Since establishment in 1987 in Five Dock, NSW, Independent Timber Importers has been on a mission to redefine the timber industry wholesale/distribution landscape. ITI has worked closely with industry suppliers, customers and associations to promote the strength, beauty and environmental benefits of using timber. At the same time ITI redefined the role of the wholesaler with its distribution and service models. With its large investments in distribution centres, product development, people and service standards; in early 2002 ITI dropped the name Independent Timber Importers and replaced this with ITI and introducing the new logo with the “Innovative Timber Ideas”phrase which more accurately describes the attitude of the company.

Today ITI consists of 9 distribution sites across Australia with over 130,000m2 of undercover storage, a state of the art re-manufacturing, treating and priming plant in Chile, an office in Indonesia, 3 distribution locations in New Zealand and growing sales in the USA.

True to its name, the success of ITI lies in its commitment to innovation in both service and product development. This commitment has led to premier brands such as Design Pine, EziTrim Plus and Spec Beam along with the distribution of market leading products such as Pacific Woodtech, Metsa Wood, Weathertex and Modwood. ITI has also led the way with service standards winning countless industry awards for its service.

ITI source Engineered Wood Products from leading manufacturers to ensure the needs of building designers through to the end users are met with the best available product.

ITI Engineered Wood Products offering is comprised of 3 major products with each intended on complimenting the next. Laminated Veneer Lumber (LVL), I-Joists and Glue Laminated Timber Beams (GL). These products along with innovated construction details and dedicated support staff form an innovative platform which set ITI Engineered Wood Products apart from the rest.

Available from ITI Australia is ITI Design Spec. A single member design software developed to assist industry professional with the specification of ITI’s vast range of structural timber products. Free licences are available to suit builders, timber merchants, frame & truss professionals and engineers. Email ewp@iti.net.au for details on how to accesss.

Metsä Kerto® LVL T-stud, proudly distributed by ITI (Australia), is a lightweight laminated veneer lumber product specifically developed for use in wall framing. Kerto® LVL T-stud is easy to handle, has fit for purpose strength and will provide trades people with a building material they will love using. Deliver your clients an expert quality finish using Kerto® LVL T-stud as the unseen structural hero.

Metsä Kerto® LVL T-stud framing is a seemless substitute for MGP10 Kiln Dried Pine in Wall Framing (Studs & Plates) up to 3050mm high for Wind Load Zones of N3 and below. Additional specification may be provided via the Metsä Kerto® LVL T-stud Wall Framing Specifcation Guide or the ITI Design Spec software available for free download from www.itiaustralia.com.au

Kerto LVL is produced from 3 mm thick, rotary-peeled softwood veneers that are glued together to form a continuous billet. The billet is cut to length and sawn into a wide range of LVL beams. Raw wood material comes from the sustainably managed and PEFC-certified forests of Metsä Group’s Finnish forest owner members, ensuring that the origin of the raw material is traceable.

It is a requirement of the Australian standard for manufacturing Laminated Veneer Lumber that an external ‘A Bond’ be achieved between the veneers by using a phenolic type adhesive.

Determining Roof Load Width (RLW) at Supports -

Overhang

Determining Floor Load Width (FLW) at Supports FLW

Additional Blocking required under joint

Roof Beam or Girder Truss

Joint in plate off stud supporting Rafter or Truss

Rafters or Trusses

600mm Max. Spacing between nails

600mm Max. Spacing between nails

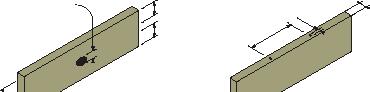

Where multiple ply studs are required they are to be laminated using framing nails, or minimum 10 gauge screws, at 600mm centres maximum. Drive fixings alternately from either side of studs where possible.

Where multiple plates are required 2x nails are required to be installed at no greater than 600mm centres. All joists in bottom plates are to be over floor joists, solid block or over a concrete slab.

Where multiple Top Plates are used, joints are permissable off stud however if a rafter or truss are supported over the plates span additional blocking is required under the joint.

Metsa Kerto T-stud is a light weight timber product which provides the end user with numerous benefits. As a result of this light nature additional attention should be given when assessing point loads which have been applied to the top plates.

Studs Depth Studs Breadth

3x Stud Depth spacing between any holes and notches

Max. 18mm

Max. 10mm

Max. 25mm diameter holes to face of Stud only

Max. 25mm diameter holes to face of Plate only

50mm max.

Greater than Hole Dia. 50mm min.

D, <200mm

Common studs are evenly spaced at a distance suitable of supporting the loads along with providing adequate fixing for external wall claddings and internal plasterboard. Common Studs are fixed to horizontal timber plates at either end and require additional restraint noggins which is provided by noggins.

