Our passion for screening was conceived at the end of the 1970s

We have always demonstrated intuition and enthusiasm, thanks to which we have successfully established ourselves in the world of screening.

Our way of working is characterised by a high level of flexibility, which allows us to obtain significant immediate results Direct contact with customer issues constantly stimulates our planning.

We offer an absolute guarantee of quality, and we have always guaranteed optimum operation of the vibrating screen made ad personam

We are a 100% Made in Italy company; every one of our vibrating screens is entirely made in-house.

Our vibrating screens are able to cope with very difficult screening and high hourly flow rates, thanks to the special vibrating motors installed, designed to operate continuously 24 hours a day, 365 days a year.

01-32

BAKING SUPPLIES, EQUIPMENT AND INGREDIENTS

33-65 PROCESSES AND PACKAGING

66-80

POWDER - BULK SOLIDS

84- 98 NEWS

99-113 AUTOMATION

114 -124 EXHIBITIONS

SONIA V. MAFFIZZONI Editorial Manager

RE PIETRO SRL

POPPING MACHINE RP-EVO. PG. 20/22

UNIVERSAL PACK SRL

60 YEARS OF INNOVATION, SUSTAINABILITY AND GLOBAL EXCELLENCE. PG. 42/44

TARNOS S.A.

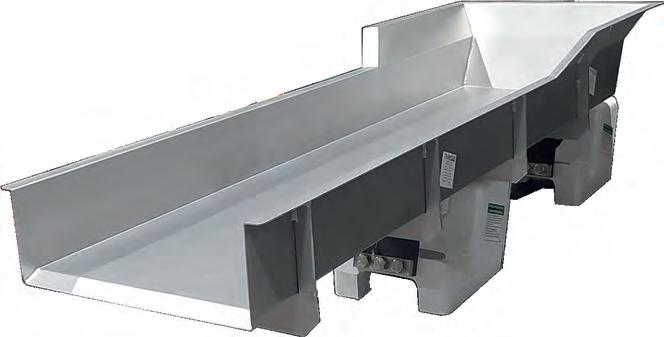

ELECTROMAGNETIC VIBRATING FEEDERS: A SMART MOVE FOR FOOD AND PACKAGING LINES. PG. 70/72

In this issue we explore three perspectives currently shaping the food processing industry: bakery and confectionery innovations presented at IBIE in Las Vegas, packaging and labeling technologies highlighted at Fachpack in Nuremberg, and powder processing solutions showcased at Powtech. These events demonstrate how tradition and innovation converge.

Bakery and confectionery rely on centuries-old know-how, now enriched by biotechnology, data-driven processes, and smart automation. Packaging and labeling increasingly respond to demands for sustainability, traceability, and stronger brand identity. Powder technologies ensure efficiency and consistency in countless formulations, securing reliability from raw materials to finished products. Across these sectors, the common thread is evident: the industry is evolving toward smarter, safer, and more sustainable solutions, capable of addressing performance, health, and global challenges while keeping human expertise and creativity at the core.

editorial management and registered office: Editrice Zeus Srl: Via Cesare Cantù, 16 20831 Seregno (MB) - Italy

Tel. +39 0362 244182 / +39 0362 244186 web site: www.editricezeus.com e-mail: redazione@editricezeus.com portal: www.itfoodonline.com skypeTM: editricezeus

Editrice Zeus: +39 379 2421278

Machineries, plants and equipment for food and beverage industry year XXXVI - issue n. 4 - September 2025

editorial manager

S.V. Maffizzoni redazione@editricezeus.com

editorial production Sonia Bennati bennati@editricezeus.com

account dep. manager Elena Costanzo amministrazione@editricezeus.com

project and layout design

ZEUS Agency grafica@editricezeus.com

creative dep ZEUS Agency grafica@editricezeus.com translations ZEUS Agency in partnership with: Thai-Italian Chamber of Commerce info@thaitch.org printing ZEUS Agency

Italian Magazine Food Processing

Europe: single issue: Euro 25 Annual (six issues): Euro 120

Outside Europe: single issue: US$ 30 Annual (six issues): US$ 170

Subscription payment can be made in the name of Editrice Zeus srl, by bank money transfer or cheque.

Italian Magazine Food Processing

An outline of the suppliers of machines, plants, products and equipment for the food industry. Published: monthly. Registration: Court of Monza no.10 of 05.09.2018. Shipment by air mail art.2 comma 20/b law 662/96 Milan. Panorama dei fornitori di macchine, impianti, prodotti e attrezzature per l’industria alimentare Periodicità: mensile. Autorizzazione del Tribunale di Monza, n.10 del 05.09.2018

Spedizione in a. p. 45% art. 2 comma 20/b legge 662/96 Filiale di Milano

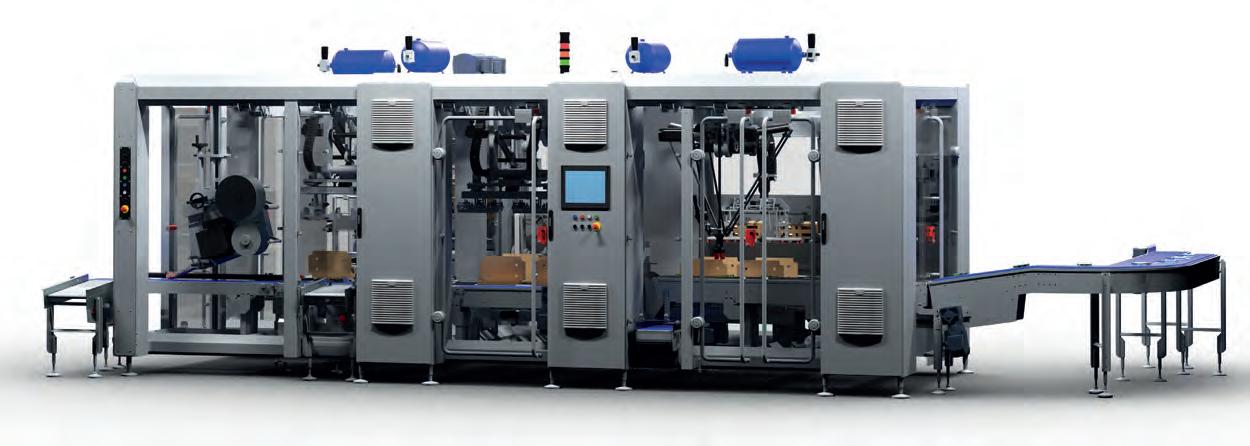

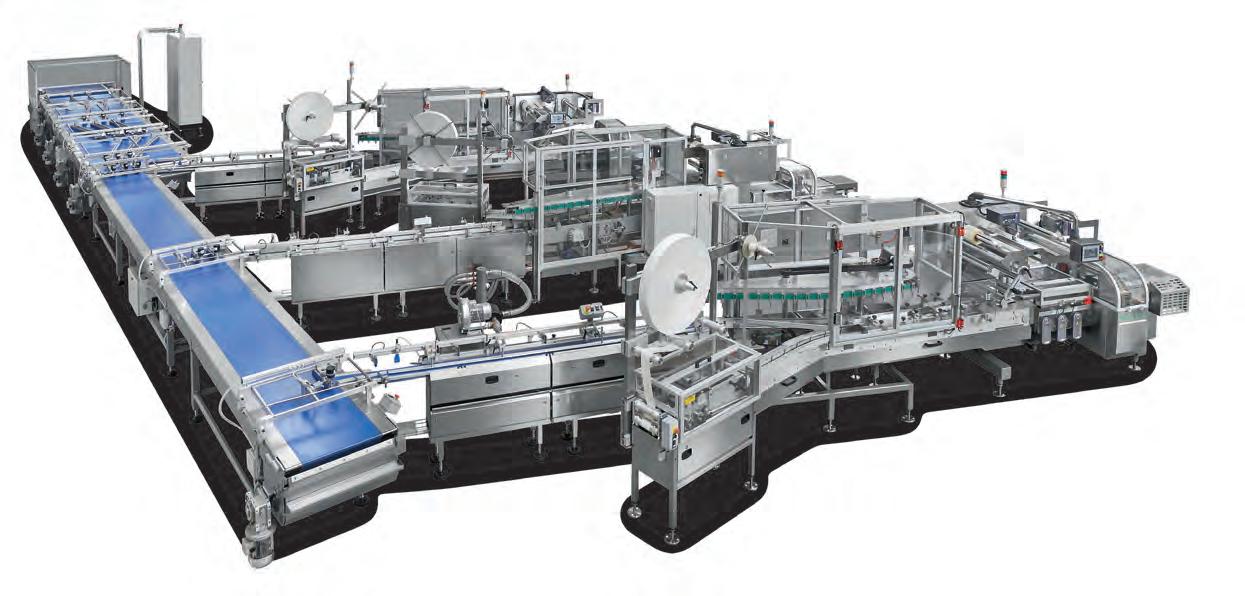

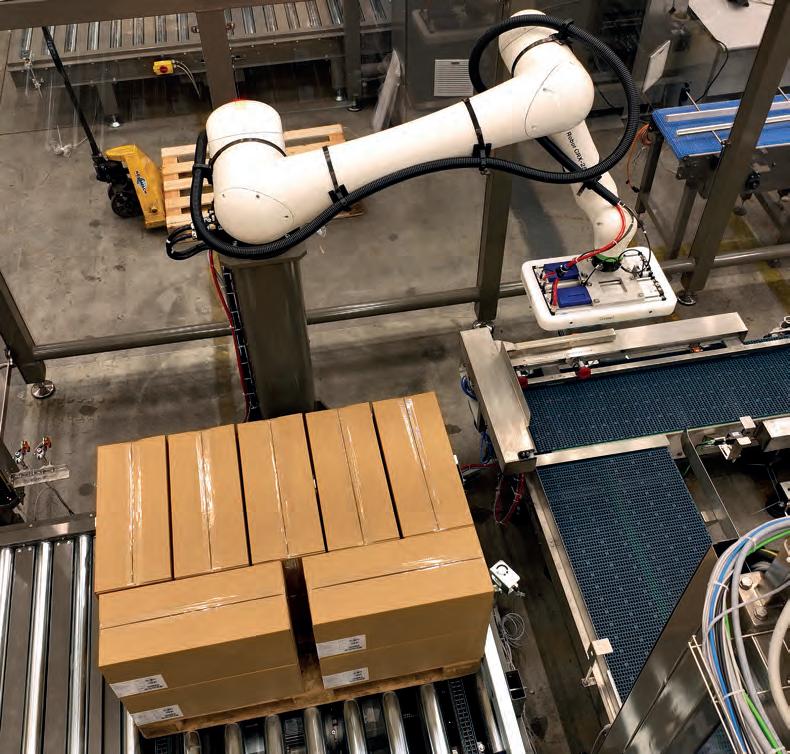

Cama Group develops a multi-machine replacement programme that will see competitor’s overly complicated machines replaced by state-of-the-art, quick-changeover packaging technology

Uptime is one of the most important metrics a packaging technology OEM can offer. With operational equipment effectiveness (OEE) maximised, end-user customers can get the best possible return on investment thanks to high levels of high efficiency throughput, with minimal interruptions.

Maximum uptime is a primary feature of machines developed by the Cama Group, even those designed to handle multiple product sizes and counts.

