Challenge Accepted

Behind every obstacle, there is opportunity for growth. How does your business achieve success when faced with adversity?

Behind every obstacle, there is opportunity for growth. How does your business achieve success when faced with adversity?

Editor: Sarah Peiper

Contributors:

Stephen Alberts

Nancy Busch

Paul “Max” Le Pera

Austin Maxwell

Jessica McNaughton

Tim Saddoris

Ed Young

Proofreader:

Marsha Jo Scott

Design:

V2 Marketing & Management

Printing and Distribution: LSC Communications

Countertops & Architectural Surfaces (ISSN 2372-983X) is published quarterly by the International Surface Fabricators Association (ISFA), with a fifth edition, a Buyers Guide, publishing in October.

Individual copies of Countertops & Architectural Surfaces magazine are available at the nonmember newsstand price of $14.95. Countertops & Architectural Surfaces magazine is also available by annual subscription (five issues) for $30.00. ISFA members receive a complimentary annual subscription with every membership renewal. Special rates and charges apply for orders outside of the United States. To subscribe, call (888) 599-ISFA.

For change of address, please include old label with new information, including both old and new ZIP codes. Allow 3-6 weeks for address change to take effect.

Countertops & Architectural Surfaces magazine is proudly printed in the United States of America. Copyright © International Surface Fabricators Association 2023. All rights reserved. No part of this publication may be reprinted or otherwise reproduced without the publisher’s written consent.

Countertops & Architectural Surfaces magazine and the International Surface Fabricators Association assume no responsibility for unsolicited manuscripts or photographs. Materials will be returned only if accompanied by a stamped, self-addressed envelope.

Opinions expressed by contributors in this magazine are not necessarily the opinions of Countertops & Architectural Surfaces magazine or the International Surface Fabricators Association, but rather those of the individual writers.

Photos in this publication may not depict proper safety procedures for creative purposes. ISFA and Countertops & Architectural Surfaces magazine support the use of proper safety procedures in all cases and urge readers to take steps to institute such procedures.

Photography/graphics provided by:

BACA Systems

Bella Casa Countertops and Stone

Caesarstone

Cambria

CaraGreen

Corian Design

Cosentino

Coverlam

Crossville

Daltile

Hyundai L&C

Infinity Surfaces

Lapitec

Laser Product Industries

Lensology

LX Hausys

MSI Surfaces

Park industries

REHAU

Wilsonart

POSTMASTER: Send address changes to:

LSC Communications

c/o Countertops & Architectural Surfaces magazine

3401 Heartland Drive

Liberty, MO 64068

THE OFFICIAL PUBLICATION OF THE INTERNATIONAL SURFACE FABRICATORS ASSOCIATION

Q

14 Strengthening Your Business to Weather the Coming Storm

Planning for growth during this time of economic uncertainty requires a strategy that capitalizes on the opportunities.

20 A Two-pronged Approach to

Staffing Shortages: Practical Advice that Works

To overcome your labor challenges, you must do two

things: Find good people and figure out how to work with fewer of them.

26 New Colors & Materials

From solid surface to quartz to the ever-growing

popularity of porcelain, here’s what’s on trend in 2023.

32 Fabricator Profile:

Bella Casa Countertops and Stone

Owners Geoff and Cary Jernigan are devoted to

providing their clients with top-notch craftsmanship

and superior service.

8 Editor’s Note

10 Calendar of Events

12 Industry News

14 Education Connection

24 Sustainability Matters

38 Perspectives: Nancy Busch

39 ISFA News

45 ISFA Associate Member Directory

48 Product News

50 Perspectives: Austin Maxwell

Follow us on social media!

Calacatta Miraggio Duo boasts a combination of subtle, yet bold gold and gray veins throughout each Q Premium Natural Quartz slab. With a warm marbled background, this quartz features one-of-a-kind crackled veins, created by using MSI’s patented technology, helping embrace its natural marble look.

As part of the Studio Collection that’s made domestically in the USA, this stunning quartz features MSI’s exclusive LumaLuxe Ultra formulation that enhances how light interacts with the surface for ultimate eye-catching and immersive results.

To learn more visit, www.qfrommsi.com.

@ISFAnow.org @ISFAnow @ISFAnow

If you live near a coast, you know that when it comes to environmental predictions, only second to the weather report is the surf report. While not always 100% accurate, these reports are the best shot we have at predicting maritime conditions. They’re based on information gathered by ocean buoys set in strategic locations that record data about temperatures, pressure, precipitation, humidity, wind and more. Crossed with weather forecasts, trends and tide schedules, these reports tell us when, where and how long swells will occur. Water enthusiasts and sailors depend on reliable surf reports to understand if maritime conditions are ideal.

It’s a bit like industry outlooks and economic forecasts if you think about it. Both clock current conditions as starting points; both use data collected over time to predict trends; both inspire excitement or create anxiety, depending on your goals. If you’re a surfer, a big swell might be just what you’ve been waiting for. If you’re a fisherman, high winds and big waves mean your work is about to get a bit more complicated.

While 2023 shapes up to be a year in which we face waves of rising costs and inflation, labor and supply chain challenges that persist, and a downturn from the previous years’ remodeling booms, it begs the question: How do you prepare for changing tides and big swells? What tools do you rely on to tell you how to pivot your direction in favor of, or away from, the challenges ahead?

If you’re a fabricator, you might take this time to shore up your business. You might revisit your priorities and lean into the work that brings you the best margins. You might take this time to review your processes and procedures to ensure you’re working smarter, not harder, which could help you overcome the skilled labor shortage. You might look into new lines of business or diversify your offerings to include products and materials that are readily available, easy to work with, or fit a new trend. Ed Young of Fabricator’s Business Coach shares some strategies along these lines on pages 14-15, as does this year’s ISFA president, Austin Maxwell of Maxwell Counters (page 50).

In this issue’s ISFA Fabricator Profile (page 32), we have Bella Casa Countertops and Stone of Littleton, Colorado, a fabrication company always keeping an eye on the next big thing. They’ve positioned themselves to be one of the best fabricators of ultracompact surfaces and one of the only fabricators in the Denver area providing porcelain materials, including Dekton.

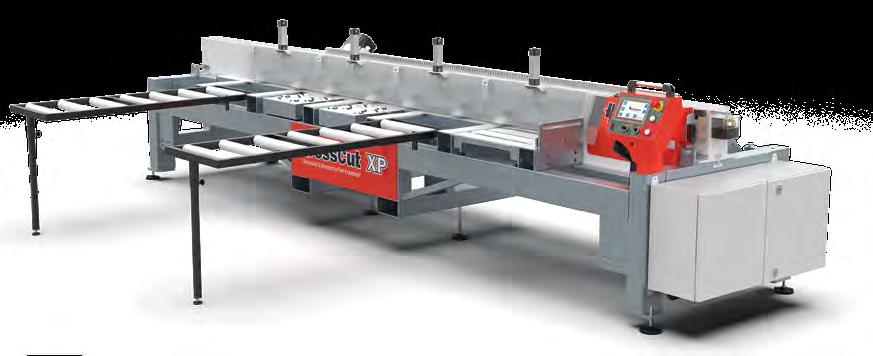

If you’re a manufacturer or supplier, you’re looking at ways to provide the industry with smart, durable, forward-thinking solutions. For example, we have Lapitec, which has developed a special blade for sintered surfaces that can cut fabrication time by 75% (page 48). And then there’s Caesarstone, which continues to lead the countertop industry with the launch of its multimaterial portfolio — most notable is its expansion to porcelain (page 12). Or Park Industries, which recently launched an upgraded miter saw to meet the demand for a growing trend in surface fabrication — you guessed it — mitered edges (page 12). These companies are paying attention to the trends; they’re listening to the surf report.

There’s a big wave surfing tournament, The Eddie, held annually in Hawaii on the North Shore of Oahu — in theory. Since its inception in 1985, the contest has been held only 10 times due to a precondition that swells produce a wave face height of over 30 feet. It’s named after champion big wave surfer and Waimea Bay lifeguard Eddie Aikau, a Hawaiian hero who saved hundreds of lives, pulling people out of waves that no one else would dare to.

During the first Eddie contest, the conditions were extremely dangerous. While the contest organizers were discussing whether to proceed with the event, Mark Foo looked out at those walls of water and decided, “Eddie would go.” And so the contest was on. For nearly 40 years, that phrase has stuck, and it’s widely used to encourage others to do something daring or difficult. When extraordinary conditions are all around you, be inspired by Eddie Aikau and find the strength to overcome the challenges you face. Go.

