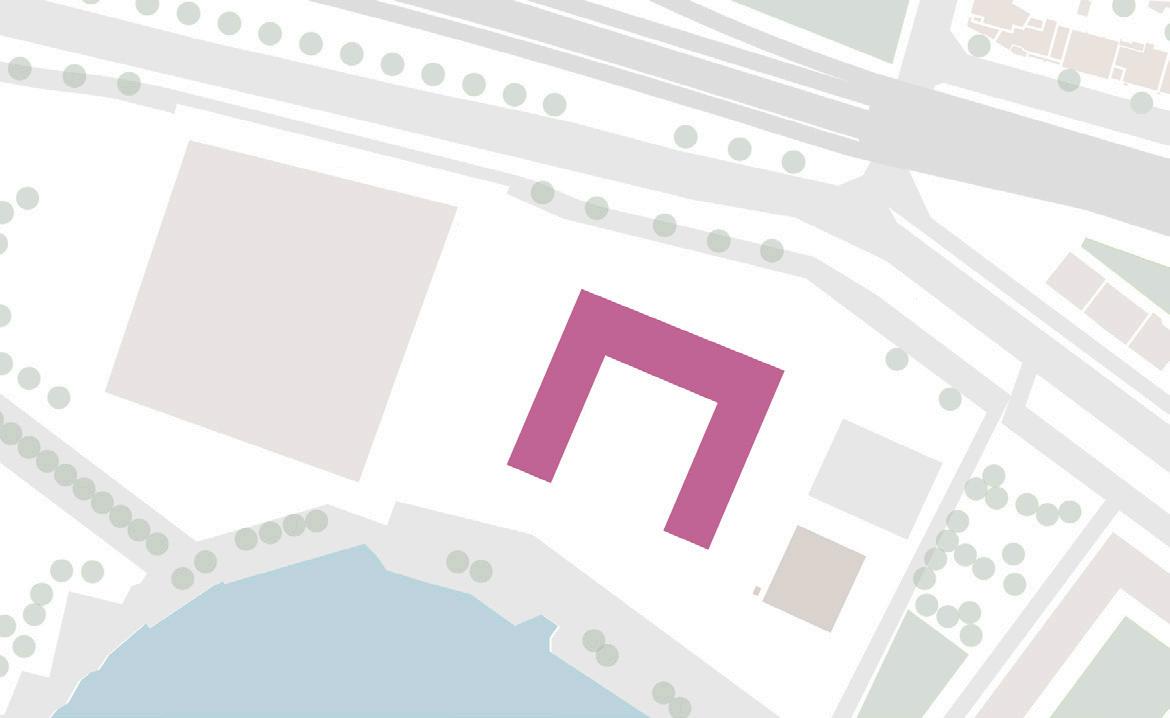

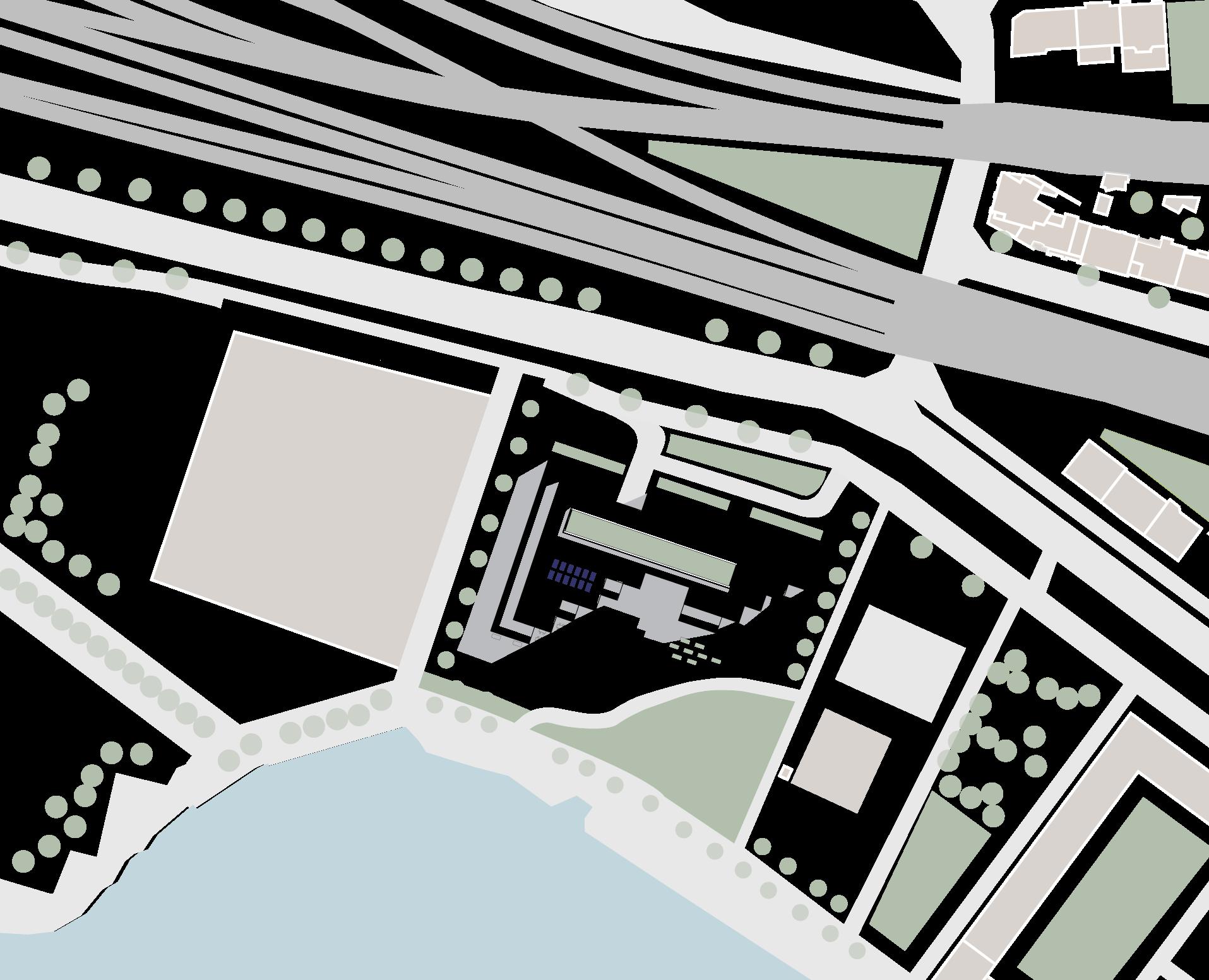

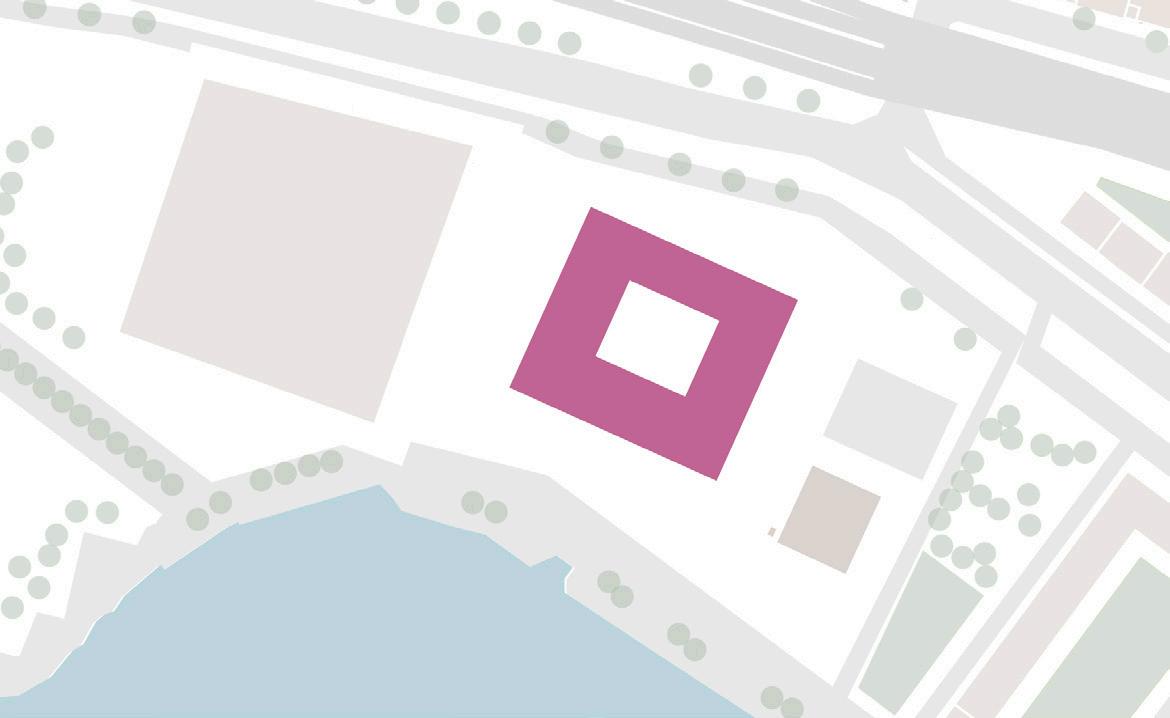

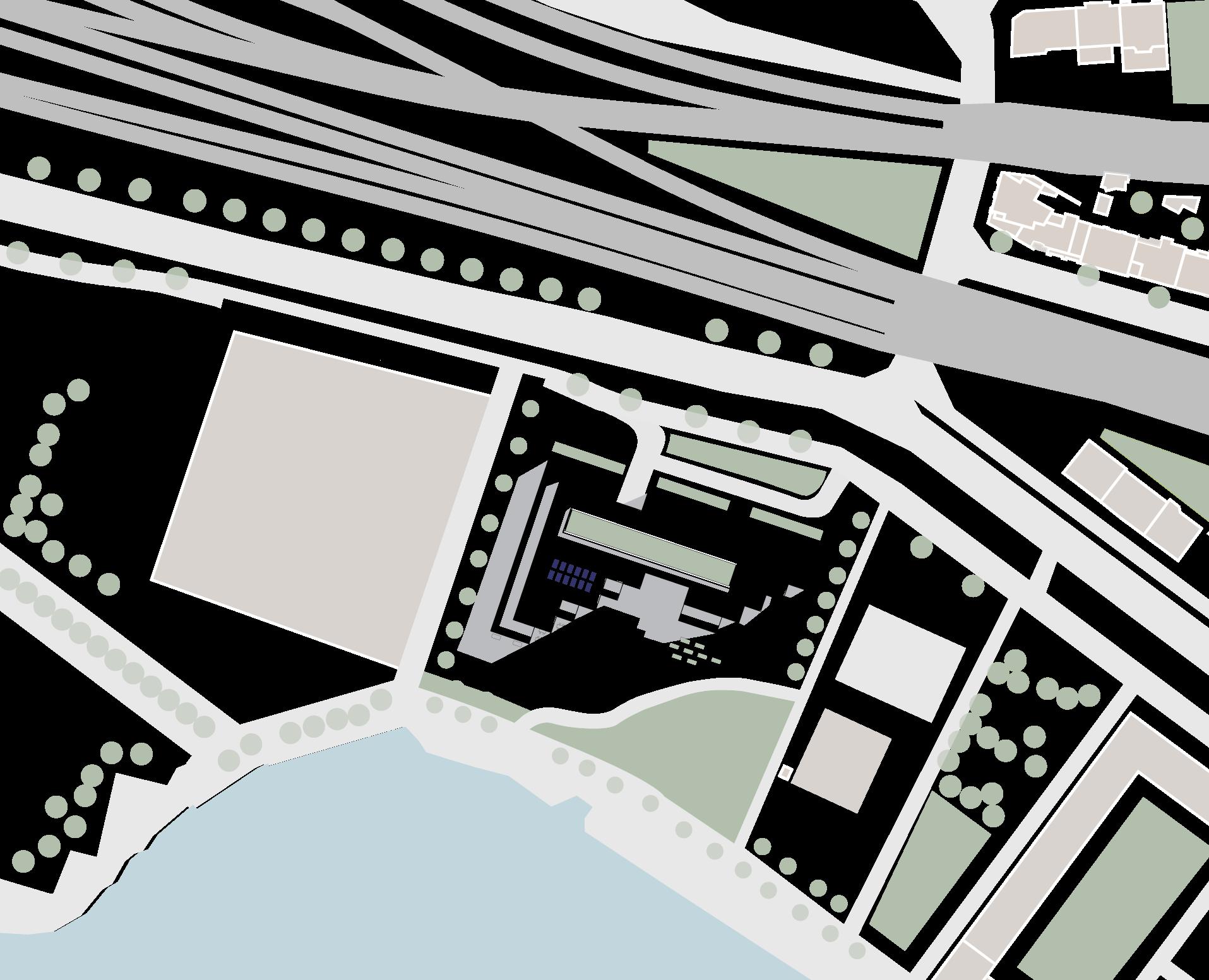

The site selected for the case study project is located in Rummelsburg, Berlin, which is in the inner city. The highlight is the 1.6km waterfront promenade along the Rummelsburg See. The bay is used for recreation and boats. The area features modern buildings and green spaces (Berlin.de, 2022).

Berlin was chosen for its dense urban environment and the need for more affordable housing, prompting a surge of construction and renovation projects in the city.

32 < Case study design

3.2 Site

Fig.

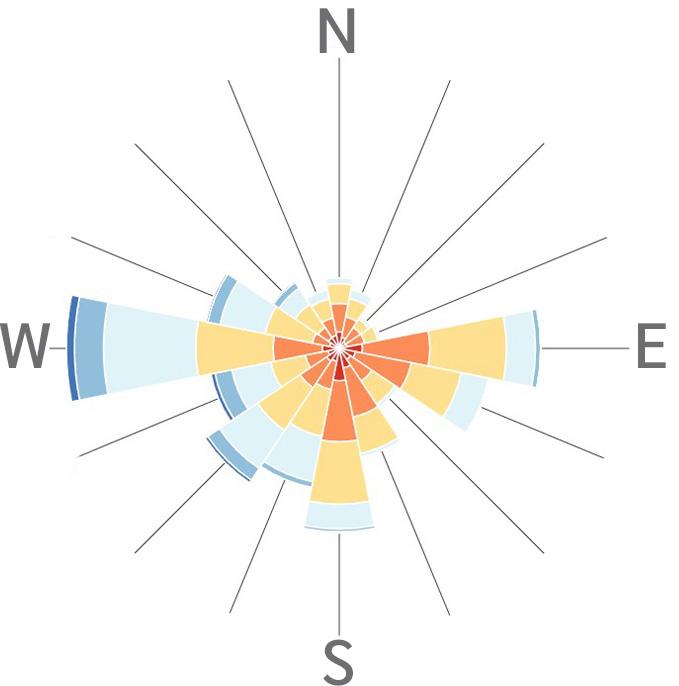

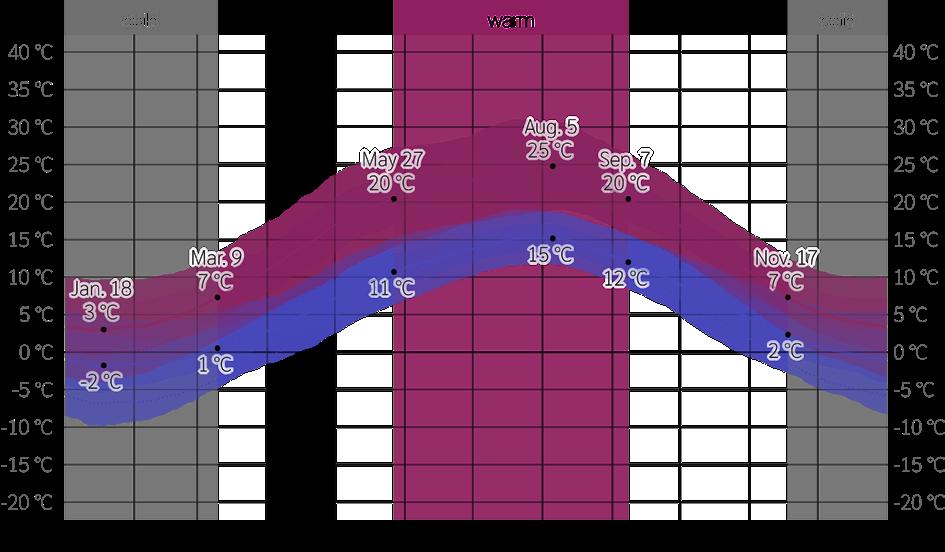

Climate

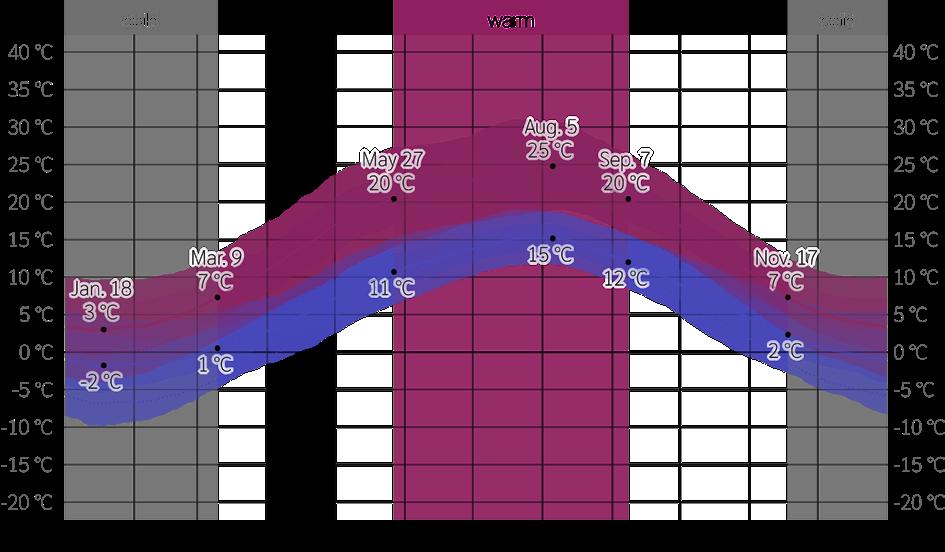

The Koppen-Gieger climate classification for Berlin is Dfb which refers to humid continental. It is typified by four distinct seasons with very warm summers and freezing winters. The least amount of rainfall occurs in February and the most in July (Climate-Data.org, n.d.).

Average Temperature: 10.1 °C

Yearly Rainfall: 669mm per year

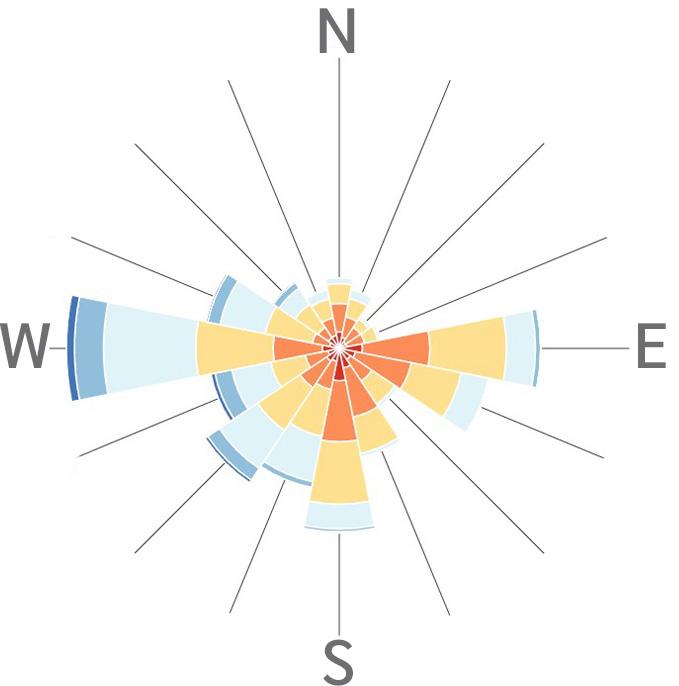

Beaufort Scale

11.1 - 13.9 m/s Strong Breeze

8.5 - 111.1 m/s, Fresh Breeze

5.4 - 8.5 m/s, Freeze Breeze

3.3 - 5.4 m/s, Gentle Breeze

1.8 - 3.3 m/s, Light Breeze

0 - 1.8 m/s, Light Air

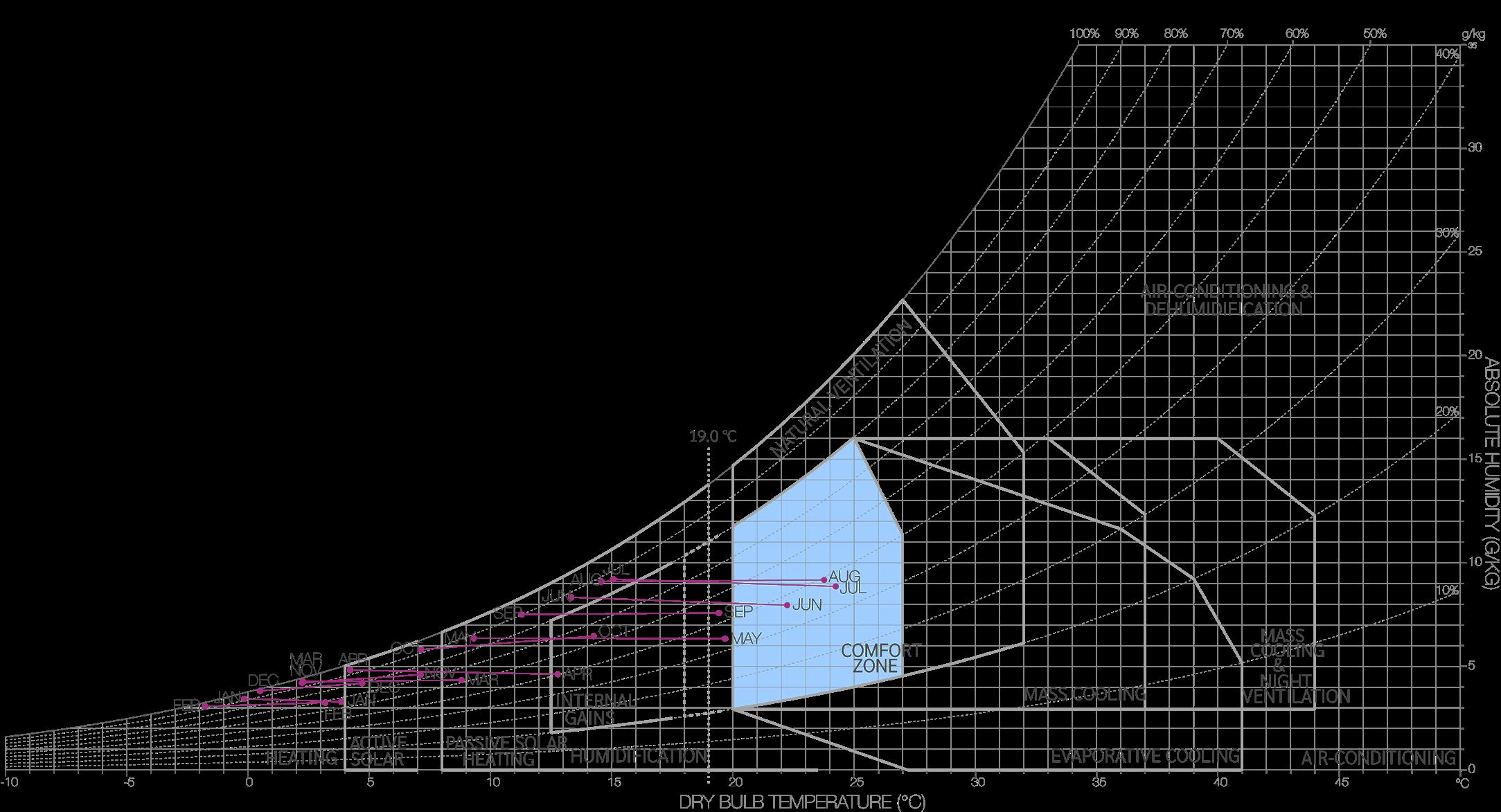

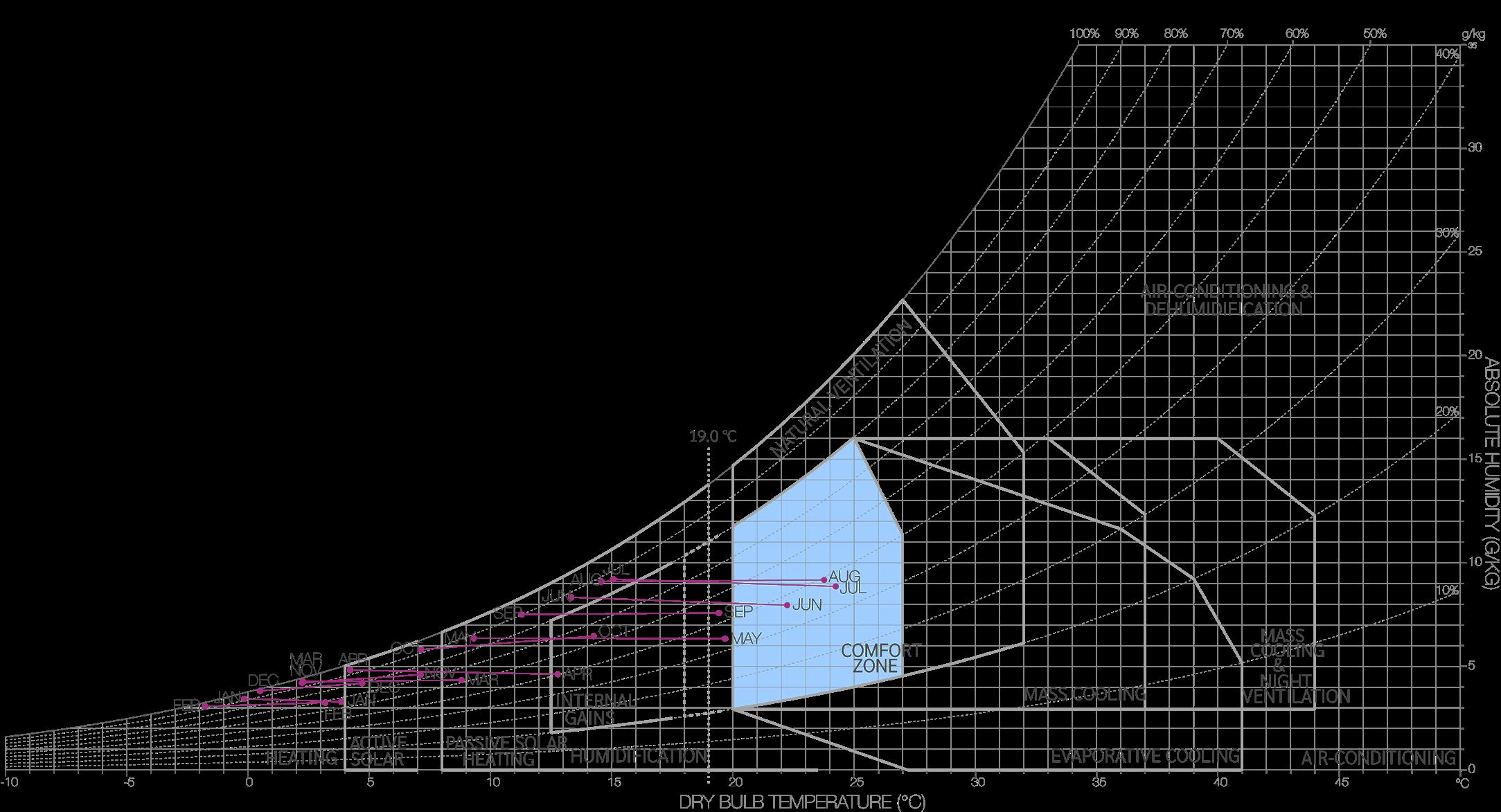

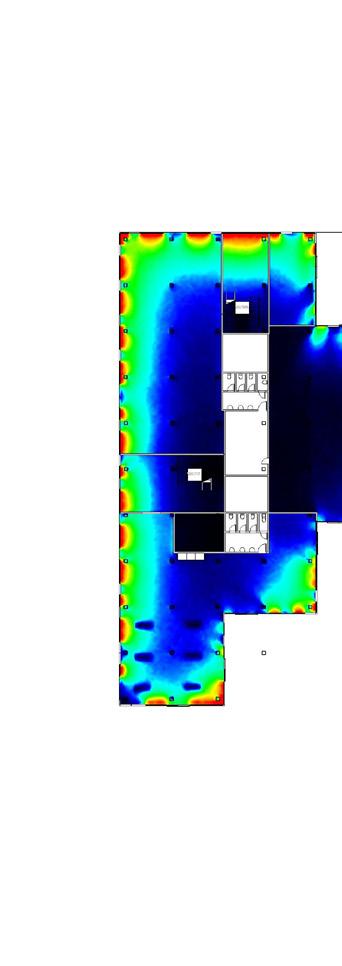

Bioclimatic Design

The Psychrometric chart derived from climate data in Berlin presents passive strategies for achieving thermal comfort according to the ASHRAE 55 standards. The main strategies highlighted are natural ventilation, active solar heating, passive solar heating, internal gains, and humidification.

Design responses to these strategies should be considered to minimize active heating and cooling use to attain user comfort levels.