Through clever design and highly flexible architectures, the Italian packaging technology expert can completely remove some changeover routines, and for those that are unavoidable

complexity and time are kept to an absolute minimum thanks toolless fasteners, RFID-coded parts and intuitive AR/VR interfaces, which create unambiguous easy-to-follow instructions.

This capability was recently highlighted in a packaging solution developed to package four different sizes of bakery products, in seven different packaging counts, Cama’s technology is replacing older packaging machines from a competitor that are overly complex, inefficient to changeover and demand a lot of maintenance.

“The contract is to replace all 15 machines,” explains Davide Di Lorenzo, Sales Engineer Manager at Cama Group.

“We are confident that the initial designs are as close to spec as we can get them, but we have built a framework into the contract where we will

regularly liaise with the customer to ascertain if any improvements can be made for the next batch of machines.

Our highly flexible automation, robotics, and mechanical architecture means we can keep our designs and their method of operation highly agile.”

In operation products are oriented by lineside personal on an infeed conveyor.

A vision system is used to ascertain locations before delta robots – developed in house by Cama specifically for packaging operations – pick them and place them into boxes, which are formed in pairs and placed into a rotary phasing unit.

All boxes receive a leaflet, which is put in place using a directional inserter and, depending on the product size and count, an interlayer is also inserted for extra protection between layers.

Once filled, the boxes are sealed, weighed and labelled before being checked with an advanced vision system.

The only changeover required between batches is for the forming and closing system. This is in stark contrast to the machines they are replacing, where virtually every module had to be replaced when the size or product count was changed.

“Our machines have also been designed to offer maximum accessibili-

ty,” explains Di Lorenzo, “so changeovers and scheduled maintenance are as easy as possible.

This openness is even more impressive when you consider the real estate we had to work with. The production floor is very tight on space, but we were able to create a machine just 7.5 m long (9 m with infeed conveyor).

This compact design is due to the flexibility of our modular sections where we can fit six operations into three modules, which, when combined with a rotary box phaser keeps size to an absolute minimum.”

Compared to the machines they are replacing the Cama technology makes effective use of more modern technology and does so without complicating operator interactions and operations.

“The customer had realised that its existing machines were overly complicated and, if anything, too articulated, and they required far too much time and effort for changeovers between batches,” Di Lorenzo adds. “Although our machines are technologically more capable, our incor-

poration of RFID, AR and VR systems means that what little changeover and maintenance steps there are, can all be achieved much more easily and quickly.

Aside from the technology angle, the customer had also created a very strong relationship with Cama”

This is another example of Cama’s forward-thinking approach to packaging technology.

By understanding its customers’ pain points and then designing simple and fast ways to overcome them, Cama has developed yet another solution that set the pace in terms of operability, real estate use, ease of use/access and throughput

www.camagroup.com

Dolcezze Savini is a company based in Tuscany that for three generations has passionately been working in the art of bread and pastry making, using old processing techniques and carefully selected ingredients. From its factories in Valdarno, for over fifty years Dolcez-

ze Savini has been baking high-quality products such as the famous bread cooked in a wood-burning oven, made with Tuscan wheat.

In addition to the different varieties of bread and pizza made with different types of flour, the Valdarno brand bo-

asts a rich pastry production that also includes the typical traditional pastries from Siena produced by the historic company Fiore 1827, acquired by Dolcezze Savini in 2017.

Among these specialities there are three important IGP products: two of them are from Siena and they are Panforte and Ricciarelli, while the almond biscuits named Cantuccini are linked to the Tuscan territory. For a long time, Dolcezze Savini has focused its activity on a production that pays particular attention to the importance of some elements such as natural ingredients, reduced gluten products, palm oil-free products and a clearer labelling system.

The current size of the company, which counts more than a hundred employees in total, has not affected the original characteristics of Dolcezze Savini, confirming its vocation for craftsmanship, its dedication to quality and its desire to be at the forefront of the technology used in its factories.

In this regard, in 2019 the company built a new production plant of over 4,000 meters with the clear intention of investing in technological innovation. Alongside the integration of two new semi-automatic lines for the production of partially baked bread, the new investment has opened more space for

artisanal production with the strengthening of the production of handmade pizza dough. The company has also developed a complete electronic management system, making it part of the world of industry 4.0. This innovation process has found full achievement in the strengthening of its packaging

sector, for which Dolcezze Savini has called upon the group Tecno Pack, a leading company in the supply of packaging technologies.

For over 30 years Tecno Pack has been designing, manufacturing and distributing horizontal packaging machines and automatic packaging systems for the food industry and other sectors. Tecno Pack is a group of companies including Tecno Pack, IFP and GSP. Based in Schio, in the pro-

vince of Vicenza, Tecno Pack stands out for being a pioneer and innovator in the packaging industry, developing cutting-edge solutions, increasing the digitalization of machines and plants, offering its customers excellent results with limited investments.

The partnership between Tecno Pack and Dolcezze Savini has resulted in the development of three packaging lines, specifically designed by the group for the bread sector of the Tuscan company. These, in detail, are

the new packaging lines implemented in the production system of Dolcezze Savini: •Monopiega Diamond 650 wrapper. This is an innovative and highperformance shrink wrapping machi-

ne, designed to wrap small, medium and large-sized items as well as thin solid products;

• Flow pack ATM FP 025 line suitable for pizza dough and ideal for “pinsa” (a traditional pizza made with an ancient Roman recipe). This horizontal packaging machine is specific for modified atmosphere packaging thanks to the tight packs granted by the sealing system. It is the most suitable flow-wrapper when aesthetically good-looking packages with high-quality side gussets and thick wrapping materials are required;

• The FP 015 line for sandwiches. This horizontal pillow pack wrapper

has a particular cantilevered frame with easy accessibility that helps sanitation, both for hygienic and maintenance reasons, guaranteeing full safety at work.

At the same time, the historical production carried out by Fiore 1827 was also implemented with the purchase of a vertical + multi-head packaging machine to improve the type of packaging and achieve greater production efficiency.

With the selection of these tailormade solutions, designed according to the production needs of Dolcezze Savini, the Tecno Pack

group not only proves to be a leading manufacturer in the sector of packaging machines and systems but also confirms to be the ideal partner to integrate new technologies created as “tailor-made” solutions according to specific automation requirements

The precious and fruitful collaboration between the Tecno Pack group and Dolcezze Savini represents the utmost expression of the most recent technological innovation combined with traditional working procedures for the production of a great variety of quality products with an authentic artisanal flavour.

“

Bread is as old as civilization itself, but today it looks to the future with new eyes. Hybrid fermentations, predictive data and artificial intelligence are transforming the white art into an evolved science. Technology and tradition are not mutually exclusive: they reinforce one another. Because even a dough can become intelligent-if it’s thoughtfully conceived.

Tby Sonia V. Maffizzoni

he time of bread and the time of innovation

Bread is one of humanity’s oldest foods. A symbol of sharing, work, and family. Yet, more than ever, this millennia-old food is undergoing a radical transformation-quiet, yet concrete. Today’s baking comes with new expectations: sustainability, traceability, health, and cost control.

Just to share some data: according to Innova Market Insights, 55% of global consumers seek foods that offer measurable functional benefits, while Euromonitor reports that over 60% of baked goods launched in 2024 include at least one health-related claim on the label. The message is clear: it’s no longer enough for bread to be good-it must do good, tell a story, and adapt to a changing society (perhaps because it is its symbol). When we talk about “smart bread”, we don’t mean just algorithms. We’re talking about bread that stems from a deeper mindset: smart is what adapts. A “smart” bread reads its context, integrates nutritional needs, responds flexibly to raw materials, optimizes processing times, reduces waste, and respects the environment.

Intelligence in baking is therefore both artificial and real: technical, but also cultural. It’s the result of a deep connection between human expertise, fermentation, and innovation.

Where does the dough’s intelligence begin?

It starts with fermentation. That’s where most innovation is focused today.

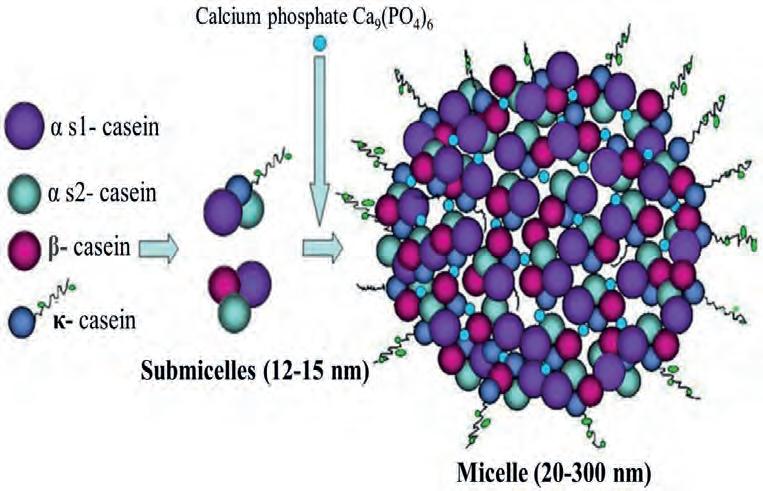

As baking professionals know, yeasts are no longer limited to traditional strains. Today, selected strains are engineered for specific functions-boosting nutrient bioavailability or reducing simple sugar formation. Hybrid fermentations, combining yeast and lactic acid bacteria, improve digestibility, flavor complexity, and shelf life.

Even the pre-ferment is no longer a standard preparation, but a dynamic system. Fermentation is now modulated over time and calibrated according to the enzymatic content of the flour, ambient temperature, and humidity. Some plants, for example, use sensors to monitor microbial metabolic activity in real time. This allows proactive adjustment of the process, minimizing waste and flavor deviations.

The result is more stable doughs, with batch-to-batch consistency-an essential condition for industries seeking both artisanal appeal and quality standards.

If yeast is the living heart of dough, artificial intelligence is its analytical brain. Today, AI can process thousands of production data points: rheological curves, water absorption rates, ambient temperature, flour strength variations.

In one real-world case, an industrial bakery with smart systems integrated in-line sensors and predictive software to analyze the dough’s behavior during proofing. This enabled automatic adjustment of resting times based on humidity and flour strength, reducing texture variability by 15% and ensuring consistent quality in the finished product.

Once the domain of expert bakers’ eyes and hands, these data are now systematically processed by predictive algorithms-delivering more accurate, constant, and documentable control.

In some facilities, digital twins simulate the dough’s entire journey-mixing, proofing, baking-in a virtual environment. This allows parameter testing without halting production. Integrated AI systems can already correct mixing speed or proofing time in real time, based on incoming raw material.

Smart bread is no longer just a lab dream: it’s already being implemented.

Efficiency, flavor, and wellness: the new bread triangle

Price used to be the key issue. Today, bread is also about positioning, health, and perceived value. According to Mintel, over 40% of European consumers view bread as “healthy only if it’s rich in fiber or protein.” And a 2024 FMCG Gurus report says more than 30% of buyers look for digestive benefits on bread labels. Hybrid fermentations enhance the nutritional profile without compromising taste. New functional flours, combined with selected yeasts, produce low-glycemic breads rich in soluble fiber or bioavailable phytocompounds. At the same time, technology enables more efficient resource management: less waste, less energy, faster output. The future of bread rests on three inseparable pillars: production efficiency, perceived wellness, and sensory pleasure. Flavor is part of the value. Intelligence, here, means designing it systemically.

