Farm Safety

John M. Steiner / The Jamestown Sun

A firefighter for the Jamestown Rural Fire Department walks into a burning grass fire scene March 9, 2021, southwest of Jamestown.

Farm fire prevention requires planning

JAMESTOWN — Farm fires cause loss of property, lost time and injuries, and prevention takes many forms, according to Brian Paulson, chief of the Jamestown Rural Fire Department.

“As harvest gets going,” he said, “farmers need to stop and make sure their equipment is clean. No chaff or dust that can start a fire if it gets hot.”

Fire extinguishers in trucks, tractors and combines are also useful in keeping small fires from growing and causing more damage, Paulson said.

Equipment fires during haying and harvest can damage equipment and pose a danger to anyone working on the machines. It can spread on the ground, creating the potential for damage to nearby buildings and equipment.

“Keep the farmyard mowed around any structures,” Paulson said. “Keep the grass short so there is less to burn.”

The shorter grass will slow the spread of a fire, allowing the use of fire extinguishers or water, if available, to prevent the structure from catching fire.

Stored hay can be another potential fire hazard, according to a publication by North Dakota State University.

If hay is baled or staked with 20% or more moisture, a chemical reaction can occur, producing heat within the hay. This can cause a spontaneous fire if the hay reaches 130 degrees.

FIRE PREVENTION: Page 4

Safety practices critical when youth are operating ATVs

BY KATHY STEINER

The Jamestown Sun

JAMESTOWN — Young people are often helping on the farm, says Angie Johnson, NDSU Extension farm and ranch safety coordinator. And they may be using an all-terrain vehicle (ATV) to do some of their work, so there are some important considerations to using it safely, she said.

Taking a safety course, matching the machine to the youth’s size,

wearing appropriate gear and riding without a passenger are all critical to operating an ATV safely, she said.

Off-highway safety course, proper size machine recommended

Johnson said 12- to 15-year-old youth who don’t have a driver’s license or a learner’s permit have to take an ATV safety certification class in order to be able to operate an

ATV on land other than their own family’s private property.

NDSU Extension works closely with the North Dakota Department of Parks and Recreation, which offers the free off-highway vehicle (OHV) youth safety course, she said. The course is designed to help educate riders on how to safely operate OHVs when out riding, according to the department.

ATV SAFETY: Page 3

Contributed / NDSU Extension North Dakota Parks and Recreation Recreation Chief Tony Hillig provides hand signals to youth ATV drivers during an ATV certification training session at the 2023 NDSU Extension youth farm safety camp in Bismarck.

ATV SAFETY

From Page 2

“Our team in Extension works with them exclusively, especially in the summer to partner and offer that ATV training during our (youth) farm safety camps,” Johnson said. “Oftentimes … these young people, they might get on a farm where they need to drive one of these machines, whether that’s for fencing purposes, rock picking, whatever the task is that they need to complete, usually oftentimes it may involve one of those machines.”

The safe driving course goes through how people use their bodies to operate an ATV safely, she said.

“The whole point of an ATV when you’re driving it is you shift your body’s weight,” Johnson said. “That’s how you manage turns, that’s how you manage climbing over rough terrain or, for example, if you’re driving over a log, it’s really using your body and its weight to be able to shift and lift that machine. So that’s what’s really awesome about that course is, it’s actually introducing kids how to properly drive and move with their machine.”

It’s important that young people operating an ATV are using one that matches their body size, Johnson said.

“Starting them out with a large adult

machine is going to set up … that young person for failure because really they can’t control it as well because they don’t have the physical ability yet to be able to maintain a turn, especially going at high speeds,” she said.

Also important is for adults to be good role models of safety for their children, she said.

“I just can’t stress enough, take the time to have your child participate in a safety training and also be an advocate for wearing a helmet and wearing a helmet every time,” Johnson said. “... If we want people to really embrace protecting themselves, so embracing safety, that means we got to start developing those habits at a young age.”

Parents who encourage and require their child to wear a helmet when they’re driving should role model that behavior as well, she said.

“Then you’re practicing it as a team and that young person is really able to understand that, you know what, this is about everybody keeping everybody safe,” Johnson said. “They’re not just telling me to do it and not practicing it themselves. It’s really all about doing the right thing and making that smart decision. So role modeling good safety behavior is paramount to developing that habit into adulthood.”

The North Dakota Department of Transportation compiles statistics for

off-highway vehicle crashes, fatalities and injuries, which include ATVs and snowmobiles. The most recent data on the NDDOT website, for the year 2021, reported 55 crashes, five fatalities and 59 injuries.

Johnson noted that not only farm and ranch families use ATVs.

“Farmers and ranchers and their families use them as a tool but then (we) also have other populations in North Dakota that use them as a recreation piece,” she said.

Appropriate gear

Young people should always wear a helmet while operating an ATV, Johnson said, whether it’s a quick drive to the mailbox and back or checking fence on rough terrain.

“That should be the standard ….,” she said because it can be difficult to recover from a traumatic brain injury from an ATV-related incident.