ISFA Webinar: Troubleshoot Your Business with Tech sponsored by Moraware

March 1

www.ISFAnow.org

Digital Stoneworking Expo by Park Industries

March 2

Anaheim, Calif.

www.parkindustries.com/dse

Behind the Surface Podcast: A Sales Rep Clinic with Justin Shaw of Stone Fabricator Elite

March 6

www.ISFAnow.org

ISFA New Member Workshop

March 15 Virtual

www.ISFAnow.org

Behind the Surface Podcast: A Colorful Conversation with Mark Woodman

March 20

www.ISFAnow.org

ISFA Summit

March 21-23

Raleigh, N.C.

www.ISFAnow.org

Tennessee Stone Summit: Take Your Organization to the Next Level

March 23

Nashville, Tenn. www.naturalstoneinstitute.com

Xiamen Stone Fair

March 26-29

Xaimen, China www.stonefair.org.cn

Solid Surface Fabrication Training

March 28-29

San Antonio, Texas

www.ISFAnow.org

Behind the Surface Podcast: Tracking Your Machines’ ROI

April 3

www.ISFAnow.org

ISFA Webinar: A Sales Rep Clinic with Justin Shaw of Stone Fabricator Elite

April 5

www.ISFAnow.org

Behind the Surface Podcast: Pro Tips for Shop Process Improvements

April 17

www.ISFAnow.org

Coverings

April 18-21

Orlando, Fla. www.coverings.com

Marble Izmir Fair 2023

April 26-29

Izmir, Turkey marble.izfas.com.tr/en

Behind the Surface Podcast: Sink Cutouts: Carving Out Hidden Revenue

May 1 www.ISFAnow.org

HD Expo & Conference

May 2-4

Las Vegas www.hdexpo.hospitalitydesign.com

ISFA Webinar: A Sales Rep Clinic with Justin Shaw of Stone Fabricator Elite

May 3

www.ISFAnow.org

Utah Stone Summit: Know Your Business

May 4

West Valley City, Utah

www.naturalstoneinstitute.com

ISFA Roundtable

May 10-11

Anaheim, Calif.

www.ISFAnow.org

Behind the Surface Podcast: Tooling Tips for Mineral Surfaces

May 15

www.ISFAnow.org

ISFA MemberConnect Meeting

May 18

Virtual www.ISFAnow.org

Behind the Surface Podcast: Slab Yield and Material Optimization

May 29

www.ISFAnow.org

Minnesota Stone Summit: Dynamic Intentionality

June 1

Plymouth, Minn. www.naturalstoneinstitute.com

Solid Surface Fabrication Training

June 6-7

Lakewood, Wash. www.ISFAnow.org

ISFA Webinar: A Sales Rep Clinic with Justin Shaw of Stone Fabricator Elite

June 7 www.ISFAnow.org

AIA Conference on Architecture

June 7-10

San Francisco

www.conferenceonarchitecture.com

Behind the Surface Podcast: Silica Safety and Industry Standards with NIOSH

June 12

www.ISFAnow.org

Oregon Stone Summit: Know Your Business

June 15

Beaverton, Ore.

www.naturalstoneinstitute.com

Behind the Surface Podcast: On the Cutting Edge with Park Industries

June 26

www.ISFAnow.org

Quartz surfacing pioneer adds porcelain and natural stone to offerings while continuing to focus on sustainability.

Caesarstone aims to transform the countertop industry in North America in 2023 with the monumental launch of its multimaterial surfaces portfolio: Porcelain and natural stone will join the quartz and outdoor quartz portfolio for which the company is so well known. The expanded portfolio of more than 100 colors tastefully combines the company’s innovative technology with its powerful design passion, empowering consumers to design with freedom. The new additions to the Caesarstone portfolio debuted at the 2023 Kitchen & Bath Industry Show (KBIS).

“This is a pivotal moment for Caesarstone,” said Ken Williams, president and CEO of Caesarstone The Americas. “We wanted to make it easy for people to design their dream spaces by offering our multimaterial surface solutions all in one place. Across the world, people choose Caesarstone because we bring joy and freedom to the design process. We strive to be a leader in design, innovation and sustainability.”

Expanding its product portfolio is just one of many initiatives Caesarstone is undertaking to achieve its strategic mission to become the leading multimaterial surfaces brand and the first brand of choice for countertops worldwide. Adding porcelain and natural stone allows Caesarstone to expand its product offering with new designs and application possibilities creating a mixed portfolio of infinite options.

For the new porcelain range, Caesarstone leverages its technical expertise and design leadership to capture the visual qualities of a wide range of material types: from natural marble to the industrial aspects of concrete and metal. The porcelain collection’s heightened veining, palpable textures and dynamic patterns are available in a highly curated range of 25. The product marks a leap forward in technology, functionality and design, developed explicitly for countertop applications:

• Superior durability to withstand stains, scratches and outdoor elements.

• Extreme heat resistance.

• Designs with striking color schemes, bolder veins, textures and patterns.

Caesarstone porcelain offers the same nonporous, hygienic health and easy maintenance benefits as the company’s quartz offerings.

A curated collection of responsibly sourced, high-quality natural stone also joins the Caesarstone portfolio in select markets around the country. Stock will vary from location to location and include some of the world’s most beautiful and exotic marbles, granites and quartzites.

Caesarstone outdoor quartz was the first of its kind in the surfaces industry. Designed and tested to withstand the sun’s rays and the most extreme outdoor weather conditions year after year, Caesarstone’s outdoor surfaces answer every homeowner’s desire to cook, dine and entertain from the comforts of their own outdoor space.

• The collection is nonporous, durable, scratch-, stain-, mold- and mildew-resistant, and easy to clean.

• Materials can sustain a high temperature of 122 degrees F (50 Celsius) to as low as -22 degrees (-30 Celsius).

All Caesarstone manufactured surfaces are independently certified as low-emitting by GREENGUARD and are SNFcertified. All Caesarstone manufactured surfaces are longlasting and durable, providing improved life-cycle cost and additional investment value. All are backed by lifetime warranties to reflect high performance and durability while meeting stringent product emission standards and having little impact on indoor air quality.

All the new Caesarstone designs will be available nationwide in the summer of 2023.

C.H. Briggs Company, an independently owned wholesale distributor of interior specialty building materials for more than 55 years, announced that it will be winding down operations and closing the business.

The company’s decision to close was made after efforts to restructure its relationship with its primary supplier were unsuccessful. The closure impacts 130 employees across its five locations. A small team will remain in place through March 31, 2023, to finalize operational details of the closure.

“To say we are sad and disappointed would be an understatement,” said Julia Klein, chairwoman for C.H. Briggs Company. “Changes in the supply chains we depended on mean we can no longer provide the quality of products and customer service that was the hallmark of our business. We made every attempt to avoid this outcome. Our efforts were exhaustive, but we were left with no other option but to wind down our operations.

“We recognize how painful this decision is for our co-workers and customers,” she continued, “which is why we worked so hard

to avoid it. We have a talented team, and we are doing all we can to help them be successful in the next phase of their careers. We are deeply grateful to our co-workers, customers and suppliers for more than a half-century of empowering, elevating and enriching the lives of the communities we serve. C.H. Briggs is more than just a distributor of specialty building materials. Our work has always been about creating exceptional spaces where we can all live, work, learn, play and heal. Our hope is that those spaces, and the people who design and build them, will be our legacy.”

C.H. Briggs was founded in 1967 by Harry and Georgeanna Briggs. In addition to its corporate office in Reading, Pennsylvania, the company has offices in Lansdale, Pennsylvania.; Richmond, Virginia; Charlotte, North Carolina; and Norcross, Georgia. In addition to distributing Corian solid surface, quartz and Endura products, Briggs has most recently represented Kohler, Rev-A-Shelf and other companies.

Customers with product and order inquiries are asked to call C.H. Briggs customer service at 1-800-355-1000.

Planning for growth during this time of economic uncertainty means you have a strategy to capitalize on the opportunities that will occur — a strategy to increase profitability.

By Ed Young, Fabricator’s Business CoachImagine you are in a 50-foot sailboat, 100 miles from shore, experiencing gale-force winds and 40-foot seas. You haven’t eaten or slept in a few days, and the only other person on the boat with you is seriously injured. How do you prepare to survive in those circumstances?

Obviously, that is a dire situation that few of us will ever face. And, while the current consensus is economic conditions will not be dire over the next two years, we can count on some business challenges to be headed our way. The question is: How do you survive the challenging economy ahead?