Yeast and machine: alliance, not opposition

Technology does not erase human expertise-it amplifies it. Master bakers in industrial contexts are now called to interpret data, read dough behavior, and interact

with learning machines. An experienced baker knows by touch when hydration is right, or when dough needs more time or warmth. Today, that knowledge can be recorded, shared, and replicated. Data becomes collective memory, company heritage-even a training tool. In many plants, the baker has evolved into a “process baker”: a professional who guides machines while preserving artisanal sensibility. It’s not about replacing the human touch-it’s about extending and industrializing it. Even gestures become smart.

Beyond flour: bread as a social interface

Bread has always been more than food. It’s a daily act, a shared culture, a symbol of connection. Baking the future means recognizing this and putting it at the core of transformation.

In a world where every ingredient can be traced, every process optimized, and every choice narrated, bread becomes an interface between maker and consumer. Innovation is not just technical: it’s the possibility to build more conscious, inclusive, and sustainable supply chains.

In the world of baking, pastrymaking and pizzerias, precision in dough mixing time control is essential to ensure quality and repeatability in production processes. Sitec, a company specializing in the production of professional timers and temperature controllers, presents the new Timer 144 OLED Blue, a technological evolution that combines reliability, ease of use, and advanced functionality.

This new model is the natural successor to the Double Timer 72x144, maintaining mechanical and electrical compatibility with the previous version while introducing a renewed interface. The main innovation is the 2.42-inch Blue OLED display, which ensures high resolution and high contrast, making it easier to read information.

Equipped with a dial with 11 LEDs for intuitive adjustment, the Blue OLED Timer 144 allows optimal control of the mixing time for dough mixers with two or three mixing phases In addition, the presence of four additional LEDs provides a clear indication of the movement of the bowl and spiral,

with a warning LED for immediate monitoring of the work cycle.

Notable features include pre-mixing time management with reverse bowl rotation, the ability to program mixing times up to 60 minutes, and storage of up to 10 customizable recipes.

These functions help to standardize processes, reduce errors, and improve production efficiency.

For those needing even more advanced control, Sitec offers models with additional features, including dough temperature display and the management of inverter motor for even greater recipe customization.

With its combination of advanced technology, reliability and practicality, the Blue OLED Timer 144 proves to be an ideal solution for industry professionals, helping to raise the standards of precision and quality in machining processes. Visit:

The new Sitec electronic timer combines the practicality of a manual dial with the precision of digital technology

• Up to 10 stored recipes

• Simplified installation: Plug and Play with the traditional Sitec timer

• Adjustable working times settings via LED dial and indications on display for easy control

• Control of up to three working times

• Management of bowl rotation direction and spiral speed, with possible reverse time setting of the first bowl speed.

• 2.42” blue OLED display for high contrast and ease of reading

Option to add an additional board for:

• Inverter motor control for bowl and spiral

• Dough temperature visualization

• Temperature alarm thresholds

ENHANCE THE VALUE OF YOUR MIXERS WITH SITEC PRODUCTS

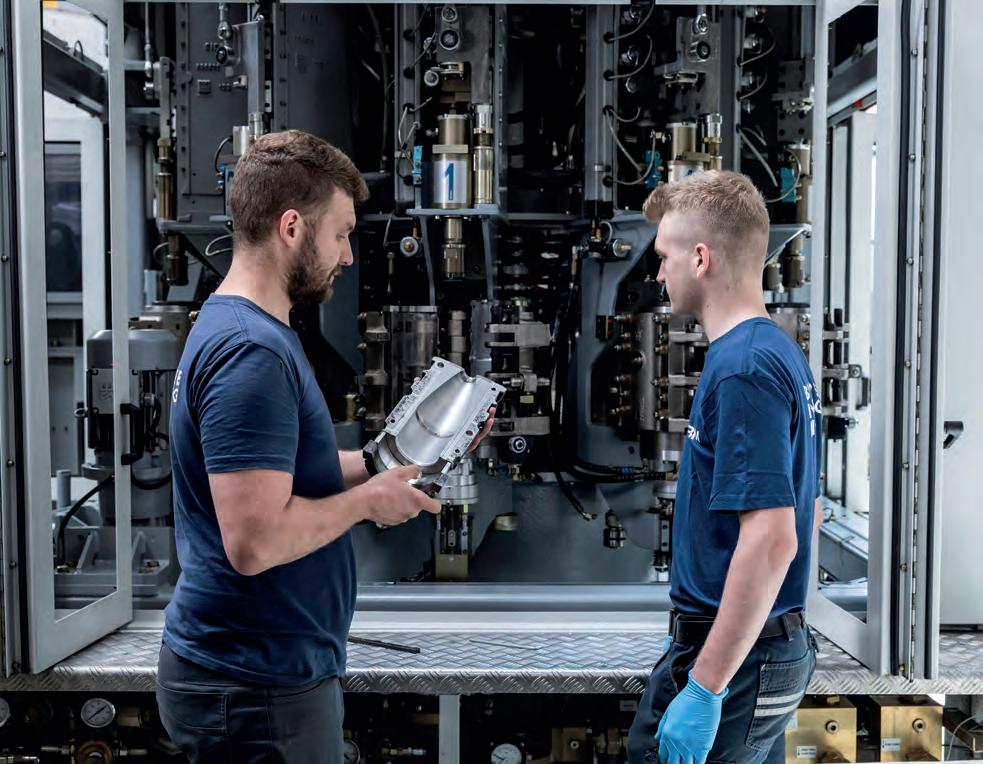

The POPPING MACHINE RPEVO is the latest-generation press designed by Re Pietro Srl for the production of both cereal cakes and no-fried popped snacks and popped chips. In line with the global shift towards healthier alternatives, these products are seeing a continuous rise in demand. Re Pietro Srl, with its commitment to innovation, is setting new industry standards for popped chips production, offering a cutting-edge solution that simplifies and revolutionizes the manufacturing process.

With the POPPING MACHINE RPEVO, once the mold is chosen and installed, you can effortlessly transform cereals or micro-pellets into delicious, fragrant cakes or crispy popped snacks and popped chips. Its versatility and efficiency allow for two different products to be made with a single machine.

These products are increasingly popular, not only as healthier alternatives to traditional bread but also as a quick snack - with or without protein content- or even as decorative elements for dishes and desserts.

Thanks to the POPPING MACHINE RP-EVO, you can preserve the taste and freshness of the raw materials— whether rice, legumes, corn, cereal mixes, or micro-pellets—ensuring your customers receive a healthy, flavorful product with an array of shapes and flavors.

When it comes to mold options, the possibilities are vast. The press can create large and small round shapes, ridged rounds, triangles, squares, hexagons, and rectangles, just to name a few.

Custom molds can also be created based on specific customer requests.

Focus on the Popping Machine RP-EVO

The machine features a robust nickelcoated steel structure, food-grade certified materials, and a stainless-steel electric panel.

Its touch screen control panel, which swivels and rotates to eye-level, makes the operation user-friendly.

Equipped with a hydraulic system, the POPPING MACHINE RP-EVO generates the high pressure necessary for the expansion of cereals or micro-pellets, turning them into crispy popped snacks and popped chips or fragrant puffed cakes. The volumetric dosing is managed by a pneumatically operated feeding plate, ensuring precision.

The molds used to shape the puffed cakes, popped snacks and popped chips are made from hardened steel, coated with titanium nitride to guarantee durability and prevent sticking.

These molds, along with all parts in direct contact with the product, comply with MOCA (Materials and Articles in Contact with Food) regulations under EU Regulation No. 1935/2004, ensuring food safety standards are met. Both the upper and lower molds are heated with separate cartridge heaters, which are controlled by thermoregulators for optimal temperature management.

Each machine is equipped with its own PLC (Siemens S7-1200) and a 7” control panel. The HMI (Human Machine Interface) allows for easy adjustment of production phases, recipe storage, and troubleshooting through its advanced diagnostic system.

Pietro

The POPPING MACHINE RP-EVO marks another milestone in Re Pietro Srl’s long history of excellence. For

over 90 years, the company has been a leader in food processing machine manufacturing, combining cutting-edge technology with solid experience, while maintaining the exceptional quality that comes with the “Made in Italy “ brand.

Not just technology, but passionate people behind Re Pietro’s success

Re Pietro will assist you from the beginning till the end to manufacture an “ad hoc” plant that fully satisfies your

requests, and you can rely on us for any assistance required.

With installation and training, its fast and reliable after-sale assistance from remote or on site, Re Pietro is a valuable partner: talk to us about your new project of popped snacks, popped chips or puffed cakes production, we can help you to develop it.

For more information, visit our website www.repietro.com

For over 50 years, Colussi Ermes has been synonymous with innovation and quality, but at the heart of the success lies the dedication of the people behind the brand. Engineers, technicians, designers, and customer support specialists work with passion every day to satisfy all customers’ needs and to develop solutions that truly make a difference. Compact machine design, energy consumption reduction, minimal consumption in water and detergent use, automatic cycles, loading/offloading automation, and analytical and monitoring tools are just a few of Colussi Ermes sustainability benefits. Hygienic design, rounded shapes, impecca-

ble water draining, and easy access to any zone, guarantee absolute hygiene.

Global leader in the design and production of advanced washing and drying systems for the food industry, Colussi Ermes has become specialized not only in the bakery, confectionery, fruit & vegetables,

meat, dairy, poultry, and fishery sectors, but also in more complex fields such as the pharmaceutical, hospital, logistics and automotive sectors. Colussi Ermes is a globally recognized company with over 7,000 washing systems installed worldwide. Since July 2022, it has been a proud division of Middleby Food Processing,

a leader in the industry that brings together a portfolio of world-class brands with cutting-edge, complementary technologies. As part of Middleby, Colussi Ermes contributes to delivering best-in-class, full-line solutions for food production, ensuring the highest standards of quality, efficiency, and innovation for customers worldwide.

Here’s an exclusive preview of the innovative systems you’ll discover at IBIE 2025!

Automatic and highly versatile systems for washing and sanitizing crates and baskets, suitable for all sectors of production, ensuring impeccable washing for any type of crate, and providing the best results in terms of hygiene. The production range includes cabin or tunnel systems for washing trays with the possibility of selecting various options: one, two, or three tracks, horizontal or vertical. Advanced automation and intelligent handling systems improve workflow, maximizing productivity. Customization of hourly wash cycles, from just a few pieces up to 10,000 crates/hour, allows for maximum flexibility to meet diverse production needs.

High capacities – up to 4200 crates/hour with the double-rotor spin-dryer and up to 2100 crates/ hour with the single-rotor spin-dryer – speed and perfect drying result are the key features that set apart this new generation of Colussi Ermes spin-dryers along with the possibility to dry different type of crates, foldable or rigid. this machine can dry a high number of crates with a minimum footprint.

In just a few seconds the Colussi Ermes spin-dryer can achieve excellent drying with low electrical energy consumption, making this both an efficient and cost-effective solution.