Case study design > 33

Fig. 31, Berlin temperature and humidity (WeatherSpark.com, 2016)

32, Wind Rose (epwvis, 2022)

Fig. 33, Psychrometric Chart

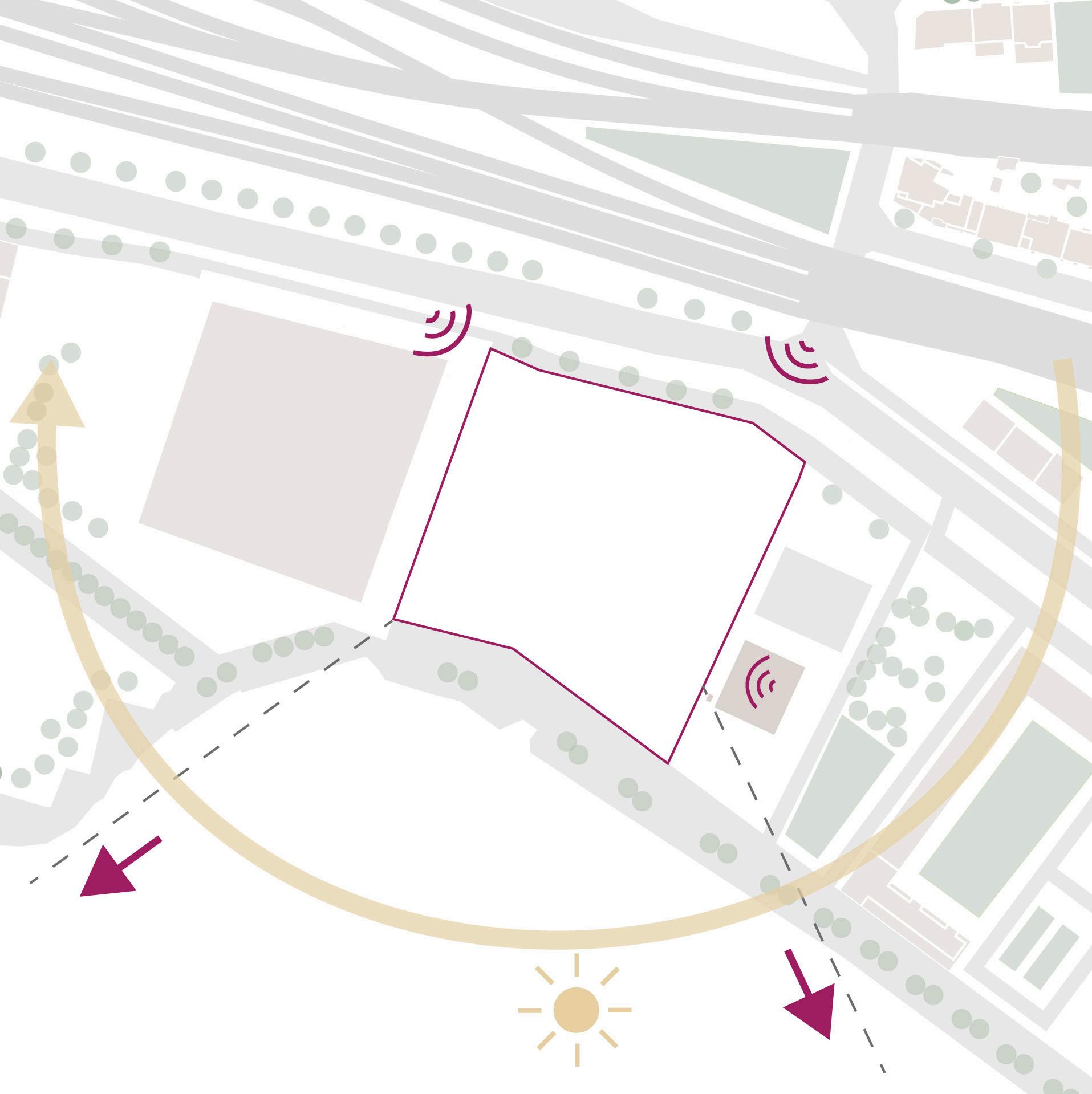

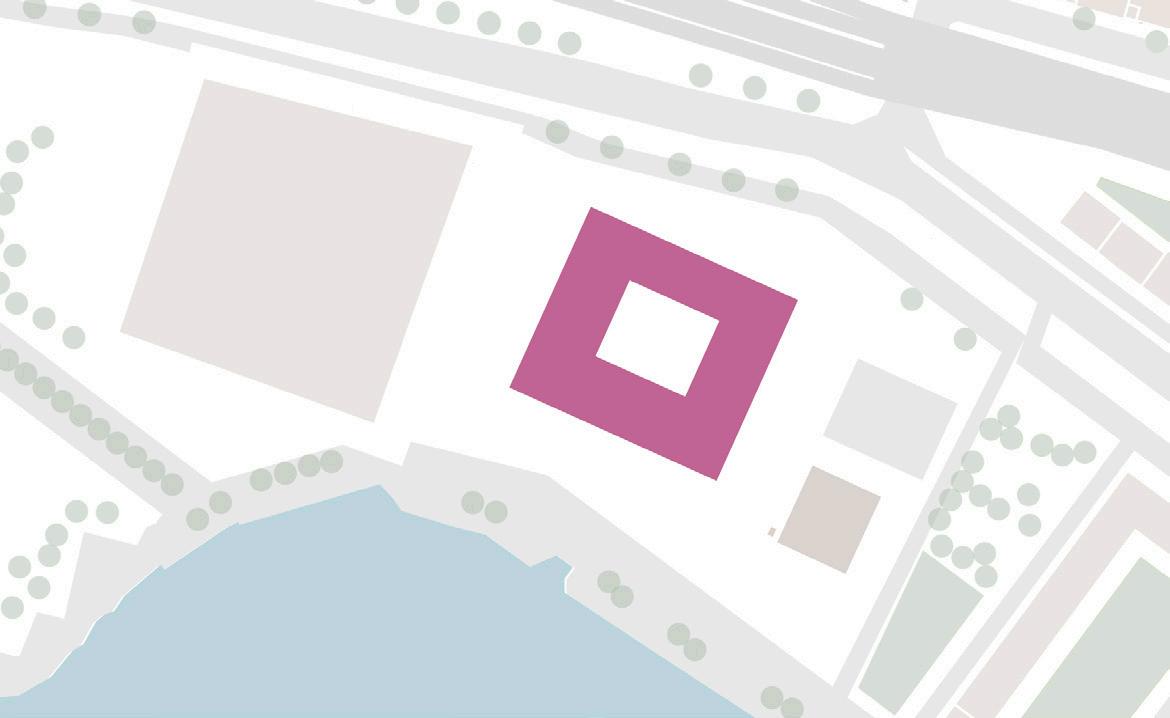

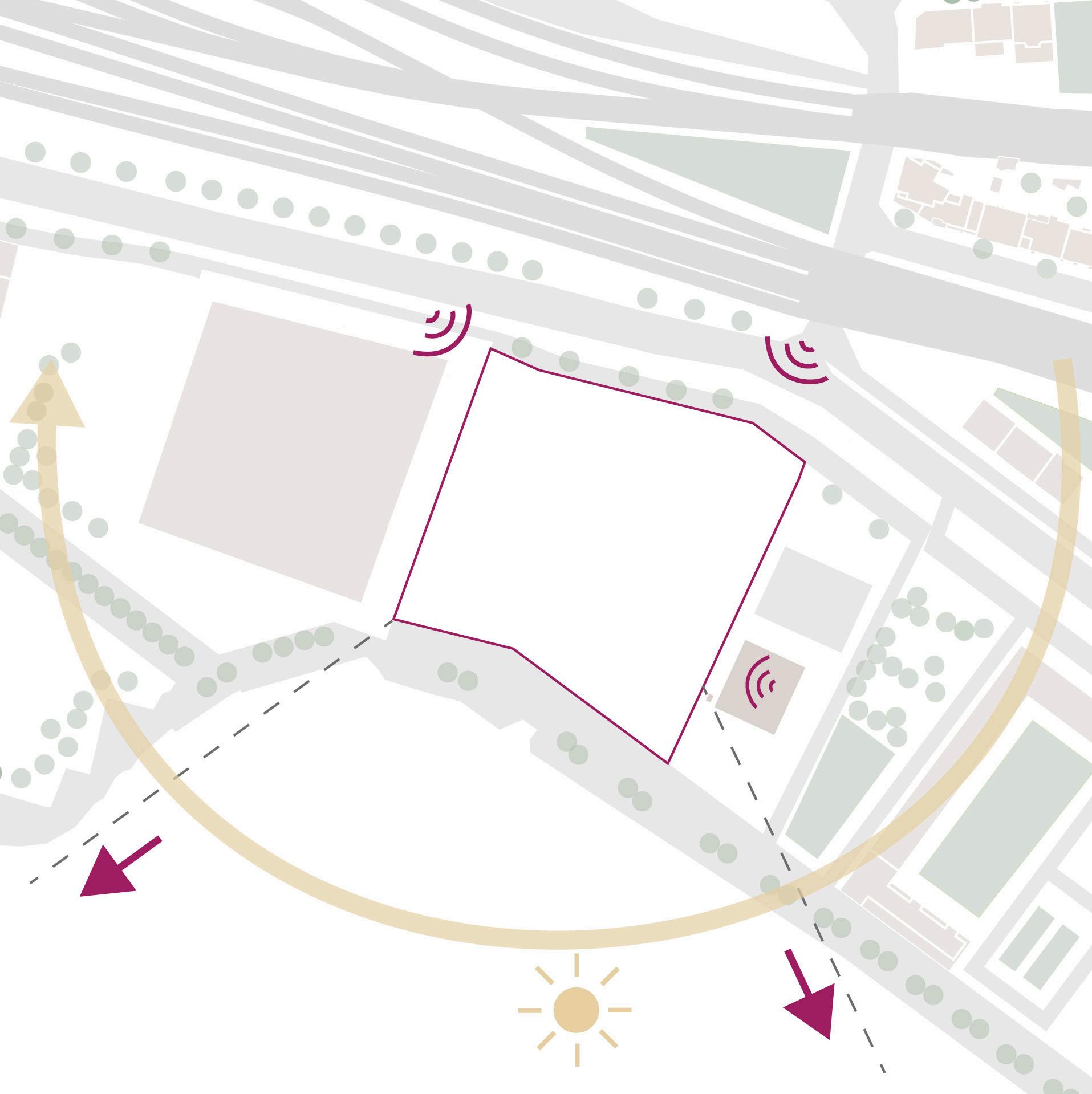

Urban Location Analysis

Rummelsburg is mainly zoned for residential purposes. The only non-residential and transport spaces are a few offices, one bakery, a kindergarten, and a skate park. The promenade along the ufer has some green spaces and benches to relax, but it lacks any social spaces or stores to buy some food or drinks.

The North side of the site is located on Hauptstraße. It is in close proximity to a bus stop, tram stop, S-Bahn station, and the Ostkreuz railway station, and the South side faces the picturesque Rummelsburg See. The site dimensions are typical of the blocks along Hauptstraße at 98m East to West, and 105m North to South.

34 < Case study design

legend Commercial Education Public Train Stop Tram Stop Residential

Fig. 34, Site location plan

Site Analysis

The side facing Hauptstraße is extremely noisy with the sounds of traffic, trams, and trains. It would also have related dust and pollution concerns. The South side, on the other hand, is very peaceful, with a running and bike path, views to the ufer and green spaces around. It provides opportunities for terraces, waterfront cafes, and communal and private outdoor spaces.

Directly adjacent is a kindergarten and a skatepark which will require design solutions for privacy and sound during the day. The neighboring buildings along the ufer include courtyard gardens, swales to catch rainwater, and green roofs.

views to the Rummelsburg See

tram, traffic, and railway noise

noise from kindergarten

views to the Rummelsburg See

Case study design > 35

Hauptstrasse

RummelsburgUfer

Fig. 35, Site analysis

Building Program

The real estate market in Berlin is complex, with the current trend of rising rents leading to a shortage of affordable housing. The city of Berlin has set explicit goals with the number of new units to be released into the market every year to help meet the rising demand (Hansson, 2018). The German market is predominantly rental housing, and private housing developers are not inclined to build affordable housing unless the German government subsidizes it (McGath, 2021). Inclusionary zoning (Baulandmodelle), which involves policies to involve affordable housing in market-rate projects to help combat gentrification and create mixed-income neighborhoods, is in place in Berlin. Therefore the design would need to consider the needs of diverse user groups.

Additionally, user needs are constantly changing. For example, the COVID-19 pandemic has led to a shift towards home offices and temporary co-working spaces. The use of delivery services for products and food has significantly increased, leading to a need for an adequate delivery drop of points and packet stations and a reduced need for retail shops.

The building program is designed to meet the current needs for affordable housing, delivery services, co-working spaces, and what has been identified as lacking in the area, such as cafes, convenience stores, and exercise facilities. However, it can also adapt to different needs in the future.

36 < Case study design

TECHNICAL

CIRCULATION FOOD &

EDUCATIONAL TECHNICAL COMMERCIAL RESIDENTIAL CIRCULATION FLEXIBLE WORK/LIVE

Current planned program Future possible programs

FAMILY HOUSING

FLEXIBLE DELIVERY SERVICES

BEVERAGE SHARED FLATS

SPACES

Fig. 36, Building program

Massing options

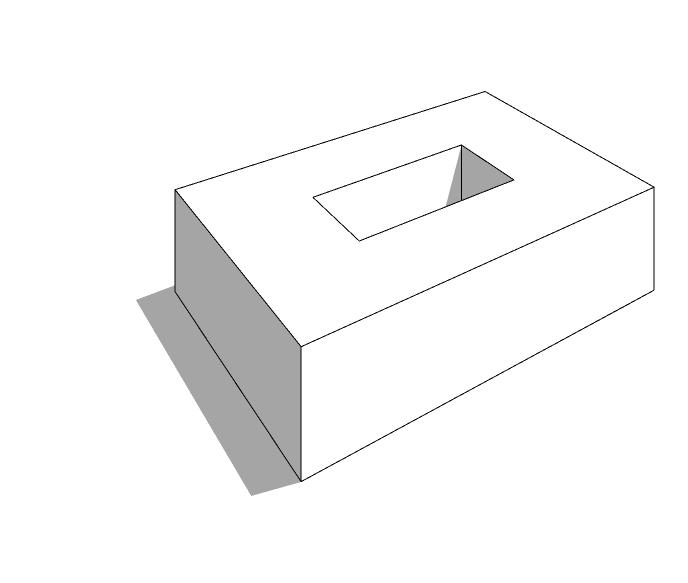

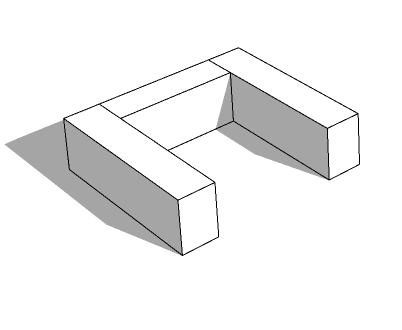

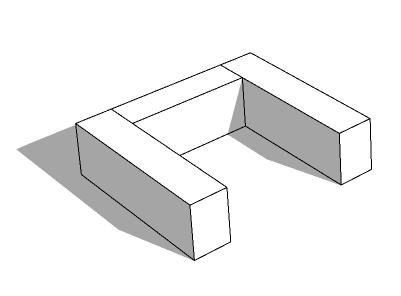

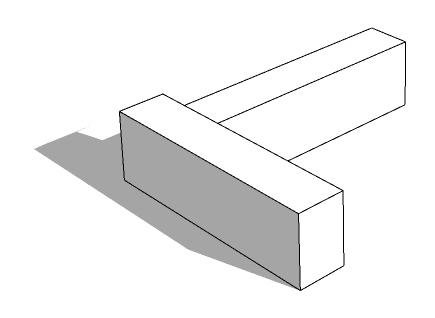

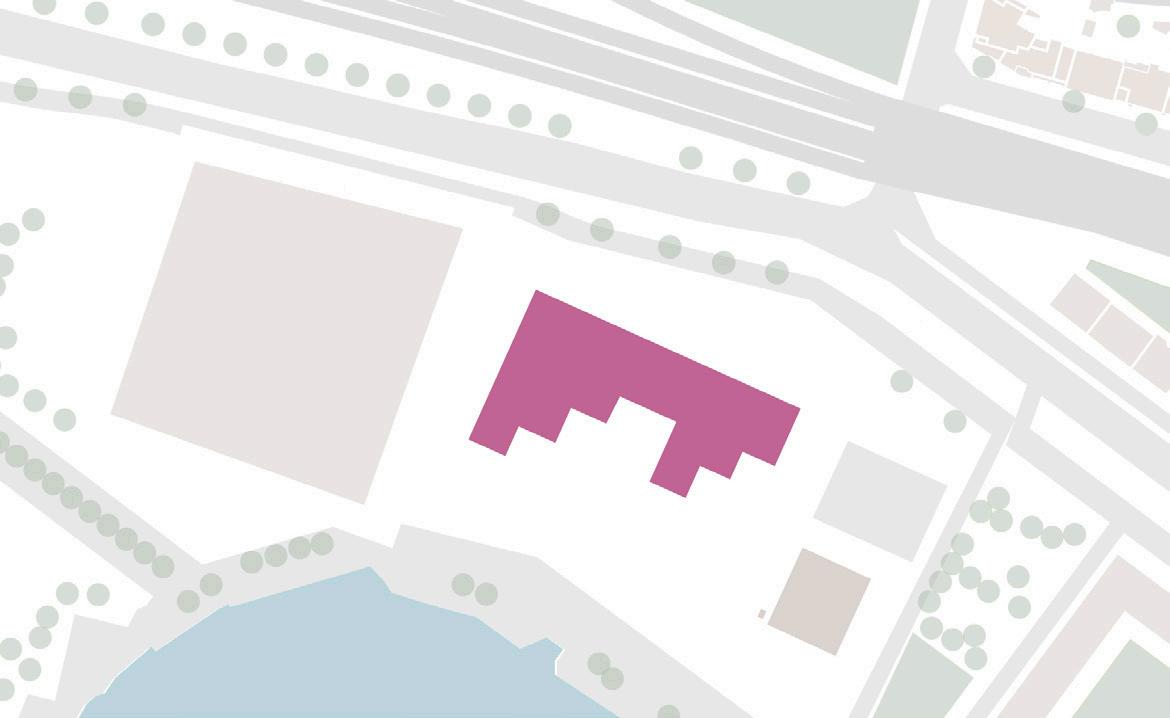

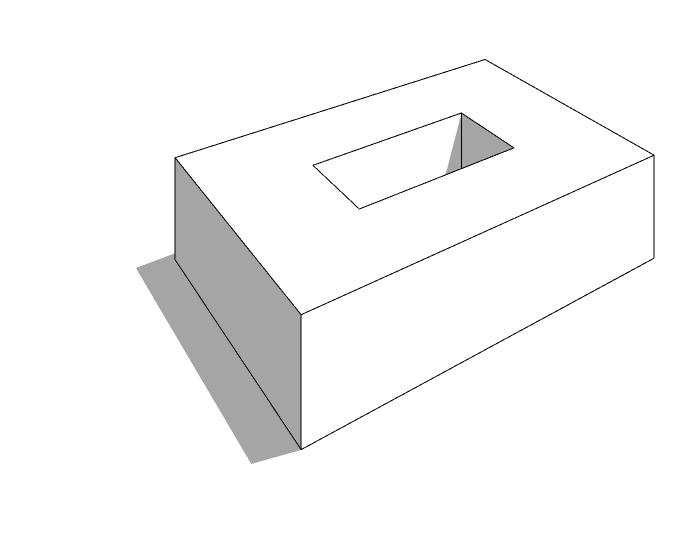

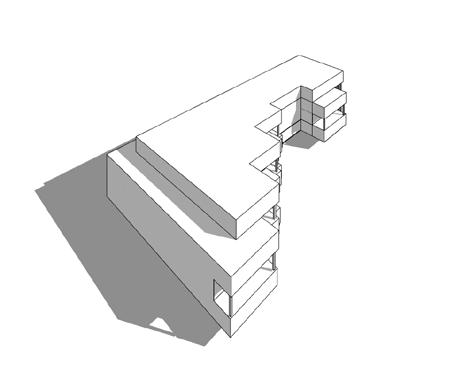

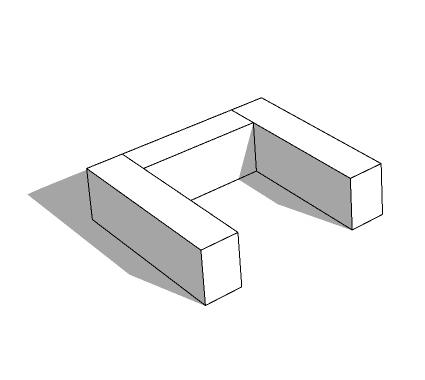

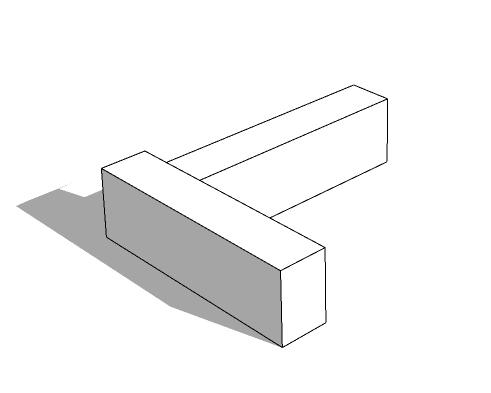

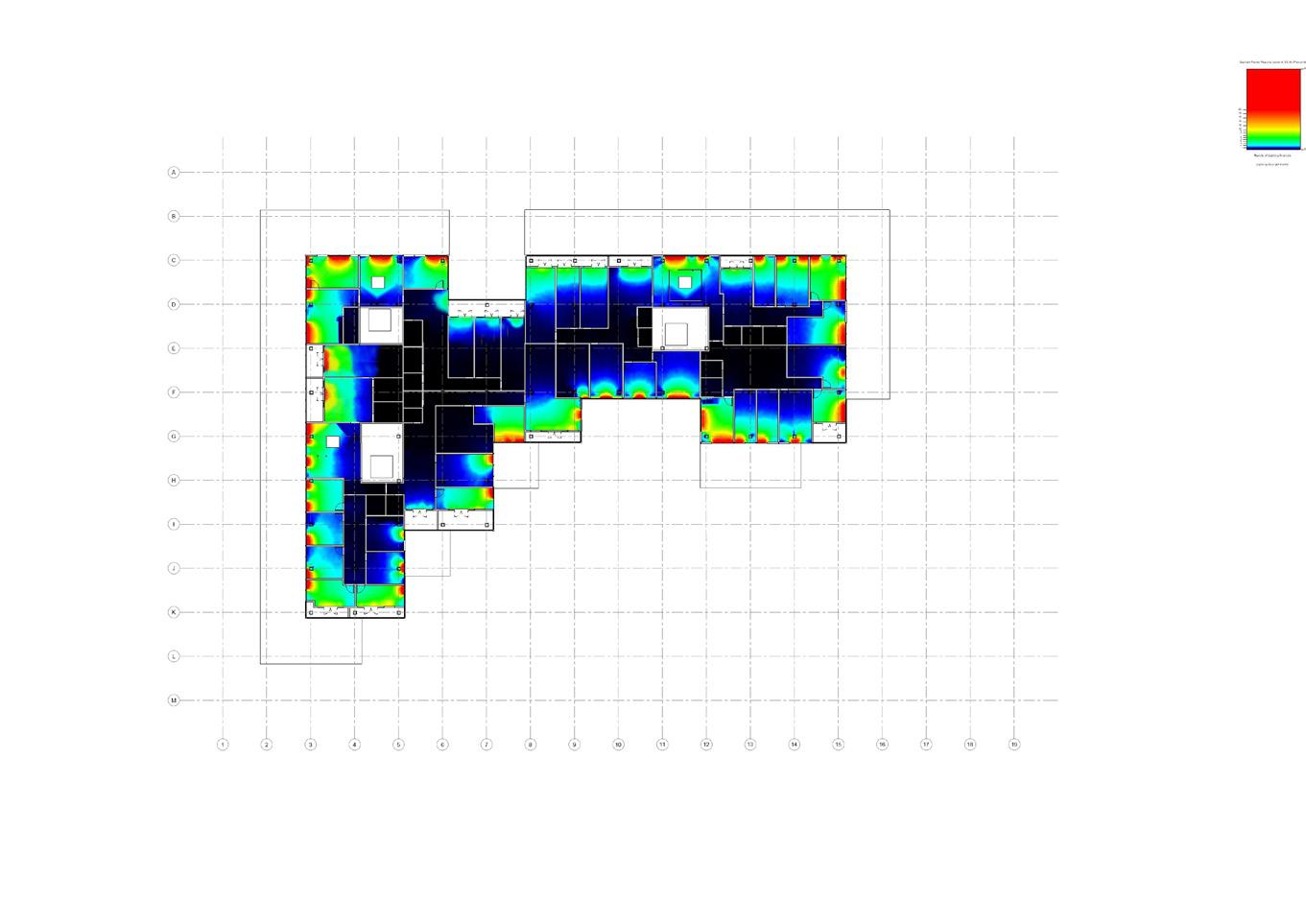

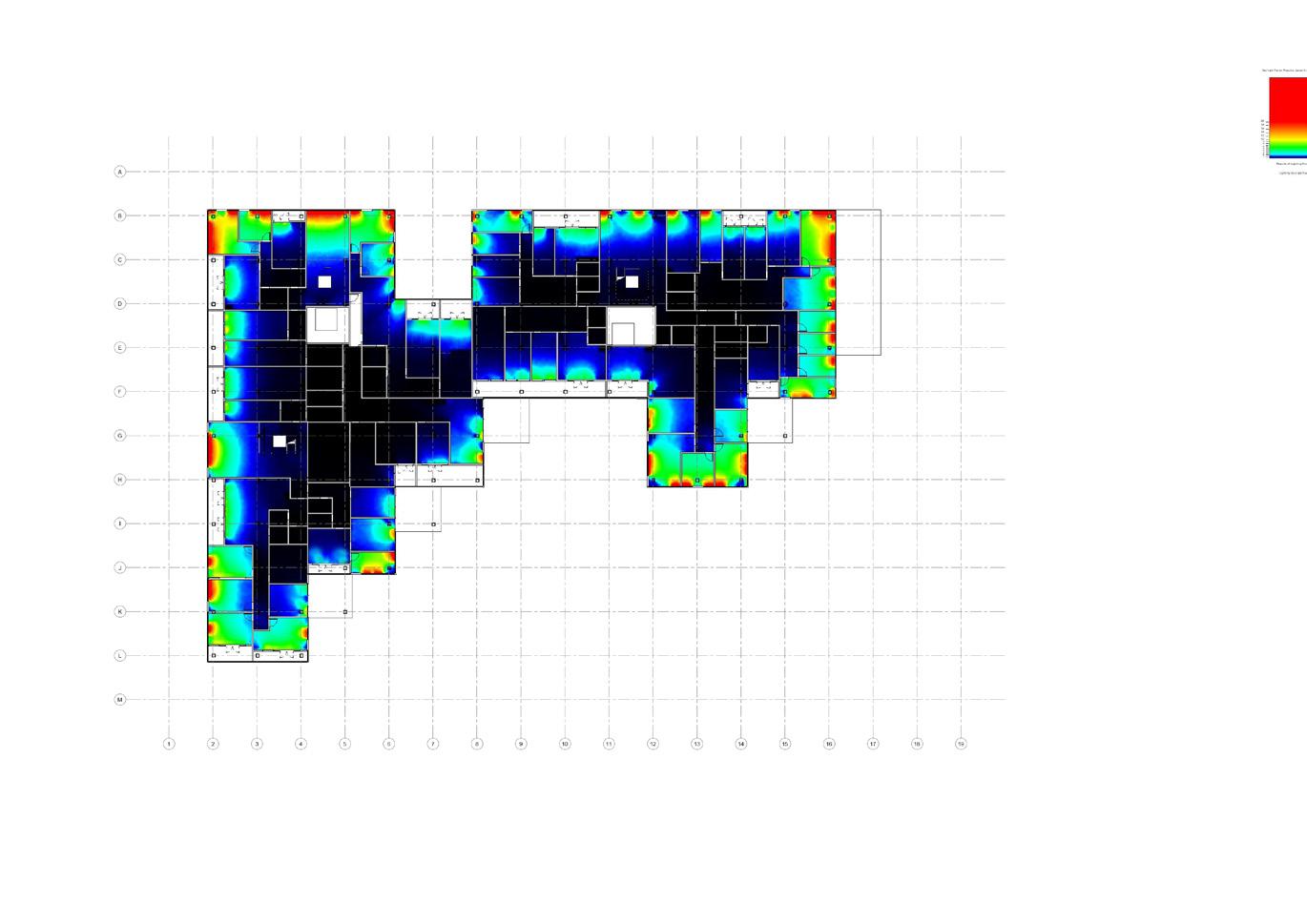

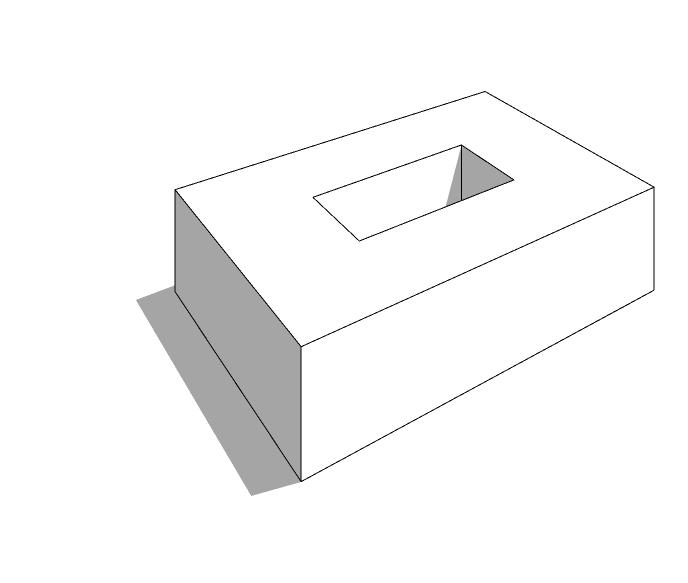

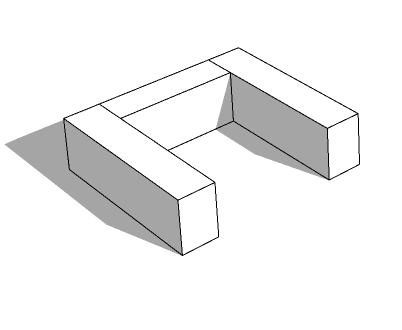

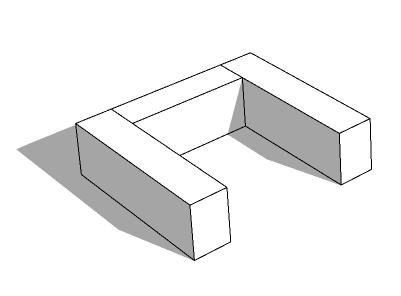

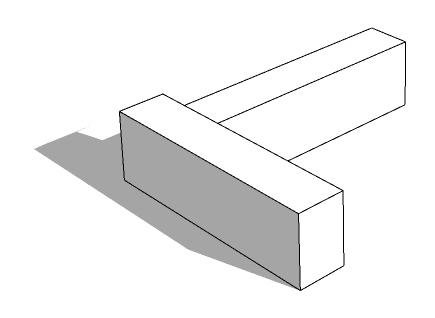

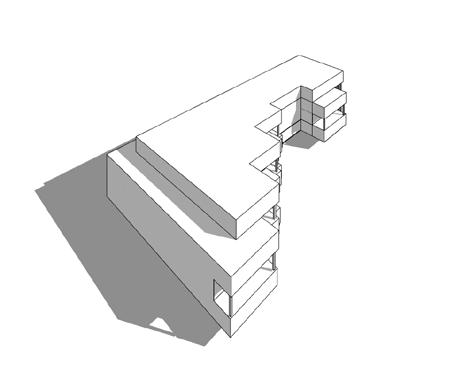

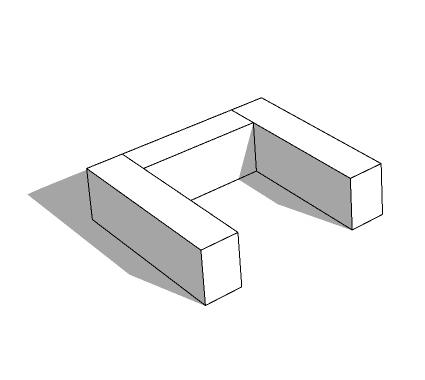

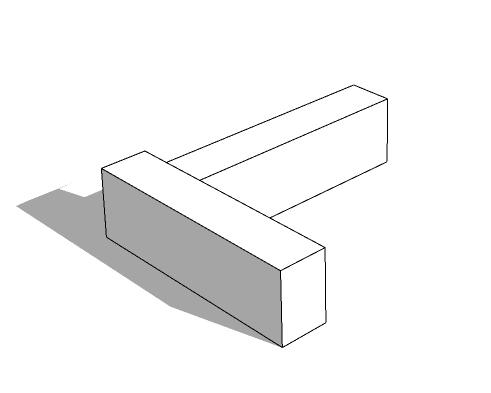

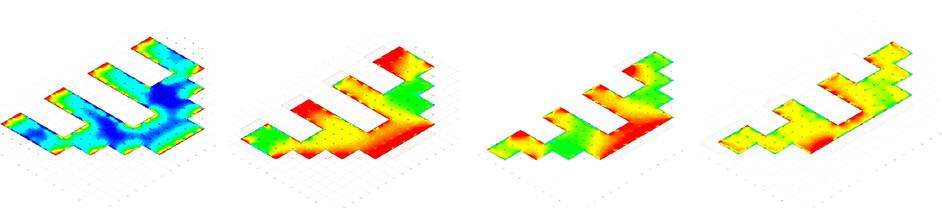

Four mass forms were modeled and assessed. A 5m x 5m grid was selected. The forms were selected by studying the buildings in the urban context, and a general overlook forward urban typologies in Berlin. The L shape was selected to create a mass that is open toward the water views. The modern buildings along Hauptstraße inspired the U shape. The massive shape with a courtyard in the center was inpired by the ‘Mietskasernen,’ which refers to multi-story residential blocks with inner courtyards built primarily during the industrialization period as accommodation for workers and employees(Bruning, 2013, p.273). The staggered form responded to the site conditions and design quality goals.