Appropriate gear also includes shoes, clothing and eye/face protection. It’s important to wear good boots and pants to protect skin from getting burned by the machine’s engine, she said. Having some type of eye protection or a wind shield can prevent rocks or other debris from hitting your face. Even rain can feel sharp like glass when driving, she said.

Johnson recalls an injury she sustained

Auger16-104$15,000

when she wasn’t using eye protection.

“I had a really bad incident when I was a young person,” she said. “I almost lost sight in my eye due to being hit by a wasp as I was driving my ATV. I didn’t have goggles on …”

Not only is appropriate gear important, but the equipment young people use should be updated when necessary.

“… it may sound like a nuisance to have to buy another helmet again, but that’s just part of being a young person and growing is you’ve got to adapt and make sure you have the right size,” Johnson said.

When the ATV isn’t in use, remove the keys, she added.

“Don’t leave the keys in the machine,” Johnson said. “... that’s just a recipe for something bad to happen.”

No passengers on ATVs, slow down

Johnson said there should be no passengers on an ATV, whether it’s a youth operating one or an adult.

“... when you look at an ATV, especially … what I would classify as an adult-size ATV, if you’ve ever looked at the seat, it actually, the seat looks really big,” she said. “The seat looks like it was actually designed for two people but the reality is, it’s not. That seat is large because it needs to be able to allow the driver to

SPEED: Page 5

FIRE PREVENTION

From Page 2

The fires usually occur within six weeks of the hay being baled. Making sure the grass is dry enough before baling is the best prevention, according to the NDSU website. If in doubt, the temperature of the bales can be monitored, especially if the hay has a musty smell.

Questionable hay should not be stored inside. If a fire does occur, spray the hay with water and insert the water into the bales using pipes connected to water hoses to reach hot spots.

Grass and brush fires are always a concern although the Jamestown Rural Fire Department has seen relatively few this year, Paulson said.

“A couple of dry weeks could bring us right back into it,” he said.

Farmers who are planning any controlled burns should monitor the fire danger index and create fire breaks, plowed ground around the planned fire area, to prevent the fire from spreading. Farmers should also monitor wind speed and direction to prevent an unanticipated spread of the fire.

Open burning is prohibited in Stutsman County when the fire danger rating issued by the U.S. Forest Service is in the very high or extreme rating or the National Weather Service has issued a red flag warning.

Fire danger ratings are posted to www.co.stutsman.nd.us/fire-danger every day during the summer season.

Violations of the fire ordinance can result in a Class B misdemeanor punishable by 30 days in jail and a fine of $1,500.