Automatic systems designed to wash and sanitize pans - stand-alone or inline - are available in tunnel or cabin versions, with variable capacities, up to over 30 items/minute, bottomdown loading and infeed heights of up to 4”. They offer the flexibility to wash pans of various shapes, types, heights, and sizes.

In the cabin version, the trays are placed on special trolleys that are perfectly washed thanks to the slow rotation of the loading platform, which allows the washing solution to reach the entire surface of the trays and components: its unique and innovative centrifugal system allows a significant reduction of energy consumption and space while guaranteeing the maximum efficiency on washing and drying.

The cabin can be equipped with one or two doors, available in manual, automatic, or pass-through options. With manual or automatic loading and unloading options, these pan washer machines can be fully customized to seamlessly integrate into the production line. They ensure maximum hygiene and impeccable microbiological results while preserving the integrity of the pans and optimizing water consumption.

www.colussiermes.com

“Come on, it’s just a conveyor belt, right?” Wrong. It’s not just a belt.

In the world of food production, a conveyor is never a neutral component. It connects machines, yes-but it’s also where efficiency, hygiene, safety, and ultimately product quality are put to the test. Yet too often, the choice of conveyor is underestimated-as if all belts were the same.

They’re not.

Each application has its own requirements. Each product behaves differently. Each production environment poses unique challenges.

Overlooking these factors can lead to downtime, contamination, waste, and safety risks.

Let’s take unwrapped products. Even saying “unwrapped” isn’t enough: a dry croissant is nothing like a honeycovered bar or a slice of filled cake. Some products are sticky. Others produce crumbs. Some are incredibly fragile.

In fresh food processing, hygiene demands are at their highest. Here, belts must be washable, cavity-free, and easy to sanitize.

Belts with internal fabric layers are unsuitable-if the fabric is exposed, it becomes impossible to clean. That’s why monolithic belts, with no internal reinforcement, are often used. Sure, they’re stiffer and not ideal for tight curves or small transitions-but they guarantee maximum hygiene. In dry food processing, the picture changes.

Crumbly products like crackers or cookies? A modular chain works wellthe crumbs can fall through and be removed easily.

But if the product is coated or contains fillings, you’ll need PU belts that can be scraped clean.

Each situation requires its own level of care.

Even wrapped products raise key questions:

Is it a white zone or a grey zone?

Does the conveyor need to be washable?

Are high speeds involved?

Are there narrow spaces?

Is low noise a must?

In general:

• Tabletop chains are ideal for heavy loads, high speeds, and complex layouts.

• Modular belts offer more flexibility but may be noisier.

• If it’s a washable area, even the frame matters: at the very least, legs

should be stainless steel-if not the entire structure.

(invisible)

There are also crucial-but less obviousfactors:

• Is the conveyor on the ground or suspended?

• Will it require frequent maintenance?

• How many different formats will it carry?

If the conveyor is suspended, durability becomes a priority since maintenance is harder. If it’s on the floor, operator safety is key-requiring short pitch designs to reduce risk. And if your line needs to manage multiple formats, you’ll need a solution that’s both flexible and adaptable. Finally, remember: no machine works in perfect sync with the next. That’s why accumulation systems or buffers are essential to ensure continuous flow. But that’s a story for another post.

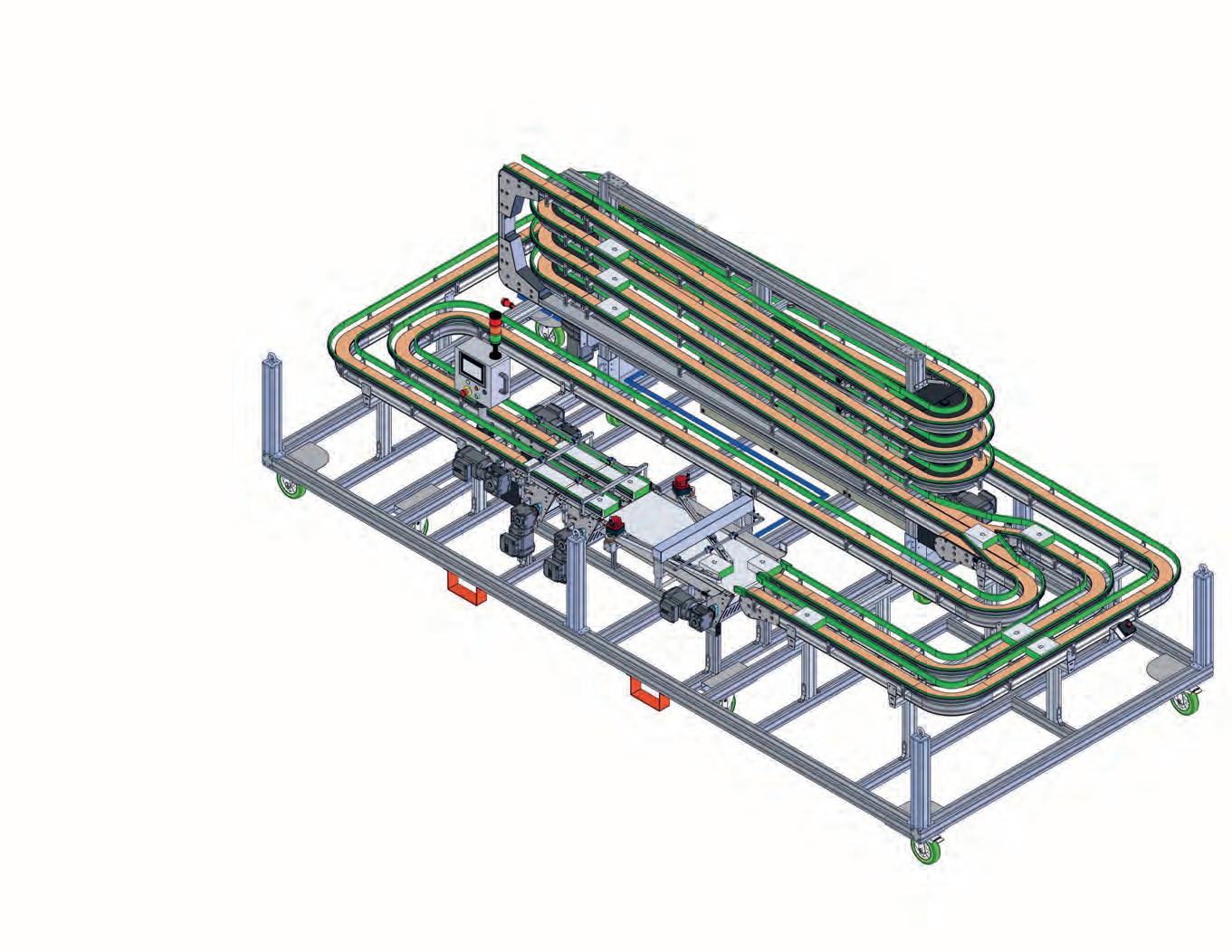

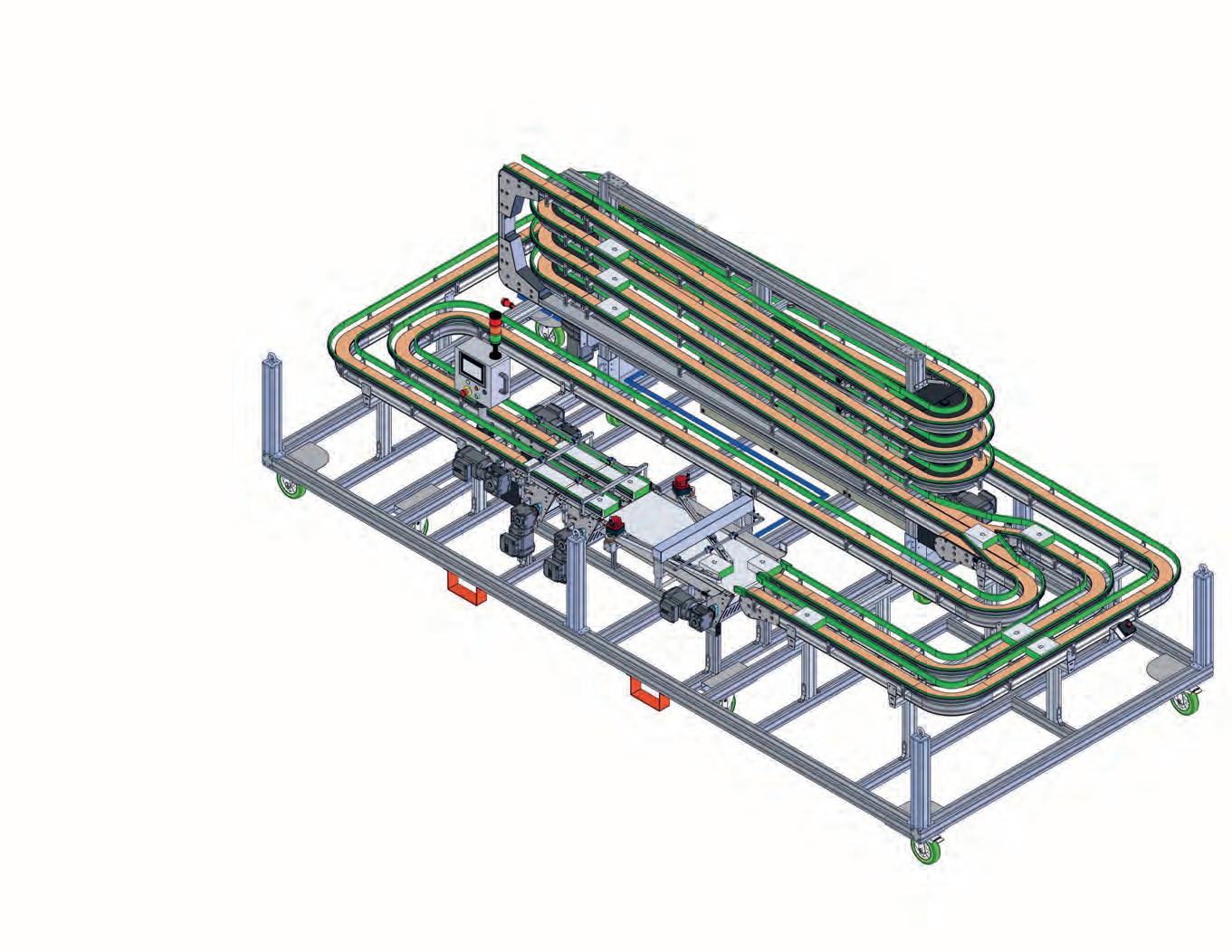

At M.H. Material Handling, we understand these challenges. For nearly 40 years, we’ve been designing custom conveyors for every kind of line, product, and need-from fresh to packaged goods.

From our SaniFlex washable series, to our BAT accumulation system with USC chain, to the ModulFlex range with modular belts-each solution is built on real listening and deep expertise.

When you choose a conveyor, you’re not choosing a part.

You’re choosing a result. And for that, you need someone who truly knows the craft. Want to learn more? Get in touch-we’ll show you how to make your line more efficient. mhmaterialhandling.com

Functional flours are no longer a niche product-they are a strategic asset for the food industry. From health to sustainability, from processing to perceived value, these ingredients are redefining the very concept of raw materials. In a constantly evolving scenario, personalization, traceability, and technology are the key words… as flour becomes a true protagonist of innovation.