Refer to page 20 for specification notes

Noggins at 1350mm max.

Upper Level Framing Supported Floor Framing Common Stud

Supported Floor Framing

Supporting Wall

Concentrated Load Studs are used in addition to Common Studs to directly support imposed loads from Girder Trusses, Roof Beams and Floor Beams.

Roof Loads Only

Truss or Roof Beam

Jamb Studs are clusters of studs used to support lintels over windows and doors. Each cluster contains full height Jamb studs and Secondary Jamb Studs, also known as Prop Studs, which are used to support the lintel.

Where Lintels support additional imposed loads from Girder Trusses, Roof Beams or Floor Beams the cluster shall be increased, as a minimum, by the size of the Concentrated Studs required to support the imposed load (Refer to Concentrated Load Studs in the guide).

Where the imposed load is located in the central third of the Lintels span, the breadth of the Jamb Stud cluster on boths side shall increase by a minimum of half the required Concentrated Load Stud breadth.

Where the imposed load is located in the outer third of the lintel span or directly over the jamb studs, the breadth of the cluster shall increase required Concentrated Load Stud breadth. In addition the breadth of the Secondary Jamb / Prop Studs shall meet the minimum required size to provide adequate bearing support for the supported lintel.

Top Plates, where the design permits, may be made up of either single member or a 2 ply Top & Ribbon Plate configuration. Top Plates are designed to span across the studs below. Top Plate are to be provided along the full length of all walls, including over openings.

Bottom Plates are designed to span across lower supporting Floor Joists. Where the bottom plate is fully supported by a concrete slab, continuous blocking or rimboard they shall be a minimum of 35mm wide x the breadth of the supported studs over.

Ends of Bottom Plates may be butt-jointed provided they are fully supported by floor joists, blocking or a concrete slab.

Bottom Plates supporting Jamb Studs to openings greater than 1200mm, or below Concentrated Load Studs, shall be fully supported.

Level Framing

For external non load bearing gable end walls the size of the stud is to be detemined by considering the averaging height of the 5 longest studs against the table below. Noggins are to be installed at 1350mm centres maximum.

Noggins at 1350mm max.

1. Floor framing members are to be installed per AS1684.2, AS1684.3 and good building practice.

2. Maximum roof load width of 7500mm considered across all applicable designs.

3. All member designs based on N2 wind loading.

4. Maximum roof pitch of 35 degrees.

5. Lower level member designs based on an upper level frame height of 2740 supporting a combined total of 25kg/m2 of external cladding and internal lining.

6. Floor live loadings based on residential 1.5 kPa distributed load & 1.8 kN concentrated.

7. Floor dead loads based on 42 kg/m2 or 19mm particle board flooring and 10mm plasterboard ceiling.

8. Maximum square metre load area considered for a concentrated load is 40m2

9. Concentrated Load Studs are designed to support verticle loads only. No horizontal wind loads have been considered.

10. Jamb Stud designs subject to the required bearing width for the supported Lintel.

11. Widest frame opening considered for Jamb Stud design is 6000mm.

12. Frame openings for Jamb Studs considered in 300mm increments.

13. Top Plates to be tied-down at 1800mm centres maximum.

14. Raking Wall Studs are not designed to support any roof framing. Where outriggers cantilever off the top of the wall the studs should be designed with the appropriate roof load width.

15. Lower Lintels designed to support a 2740mm high wall frames over supporting 25 kg/m2 of combined external cladding and internal wall lining.

16. Member sizes nominated are based on the product being fully protected from moisture and maintains an average moisture content of 15%, or less, over a period of 12 months i.e. K4 = 1.0 per AS1720.1 clause 2.4.2.3.

17. Member sizes nominated are based on construction in coastal areas south of latitude 250 and south of latitude 160 in all other areas i.e. k6 = 1.0 per AS1720.1 clause 2.4.3

Kerto® products – like all other engineered wood products – must be handled and stored properly and carefully. Incorrect handling and storage may introduce defects on product’s surfaces, edges or corners. Furthermore, the dimensional stability of the product may suffer.

While transporting or storing the product, increased moisture caused by rain or splashing must be avoided. If Kerto products are moved with a forklift truck, wide enough forks must be used in order to avoid damaging the product. When lifting several packs at a time, the distance between forks must be wide enough to ensure safe lifting. Surface-treated products should be delivered direct to site without additional, unnecessary off-loading during delivery.

