International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

MD Momenur Rahaman1

1 Engineer (Civil) at Larsen & Toubro (L&T) & B. Tech Student in Construction Technology at VIT, Vellore***

Abstract - The construction sector is a key driver of economic progress, yet it continues to face recurring issues with time and cost overrun, resulting in financial losses and project delays. Pipeline infrastructure projects in India are particularly hit because of regulatory complications, inefficiency in procurement, and unexpected site conditions. This research includes an intensive study of cost and time overruns determinants in Indian pipeline projects based on a comprehensive case study of one under-progress project.

A systematic approach with survey-based statistical analysis (Cronbach's Alpha, Relative Importance Index) has been adopted. The research includes identification of major delay factors, their cost impact assessment, andstrategicmitigation suggestions. In addition, an ML model that employs 11 algorithms has been created to estimate project cost and completion time accurately, dynamically learning from new project data. The findings show that predictive analytics and data-driven insights can greatlyenhanceprojectplanningand execution effectiveness.

The results emphasize the importance of proactive risk management, collaboration with stakeholders, and AI-based decision-making in Indian pipeline construction projects. The study is helpful for both scholarly enlightenment and realworld industry uses, providing an inclusive framework that is helpful in reducing uncertainties in subsequent projects.

Key Words: Cost & Time Overruns, Pipeline Construction, Statistical Analysis, Case Study, Machine Learning, Project Cost & Duration Prediction, Construction Delays, Predictive Analytics

1.1 General

The construction industry is a key economic growth driver,adding6–9%oftheGrossDomesticProduct(GDP)in India. Cost and time overruns, however, are key concerns significantly impacting the profitability of projects and economicefficiency.Delaysininfrastructureprojectshavea natural tendency to create increased costs, extended deadlines, and reduced profitability, affecting the stakeholdersateverylevel.FortheIndianscenario,pipeline constructionprojects(watersupply,wastewater,andUrban Water&WaterManagement)arehighlysusceptibletosuch concernswithregulatoryissues,procurementdelays,andsite problems.

AsofMay2024,theMinistryofStatisticsandProgramme Implementation (MoSPI) data reported that 458 Indian infrastructureprojectshadcostoverrunsof₹5.71lakhcrore, and831projectsweredelayed.Thesenumbersunderscore the importance of systematic risk analysis, predictive modeling,andstrategicinterventionstoavoidcostandtime overrunsintheconstructionindustry.[2]

Cost Overrun: Occurs when the cost incurred on the projectexceedsthebudgetedamountduetoinflation,supply chainissues,scopechange,inefficientuseofresourcesetc.

TimeOverrun:Relatetolateprojectcompletionbeyond plannedtime,typicallycausedbyconflictingstakeholders, government approvals, poor planning, and unexpected groundconditions.

Due to their physical scale, dependence on external approvals,andmaterial-basednature,pipelineprojectsare particularlysusceptibletocostandtimeoverruns.

Thecentralpurposeofthecurrentstudyistoexamine andforecastthecausativefactorsaswellasimpactsofcost overrunsanddelayonpipelineschemesinIndia.Themain objectivesare:

A. Identifyingtheprimarycausativefactorsofthecost anddelaysbasedonstatisticalanalysis

B. Evaluating the cost consequences of late projects througharichcasestudy.

C. Developing a machine learning (ML) model framework for project cost and time prediction basedonpastexperience.

D. Suggesting measures to reduce overruns and enhanceprojectplanningeffectiveness.

The research is on schemes of pipeline infrastructure in India,thatis,watersupplyandwastewater&urbanwater andwatermanagementschemes.Theresearchincludes:

A. A literature review and industry survey to determinefactorsofinfluence.

B. Statisticalanalysisofsurveyanswers(Cronbach's Alpha,RelativeImportanceIndex).

C. Case study of an existing pipeline project in West Bengalinordertogaugecosteffectbydelay.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

D. Apredictive(ML)MachineLearningmodeltrained on project-specific parameters like major scope, workingconditions,andconstructionprogress.

Theresultsofthecurrentresearchareintendedtosupport construction practitioners, project management practitioners, policymakers, and researchers by providing evidence-based recommendations and AI/ML-based predictiontooltoreduceuncertaintiesinprojects.

2.1 Overview

Costandtimeoverrunsareprevalentintheconstruction sector, leading to inflation of costs, delays, and economic losses. Various studies have endeavoured to determine causes,effect,andmitigationmethodsoftheoverrunsbased onstatistics,casestudy,andmachinelearningmethods.The present section discusses previous studies to lay the groundwork for the present study and uncover research gapsfor Timeand CostOverrun in pipelineinfrastructure projects.

