BUILDING SOLUTIONS 2025

For decades, ITI Australia has been at the forefront of providing high-performance engineered wood products (EWP) for the residential and commercial construction sectors. With a strong national presence and an extensive distribution network, ITI delivers innovative building solutions that help tradies, builders, and developers work smarter, faster, and more efficiently.

Our EWP range includes LVL, Glulam, I-Joists, and other structural timber products designed to meet the evolving demands of modern construction. Whether it’s strength, reliability, or ease of installation, ITI’s products are engineered to save time on-site, reduce waste, and increase productivity.

Backed by global sourcing expertise, ITI Australia ensures access to premium quality materials from trusted suppliers worldwide. Our commitment to performance, durability, and efficiency makes ITI the preferred partner for projects of all scales—from residential builds to large-scale commercial developments.

Explore Building Solutions by ITI Australia and discover why we’re a leader in engineered timber solutions.

ITI Australia has had a long history of delivering high quality, innovative structural building products to the Australian marketplace. Ensuring quality, sustainability and innovation offers you peace of mind that the structure of the building is going to stand the test of time.

Choosing the right product for your home or building project can be a daunting process and at ITI Australia we understand that.

In recent times the selection of products or components has become a mine field of environmental responsibility, product conformity & compliance and a general challenge trying to determine if multiple products that look the same are accredited to be used in the same application.

The Australian Building Codes Boards defines that all persons or companies in the supply and building chain are responsible for ensuring the correct products are used in the correct application and that the products demonstrate compliance with the National Construction Codes. This includes the manufacturer, or importer, the building product suppliers, the builder, the building surveyor and the home owner.

The easiest pathway to navigate this monumental task is to select products distributed by ITI Australia.

That is why at ITI Australia there is a product in our range for every application. We have you sorted at ITI!

Design Link: An environment of design, technology and processing

ITI Australia’s service offer surpasses providing quality, conforming building materials. With the ongoing implementation of complimenting technology, ITI can provide building professionals with a plan to site building solution for structural timber floor and roof systems.

Some of the features of Design Link include:

Docked to length timber components: Remove the demand of determining the lengths of materials during installation. Eliminate the posibility of cutting the wrong piece of timber and get the components installed faster.

Pre-cut service holes: Toilets, heating, rangehoods and exhaust fans can all be pre-cut into ITI’s range of I-Joists. Assessed and located in the correct locations to avoid any guessing which may occure onsite.

Augmenting & Notching: Complicated cuts in I-Joists and LVL beams will be pre-cut prior to delivery to site.

Internal engineering: ITI Australia understand our products better than anyone. Our internal engineering experts can provide bespoke solutions to create better onsite construction outcomes.

Less waste onsite: Reduce the amount of waste being made onsite. Reduce the amount being spent to remove the waste being made onsite.

Printed member identification numbers: Always use the right piece of timber in the right location. Every timber component come with the member ID number printed on it matching that on the layout.

IFC & DWG data file sharing: Get all fabrication based trades and suppliers on the same page. By sharing IFC 3D modelling files all trades can understand where they fit in the overall structure and eliminante costly mistakes caused by set out heights.

Showroom 3D Models: Showroom 3D models are a great way of exploring what ITI have specifed and how how it will be installed before stepping foot on site. Life size model walk throughs are also possible using a Virtual Reality headset.

ITI Australia offer a free design, re-specifcation and take-off service for anyone who intends on building with the products incorporated in this guide. Our Design & Specifcation offer covers:

Floor Framing, Pitched Skillion or Gable Roof Framing using ITI’s range of I-Joists, Laminated Veneer Lumber (LVL) and Glue Laminated Timber Beams (GLT)

Particleboard flooring and Wet Area Flooring using a stock ITI sheet product such as OxyMag or James Hardie Secura Flooring

Balconies and Decks attached to an ITI designed First Floor using treated pine, Flame Fixx, Design Pine or any other ITI structural products

Why use ITI’s free design, re-specification & take-off service?

ITI only specify products which are available

Our layouts are easy for site trades to read ITI can provide DWG and IFC files for our designs to assist other trades or suppliers such as Steel Fabricators or Frame & Truss manufacturers

ITI’s range of structural timber products is the largest in Australia

Systems designed by ITI qualify for our Design Link additional processing service offer

Our designs are supported by local technical staff who can meet in person or talk on the phone about the designs prior to being delivered to site

ITI Australia offers a variety of design tools to cater to professionals across all levels of expertise in structural timber design including builders, estimators, timber system designers and engineeres.

This tool is available subject to assessment requirements outlined in the ABCB Design Software Protocol. ITI DesignSpec2 is specifically targeted at full-time, experienced timber and truss designers or estimators. Its foundation lies in load linking, enabling users to efficiently determine member sizes for complex designs with relative ease.