STAGGERED MASSIVE

Case study design > 37

U-SHAPE L-SHAPE

3.3 Massing

Fig. 37, Massing options

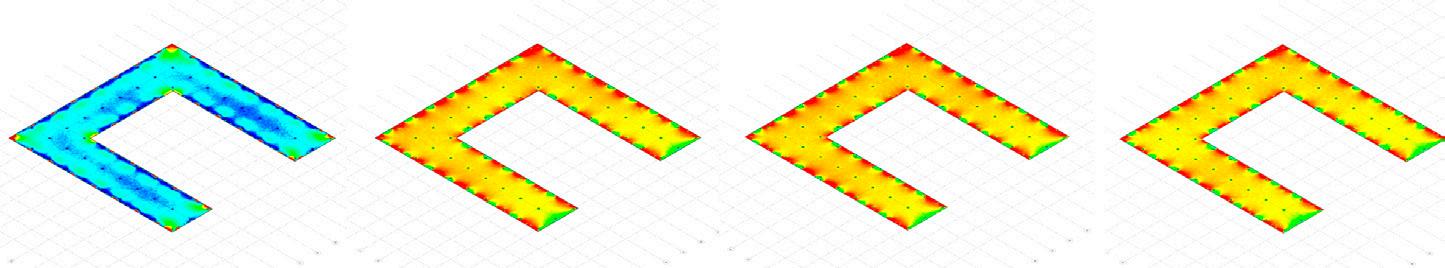

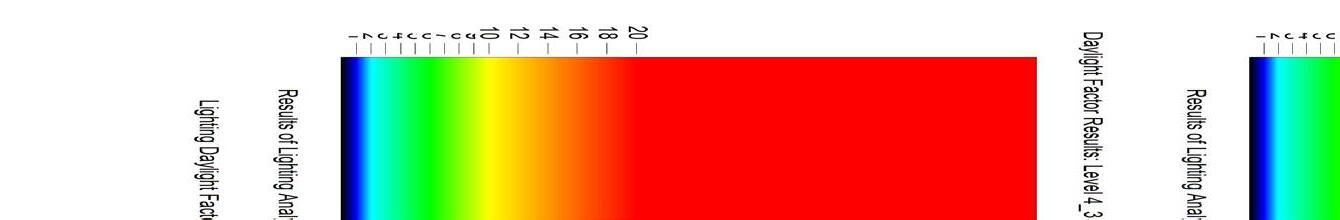

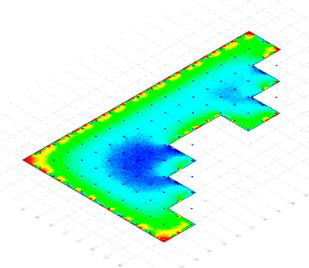

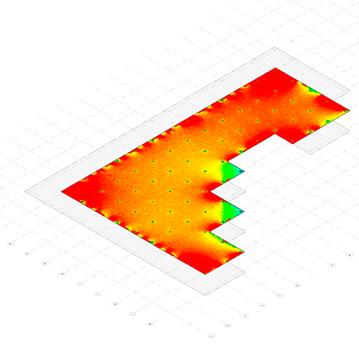

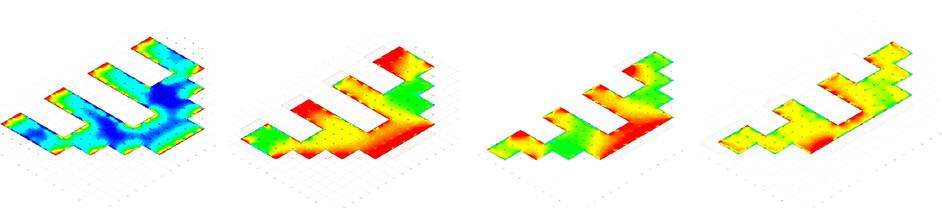

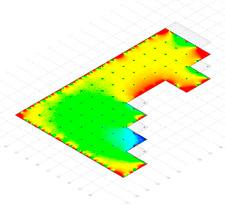

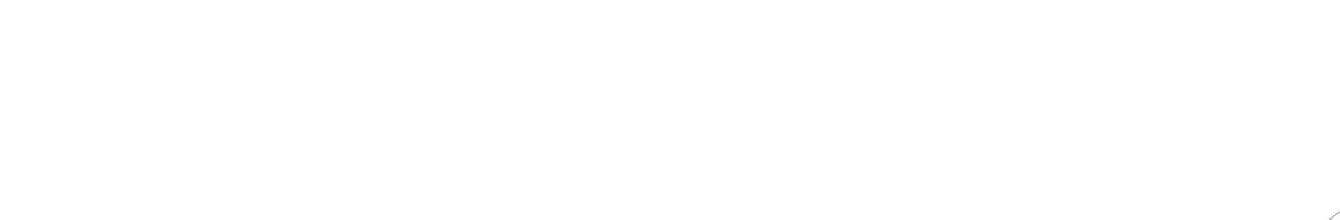

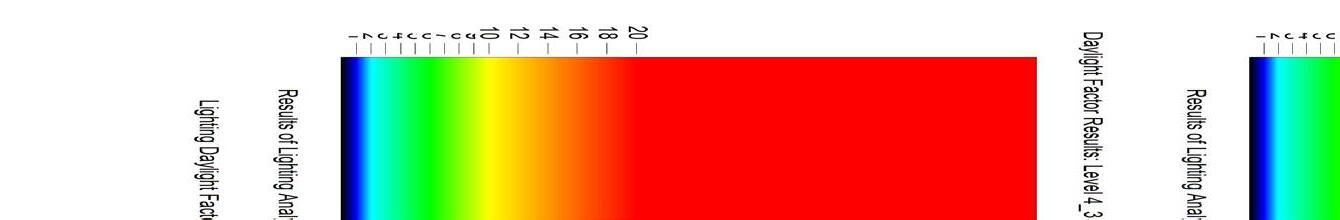

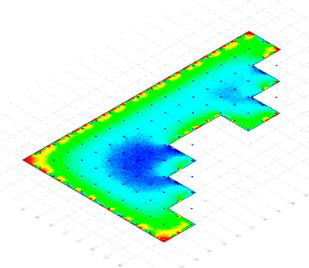

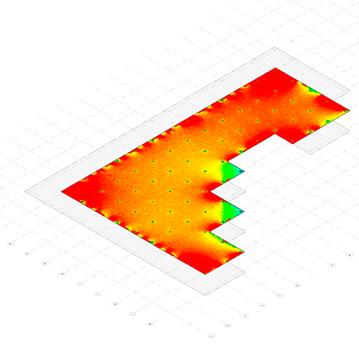

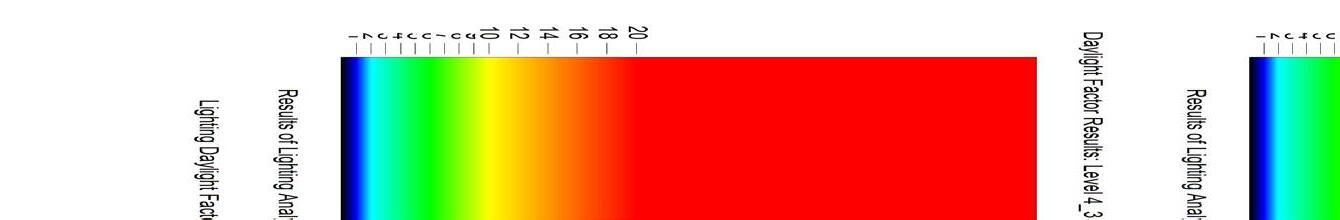

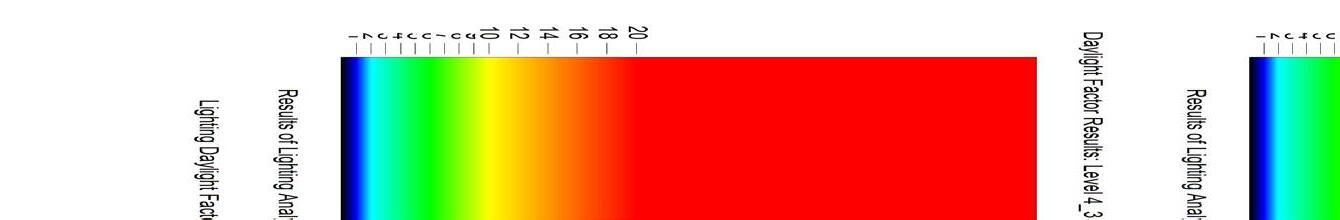

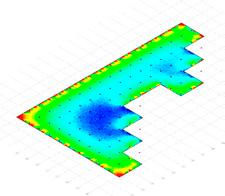

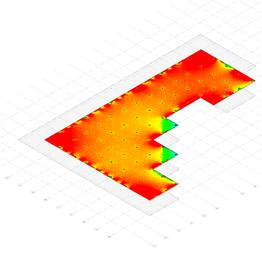

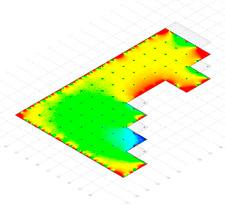

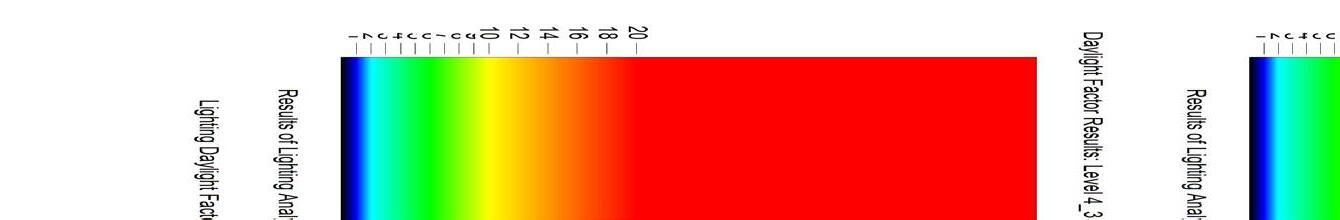

L-shape

Total floor area: 4008 m2

Total material volume: 2206 m3

Average daylight factor: 8.2%

U-shape

Total floor area: 5400 m2

Total material volume: 2905 m3

Average daylight factor: 10.3%

38 < Case study design

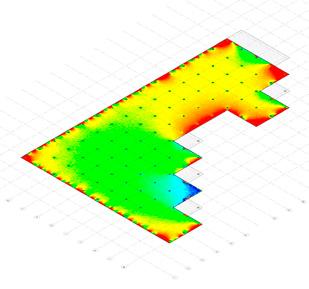

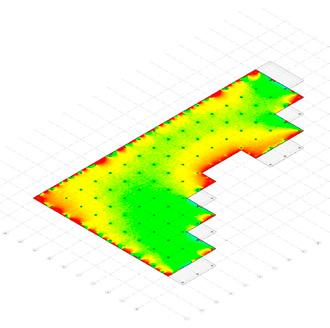

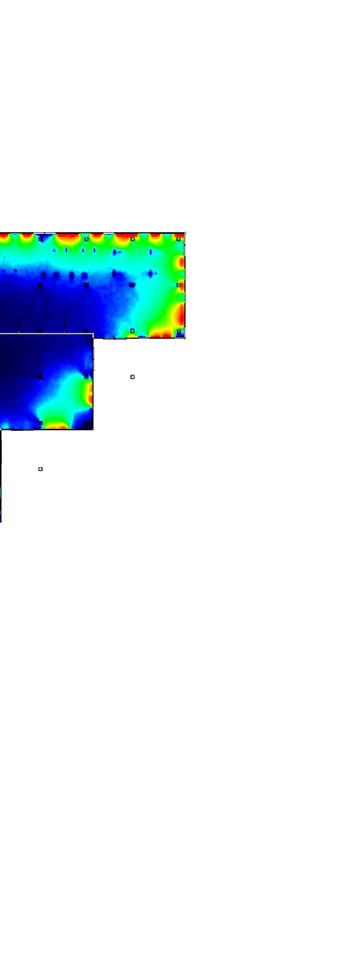

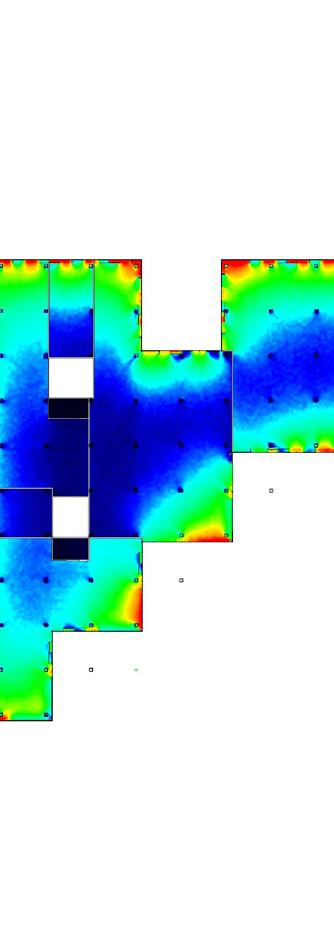

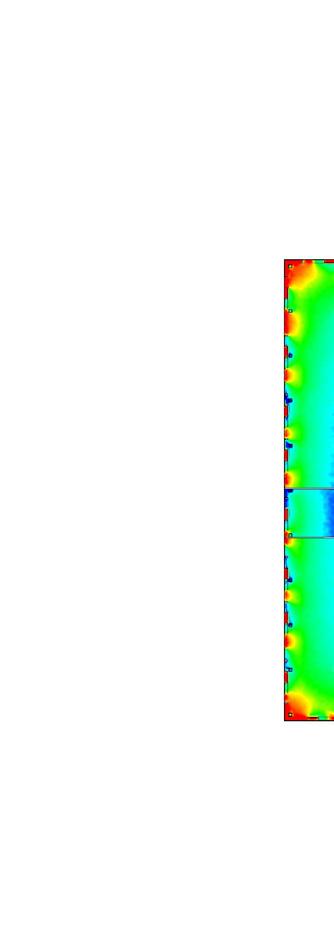

Fig. 38, L-shape site plan

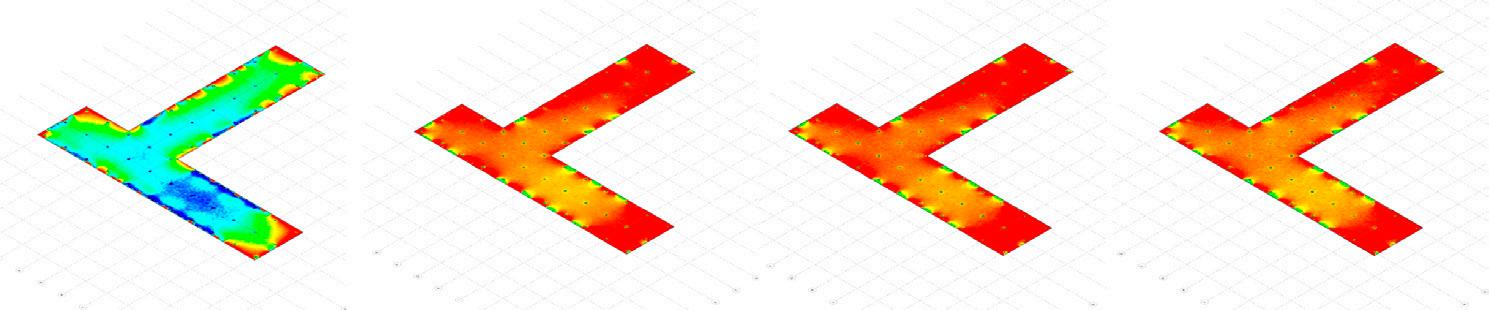

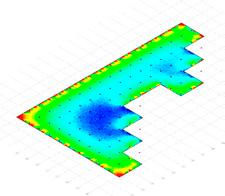

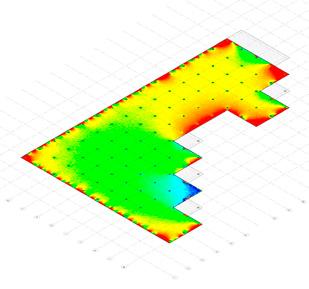

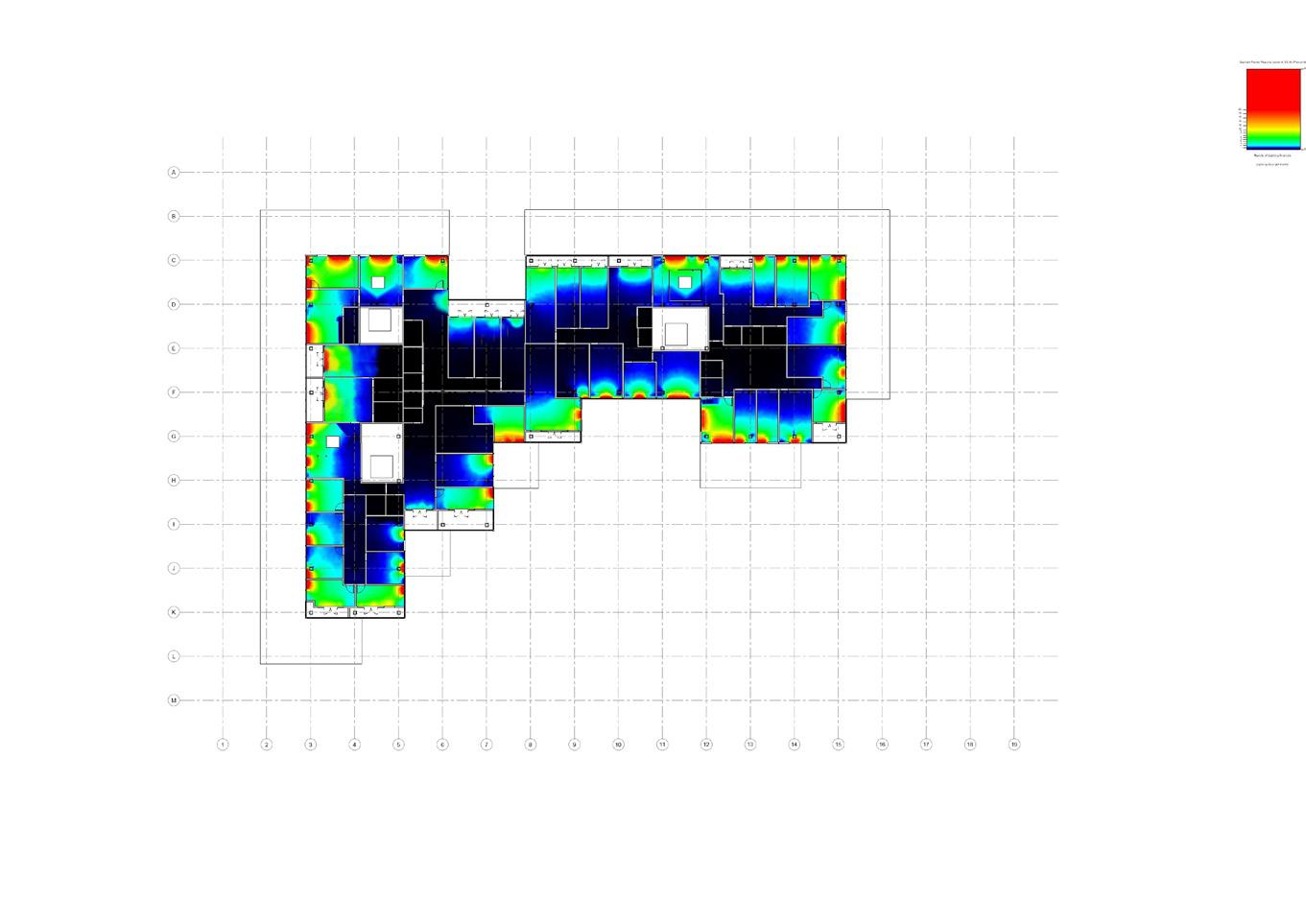

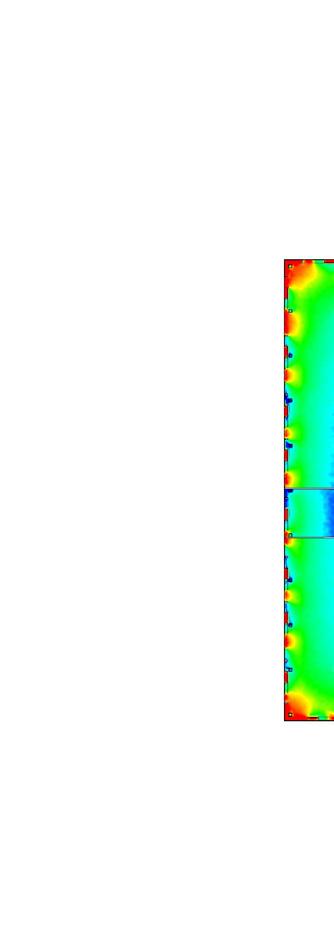

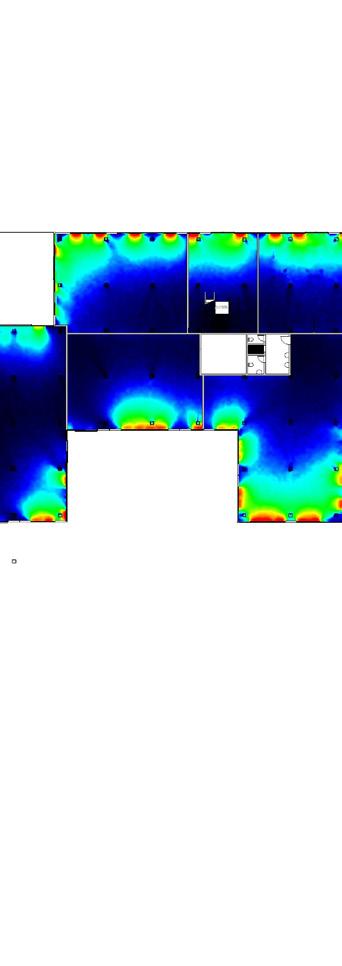

Fig. 39, L-shape daylight analysis

Fig. 40, U-shape site plan

0 10 20 5 Daylight Factor in % 0 10 20 5 Daylight Factor in %

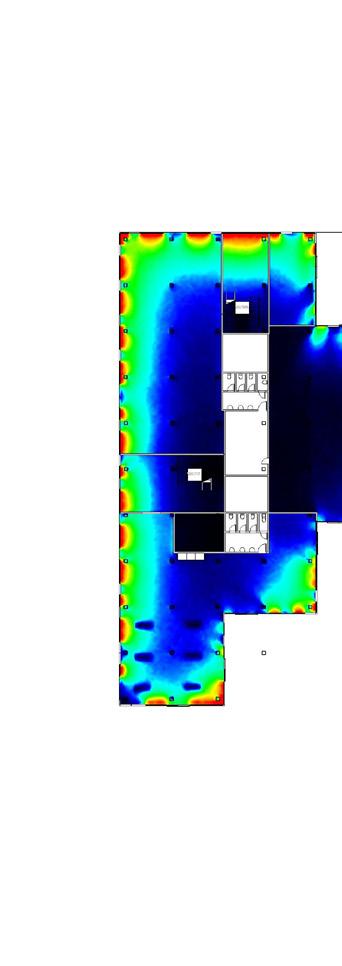

Fig. 41, U-shape daylight analysis

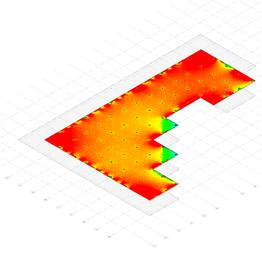

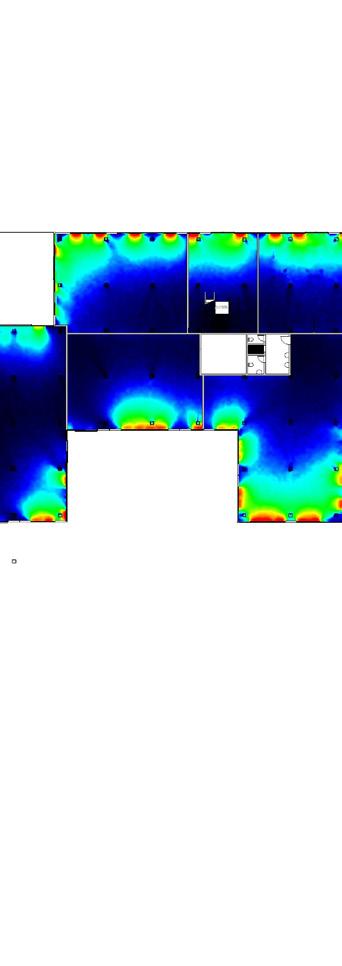

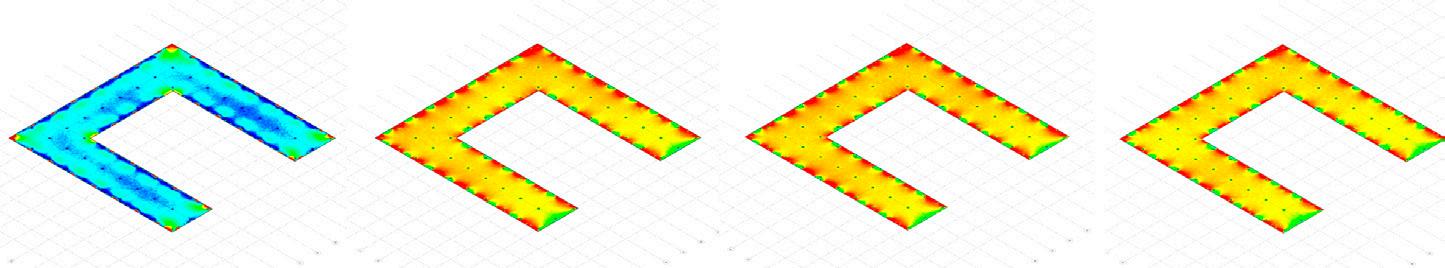

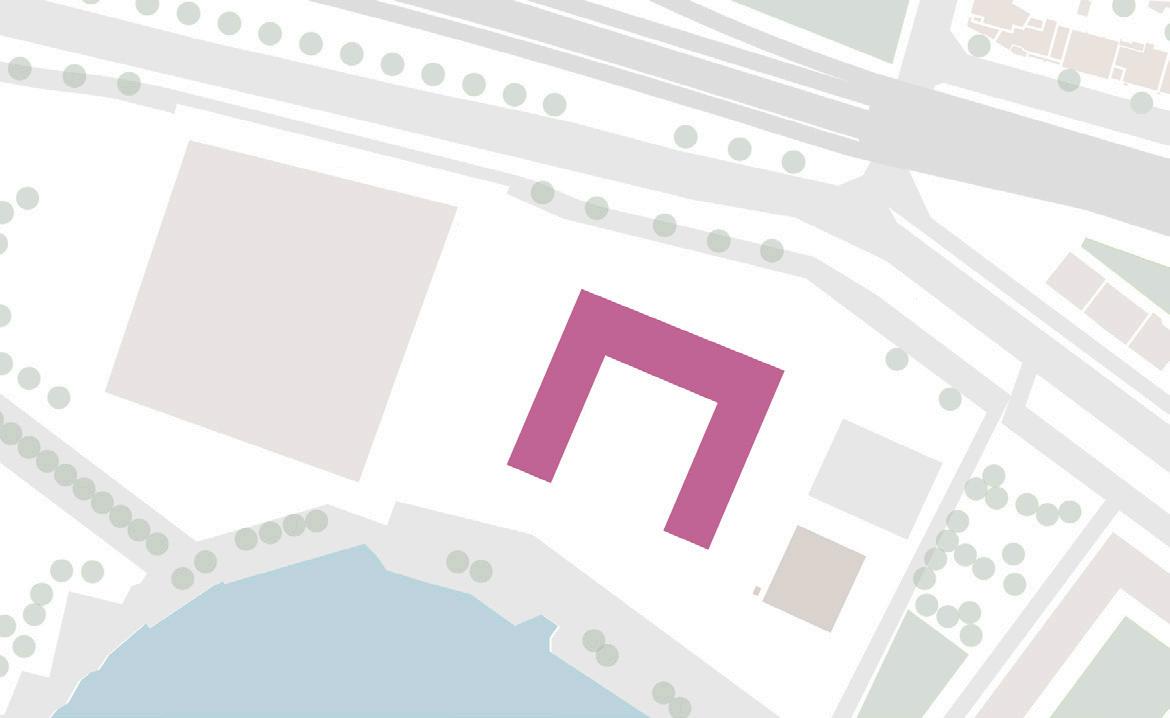

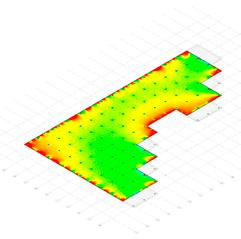

Massive

Total floor area: 8540 m2

Total material volume: 4286 m3

Average daylight factor: 4.9%

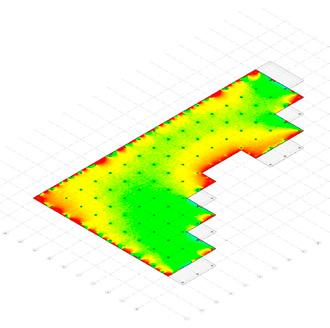

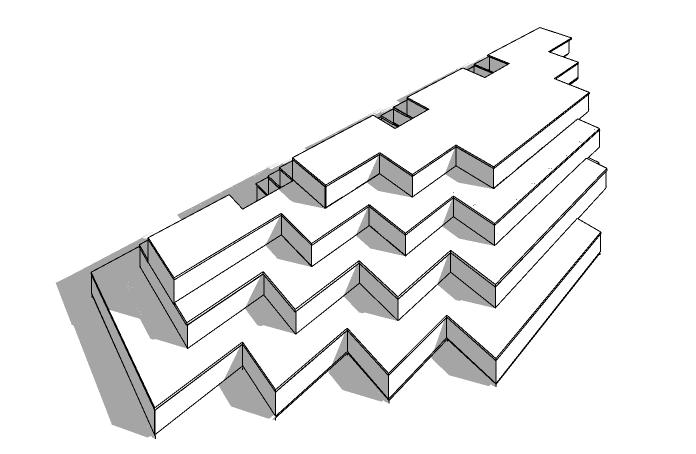

Staggered

Total floor area: 8527 m2

Total material volume: 4604 m3

Average daylight factor: 10.18 %

Fig. 42, Massive shape site plan

Fig. 43, Massive shape daylight analysis

Fig. 44, Staggered shape site plan

Fig. 42, Massive shape site plan

Fig. 43, Massive shape daylight analysis

Fig. 44, Staggered shape site plan

0 10 20 5 Daylight Factor

% 0 10 20 5 Daylight Factor in %

Fig. 45, Staggered shape daylight analysis

in

Pros

Comparison Matrix

fits in architectural context ideal plan depth simple grid and form easy fire escape design

fits in architectural context ideal plan depth simple grid and form easy fire escape design