A sailor preparing to go to sea will consider many factors related to their voyage.

A sailor has a destination — an objective; there is somewhere they want or need to go. So, what’s your destination for the next two years? What are your objectives?

Is your plan simply to survive?

Survival mode might mean laying off employees to control overhead. It means spending as little as possible and not making any investments. It means taking any business you can get, regardless of the price, just to stay busy.

If you expect to be in survival mode, then it is

time to plan for how you will handle decreasing sales volume. Which employees can you most easily do without? At what sales or profit level should you make the first headcount reduction — and the next and the next? What other expenses can you reduce or eliminate?

A typical survival mode strategy would include eliminating organizational memberships, subscriptions and outside services like auto maintenance and accounting. All expenses are reviewed for either elimination or reduction.

Survival mode assumes there are few options for growth and success. Survival mode means focusing only on preserving life — conserving the business at all costs. It’s purely a defensive strategy.

Or is your objective to succeed and grow over the next two years?

Planning for growth during this time of economic uncertainty means you have a strategy to capitalize on the opportunities that will occur — a strategy to increase profitability. It requires strengthening all aspects of the business.

With this mindset, you will have invested in technology that will reduce your reliance on labor while increasing productivity and quality. You have upgraded computer hardware and software for your CAD and front offices. You have a training program

in place that includes cross-training on technical skills. You have completed or planned training to improve your managers’ leadership skills so the entire organization’s performance improves.

You have a solid sales and marketing strategy. You have trained your salespeople to qualify prospects and to sell more effectively. You have analyzed your market segments and know which have the most opportunities for you and are the most profitable. You have a marketing plan that identifies which messaging vehicles are most effective for your selected market segments. You understand the shortcomings of your competition and have crafted a clear, unique value proposition that sets you apart.

By planning to succeed and grow during these times, you have decided not to be at the mercy of the economic winds. Like a sailor, you’ll harness those winds in your sails and keep cruising.

A sailor studies the conditions they could face during the voyage; they have a plan to deal with the changing conditions that will occur. When the winds reach a certain speed, they’ll reduce the sail area by a predetermined amount. As the weather changes, they adapt how they manage the boat to take advantage of that change.

They learn all they can about the characteristics of the destination harbor and all of those along the way. They never know when conditions may force them to pull into a harbor that wasn’t in the plan. Business objectives require similar flexibility.

As a sailor studies weather forecasts, business owners need to check economic forecasts. Owners need a continuous pipeline of economic data. National-level data from financial publications are helpful for understanding long-term trends, as is analysis from groups like ITR Economics. This information should be combined with local and regional data.

Regional economic development organizations and state commerce departments are good starting points. They can give you an understanding of the forces driving your regional economy. What

businesses are moving into the area? Do those businesses plan to employ more hourly production laborers or executives and white-collar staff? How will those dynamics impact population growth and housing?

Many shops I talk to aren’t involved in their local homebuilder associations because they haven’t gotten any business from those efforts. However, there is a lot of information available in these groups. While your customers may not be members, other similar companies are. Asking open-ended questions about their plans for the next 12 months, whether they expect an increase or decrease in activity, and how much of a change they expect is all good information to know. Asking your current B2B customers these same questions will help you develop a sense of what will be happening in the next few months.

Keeping this information pipeline flowing is essential to strengthening your business for these challenging times.

A sailor knows the capability of the boat and crew: They know how each will react to various situations. They know the load-carrying capacity of the boat and the speed it is capable of. They know the skill set of the crew members, where there is redundancy and where there is scarcity.

A business owner needs to know their numbers. How fast do you burn cash every day? How profitable were you yesterday? How much profit do you plan to generate next Thursday? Are you on track to hit your profit goals for this month? If not, what is your plan to change that?

Are you the captain of your ship? Do you want to be totally at the mercy of the storm and end up wherever the wind blows, or do you want to be able to navigate the storm toward the destination of your choosing effectively?

Remember, your business is running exactly how you designed it to run. If you want to achieve your goals, you must have good information and a sound plan. You deserve to have a business that makes you money and allows you time to enjoy it. C

Ed Young is the owner of Fabricator’s Business Coach, a consulting firm designed to strengthen and elevate fabrication shops of all sizes. A former shop manager, Ed fully understands the challenges of today’s professionals. He has consulted with a range of businesses, from one-person startups to international Fortune 100 corporations, covering a broad array of products and processes. As a result, Ed knows that each business needs an appropriate structure for its unique situation. To learn more about how Fabricator’s Business Coach can take your shop to the next level, visit www. fabricatorscoach.com or reach Ed directly at Ed@fabricatorscoach.com.

The International Surface Fabricators Association (ISFA) has announced its 2023 Solid Surface Fabrication Training schedule with dates in March, June and August of 2023. This ISFA Certified Professional Solid Surface Fabrication Training program is the gold standard course for fabricating solid surface. The program is recognized by all major manufacturers and their network of certified fabricator partners.

Sponsored by Aristech Surfaces, these hands-on, two-day sessions provide attendees with the skills and knowledge in all facets of the fabrication process, including layout, templating, seaming, support, sanding, edges, cutouts, backsplashes, thermoforming, finishing

and installation. Participants will complete a vanity application that includes an integral bowl sink, built-up edge profile, edge inlay, and examples of coved and set-on style backsplashes.

“Partnering with ISFA to provide core knowledge and expert fabrication training is essential to foster the expertise necessary in every region, driving the surfaces industry forward,” said Jana Bartlett, global marketing manager for Aristech Surfaces. “Our fabrication expert, Aaron Davis, has more than 20 years of experience working with solid surface. He leads the training sessions and demonstrates the traditional and innovative techniques needed to thrive in our industry. Together with ISFA, we are elated to provide the tools and resources necessary for future generations of fabricators.”

Registration fees are $599 per person for ISFA members; nonmembers can register for $799 per person, which includes a one-year membership to ISFA (a $499 value). An observer option is also available. It is designed for those with roles adjacent to fabrication but would benefit from the context around the process,

Registration for the following sessions is now open:

• March 28-29, 2023, in San Antonio, Texas

• June 6-7, 2023, in Lakewood, Wash.

• August 8-9, 2023, in San Antonio, Texas

such as sales or marketing associates. Observers do not actively participate in the hands-on project, but they can watch, ask questions and otherwise participate in the sessions. The observer registration fee is $399.

“I registered my staff for the ISFA Solid Surface Fabrication class in San Antonio since we were looking to expand our flooring business to include countertops and shower surrounds,” recalled Topher Sieverson, Floor Covering Express. “My staff was able to leave with the knowledge and skills to expand our business. They enjoyed their time with Aaron and left there ready to make our business better.”

In addition to these scheduled training dates, ISFA offers a training option that is conducted on-site at the registrant’s shop. This is ideal for fabrication shops, facility management and maintenance companies, and other technical trade businesses with several staff members who need training and would benefit from having it in their own space. On-site training includes the same fabrication coursework, and it is led by Aaron Davis, who ships training materials directly to the location. Registration fees for on-site training vary based on the number of attendees. For more information about on-site training, contact Trainer@ISFAnow.org

“The ISFA solid surface fabrication class was very beneficial to our business,” said Greg Howard, Adobe Walls Stoneworks. “We are fabricators of quartz, granite and quartzite, and we wanted to expand to solid surface, and the class got us up to speed quickly.”

Active participants who complete the training course’s project with a satisfactory result will receive a certificate recognizing that they are an ISFA Certified Professional.

“Solid surface fabricators founded our association to provide educational and growth opportunities for professionals within the decorative surfaces industry,” said Nancy Busch, executive director of ISFA. “ISFA is dedicated to delivering the tools and resources fabricators need to find success. In this challenging labor market and economy, the solid surface training program is a great way to train new hires who lack experience or diversify an existing business into new lines of work.”

For more information about the International Surface Fabricators Association and all its training programs, visit www.ISFAnow.org C

A

When marketing your countertop shop online, you want to make sure you are targeting the right audience. It starts with good search engine optimization, ensuring your website appears wherever and however potential clients are searching for it. Google ads and Facebook/Instagram ads work well for shops, but I’ve seen many shops burn money by not having them set up correctly. Regardless of the platform, before you schedule your next ad campaign, consider these strategies that will help you leave a lasting impression.

When working on an SEO campaign for your fabrication shop, you want to rank higher on the Google search page. The higher you rank in Google, the more traffic you will get to your website. With SEO, you need to think like your customer. What are they going to type into Google to find a countertop?