Taking extra time helps avoid accidents during harvest season

BY MASAKI OVA

The Jamestown Sun

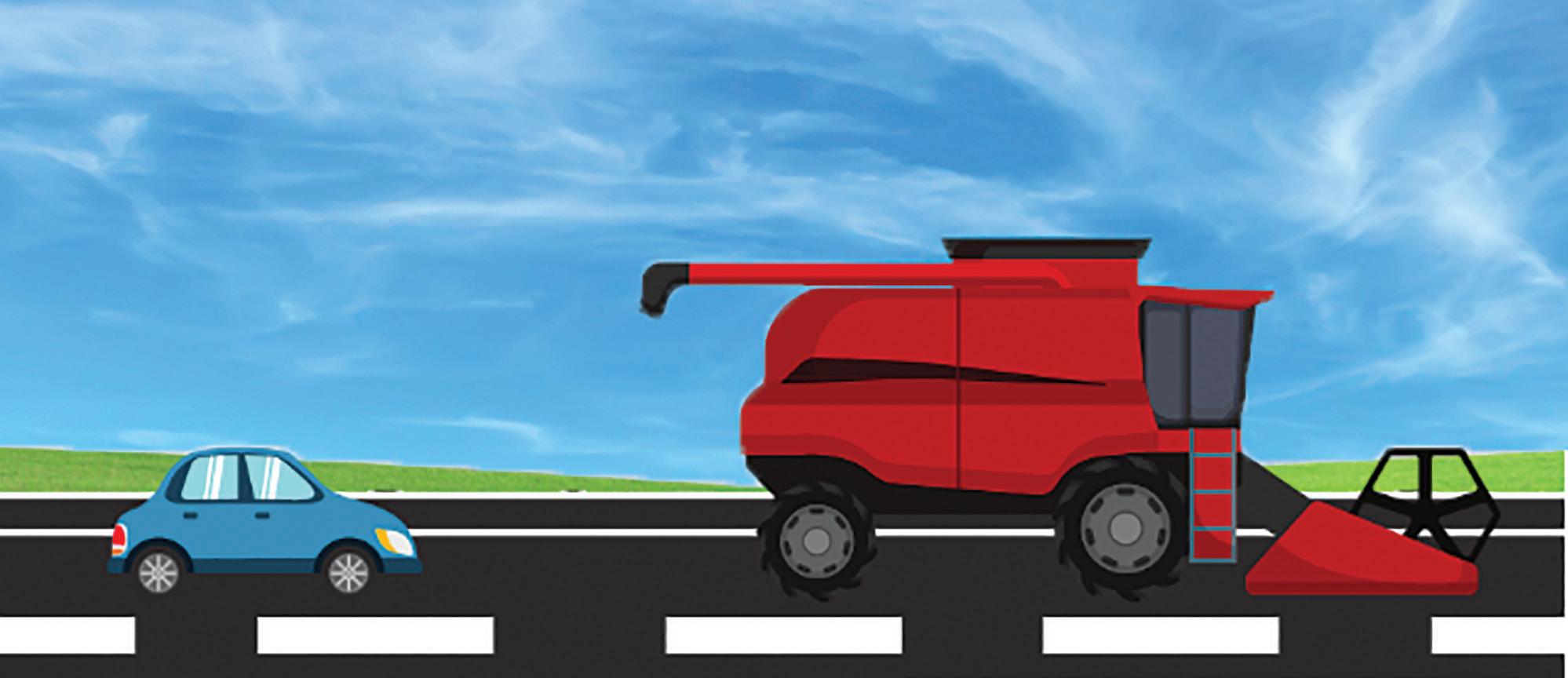

JAMESTOWN — Avoiding accidents during harvest season comes down to being patient and taking extra time to ensure safety, according to Sgt. Evan Savageau with the North Dakota Highway Patrol.

“We want everybody to be safe and enjoy a really nice harvest season that’s coming up,” he said.

Savageau said common accidents that law enforcement see during harvest season include motorists rear-ending farm equipment and motorists not giving themselves sufficient distance to pass the machinery. He said motorists sometimes misjudge how slow the farm equipment is moving, causing the vehicle to rearend the farm equipment. When trying to pass farm machinery, he said motorists should have at least 1,500 feet of distance to make a safe pass.

ACCIDENT PREVENTION: Page 6

John M. Steiner / The Jamestown Sun file photo Motorists should pull their vehicle into a nearby approach to let farm equipment pass on narrower roads, said Sgt. Evan Savageau with the North Dakota Highway Patrol.

SPEED

From Page 3

shift their body back and forth and to the side. And that’s, again, what helps you drive and operate that machine through rough terrain. And so I can’t stress that enough is that ATVs, they are not designed for two riders.”

Johnson said excessively high speeds aren’t needed when driving an ATV for farm-related tasks or recreation.

“We have to remember the word ATV stands for all-terrain vehicle and so when we’re operating on different terrains, speed can just really, it just exemplifies how fast something bad can happen is when we’re traveling too fast through that rough terrain,” she said.

Driving slower helps ensure you can react, she said.

“If you’re going too fast, we just can’t react enough to stop before something bad happens,” she said.

Johnson said ATVs are not designed for highway use.

“The tread is just so much bigger,” she said. “... Oftentimes, you’ll see them on a gravel road or on paved highway … they’re designed to go in different kinds of terrain. They’re designed to grip, that’s why we’ve got the excessively grip tires and so they can’t grip well on highway and gravel surfaces especially going at high speeds.”

It’s important to stay off public roadways, she said.

“We have to remember we don’t have blinkers. We don’t have turn signals,” Johnson said. “There’s no rear-view mirrors on our ATVS. Our UTVs are a little bit different. They’ve got mirror systems installed and so that changes things a little bit. But for our ATVs, they’re just not designed for on-highway use.”

Johnson noted people have to be licensed to drive on a public road and abide by speed limits, but said she doesn’t want to see those machines driving that fast.

“If they’re going that fast, that means

I just can’t stress enough, take the time to have your child participate in a safety training and also be an advocate for wearing a helmet and wearing a helmet every time.

- ANGIE JOHNSON, NDSU Extension farm and ranch safety coordinator

their ability to control that machine has reduced,” she said. “So If you need to turn and you’re going 55 miles an hour on gravel or pavement, you can’t react fast enough and your machine does not have that ability to grip on that surface so that really increases your chance and your risk of rolling that machine. So that’s why I’m not an advocate for driving ATVs on public roadways, A, because you got to be licensed in order to do it but B, you’ve got to be able to keep up with the traffic conditions …You’re better off not taking that machine on those road surfaces just because it’s not designed or meant for those road surfaces.”

For information on laws related to OHVs, visit North Dakota Parks and Recreation at https://bit.ly/3qy3kZA

Communication, awareness during harvest

Johnson said communication during harvest is really important. It’s about knowing whether young people are helping with that harvest or just getting home after school and wanting to go for a drive. Communicating can be as simple as just letting people know where everyone is going to be, she said.

“Dad, grandma, grandpa, uncle, they’re going to be driving semi through the yard many, many times tonight with loads of grain so … these next few days aren’t going to be safe days to drive the ATV in the yard,” she said as an example.

She said just communicating together on where it’s safe to drive and when is important as well as always letting someone know when you’re going to be driving.

“Simple communication,” she said. “It doesn’t have to be anything extravagant, it’s just an awareness of helping each other out, identify when there’s risks such as excessive traffic on the road, or just in the driveway, in the yard. Taking the time to time to talk to each other and putting a plan together.”

ksteiner@jamestownsun.com

(701) 952-8449

ACCIDENT PREVENTION

From Page 4

He said when larger farm machinery is approaching motorists on narrower roads, drivers should pull their vehicle into an approach, if one is nearby, to let the equipment go by.