Cons

lowest material efficiency smaller built up area non innovative form

smaller built up area non innovative form

largest built up area private community area

highest material efficency large built up area outdoor access views to ufer innovative form

daylight access least views to ufer non innovative form

plan depth exceeds desired depth of 20m

40 < Case study design

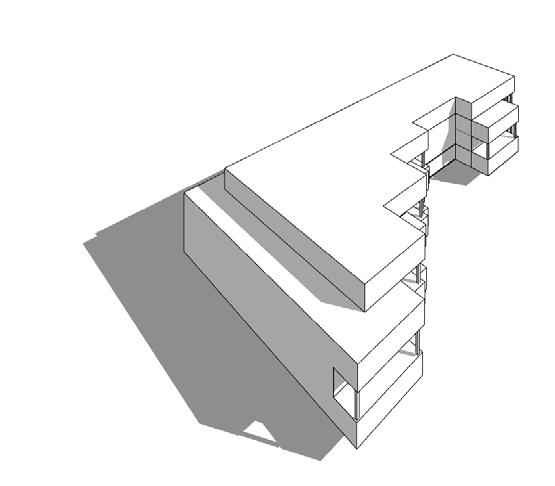

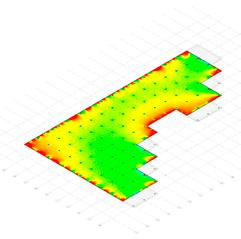

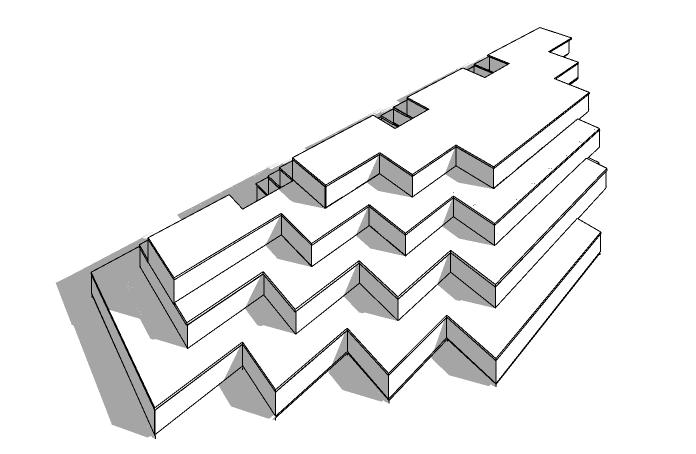

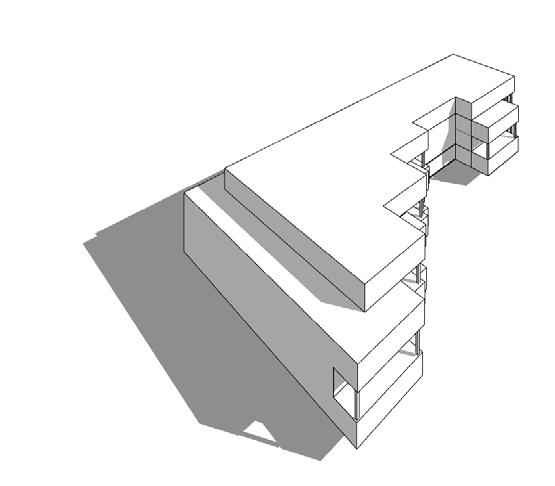

Staggered Iterations

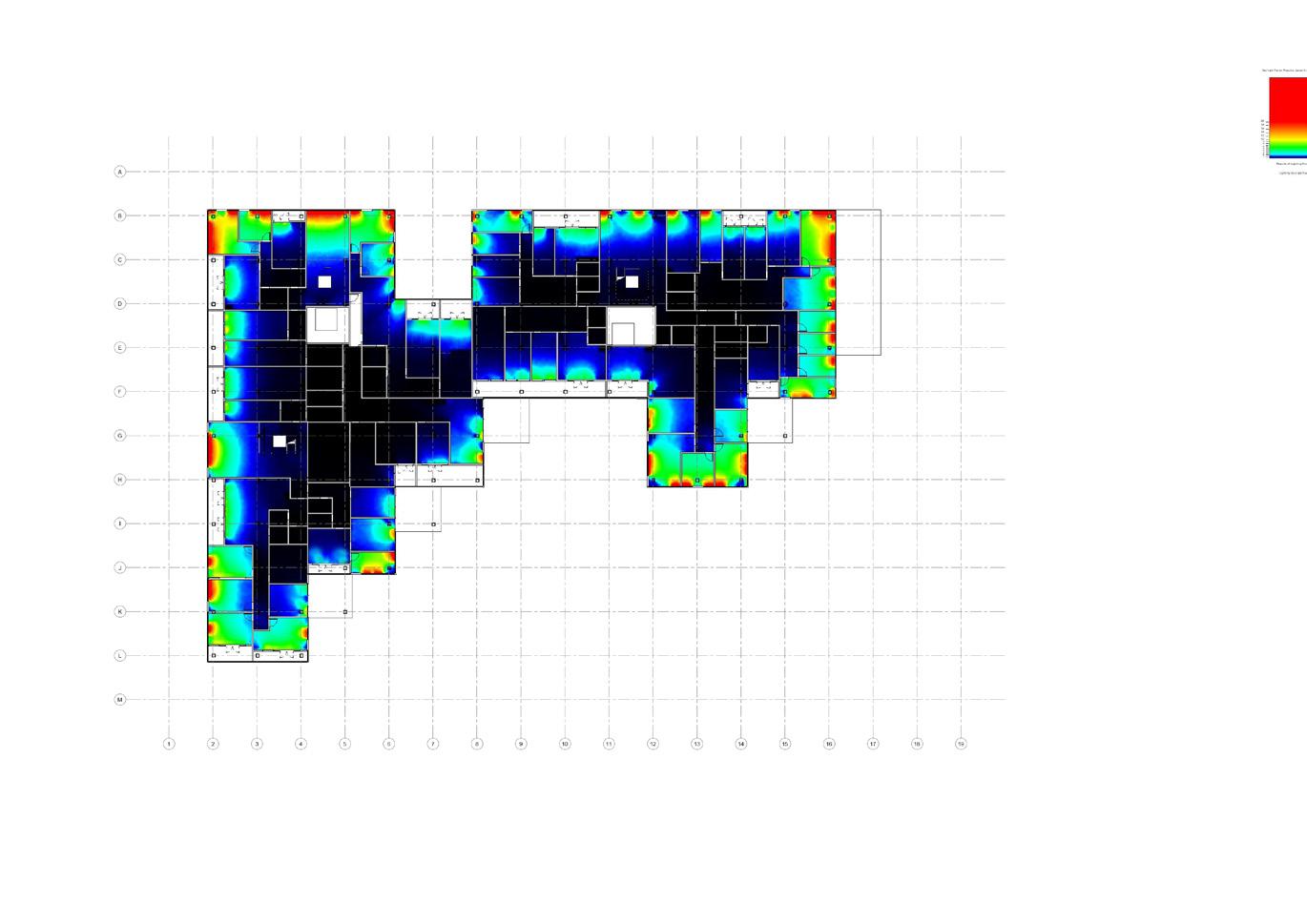

Two versions of the staggered design were created with fully solved floor plans and 3D models. The iterations were tested against each other on each of the measures for good design, circularity and adaptability.

Iteration 1

Design iteration 1 features a symmetrical plan. It has four access points and circulation cores towards Hauptstraße. It was not selected because it was not the best fit into the urban context and did not perform as well in daylight access and floor area to material volume ratio.

Iteration 2

Design iteration 2 features a more linear facade towards Hauptstraße, similar to existing buildings in line. It has a dynamic staggered facade towards the ufer. This design was selected because it responded better to the context and performed better in daylight and floor area to material volume ratio.

Case study design

Fig. 46, Iteration 1 comparison Fig. 47, Iteration 2 comparison 0 0 10 10 20 20 5 5 Daylight Factor in % Daylight Factor in %

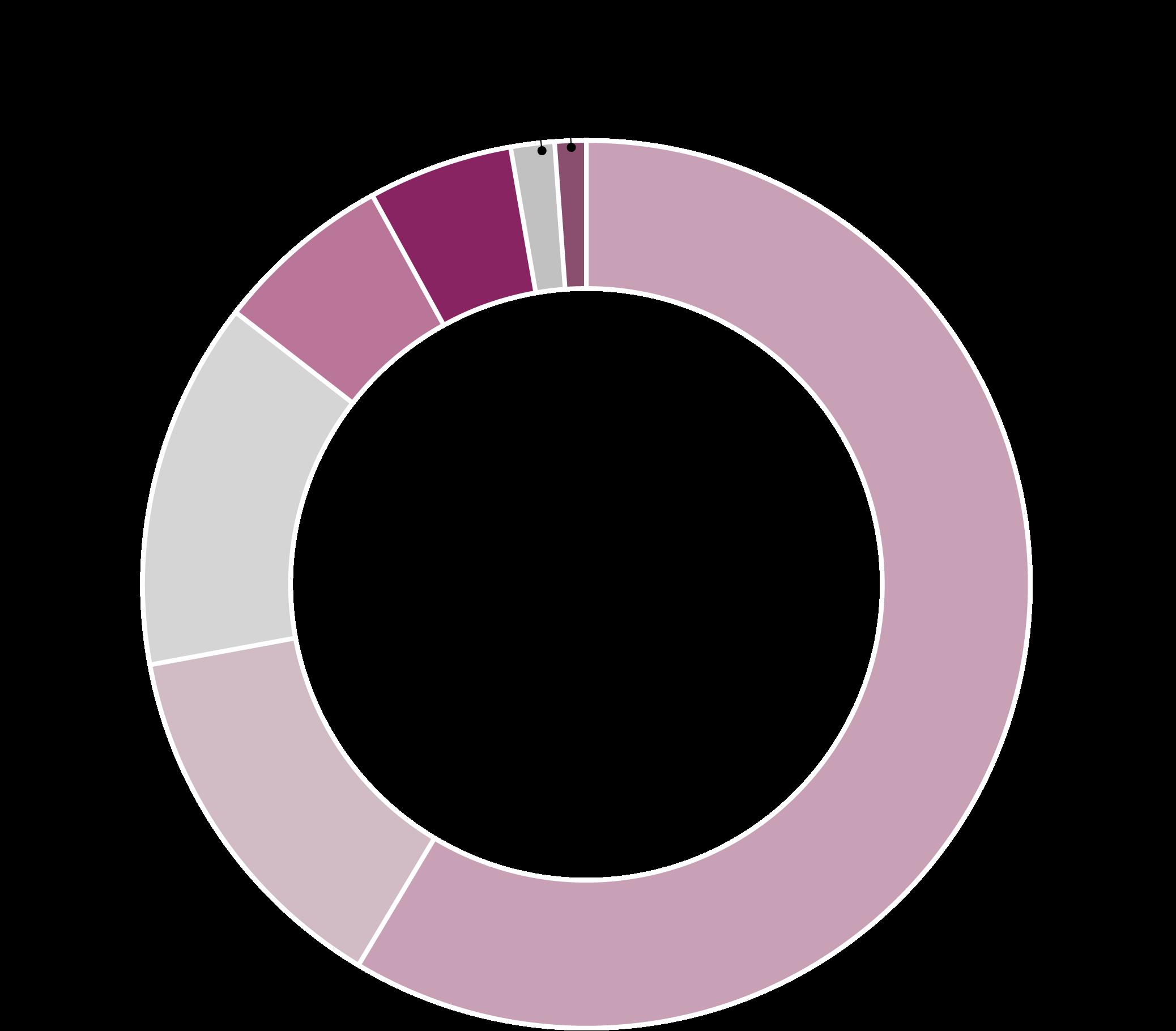

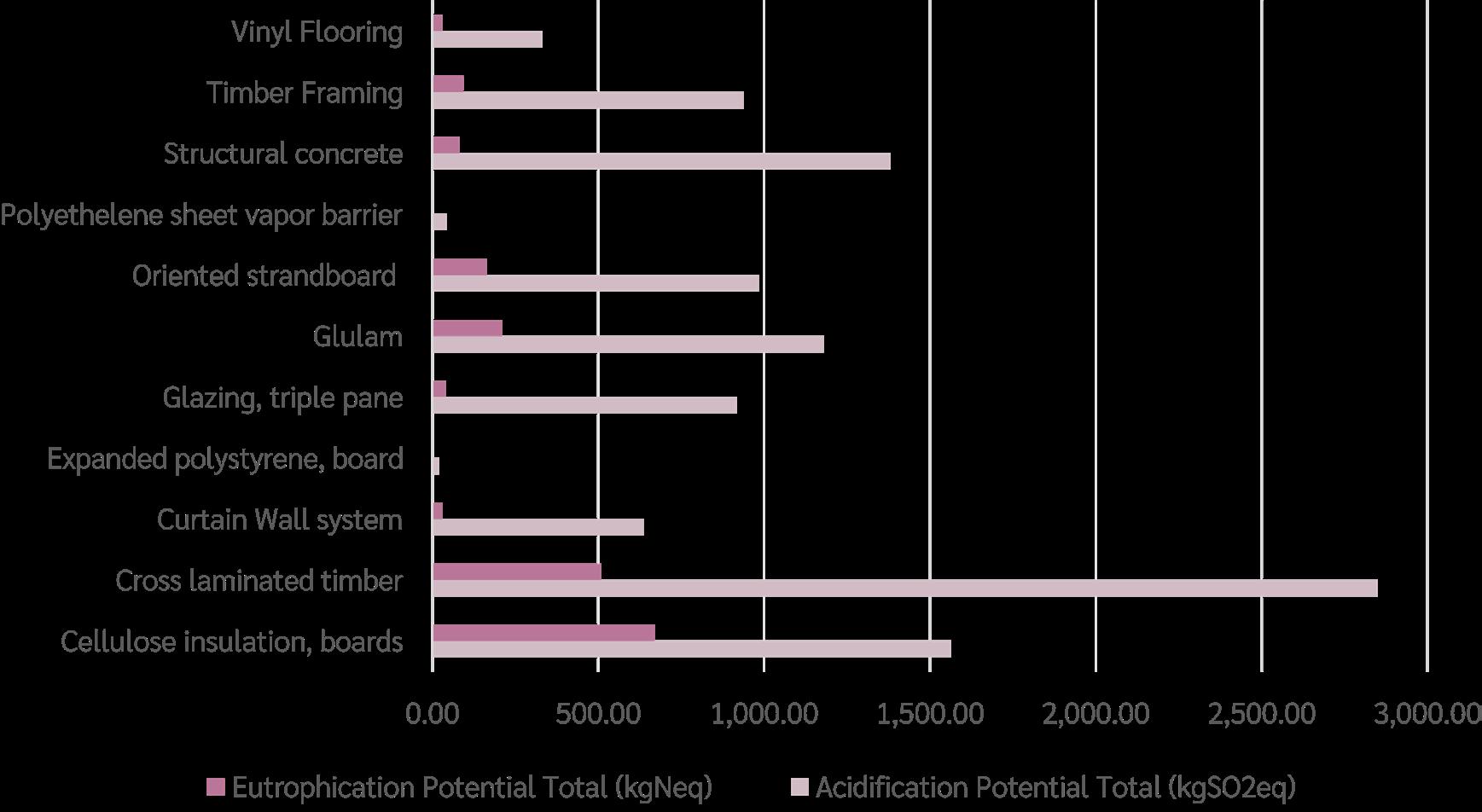

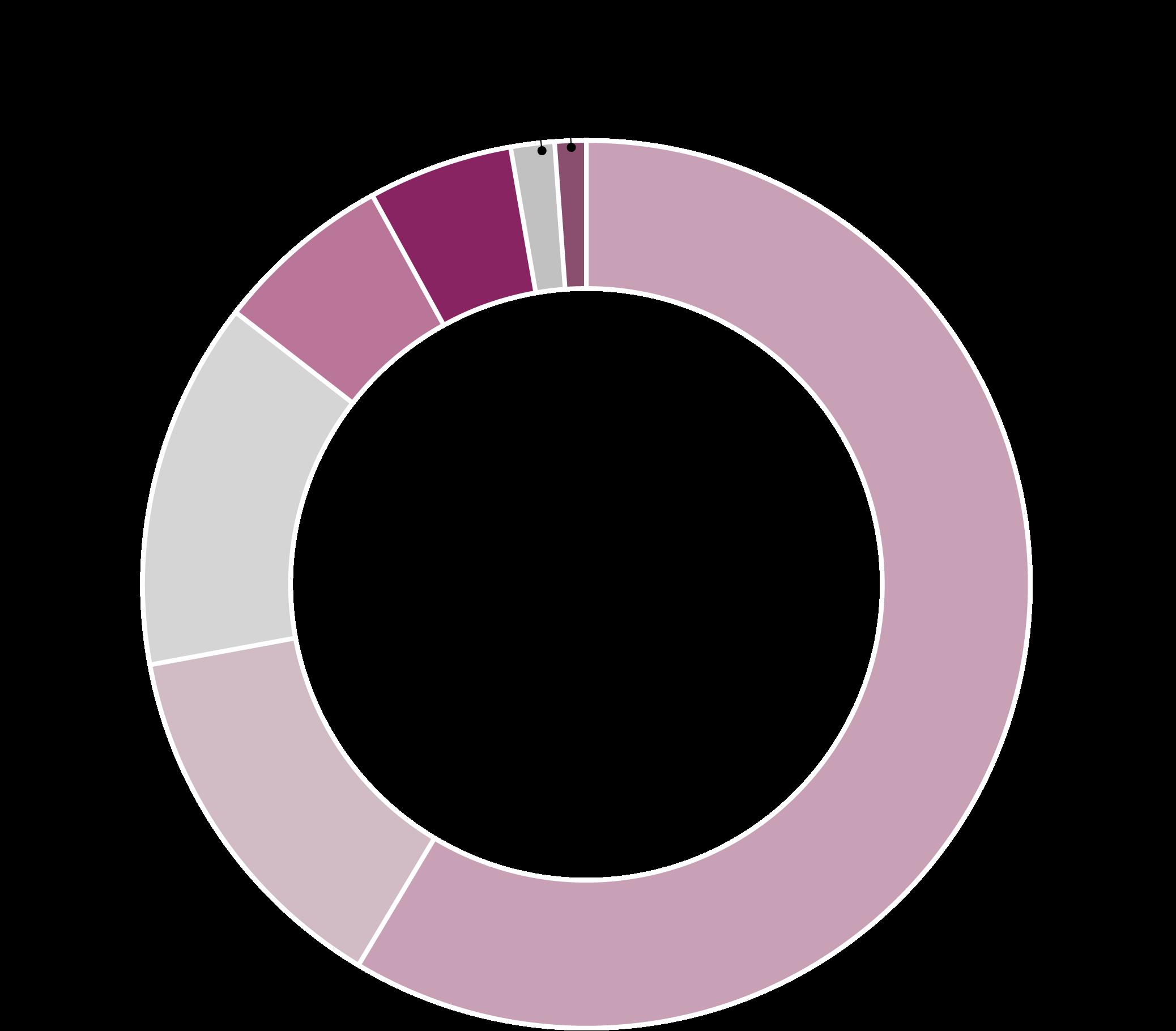

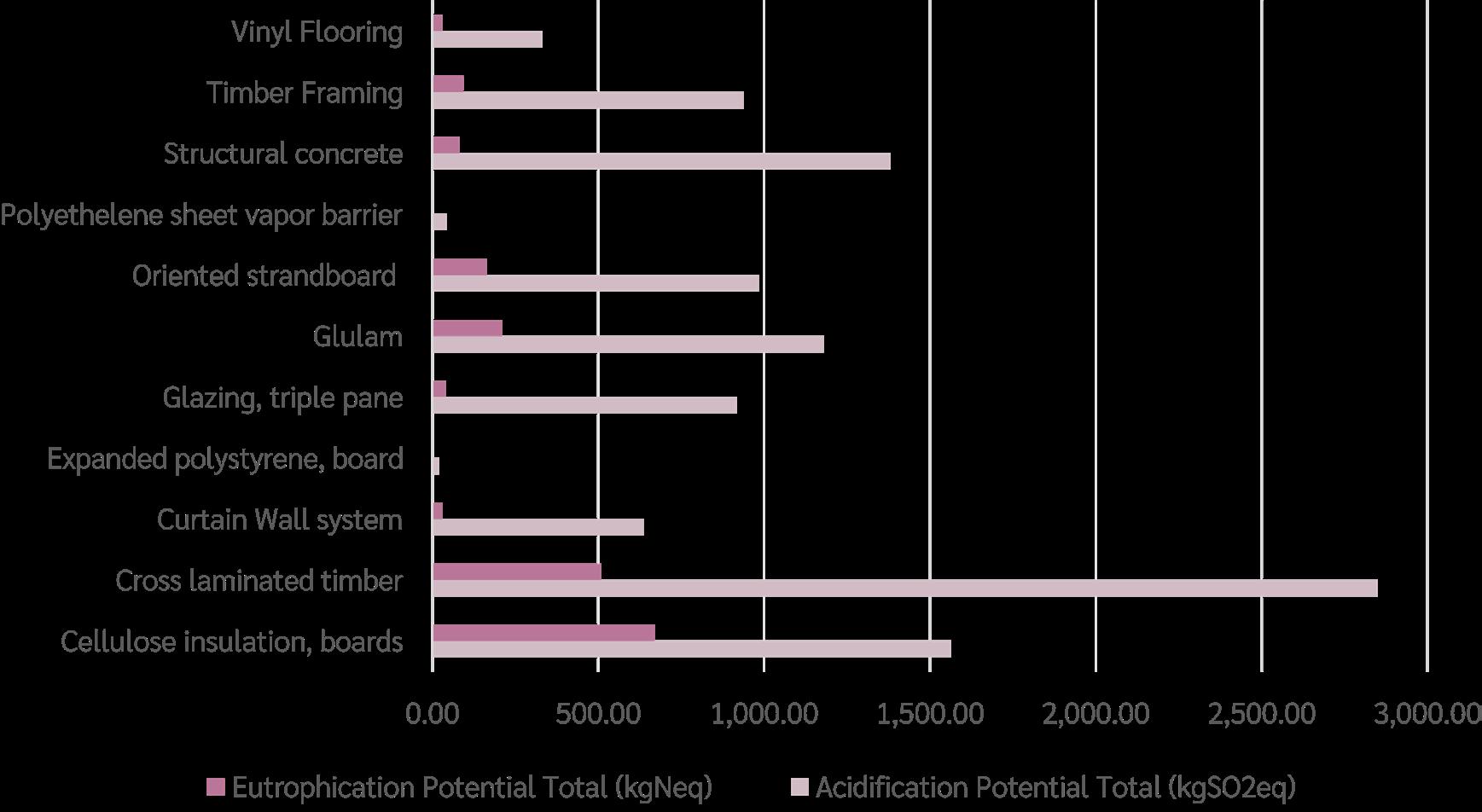

Materials are evaluated based on a modified version of the checklist designed by Amory, 2019. The checklist includes the material typology classified by Durmisevic according to the catagories Biological, Technical and Hybrid (2006).

Foundation options

Helical screw piles manufactured by Uretek provide stability by going over 20 meters deep into the ground assembled in sections with strong bolts. They offer the benefits of being able to be removed at the end of life and reused. It allows for a foundation system without the need for concrete (Uretek, n.d.). However, due to the swampy soil conditions in the Berlin Rummelsburg area, this option is not viable. Concrete foundations can be installed in two methods, cast-in-place or prefabricated. Prefabricated offers the advantage of being produced in a controlled environment leading to more precise higher quality results, however the transportation and installation is more expensive. Therefore a conventional in-situ foundation is selected. The foundation uses reusable metal formwork, eliminating that particular onsite waste.

42 < Case study design Development Utility End of Life Typology Foundation Refuse/Reduce Impact Prolong Life Recover Outputs Reused Material Optimised Manufacture Process Durable Materials Recyclable/ Renewable Materials Recycling Infrastructure Separability Biological Technical Hybrid Uretek piles X X X Prefabricated concrete blocks X X X X X Poured concrete using metal form-work X X X X X Tires with filled with concrete X X X X

3.4 Materials

Fig. 48. Foundation comparison table

Life cycle of concrete

The production of concrete is an energy intensive procress. However, foundations have lifespans much longer than the standard 60 years; therefore, designing the building with a regular grid system will allow the same foundation system to be reused in the next life cycle of the building. As concrete recycling in Germany is common practice, a mix of fly ash and slag can be used to lower the emobdied emissions.

Waste generated on site includes scaffolding, formwork and formwork support (Mah, Fujiwara and Ho, 2017). To counter this, metal scaffolding and formwork should be used. It can be designed as reusable which would imply the onsite time and resource cost to remove it, or permanent where it is designed as part of the structure (Löfgren and Gylltoft, 2017).

Case study design > 43

Fig. 49, Poured concrete life cycle

Loadbearing structure options

Common construction typologies include skeleton frame construction, load-bearing wall construction, and hybrid construction. Skeleton frame construction favors a circular and adaptable process as it offers the flexibility of the internal program, encourages separation of functions within a building element, and can be altered for maintenance or expansion without compromising the structural integrity of the rest of the building. Alternately, loadbearing wall structures are solid and durable, usually easier to fit into fire regulation guidelines, and widely used in the construction industry, so it is not hard to find trained professionals to design and construct them (Meistermann, 2017). A hybrid construction can include a variety of configurations. One option is a building with a loadbearing core and a post and beam structure around it, another is a building with load bearing external walls and a post and beam structure inside.

A glue laminated timber skeleton structure was chosen for its ability to sequester carbon, the initiatives by the German government to support timber construction, and the technology to create joints that can be disassembled for future use. The design of the grid for the design will be determined by the material properties and spans of glulam.

44 < Case study design Development Utility End of Life Typology Loadbearing Structure Refuse/Reduce Impact Prolong Life Recover Outputs Reused Material Optimised Manufacture Process Durable Materials Recyclable/ Renewable Materials Recycling Infrastructure Separability Biological Technical Hybrid Prefabricated Concrete Walls X X X X X Glue laminated Timber X X X X X Galvanized Steel Frame X X X X X Rammed Earth Walls X X X

Fig. 50.