2.2 Previous Studies on Cost & Time Overruns

2.2.1 International Studies

Ahmed Senouci, Alaa Ismail, and Neil Eldin (2016) conductedastudyinQatar,whichwaspublishedinProcedia Engineering.ThestudyusedANOVAandregressionmethods to examine project delays. Delays were significant concerningprojectduration,whilecostoverrunsvariedby completionyear,beinglowerforprojectsfinishedbetween 2007-2013 than 2000-2007. Regression analysis showed costoverrunsincreasedwithcontractpricesforbuildings but decreased for drainage projects, though data confidentialitylimitedmodelrobustness.[3]

Shahela Mamter, Nur Syahirah Ahmad Shabri, Mohd Esham Mamat, and NorazlinMatSalleh (2022) undertook astudyinMalaysia,whichwaspublishedintheInternational Journal of Academic Research in Accounting, Finance and Management Sciences. The study employed descriptive analysisthroughtheapplicationofSPSSsoftwaretoexamine the most important factors leading to postponement of projects Thestudycategorized16rootcausesunderclients, contractors, consultants, and external factors, identifying financial issues,constructionerrors,poorcommunication, andaccidentsasprimaryreasons.Findingshighlightedthat contractorshadthehighestimpactonprojectdelays,with solutions including accurate cost estimates, SOPs for external risks, and selecting the right consultants and contractors. The study's insights aim to help stakeholders improveprojectsuccessrates.[9]

Suad Hosny, Elshaimaa Elsaid and Hossam (2023) carried out research in Egypt, whichwas publishedinthe AsianJournalofCivilEngineering.Theresearchintroduced ARIMA and multiple regression models in forecasting construction material prices in an unstable economic

environment. The research presented reliable forecasting techniquesthatwouldhelpstakeholdersinriskmanagement ofunstablematerialprices,thusenhancingdecision-making inEgypt'sconstructionsector.[10]

Nisar Ali Ansari and R. M. Swamy (2018) carriedouta study in India that was published in the International Research Journal of Engineering and Technology. Relative ImportanceIndex(RII)andImportantIndex(II)techniques wereappliedintheresearchtoexaminethedelaycausesin Indian residential building construction projects. The researchunderscoredtheneedforbetterpaymentsystems, better planning, and better coordination in an effort to reduce the delays and facilitate smoother project implementation.[4]

P. Asmitha (2019) conductedastudyinTamilnaduthat waspublishedinIconicResearchAndEngineeringJournals WheresheusedFrequencyindextostudyhighwayprojects inTamilNadutoascertaincostandtimeoverruns.Thestudy identified key cost factors such as rising material costs, inaccurateestimates,andcostunderestimation,whilemajor time-related factors included unforeseen site conditions, projectscopechanges,delayedpayments,andpoorplanning. Findings emphasized the need for better planning, scheduling, and cost evaluation to minimize overruns and improveprojectsuccess.[5]

Priyesh Mulye and Akash Gandhi (2021) conducteda research study in India that was published in the International Journal for Research in Applied Science and EngineeringTechnology.Usingrankingindexes,keyfactors identifiedincludeddelayedpayments,resourceshortages, designchanges,andpoorplanning.Costoverrunsstemmed frompricefluctuations,estimationerrors,andconstruction defects. The study proposed mitigation strategies like accurate project scoping, integrated approvals, and better coordination, aiding in developing a model to minimize overrunsandenhanceprojectefficiency.[7]

Kumar Gourav Shakya and Er. Himmi Gupta (2022) conducted research in India that was published in the International Journal for Research in Applied Science and Engineering Technology. The research identifies factors impactingtimeandcostoverrunsinconstructionprojects. The study utilized data from over seventy construction stakeholders,includingengineers,contractors,developers, architects, and government officials, collected through a standardized questionnaire. The research analyzed 47 factors related to cost, time, quality, client satisfaction, productivity, regulations, community impact, health, and environment. The study employed statistical techniques such as ANOVA hypothesis testing, relative importance index, coefficient of variance, and standard deviation analysis to identify the most critical factors influencing projectoverruns.[8]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Although existing research provides useful insights regardingcostandtimeoverruns,theyaremarkedbythe followinglimitations:

A. Limitedfocusonpipelineinfrastructureprojects:Most of the studies address residential, highway, and commercialprojectswithverylittlecoverageofutility pipelinesinIndia.

B. Lack of cost impact quantification: Although most studiescitedelaycauses,veryfewofthemquantifythe costeffectofdelaysusingextensivecasestudies.