Granite countertops

Quartz countertops

Marble countertops

Countertops near me

Kitchen countertops

Bathroom countertops

Now it’s impossible to know whether it’s a homeowner doing the searching; it could be a restaurant, a builder or a contractor looking for a shop. That said, most of the leads from organic Google search results are homeowners (about 90%).

Do’s and Don’ts:

• Do have a strategy with SEO, whether you are working with someone or doing it in-house. If this isn’t a skill set you have among your staff, outsource it, and don’t overlook it.

• Do make a thorough list of keywords that you want to leverage in Google and then create specific pages for each one.

• Do make sure to use all the major keywords you want to leverage on your homepage.

• Don’t ignore your homepage. We see this often, a homepage that barely has any content in terms of words. Your homepage is the most visited page on your site, so you want Google to see that you sell marble countertops or that you specialize in fabricating kitchen and bathroom countertops.

Now that you know about keywords and have a plan for SEO and organic search results, you can use a similar strategy with Google ads. These ads usually show at the top of a search page, just above where the organic results appear. Sometimes you’ll find ads at the bottom as well.

When running these ads, you pay for each time someone clicks on it, either a search ad or a display ad. A search ad is the Google search result for your company, but you essentially pay Google to appear at the top of the list. You’ll leverage the exact keywords you’re using for SEO.

A display ad is a banner ad that appears throughout websites like weather.com and news sites. You can set up different audiences to see your display ads. For instance, you can show to people who are age 35+ and in the top 10-50% income level. Google will place your ads on sites in front of this audience. Again, you won’t know if a tradesperson or consumer is clicking on these, but you can assume most traffic will be from consumers.

With Google ads, you can do a couple of things:

1. Break out your campaign so you have your keywords in certain ad groups. For instance, your kitchen countertop terms should be in a kitchen countertop ad group. And within that ad group, you should have kitchen countertop ads. And then, when someone clicks that ad, they should land on a page about kitchen countertops. The journey will be super relevant and convert more traffic into leads. Make sure that the page they

land on references that specific search term.

2. With display ads and even search ads, you can add an audience to target. Demographics, including age, sex, marital status, education, income, geographic area and personal interests, determine audiences. Consider fencing your ads in a specific geographic area or targeting certain income levels or age ranges — ones that might be more likely to take on a home remodel project.

• Don’t waste money on bad keywords. Ensure you’re using keywords that will appeal to your business and draw in the right customer.

• Don’t forget about negative keywords. What is a negative keyword? Let’s say you are a higher-end shop and don’t want to show when people type in “affordable countertops.” Add “affordable” as a negative keyword. You are telling Google not to show your company when someone types in that word.

• Do keep it relevant. Make sure to reference each search term when someone lands on that page. If they land on a page that doesn’t support the keywords, they’ll bounce by clicking that back button, and then you’ve just wasted money on a click that won’t result in a lead.

Facebook and Instagram run on the same ad platform. You can dig into different targeting strategies and an audience’s demographic when running these ad campaigns. Unfortunately, if you want to go after homeowners, you can’t pick a “homeowner” interest to target anymore. Facebook removed that, so you will have to get clever about it. Maybe you target 25- to 65-year-olds around your area who like home and garden topics like interior design, furnishings or kitchen interests. Or, if you want to go after a builder, you can target a home construction interest and then pair it with relevant tool company names.

Social media is very visual, so what you can do here more than in Google is call out the audience in the ad. If you want to reach more homeowners, try speaking to them in the ad. Maybe you have a kitchen countertop package or want to promote how quick your turnaround times are. If a builder sees this, they might scroll by it since it doesn’t speak to their needs as much. To attract a builder’s attention, talk about how you work with builders and contractors in the area and how easy it is to subcontract the work to your shop.

Do’s and Don’ts:

• Do get specific. You want to target individuals, not just your whole area’s population. With social media ads, you are paying for the reach, which amounts to impressions — the number of times users see that ad.

• Don’t spend your money all in one place. Social media ads run for a period of time based on the spend. When the ad spends out, the campaign pauses until you put more money against it. Start small, see what works, and keep spending if you see the results you want.

• Don’t rest on just one campaign or one demographic. Try different approaches to reaching a potential customer and learn as you go. Test other interests for targeting. For example, if you want to target higher-end customers, maybe you target people who like luxury cars. Think outside the box with your audience targeting!

The days of the Yellow Pages are long gone. When homeowners want a countertop, they hit the internet from their phone or computer. You must be right there, front and center, when they are searching. The beauty of digital marketing is that you are in control. You choose the keywords that represent your business, you pick the audiences to target, and you set the budget. After your marketing campaigns are dialed in, you’ll have a predictable way to grow your business. C

Stephen Alberts is the owner of the Countertop Marketing Co. and STONE ENGAGE. They specialize in helping countertop companies grow the retail side of their business outside of word-of-mouth and referrals. They also offer software to help you engage more with customers and close more countertop projects. To learn more, visit https:// countertopmarketingco. com/ or https:// stonengage.com/. You can also email Stephen at steve@countertop marketingco.com.

Hiring is hard, especially when you’re looking for skilled workers. In 2021, more than half of businesses surveyed said they had difficulty finding qualified workers. A year later, more than three-quarters of companies surveyed said the labor shortage has worsened. With business on the books and the opportunity for more jobs on the horizon, you can’t ignore the need. To overcome your labor challenges, you must do two things: Find good people and figure out how to work with fewer of them.

Let’s start with hiring. If you want to find quality workers, it’s time to change your mindset.

In the past, the hiring process centered around applicants selling you on why you should hire them. Today, it’s the opposite. You need to flip the script and let people know what’s in it for them if they work for you. It sounds simple, but it’s a significant shift for many. Consider it in terms of advertising and marketing. If you’re trying to attract customers, you carefully craft a brand image, demonstrate the benefits of your products, and explain how you can be of service — a value proposition. Now think about your potential hires as customers. Explain what your company has to offer and how this job helps them achieve their goals.

See Figure 1 for an example of a job description and how it can be reworked to sell the advantages rather than the requirements.

Stop demanding long lists of qualifications in your job descriptions. They can serve only as checklists for potential job applicants. They go down the list, and when they see they don’t have everything you want, they may never apply — even if they’d

be a great job candidate. List only the most essential skills you must have and forget the rest. You can always probe more deeply in the interview process.

One East Coast fabricator we worked with wanted to find a salesperson with design skills who knew a specific type of software. They got applications, including some strong salespeople and some designers, but nobody had experience with the software. They passed up some potentially great candidates because they were looking for the perfect candidate. Those unicorns rarely exist.

When hiring, think about what you must have in an employee and what you can train. Can you take that high-performing salesperson and teach them how to use the software? In our experience, finding the person with the basic skills you must have, along with the right attitude and cultural fit, and upskilling them is often the best solution.

As Jim Collins put it in his book, Good to Great, companies that went from good to great didn’t focus on where to drive the bus until they first got the right people on the bus. He says, “If we get the right people on the bus, the right people in the right seats, and the wrong people off the bus, then we’ll figure out how to take it someplace great.”

In small businesses, a common complaint from workers is that there’s no room for career advancement. Can you take someone already on your team, train them for a higher-level opening and promote them? Large companies create “feeder positions” to help give employees the experience they need to move to the next level. Doing so can let you hire people at an entry level, do some training, and ensure they’re the right fit for the next level. If so,

{company name} is a womanowned, small business looking to add a member to our design team. You must be self-motivated and energetic. Ready to expand on our past success with fresh ideas and concepts that can add a virtual experience to our brickand-mortar storefront.

Experience with design is required. (20-20 is the design program recommended. Virtual platform skills are highly recommended.)

Benefit Conditions:

Waiting period may apply

Only full time employees are eligible

COVID-19 Precaution(s):

Remote interview process

Personal protective e quipment provided or required

Social distancing guidelines in place

Virtual meetings

Sanitizing, disinfecting, or cleaning procedures in place

Work Remotely — No

Job Type: Full time, Part time

Pay: $15.00 - $18.00 per hour

Be valued, and enjoy sharing your talent!

Now Hiring Experienced Kitchen Designer! {company name} is hiring an experienced kitchen designer for our countertop showroom to help build a residential retail department. This is a great position for an energetic self-starter who loves talking to customers, designing beautiful kitchens, and building sales and relationships! With a flexible schedule during business hours, this role can be full or part time. Don’t settle for a boring, strict and stuffy work environment.

At {company name}, many team members have been here for over 30 years, proving we put relationships and family first. Be part of a great team that values YOU!