Loadbearing structure comparison table

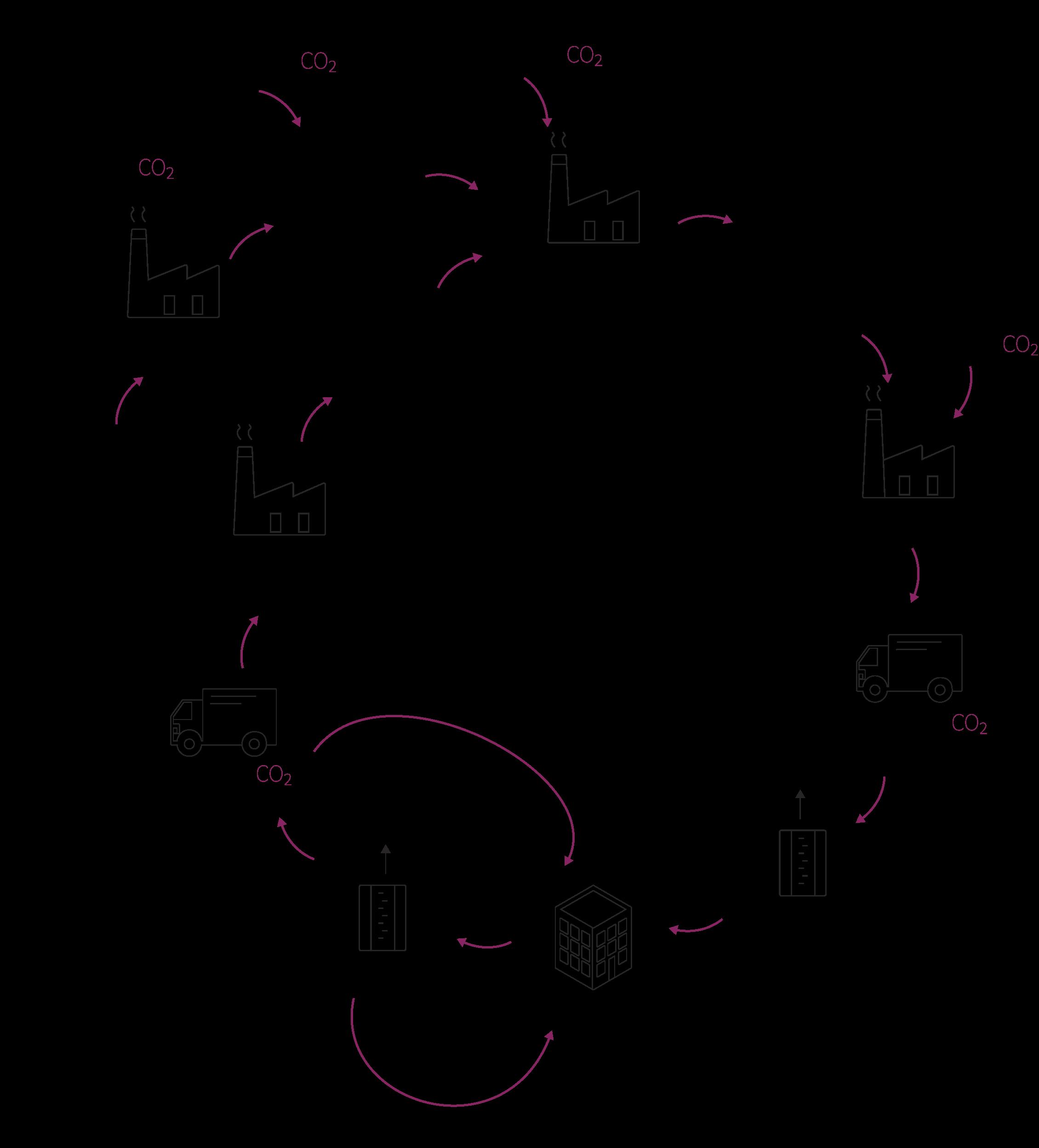

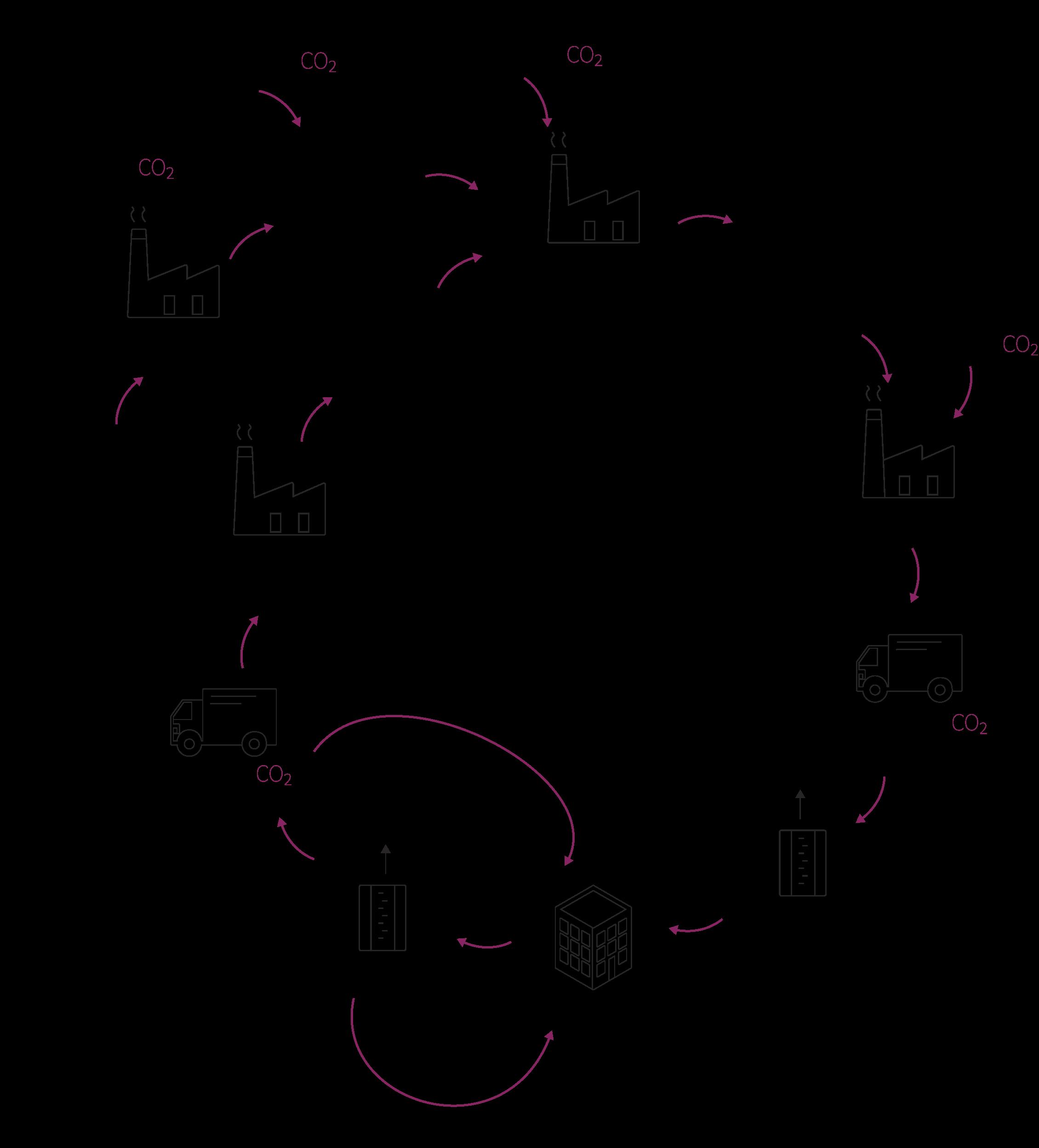

Life cycle of Glulam timber

Glue laminated timber elements are prefabricated and delivered to site. The actual energy consumption during assembly and disassembly on site depends on the building context and can be neglected. Any surface treatment required is applied under factory conditions reducing on site construction time. Wood chips generated from the production process can be incinerated for energy (Oekobaudat, 2021).

Timber from sustainably grown forests certified by the Programme for the Endorsement of Forest is sourced by Mayr-Melnhof Holz Group. It is then strength-graded and planed & parallel-glued. The wood is sourced from Leoben (AT), Paskov (CZ), Insjön (SW), Blyberg (SW), Mora (SW) and Efimovskij (RU).

Case study design > 45

Fig. 51, Poured concrete life cycle

Insulation options

The project requires two types of insulation, a rigid foam insulation for use in the slab to ground connection point and on the roof, and a batt and roll insulation to use between the structural elements. Below is a comparison of the batt and roll options.

Structural insulated panels consist of an insulating straw foam core sandwiched between two oriented strand boards. However, they are not suitable for a skeleton structure building. Mineral wool insulation is formed by spinning molten rock materials. Mineral fibers can become airborne and pose a health risk if we breathe them. Hemp insulation is a composite material made of plant fibers bound with chemical substances. Cellulose fiber insulation is made from recycled newspapers and has a lower composition of chemical compounds, making it a better choice for this scenario (Silvestre, de Brito and Pinheiro, 2011). Installation methods include loose-fill, dry blown, wet spray where water and binders are added during installation to make it stick to walls or as premanufactured boarrds.

46 < Case study design Development Utility End of Life Typology Insulation Material Refuse/Reduce Impact Prolong Life Recover Outputs Reused Material Optimised Manufacture Process Durable Materials Recyclable/ Renewable Materials Recycling Infrastructure Separability Biological Technical Hybrid Hemp X X X X Cellulose Fiber X X X X X Straw Core insulated panel Mineral Wool X X X X X

Fig. 52. Loadbearing structure comparison table

Life cycle of cellulose fiber insulation

Cellulose fiber is manufactured as loose fibers or insulating boards. It is a nonloadable insulating material and should be used as cavity insulation within a structural frame. The insulation boards are premanufactured and delivered to the site, and waste would include offcuts while cutting to fit into the timber frame. The primary raw material is waste paper fibers, processed into a pulp by mechanical crushing and then extruded similarly to synthetic fibers like polyester. Minerals like boron are added to increase fire protection and make it resistant to bio attacks (Holzforschung, 2022).

Due to the added minerals, recycling cellulose is not advised, and it is incinerated or sent to landfill. Boron is a healthy micronutrient for plants, and the low composition within the insulation material makes it safe for landfill disposal (Alex Wilson, 1993).

Case study design > 47

Fig. 53 Poured concrete life cycle

Rigid insulation options

Rigid insulations can be applied in loadable scenarios like underfloor applications. The three options considered are allExpanded polystyrene foam (EPS) is a closed-cell form of foam insulation and performs well even if installed in wet conditions. At end of life, it can be downgraded to use as packaging material or be sent to landfill. Extruded polystyrene (XPS) insulation is made from polystyrene crystals combined with additives and gas blowing agents, it retains the highest amount of moisture among the three. Polyisocyanurate (Polyiso) foam is a rigid insulation that has superior performance and can be sent for recycling at end of life. However, it is the most expensive and has the highest related emissions during production. Both XPS and Polyiso degrade over time, making them unfavorable choices in this scenario (Silvestre, de Brito and Pinheiro, 2011).

Polyisocyanurate foam insulation

Exstruded polystyrene foam (XPS) X X X

48 < Case study design Development Utility End of Life Typology Insulation Material Refuse/Reduce Impact Prolong Life Recover Outputs Reused Material Optimised Manufacture Process Durable Materials Recyclable/ Renewable Materials Recycling Infrastructure Separability Biological Technical

Hybrid Expanded polystrenefoam (EPS) X X X X

Fig. 54. Rigid insulation comparison table

Life cycle of expanded polystyrene

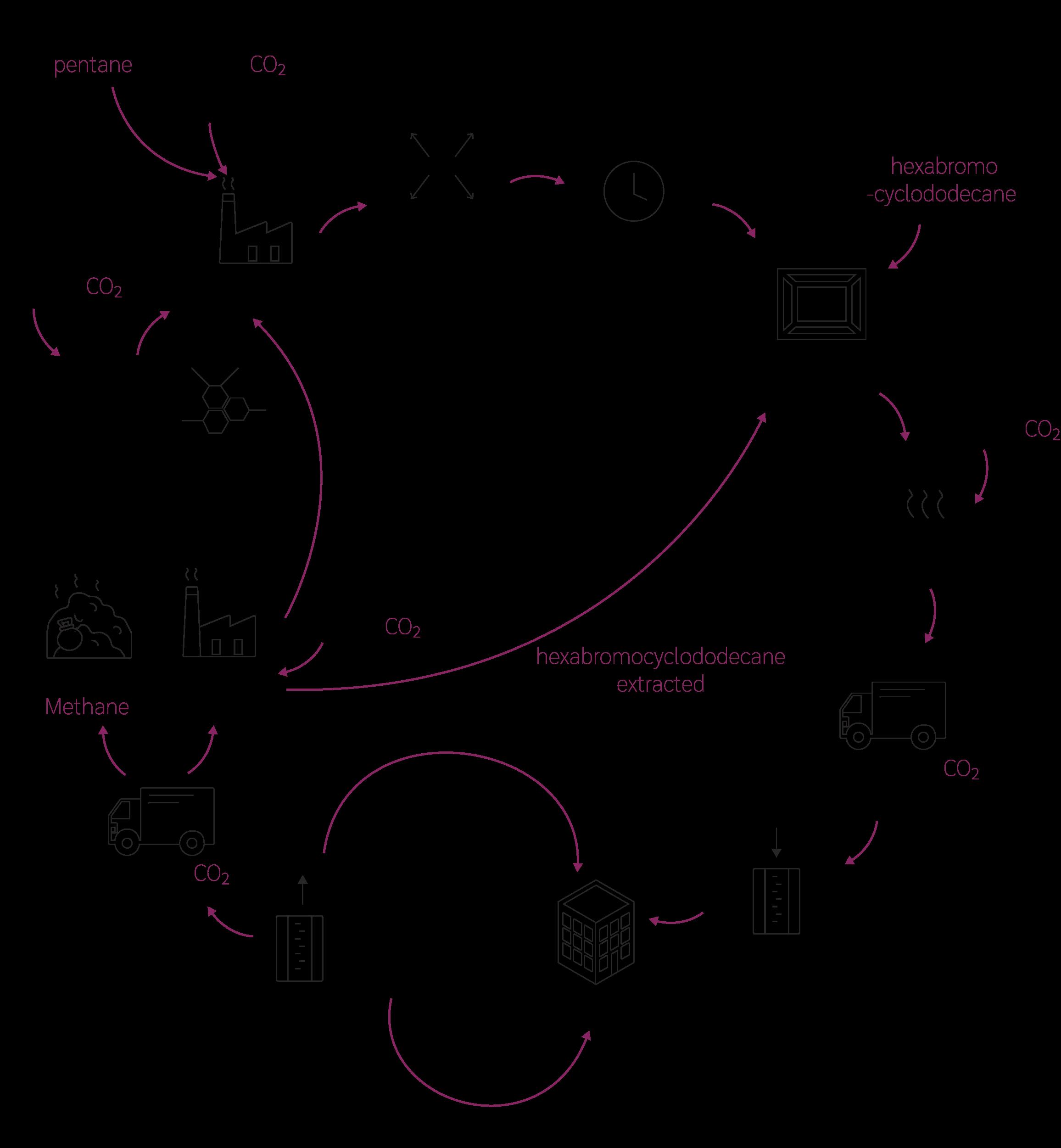

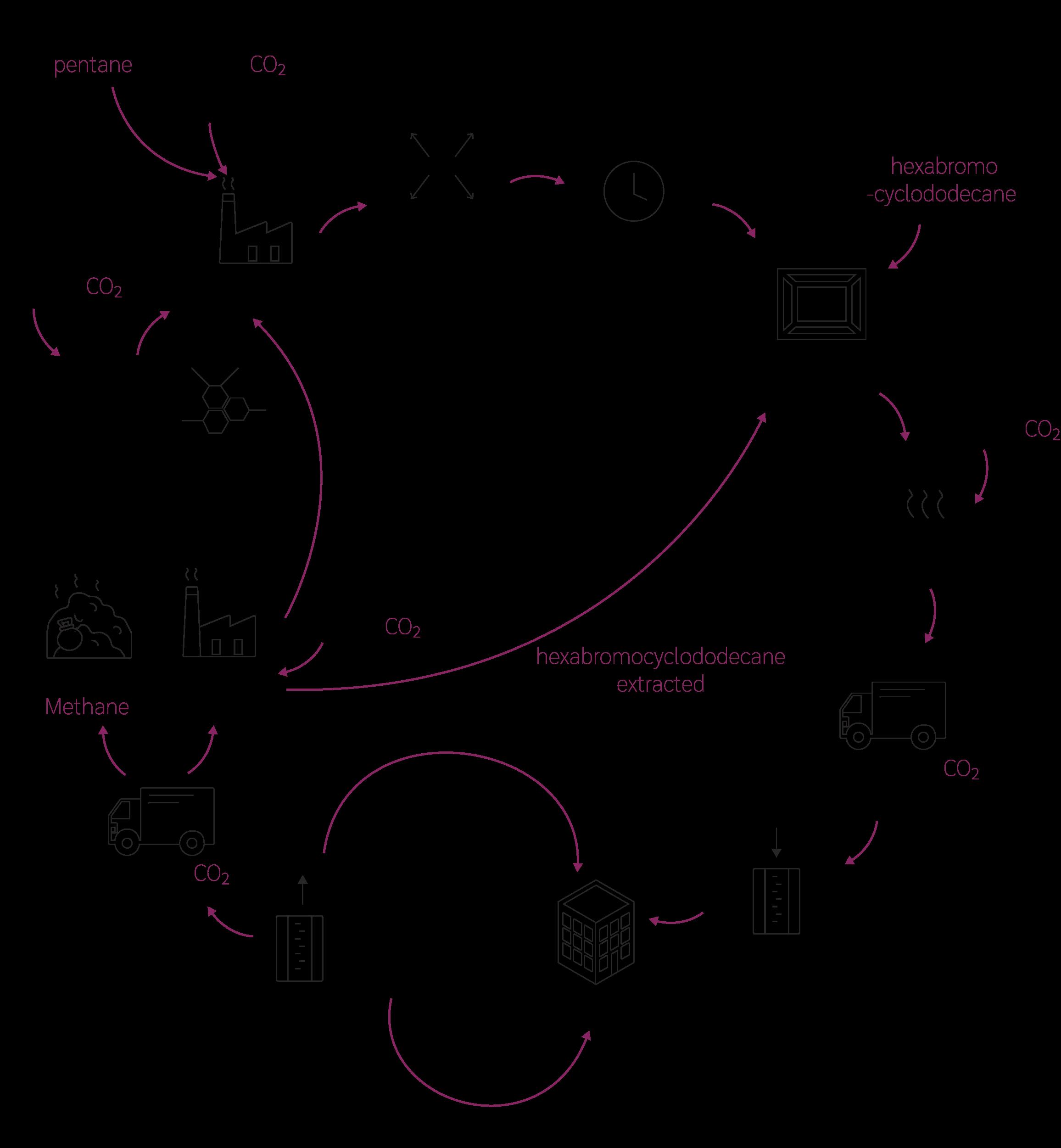

Expanded polystyrene is derived from benzene which comes from a petrochemical process, and ethylene which occurs in plants and is extracted by heating natural gas. The manufacturing process is energy-intensive and involves many stages. Recycling for rigid insulations is in its infancy. The PolyStyreneLoop corporation was founded to conduct research and build a pilot plant to recycle polystyrene foam. The foam is recycled using the CreaSolv® Process. It dissolved in a suitable solvent and then precipitated. This process is done to separate the flame retardant Hexabromocyclododecane (HBCDD) which can then be incinerated, and the bromine recovered. A life cycle assessment of this process conducted by TÜV Rheinland concludes a lower environmental impact. The use of this data is validated on a laboratory scale and will be tested when the pilot plant phase is complete (PolyStyreneLoop, 2020).

Case study design > 49

Fig. 55, Expanded Polystrene life cycle

Non loadbearing external walls options

Two types of external walls are required; one is for the main building envelope, and the second is for the balcony walls. Choosing a skeleton construction system means the external walls only need to bear their own load.

Pre-cast concrete panels have quick installation times, are durable and affordable, and can be designed with mechanical joints to allow disassembly. However, the related emissions of using concrete are very high (Jaillon and Poon, 2017). Using lime mortar in brick walls would allow the bricks to be reused at the end of life, although it would be energy and water-intensive. Timber structure walls with vertical timber cladding would have negative carbon emissions, making them a good choice for the balcony walls. Modular facade panels mounted on steel hangers with aluminum and timber framing would allow many materials to be used.

50 < Case study design Development Utility End of Life Typology Non Structural External Walls Refuse/Reduce Impact Prolong Life Recover Outputs Reused Material Optimised Manufacture Process Durable Materials Recyclable/ Renewable Materials Recycling Infrastructure Separability Biological Technical Hybrid Brick with lime mortar X X X X Concrete external walls X X X

Modular unitized panel facade system X X X

Timber frame walls will timber cladding

X X

X X X

X X X X

Fig. 56, Non loadbearing external walls comparison table

Modular facade panel material options

The service life of aluminum extends far beyond the 60-year life span identified for buildings. At the end of use phase, it can be recycled for a fraction of the energy required to use raw aluminum (Grimaud et al., 2016).

An example of options to be used as cladding could be an energy scheme where apartment owners can contribute to installing building-integrated photovoltaic panels onto the modules and receive an energy cut on their bills. Waste materials such as brick, timber, tile, or corrugated metal could also be alternatives, creating a dynamic facade with different aesthetic and cultural connotations.

Case study design > 51

Fig. 57, Aluminium life cycle

Floor finishing options

A flooring system that is adhesive and screed free will promote adaptability and disassembly and allow users to customize and change their flooring. Hardwood flooring is an option however, it is expensive to source sustainably grown timber in Germany for this purpose. There are several manufacturers of recycled carpets in Germany, but due to their shorter lifespan, maintenance issues, and design norms in the German residential market, it is not selected.

Funded by the European Union’s Research and Innovation funding program 2014 - 2020, the Circular Flooring initiative aims to prevent usable resources such as PVC from being sent to landfill, reducing harmful emissions and contamination of groundwater and soil. Flooring tiles made from recycled vinyl can be loose-laid with a click-in-place system.

52 < Case study design Development Utility End of Life Typology Flooring Refuse/Reduce Impact Prolong Life Recover Outputs Reused Material Optimised Manufacture Process Durable Materials Recyclable/ Renewable Materials Recycling Infrastructure Separability Biological Technical Hybrid Recycled vinyl flooring X X X X Ceramic tiles X X X X X Hardwood flooring X X X X X X Carpet from recycled materials X X X X

Fig. 58, Floor finishing comparison table

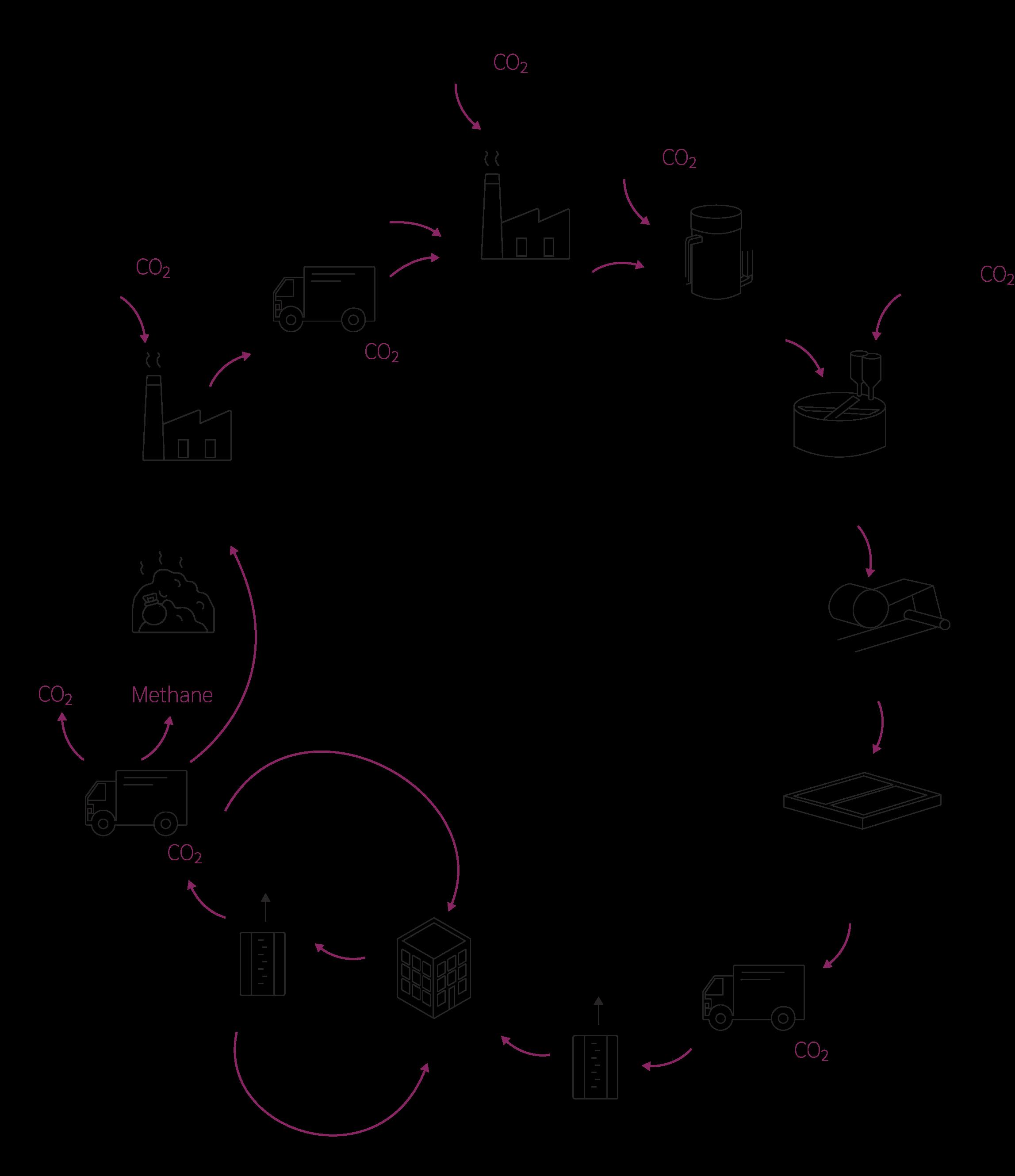

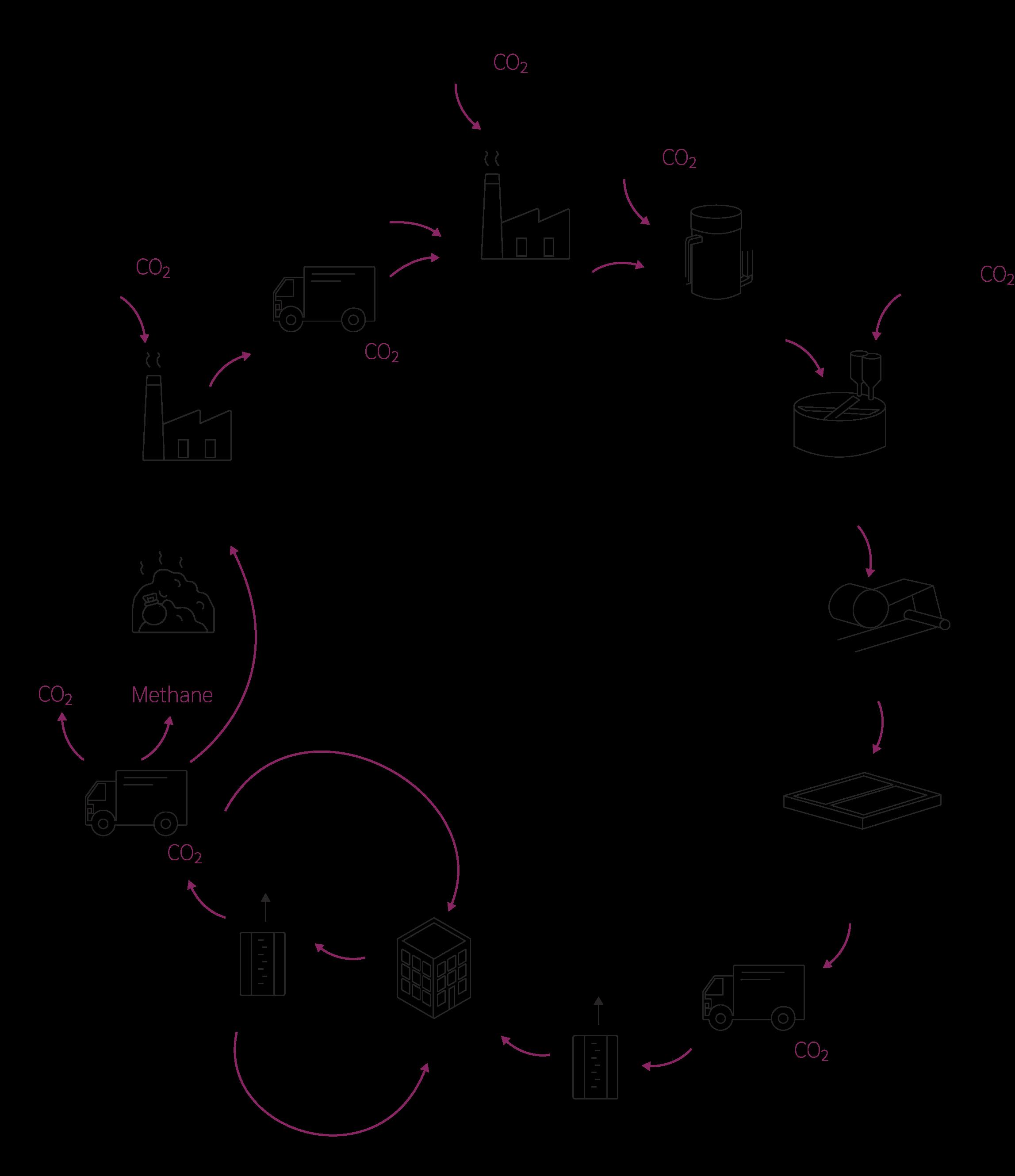

Recycled vinyl flooring

Similar alternate options are available in Germany but Tarkett was selected for the analysis due to their transparent manufacturing process. Tarkett is an international flooring company that works with local materials, and Recovinyl and VinylPlus participate in EU Circular Plastic Alliance by collecting and processing post-consumer plastic waste. Their PVC flooring system uses 15% recycled and 16% renewable materials to reduce the amount of virgin materials being used. They are developing phthalate-free plasticizers, using 65% renewable energy at processing plants. The carpet recycling facility in Ronneby, Sweden, enables Tarkett to fully close the loop on the life cycle of commercial vinyl. Their click-in-place flooring allows for adhesive-free installation and uninstallation for reuse or recycling at the end of life (Tarkett, 2021).

Case study design > 53

Fig. 59, Recycled PVC flooring life cycle

Internal wall system options

Standard internal wall materials and construction include framing, drywall, and plaster applied. When the internal layout is upgraded, the plasterboard is usually demolished and sent to be recycled or to landfill. A solution is to install the frame for the cladding materials on a steel channel so they can be disassembled and reused at the end of life. Cladding manufacturers like Gyproc produce steel channels with an integral neoprene acoustic isolator to reduce impact sound transmission (Gyproc Saint-Gobain, 2020).

The the options being considered for cladding materials are boards that are cut to a standard size so they can be used in other locations when the space plan changes, such as gypsum, plywood, and oriented strand board (OSB). Multiple options will be selected for use in different locations. For example, gypsum will be used in the circulation cores and fire escape routes due to its fire protection properties (Quintana et al., 2018).