C. Absenceofmachinelearning-basedpredictions:Lackof machine learning-based prediction models used to analysedtimeandcostoverruninpipelineconstruction projectandforecastthetimeandcostrequiredforany upcomingpipelineconstructionprojectinIndia.

D. Sector-specific recommendations: No pipeline construction-specificsuggestionstoaddressproblems suchaslandacquisition,regulation,andsupplychain interruptionareofferedinexistingresearch.

2.4 Summary

Thisstudyaddressestheidentifiedgapsby:

A. FocusingonIndiapipelineprojects,watersupply,and seweragesystems.

B. Conducting a comprehensive case study to analyse thecostimpactofprojectdelays.

C. Developing a machine learning-based predictive modelforenhancingforecastingaccuracyforcostand timeoverruns.

D. Proposingsector-specificmitigationstrategiesbased onexpertadviceandindustrybestpractices.

3.1

Thepresentstudytakesasystematicresearchapproach to examine cost and time overruns in India's pipeline construction industry by employing a perfect blend of statistical analysis, case study appraisal, and machine learning-drivenpredictivemodel.Themethodologyhasfive mainphases:

A. Identification of factors affecting cost and time overruns by reviewing literature and consulting industryexperts

B. Statistical analysisusingsurveys toidentifythemost criticalinfluencingfactorsofcostandtimeoverruns

C. Casestudyanalysistodeterminethemonetaryeffectof projectdelay

D. Developing of a machine learning (ML) predictive modelforcostanddurationestimationofprojects

E. Developingstrategicapproachforpreventingoverruns inpipelineconstructionprojectsinIndia

A thorough review of available literature and industry reportswasstudiedtodeterminesignificantcausesofcost andtimeoverrunsinconstructionprojects. Withindustry experts'consultation,aninitiallistof60factors(30oncost overrunsand30ontimeoverruns)werenarroweddownto 38keyfactors,withpipelineinfrastructureprojectsinIndia inmind

3.3.1

A structured questionnaire survey was prepared to evaluatetheeffectoftheknowncriticalfactors.Thesurvey was sent out to construction professionals from all over India,and110validresponseswerereceived.Datacleaning wasconductedtodiscardirrelevantorincompleteanswers, therebymaintainingmaximumdataintegrity

3.3.2

Inanalysingtheresponses,thefollowingstatisticaltools wereutilized:

A. Cronbach's Alpha Coefficient: Employed to check for theinternalconsistencyandreliabilityofthedataset.

B. RelativeImportanceIndex(RII):Usedtoprioritizeand rankthemostcriticaldelaycauses.

C. ImpactIndexAnalysis:Weighedcostandtimeimpacts invaryingprojectfunctions.

3.3.3

A thorough case study of a ongoing ₹185 Cr pipeline projectinWestBengal,whichsufferedcostandtimeoverrun asaresultofseveralissues,wasundertaken.

A. Project Details & Analysis: The project, which was awardedto"Contractor–X"in2019,initiallyhada36monthcompletiondate but hasbeenpushed back by regulatory approvals, procurement inefficiencies, designchanges,andanumberofotherfactors