Hyne Design provides user access levels ranging from Basic User to Engineer As the industry-standard application for structural timber design, it simplifies complex tasks with a straightforward interface. Users can access comprehensive reporting and certifications, making it an indispensable tool for professionals.

ClearCalcs is designed for registered engineers capable of self-certifying designs. This web-based platform offers structural engineering calculations for wood, steel, and concrete structures, providing flexibility and precision for modern engineering needs. powered by

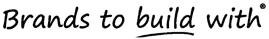

Metsä Wood is a leading European producer of high-performance engineered wood solutions, tailored for the construction, industrial, and distribution sectors. Metsä Wood transforms sustainably sourced wood into advanced, efficient products that deliver strength, durability, and versatility. Metsä Wood offers Kerto LVL, birch and spruce plywood, as well as enhanced wood products, all designed to meet the demanding needs of modern building projects.

Metsä Group has its roots in the cooperatives of the early 1900s. Metsäliitto Cooperative, the parent company of Metsä Group, was founded in 1934 and established its first sawmills in 1949. Metsä Wood, part of Metsä Group, produces engineers wood products like laminated veneer lumber, plywood and timber upgrades.

Metsä Wood’s sustainability efforts focus on using sustainably sourced wood from managed forests where growth exceeds use. Their wood products, like Kerto LVL and plywood, are designed to store carbon, reducing environmental impact. Metsä Wood prioritizes resource and energy efficiency, utilizing 96% of production side streams and aiming to minimise fossil fuel use.

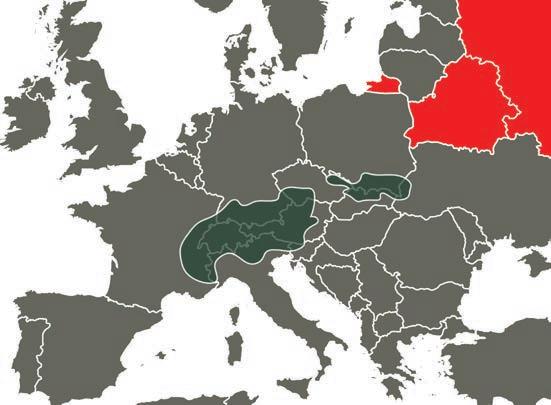

Kerto LVL is a lightweight, high-performance structural material ideal for various construction projects, including new builds and renovations. Crafted from 3 mm thick rotary-peeled softwood veneers bonded with weather-resistant phenol formaldehyde adhesive, it provides material efficiency, strength, rigidity, and dimensional stability. Custom-cut into beams, planks, and panels, Kerto LVL products meet all the requiredments of AS/NZS 4357.0 and contain no conflict woof fibre from Russia or Belarussia.

Ease the pain of lifting wall frames into postion. Kerto T-stud E9.2 is the lightest wall framing product available. With a 90x36 Stud weighing as little as 3.4kg high quality, engineered wall frames doesn’t need to be heavy. Kerto T-stud is a direct substitution for MGP10 pine in non-cyclonic applications in frames up to 3.0m high.

Kerto S-beam E13.2 LVL is easy to lift and easy to nail giving it the repuation as the timber beam preffered by on site trades. Available in sections ranging from 90x36 through to 400x75 there is a Kerto S-beam LVL suited to all timber framing applications.

Kerto S-beam PLUS E14.5 LVL is the modern, sustainable, alternative to F17 hardwood beams. Using a combination of European plantation grown Spruce and Birch to provide the perfect balance of weight and strength. Available in sections from 90x45 through to 290x45, use Kerto S-beam PLUS LVL is any protected strcutural application you’d use tradition F17 hardwood.

E13.2 Kerto® LVL

S-beam

Kerto® LVL S-beam PLUS

E14.5

E9.2 Kerto® LVL T-stud

More than 75% of Finland is covered with forests

Metsä Group is owned by a cooperative of over 90,000 Finnish forest owners

The cooperative owners hold over half of Finland’s forests

Metsä Group forests are growing roughly at a rate of 110 million m3 per year

Forest harvesting and natural loses equate to roughly 90 million m3 per year

Available with PEFC Certification (PEFC/21-31-199)

Metsä Wood’s Lohja mill, established in 1916, specialises in the production of Kerto LVL products. With an annual production capacity of approximately 90,000 m³, the facility employs 115 people.

the doorstep of the Yangtze River, Kemian Wood have access to an abundant supply raw materials and export logistics infrastructure.

BEAMS || RAFTERS || JOISTS

Suppliers tasked with the supply of logs for the manufacturing of Spec Beam LD LVL are required to demonstrate compliance with the Australian Illegal Logging Act.