Kerto products must be stored under cover. When storing the products temporarily on site, a solid, straight and dry platform should be used. The height of ground bearers must be at least 300 mm. To avoid twisting of the product, the bearers between packs must be aligned vertically with the ground bearing timbers. The plastic wrapping of each pack must be cut open from underneath to enable moisture to evaporate from the bundles. If the products are stored on site for longer than one week, the bundles must be covered with an additional protective covering. Conditions of the products and protective cover must be monitored regularly during storage.

Kerto product packs may be unloaded on site with either a forklift or a crane. Approved webbing slings must be used if unloading with crane. It is forbidden to use chains or wires. If unloading is done manually, the pack is opened and the products are carried one-by-one. While cutting the banding, beware of band’s ends. Kerto products should not be dragged or dropped.

Kerto is a light-weight material and is easy to shape, which means notable time and cost savings in construction. Kerto products can be processed with conventional wood working and power tools. There is no need for separate specialist tools.

Surface-treated products should be unloaded individually. If needed, a cellular plastic padding that does not stain, should be used under the webbing slings.

Spec Frame 10.0 is ITI’s engineered Laminated Veneer Lumber (LVL) alternative to MGP10. Make wall framing straight the first time and eliminate the need to sight your framing for bow, spring or twist. With a joint group of JD3, Spec Frame 10.0, provides superior fixing capacity for bracing components.

Spec Frame 12.1 is ITI’s engineered Laminated Veneer Lumber (LVL) alternative to MGP12. Make wall framing straight the first time and eliminate the need to sight your framing for bow, spring or twist. With a joint group of JD3, Spec Frame 12.1, provides superior fixing capacity for bracing components.

Spec Beam 13.2 is the economical choice for LVL E13.2. Available in all the commonly specified sizes by engineering professionals you can always find an option for your beams, rafters or joists. ITI laminated veneer lumber products are compliant to Australian regulations for structural adequacy as well as responsible forestry.

Available in Victoria and Tasmania, Spec Beam 14.5 is the simple, modern, sustainable, alternative to F17 hardwood and a direct replacement for 42mm LVL 15. It is available in the same section sizes as traditional F17 hardwoods. Readility available in long straight lengths and is easy to hande.

Form Spec LVL is either lightweight New Zealand Radiata Pine or Europen Spruce designed specifically for concrete soffit forming. Weighing as much as 25% less than other products available in Australia, Form Spec LVL is ideally suited for the agile process of form working.

Edge Form is a concrete edge forming laminated veneer lumber board designed to resist deformation generated by uneven uptake of moisture which occurs during the concrete pouring process. It boasts high quality veneers to the outer faces for a clean finish and small pencil round corners for ease of handling.

Available in New South Wales & Queensland, Spec Joists Wooden I-Joists are comprised of high grave LVL top & bottom flanges with as OSB web. The combination of these components creates an ideal timber joist with a 300mm deep option capable of spanning 6.0m. Spec Joists can be provided docked to length and with service holes pre-cut to save time on site - consult your local timber supplier for more details.

Spec Lam 15+ is an Australian-manufactured structural gluelaminated beam product developed specifically to match the depth of ITI’s broader range of Laminated Veneer Lumber and Wooden I-Joist products, along with open-web trusses commonly used in floor framing systems. Spec Lam 15+ is a non-visual / structural grade replacement for GL17 timber glue laminated beams.

ITI Technical Support Centre

68-80 Kirkham Road West, Keysborough, Victoria 3173

P || 03 9394 8400

E || ewp@iti.net.au

ITI Queensland (Townsville)

54-62 Enterprise Street, Bohle, Queensland 4818

P || 07 4724 5509

E || ewpqld@iti.net.au

ITI Queensland (Brisbane) 62 Creek Street, Bundamba, Queensland 4034

P || 07 3436 8400

E || ewpqld@iti.net.au

ITI New South Wales (Newcastle) 19 Nelson Road, Cardiff, New South Wales 2285

P || 02 4953 7666

E || ewpnsw@iti.net.au

ITI New South Wales (Sydney) 59 Dunheved Circuit, St Marys, New South Wales 2760

P || 02 8805 5000

E || ewpnsw@iti.net.au

ITI Victoria (Melbourne) 68-80 Kirkham Road West, Keysborough, Victoria 3173

P || 03 9394 8400

E || ewpvic@iti.net.au

ITI TASMANIA (BELL BAY) 17 Bell Bay Road Bell Bay, Tasmania 7253

P || 03 9394 8400

E || ewptas@iti.net.au

ITI South Australia (Adelaide) 82-94 Grand Trunkway, Gillman, South Australia 5013

P || 08 8447 0400

E || ewpsa@iti.net.au

ITI Western Australia (Perth) 102-108 Bannister Road, Canning Vale, Western Australia 6155

P || 08 9256 5700

E || ewpwa@iti.net.au