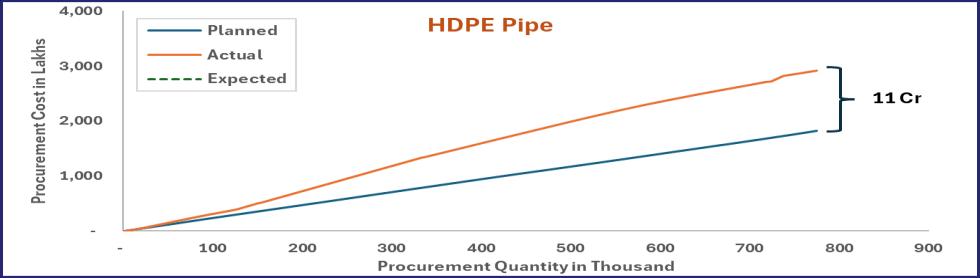

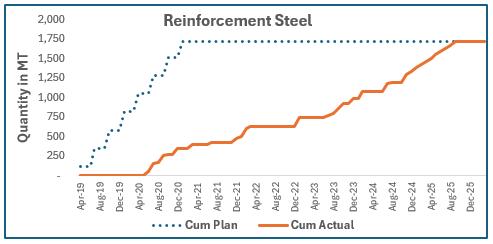

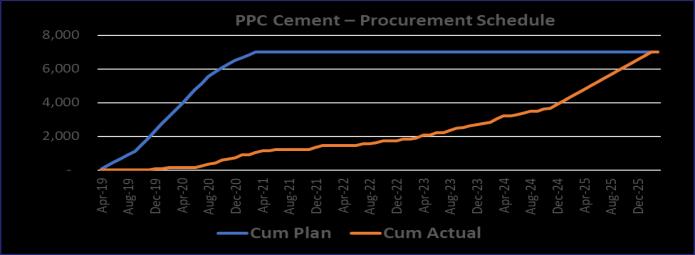

B. Impact on Major Supply Cost: DI pipe procurement costs, HDPE pipe procurement costs, MS pipe procurement costs, cement costs, and reinforcement steelcostswereanalysedtoestimatethecostofdelays which amount to around 80% of the overall Supply Cost.

C. ImpactonIndirectCost:Overheadcosts,includingsite management, equipment rentals, and extended administrativeexpenses,wereanalysedasawhole

This case study provides measurable information regarding how project delays affect cost escalation. The project is ongoing but timely completion would have prevented the client and contractor from incurring unnecessaryadditionalcosts.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

3.3.4.1

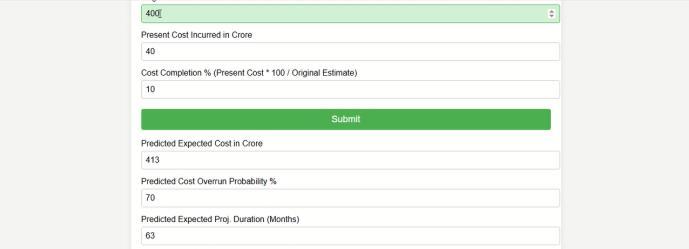

Thehistoricalprojectdatawasusedtotrainthepredictive model with parameters like project's major scope, site conditions(analysedandfoundbysurveyresults)&status of project completion. The dataset was divided into 80% trainingand20%validationforhighaccuracy.Astherewas nohistoricalpipelineprojectdatainIndiaavailablewithme, adummydatasetwascreatedforthisresearch.Thisdataset could be replaced at any point of time with actual project dataforbetteraccuracyinprediction

3.3.4.2

The study employed 11 different machine learning algorithms,including:

I. LinearRegression

II. RandomForestRegressor

III. XGBRegressor(ExtremeGradientBoosting)

IV. GradientBoostingRegressor

V. SupportVectorRegressor(SVR)

VI. DecisionTreeRegressor

VII. CatBoostRegressor

VIII. K-NearestNeighbors(KNN)Regressor

IX. LassoRegression

X. GaussianNaïveBayes

XI. LinearGeneralizedAdditiveModel(LinearGAM)

3.3.4.3 Model Evaluation & Selection

Eachalgorithmwasevaluatedandtestedonthebasisof R-squared (R²) score. The highest-performing model was automatically chosen on the basis of accuracy. The final modelwasmadetodynamicallyretrainitselfwhenevernew project data isintroduced, enhancing its predictiveability overtime.

ThisMLmodelallowsbuildingcompaniestopredictcost andtimeoverrunswithgreataccuracy,enablingdecisionmakinginprojectplanningtobeproactive.Itisalsoauseful toolforTenderandProposalTeam,aidingtheminanalysing andpredictingfuturetendersmoreeffectively.

3.3.4.4 Summary

Thisapproachcombinessurveystatisticalanalysis,field case study assessment, and AI/ML-based predictive modelling in formulating an all-around framework for detecting and reducing cost and time overruns in Indian pipeline construction projects.The researchoffersa datadriven decision support system that helps construction professionalsandprojectmanagementprofessionalsreduce uncertaintyandimproveprojectplanningeffectiveness.

4.1.1

A total of 110 valid survey responses were analysed to identifykeyfactorscontributingtocostandtimeoverrunsin pipelineconstructionprojects.Afterstatisticalvalidation,38 criticalfactorswereidentified,categorizedinto:

A. Cost Overrun Factors – Market price fluctuations, Project delays, Supply chain disruptions, Scope changes,andProcurementinefficienciesetc.

B. TimeOverrunFactors–Delaysinregulatoryapprovals, Poor planning, Shortage of skilled labor, Contract disputes,andChangesinprojectspecificationsetc. The statistical results confirmed that regulatory delays and procurement inefficiencies were the most significant causesoftimeandcostoverrunsinpipelineprojects.