The new face of flour

Over the past five years, flour has stopped being a simple commodity and has become a strategic ingredient capable of defining brand identity and shelf positioning. The double-digit growth of the “functional flours” segment—which includes protein-rich, fiber-rich, mineralrich, or naturally gluten-free varieties—is driven by a mix of factors: focus on well-being, curiosity for new sensory profiles, and the need for differentiation in a saturated market.

According to a 2024 Euromonitor report, the functional flour segment recorded a compound annual growth rate (CAGR) of 7.5% in Europe, peaking at 10% in markets such as Germany, Scandinavia, and Italy. Alternative grains are also gaining ground: sorghum flour consumption,

by Elisa Crotti

for instance, has increased by 22% in Western Europe over the past three years. The real turning point, however, is that demand is no longer coming only from end consumers. Buyers, retailers, and co-packers are now seeking short, traceable supply chains with high technological value and consistent industrial performance.

What are consumers and buyers looking for?

Health, for sure—but not at the expense of taste. The 2025 consumer profile includes clear claims—high protein, source of fiber, gluten-free, low carb—backed by solid certifications and credible storytelling. According to NielsenIQ, more than 62% of European consumers regularly read nutrition labels, and 48% say they are willing to pay more for products perceived as healthier. In other words, today’s consumers are more mature and aware, including about greenwashing practices.

That’s why ethics and transparency must go beyond the label; they must be demonstrated through numbers, audits, and impact reports.

Several studies on blends of traditional and legumebased flours have shown that substitutions between 20% and 35% can significantly increase protein content while improving the overall nutritional quality of the final product. For example, incorporating sorghum or dehulled lentils allows for bakery products with “source

of iron” claims and sensory profiles positively accepted by consumers.

Meanwhile, ingredients like red lentil flour and fermented oats are gaining popularity due to their nutritional profile and excellent baking performance. The former is naturally rich in protein and bioavailable iron; the latter enhances digestibility and delivers a rounded, full flavor.

Not all flours behave the same. Functional flours don’t perform like standard white flour: they absorb more water, alter dough rheology, and respond differently to oven and fryer heat curves. This calls for flexible equipment, in-line sensors, and advanced rheological expertise. In modern mixers, micro-dosing systems reduce waste due to granularity variation by 15%. In industrial sourdough systems, hybrid starters cut fermentation time while ensuring soft textures, even with low gluten levels.

A concrete example is the use of climate-controlled chambers integrated with rheologically controlled mixers, which can adjust in real-time to the water absorption variations typical of protein-rich or high-resistant starch flours. This ensures consistent dough quality and minimizes waste and rework.

Thus, quality is measured as much in the lab as on the production line.

From field to shelf, the keyword is “credibility.” Flours derived from regenerative crops or by-products (e.g., stabilized rice bran) not only reduce environmental impact but also justify a premium price in the eyes of increasingly conscious consumers.

According to Innova Market Insights, 52% of European consumers want to reward companies that demonstrate ethical and environmental commitment. B Corp certifications, blockchain traceability, and comparative LCAs are now essential tools: those who adopt them see an average 20% increase in purchase intent. The “green badge” alone is no longer enough; the story of the ingredient, the relationships with producers, and the social impact must all be communicated. When ethics are tangible, price becomes an investment.

The future speaks a clear language: personalization. Today, mills, ingredient suppliers, and manufacturers are co-developing custom flour blends tailored to nutritional needs (more plant protein for meal replacement, more beta-glucans for heart health) or processing needs (controlled water absorption, color stability after baking). The goal is a portfolio that adapts in real-time to market trends and agricultural availability, rendering rigid categories like soft and hard wheat obsolete.

A recent project developed a blend of heat-treated oats, dehulled lentils, and apple fiber, based on European studies on highly stable functional blends with claimable nutritional value.

The evolution won’t stop at varietal selection. The first artificial intelligence platforms are already analyzing millions of rheological, climatic, and sensory data points to predict the behavior of a new flour before it’s even milled.

Start-ups and international research centers are developing digital twins of doughs to simulate the entire processing workflow—kneading, fermentation, and baking—in a virtual environment. This will allow for “line-proof” blend design, reduce time-to-market by over 30%, and minimize waste. AI-based predictive systems can also suggest the optimal time to switch batches or adjust process parameters according to available raw materials.

Flour has become a vehicle for health, ethics, and technological innovation. Those who combine agronomic research, process expertise, and authentic storytelling will lead a thriving market that rewards those who transform an ancient ingredient into a driver of added value.

High-performance ALritma labelling head:

• Modular structure with swiveling components.

• High-torque stepper motor.

• Unwinder with expansion locking system.

• Rewinder with collapsible device for easy liner removal.

• Harsh-environment kit: IP55 protection, stainless steel bearings.

• Separate IP55 fanless control box.

• Microprocessor control for high accuracy at variable speed.

• 7” multilingual touchscreen panel with 100 recipes and Industry 4.0 connectivity.

Innovation or conservation? These philosophies are apparently opposite and irreconcilable. The former promises superior performance and new features. The latter guarantees the reliability and practicality typical of tried and tested solutions.

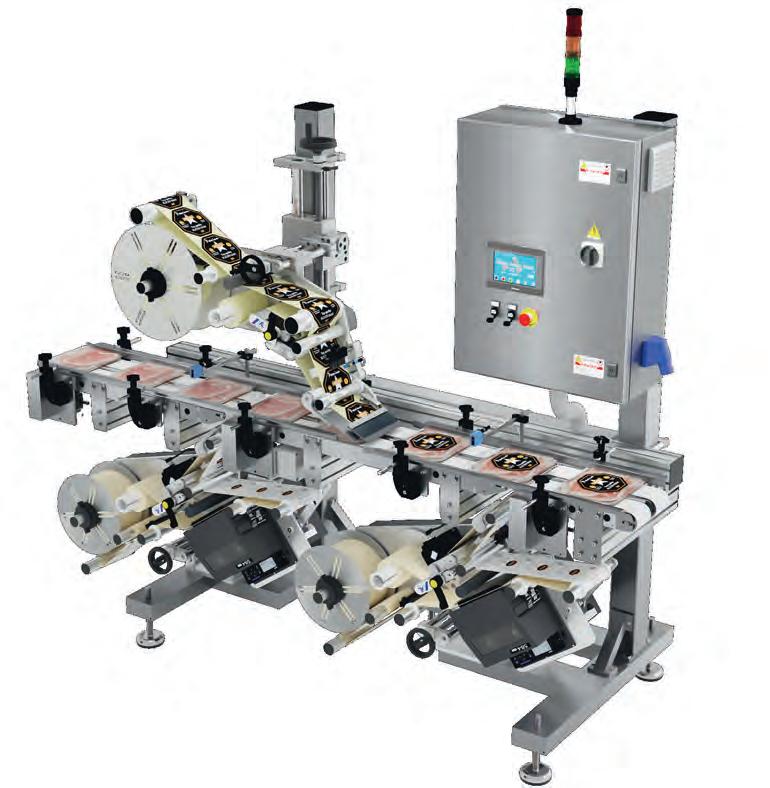

ALTECH is committed to both innovation and conservation in our labelling machines. Each of them contains the most innovative technologies, but it is also the result of design refinements based on 30,000 acceptance tests. Thanks to such technical expertise, we are able to state that every labeller we offer is not only state-of-the-art, but it is also user-friendly, functional, and reliable.

An example? Our ALritma labelling head.

ALTECH Srl

Viale de Gasperi, 70 20008 Bareggio (MI) - Italy

Tel. +39 02 90363464

info@altech.it

www.altech.it

The ALTECH labelling systems of the ALbelt series provide an excellent price/performance ratio, without any compromise concerning reliability and robustness.

The ALbelt systems come in numerous configurations based on specific labelling needs and can label different types of products, such as bottles, cans, jars, tubs, boxes, and trays.

The ALbelt systems are fitted with ALstep or ALritma labelling heads and can be equipped with printers to customise labels with variable data, as well as with product spacers, wrapping units for cylindrical products, adapters and bending units for corner labels.

If necessary, the ALbelt systems can take on specific configurations to meet particular needs, such as top and bottom labelling or non-stop configurations.

ALTECH has recently supplied a system featuring both capabilities to an important producer of cold cuts in Italy.

The system is fitted with two ALritma labelling heads, which are positioned in such a way as to apply a label on the bottom of trays.

The operational logic allows it to detect the end of labels on the first head and automatically activate the second one, thus making it possible to change labels without stopping the labelling process.

A third labelling head on the top is set up to apply a “hook” label to hang the tray on a display rack.

All functions and parameters are managed via a PLC system featuring a

7-inch colour touchscreen panel that can store and manage up to 100 labelling formats.

The system can be interfaced via Ethernet, which enables remote access to monitor its health and status, e.g. for remote assistance. Moreover, the OPC-UA protocol makes the machine

compliant with Industry 4.0 requirements.

ALTECH Srl is a leading Italian company specialised in the production of material coding, identification, and labelling systems.