“It takes you an extra minute or two and that thing clears past you and then you can safely travel down the roadway,” Savageau said. “It’s just asking drivers to essentially be patient and be observant about what is moving around in their area that they are traveling in.”

With school being back in session, he said there will be more younger drivers on the roadways who don’t have much experience driving. He said law enforcement just wants those young drivers to pay attention to their surroundings and not be distracted.

He said motorists need to stay off their phones while driving. He said distracted driving is a major factor of motorists not being able to react appropriately.

“Being distracted is going to put you in a situation that’s extremely hazardous for yourself and that other person,” he said.

Savageau said farm equipment operators need to also pay attention and not get distracted because the machinery is moving much slower compared to the traffic.

He said farmers understand the lighting and reflective requirements on their machinery and should take extra time to wipe the dust or mud off their lights and reflective tape.

“It takes us an extra minute or two at most,” Savageau said. “That way you can be seen as much as possible at these times when we are having to move pieces of equipment from field to field and we are going to be on the roadway.”

Farm equipment operators should also take extra precautions when approaching rural railroad crossings. Savageau said rural railroad crossings don’t have crossarms to warn operators or motorists of

Semitrailer drivers need to be aware of the extra weight

according to Sgt. Evan Savageau with the North Dakota

avoid distracted driving.

an approaching train.

“We just ask some of our farm equipment operators that as we are approaching, we slow down, we really make sure we are looking both directions because this vehicle that you are operating isn’t able to stop or accelerate as a normal motor vehicle,” he said. “ Taking that extra few minutes to really make sure it’s safe for you to enter and cross that railroad grade crossing is imperative. A lot of times it (preventing accidents with trains) just comes down to the fact where

PREVENTION: Page 7

and

John M. Steiner / The Jamestown Sun file photo

they are hauling

how that will affect the acceleration and braking distance,

Highway Patrol. He also said motorists need to be aware of their surroundings and

maybe it’s noisy, we aren’t paying attention, we didn’t hear a whistle or we didn’t try to check both directions twice to be able to safely make this movement.”

Driving semitrailers safely

Semitrailer drivers should be aware that the extra weight they are hauling will affect the acceleration and braking distance, Savageau said. He said more following distance for semitrailer drivers will allow them to read and react to make a proper movement if something happens in front of them.

Over the years, he said law enforcement has seen semitrailers going into a field take a turn too fast and roll because the driver didn’t compensate for the extra weight being hauled.

“The other side too, obviously we are having semis with larger trailers that are hauling grain or corn, product from the field and they are entering the roadway from the field,” he said. “Give yourself enough time to be able to pull out and make that turn and gain some speed and not put yourself in a position where traffic is approaching and we didn’t leave a sufficient time and distance for us to make a safe movement.”

UTV/ATV safety

-

ASHLEY WOLFF, agriculture and natural resources Extension agent for Stutsman County

Savageau said law enforcement has seen more UTVs and ATVs. He said UTVs might seem like a smaller vehicle but they don’t have the safety features that are in motor vehicles such as airbags, side-curtain airbags and advanced warning systems.

He said seat belts should be used in UTVS and helmets are recommended when operating ATVs.

Savageau said law enforcement tells people driving ATVs or UTVs to take extra time to make sure an intersection is clear before entering it. He also said ATVs and UTVs can sometimes be driven in areas not on the roadway.

“If I can ride down in the ditch line, great,” he said. “That probably alleviates a couple of situations for you where we aren’t out into traffic.”

Savageau added that UTV and ATV operators should not engage in risky

behaviors that come with driving the off-highway vehicles even though they are fun to operate.

UTV and ATV operators should drive at a safe speed, said Ashley Wolff, agriculture and natural resources extension agent for Stutsman County. She said some terrain might be unfamiliar or the operators might not be aware of the holes in the ground.

Operating farm equipment while impaired

Savageau said consuming alcohol or drugs reduces motorists’ reaction time, judgment and opportunities to be conscious about their surroundings.

“When you place an impaired person especially underneath alcohol or drugs behind the wheel of very large heavy machinery that’s moving slower than traffic around you … it creates a significant hazard to the motoring public

and a significant hazard to that person who’s operating that machinery,” he said. “ … It just poses such a hazardous risk to the public and themselves when that happens.”

Savageau said law enforcement has made significant efforts in the last 15 years to educate people about the dangers of impaired driving.

“I believe people are getting more and more educated about it,” he said.

Preventing other farm-related accidents

Farmers need to take extra time and precautions to avoid other farm-related accidents, Wolff said.

Wolff said power take-off accidents happen when farmers are in a rush. PTO accidents happen when clothing or limbs get entangled in a rotating PTO.

“I have heard of PTO accidents in maybe the last year where somebody was maybe helping to hook up a trailer or a piece of equipment and the PTO was engaged and the person wasn’t realizing the person was back there, that sort of thing,” she said. “It’s just being aware of the surroundings and who’s helping you and where that person is at is really important to help prevent any of those injuries.”

ACCIDENTS

To prevent PTO accidents, individuals should step away from the machinery once their job is done and let the operator finish what they are doing, Wolff said.