SurveyLink:“https://forms.office.com/r/9rgKwfBbA3”

4.1.2 Statistical

1)ReliabilityAssessmentUsingCronbach’sAlpha: Toevaluatethereliability/dataconsistencyofthesurvey responses,Cronbach’sAlphaCoefficientwascalculated

Table -1: Cronbach’sAlphaCoefficient Cronbach’sAlphaCoefficient

FactorCategory Cronbach’s Alpha(α) Reliability Interpretation

TimeOverrunFactors 0.94 Excellent

Sinceallvaluesexceed0.90,thesurveydatademonstrates high internal consistency, confirming the reliability of the dataset.[11][15]

4.1.3

The Relative Importance Index (RII) was calculated for each factor to determine its significance in cost and time overruns.

Table -2: CriticalCostOverrunFactors

Critical Cost Overrun Factors

RIIScore

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net

Adetailedcasestudywasconductedona₹185Crwater supply pipeline project in West Bengal, awarded to “Contractor-X”,tomaintainconfidentialityprojectnameand contractor’snamekeptanonyms.

The delay in project execution and procurement inefficiencies contributed the most to cost escalations in pipelineprojects.[12]

Table -3: CriticalTimeOverrunFactors Critical Time Overrun Factors

These findings confirm that delays in regulatory approvals,workforceshortages,andpaymentdelayswere theprimarydriversofconstructionscheduleoverruns.[12]

Table-4: ImpactIndexbyDepartments Impact Index by Departments

TheabovefindingsconfirmedthatProjectManagement, Planning, Execution, Billing and Tender/Contracts departmentsarethemostcrucialandleadstoTimeandCost overrun for any construction project in India.

A)ProjectDelayAnalysis

o OriginalContractPeriod:36months

o ExpectedProjectCompletion:March2026(delayed by~48months)

o CurrentWorkProgress:60-65%completed

o Major Delay Factors: Client-side delays, procurementissues,regulatoryapprovals

B)CostImpactAnalysis

o Afinancialanalysiswasconductedtodeterminethe impactofdelaysontheproject’stotalcost.

Based on the above charts, it is evident that the procurementofDuctileIron(DI)pipeswasinitiallyplanned tostartinJanuary2020andbecompletedbyFebruary2021. However, due to several issues, the actual schedule was disrupted.Althoughprocurementbeganamonthearlierin December 2019, only 82% of the work was completed by November2024.Theremainingportionisnowexpectedto becompletedbyMarch2026

Furthermore,whenwecorrelatethepricewiththe quantity procured, it becomes clear that from the procurement of the first ~30 KM of pipes onwards, the projectbeganincurringhighercostsforthesamequantity. This trend is projected to result in a total cost overrun of approximately₹41crorebytheendoftheprojectinMarch ‘2026.

*Likewise other charts also need to be interpreted

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Chart -2: CostImpactof(HighDensityPolyEtheline) HDPEPipe

Chart -3: CostImpactofReinforcementSteel

Chart -4: CostImpactof(MildSteel)MSPipe

Chart -5: CostImpactofPortlandPozzolanaCement

Chart -6: CostImpactofIDC(IndirectCost)

Table -5: CostImpactAnalysis Cost Impact Analysis

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Amachinelearningmodelwasdevelopedandtrainedto predictcostandtimerequirementbasedonproject-specific parameters. The model evaluated 11 different algorithms, andthetop-performingmodelswere:

Table -6: MachineLearningModelsValidationAccuracy

Machine Learning Model’s Training & Validation Accuracy

C) Case Study Constraints: The financial impact analysis is based on a single case study in West Bengal, which may not represent national trends. Further since the case study project is still not completed hence there might be a chance for deviations from the expected cost impact to the actualimpact.

D) Regulatory&EconomicVariability:Externalfactors suchaspolicychanges,andunexpectedevents(e.g., pandemics)arenotexplicitlymodeled.

E) Model Generalization: Although the machine learning model performed well on training data, furthervalidationisneededwithdiversereal-world datasetstoenhanceitspredictivereliability.

Systematic investigation of cost and time overruns in India'spipelineconstructionprojectshasbeencarriedoutin this research using survey-based statistical analysis, a comprehensive case study, and machine learning-based predictivemodel.Thekeyfindingsareasbelow:

A) Regulatory delays and procurement inefficiencies werefoundtobetheforemostcausesofprojecttime overruns, as tested by Relative Importance Index (RII)analysis.

B) Costoverrunsweremajorlyfuelledbymarketprice fluctuations, project execution delays, and supply chaindisruptions,havingsignificantmonetaryeffects

C) Thecasestudyofa₹185CrpipelineprojectinWest Bengaluncoveredthefactthatprojectdelaysledto an approximated cost escalation of ₹66 Cr (95% of the project's major supply & indirect cost value) basedonprolongedindirectcostsandprocurement variations.