For further information: info@altech.it - www.altech.it

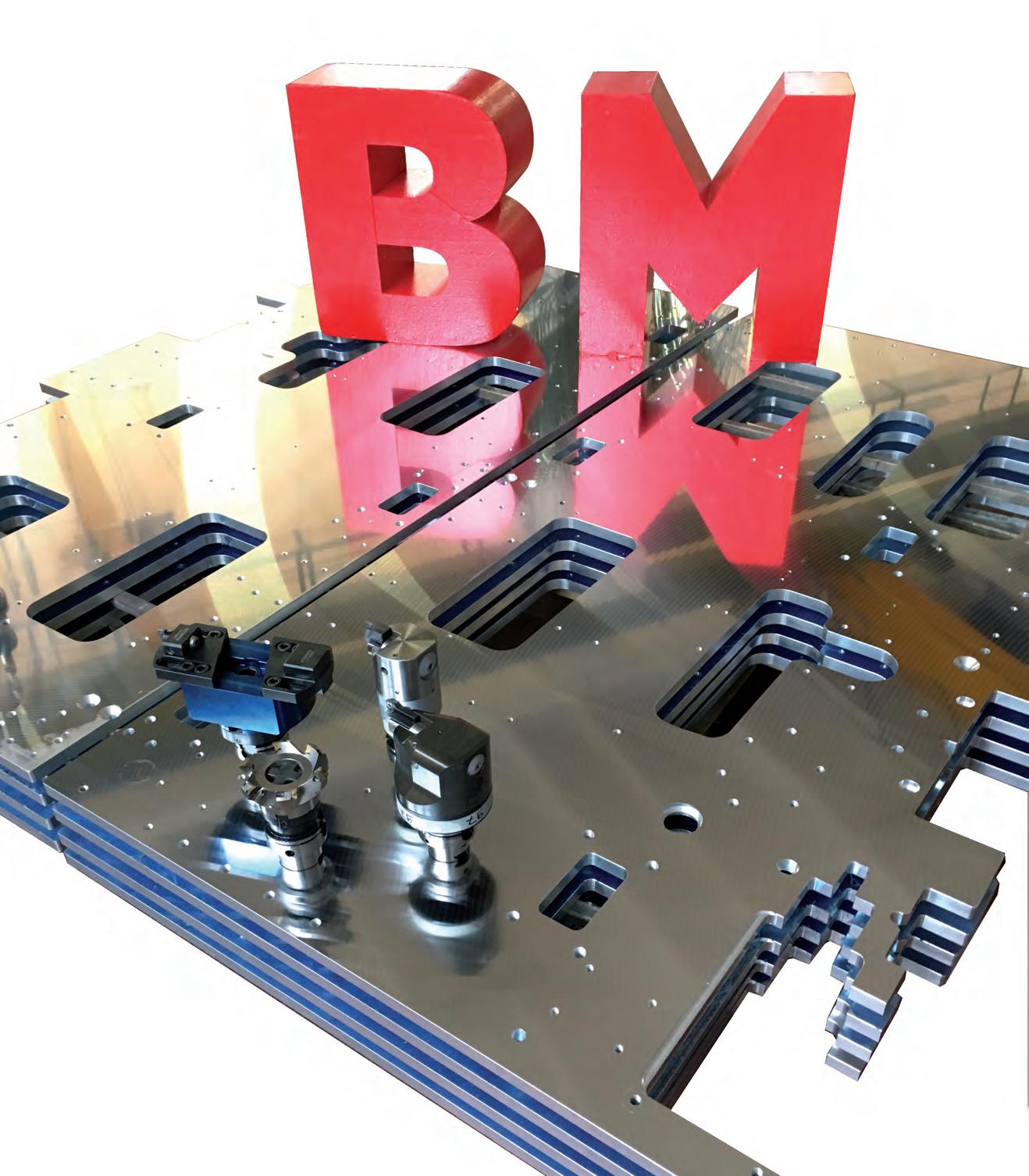

Quality, speed and service are our strenghts MACHINING

With over fifty years of experience, the Venetian company stands out for its cutting-edge solutions in CNC machining, surface treatments, and aluminum anodizing, ensuring quality, speed, and international certifications.

Founded over fifty years ago, B.M. Group S.r.l. has established itself as a leader in aluminum machining and treatment, offering complete and certified solutions for the food industry and other industrial sectors. The company, based in the province of Vicen-

za, operates two strategically located production hubs in Thiene and Zanè, both easily accessible from major highways.

This prime location enhances logistics efficiency and ensures rapid response times to customer needs.

At the helm of B.M. Group is Silvano Busin, the company’s President and a key industry figure with deep sector expertise, who personally oversees the technical department.

Alongside him, Vice President Marina Vitacca manages communica-

tion strategies and research departments, ensuring an innovative and forward-thinking approach. The company’s team consists of young, skilled professionals committed to continuous improvement and professional development.

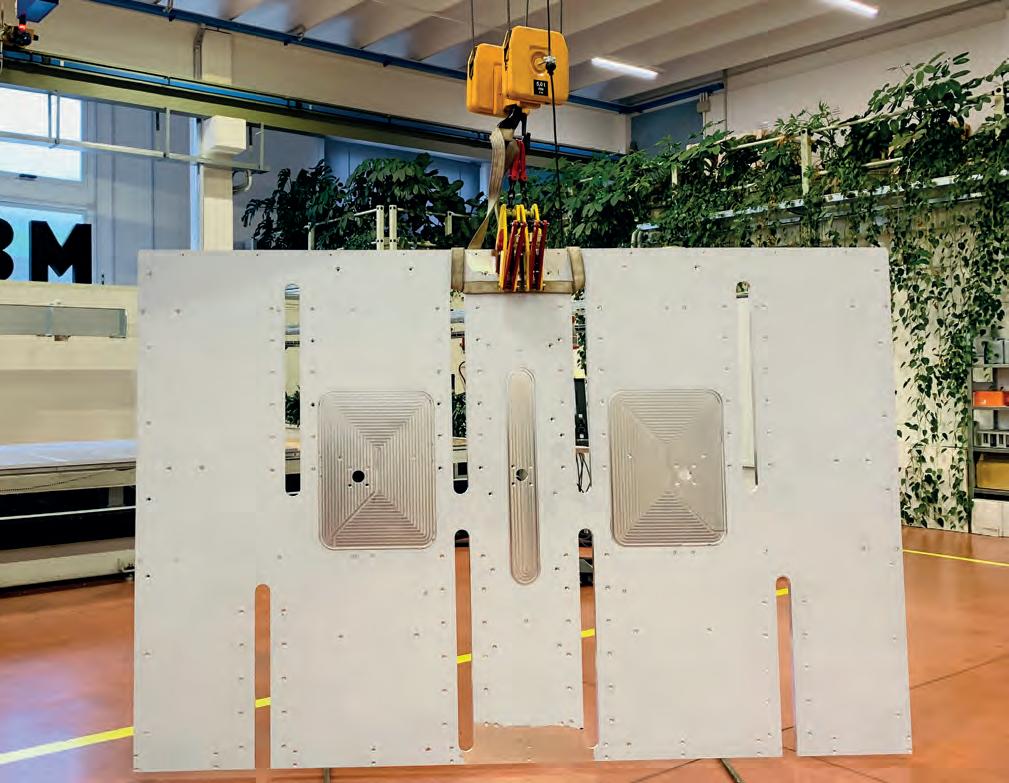

One of the company’s main strengths is its ability to perform CNC machining on large aluminum plates, utilizing machinery capable of processing pieces up to 13 meters in length and 2.5 meters in width. This expertise has allowed B.M. Group to establish itself in key European markets, catering to the needs of a niche sector with high-quality standards.

In addition to mechanical processing, the company provides a comprehensive range of preliminary treatments, including mechanical brushing with various finishes, chemical pre-treatments, and aluminum anodizing.

These integrated services ensure tailored solutions and a high level of customization for clients.

The company’s efficiency is further enhanced by a large warehouse that stocks materials in various al-

loys (such as 5083, 6082, 7075) and different thicknesses. This enables B.M. Group to promptly meet customer demands, reducing lead times and optimizing production efficiency.

The quality of its processes and products is certified by the ISO 9001:2015 standard, demonstrating a firm commitment to excellence. Upon request, B.M. Group can provide order compliance declarations, MOCA certifications (for materials and objects in contact with food), measurement reports, anodizing certificates, and material certificates, all in accordance with the UNI EN 10204 European standard. By combining experience, know-how, and passion, B.M. Group positions itself as a reliable and innovative partner for companies seeking cutting-edge solutions in aluminum processing and treatment. Its

dedication to continuous improvement and focus on specific customer needs make it a key reference point in the sector, capable of making a difference in the global market.

www.bmgroupsrl.com

by Thomas Dohse Director of interpack

The trade fair world never stops.

Among long-standing events and new projects, interpack stands as an undisputed benchmark for the international packaging and processing industry.

The next edition is scheduled to take place in Düsseldorf from 7 to 13 May 2026, returning after three years with impressive figures and top-level content.

During our recent visit to Düsseldorf, we had the opportunity to meet Thomas Dohse, Director of interpack and one of the most authoritative voices on the global exhibition scene. Together, we explored what’s happening behind the scenes of one of the industry’s most anticipated events.

Thomas, interpack is widely regarded as the premier event for the packaging world. What can we expect in 2026?

Sonia, we’re less than a year away from opening the halls, and I can already confirm: we are completely sold out.

Every square metre has been assigned, and we’re preparing for a rich, vibrant edition with exhibitors from all over the globe, thousands of visitors, and an international atmosphere that’s part of interpack’s identity. After three years, we’re back with full energy. It will be, I assure you, a truly unique trade fair.

Edited by SONIA V. MAFFIZZONI BENNATI

As we know, interpack covers a broad spectrum of equipment, technologies, production lines and materials, as well as packaging trends. What will be the central themes this time? We’ve identified three main thematic pillars that reflect the industry’s current priorities and the ongoing changes.

The first of these is smart manufacturing: everything related to intelligence in processes, automation, and the ability of machines to collect and interpret data.

Artificial intelligence is now making a strong entrance into our sector.

The second pillar focuses on innovative materials. We’ll feature at least 1,000 exhibitors dedicated to packaging materials, and we expect major developments in terms of sustainability, performance, weight reduction, and recyclability.

Finally, the third theme is future skills, the growing need for new expertise, new professional profiles, and new approaches. interpack will also serve as a forum for this.

Technological innovation alone isn’t enough and cultural innovation is just as crucial.

There’s still some time to go, but expectations are already high.

What’s the mood behind the scenes?

There’s a great buzz.

interpack is unlike any other trade fair. I say this with conviction: for many companies, this is where they decide “how to present themselves to the world”.

Exhibitors begin planning months, sometimes even years, in advance, deciding what to showcase, which solutions to highlightand what message to convey. The same applies to visitors. People don’t come to interpack by chance; they come because they know they’ll find real innovation, global partnerships, and concrete solutions.

And in terms of international visitors?

What’s your strategy?

We’ve already launched a comprehensive global programme.

Soon, I’ll be travelling across continents for official presentations, engage with new stakeholders and strengthen ties with our long-standing partners. We invite everyone to start preparing now, including arranging flights, hotels and documents.interpack is a major event, so getting organised early will give youa real advantage.

interpack 2026 is shaping up to be an edition full of content, but also of responsibility.

It will be tasked with interpreting a rapidly evolving industry, suspended between industrial demands, technological progress, and shifting market expectations.

In this context, the fair won’t just be a showcase, but also a privileged observation point for a transforming sector.

As the halls take shape, the agenda is defined and the industry gears up, interpack 2026 stands out as much more than an exhibition, it will be a pivotal moment to witness the industry’s evolution, understand where it’s heading, and measure its pace.

Save the date for interpack 2026 and explore all the innovations that are reshaping the future of packaging.

www.interpack.com

In 2025, Universal Pack celebrates a major milestone: 60 years of business. This journey of continuous growth has been driven by a relentless pursuit of technological innovation, a deep-rooted commitment to environmental responsibility, and strong, long-standing relationships with customers across the globe.

FACHPACK 2025 (Hall 2, Stand 2-509) will be the perfect opportunity to celebrate this legacy of excellence and to unveil next-generation single-dose packaging solutions that seamlessly combine sustainability, efficiency, and reliability—the core pillars of the company’s vision for the future.

Sustainable packaging: a responsible choice for the future

At Universal Pack, sustainability is not

with compostable, recyclable, and recycled films.

Leveraging rigorous testing protocols and advanced tools such as Life Cycle Assessment (LCA), Universal Pack is able to quantify and minimise environmental impact without ever compromising on packaging quality, machine performance or regulatory compliance.

This proactive, science-based approach positions Universal Pack as a strategic partner for companies ai-

ming to reduce their ecological footprint while enhancing product value.

To stay at the forefront of innovation, Universal Pack fosters close collaborations with leading international film manufacturers, multinational companies, and prestigious academic research centres. These partnerships enable the co-development of new, forward-thinking materials and packaging concepts that meet both environmental and functional requirements.

Each material undergoes extensive testing on Universal Pack’s proprietary systems, ensuring optimal machine compatibility and performance. The result is a portfolio of solutions that deliver not only sustainability, but also exceptional efficiency, safety, and shelf appeal—designed to meet the evolving needs of a competitive global market.