Who’s this role right for? A team member who is:

• An experienced kitchen designer tired of big box store employment corporate rules, boring work and strict schedules.

• Comfortable using 20-20 software design program.

• Ready to work full time OR part time, whatever best suits your schedule.

• Comfortable with sales meeting new customers, following up on leads, creating sales.

What {company name} offers:

• Flexible role: part time or full time.

• Ownership of your job: Build a department using your experience and knowledge.

• Earn more! Leverage relationships to earn more commission!

• Up to $18 per hour plus unlimited commission.

• A people person — maintaining and developing vendor relationships.

• Self-motivated, up-to-the-challenge of building a residential design department.

• Ready to work a flexible schedule on-site during open hours of Tuesday-Saturday, 11 a.m.-7 p.m.

• Health insurance and IRA.

• Free financial ad viser.

• Paid vacation and sick leave.

Awesome work environment at a 50-year-old company with loyal team members who value YOU! Get in touch today, and let’s talk about how working at the {company name} can be a great next step for you!

Figure 1

great! Then, you can hire their replacement, which helps with filling that job because you can show how the feeder job can lead to growth opportunities.

Are there labor pools you can pull from other industries that have some overlap that you may be able to offer a better opportunity? For fabricators, we’ve found a great place to look is in roofing. Roofing is seasonal in most parts of the country. Jobs can be unpredictable, and there may not be any work during the cold, snowy winter months. It’s also rather dangerous. There might be a pool of these laborers looking elsewhere, and roofers have some compatible skills with installers. Most are handy with tools, comfortable dealing with homeowners, and they’re hard workers. As a fabricator, maybe you can offer them a better deal. Compared to roofing, you can provide plenty of hours, year-round work, and a steady paycheck — even a benefits program. And they’ll still get paid if it’s raining!

Today’s workers are also looking for more than just a paycheck. The pandemic changed a lot about how people approach work these days. They want value and satisfaction, and they want purpose. They want to work for an organization they believe in and whose values match theirs. They expect the company they work for to have a strong ethical compass.

At the same time, they also want a company that cares about their employees’ well-being and provides some semblance of a work-life balance. While salary is still one key driver in attracting and retaining quality workers, a purpose-driven organization with an employee-centric culture is an important factor, especially for younger workers.

Have you ever wondered why some companies have no trouble hiring while others are always trying to fill positions? Often, it’s because of the way they approach the hiring process.

Here’s an example: Turnover is huge in the fast-food industry, and despite raising wages, restaurants are struggling to find people willing to do the job.

A manager at one Chick-Fil-A took a different approach than their competitors by moving to three-day, 40-hour workweeks. In an industry that sees, on average, a 144% turnover rate, he went more than nine months without any turnover. For a single job opening, more than 420 people apply.

Meanwhile, his competitors are begging people to work for them and continually raising wages.

Rather than keep increasing pay, look for how the job can be done so one person can accomplish more within the same amount of time. By default, this increases productivity and makes the position more profitable.

Can you create different ways to approach the job to offer flexibility? For example, can you let people work on flexible schedules: three- or four-day workweeks, guaranteed weekends off, or offer bonuses for performance rather than just hourly wages?

Look at ways to improve the work, especially if you have roles with high turnover.

Early in my career, I worked at a pudding plant. It was a large facility with plenty of managers and supervisors working with a lot of entry-level people. Everybody loved this one high-level manager, Ron. If he needed something done, people would bend over backward to make it happen.

It turned out that when Ron came aboard, the first thing he did was ask his team what the most arduous task was. Everyone said cleaning interior product contact surfaces without disassembling the food processing tanks. Everybody hated it. It’s a complex job that takes an entire eight-hour shift. Plus, if it’s done wrong, the pudding can become toxic. (No pressure!)

So, Ron picked the best guy and asked him to teach him how to do it. Over the next three weeks, Ron cleaned those tanks every day and discovered several ways to improve the process. In doing so, he gained trust and favor with his team because he was willing to get his hands dirty and make the job easier by eliminating steps.

As a business owner or manager, it’s your job to fix problems.

It’s time for a change. You must be willing to rethink how you approach hiring and how the job gets done.

If the problem is that nobody wants to be an installer, it may be because the job is frustrating. So, dig in and do it yourself. You’ll learn the roadblocks firsthand and maybe find a way to streamline processes or improve the job, and you’ll likely earn some appreciation from your crew.

For fabricators, scheduling can be a pain. It isn’t a complicated job, but it can be cumbersome. You’re ready to go on a job, but the sink hasn’t arrived, or the quartz isn’t ready. It can be challenging to keep things moving. If you have a solid system to track your jobs and inventory, is there a reason someone couldn’t handle scheduling from home?

By eliminating the requirement to come into the office, you’re tapping into an entirely different pool of job applicants and providing workers with benefits that don’t really cost you anything. Without having to raise wages, you can increase their take-home pay by eliminating travel time on the road. Think about it: employees might spend $50 to $100 per week on gas — a cost they shoulder just to show up for work. At $18/hour, they have to work 3-5 hours per week just to break even on the gas, and we haven’t even considered wear and tear on their vehicle and maintenance costs. Plus, they lose personal time commuting that they could be spending with their family. Even flexibility one or two days per week can make a big difference in someone’s work-life balance.

Now let’s talk about the second part of the equation: working with less. Whether we like it or not, we all have to work with fewer people these days, but there’s a right way and a wrong way to do this.

It’s not just about piling tasks on the rest of the staff; that’s a surefire way to burn people out and create turnover. In today’s environment, it’s more

about finding efficiencies to make the job easier. Often, you can accomplish this by rethinking your workflow and processes. When you don’t have people available to handle the work, I approach it using ADE, which stands for Automate, Delegate, or Eliminate.

If there’s a portion of a job you can automate, do it as soon as possible. It reduces manual work, increases accuracy, and it frees up your employees to focus on more critical tasks that you can’t automate. The easiest way to do this is through machines or software. Can you delegate some portions of work to others to reduce the burden on certain individuals? Finally, can you eliminate steps or organize work differently to make it more efficient?

Many managers struggle with delegation. Workers today want autonomy and the ability to make decisions without always having to check with the manager. Recently, I had dinner with a business owner who shared his frustrations with his chief operating officer. The COO came highly recommended with a high pedigree and fit the culture, but he just wasn’t making any decisions on his own. It came to a head when his COO asked him what color carpeting he wanted to put in one of the company’s locations. The owner began to wonder: why is he paying this person if he can’t make simple decisions?

The problem, it turned out, wasn’t the COO; it was the owner. He was a micromanager. This micromanagement paralyzed the COO because he needed to get the owner to sign off on every decision or face the wrath of a “wrong” decision.

As an owner or manager, you must be able to delegate nonessential decisions and live with occasional mistakes. Use those mistakes as teachable moments — opportunities to explain to employees how to improve for next time.

The bottom line: It’s time for a change. Hiring isn’t likely to get any easier in 2023. With more skilled workers retiring, it will be critical for owners to find, train and retain replacements while creating efficiencies in the work. You must be willing to rethink how you approach hiring and how the job gets done. C

Tim Saddoris is the president of Grand Onyx, a firm dedicated to building world-class surface fabricators. Grand Onyx helps companies define operational processes and create road maps to achievements that enable more predictable revenue and stronger margins, and foster legacy businesses that stand the test of time. To learn how Grand Onyx can help with hiring or automating your business, visit www.GrandOnyx.Pro.

Surface fabrication is a dynamic business; it’s often managed on the day-to-day and putting out fires is the name of the game. While necessary, the cost comes at neglecting to focus on factors that may impact the business in the long term. As 2023 shapes up to be another challenging year in this industry, position your business for success by understanding industry shifts in marketing, information technology and sustainability — specifically those affecting the countertop markets within the enterprise chain: fabricators, distributors and manufacturers.

For example, the last few years have seen a massive shift in how your customers do research and procure information. Foot traffic has become a fast-paced, fact-finding mission executed on a keyboard. Information is at everyone’s fingertips and decisions are made in increasingly shorter time frames.

Your fabrication business’s online presence matters more now than ever before. With this comes easier discoverability, cheaper and more navigable marketing tools, and a shift from cluttered gluts of information in the form of manuals, guides and specifications, to online tools that provide the latest information in real time.

With online inventory tools, artificial intelligence chat solutions, online sampling and product databases becoming the new norm in research and discoverability, we see this shift integral to more modern sustainable practices. Unfamiliar product names will begin to cross your desk in specifications and you will need to figure out what it is, where to get it and how you cut it. Buffer yourself from slowdowns by getting ahead of these trends.

