International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1Student, Department of Environmental Engineering, MCET, Desamangalam 679532, Kerala, India 2 professor, Department of Environmental engineering, MCET, Desamangalam 679532, Kerala, India ***

Abstract Car wash industry consumes tidy sum of water for laundry of cars. Effluent water generated from car wash station contains great amount of chemical characters they contribute an honest deal of environmental contamination. The effluent water carries different parameters like pH, turbidity, Chemical oxygen demand, oil and grease, were characterized for the collected car washwater.Oilandgrease, Chemical oxygen demand contributes to the majority of pollution. The pilot study result show that electro coagulation has better removal efficiency of oil and grease, Chemical oxygen demand, turbidity, total solidsetc.Thetreatmentplant comprised screening, grit chamber, collection tank, electro coagulation unit, tube settler, pressure sand filter and carbon filter. Supported treatment resultsthetreatedwatercanreuse for under wash of cars and other washing purposes like cleaning of floor of car wash station. Each operation units dimensions are calculated are, flow is 0.25m3/ hr and every one chambers are designed rectangular sections except filtration units.

Key Words: Car wash waste water, Electro-coagulation, pH, oil and grease, COD, TSS, TDS

Urbanization has made the opportunity for increasing the growth of automobile industry. Therefore, usage of bikes, cars,andtruckareincreased,andalsotheyledtogrowthof automobileservicestations.Automobileservicestationsare washing(exteriorandinterior)ofvehicle,serviceandrepair thevehicleparts.Basedonsurveyofinternationalcarwash associationaround100 200litersofwaterisusedforsingle car wash. That literally indicates that car wash industry consumelargeamountofwater.Aroundallcarwashstations theycontaina freshwatersourceforwashingpurpose.In futureconsumptionoffresh water isledto waterscarcity problem.Thecarwasheffluentwatercontainshugeamount of contaminants like COD, TSS,TDS, turbidity pH , oil and greaseetc.Afterwashingofvehicletheeffluentdischargein tonearmunicipalsewersorwaterbodywhichisdecrease thewaterquality,harmfullyeffectonaquaticlife.Soitisvery necessarytotreateffluentwater.Theusageofwatercannot bedecreased,soitcanbetreatingeffluentwater,recycleand alsoreusethetreatedwater.Thestudyintroducedelectro coagulation(EC)techniqueforremovalofallcontaminants and emulsified oil and grease, AL used as electrodes in

electro coagulation process. The treatment plant consists screen,gritchamber,ECunit,tubesettler,andfiltrationunit (pressuresandfilterandactivatedcarbonfilter). It’svery necessarythattreatmentplantuselesschemicalsfortreat water, eco friendly, and sustain for long period. The main objectiveofprojectremovesallcontaminantsandreuseof treatedwater.

Carwashfirstlystartedin1914atUnitedNations.It'salso knownas“automaticlaundry”.Acarwashisdefinedasnon domesticinstallationforexternalleaningofcarforgetmore attractive and clean. In early days the cars were impelled manually through a tunnel, workers are dispensed soap, washed, rinsed and dried by manually using hands. After revolutions the new technology are amended on the car wash systems. In 1946 Thomas Simpsons brought semi automatic car wash system and on period of 1950 60 Andersonbrothersdiscoverfullyautomaticcarwashonthe same period India is firstly implemented car wash technology.Otherinventionsaresofttouch,nontouch,and rinselesscarwash

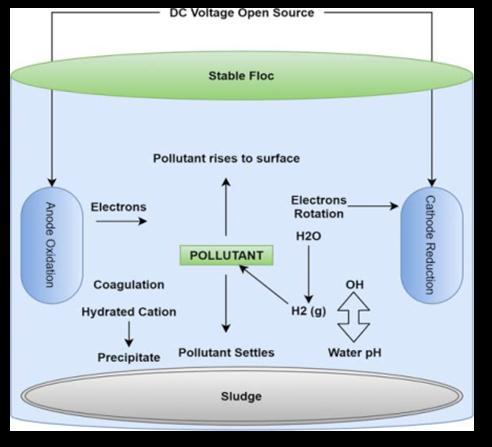

Electro coagulation (EC) is an electrochemical process that simultaneously removes heavy metals, suspended solids, emulsified organics and many other contaminants from water and wastewater using electricity instead of expensive chemical reagents. EC is a technique used for wastewatertreatment,washwatertreatmentandmedical treatment. Although the electro coagulation mechanisms resemblechemicalcoagulationinthatthecationicspecies are responsible for neutralization of surface charges. The producedflockswilltendtocontainlessboundwaterand more shear resistant, so it can more readily filterable. EC unitcontainelectrolyticcell,eachwiththepairofcorrosive metalsheets(anodeandcathode)theseelectrodesmadeup ofaluminumorironwhichcanbeorganized,arrangements spacingandlengths,whichdependuponremovalefficiency. Anodecontinuouslyproduceionsandneedtobereplaced, which are often called sacrificial anode, the plates are connectedextremelyapowersourceandimmersedinthe waste water, which supply electron current that drives chemicalreactionattheelectrode.Thevoltageneededfor