54 < Case study design Development Utility End of Life Typology Internal wall Refuse/Reduce Impact Prolong Life Recover Outputs Reused Material Optimised Manufacture Process Durable Materials Recyclable/ Renewable Materials Recycling Infrastructure Separability Biological Technical Hybrid Steel channel acoustic rails X

Juuno internal wall system X X

Plywood internal walls Gysum drywall

X X X

X X

Fig. 60, Internal walls comparison table

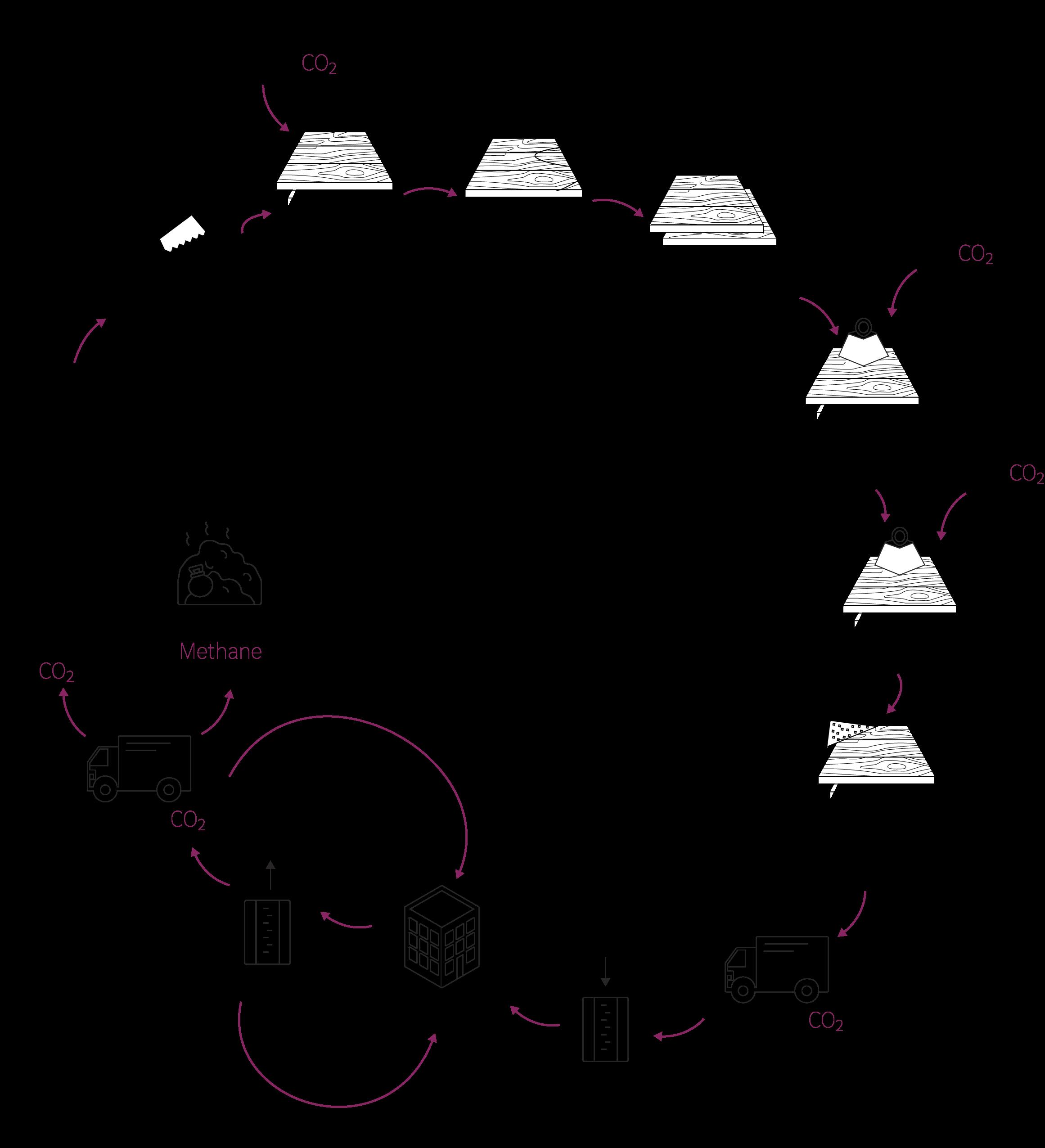

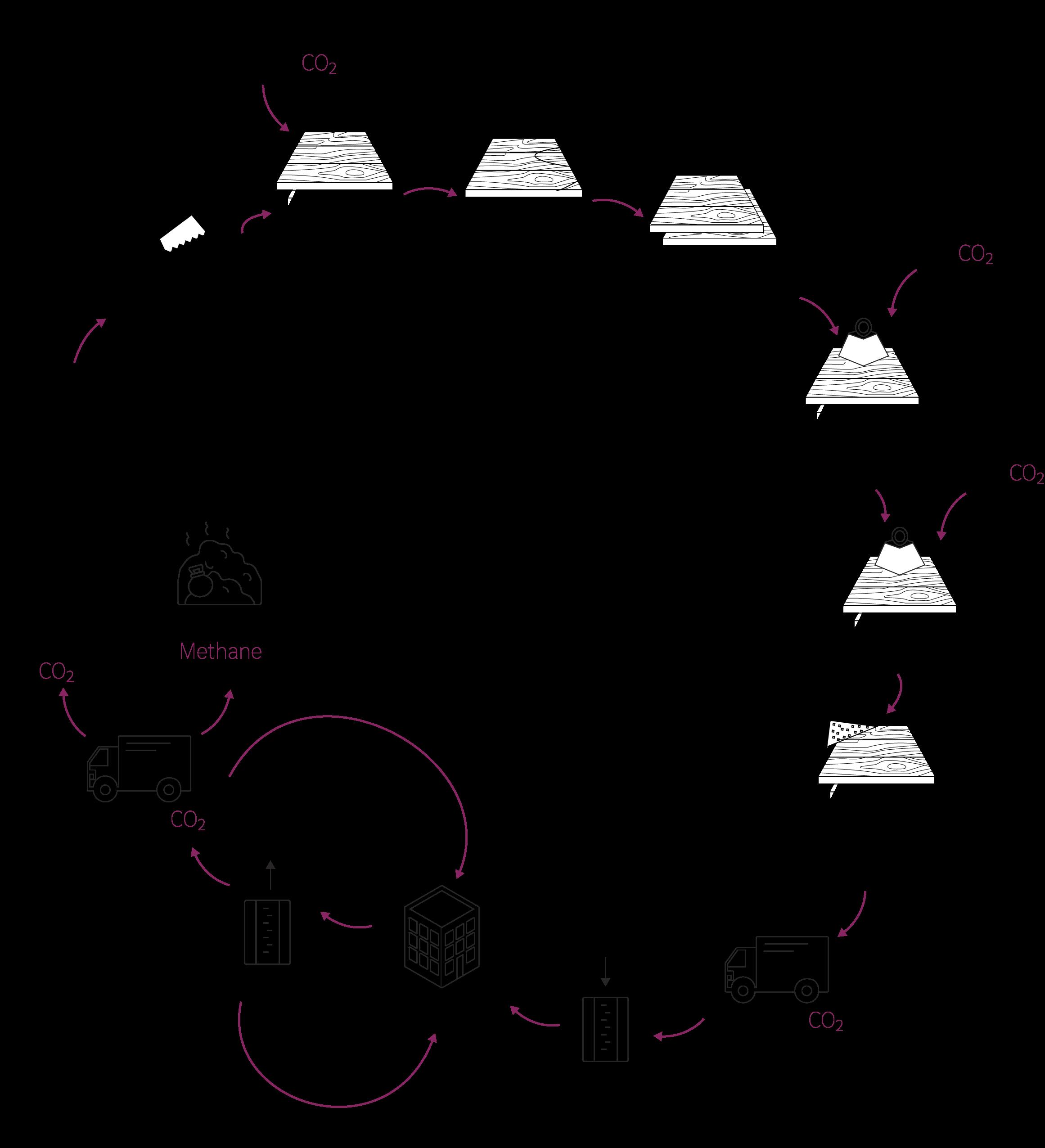

Plywood internal wall cladding

Plywood produced from sustainable forestry and attached with mechanical fixings can be easily disassembled and reused, upcycled, or downcycled at the end of life. They can be used in dry or moderately humid indoor area, and are expected to have the same service life as structural wood at over 100 years. They are made of birch wood, glue and a protective agent (UPM Plywood Oy, 2019). However, most timber for plywood is grown and processed in China. This would involve very high related emissions. Plywood as a cladding option in this scenario is based upon European manufactured plywood if the budget for the project allows it.

Case study design > 55

Fig. 61, Plywood cladding life cycle

Gypsum internal wall cladding

Gypsum is made from sulphate dihydrate. Its properties can be repeatedly changed through a reversible hydration reaction. Recycling gypsum reduces emissions and contributes to meeting the European guidelines for construction and demolition waste disposal (Jiménez Rivero, Sathre and García Navarro, 2016).

MUEG Mitteldeutsche Umwelt und Entsorgung GmbG was Germany’s first stationary treatment plant for recycling of gypsum containing waste. It was opened in 2014. The accept gypsum boards, moulting plaster and cacium sulphate raw material and sell finely ground gypsum to be converted to gypsum boards by manufacturers. There is currently operational factory in Saxony, and an interest to expand to Berlin in the future (MUEG Mitteldeutsche Umwelt- und Entsorgung GmbH, n.d.).

56 < Case study design

Fig. 62, Gypsum board life cycle

Prefabricated bathroom modules

Wet areas are complex to design without using screed and waterproofing layers. In multistorey buildings, the potential for mould to enter the structural elements would have costly results. This issue can be solved either by using non-deconstructable layering or through the use of prefabricated modules. Customizable prefabricated bathroom modules come with walls, ceilings, and floors cast in reinforced concrete. The floors are cast in an upside-down tray-like mould. The elements have waterproofing and sealants. They provide an easy solution and work with local manufacturers that use high quality environmentally friendly products (Hellweg Badsystem, 2013).

Modular planters on roof

Green roofs and swales are integral design features in the Rummelsburg area as there is no conventional stormwater drainage (Gloria Kurnik, 2017). Traditional green roof systems require material layering that does not lend to disassembly. An alternative is to use modular planter boxes encased in concrete with independent waterproofing. The planter boxes would have discharge points to drain water into a drainage system.

Elevator

There are two main type of eevator systems, traction and hydraulic. Hydraulic elevators are free standing and works on a piston system where vegetable oil is used to move the lift car up and gravitational force to push it down. Using a machine room-less hyraulic system allows all the mechanisms to be located in the hoistway (Hussey, 2018). This option is preferrred to comply with the principles outlined by Durmisevic to seperate the functions in a building (2006).

Staircase

The Musterbauordnung is the building model code in Germany. The code states that buildings must have two means of eggress. The second mode of eggress is not required if the first mode is a pressurized fire stair core. As the building is under the 22 meter limit above which a building is classified as a high rise, the balconies and windows can be considered as the second mode of egress as aeiral apparatuses can reach them (Speckert, 2020).

The internal walls of the circulation cores will be clad with a fire rated gypsum cladding and the staircase structure will have a fire resistant cover to the underside of the staircase to meet fire regulations. The staircase will have an independent load bearing structure to meet the Design for Disassembly principles outlined by Durmisevic (2006).

Case study design > 57

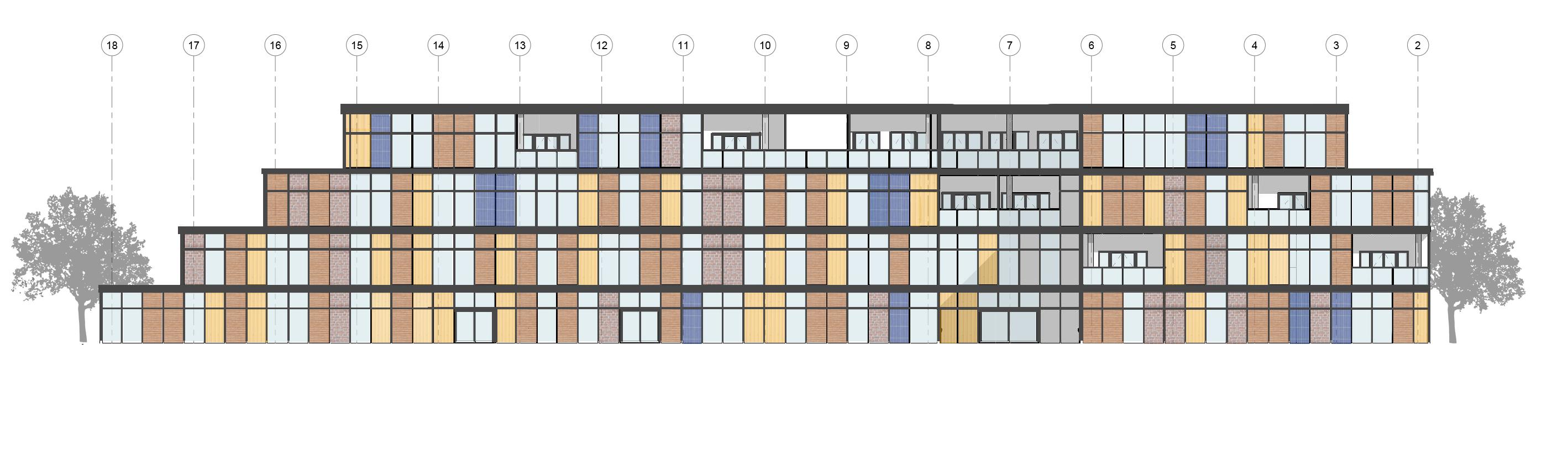

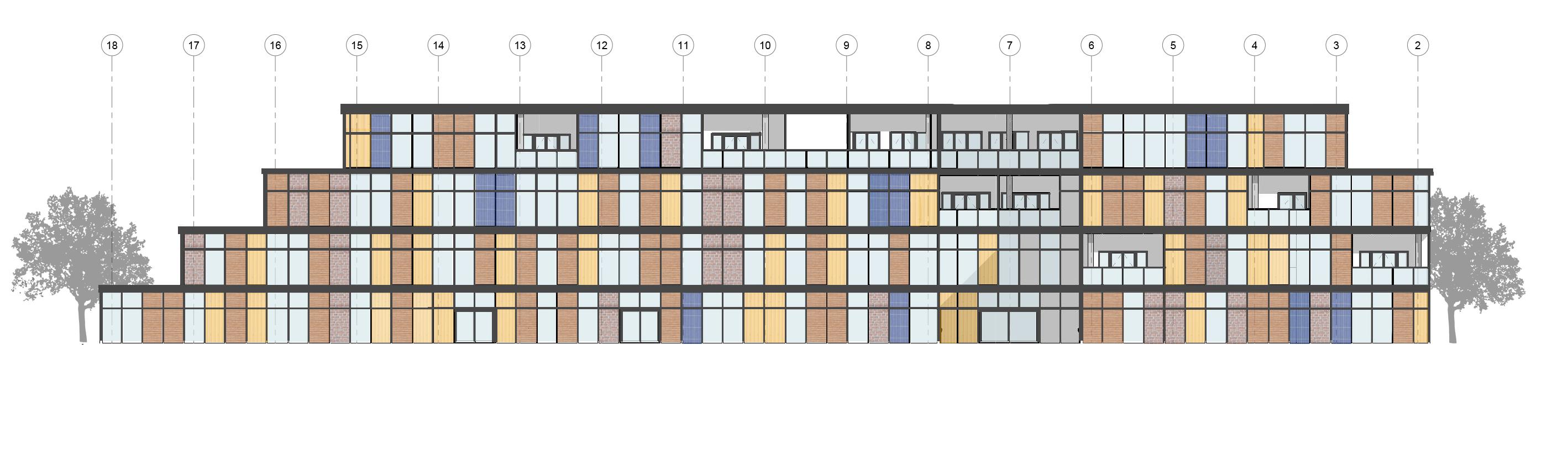

3.5 Final design

3D views from Rummelsburger See

58 < Case study design

Community garden and landscaping

South facing facade

South facing facade panorama

3D views from Hauptstraße

Case study design > 59

North facing facade

North facing facade panorama

Connection point from Rummelsburg S-Bahn, tramstop and bus stop

Site Plan

Main Access from Hauptstraße, secondary access from Rummelsburger See promenade . Access routes from the West towards Ostkreuzr railway station. Delivery access points from Hauptstraße and West entrance.

Hauptstrasse

Rummelsburger See

60 < Case study design

First Floor Plan Program:

cafe, co-working space, gym, packet store, convenience store, flexible space for cultural and social events, zero waste food store, upcycling workshop, outdoor community garden,

Case study design > 61

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 A B C D E F G H J K L M 1 2 5 10

Second Floor Plan Program:

laundry room mixed apartments - share house, family apartments, individual apartments

62 < Case study design 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 A B C D E F G H I J K L M 54 m² Circulation 2 200.b

1 2 5 10

Third Floor Plan Program: mixed apartments - share house, family apartments, individual apartments

Case study design > 63 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 A B C D E F G H I J K L M

1 2 5 10

Fourth Floor Plan Program: mixed apartments - larger rooms

64 < Case study design

DN 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 A B C D E F G H I J K L M 1 2 5 10

Case study design > 65 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 A B C D E F G H J K L M