Universal Lab: science at the heart of packaging

The beating heart of Universal Pack’s innovation lies in Universal Lab, the company’s in-house research and development centre.

For over three decades, its multidisciplinary team of highly qualified scientists and engineers has been dedicated to the precise analysis of materials and products. Their expertise ensures that every packaging machine is tailor-made to the specific properties of the product and the laminate being used.

From flowability and sealing behaviour to barrier properties and thickness tolerance, every variable is carefully considered. This scientific and methodical approach empowers Universal Pack to deliver fully customised, highly performant packaging solutions, capable of meeting even the most demanding technical and regulatory specifications.

Founded in 1965, Universal Pack marks its 60th anniversary in 2025—a remarkable achievement that underscores the company’s enduring commitment to innovation, manufacturing excellence, and sustainable development.

Over the decades, the company has installed more than 8,000 packaging systems in over 160 countries, becoming a trusted partner for lea-

ding global brands in both the food and pharmaceutical industries. Driven by a culture of passion, strategic vision, and customer-centricity, Universal Pack has built a reputation for delivering reliable, future-ready solutions that add value and drive growth.

This landmark anniversary is not only a time to reflect on past achievements but also a launchpad

towards exciting new horizons. With a sharp focus on the future, Universal Pack continues to invest in Industry 4.0 technologies, ecoconscious materials, and advanced packaging solutions—including stick-pack machines, four-side seal sachet equipment, and fully integrated packaging line. Visit: www.universalpack.it

by Stefano Astori

Spare Parts Manager of BBM

Based in northern Italy and with an international scope, BBM is a benchmark in the regeneration and supply of complete packaging lines for the food & beverage industry. Combining cost-efficiency, innovation and customisation, the company responds to growing market demand, driven by increasingly complex technical, environmental and regulatory requirements.

BBM specialises in revamping and supplying complete packaging lines: how much has the demand for refurbished solutions grown and what advantages do they offer compared to new equipment?

Over the past twenty years, we’ve seen a constant growth in interest for refurbished solutions. This is due to several reasons. First of all, a regenerative approach effectively addresses new production needs, for example, the introduction of tethered caps, the use of recycled PET or increasingly frequent format changes. All this can be achieved with significantly lower investment compared to purchasing new machinery.

For many companies, it’s the perfect compromise: they can get a line that meets modern standards, with performance close to new equipment, but at up to 50% lower cost and with much shorter lead times.

Furthermore, sustainability has become a key driver: refurbishing machinery extends its life cycle, reduces waste and lowers the overall environmental impact.

Your portfolio includes long-standing brands in the beverage and food sectors: what are

the most frequent requests from these clients and how do you meet them with a tailored approach?

In most cases, international customers are looking for a reliable and skilled partner, someone who can guide and support them in solving issues that arise during the production process. We often gain their trust not only thanks to our cost-effective spare parts and upgrades,compared to OEMs, but also thanks to our fast delivery and handson support in sourcing the most suitable materials for their specific needs. Unlike OEMs, who usually offer standardised packages and spare part lists, we stand out with a customised approach: we analyse each request in detail and develop truly bespoke solutions tailored to the customer’s requirements.

Your mechanical and electronic design department also develops proprietary solutions: how does internal innovation contribute to improving plant performance? Innovation is one of our key strengths, and we develop it in-house. Our technical and R&D department is very active and able to design both mechanical and electronic upgrades. For example, we can adapt outdated machinery to work with new operating pressures, improving energy

efficiency, or we can design compatible spare parts when original ones are no longer available. Our crossfunctional expertise allows us to work on machines from different manufacturers, integrating modern electronics, advanced PLCs and remote control systems.

After-sales services, from spare parts supply to predictive maintenance, are a strong point: how strategic is it today for a food company to rely on structured technical support?

For us, support is not an add-on: it’s a core pillar of our offer. We manage an extensive internal spare parts warehouse, allowing us to ship quickly and avoid costly downtime.

Our technical team is ready to intervene even on weekends, with the kind of flexibility only an independent company can provide.

We also organise tailored training sessions for both our technicians and our customers, as we strongly believe in knowledge transfer: the more prepared the operator, the lower the risks of breakdowns, mistakes or inefficiencies.

With headquarters in Italy and operations worldwide, BBM deals with different

markets and regulations: in your view, what are the main technological and regulatory challenges that the food & beverage industry will face in the coming years?

The most complex part of working internationally is dealing with customs regulations.

Every country has its own set of rules, which means that for each destination we must prepare different documentation and follow specific procedures. This requires particular attention and constant updates on international standards.

www.bbmpackaging.com

85years of long history, within which PREO has always stood

out for the strong spirit of innovation and the technology of its products. Since its first steps in the high-precision mechanical industry, PREO has been an important point of reference worldwide.

The early 90s, an important date for the history of PREO, gave rise to the production of hot gluing systems, where the company redefined the standards in the “conception” and construction of the first systems, which were characterized by high-performance technologies and innovation that marked a historic turning point in the sector.

PREO was the first company on the market to produce gluers which over time have become true “classics”. It is known as history that the first LCD display was controlled via a rotary switch and was introduced for the first time in a gluing system. Afterwards, a few years later, the “Full Touch” version was made with a 7” display was introduced.

A further innovation brought by PREO to the world of hot-melt systems was the introduction of the design, which became a constant in all its products and marked a small but great revolution in the sector, also providing a stimulus to competition so that hotmelt systems were not just anonymous “metal boxes”.

PREO wanted to amaze and rewrite all the rules this year by launching a new series of hot-melt systems on the market that have the characteristics to become a milestone and a point of reference in the global panorama of hot-melt systems.

PREO is therefore pleased to announce and present the new line of Vela hot-melt adhesive systems!

The new gluers not only represent a step forward in adhesive application technology, but also offer several advanced features, designed to improve productivity and versatility. Vela has a light and compact structure, which facilitates transport and installation even in the smallest workspaces.

One of the most distinctive aspects of Vela is obviously its unique, innovative and elegant design. PREO paid particular attention to creating a machine that not only excelled in terms of technical specifications, but was also aesthetically pleasing and functional.

The combination of high quality materials, modern lines and attention to detail in the design demonstrate PREO’s commitment to providing products that combine aesthetics and functionality, offering a superior user experience to its customers.

Another key feature of Vela is its extraordinary modularity thanks to a system that allows flexibility and customization based on the specific needs of each customer.

The facilitated installation thanks to the plug & play connections and its easily interchangeable modules make Vela the perfect and most suitable system for different applications and types of gluing.

An additional advantage of Vela is its compatibility with other existing systems. PREO has designed this machine to easily integrate with a wide range of systems and equipment already installed in companies’ production processes so that they can upgrade their production lines without the need for expensive replacements or radical modifications.

With the launch of Vela, PREO takes a further step towards environmental sustainability. The new machine is equipped with an isolation that significantly improves the insulation system. This technological improvement, combined with a sophisticated thermoregulation algorithm of the new electronics installed, not only increases the energy efficiency of the machine, reducing energy consumption, but also contributes to reducing the environmental impact of the entire gluing process.

The external insulation keeps the internal temperature constant, reducing heat loss and ensuring a more efficient operation. This eco-sustainable approach reflects PREO’s commitment

to developing solutions that not only meet customers’ production needs, but also respect the environment, contributing to the reduction of carbon emissions.

Every part of the Vela melter has been technologically improved to offer superior performance, as well as more precise control of the gluing process. The new generation of components used in Vela, starting from the brand new 7” capacitive touch display, ensures uniform heat distribution, reducing heating times and improving the quality of the final product. Vela is equipped with an advanced technology that facilitates global interconnection. This allows the machine to communicate with other devices

and management systems, allowing real-time remote monitoring and control.

With Vela, PREO confirms its leading role in the market, offering highquality technological tools that meet the most demanding expectations, support the growth and innovation of client companies, promote sustainable practices and ensure efficient integration with existing technologies. The combination of innovative design, modularity, sustainability, compatibility and advanced interconnection makes Vela an ideal choice for companies looking for cutting-edge hot gluing solutions.

www.preo.it

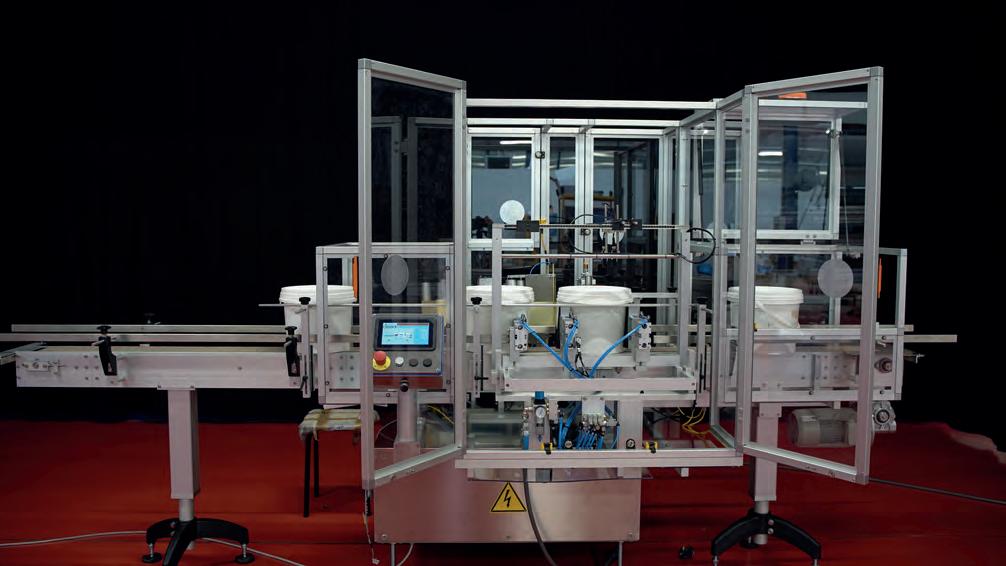

In a production context dedicated to the processing and packaging of food sauces for industrial food service, a customized solution was developed for the management of semi-wrap labelling on containers of different formats, such as cylindrical buckets with handles and rectangular jerry cans.

STAMPA SU CARTA PATINATA OPACA

The customer involved is the Middle East headquarters of a U.S. multinational corporation among the leading suppliers to Quick Service Restaurant chains and retail food service industries. The group serves hundreds of outlets in the region through integrated manufacturing and logistics facilities. The client needed to implement a single solution capable of labelling containers of different sizes, with a focus on the presence of the handle, an element that can interfere with the useful label application area.

The request included a single system that could quickly adapt to multiple formats and ensure proper label application, considering variables such as shaping and the presence of the handle

The project implemented by Etipack, is based on a compact and modular System 1 Turning configuration, designed to integrate in line with existing production. The critical issue of the handle’s presence has been overcome

using a guide that allows it to be lifted, clearing the area for labeling. In this process, the operator is responsible for correctly positioning the container at the entrance of the system to enable the guide to function properly.

The heart of the system is an Energy 200 automatic labelling machine equipped with photocell control to manage label step and stop at a predefined position.

After being dispensed, the label is held in place for semi-wrap application to the container when the product stops at a three-roller system, consist-

ing of one motorized roller and two free opposing rollers. This allows for the controlled rotation of the container, ensuring the label is applied in the intended position with accuracy.