Logs for Spec Beam LD LVL are sourced from ethical and sustainably managed plantation forests in the far east of France, across Switzerland, Austria, southern Germany and northern Italy.

Spec Beam LD LVL is available with FSC certifcation upon request.

BEAM 14.5

Available in sections from 90x45 through to 400x63, there is a Spec Beam 13.2 to suit most timber framing applications where generic pine framing lacks the strength and dimensions.

Spec Beam 14.5 is the sustainable softwood alternative to native grown F17 hardwoods. By controlling the tolerances of allowable features during the grading process Kemian Wood convert softwood into an LVL with hardwood-like properties.

All Spec LVL products are subject to over 70 quality control checks between logs arriving in the log yard and being exported as the final product.

Structural integrity is measured through descructive bending tests every 2 produiction hours and bond strength tests every 4 production hours.

Spec Beam LVL products are supported by the Bureau Veritas S-Mark Type 5 product certifcation scheme.

LIGHT DUTY FRAMING

Ideal for matching up traditional 100mm deep bearers & joists in existing hardwood in sub floors or trimming out short spans in 300mm deep floor systems, Spec Frame LVL is as robust light duty money saver.

Also available in 90mm sections for high quality wall stud and plates and 140, 190 & 240mm for balcony joists or lintels

CONCRETE FORMING

The light weight, high performing and fully certified Form Spec LVL is the safe choice for forming soffit and verticle concrete structures.

Available in 95x45, 95x63, 130x75 & 150x75

FORMSpec R 11.7 is UP TO 25% LIGHTER THAN OTHER CONCRETE SOFFIT FORMING LVL PRODUCTS AVAILABLE

Refer to ITI Australia - Form Spec R - Specifcation Guide for span tables

SpecFRAME R 11.7 and FORMSpec R 11.7 are manufactured using Radiata Pine logs from sustainably managed New Zealand forests.

The manufacturing facility and head office is located in Northen Sweden, specializing in the production of high-quality I-joists.

The factory employs advanced technology to ensure precision and efficiency in the production process, adhering to stringent environmental and quality standards.

Swelite Wooden I-Joists

Byggma Group is a publicly listed company specializing in building materials. We proudly own several renowned brands in the building industry, including Swelite, Huntonit, Forestia, Aneta Lighting, Uldal, and Smartpanel. Our focus on innovation and technological advancement is central to our growth strategy, driving us to invest in necessary equipment and expertise to maintain our leading position.

Swelite I-Joists are comprised of lightweight, 47mm thick, finger jointed pine flanges tied together using either a high performance particle board web or an Oriented Standard Board (OSB) web.

Swelite, the first European producer of I-joists, has been delivering high-quality products since 1974. We export to over 10 countries, offering high capacity and adaptability to meet the diverse needs of our clients. Environmental care and energy efficiency are at the heart of our processes, from tree to finished product.

Swelite’s factory in Rundvik combines deep-rooted traditions with extensive expertise in producing strong, light, and durable I-joists. Years of research and collaboration with technical consultants and universities have resulted in the highquality I-joists we offer today. By choosing Swelite, you are selecting a well-developed, sustainable solution that benefits both the planet and long-term building performance.

Swelite and Byggma Group prioritize using renewable forest materials to create durable products, supporting sustainable construction and enhancing carbon sequestration by encouraging new forest growth.

— At Byggma Group, we are passionate about our social responsibility. We strive to manage and develop all our operations in a sustainable direction.

Conrad Lehne Drangsland, CEO of Byggma ASA

ITI’s Spec Joists are a combination of an Oriented Strand Board (OSB) Web with Laminated Veneer Lumber (LVL) Flanges manufactured by some of the worlds leading manufacturers such as Metsä Wood UK and Pacific Woodtech USA.

Available in a range of sections suitable for floor and roof components in both residential and commercial applications.

Spec Joists are manufactured using highly efficient repetitive production processes. Using specialist, hands off, production equipment the quality is controlled and consistient while reducing the labour component of manufacturing.

Available from ITI, Spec Joists can be supplied as docked millimetre perfect, or for more complex builds, to the nearest 300mm length.

All Spec Joist products come standard with H2-S Treatment against inesct and borer attacks south of the Tropic of Capricorn.

Additional H2 LOSP, or similar, treatment is available allowing Spec Joists to be used above the Tropic of Capricorn.

Hyne Beam 13 & 15

Hyne Timber is a leading Australian producer of structural timber, renowned for innovation and sustainability since 1882.

Our GLT range caters to all applications, offering a variety of treatment levels, appearance grades, and strength ratings. Fully compliant with industry standards, it also carries the trusted ‘S’ Mark certification. Precision-engineered for longlasting performance, our GLT undergoes stringent testing and is backed by a 25-year guarantee. Made from sustainably sourced Australian plantation pine, it’s built to thrive in even the harshest Australian environments.