Understand that information is coming from platforms, not people. Data and sample fulfillment are rapidly migrating online, which means that virtual document and sample libraries are allowing customers to determine what product they want based on selection criteria. Fabricators will have informed customers who have chosen products based on what mattered to them versus what they are told by a salesperson. Being open to these new channels is imperative for fabricators to be successful as they are going to be an increasingly growing source of customers.

Material Bank, an online sample platform founded by the Sandow Group, parent company of Interior Design Magazine, is a consolidated physical library of samples for over 450 brands. Picture a massive warehouse filled with samples, which can be

accessed online by tens of thousands of designers and architects to procure samples immediately. This service is extremely valuable to the specifiers who are choosing materials, and it is free to them! (The cost is shared among the manufacturers, who pay to have their products hosted on the platform.) This means that more specifications will occur online. Choices will be made, for example, by using filter logic on things like color, price or recycled content.

This is a game changer for fabricators. The way many designers are choosing materials has shifted to online, including how they vet materials. The fabricator now can often be the first point of in-person contact on the project. It appears that the traditional function of a product representative will require some adaptation, quite possibly into a greater focus on territory management versus sampling. Other sample platforms include Swatchbox and Source.

In addition, there is a proliferation of databases that are aggregating product information. All the performance data are broken out into individual fields and hosted online in a searchable database that allows designers to see what products meet their needs. It also means a lot of product research is being done before the specification comes through. This is not just a commercial play; the same migration of data online is accessible to consumers too, who will be much more savvy when they arrive to talk about their selections. Some examples of online data aggregation platforms are Mindful Materials, ecomedes and Sustainable Minds.

Along the same lines, new technology is increasing throughput and efficiency in material development. Quartz has evolved to the point where the major innovations have been in the colors and patterns offered. There is some significant innovation in quartz unfolding as bio-based resins are developed, and companies like Breton continue to market these innovations to slab manufacturers. Cosentino has created a line of silica-free quartz; the minerals used to create the material are made in a lab. Other silica-free raw materials are being researched and developed to include mineral ores that come from post-industrial uses, affording the finished product color nuances, virtually

silica-free material, and in some instances, performance enhancers.

Sintered stone is actively addressing one of the biggest objections to the category: the throughput and fabrication time. Dekton recently announced a new formulation that allows its slabs to be cut more quickly and efficiently. Similarly, Lapitec has announced the new Veloce blade (see page 48), which can cut sintered slabs three times more quickly than a traditional blade. More blade innovations are coming as this is the perfect response to what is a major bottleneck for fabricators: enabling them to embrace the sintered category. And finally, disclosure requirements are not going away. We are used to fabricators requiring a Safety Data Sheet for anything cut in their facility. But even before the customer is getting to the fabricator, they are requiring things like Health Product Declarations and Environmental Product Declarations. As these become more commonplace, fabricators must be aware these documents exist and what they contain.

Adaptation is the key to both survival and proliferation. Information access, dissemination and accuracy are rapidly evolving. Awareness of these evolutions will necessitate strategic adoption in one way or another. Stay ahead of the game by paying attention to consumer information trends and sustainable advancements. “Busy-ness” is not business. How fabricators adjust functions and priorities to better focus on adaptation will play a major role in their companies’ sustainability and success.

Paul “Max” Le Pera is the president and founder of Proprietary Ventures, LLC, a boutique-style global firm devoted to researching, discovering and deploying disruptive and sustainably oriented proprietary products and technologies. He serves on the ISFA board of directors as vice president of standards. He can be reached at paul.l@ proprietaryventures.com.

Jessica McNaughton serves as president at CaraGreen, a provider of sustainable building materials, including many alternative surfacing materials. She has 20 years’ experience in sales, marketing, business development and strategy. Previously the director of sales and marketing at CaraGreen, Jessica has maintained her status as a LEED Accredited Professional since 2009 and she hosts a podcast, Build Green Live Green. She can be reached at jessica@caragreen.com.

From solid surface to quartz to the ever-growing popularity of porcelain, here’s what’s on trend in 2023.

Hyundai L&C is dedicated to a new lifestyle culture with the simple mission of creating satisfied customers and a more abundant world. With that mission in mind, Hyundai L&C proudly introduces their newest designs, the Opimo Collection.

HIMACS Solid Surface’s newest introduction, Pietra Collection, evokes the rugged and organic look of natural stone. The collection’s five colors — Brina, Calda, Notte, Nebbia and Ombra (shown here) — bring an aesthetic of understated luxury and are versatile enough to meet the design requirements of multiple commercial interior spaces.

Brina’s frosty allure adds a touch of luxury to modern, industrial and transitional spaces. Its light gray and soft white tones, rich texture and intricate veining yield a sophisticated appearance. Calda’s ivory and soft white hues deliver warmth and design versatility. Its long veins gently ebb and flow in both width and tonality, revealing a gentle wavelike pattern. Rugged and dark, Notte makes a dramatic statement as long, whisper-white veins expand and condense across an urbane black surface, creating light undertones and an inviting look.

As a nonporous surface, Pietra Collection offers exceptional maintenance, cost savings and hygienic advantages. Learn more at www.lxhausysusa.com/hi-macs.

Coming from the Latin word “opimus,” the Opimo Collection presents the abundance of nature’s variety and depth. Using the latest technology, Hyundai L&C has created a groundbreaking new chapter in quartz surfacing. By using this technology, they capture quartzite’s depth and translucent qualities in a manner that has never been seen in quartz surfacing. The natural color variations in each new design — Le Blanc (shown here), Matterhorn, Elba White, Eden and Patagonia — offer limitless possibilities to any design environment. For more information, please visit www.hyundailncusa.com/hanstone-featured-colors.

Cambria recently launched six new designs, including an all-new collection of four alloy-infused surfaces, suitable for both residential and commercial applications. This never-before-seen alloy veining captures the luster of brass and steel and is available in three different surface characteristics — smooth, sculpted, and satin ridge. The Alloy Collection marks a first for alloy-infused quartz surfaces and debuts as part of Cambria’s new Grandeur Series, the most luxurious of all Cambria series. In addition to Grandeur, styles Abbey and Everleigh round out this design launch, featuring cool gray and warm gold veining suitable for both modern and traditional environments. Visit www.cambriausa.com to learn more.