“If they have questions or need help, that’s where the person on the ground also has to be responsible to make sure that something like that PTO is disengaged before approaching,” he said. “ … The person on the ground has to be just as responsible as the person on the tractor and being knowledgeable enough to be around that sort of equipment to know where they need to stand or how far back or things like that.”

From Page 7 BY

She said the equipment operator needs to be aware of where other workers are at. Operators should also make sure other workers know where to stand to prevent farm-related accidents.

With semitrailers, she said drivers need to be aware of children or animals getting in the way. She said the drivers can’t see over the hood of the semitrailer.

Wolff said fatigue, heat stress and rushing contribute to accidents. She said fatigue causes farmers to be less cognizant of their surroundings and to not be as mentally sharp. She said many accidents happen because farmers are in a rush.

“Fatigue, heat stress, rushing, that’s when a lot of people just start running around and forget about these things that make sense to them and are pretty common to them,” she said. “That’s when they start to forget about some of those things and just kind of take some shortcuts and then accidents happen.”

mova@jamestownsun.com | (701) 952-8454

Assume overhead power lines are bare

Omaha, Nebraska

It is difficult to protect yourself from a hazard you don’t recognize. On the farm, electrocution claims the lives of approximately 62 agricultural workers each year (www.electrocution.com), people die in fires caused by faulty electrical systems, people are injured through electrical shocks and burns, and property is damaged or destroyed due to incidents involving electricity. Overhead power lines are a common source of on-farm electrocution fatalities. Lines may have been installed without insulation or the insulation may have worn off due to exposure from weather. The safest approach to working around overhead power lines is to assume that they are bare.

Unlike birds, that can sit on a power line without any consequence, when humans touch overhead lines, they are in contact with the ground at the same time. This gives the electricity a channel to flow through, which results in electrocution.

Other common electrocution hazards on the farm include degradation of electrical wire insulation from rodents, weathering, etc.; improper wiring, corrosion of electrical connections, moving irrigation pipes, using electricity in dusty conditions found inside agricultural buildings, and more.

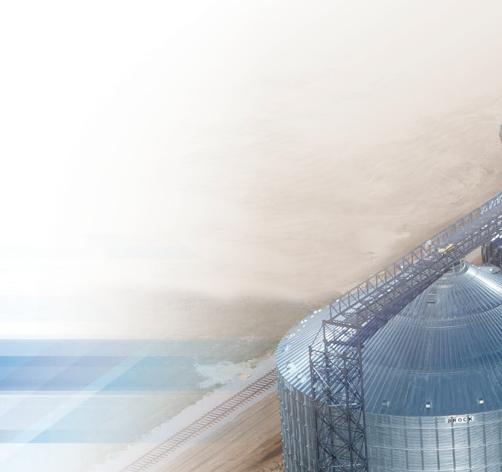

Farm equipment that’s often involved in overhead power line contact includes tractors with front-end loaders, portable grain augers and elevators, dump trucks, feed trucks, irrigation pipes, equipment with antennas, and folding implements. When using dump trucks, the operator should be aware of the location of overhead power lines

before raising the bed and should not move the truck or trailer while the bed is in the raised position. Areas with overhead lines should be clearly marked. Typically, if a raised bed contacts a power line, the operator will not be at risk as long as they remain inside the vehicle, because the tires provide insulation. However, if anyone standing on the ground touches the dump truck or trailer while it’s in contact with overhead lines, that person could be electrocuted.

A loader tractor or telescopic load may be used to handle hay. Because booms on these types of equipment may reach as high as overhead power lines, hay should not be stored under power lines.

Around grain bins, the National Electrical Safety Code (NESC) requires power lines to be at least 18 feet above the bin’s highest point of

ELECTROCUTION: Page 10

Mic hael T. Dean,

ELECTROCUTION

From Page 8

any bin constructed since 1992. Whenever a new grain bin is installed, a licensed electrician should be consulted to assist with placing electrical service lines. Lines may also be buried to reduce electrocution risk. Local utility officials can also help evaluate line height issues on the farm site.

When moving equipment beneath a power line, clearance should be at least 10 feet between the power line and the highest point on the equipment. Keep in mind that implements such as a fold-up planter will be taller when folded up than when they’re used in the field.

Everyone involved in planting and harvest activities must be trained to recognize potential electrocution hazards. Clearly identify any area where there are electrocution hazards related to overhead power lines when equipment is used or moved.

Electrocution hazards related to standby generators include using the transfer switch to remove the farm’s electrical system from the power company’s utility lines. This switch prevents electricity generated by a farm operation’s emergency power system from entering the power company’s utility lines and protects from electrocution those power company

workers who service lines during an outage. The switch also protects the generator when power is restored.

Always use the transfer switch when your standby generator is in operation. Make sure all workers know the location of the transfer switch.

If your tractor contacts a power line, stay on the tractor. Immediately ask someone to contact the local utility company to resolve the danger. In the event that there’s a need to leave the equipment (i.e. an electrical fire), jump as far away from the equipment as possible. Do not allow any part of your body to touch the equipment and the ground at the same time. Hop with your feet together to prevent electrical conduction through your legs.