Beam 13 is our solid-wood alternative to LVL beams, designed for outdoor use. Offering excellent stability and straightness in outdoor conditions, Beam 13 is ideal for applications where nail-holding strength is critical. Made from individually treated H3 laminates, it is suitable for indoor and outdoor floor, wall, and roof applications. Additionally, Beam 13 is certified with the ‘S’ Mark, ensuring full compliance with AS/NZS 1328.1:1998 standards for structural laminated timber.

Beam 15 is a high-performance structural solution designed for long spans and heavy loads. As Hyne’s strongest softwood beam, it offers a premium alternative to GL17, LVL, or steel. It’s available in Appearance Grade A with H3 treatment or Grade B with H2 treatment. Tested and certified with the ‘S’ Mark, Beam 15 meets full compliance with AS/NZS 1328.1:1998 standards.

Beam 13 & 15 come standard as Appearance Grade B. As defined in AS1328.1: This grade is intended for use in applications where surface appearance is important but a machine planed finish is acceptable. Occasional skips in the surface are permissible and blemishes, voids and manufacturing want remain un-repaired. The outer-most laminations are free of loose knots and open knot holes.

At Hyne Timber, we only use logs that are responsibly sourced from Australian PEFC certified plantations and that carry a full Chain-of-Custody certification. So, for every pine tree that is harvested another is planted in its place, and as each tree grows it absorbs carbon from our atmosphere and locks it up, long-term.

Spec Lam 15+, manufactured exclusively by Hyne Timber, is a structural glue-laminated beam product developed specifically to match the depth of ITI’s broader range of Laminated Veneer Lumber and Wooden I-Joist products, along with open-web timber trusses, commonly used in floor framing systems.

The depths of Spec Lam 15+ can eliminate time-consuming processes during construction, such as packing up beams or embedding deeper beams in wall frames above.

Available in 240, 300, 360, 400 & 500mm deep by 68 & 88mm wide sections.

Spec Lam 15+ is manufactured to an Appearance Grade C per AS 1328.1. This allows for more wood fibre to remain as part of the beam and increasing the overall performance of the member.

Appearance Grade C is intended for use in applications where appearance is not important. All blemishes and voids are acceptable. Where the member is not machined after lay-up overlap of laminations may be present.

Established in 1978, Hyne Timber’s GLT plant was one of the first in Australia and sources premium softwood from Hyne’s own mills. A $20M upgrade in 2020 introduced advanced CNC automation and a rotary press, ensuring precise and efficient production of top-quality GLT products.

S-beam

Notes: 1. Available in Queensland only 2. Available in South Australia only 3. Available in Victoria only

James Hardie

Key benefits of Hardie fibre cement products

Design versatility

Provides contemporary clean lines and pared-back aesthetics for homes with simple, bold forms.

Durable

Engineered to endure, Hardie fibre cement is fire resistant and resistant to damage from moisture and termites.

Fire resistant

Will no contribute to the spread of fire

Resistant to moisture damage

Offers dimensional stability resisting swelling, movement and warping.

Flexible colour

Pre-primed and ready to paint in any colour.

Low maintenance

Easy to clean and holds on to paint well.

Resistant to termite damage

Stands up to termite attack.

Made in Australia

Choose Hardie™ fibre cement to support local manufacturing.

It’s Possible™ to make modern like never before with James Hardie

What is fibre cement?

Fibre Reinforced Cement (FRC), or simply, fibre cement, is a popular building material developed by James Hardie in the early 1980s, when pioneering the use of alternative reinforcing materials to create building products. Hardie™ fibre cement products are manufactured in Australia,so by choosing James Hardie, you are supporting local.

What is Hardie™ fibre cement made of?

Hardie™ fibre cement is made from a mixture of cement, sand, water and cellulose fibre, sourced from sustainably grown pine trees. Small amounts of other chemical additives are used to help the process or provide products with certain characteristics. This unique mixture of materials helps to build beautiful, low-maintenance and durable home exteriors across Australia.

Some Hardie™ external cladding products look like timber, how are they different?

Hardie™ exterior cladding solutions are engineered to stand up to harsh Australian conditions, including coastal conditions. With products such as Linea™ Weatherboard and Axon™ Cladding, you can harness the features and charm of traditional weatherboard and vertical-joint timber styles without the hassles of timber and with the benefits of Hardie™ fibre cement. Durable, low maintenance and

with broad design potential, Hardie™ exterior cladding is resistant to shrinking, swelling and cracking and will hold paint longer than wood.

Why should you choose Hardie™ fibre cement products?