The entire system is configurable via HMI interface with 7” touch screen, designed with intuitive graphical logic and extensive customization possibilities, according to the line requirements. Features include parameter configuration for different formats, access management by user levels, and revision monitoring to ensure traceability of changes and operational control.

The system lends itself to use in production environments with demands for flexibility and reliability, where the variety of formats and the presence of elements such as handles require specific solutions.

The modular approach, combined with custom components and simplicity in operational management, enabled the client to integrate a versatile, robust and reliable solution capable of handling different types of packaging with a single system, while maintaining the operational simplicity required

in low manning production environments. The system’s ability to handle critical components such as handles and to adapt smoothly to containers of varying sizes made the project particularly well suited to the needs of a facility geared toward widespread distribution, where precision and ease of handling are key determinants of logistical efficiency.

Labelling plays a crucial role in the food industry, where packaging solu-

tions are very diverse and constantly evolving.

To cope with this dynamic market, Etipack has developed a complete range of tailor-made solutions for both food manufacturers and machine builders.

These solutions cover product labelling and handling, as well as complementary applications that support marketing and packaging activities.

For more information etipack.it/en/sector/food/

HHeadquartered in Karachi, IPAK was founded in 2017

eadquartered in Karachi, IPAK was founded in 2017 as a green field project to manufacture “BOPP” packaging films. The company’s state-of-the-art manu facturing facility is spanning over on area of 46 acres land, where the major machinery has been acquired from the world’s top class engineering firms such as Bruckner Maschinenbau (Germany), BOBST (United Kingdom), KAMPF (Germanyl, etc. IPAK is a bud ding yet high growth potential compa ny with a focus lo develop and deliver excellent quality packaging films to the locai as well as international markets.

Staying committed lo its unwavering strategie objectives, the company decided lo expand its business foot print, by incorporating three new subsidiaries which are enabling the group to become the only flexible packaging group of Pakistan, offering a one-window solution lor all four kinds of commonly used packaging films known as BOPP, BOPET, BOPE and CPP. Vision

To be the global leader in innovative packaging solutions.

Build IPAK as on international brand with recognition lor its quality, service and innovations in offering sustain able packaging solutions to its cus tomers.

IPAK’s commitment to sustainability is firmly rooted in adherence lo interna tional standards. The company is certi fied under ISO 900 l , ISO 1400 l, ISO 4500 l , and BRCGS lssue 7, and has also achieved ISCC Plus certification at two of its sites. Further strengthening its framework, IPAK is in the process of obtaining EN 15343 and ISO 5000 l certifications.

TECHNOLOGYPROCESSES AND PACKAGING

TECHNOLOGY

Reflecting its dedication to ethical business practices and market credibility, the company has also earned SEDEX SMETA 4-Pillar certification. In addition, IPAK aligns itself with leading international initiatives driving circularity in

Reflecting its dedication to ethical business practices and market credibility, the company has also earned SEDEX SMETA 4-Pillar certification. In addition, IPAK aligns itself with leading international initiatives driving circularity in packaging. Through RecyClass, the company follows globally recognized guidelines to enhance recyclability, ensure traceability of recycled content, and support compliance with European standards such as EN 15343. Meanwhile, by engaging with CEFLEX (Circular Economy for Flexible Packaging), IPAK incorporates best practices from across the value chain, contributing to the transformation of flexible packaging towards a more circular and sustainable model.

packaging. Through RecyClass, the company follows globally recognized guidelines to enhance recyclability, ensure traceability of recycled content, and support compliance with European standards such as EN 15343. Meanwhile,

IPAK unveils identity of its sustainability initiatives “Tajdid” an Urdu/Arabic word means “Renew”. Tajdid is further reinforced with a pictorial presentation of set of actions required now and going forward, to make our and future of our generations to come, sustainable.

IPAK unveils identity of its sustainability initiatives Tajdid an Urdu/Arabic word means “Renew”. Tajdid is further reinforced with a pictorial presentation of set of actions required now and going forward, to make our and future of our generations to come, sustainable.

IPAK unveils identity of its sustainability initiatives “Tajdid” an Urdu/Arabic word means “Renew”. Tajdid is further reinforced with a pictorial presentation of set of actions required now and going forward, to make our and future of our generations to come, sustainable.

by engaging with CEFLEX (Circular Economy for Flexible Packaging), IPAK incorporates best practices from across the value chain, contributing to the transformation of flexible packaging towards a more circular and sustainable model

Reflecting its dedication to ethical business practices and market credibility, the company has also earned SEDEX SMETA 4-Pillar certification. In addition, IPAK aligns itself with leading international initiatives driving circularity in packaging. Through RecyClass, the company follows globally recognized guidelines to enhance recyclability, ensure traceability of recycled content, and support compliance with European standards such as EN 15343. Meanwhile, by engaging with CEFLEX (Circular Economy for Flexible Packaging), IPAK incorporates best practices from across the value chain, contributing to the transformation of flexible packaging towards a more circular and sustainable model.

Reflecting its dedication to ethical business practices and market credibility, the company has also earned SEDEX SMETA 4-Pillar certification. In addition, IPAK aligns itself with leading international initiatives driving circularity in packaging. Through RecyClass, the company follows globally recognized guidelines to enhance recyclability, ensure traceability of recycled content, and support compliance with European standards such as EN 15343. Meanwhile, by engaging with CEFLEX (Circular Economy for Flexible Packaging), IPAK incorporates best practices from across the value chain, contributing to the transformation of flexible packaging towards a more circular and sustainable model.

IPAK unveils identity of its sustainability initiatives “Tajdid” an Urdu/Arabic word means “Renew”. Tajdid is further reinforced with a pictorial presentation of set of actions required now and going forward, to make our and future of our generations to come, sustainable.

Concept of Tajdid revolves around collaborations internally and externally with our vendors, 17 UNSDG’s, allied partners, clients, brand owners, consumers, institutions, Climate challenges, academies and governmental bodies to bring sustainability in our every action in daily life.

Concept of Tajdid revolves around collaborations internally and externally with our vendors, 17 UNSDG’s, allied partners, clients, brand owners, consumers, institutions, Climate challenges, academies and governmental bodies to bring sustainability in our every action in daily life.

Concept of Tajdid revolves around collaborations internally and externally with our vendors, 17 UNSDG’s, allied partners, clients, brand owners, consumers, institutions, Climate challenges, academies and governmental bodies to bring sustainability in our every action in daily life.

Concept of Tajdid revolves around collaborations internally and externally with our vendors, 17 UNSDG’s, allied partners, clients, brand owners, consumers, institutions, Climate challenges, academies and governmental bodies to bring sustainability in our every action in daily life.

IPAK continues to strengthen its decarbonization journey with significant energy and emissions achievements. Its operations are partly powered by an 8 MW solar energy system, producing around 63,500 kWh per month, reducing fossil fuel reliance and avoiding 25 tCO2 annually. In addition, waste heat recovery systems cut emissions by 1,688 tCO2eq, while optimized

IPAK continues to strengthen its decarbonization journey with significant energy and emissions achievements. Its operations are partly powered by an 8 MW solar energy system, producing around 63,500 kWh per month, reducing fossil fuel reliance and avoiding 25 tCO2 annually. In addition, waste heat recovery systems cut emissions by 1,688 tCO2eq, while optimized logistics

IPAK continues to strengthen its decarbonization journey with significant energy and emissions achievements. Its operations are partly powered by an 8 MW solar energy system, producing around 63,500 kWh per month, reducing fossil fuel reliance and avoiding 25 tCO2 annually. In addition, waste heat recovery systems cut emissions by 1,688 tCO2eq, while optimized

IPAK continues to strengthen its decarbonization journey with significant energy and emissions achievements. Its operations are partly powered by an 8 MW solar energy system, producing around 63,500 kWh per month, reducing fossil fuel reliance and avoiding 25 tCO2 annually. In addition, waste heat recovery systems cut emissions by 1,688 tCO2eq, while optimized

logistics practices prevented 7,568 kgCO2 emissions and saved 2,810 liters of fuel. To advance resource stewardship, IPAK has deployed comprehensive water monitoring and management across all sites. Initiatives such as reusing cooling tower blowdown water for solar panel cleaning are generating annual savings of approximately 105,876 m³, reinforcing IPAK’s commitment to water conservation.

logistics practices prevented 7,568 kgCO2 emissions and saved 2,810 liters of fuel. To advance resource stewardship, IPAK has deployed comprehensive water monitoring and management across all sites. Initiatives such as reusing cooling tower blowdown water for solar panel cleaning are generating annual savings of approximately 105,876 m³, reinforcing IPAK’s commitment to water conservation.

practices prevented 7,568 kgCO2 emissions and saved 2,810 liters of fuel. To advance resource stewardship, IPAK has deployed compre- hensive water monitoring and manage- ment across all sites. Initiatives such as reusing cooling tower blowdown water for solar panel cleaning are generating annual savings of approximately 105,876 m³, reinforcing IPAK’s commitment to water

logistics practices prevented 7,568 kgCO2 emissions and saved 2,810 liters of fuel. To advance resource stewardship, IPAK has deployed comprehensive water monitoring and management across all sites. Initiatives such as reusing cooling tower blowdown water for solar panel cleaning are generating annual savings of approximately 105,876 m³, reinforcing IPAK’s commitment to water conservation.

Tajdid is structured around three dedicated sustainability brands: tameer, zeest and tarmim. Together, these pillars of Tajdid form a holistic framework that honors our shared responsibility to protect and renew the world we live in — one action, one partnership, and one community at a time. The pictorial presentation of sustainability brands can be seen below:

Tajdid is structured around three dedicated sustainability brands: tameer, zeest and tarmim. Together, these pillars of Tajdid form a holistic framework that honors our shared responsibility to protect and renew the world we live in — one action, one partnership, and one community at a time. The pictorial presentation of sustainability brands can be seen below:

Tajdid is structured around three dedicated sustainability brands: tameer, zeest and tarmim. Together, these pillars of Tajdid form a holistic framework that honors our shared responsibility to protect and renew the world we live in — one action, one partnership, and one community at a time. The pictorial presentation of sustainability brands can be seen below:

conservation. Tajdid is structured around three dedicated sustainability brands: tameer, zeest and tarmim. Together, these pillars of Tajdid form a holistic framework that honors our shared responsibility to protect and renew the world we live in — one action, one partnership, and one community at a time. The pictorial presentation of sustainability brands can be seen below:

At IPAK, innovation drives progress. Our Research & Development department continues to set new standards in flexible packaging, addressing global challenges with cutting-edge solutions and sustainable alternatives. Our latest developments reflect our unwavering commitment to

At IPAK, innovation drives progress. Our Research & Development department continues to set new standards in flexible packaging, addressing global challenges with cutting-edge solutions and sustainable alternatives. Our latest developments reflect our unwavering commitment to

At IPAK, innovation drives progress. Our Research & Development department continues to set new standards in flexible packaging, addressing global challenges with cutting-edge solutions and sustainable alternatives. Our latest developments reflect our unwavering commitment to performance,

performance, circularity, and excellence. The 7 Tajdid Packaging Strategies outline a holistic approach to sustainable packaging. They focus on reducing material and energy use, revamping processes for efficiency, designing for recycling, refusing harmful substances, rethinking