Once you’re away from the equipment, never attempt to get back on it or touch it. It’s not unusual from an operator to dismount the equipment and, realizing that they’re okay, to get back on the equipment and being electrocuted in the process.

Prevention is the best way to avoid emergencies. Respect electricity and take every precaution to avoid contact with overhead power lines.

Four important electrical safety devices and features to be aware of are fuses and circuit breakers, GFCIs, grounding, and

DEVICES: Page 11

© CanStock photo by samurkas

Electrocution threats exist wherever high lines or electrical current is present.

DEVICES

From Page 10

polarization. Fuses and circuit breakers help protect an electrical system from current overload, but they don’t protect people from electrical shock.

A ground wire provides an alternate path for electricity to flow back to ground potential if an electrical short occurs. Never destroy or cut off a grounding prong on a plug to make I fit into a socket or extension cord that doesn’t accommodate the prong. If you work with equipment that doesn’t have a grounding wire, consider rewiring the device to accommodate this feature.

GFCIs – Ground Fault Circuit Interrupter – monitors current flow to an electrical device, comparing it to the amount of current flowing back. If there’s a difference between the two, which indicates a malfunction, the GFCI stops the current flow before harmful amounts of current can flow through an individual.

Polarization refers to plugs and outlets that have two different-sized prongs or slots. This helps protect you from accidental contact with an energized socket. Additional safety practices around electrical power include:

1. Choose a route on your farm site that avoids potential contact with overhead power lines.

2. Never touch a power line.

3. Contact your local power company if an incident occurs.

4. Never use ladders around power lines.

5. Contact your power company to determine the height of power lines on your farm site.

6. Review safety measures with all individuals working on our farm, whether full-time, part-time, seasonal, or voluntary.

7. Remember that even non-metallic objects such as tree limbs, ropes, and straw can conduct electricity.

8. Install and use electrical safety devices.

9. Check the condition of all power cords and devices and repair or replace as necessary.

10. Make sure power is disconnected before working on any electrical device.

11. Use double insulated tools, which

put an additional barrier between you and electricity.

12. Use waterproof, dustproof, and even explosion proof electrical boxes, outlets, and motors in uniquely troublesome environments of livestock facilities.

Funding for this educational article comes from the Central States Center for Agricultural Safety and Health and the University of Nebraska Medical Center.

Grain bin safety: Don’t sidestep the principles

BY THE UNIVERSITY

OF NEBRASKA MEDICAL CENTER, CENTER FOR AGRICULTURAL SAFETY AND HEALTH

Omaha, Nebraska

There is a direct correlation between out-of-condition grain and an increased likelihood of worker exposure to entrapment situations, according to Purdue University’s 2020 Summary of U.S. Agricultural Confined Space-Related Injuries and Fatalities. “Whenever a farmer or elevator employee has to ‘fight’ to get the grain to flow out of (a bin), there is a strong temptation to by-pass safe work practices be entering the structure in order to keep the grain flowing.” the summary says.

Identifying grain handling safety principles is one of the aims of Central States Center for Agricultural Safety and Health (CS-CASH). This University of Nebraska Medical Center group ( https://www. unmc.edu/publichealth/feedyard/ ) is conducting two research projects (funded by the National Institutes of occupational Safety and Health) that are designed to make a positive impact on the sustainability of cattle feedyards through

increased safety and health efforts.

Sometimes a crusted layer forms on the surface of grain inside a bin or within the grain mass. That leads to a void above the outlets as grain is removed from the bin. If the crusted grain breaks up during the removal process, it may block the bin outlets, reducing or stopping the flow. In other situations, vertically crusted grain can cling to the walls of the bin or form free-standing piles. The piles may contain tons of grain, which can collapse without warning.

“If the grain won’t flow, it’s already too late to debate what was or was not done to prepare the grain for safe storage,” the summary reads. “The issue at hand is to remove the grain without putting anyone at risk of entrapment.”

The summary notes that “although the following steps may not be the most profitable,” they will help keep everyone safe when handling grain.

1. Never enter a bin where there is evidence of crusting on the surface or within the grain mass. If grain has been removed from the structure and the surface has not flowed toward the outlet – stay out.

GRAIN BIN SAFETY: Page 13

© CanStock photo by Keifer

Take steps to handle grain safely.

This is a clear sign that a large void has formed over the outlet.

2. If there is any sign that the grain is going out-of-condition, or has already done so, it needs to be moved immediately. The condition of the grain will not improve if left in storage, and will only worsen as warm weather arrives, which causes biological and insect activity to increase.

3. Perform all observations or unplugging efforts from outside the bin, at the top access hatch. Again, if there is evidence of crusting, spoilage, or excessive heating – stay ou. The risk is too great. In some cases, long pipes, rebar, or other probes can be inserted into the grain mass to break up crusted grain or trash that is plugging the outlet. Watch out for overhead power lines when handling these long probes.