Building with Hardie™ fibre cement products give you the power to realise your vision. Bold forms, clean, sleek lines, and façade articulations – the possibilities are endless.The Hardie™ Architectural Collection combines the renowned durability and product performance of our existing exterior cladding portfolio with new distinctive textures and profiles. Created to complement each other, this curated cladding collection offers endless design possibilities so you can build modern homes from the ground up, with confidence. The Hardie™ Architectural Collection is backed by a suite of solutions, from guides to technical support and expert advice, giving Builders, Architects and Designers an uncomplicated framework to deliver full lightweight homes efficiently andwith confidence. Follow us at

Secura™ Exterior Flooring is an external structural flooring substrate for tile finishes over timber or lightweight steel floor joists. Simple and fast to install, Secura™ Exterior Flooring helps give you extra peace of mind against moisture damage to balconies and decks.

Secura™ Exterior Flooring is suitable for use as an external substrate for tiled residential balconies and decks. It’s an alternative to particle board, plywood or compressed fibre cement.

* Selling Units Per Pack: 20 Sheets

Hardie™ Drive Screw 41mm Square Drive

A class 3 self-tapping wing-tipped screw for fastening to 0.5mm to 1.6mm BMT light gauge steel frames.

Selling unit: 1,000 per box

Hardie™ Blade 185mm

A poly-diamond blade for fast and clean cutting of Hardie™ fibre cement products.

Diameter: 185mm

Selling unit: 1 each

Hardie™ Joint Sealant^ 300mL Cartridge

A general purpose, paintable, exterior grade polyurethane joint sealant.

300mL cartridge

Selling unit: 20 per box

Hardie™ Drive Screw 41mm Phillips Drive

A class 3 self-tapping wing-tipped screw for fastening to 0.5mm to 1.6mm BMT light gauge steel frames.

Suitable for use in most auto feed screw guns.

Selling unit: 1,000 per box

Hardie™ Blade 254mm

A poly-diamond blade for fast and clean cutting of Hardie™ fibre cement products.

Diameter: 254mm

Selling unit: 1 each

Hardie™ Joint Sealant® 300mL Sausage

A general purpose, paintable, exterior grade polyurethane joint sealant.

600mL sausage

Selling unit: 20 per box

Notes:

All dimensions and masses provided are approximate only and subject to manufacturing tolerances.

Products are to be installed in accordance with the relevant and current Product Installation Guide and Technical Documentation. For information relating to installation, best practices, warnings and warranties visit www.jameshardie.com.au or phone us on 13 11 03.

Key:

^ Hardie™ Joint Sealant is unsuitable as a fire rated sealant. ° Excludes pallet, glut and packaging.

Secura™ Interior Flooring is a heavy-duty yet lightweight structural flooring substrate that does double duty – it can be easily used for tile, vinyl and carpet finishes over timber or steel floor joists in both residential general interiors and wet areas. Simple and fast to install, Secura™ Interior Flooring is an easy way to get top protection against

moisture damage to all interior floors.

Secura™ Interior Flooring is suitable for use as a substrate for direct fixing of tiles, vinyl and carpet in residential floors and wet areas, as an alternative to particle board, plywood or compressed fibre cement.

Selling Units Per Pack: 20 Sheets

Hardie™ Drive Screw 41mm Square Drive

A class 3 self-tapping wing-tipped screw for fastening to 0.5mm to 1.6mm BMT light gauge steel frames.

Selling unit: 1,000 per box

Hardie™ Blade 185mm

A poly-diamond blade for fast and clean cutting of Hardie™ fibre cement products.

Diameter: 185mm

Selling unit: 1 each

Hardie™ Joint Sealant^ 300mL Cartridge

A general purpose, paintable, exterior grade polyurethane joint sealant.

300mL cartridge

Selling unit: 20 per box

Hardie™ Drive Screw 41mm Phillips Drive

A class 3 self-tapping wing-tipped screw for fastening to 0.5mm to 1.6mm BMT light gauge steel frames. Suitable for use in most auto feed screw guns.

Selling unit: 1,000 per box

Hardie™ Blade 254mm

A poly-diamond blade for fast and clean cutting of Hardie™ fibre cement products.

Diameter: 254mm

Selling unit: 1 each

Hardie™ Joint Sealant® 300mL Sausage

A general purpose, paintable, exterior grade polyurethane joint sealant.

600mL sausage

Selling unit: 20 per box

Notes:

All dimensions and masses provided are approximate only and subject to manufacturing tolerances.

Products are to be installed in accordance with the relevant and current Product Installation Guide and Technical Documentation. For information relating to installation, best practices, warnings and warranties visit www.jameshardie.com.au or phone us on 13 11 03.