The Gradient Boosting Regressor demonstrated the highest accuracy, making it the most reliable predictive modelforestimatingconstructioncostandtimeoverruns.

Despite the comprehensive analysis, this study has certainlimitations:

A) LimitedDataAvailability:Duetorestrictedaccessto historicalprojectdata,adummydatasetwasused for the machine learning model’s training. The accuracymayimprovewithrealprojectdatafrom multiplesources.

B) Sector-SpecificFocus:Thestudyfocusesonpipeline infrastructure projects, and findings may not be directlyapplicabletootherconstructionsectorslike highways,bridges,orresidentialprojects.

D) A predictive model using machine learning was formulated to dynamically estimate cost and time demand.Thehighestaccuracy(95.8%)wasachieved bytheGradientBoostingRegressormodel,indicating its feasibility for real-time forecasting and risk estimationinpipelineconstructionprojectsinIndia.

The results highlight the critical need for data-driven project planning, sophisticated predictive analytics, and processimprovementtoincreaseconstructionefficiencyand financial sustainability for utility pipeline construction projectsofIndia

Onthebasisoftheabovefindingsandconsultationswith the industry experts, the following strategic interventions areproposedtoreducecostandtimeoverrunsinpipeline constructionprojectsinIndia:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

A. RegulatoryStreamlining&PolicyReforms:

a. StreamlineROWapprovalsandenvironmentclearances by having specialized regulatory teams for infrastructureprojects

b. Implementasingle-windowclearancesystemtoavoid bureaucraticdelaysandnormalizeapprovaldurations

B. ProactiveProcurement&SupplyChainOptimization:

a. Acquireatleast75%ofcriticalmaterials(equipment, cement,pipes,reinforcementsteel,andfittings)during theinitial phase oftheprojecttoavoiddelays dueto procurement.

b. AdoptAI-baseddemandforecastingmodelstopredict price variationsandstrategizematerial procurement moreeffectively.

C. MachineLearning&AI-DrivenProjectManagement:

a. IncorporateAI-basedpredictiveanalyticsmodelsinto projectplanningsystemstopredictlikelycostandtime overrunspriortotheiroccurrence

b. Createdynamicprojectmanagerdashboardstotrack importantriskindicators,schedulevariances,andcost variationsinrealtime

D. Workforce&ContractorPerformanceEnhancement:

a. Createsystematictrainingprogramstofilltheskillgap in pipeline infrastructure projects and minimize relianceonspecializedsubcontractorsoragencies.

b. Create contractor performance monitoring systems with incentive and penalty clauses to enforce compliance with project schedules and quality requirements

E. Risk-BasedFinancial&ProjectPlanning:

a. Implementcontingencybudgetingmodelsgroundedin pastprojectriskevaluationstocounteractunexpected costincreases

b. Establishdynamiccontractmodelsthatintegraterealtime financial modifications based on project advancement,inflationlevels,andmaterialprices.

Through the application of these measures, construction stakeholders can effectively increase project efficiency, minimizefinancialrisks,andfacilitatesustainablegrowthin India'spipelineinfrastructureindustry

6.1.3 Future Scope of Study

Althoughthisresearchprovidesvaluableinsights,further studiescanbeconductedto:

A. Establish deep learning models for enhanced precision in cost and time overrun estimation, includingintricateinterdependenciesamongproject variables

B. Integrate Internet of Things -based real-time monitoringsystemsforpredictivemaintenance,asset tracking,andautonomousprojectriskevaluations.

C. Broaden the research to several infrastructure sectors,includingroads,bridges,andtallbuildings,to set industry standards for cost and time overrun analysis

D. Investigate how changes in policies and regulatory reforms affect project efficiency and bottom-line financialperformance

E. Enhance decision-making frameworks through the integration of predictive analytics and Building InformationModeling(BIM)forinstantvisualization ofprojectsandrisksimulations.

F. Throughtheexploitationofbigdataanalytics,digital transformation,andpolicyinnovations,futurestudies areabletobetterrefineriskpreventionandproject managementstrategiesinconstruction.

The research upholds that cost and time overruns in pipelineconstructionprojectsinIndiaareledpredominantly by inefficiencies in systemic procedures of approval, procurement, and contractor handling. The inclusion of machine learning-driven predictive models along with strategicplanningframeworksishighlycapableofcurtailing uncertainties,enhancingtheefficiencyofprojectexecution, aswellasachievingimprovedfinancialmanagement.