4. If the grain has become so crusted, or the floor outlets become plugged, preventing grain removal according to the bin manufacturer’s recommendations, contact a professional grain salvage service that has the experience and equipment to break up and remove out-of-condition grain. These services are expensive but can save lives and salvage some of the grain. In some regions there is a market

for damaged grain which helps make the salvage operation a little less costly.

At the end of 2020, the Purdue Agricultural Confined Space Incident Database (PACSID) contained information on 1,731 cases (1962-2020) involving confined spaces, grain storage and handling facilities at both commercial and on-farm locations. All the cases resulted in an injury, fatality or required emergency extrication by first responders. Of these cases, 1,731 (72%) involved grain storage and handling facilities, and grain transport vehicles.

“There is no claim that the data presented accounts for all incidents involving agricultural and confined spaces,” the

summary states. This is due, among other things, to the fact that there is no accurate accumulative public record of these types of incidents, and no comprehensive or mandatory incident/injury reporting system for most of agriculture. “There has been reluctance on the part of some victims and employers to report ‘near misses’ or non-fatal confined space-related incidents, especially those occurring at farms, feedlots, and seed processing operations not covered by federal OSHA injury reporting requirements.”

In 2020, there were a total of 64 cases of agricultural-confined space-related cases, Including:

► 35 grain entrapments

► 7 falls into or from grain storage structures

► 4 asphyxiations due to deficient oxygen levels or toxic environments

► 12 equipment entanglements (such as those involving in-floor and sweep augers) that occurred while working inside or around agricultural confined spaces

The total of 64 represented a 4.5% decrease from the number of cases documented in 2019, when 67 were recorded. However, the number of 2020 total confined space-related cases was well above the five-year average (61.2 cases/ year) and above the 10-year average (60.9 cases/year).

“Regardless, the frequency of documented cases remains a concern considering the substantial resources being invested in solving the problem,” the summary states.

In 2020, the state with the most documented grain entrapments (fatal and non-fatal), was Illinois, with 10 cases total. North Dakota reported 5, Minnesota reported 4, and Indiana and South Dakota each reported 3.

With support from a Susan Harwood Grant from the U.S. Department of Labor, www.agconfinedspaces.org was developed to provide resources for those conducting safety and health training in the area of agricultural confined spaces, with an emphasis on grain storage and handling hazards. Training material, frequently asked questions, past summaries of injuries and fatalities, and an extensive list of resources can be found at the site.

Additional information on grain handling safety can be found at: www.grainsafety.org

https://apps.npr.org/buried-in-grain/ www.agsafety4youth.info

Funding for this educational article comes from the Central States Center for Agricultural Safety and Health and the University of Nebraska Medical Center.

Missing sleep may cost more than you realize

BY THE UNIVERSITY

OF NEBRASKA MEDICAL CENTER, CENTER FOR

AGRICULTURAL

SAFETY AND HEALTH

Omaha, Nebraska

It’s no big deal to lose a couple of hours of sleep for a few months, right?

A sleep study conducted by University of Nebraska Medical Center’s Amanda Prokasky, Ph.D., Education and Child Development, Munroe-Meyer Institute in Omaha and retired Susan Harris, Nebraska Extension educator, Institute of Agricultural and Natural Resources, reveals that sleeplessness leads to lack of concentration, slower reaction times or distractibility. Losing 30 minutes for one night has little effect, however, a 30-minute deficit each night for four to six weeks will take a physical and mental toll.

“Susan Harris and I met after I completed a five-year federally funded research study examining sleep habits of toddlers,” Prokasky says. “Susan was interested in measuring the effects of sleep loss in farmers and ranchers, but we were unsure how to measure that. Written surveys completed by participants are generally somewhat skewed as many of us perceive that we sleep longer than we actually do.”

Prokasky and Harris enlisted 40 farmers/ranchers in the Midwestern states of Nebraska, Iowa, Kansas, North Dakota, South Dakota and Missouri who raise crops and livestock. Ranchers who don’t raise crops are likely to lose sleep during calving season. They used an Actigraph Spectrum Plus, a wrist device (essentially an expensive Fitbit) that monitors and records continuous data on daily motion and activity levels, to obtain data for the study. Study participants wore the device for one week

during harvest or planting, then again during a more routine week.

“The device gives a clear and objective picture of actual sleeping time during the night, measuring sleep quantity and quality,” Prokasky says.

The data collected allowed the researchers to compare the amount of nighttime sleep, bedtimes and wake times, and the number and length of night wakings between busy and slower weeks. In addition to the Actigraph data, participants also completed post-project surveys.

The data verified that participants lost on average 30 minutes of sleep per night during peak activity times versus more routine periods.

“That doesn’t sound like a lot,” Prokasky says. “And for one night, the sleep loss doesn’t have much effect. However, over several weeks, the loss accumulates and has huge impacts on our health and well-being.”

Sleep flushes diseased and damaged bits of toxins and waste from our brains. It also performs a process called consolidation, which cements information in the brain that was learned throughout the day so the brain retains it. Sleep plays a role in metabolism and helps control hunger hormones. Sleeping triggers tissue growth that heals injuries and creates virus-fighting cells to boost immunity to illness.

During sleep, creativity, energy levels, and positive moods increase, and stress is reduced.