Key:

^ Hardie™ Joint Sealant is unsuitable as a fire rated sealant. ° Excludes pallet, glut and packaging.

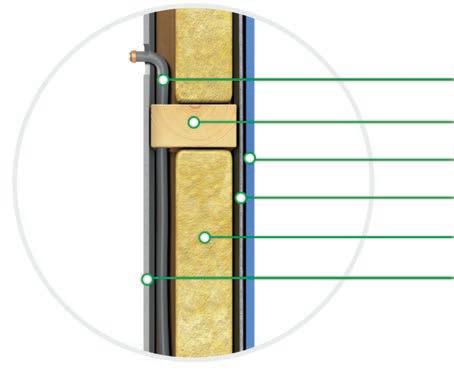

Hardie™ Boundary Wall System is a fire and acoustic rated boundary wall solution designed for Class 1 & 10a timber framed buildings. Hardie™ Boundary Wall System is up to 45% more compact than a standard brick veneer boundary wall; for every 10 lineal metres of Hardie™ Boundary Wall System, you gain up to 1.25m² of floor space#. This delivers a significant saving in usable land area while maximising property value.

Hardie™ Boundary Wall System also comes with the good looks and versatility of Hardie™ external cladding given any product 6mm or greater can be installed as part of the system.

Application(s):

Class 1 & 10a timber framed buildings.

Designed for townhouses, terraces and detached buildings where external walls are in close proximity to the boundary. Also suitable for bushfire zone areas (up to BAL-FZ).

# Compared to a standard 230mm thick brick veneer wall.

30mm cavity for services

90mm timber stud wall

Hardie™ external cladding (6mm or thicker)

Hardie™ Wrap Weather Barrier

60mm Hardie™ Fire Insulation

Hardie™ internal lining (6mm or thicker)

* Refer to the relevant Hardie™ Smart Fire & Acoustic Wall Systems Design Guide for further information.

www.jameshardie.com.au

per pack: 1 each

* Specifier is responsible for confirming of Hardie™ Wrap Weather Barrier for a specific design and climate zone with the selected external

Selling units per pack: 9mm - 30 sheets or 1 each

^ Unavaliable in WA

* Piece weight covers the physcial product weight per plank/sheet

The Latest Innovation in Cement Floor Boards

Based on the latest advancements in cement and fibre-reinforcement technology, OxyMag 16mm & 19mm floor boards are STRONGER, LIGHTER, CHEAPER & SAFER than Fibre Cement boards. Notably, OxyMag floor boards have a greater flexural bending strength than thicker, heavier Fibre Cement (FC) boards. This results in a load capacity that is greater than FC boards.

Independently tested and certified to meet NCC/BCA DEEMED-TO-SATISFY structural requirements for floor loadings to AS/NZS 1170.1 Table 3.1. See OxyMag Design & Load Tables* for more information

Suitable for RESIDENTIAL & LIGHT COMMERCIAL applications - see Design & Load Tables*

Suitable for INTERNAL, EXTERNAL and WET AREA applications

NON-COMBUSTIBLE per AS 1530.1

Less than 1% Crystalline Silica - Thus, safe/non-hazardous for workers to use/cut and not subject to Safe Work Australia's stringent work requirements.

Tongue-and-grooved for easy installation

Can be fixed with screws or a nail-gun

Green and eco-friendly production

Mould, rot and termite resistant

Free of potentially corrosion inducing chloride ions

From December 2023, we are transitioning to have all OxyMag floor boards supplied with OxyMag-branded selfadhesive builder plastic adhered to the rough side of the boards (which must face up) in order to provide temporary weather/water protection to the boards.

Tested to relevant Australian Standards - see Physical Properties Schedule*

Stronger - OxyMag floor boards are fibreglass reinforced and, thus, have a superior flexural bending strength relative to typical FC floor boards. As a result, OxyMag offers floor solutions using both 16mm and 19mm thick boards which are comparable to thicker FC floor boards - See tables below.

Lighter - OxyMag floor boards are up to 7kg lighter per board than comparable, thicker FC floor boards. This results in easier handling and faster installation.

Cheaper - By replacing FC floor boards with OxyMag floor boards, the builder can benefit from significant material cost savings. Easier handling and faster installation will also reduce labor costs.

Less than 1% Crystalline Silica (CS) = Not Hazardous - CS, when inhaled as dust particles, is a significant health hazard to workers which can lead to serious lung diseases such as silicosis and lung cancer. Fibre Cement boards contain significant levels of respirable CS and, thus, their use must adhere to the stringent work requirements issued by Safe Work Australia in order to keep workers safe. In contrast, OxyMag boards contain less than 1% CS and, thus, they are safe for workers to use/cut and Safe Work Australia’s stringent work requirements do not apply.