1 2 5 10

Roof Plan

1 2 5 10 1 2 5 10

Case study design > 67 South elevation North elevation 1 2 5 10 1 2 5 10

68 < Case study design

Section A-A

1 2 5 10 1 2 5 10 A A B B

Section B-B

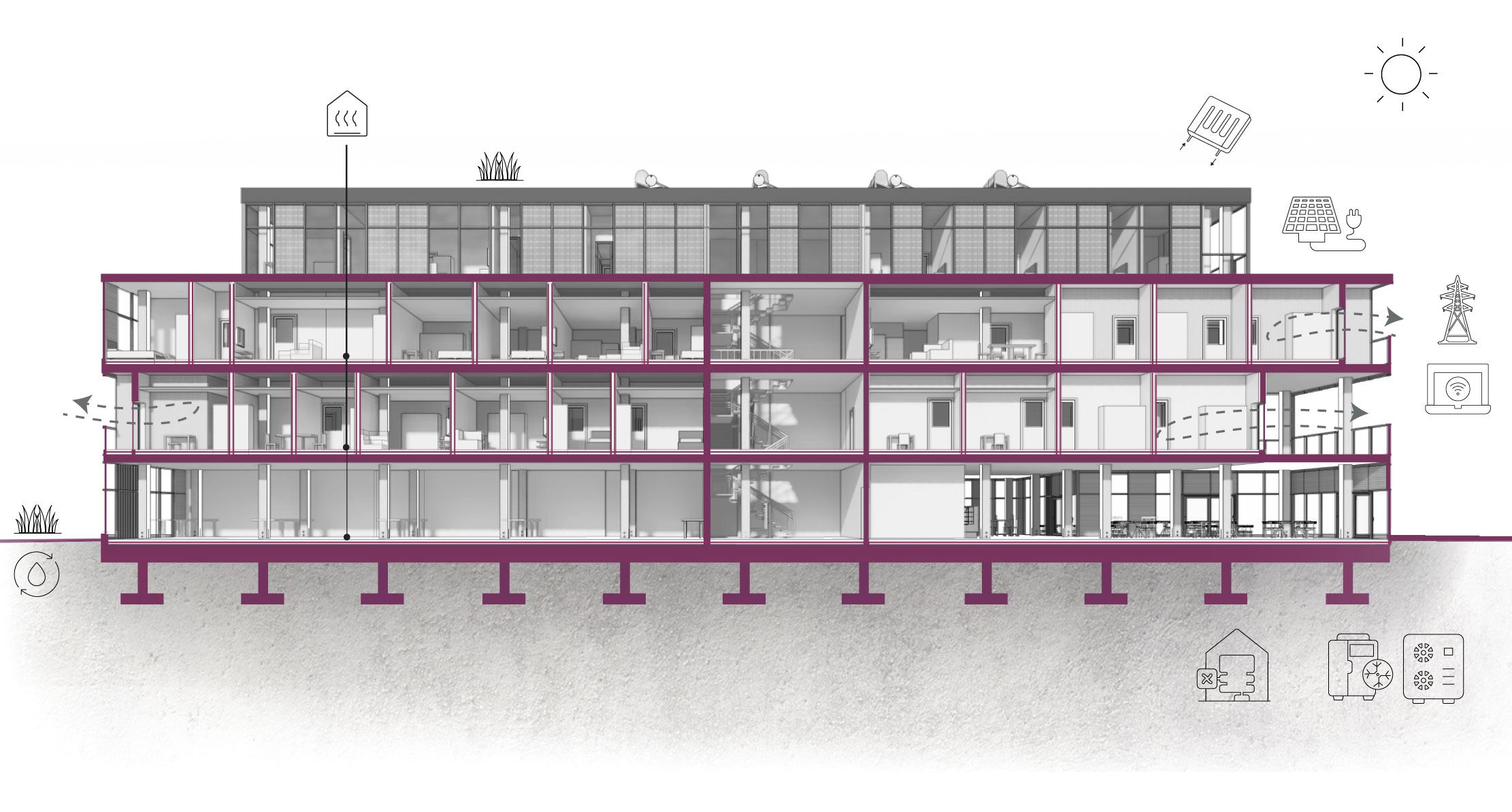

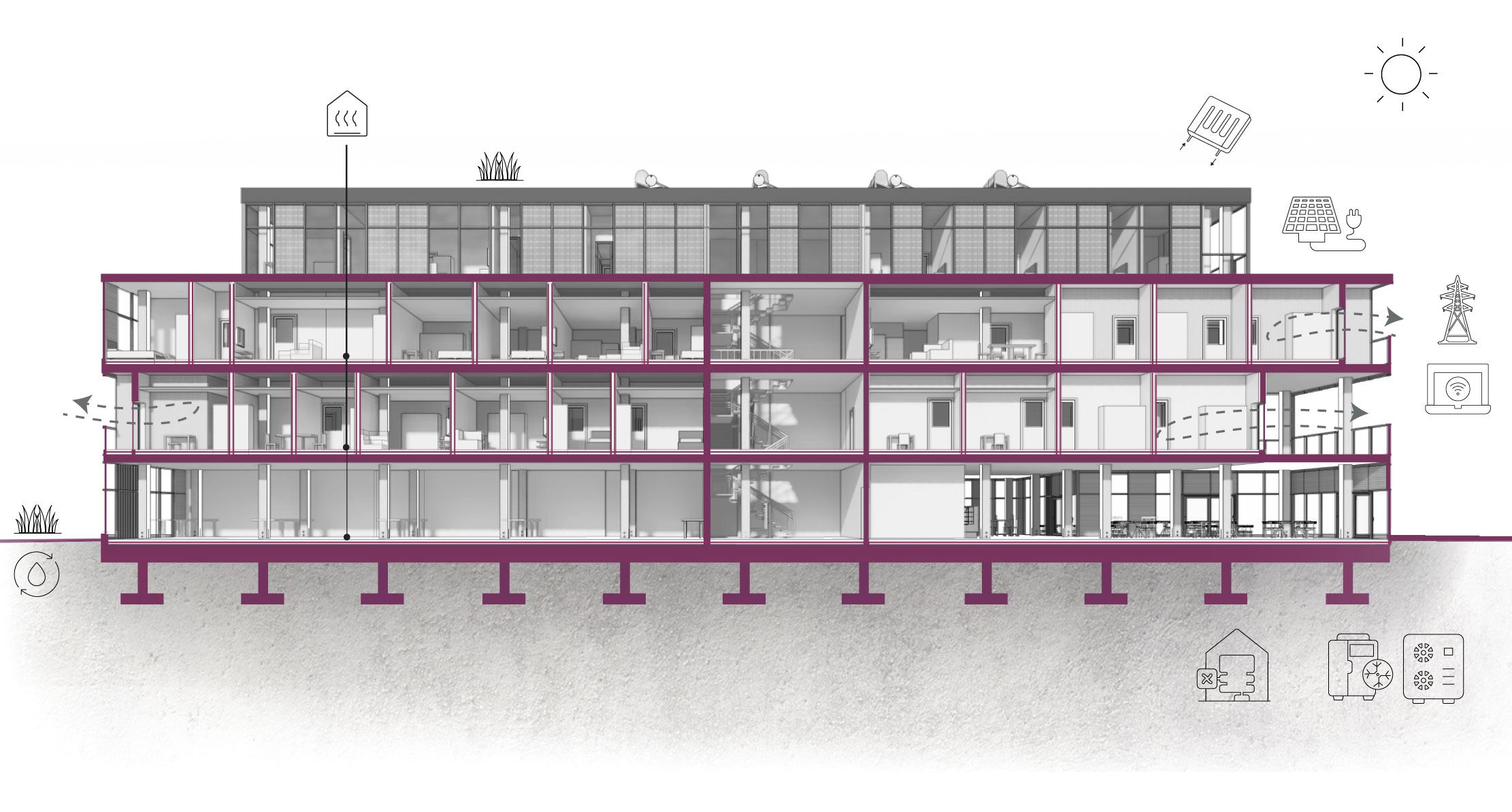

Case study design > 69 Energy system strategy section

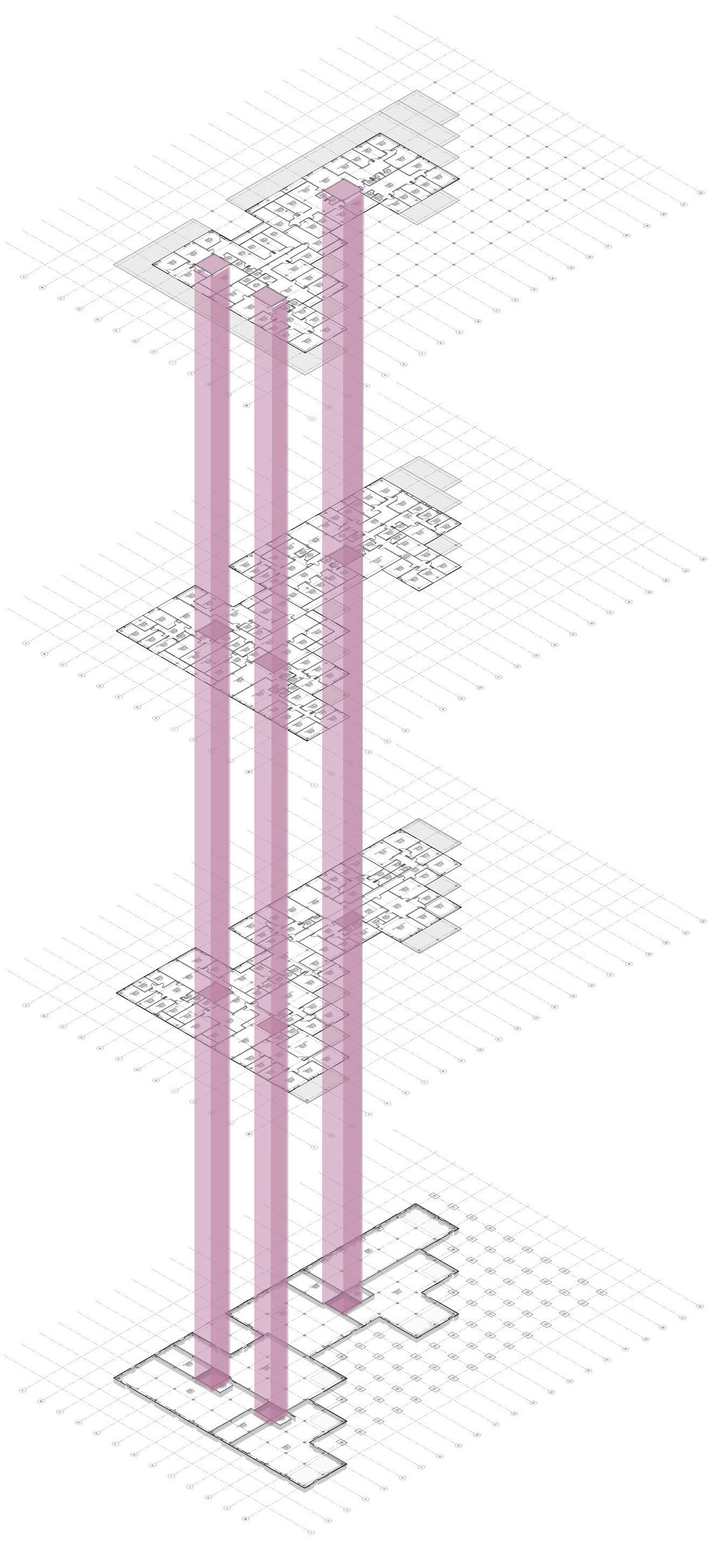

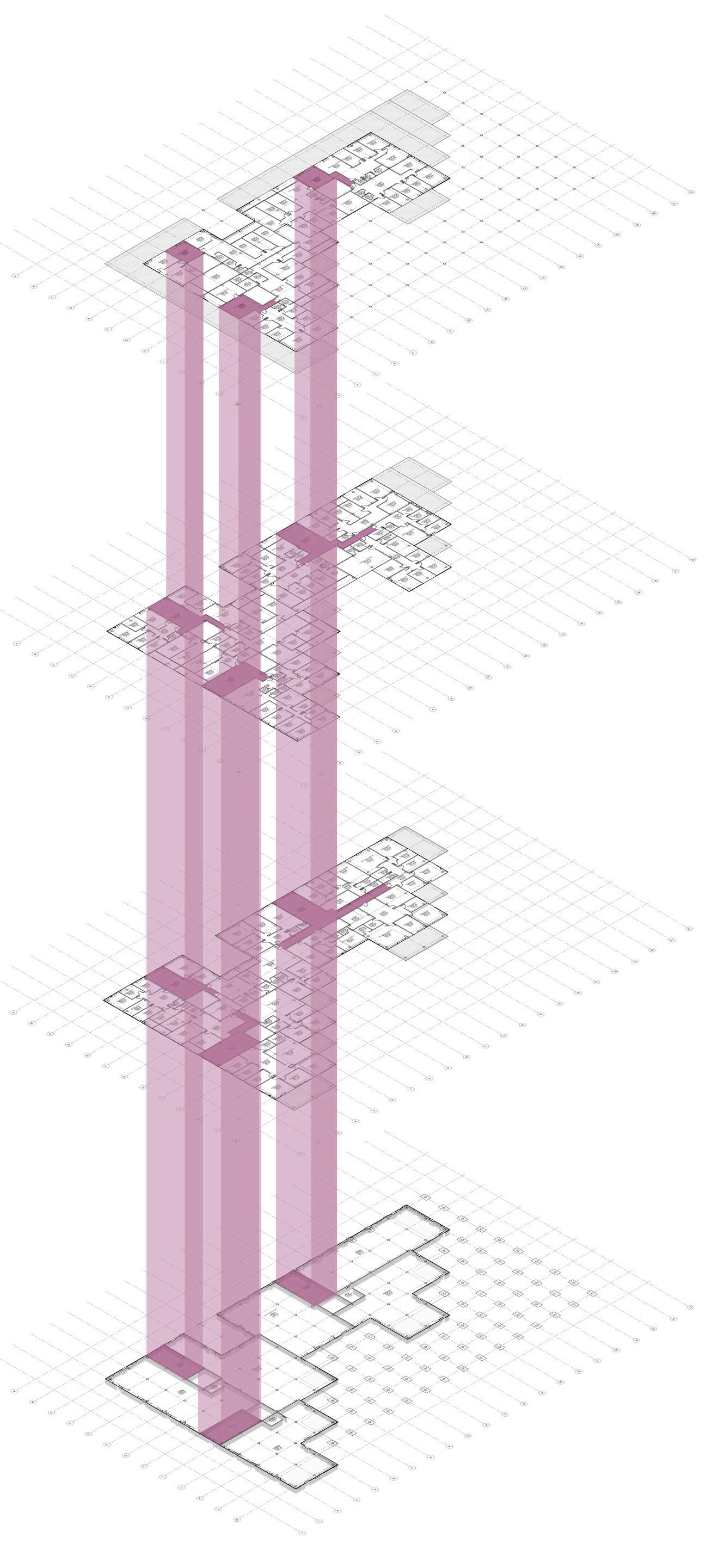

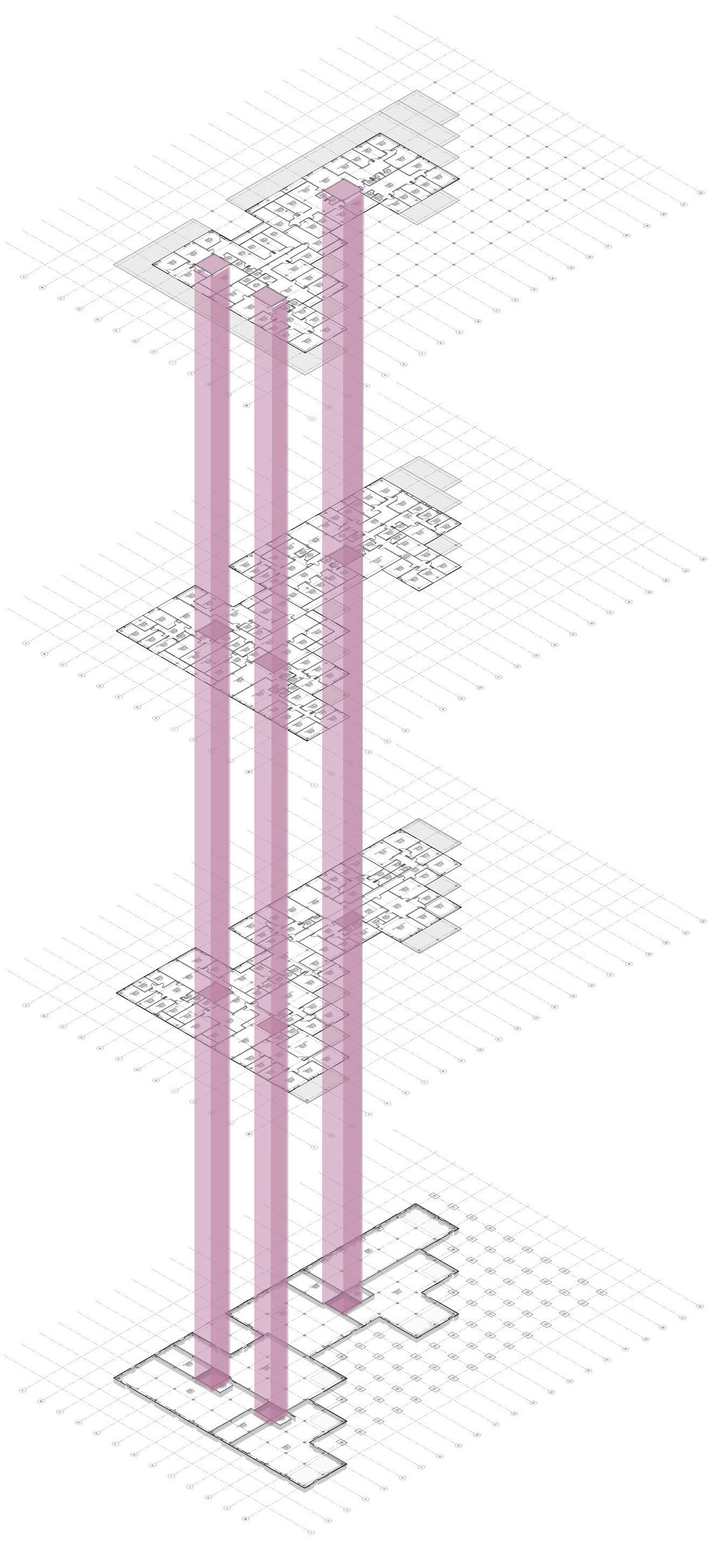

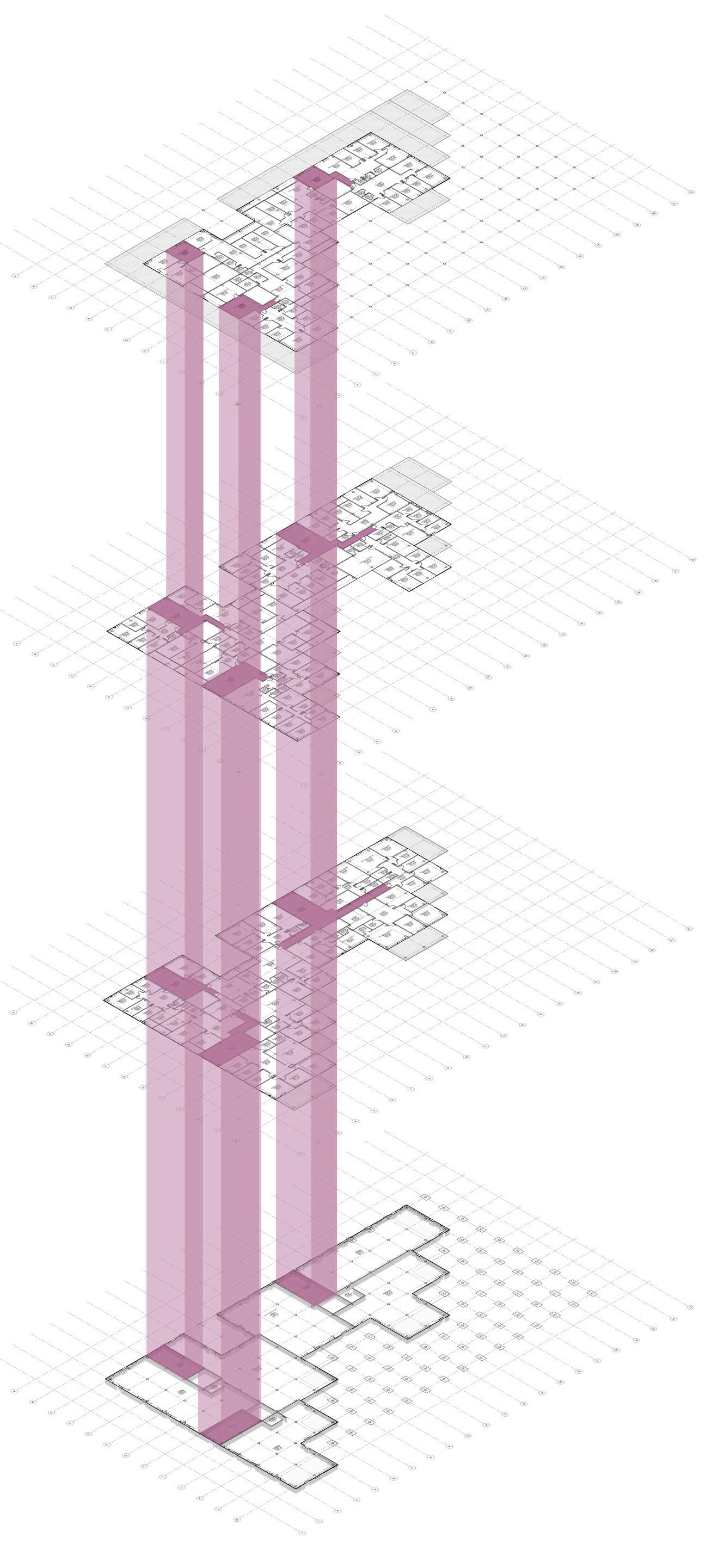

Circulation and MEP Cores

The circulation and technical cores are adjacent to each other. They function as circulation spaces for people but also centralised locations for plumbing and technical services.

Circulation core

Technical services core

70 < Case study design

Fig. 63, Circulation core and technical core diagram

Designing for disassembly

Based on the state of the art review, the design of material layering and connection points is imperative in achieving a design that is suited for disassembly. The selection of the systems have taken into consideration the principles of function, technical and physical decomposition where possible.

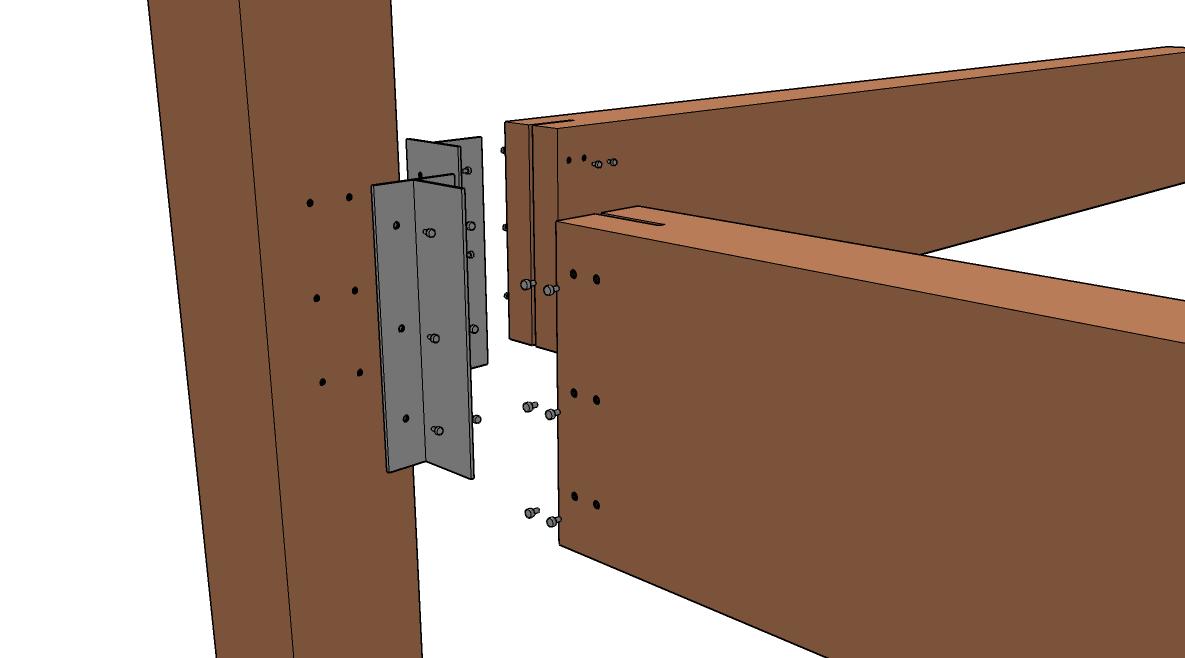

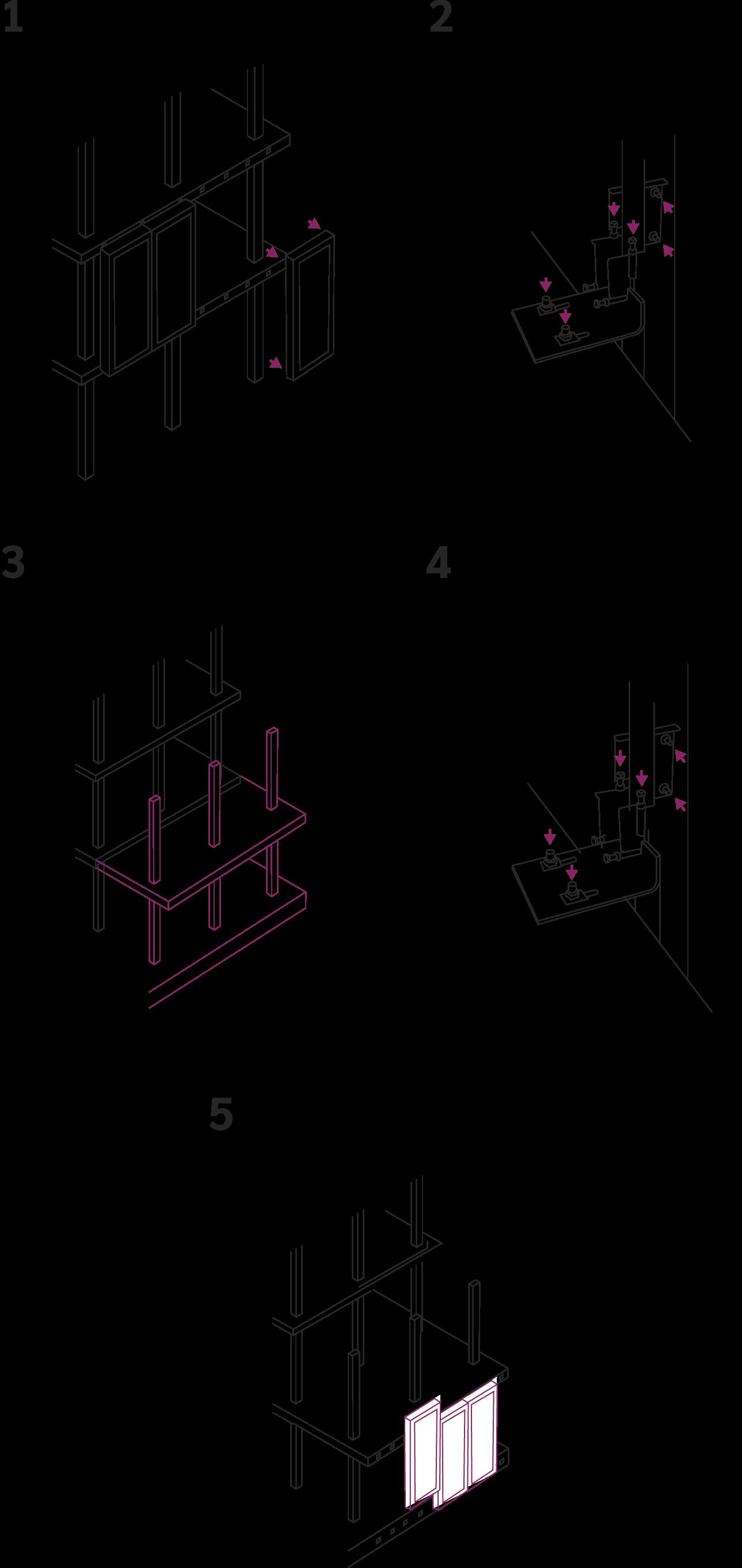

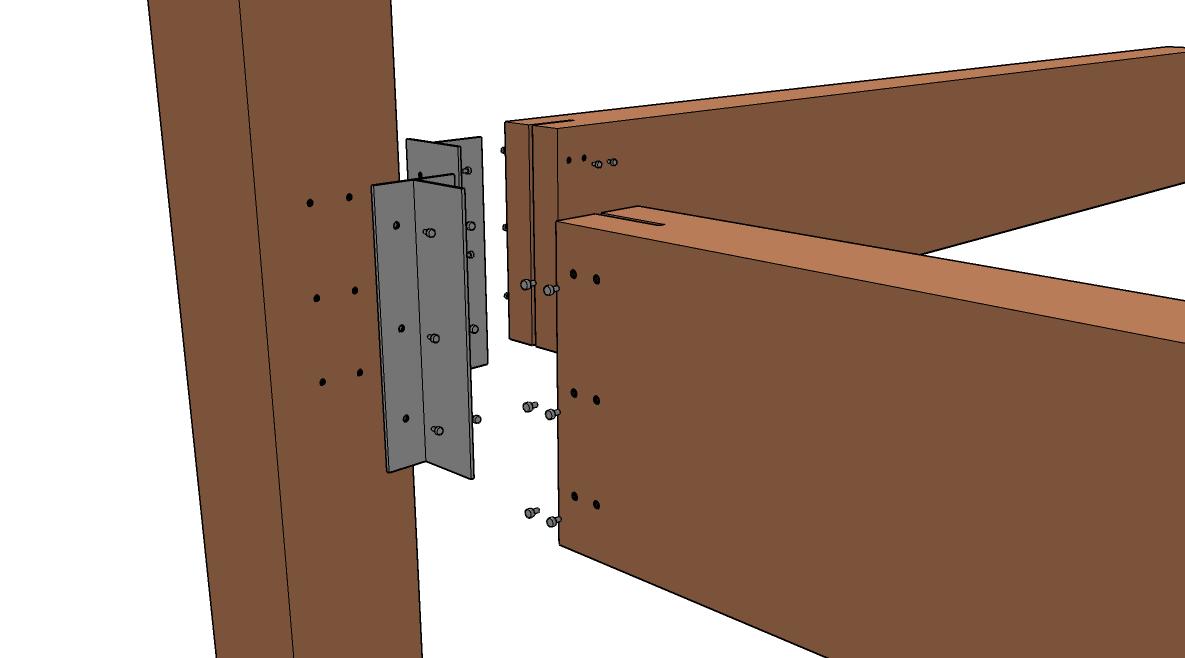

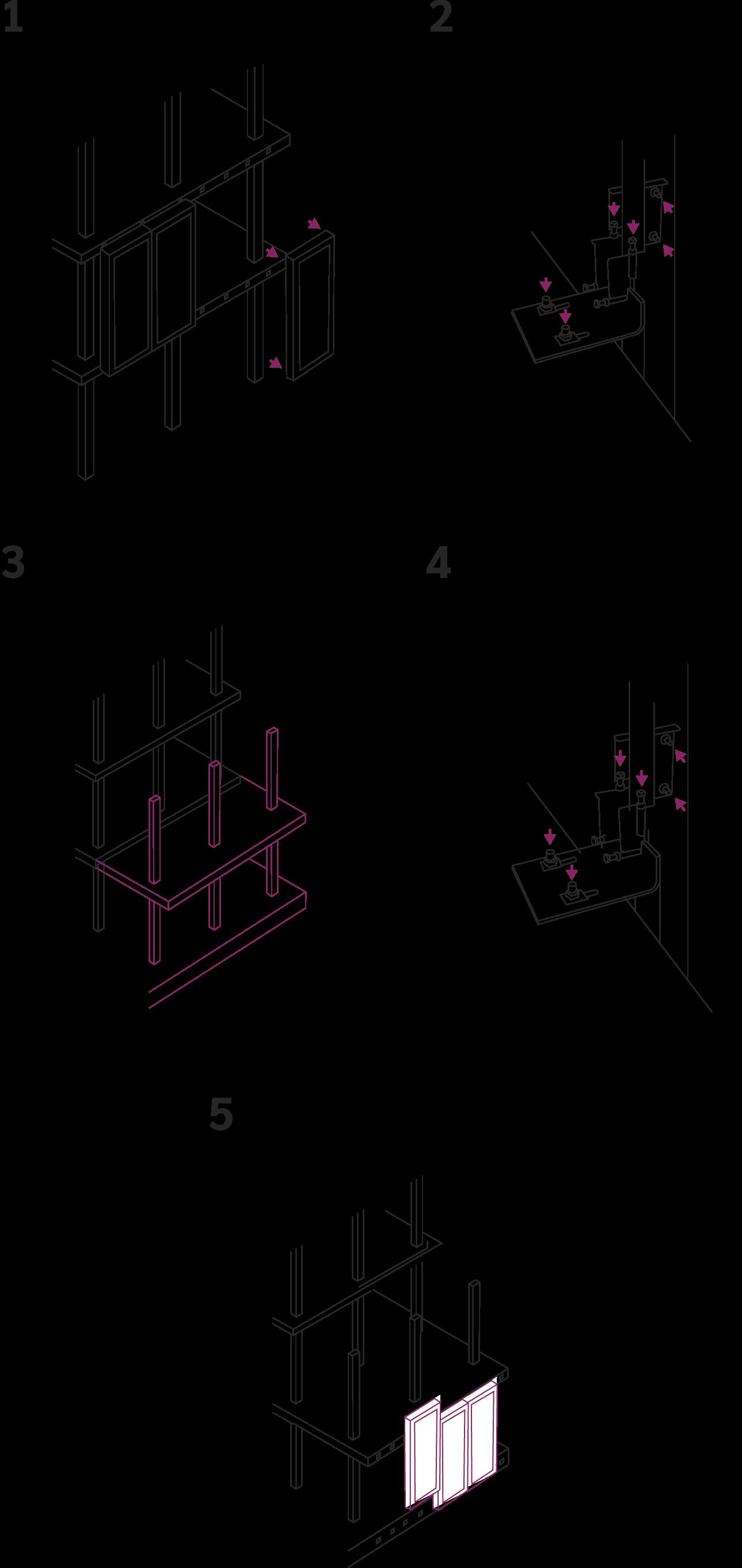

Column and beam assembly

Glulam beams can be connected with mechanical fasteners for disassembly. There are multiple detail options for this, including a concealed plate version; however, the aesthetic of revealing the connections and emphasizing the disassembly is part of the design language.

Case study design > 71

1. Glulam column

2.Connection plate

3. Bolts for connection plate

4. Glulam beam

1 3 4 2

3.6 Assembly

Fig. 64, Column and beam assembly diagram

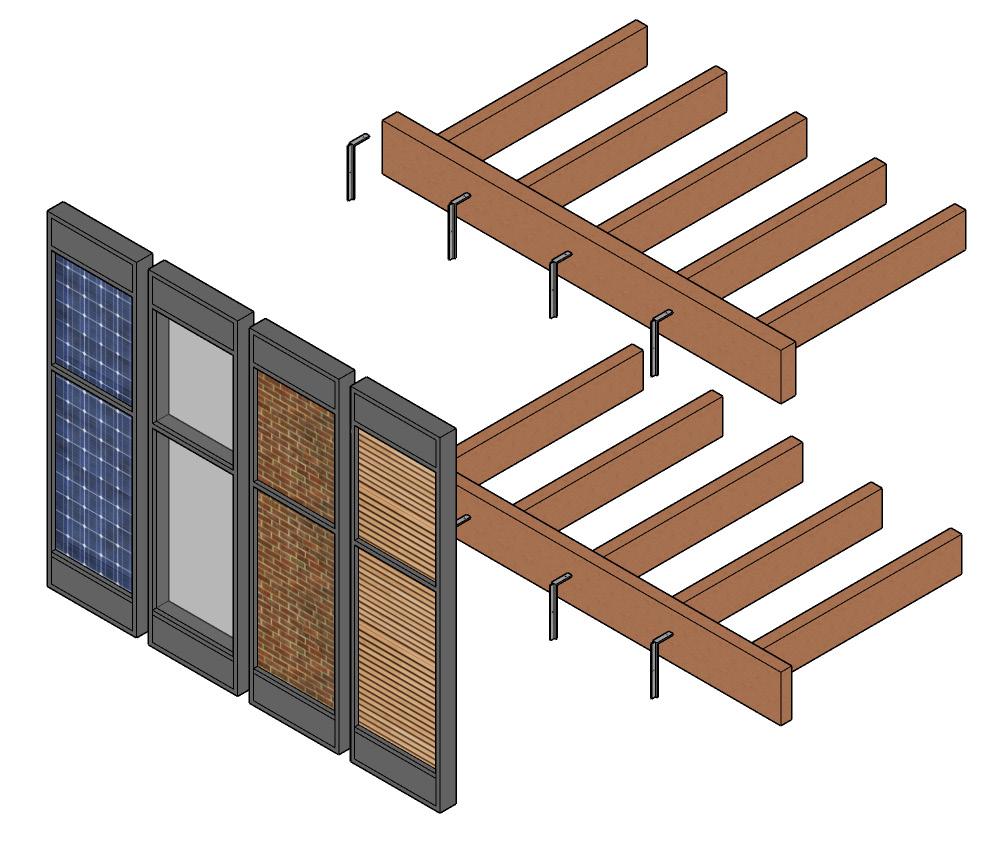

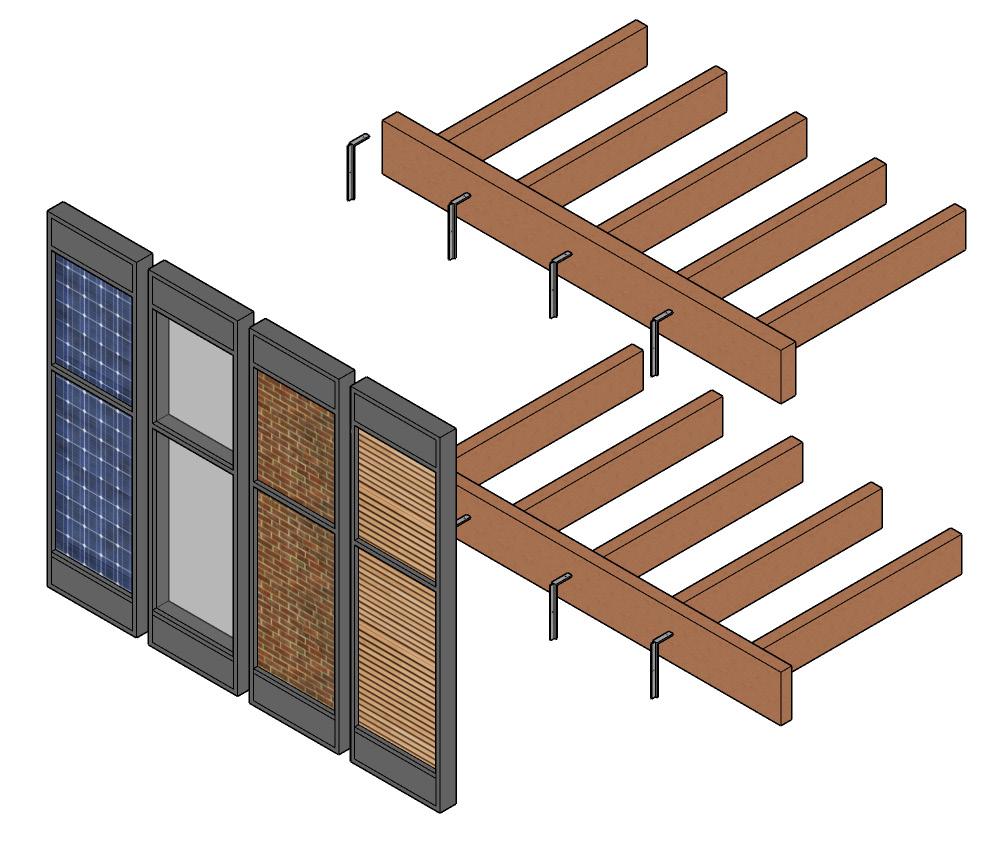

Modular facade panel assembly

Unitized panels installed onto steel facade hangers. Panels with multiple cladding options : upcycled wood cladding, reused brick cladding, triple glazing, building integrated photovoltaic panels.

72 < Case study design

3 2

1

1. Modular panels

2. Hanging brackets

3. Glulam floor structure

Fig. 65, Module facade panel assembly diagram

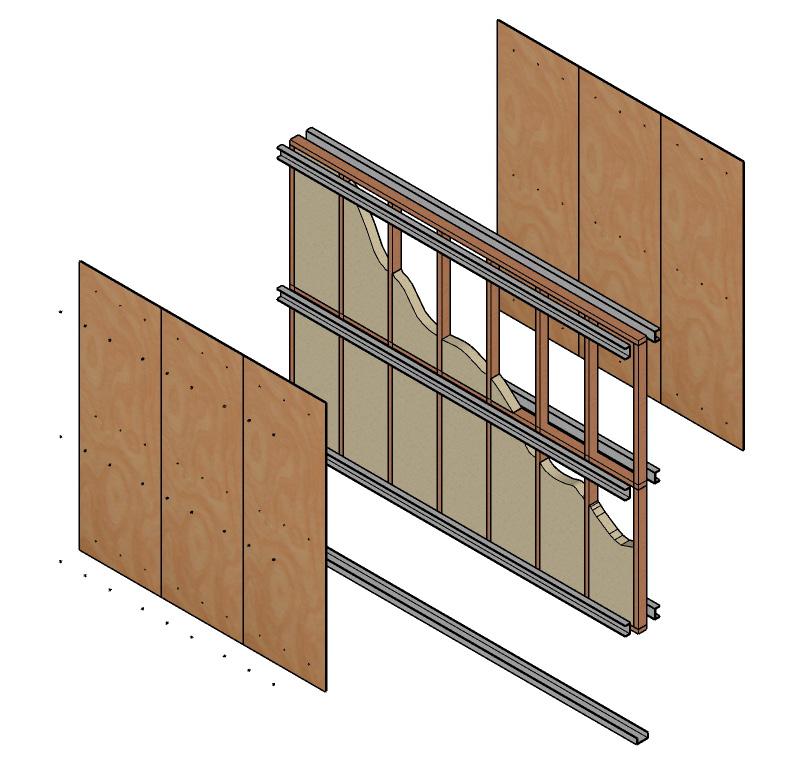

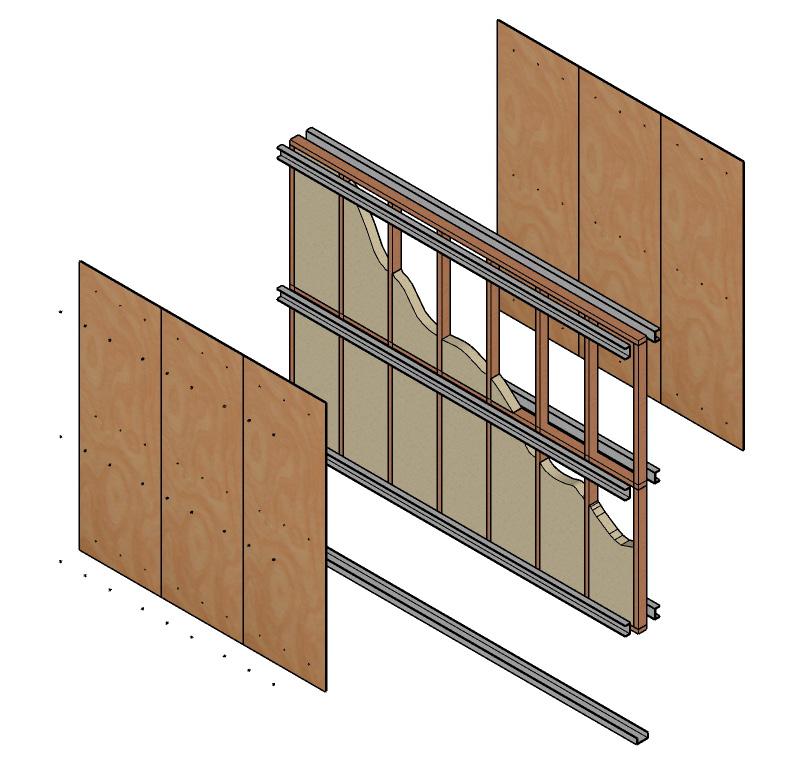

Internal wall assembly

Case study design > 73 1 2 3

4 6 7

1. Countersunk screws

2.Plywood internal cladding

3. Base plate to fix internal walls

Timber frame internal wall construction, with brackets to attach internal cladding.