This study is a template for AI-enabled management of constructionprojectsandoffersactionable,sector-specific advice to curtail cost overruns and achieve timely project delivery.Institutionalizationofdata-drivendecision-making supporttools,policychanges,anddigitalizationdrivescan make a remarkable difference in India's infrastructure industry, leading to economic growth and project sustainability.

7.1.

A. AGenderDistribution:

a. Male:96%

b. Female:4%

B. AgeGroupDistribution:

a. Lessthan18years:1%

b. Between18-25years:7%

c. Between25-30years:43%

d. Between30-35years:28%

e. Between35-40years:18%

f. Between40-45years:7%

g. Between45-50years:3%

h. Between50-60years:5%

C. YearsofExperience:

a. Lessthan2years:8%

b. 2-5years:7%

c. 5-10years:37%

d. 10-15years:26%

e. 15-20years:18%

f. Morethan20years:7%

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

D. Departments:

a. SiteExecution:31%

b. Planning&Billing:28%

c. ProjectManagement:20%

d. Safety&Quality:15%

e. Accounts&Admin:9%

f. Others:9%

7.1.2 Project Characteristics

A. ProjectType:

a. PipelineProjects:93%

b. IrrigationProjects:4%

c. RoadProjects:4%

d. Others:11%

B. ProjectValueDistribution:

a. <10Cr:3%

b. 10-100Cr:14%

c. 100-300Cr:29%

d. 300-500Cr:33%

e. 500-1000Cr:7%

f. >1000Cr:14%

C. ProjectDuration:

a. <12Months:2%

b. 12-24Months:20%

c. 24-36Months:54%

d. 36-48Months:27%

e. >48Months:9%

7.1.3 Project Performance Insights

A. TimeOverrun:

a. NoOverrun:8%

b. <2%:8%

c. 2-5%:10%

d. 5-10%:12%

e. 10-20%:18%

f. 20-30%:20%

g. >30%:38%

B. CostOverrun:

a. NoOverrun:18%

b. <2%:12%

c. 2-5%:24%

d. 5-10%:24%

e. 10-20%:16%

f. 20-30%:12%

g. >30%:6%

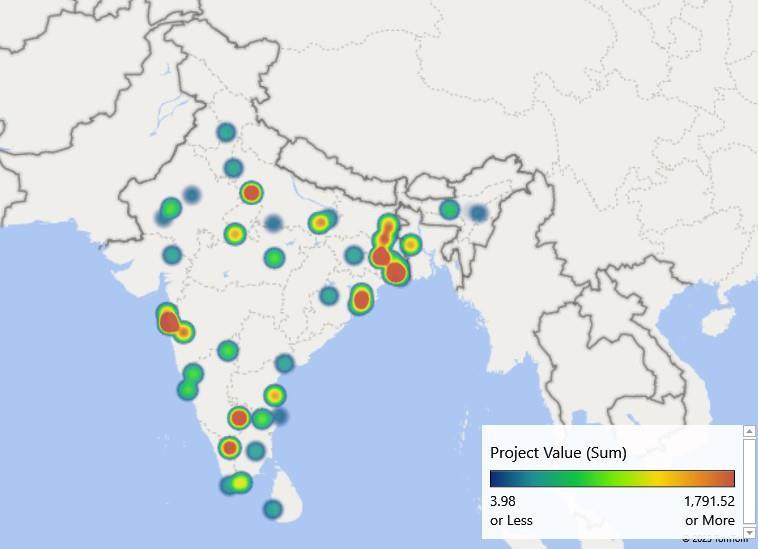

7.1.4 Geographical Distribution

The survey responses and project locations are widely spread across India, with significant project values concentrated in key regions. West Bengal, Tamil Nadu, Maharashtra & Delhi are the major region from where projectsaresampledforthissurvey.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

7.2.3 Survey Questionnaires

Section:1

Section:2

Section:3

[1] Flyvbjerg, B., Holm, M. S., & Buhl, S. L. (2002). Underestimatingcostsinpublicworksprojects:Errororlie? Journal of the American Planning Association, 68(3), 279295.DOI:10.1080/01944360208976273

[2]MinistryofStatisticsandProgrammeImplementation (MoSPI). (2024). Infrastructure Project Delays and Cost Overruns in India – Report May 2024. Available at: https://mospi.gov.in

[3]AhmedSenouci,AlaaIsmail,&NeilEldin.(2016).Time Delay and Cost Overrun in Qatari Public Construction Projects. Procedia Engineering, 164, 368-375. DOI: 10.1016/j.proeng.2016.11.632

[4]NisarAliAnsari&R.M.Swamy.(2018).Methodology to Analyze Delay and Its Impact on Construction Projects. International Research Journal of Engineering and Technology (IRJET), 5(2), 2387-2392. Available at: https://www.irjet.net/archives/V5/i2/IRJET-V5I2387.pdf