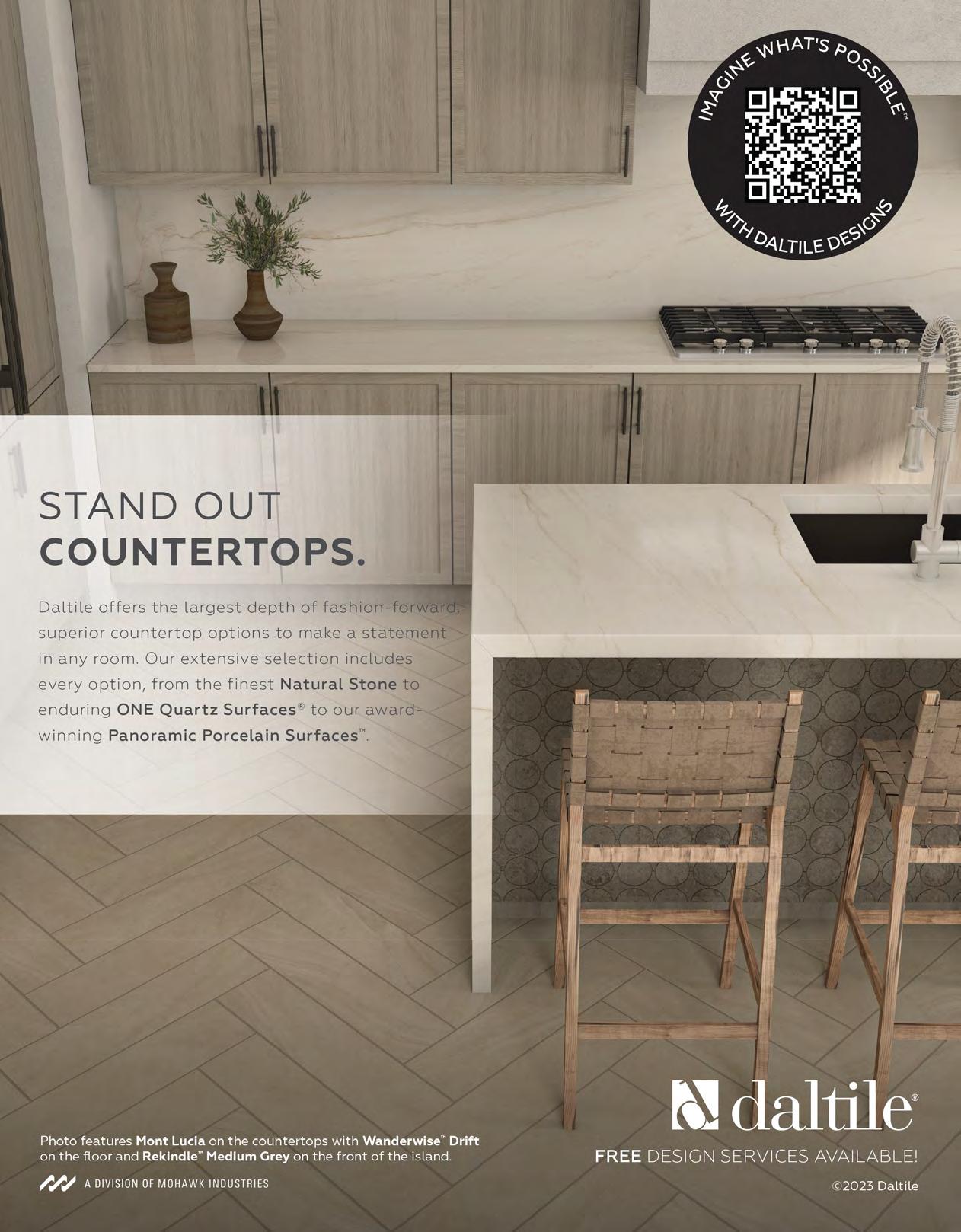

Daltile’s ONE Quartz Surfaces can be cut for almost any application, creating the perfect product for a seamless design or monochromatic look, and now they’re available in extra large slab sizes. Daltile uses more than 90% quartz in their ONE Quartz Surfaces along with resins that act as binders and colors that give the product its beauty. They have unsurpassed durability, design flexibility, ease of maintenance and consistency. The many color choices and stone-look designs in quartz make the look of marble or other exotic natural stones a possibility where they might otherwise be prohibitive. Pictured here is Arabescato Twilight, one of four new designs released in 2022. Increase the style in your space with majestic quartz countertops, and seamless quartz floors or walls in your design. For more information on ONE Quartz and other surfaces from Daltile, visit www.daltile.com.

Silestone with HybriQ+ Technology is a true testament to Cosentino’s commitment to sustainability and taking care of the present to protect the future. HybriQ+ Technology is a high-performance blend of premium minerals, quartz and recycled materials. The innovative technology marks an entirely new product composition and manufacturing method for Silestone — with a newly debuted sustainable manufacturing process that uses 99% reused water, 100% renewable electric energy, zero water waste and a minimum of 20% recycled raw materials within HybriQ+ products’ composition. Learn more at www.cosentino.com/usa/silestone/hybriq-technology.

Corian Endura is a premium highperformance porcelain made from a recipe of natural minerals and cutting-edge technology. Compressed together under extreme pressure and then heated at high temperature in a similar way to how nature forges a diamond, this innovative material is a densely packed mass characterized by its durability and beauty. Corian Endura offers superior resistance to extreme heat, abrasions, scratches and stains. It offers superior hardness, is nonporous and does not promote the growth of mold, bacteria and mildew. Select from four product families made up of monochromatic, marble, metal and cement aesthetics. Pictured here is Cool Marble. The color palette matches up effortlessly with a wide selection of kitchen styles, from sleek modern interiors for the city to traditional settings suitable for country living. Learn more at www.endura.corian.com/.

The wide range of Coverlam products is extended this season with the enticing metallic texture of the Distrito series in Aluminum, Corten, Zinc, Iron (shown here) and Ivory colors. This collection closely recalls the look of metal sheets that have been exposed to the weather, creating visually rich surfaces. This ultra-thin (5.6 mm and 3.5 mm) porcelain collection is available in large-format pieces: 1200 by 2600 mm, 1000 by 3000 mm, 1200 by 1200 mm and 600 by 1200 mm. It’s also available for kitchen countertops in Iron, Aluminum and Ivory colors in 1620 mm by 3240 mm and 1000 mm by 3000 mm sizes, and 12mm and 10.5 mm thicknesses. Find more information at www.coverlambygrespania.com.

MSI’s USA Quartz Factory is meeting product demands and distribution needs of customers in this highly desirable category. With advanced technology and patents for miles, MSI is producing Q Premium Natural Quartz that is exquisite and durable.

Located in Latta, South Carolina, MSI’s state-of-the-art manufacturing facility is a producing over 1,000 premium natural quartz slabs daily at its maximum capacity. The 360,000 square-foot facility is equipped with advanced machinery and a patented veining process, allowing MSI to produce the highest-quality quartz and the most realistic and natural patterns with a level of detail and accuracy that is unrivaled in the industry. Developed with LumaLuxe Ultra, MSI’s proprietary formula enhances how light interacts with the countertop surface, pushing the boundaries of realism with increased depth and dramatic veining, resulting in more immersive colors. This new technology has paved the way for this next-generation quartz.

One of the key features of MSI’s factory is its focus on innovation and design. The factory is home to the Q Studio Collection, which features quartz designed to be beautiful, on trend and functional. Calacatta Miraggio Duo, Calacatta Miraggio Gold, and Calacatta Miraggio are realistic marble looks — part of the expanding Q Studio Collection. Known for their beautiful neutral color palettes, unique veining, and superior

white backgrounds, the features of Q Studio provide ultimate design flexibility.

The newest addition, Calacatta Miraggio Duo, is a standout product. This quartz boasts a unique duo-tone design, combining subtle yet bold gold and gray veins throughout each slab, adding depth and interest to the surface.

Calacatta Miraggio Gold is another popular choice that offers a bold and dramatic look for those who want to make a statement with their countertops, by introducing a hint of warmth into a space with elegant golden-brown veining and a crisp white background.

And finally, Calacatta Miraggio, the original color in the Q Studio Collection, is a cool, white marble with a glossy polished finish and a classic, timeless look.

Overall, The Studio Collection is perfect for those who want the authentic beauty of marble without the maintenance and durability issues of natural stone.

MSI’s design and product team continues to expand the Studio Collection produced in its U.S. manufacturing facility. New products are scheduled for release throughout 2023, including Calacatta Cielo which will feature dark silver and navy long veins on a gray Carrara background. Stay tuned online at www.qfrommsi.com, or visit one of over 40 MSI showrooms and distribution centers nationwide to make your dream surfaces attainable.

Stay tuned online at www.qfrommsi.com, or visit one of over 40 MSI showrooms and distribution centers nationwide to make your dream surfaces attainable.

Caesarstone’s porcelain products mark a leap in technology, functionality and design by introducing three innovative properties that deliver a high degree of durability, strength and style. This product is based on three innovative properties developed by the brand to unleash the full potential of porcelain, making it a high-performance material particularly suited for present-day lifestyle:

• Fortified frame — incredibly hard material.

• High heat — extremely resistant to high temperatures.

• Forward design — striking color schemes, bolder veins, textures and patterns. For 35 years, Caesarstone has been turning design dreams into a reality. Now, with the addition of porcelain, consumers can find their dream surface no matter the material. A Caesarstone countertop lets life unfold around it because it is made for whatever life brings. Surface the possibilities. To learn more, visit www.caesarstoneus.com.

Wilsonart brings real wood and custom veneer staining to laminate with the introduction of its new Woodgrain Staining collection. This innovation within the Wilsonart High Pressure Laminate (HPL) portfolio allows designers to achieve the look of stained wood or veneer in virtually any color. Blending versatile style and powerful technology, Wilsonart Woodgrain Staining offers customization of classic woodgrains, like oak and walnut, and allows designers to match any hue from a variety of color palettes. This customization is available through an easy online ordering process with expedited delivery timelines of just a few weeks. Wilsonart also offers 28 pre-curated designs for those who desire a stained look but don’t need to achieve a color match. Combined with the high-performance durability of sustainable Wilsonart HPL, the collection evokes the aesthetics of real wood and is ideal for high-traffic commercial applications. For more information, visit www.wilsonart.com/woodgrain-staining.

This new series draws inspiration from a journey through California’s stunning coastline, as told through Carrara and Ivory White marble inspired designs. It marks the first collection to feature the brand’s new Quick Cut technology — an innovation at the molecular level of the material that makes it lighter and easier to cut, while maintaining its industry-leading performance and durability. The result: a product that is three times faster to cut, easier to transport and install, with less tool wear and cleaner edges.