More Versatile - 16mm and 19mm OxyMag floor boards can be used internally, externally and in wet areas. Both OxyMag board thicknesses can be used for residential applications while 19mm OxyMag boards can also be used for light commercial applications. One board - multiple applications.

Greener Production Process - OxyMag floor boards have significantly less embodied energy than FC boards.

EziPly® Structural Panels are laid up on a hardwood core using exterior Phenol-Formaldehyde resin for consistent quality and performance. Certified to AS/NZS 2269, it gives you the assurance that it has structural integrity.

Techincal Information

• A Bond Glue

• Hardwood Core

• Complies with AS/NZS 2269

• 100% FSC® Certified

• Long Band Surface

B Face Grade

• Not recommended for aesthetic appearance

• Allows filled Holes up to 50mm

• Allows splits up to 12mm wide x 600mm long

• Allows for patches up to 75mm

• Any defect must be filled

**Available in packs and job lots (surcharge applies)

Storage & Handling

• Store Under Cover

• Keep Dry

• Do not stack directly on ground

• Always stack on a minimum of three evenly spaced bearers

While all care is taken to provide a high-quality product, plywood is still a natural timber

C Face Grade

• Not recommended for aesthetic appearance

• Allows open defects up to 75mm (i.e. knot holes)

• Allows splits up to 25mm

and as such will exhibit the same characteristics of timber anf therefore should be treated the same way.

EziPly® Panels are laid up on a hardwood core using a WBP resin for consistent quality and performance. The Non-Structural range of EziPly® products are no tested to the AS/NZS 2269 standard, however, all panels are manufactured under strict quality controlled conditions.

Techincal Information

• WBP Glue

• Hardwood Core

• 100% FSC® Certified

• Long Band Surface

B Face Grade

• Not recommended for aesthetic appearance

• Allows filled Holes up to 50mm

• Allows splits up to 12mm wide x 600mm long

• Allows for patches up to 75mm

• Any defect must be filled

**Available in packs and job lots (surcharge applies)

Storage & Handling

• Store Under Cover

• Keep Dry

• Do not stack directly on ground

• Always stack on a minimum of three evenly spaced bearers

C Face Grade

• Not recommended for aesthetic appearance

• Allows open defects up to 75mm (i.e. knot holes)

• Allows splits up to 25mm

While all care is taken to provide a high-quality product, plywood is still a natural timber product and as such will exhibit the same characteristics of timber anf therefore should be treated the same way.

Formply is traditionally used for creating forms for concreting and is designed to be reusable. in recent years Formply has seen a growth in a popularity for uses such as furniture making and shop fitting. Overlaid with a smooth resin paper Formply is designed to better handle the elements creating a product that is more suitable for use in exposed environments.

Features

• F17 Structual Rating

• AS/NZS 6669 Ceritified

• FSC® Certified

• A-Bond Glue Line

• Eucalyptus Core

• Available as Film Face Non-Structural

Sizes Available

**Available in packs and job lots (surcharge applies)

Storage & Handling

• Store Under Cover

• Keep Dry

• Do not stack directly on ground

• Always stack on a minimum of three evenly spaced bearers

While all care is taken to provide a high-quality product, plywood is still a natural timber product and as such will exhibit the same characteristics of timber anf therefore should be treated the same way.

EziPly® Tongue & Groove Plywood is a strong and durable panel suitable for structural and non-structural flooring in residential, commercial and industrial applications. EziPly® Tongue & Groove Plywood is available in multiple thicknesses and has machine grooved long edges with a plastic tongue to form a tongue and groove joint between sheets.

• All EziPly Structural products use an A Bond Glue

• Tested to AS/NZS 2098

• FSC® Certified

• Not recommended for aesthetic appearance

• Allows filled Holes up to 50mm

• Allows splits up to 12mm wide x 600mm long

• Allows for patches up to 75mm

• Any defect must be filled

• Not recommended for aesthetic appearance

• Allows open defects up to 75mm (i.e. knot holes)

• Allows splits up to 25mm

**Available in packs and job lots (surcharge applies)

Storage & Handling

• Store Under Cover

• Keep Dry

• Do not stack directly on ground

• Always stack on a minimum of three evenly spaced bearers

While

Marine Ply is traditionally used for boat building but over the years has been used in many other situations where a durable plywood is required. Selected species are used in Marine Ply based on density, bendingstrength, impact resistance and surface finishing characteristics. Combined with an ’A’ Bond glue line this results in a plywood that is superior in performance to traditional plywoods

Technical Information

• Complies with BS1088 Standard

• A-Bond Glue Line

• Select Species Only

• Highest Quality Veneers

• Used for Clear Finish

• Allows filled Holes up 6mm (max 4 per sheet)