[5]P.Asmitha.(2019).TimeDelayandCostOverrunin Construction Projects: A Case Study in Tamil Nadu. Iconic Research and Engineering Journals (IREJ), 2(3), 45-52. Available at: https://www.irejournals.com/formatedpaper/1701733.pdf

[6]SurabattuniMurali&SanjeetKumar.(2019).Factors Affecting Overruns in Construction Time and Cost: A Case Study. International Journal of Recent Technology and Engineering (IJRTE), 8(2), 55-62. DOI: 10.35940/ijrte.B1007.078219

[7]PriyeshMulye &Akash Gandhi.(2021). Significance andAnalysisofTimeandCostOverrunintheConstruction Industry of Mumbai. International Journal for Research in Applied Science and Engineering Technology (IJRASET), 9(6),1482-1491.DOI:10.22214/ijraset.2021.38789

[8] Kumar Gourav Shakya & Himmi Gupta. (2022). OptimizationofFactorsthatCriticallyImpactTimeandCost OverruninConstructionProjects.InternationalJournalfor Research in Applied Science and Engineering Technology (IJRASET), 10(3), 200-208. DOI: 10.22214/ijraset.2022.47775

[9]ShahelaMamter,NurSyahirahAhmadShabri,Mohd EshamMamat,&NorazlinMatSalleh.(2022).RootCausesof Project Postponements in Malaysia: Developers’ Perspectives.InternationalJournalofAcademicResearchin Accounting,FinanceandManagementSciences,12(3),78-91. DOI:10.6007/IJARAFMS/v12-i3/14494

[10] Suad Hosny, Elshaimaa Elsaid, & Hossam Hosny. (2023). Prediction of Construction Material Prices Using ARIMA and Multiple Regression Models. Asian Journal of

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Civil Engineering, 24(1), 102-117. DOI: 10.21203/rs.3.rs2481703/v1

[11] Cronbach, L. J. (1951). Coefficient Alpha and the InternalStructureofTests.Psychometrika,16(3),297-334. DOI:10.1007/BF02310555

[12] Mose, J. & Gwaya, A. (2019). Use of Relative Importance Index (RII) in Ranking Delay Factors in the ConstructionIndustry.JournalofCivilEngineeringResearch, 9(1),35-42.DOI:10.5923/j.jce.20190901.04

[13] India Construction Market Report. (2024). Market Growth Trends and Forecast (2024-2030). Available at:

https://www.nextmsc.com/report/india-constructionmarket

[14] Economic Times Report. (2024). As Many as 458 Infra Projects Hit by Cost Overrun of ₹5.71 Lakh Crore in May. Available at: https://economictimes.indiatimes.com/news/economy/infr astructure/

[15]HowtoCalculateCronbach’sAlphainExcel.(2024). Available at: https://uedufy.com/how-to-calculatecronbachs-alpha-in-excel/

MD Momenur Rahaman is currently serving as an Operations & Digital Coordinator at Larsen & Toubro(L&T)Limited,bringingover 7.5 years of diverse industry experience inthefieldofcivil engineeringanddigitalconstruction.Hebeganhiscareerasa Site Engineer ona constructionof citylevel road infrastructure project in Nava Raipur – Chhattisgarh,gaininghands-onfieldexperience. Following this, he moved to L&T’s Chennai Headquarters, where he worked as a Cluster and subsequentlya Segment MIS (Management Information System) Coordinator,supportingvarious large-scalewaterandwastewaterinfrastructureprojects.Inthelastyear,hehastransitionedtoKolkata, takingontheroleof Cluster Operations & Digital Coordinator.

He specializes in data analytics, business process automation, AI/ML applications, and digital transformationinitiativeswithintheconstructionindustry.HistechnicalproficiencyspansAdvanced Excel, Excel VBA, Power BI, Power Automate, Power Apps, and PowerPoint, which he leverages to optimizeworkflowsandenhanceprojectperformance.

HeisinthefinalsemesterofhisB.TechinConstructionTechnologyfromVelloreInstituteofTechnology (VIT), Vellore, pursued under L&T’s Work Integrated Learning Program (WILP). The program is deliveredinablendedofflineandonlinemode,allowinghimtogainacademicinsightswhileactively contributingtoreal-worldconstructionenvironments.

EmailID:md.momenur,rahaman@gmail.com

Linkedin:https://www.linkedin.com/in/momenurrahaman/ Website:https://mdmomenurrahaman.page4.me/

8.315 |