Muscles and organs rebuild critical cells during sleep. Lack of sleep may result in irritability, confusion,

memory loss, concentration problems or depression. All these consequences can be deadly for producers working with heavy equipment, chemicals, or livestock.

“Taking brief breaks or naps during busy times like planting and harvest could help lessen these consequences,” Prokasky says. “However, ongoing sleep deprivation will take a toll.”

Prokasky points to a New Zealand study of dairy farmers who were getting up during the night to milk cows as was part of their schedule for milking three times per day. Researchers were able to convince the farmers to change their milking schedule so their nighttime sleep wasn’t disturbed.

“Their overall sleep quality was noticeably improved as a result,” Prokasky says. “When we’re losing sleep over several weeks, we may believe we can ‘catch up’ at some point, but that rarely happens. If it’s not possible to avoid depriving yourself of some sleep each day for a long period, take 20-minute naps during the day, which can have a positive impact on overall sleep quality.”

“There are many things about agriculture that farmers cannot control,” she adds. “Weather and equipment issues are just two factors. By using this data, we can provide practical advice to farmers and ranchers so they can make quality decisions that affect their health and well-being as they accomplish their tasks.”

Funding for this educational article comes from the Central States Center for Agricultural Safety and Health and the University of Nebraska Medical Center.

4 miles North of Gackle, ND

offer the best Free Standing Cattle Panels on the market. See our products at doublejmfg.com or Call James or Darcy at 701-485-3511.

BY

Know the risks of handling large bales

THE UNIVERSITY OF NEBRASKA MEDICAL CENTER, CENTER FOR AGRICULTURAL SAFETY AND HEALTH

Omaha, Nebraska

How can the weight of a large round bale become a deadly force?

Aaron Yoder, Ph.D., associate professor, Department of Environmental, Agricultural & Occupational Health at the University of Nebraska Medical Center (UNMC), says understanding the role center of gravity (CG) plays in handling bales that weigh between 500 and 2,500 pounds is a key element in avoiding a tractor or loader rollover.

A tractor’s CG is the point where all parts balance one another. Approximately 30% of the tractor weight is on the front axle and 70% is on the rear axle. Adding weight to the tractor can affect the CG. For a tractor to stay upright, its CG must stay within the stability baseline or where the tires touch the ground. The position of the CG can change if the tractor moves from a level position onto a slope, or significant weight is added to either the front or rear of the tractor.

“When a tractor or loader carries a bale, the center of gravity on that equipment shifts,” Yoder says. “The center of gravity raises, increasing the risk for a tractor or loader rollover. That risk is increased if the equipment loses traction when operating on rough or wet terrain.”

To offset the center of gravity shift, Yoder advises modifications to the tractor/loader such as widening the wheelbase or using ballast fluid in the tires or additional counterweights. If the center of gravity shifts to the rear of the tractor, it can cause the front end to rise. If the front rises too much, the front tires lose stability, and steering is impaired.

Tractors used to move bales should be equipped with a rollover protective structure (ROPS), and the operator should always buckle the tractor’s seat belt. A ROPS limits the degree of rollover, helping protect the operator. A ROPS is not designed to protect the tractor operator from the weight of a falling bale.

Most front-end loaders have a load capacity either stamped on the equipment or listed in a decal on the machine. The information should also be found in the equipment manual. Overloading the equipment greatly increases the risk of

CITY DIESEL

injury to the operator as well as damage to the machine.

“Using a grapple hook or bale spear to move a bale reduces potential for the bale to roll back onto the loader arms or operator,” Yoder says. “If the bales are stored uncovered outside, be aware that recent moisture can add a significant amount of weight to the bale.”

While moving a large round bale, avoid lifting it too high off the ground, which also results in a center of gravity shift. The bale should be high enough off the ground that it doesn’t come in contact with anything, but it should never be lifted high enough that the equipment operator can see beneath the bale.

“Make sure you can see over the top of the bale,” Yoder says. “Lifting it any higher increases the risk of a rollover.”

Be aware of any overhead wires in the vicinity where bales are being moved. Keep speed at a minimum during the move, avoid “jerky” movements, and drive along terrain that’s as flat and even as possible. Even a slight embankment can lead to a tractor overturn.

Yoder notes that co-workers, bystanders, or children should not be allowed to be in the area when bales are being

moved. Vision is hindered when moving a large bale. Be aware of animals in the area also.

Because of their tremendous weight, if a large round bale falls from a stack or tears loose from a grapple hook, it can crush nearly anything in its path. If multiple bales are being moved, appropriate respiratory personal protection equipment (PPE) and proper clothing and footwear are recommended to protect against animal feces and diseases such as hantavirus, animals, bees or wasps.

Use of respiratory equipment is especially critical when bales are ground. Tub grinders produce an immense amount of dust.

If the equipment operator must exit the equipment before depositing a bale on the ground, the operator should lower the bale to ground level and turn off the engine before getting out of the tractor/loader.

“The stored energy in a hydraulic system can fail, with the potential that the bale could fall on anyone or anything that’s beneath it. Never leave a bale suspended in the air if you must leave the tractor/loader.”