“With its unrivaled durability and sophisticated designs, Dekton SilverKoast allows our clients to bring the beauty, harmony and warmth of the coveted California coast into a wide variety of residential, commercial and hospitality projects — indoors and out,” said Director of Product R&D Valentin Garcia.

Inspired by the serene whites of the Pacific, as well as some of the brand’s bestselling Silestone designs, Dekton SilverKoast brings functional beauty to any architectural project. The performance features of Dekton such as high resistance to UV rays, scratches, abrasions and water, make it ideal for both interior and exterior applications.

The collection is available in two colors and offered in a velvet matte, as well as polished finish — which boasts Cosentino’s XGloss technology to produce a dazzling crystalline shine. Learn more at www.cosentino.com.

Made in Italy, Infinity slabs can be applied to indoor and outdoor walls and floors, and transformed to create decorative furnishing items and countertops. Infinity has developed the exclusive Natura-Vein Tech technology — an innovation that allows a perfect and controlled sedimentation of minerals during the production process, crossing the entire thickness of the slab, obtaining perfect consistency between surface and mixture as seen here in this stunning kitchen, which features Cucina Alta. To find out more about Infinity Surfaces, visit www.infinitysurfaces.it.

REHAU announces the newest application of its RAUVISIO noir monotonic matte surface, RAUVISIO noir compact.

Scratch- and fingerprint-resistant, the durable, light-absorbent surface is made for real-life applications. Yet, the touchable matte finish adds a rich elegance designed to transform any room into a feast for the senses. The monotonic surface retains all its elemental properties while delivering a safe, durable and family-friendly product that enhances spaces. Forged in Italy from the finest materials, RAUVISIO noir compact boasts unwavering style that has been infused with the intensely rich and muted aesthetic of the film noir genre. The newest, specifically designed for vertical and horizontal applications, features a compact design that is uniquely versatile, highly resilient, environmentally friendly and hygienic. For more information, visit www.rehau.com.

Bella Casa Countertops and Stone is a full-service surface fabrication and installation company located in Littleton, Colorado, a charming suburb in the foothills of Denver. With a background in construction management, Geoff Jernigan started a remodeling company in 2002, growing the business organically and constantly advancing every year. He began experimenting with surface fabrication while running the remodeling company. The explosive housing and population growth encouraged him to transition the business to countertops and surfaces exclusively in 2010.

Geoff’s experience overseeing complete construction projects offered perspective into the service trades and a better understanding of homeowner needs. “We understand the bigger picture, and we can help problem solve for the builder, homeowner and our business,” he recalled.

Geoff saw the need to simplify the process and better serve homeowners with custom surface fabrication and service devoted to quality and integrity. “I wanted to stay focused in a linear production process — being able to create and manufacture with efficiencies, controls and schedules, and excel in that one thing.”

“I love the transformation from slab to finished product,” Geoff continued. “It’s amazing to see the raw materials turn into something aesthetically pleasing and functional, often in the heart of a home — the kitchen. Incorporating a unique slab that defines a space is really special; it’s fun to be part of that process.” He manages the day-to-day operations, including oversight of the crew, and he is the main point person for projects and key relationships.

His wife, Cary, holds an MBA and previously worked in the financial sector in sales, marketing and customer relations. When she joined the business full time a few years ago, it made perfect sense for her to spearhead customer service, marketing and office management. She’s helped the company expand its online presence and increase marketing efforts with focused campaigns designed to grow the brand and get more visibility. She’s developed the showroom and customer experience, elevating their sales process. “These are tasks I could never devote the time to,” added Geoff. “She does all the behind-the-scenes business management stuff that takes me away from production but is still so valuable to our clients and our team.”

The Bella Casa service team has 10 dedicated professionals, including project managers, fabricators, CNC operators, installers and client service specialists. Most of the employees have been with the company for at least five years — some as many as 15 years. “We’re a tight-knit crew,” said Cary. “Some of our employees started as neighbors or friends, and now they are family. They’re here because they love what they do. We try to foster an environment where they can succeed in their work. It’s important to find

“It’s not an individual effort here,” said Geoff. “We provide a space for all our employees to have a voice and provide input into the business.”

your employees’ strengths to help them grow their careers into meaningful and successful professions.” Geoff and Cary say this is critical to employee retention.

When it comes to managing their staff, Geoff and Cary lead with kindness, and they prioritize showing their appreciation for staff. “Everyone has an opportunity to provide input,” clarified Geoff. “And not only about the day’s tasks but the broader goals. It’s not an individual effort here; we provide a space for all our employees to have a voice and provide input into the business.” Along those lines, Geoff says it’s vital to work alongside your employees at every stage of the process. “Installs, polishing, cutting — whatever it is. It teaches you their challenges and gives you a chance to troubleshoot your processes.”

“We’re working on expanding our crew,” added Cary. “We’re adding a third installation crew, production staff and templating specialists.” But Cary says the labor market in Denver is tight, and

finding the right people for the job is more challenging than ever. They leverage online job posting sites, word of mouth and referrals to find new employees.

The Jernigans are finding that young people are experimenting with their careers. “There’s a lot of movement as they try to figure out what kind of work inspires them,” said Geoff. “We get a lot of applicants that think this job is simple, and it’s just not. There is so much attention to detail. You must be willing to learn the fine aspects of the work.”

Geoff says there are people looking for work but don’t have the necessary skills, which is OK. “If you find someone who is willing to learn, it can be so rewarding,” he added. “I’m more than happy to train the right person. Everyone has different skills and perspectives that they can apply in amazing and often surprising ways. So you really have to think about who you’re hiring and why, and be open to what they can do as they grow and learn with you.”

Bella Casa’s current space is three leased units, all within the same area but physically disconnected. The production facility is about 2,500 square feet; another unit is 2,000 square feet of inventory; and the office/showroom is about 4,000 square feet. “The showroom space is fairly new to us,” clarified Cary. “We wanted a professional space to showcase materials, styles, current designs and industry

trends and meet with our clients about their projects. It’s about elevating the customer experience and being able to meet personally to discuss their project and to see the process.” It’s currently under construction and will be completed in the next few months.

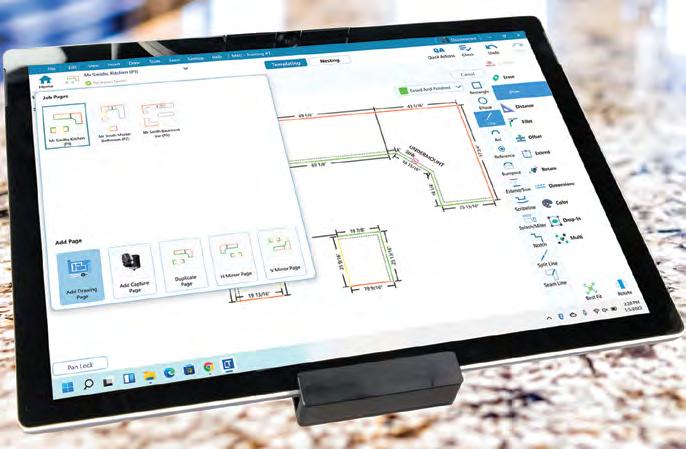

Geoff and Cary lean on technology and good internal communications to keep the shop running at maximum efficiency.

On the production side, they use the Flexijet 3D laser measuring system for templating and some heavy machinery to work the slabs. Their primary 5-axis CNC saw is a Thibaut TC600, and they just added a T812 router. “Both of these use the metric system,” said Geoff. “So we are in the process of moving all calculations and drawings throughout our procedures to metric from standard. It’s been an interesting challenge!” For filtration, Bella Casa uses GranQuartz’s Water Bear III filtration system, which cleans and recycles their water. They plan to implement Slabsmith in the next few months. Geoff likes the efficiencies it allows in queuing up the saws in advance, remnant tracking capabilities, and viewing accurate slab layouts.

And while the shop has some state-of-the-art tools to keep things running smoothly, the front end uses a few to maintain efficiency and accuracy. They run Moraware’s CounterGo for quoting and sales tracking. “I don’t know how we’d operate without it, honestly,” admitted Cary. And as a marketer, she understands the importance of brand awareness and bringing in

new business. She relies on Countertop Marketing Co. to help her with the website and search engine optimization to funnel in potential customers. “They’ve also helped us add searchable wholesaler inventories to our site, and they update it regularly, so we are always showing current and available materials,” she added. “It’s been a terrific asset.”