4. Metal hanging bracket

5. Cellulose fiber insulation

6. Timber stud frame

7. Plywood internal cladding

5

Fig. 66, Internal wall assembly diagram

74 < Case study design

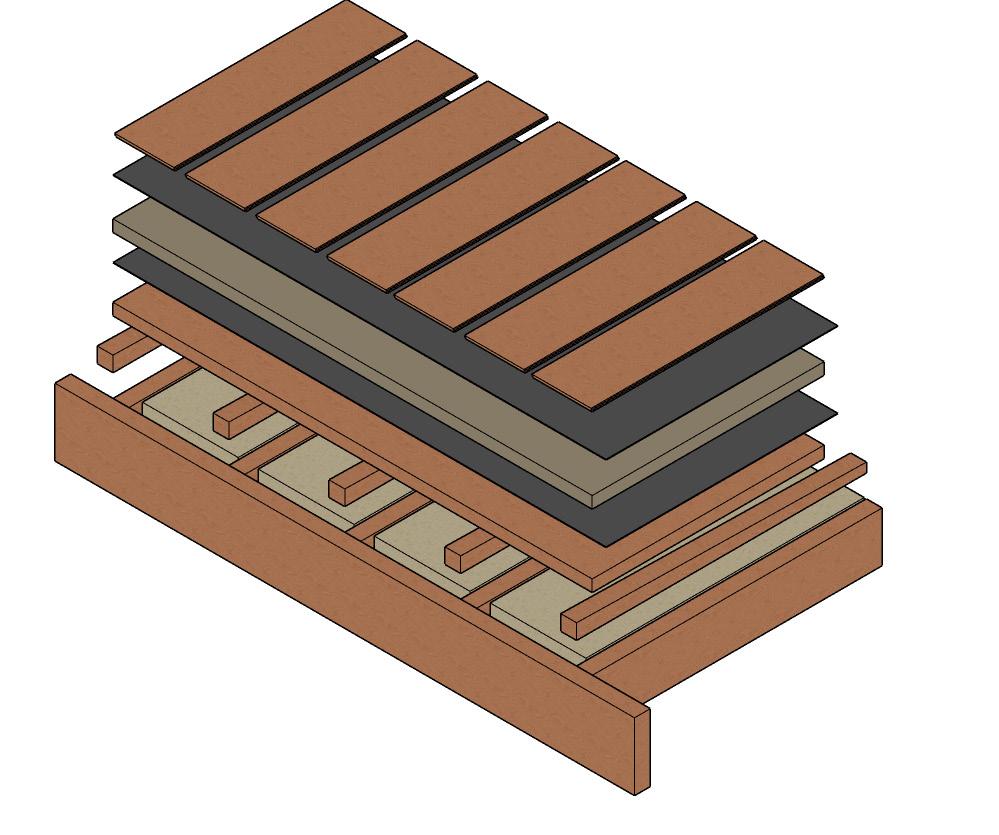

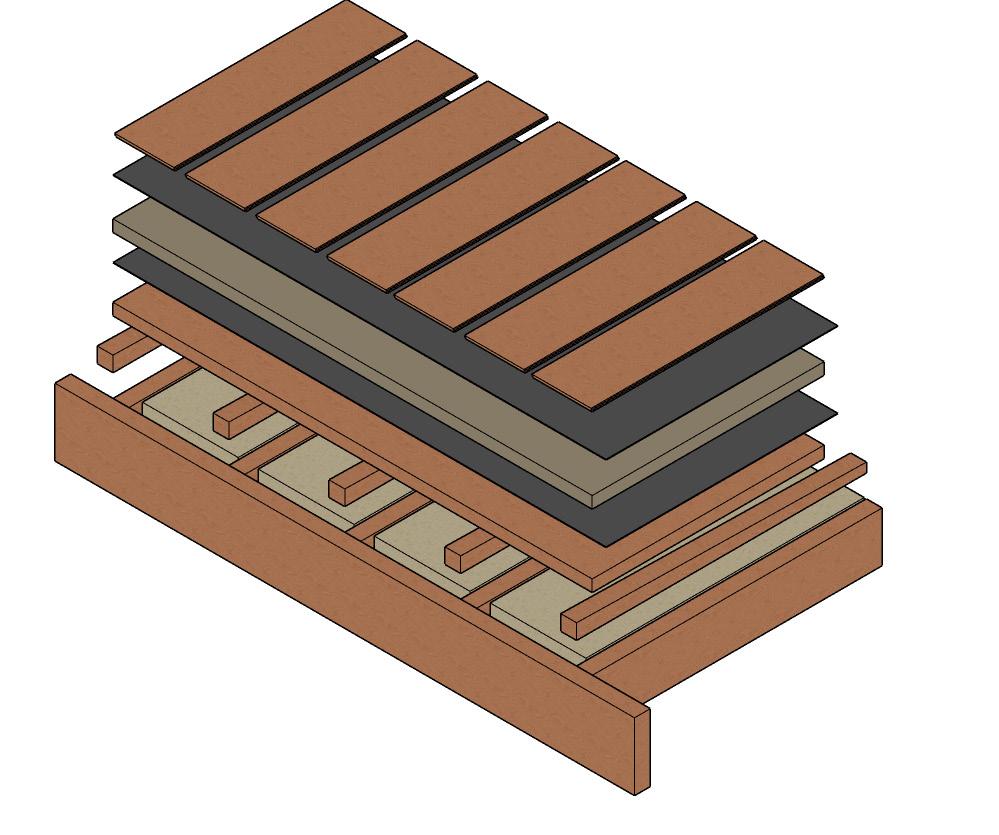

Floor to foundation slab assembly

First floor installed onto concrete foundation.

1. Concrete slab to grade

2. Waterproofing membrane

3. EPS rigid floor insulation

4. Glulam floor structure

5. Cellulose fiber insulation

6. Cross laminated timber layers

7. Aluminium plate with heating tubes

8. Vapour proof membrane non adhesive

1 2 3 4 5 6 7 8 9

9. Click in place flooring

Fig. 67, Floor to foundation slab assembly

Case study design > 75

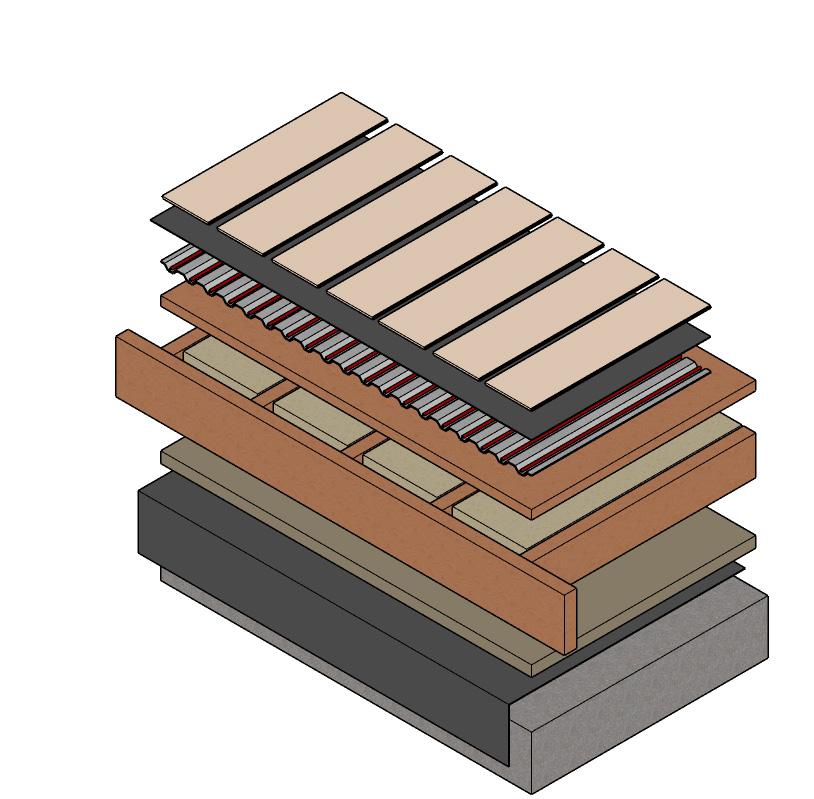

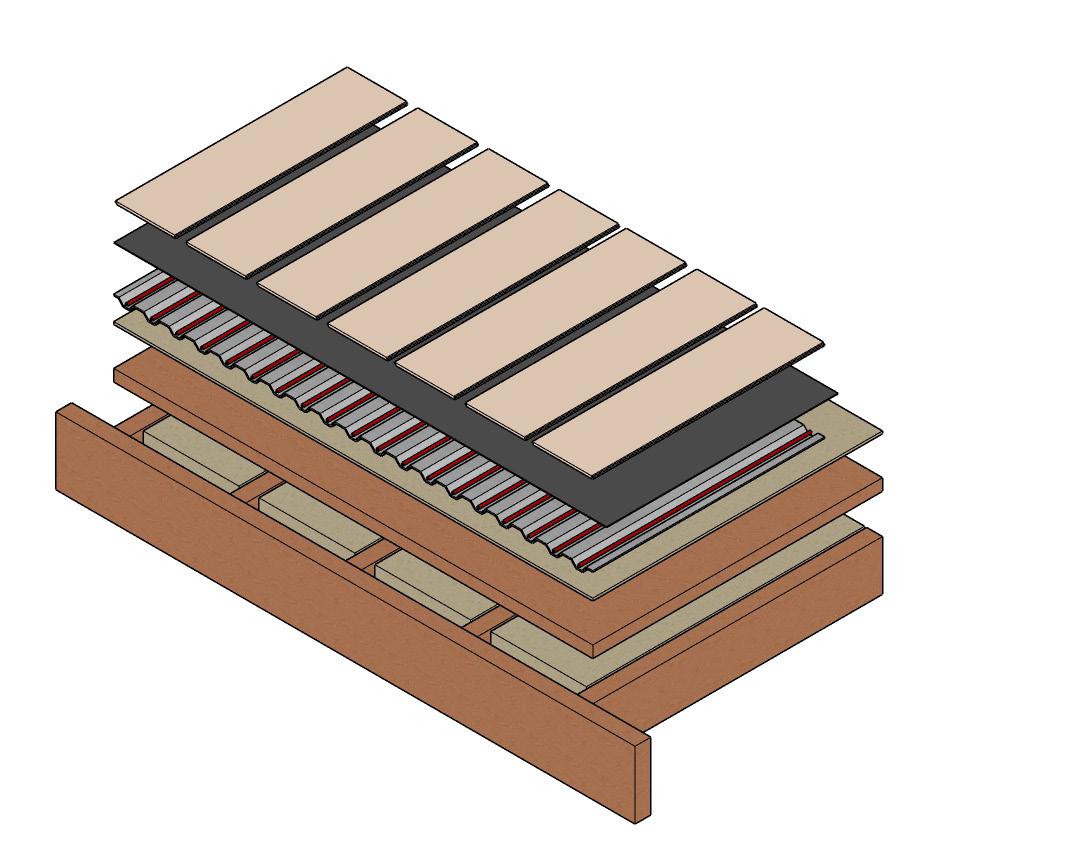

Intermediate floor structure assembly

Second and Third floor construction.

1. Glulam floor structure

2. Cellulose fiber insulation

3. Cross laminated timber

1 2 3 4 5 6 7

4. EPS rigid floor insulation

5. Aluminium plate with heating tubes

6. Vapour proof membrane non adhesive

7. Click in place flooring

Fig. 68, Intermediate floor structure assembly

76 < Case study design

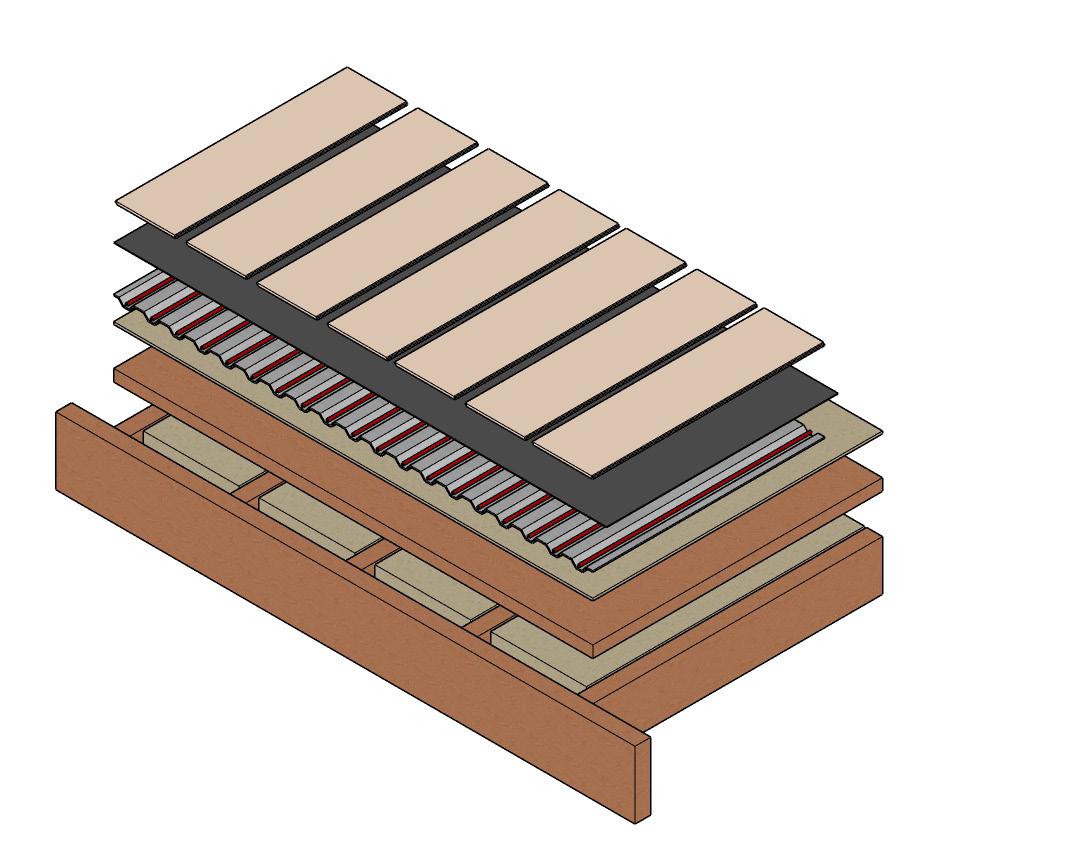

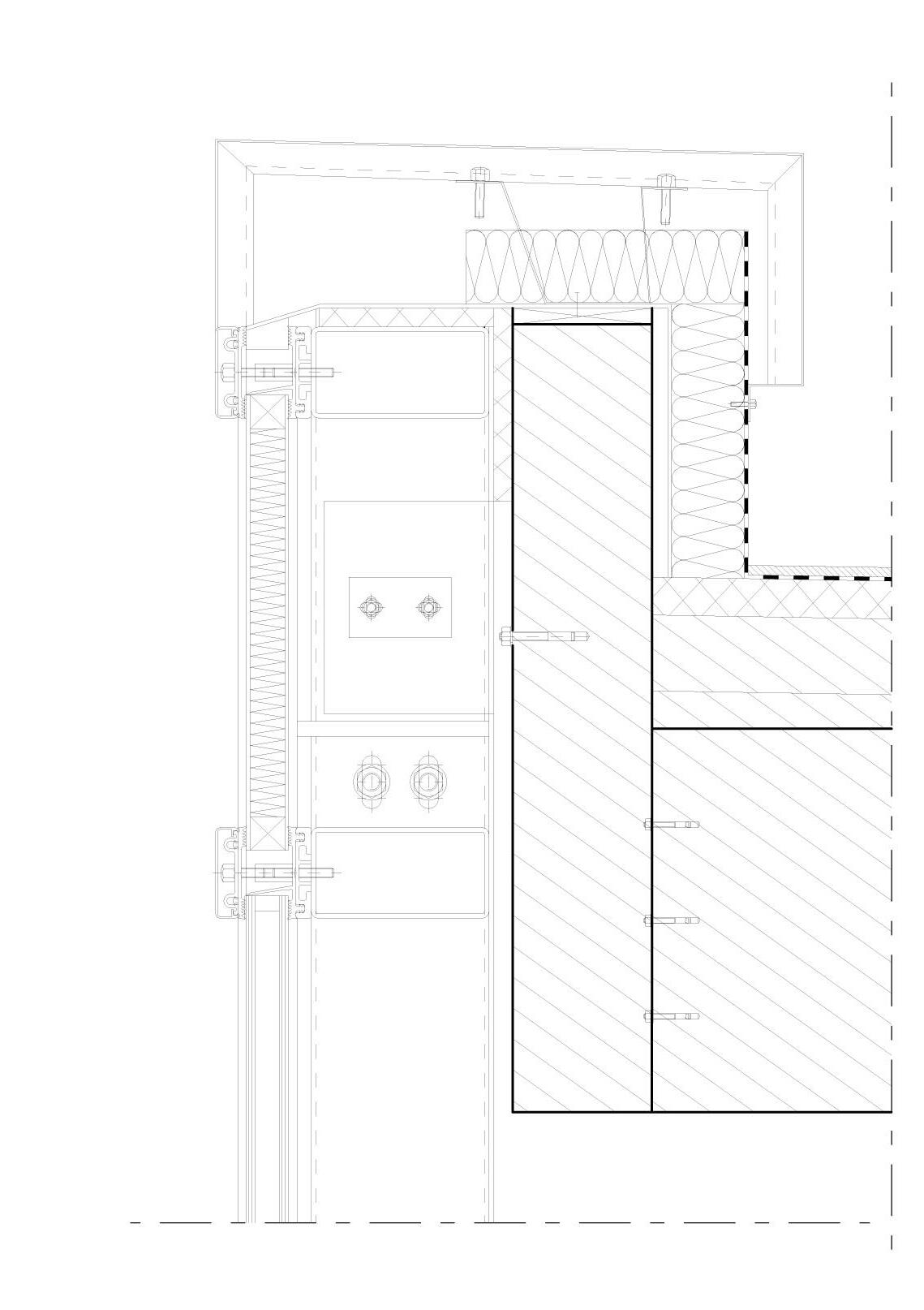

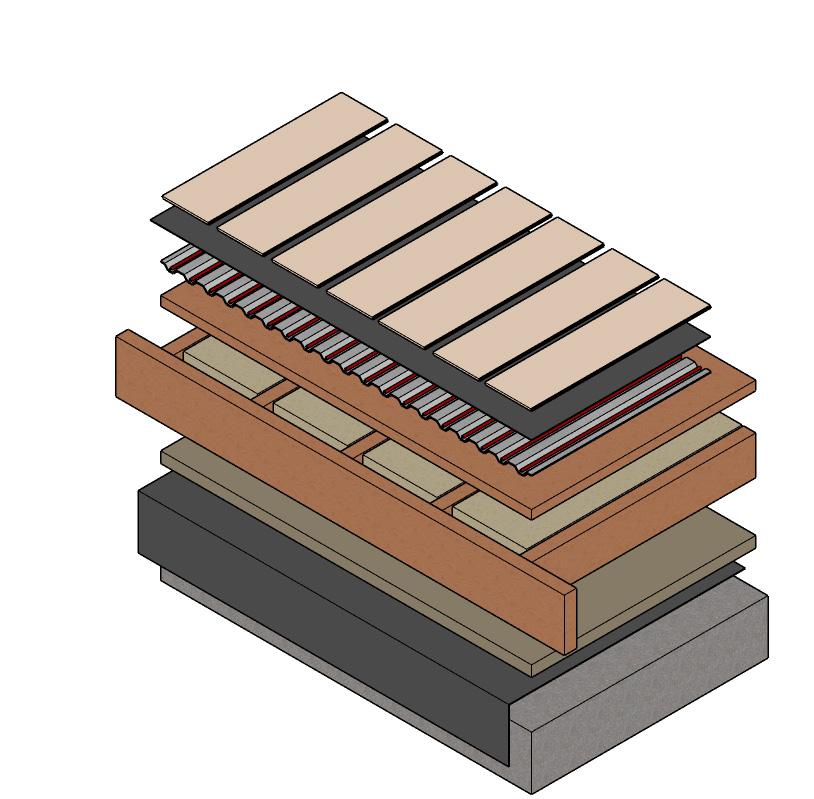

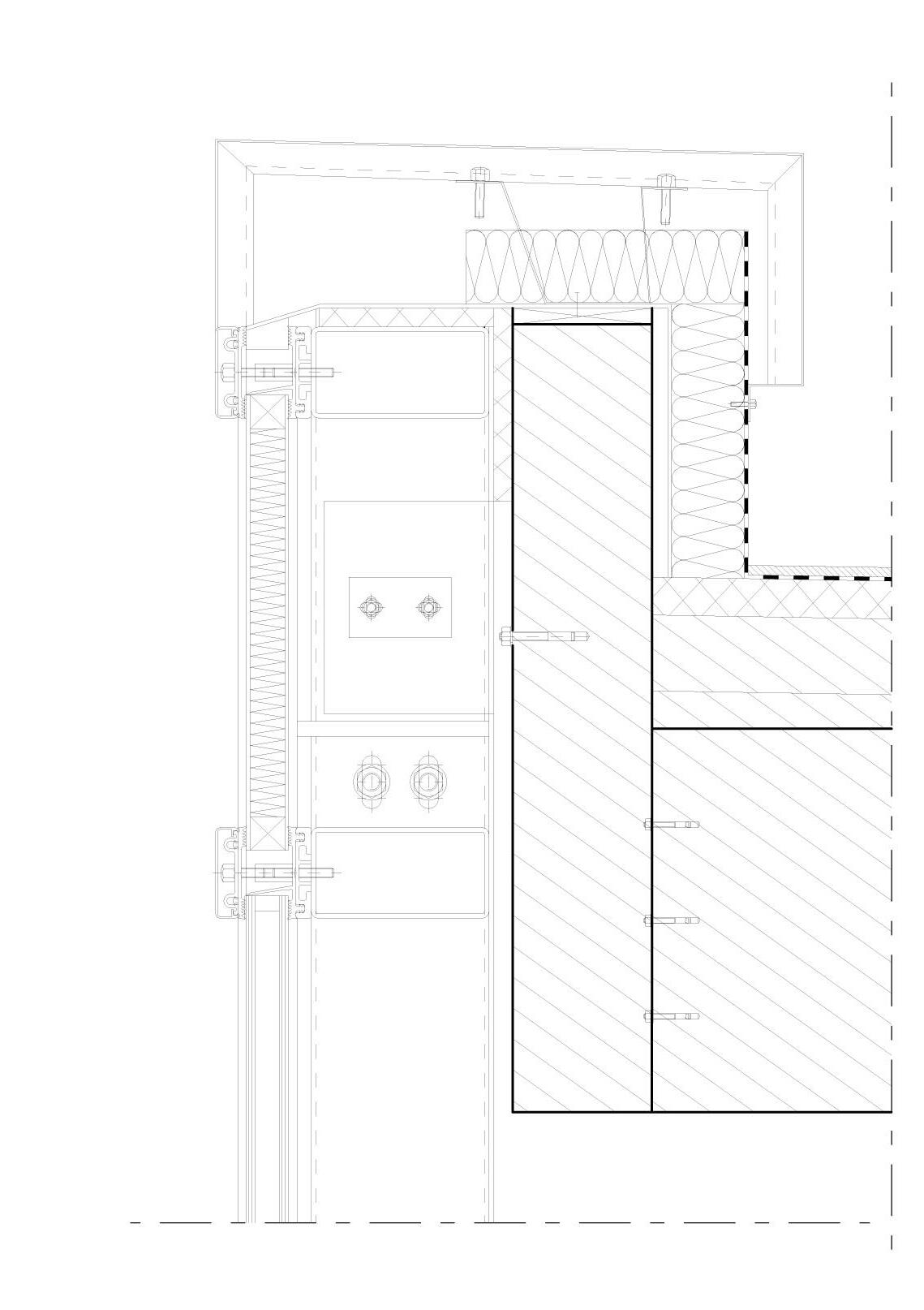

Roof assembly

Flat roof construction.

1. Glulam floor structure

2. Cellulose fiber insulation

3. Firrings to create roof slope

1 2 3 4 5 6 7

4. Cross laminated timber deck

5. Vapour proof membrane

6. EPS rigid floor insulation

7. Bitumen felt

8

8. Roof flooring finish

Fig. 69, Roof assembly diagram

Case study design > 77

1

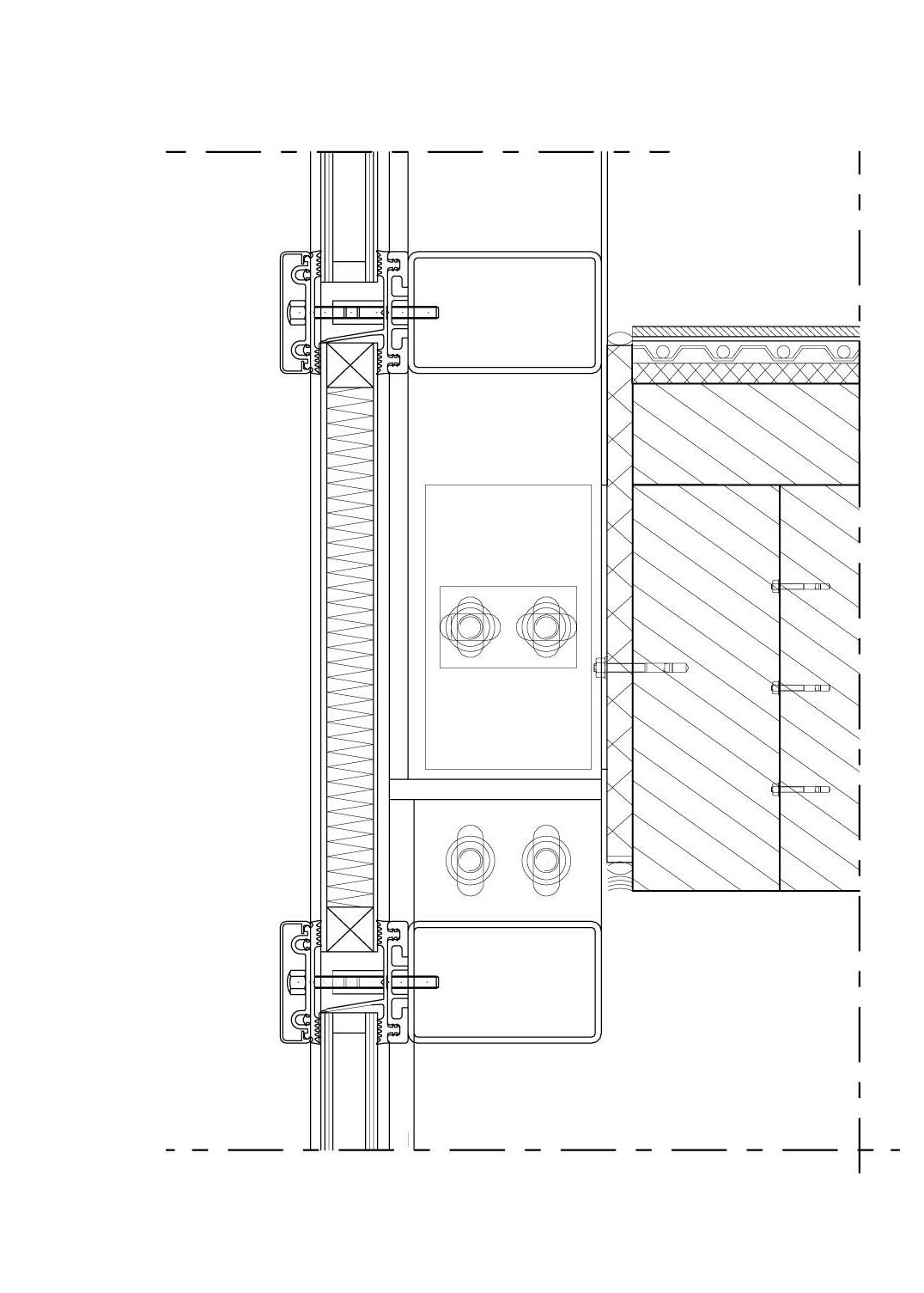

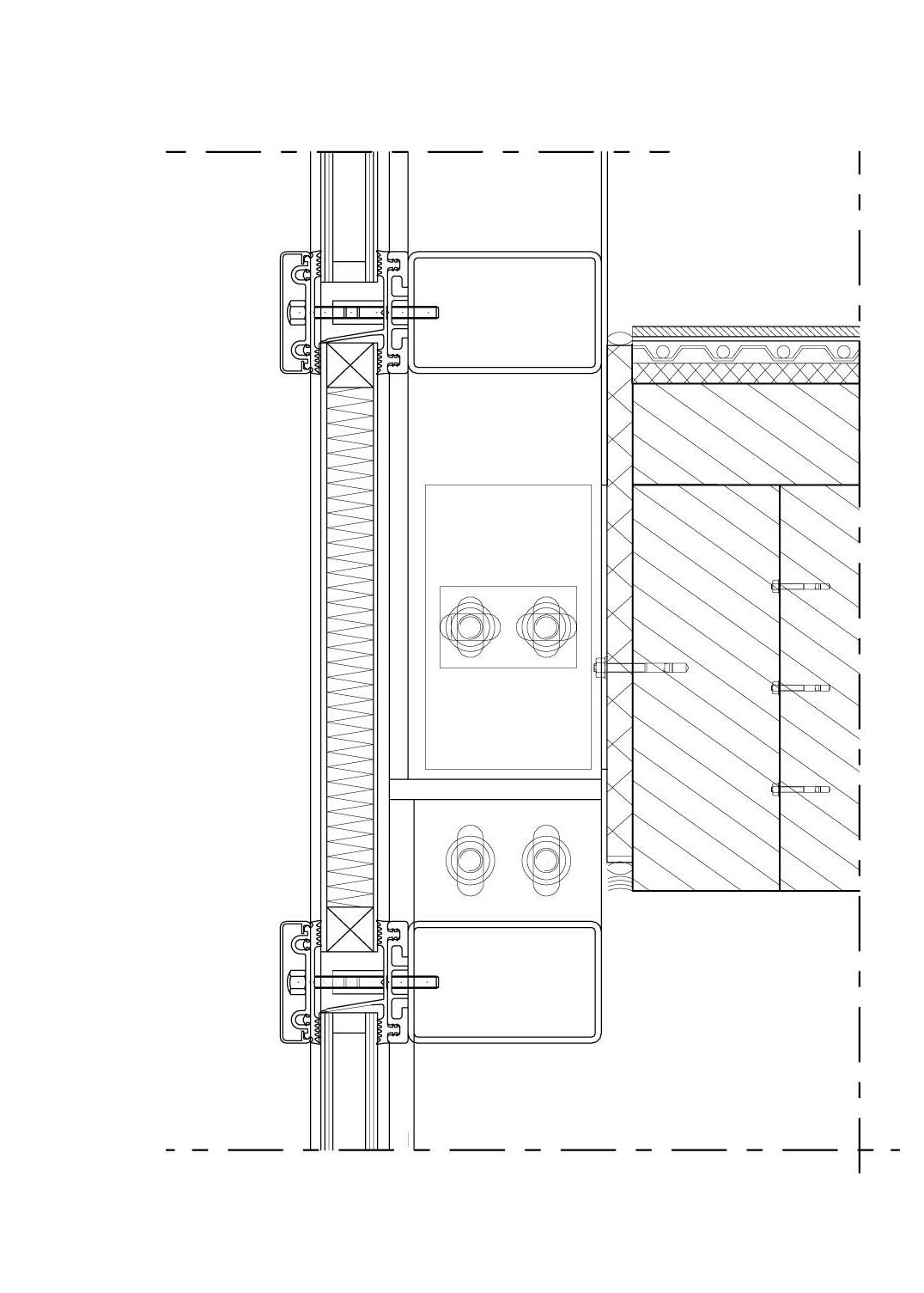

Connection details

Facade to base

Scale 1:10

1. Unitized modular panel

2. Click in place floor tiles

3. Vapour barrier

4. Aluminum plate with under floor heating tubes in heating mat

5. Cross laminated floor

6. Expanded polystyrene insulation

7. Floor structure with cellulose fiber insulation

8. Expanded polystyrene insulation

9. Waterproof membrane

10. Concrete foundation slab on grade

2 3 4 5 6 7 8 9 10 11

11. Anchor plate

Facade to intermediate floor Scale 1:10

1. Unitized modular panel

2. Click in place floor tiles

3. Vapour barrier

4. Aluminum plate with under floor heating tubes in heating mat

5. Expanded polystyrene insulation

6. Cross laminated floor

7. Floor structure with cellulose fiber insulation

1 2 3 4 5 6 7 8

8. Hanging bracket

78 < Case study design Connection details 1 2 3 4 5 6 9

Roof parapet to facade Scale 1:10

1. Roof Parapet

2. Cellulose fiber insulation

3. Unitized panel

4. Roof floor decking

5. Bitumen felt layer

6. Expanded polystyrene insulation

7. Hanging bracket

8. Cross laminated timber

9. Firring sloped to drain

7 8 10

10. Glulam structure

> 4. ANALYSIS

Case study design > 79

Design response to strategies

80 < Case study design

4.1

Fig. 70, Design response diagram (adapted from Stoyanova, 2018)