• Allows filled splits up to 3mm wide (max 450mm2 in area)

• Allows sound pin knots up to 2mm

• Any defect must be filled with colour matched putty

• Used for Clear Finish

• Allows filled Holes up 6mm (max 4 per sheet)

• Allows filled splits up to 3mm wide (max 450mm2 in area)

• Allows sound pin knots up to 2mm

• Any defect must be filled with colour matched putty

**Available in packs and job lots (surcharge applies)

Storage & Handling

• Store Under Cover

• Keep Dry

• Do not stack directly on ground

• Always stack on a minimum of three evenly spaced bearers

While all care is taken to provide a high-quality product, plywood is still a natural timber product and as such will exhibit the same characteristics of timber anf therefore should be treated the same way.

Brace Ply is manufactured to AS/NZS 2269 and is commonly used in the construction of low to medium density building to assist with bracing internal and external wall. As it is a 4mm thick plywood with excellent bracing capabilities, it can also be used in other applications such as furniture backing or lining walls in caravans.

Features

• A Bond Glueline

• Available in Untreated or H2

• Complies with AS/NZS 2269

• Super E0 Formaldehyde Emissions

Sizes Available

**Available in packs and job lots (surcharge applies)

Storage & Handling

• Store Under Cover

• Keep Dry

• Do not stack directly on ground

• Always stack on a minimum of three evenly spaced bearers

While all care is taken to provide a high-quality product, plywood is still a natural timber product and as such will exhibit the same characteristics of timber anf therefore should be treated the same way.

OSB Boards are resin-bonded, three-layer wood material boards from oriented micro-veneers (strands). The majority of wood used is debarked. fresh spruce from sustainably managed forests. Mixed wood cariants or special hardwood varieties are also used where boards must meet specific demands.

Features

• Legally Sourced Wood Fibre

• Third Party Certified

• Strong & Durable

• Moisture Resistant Surface

• Termite Resistant (H2 Only)

Sizes Available

6

6

6

**Available in packs and job lots (surcharge applies)

Storage & Handling

• Store Under Cover

• Keep Dry

• Do not stack directly on ground

• Always stack on a minimum of three evenly spaced bearers

While all care is taken to provide a high-quality product, plywood is still a natural timber product and as such will exhibit the same characteristics of timber anf therefore should be treated the same way.

Edge Spec®, a pioneering advancement in construction materials, propels the art of concrete forming to unprecedented heights. Crafted from laminated veneer lumber (LVL), Edge Spec® is meticulously engineered to excel as the quintessential edge board for concrete formwork applications. Its distinctive composition and construction render it exquisitely suitable for the rigorous demands of the construction industry.

Features

• Superior-grade veneers to ensure premium finish

• Protected from moisture ingress by an acrylic sealant

• Cross laminted veneer structer to better resist cupping

• A-Bond external grade adhesive

• Sustainably sourced, non-conflict, pine veneers

Sizes Available

**Available in packs and job lots (surcharge applies)

Storage & Handling

• Store Under Cover

• Keep Dry

• Do not stack directly on ground

• Always stack on a minimum of three evenly spaced bearers

While all care is taken to provide a high-quality product, plywood is still a natural timber product and as such will exhibit the same characteristics of timber anf therefore should be treated the same way.

HEAD OFFICE - SYDNEY

59 Dunheved Circuit, ST MARYS NSW 2760 P: 02 8805 5000 F: 02 9623 0492 salesnsw@iti.net.au

MELBOURNE

68-80 Kirkham Rd, KEYSBOROUGH VIC 3173

P: 03 9392 8400 F: 03 9391 8709 salesvic@iti.net.au

TASMANIA 17 Bell Bay Rd, BELL BAY TAS 7253 P: 03 9392 8400 F: 03 9391 8709 salestas@iti.net.au

19 Nelson Rd, CARDIFF NSW 2285 P: 02 4953 7666 F: 02 4954 3966 salesnc@iti.net.au

62 Creek Street, BUNDAMBA QLD 4304

P: 07 3436 8400 F: 07 3436 8499 salesqld@iti.net.au

54 - 62 Enterprise Street, BOHLE QLD 4818 P: 07 4724 5509 F: 07 4721 0917 salestsv@iti.net.au

INTERNATIONAL New Zealand, Indonesia & Chile

ADELAIDE

82-94 Grand Trunkway, PORT ADELAIDE SA 5015

P: 08 8447 0400 F: 08 8447 0440 salesSA@iti.net.au

102-108 Bannister Rd, Canningvale WA 6155 P: 08 9256 5700 F: 08 9455 2905 saleswa@iti.net.au

ITI accepts no responsibility for any errors, omissions, work completed or any consequences of reliance on this document. it is a guide only.