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2773

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

reactionoccursiscalledpotential.ElectricDCcurrentcause variousreactions,whichfacilitatesdissolution,coagulation, flotation, flocculation, in EC source coagulation is cations produced by degradation of anode metal and activation energyapplied,whichpromotesformationofoxides.

Theprocessdescribedbelow

Anode:Al=Al+3e(metal=metal+electron)

Cathode:2H2O+2e H+2OH

In electro coagulation process pH important factor so pH shouldmaintained4.8to8.Causticsodausedformaintain pHandsodiumchlorideisusedforincreasingconductivity

Fig 2: Carwashwastewater

The effluent sample collected and analyzed various parameterslikeBOD,COD,pH,TSS,TDS,dissolvedoxygen, turbidityetc. well waterisusedasinfluentfor washing of cars.Theanalysisvaluesareshownbelow

Table 1: Parameteranalysisofcarwashwater

Fig 1: Electro coagulationprocess

Sincethecarwashindustrydischargehighlycontaminated water soit's a necessityto seek outthe parameters for remove them by suitable method and reuse the treated waterfor laundrypurposes (under washof autoand floor cleaning)

Stepsareadministeredprocedurewithintheprojectisgiven below:

•Samplecollection

•Parameteranalysis(pilotstudy)

•Designtreatmentplant

Carwasheffluentwatersamplewerecollectedfromurban car wash station located at kadavantra. Waste water generated by washing of different cars. After washing the effluent water directly drained to municipal sewage treatment unit . The effluent water collected in a 1 liter plasticbottle.

Sl.No Parameters Influent water Effluent value 1 BOD(mg/l) 4 136 2 COD(mg/l) 88.2 392.41 3 TSS(mg/l) 0 68 4 TDS(mg/l) 140 314 5 pH 6.53 8.63 6 Turbidity (NTU) 0 98.5 7 Dissolved oxygen (mg/l)

4 3.17 8 Total solids(mg/l) 100 382 9 Oil and grease (mg/l)

0 164

Electro Coagulation (EC) method is used for treating car washwastewater.ECreactorsizeof0.75mx0.7mx1.5m hasbeenused.Thereactorismadeupofmarineplywood withleakageproof.Aluminumusedaselectrodes(anode& cathode)withsize40cmx35cmx0.1cm,andelectrodes are places 1 cm spacing. The pH of effluent sample was maintainedbetween4.9 8.1inECreactor.DCpowersupply provided through a rectifier and voltage maintained byvariac.Theexperimentalset upshowsbelow.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2774

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

0.951m

1.426m

Fig 3: Experimentalset up

Thetreatmentplantencompassdifferentoperationssuch as

Gritchamber

Electro Coagulationunit

Tubesettler

Filtration(pressuresandandactivatedcarbon)

Thedesigningofallunitoperationsaredoneseparately.As perdatacollectedfromurbancar washcenterusing3000 litersofwater(fromwell)usedforcarwashand500liters water used for complete cleaning of car wash station. So total water usage is 3500 liters. According to KPCB consideration80%oftotalconsumedwaterconvertedinto effluentwater,so2800literwastewaterproducedinacar washindustryand5%safetyfactorisprovided.Therefore thecapacityoftreatmentplantis3KLD.Totalworkinghours takenas12hours.Thenflowrate0.25m3/hrs.100Lwater consumedforsinglecarwash.

Assumedepthbywidthratioofrectangularsectionsis1.5, andalsoallcomprisedunitsarerectangularinsectionexcept filtrationunitstheyatecircularinsection.

Thedesignbeginswithcollectiontank, Volume=0.25x4(retentionperiod) =1m3

Asassumebreadthas0.951mthendepthis1.426msothe lengthis0.724m.

0.724m

Screens are placed 60 degree inclination for retain large particleseasily.Manuallycleanedscreensareused.Assume Surfaceoverflowrate(SOR)as2m3/hrm.Flowrate0.25 m3/hr

Areaofscreen=flowrate/SOR =0.5m2

AssumerectangularsectionDepth/widthratiois1.5

Depthofchannel=1.5wxw{D/W=1.5){area=0.5}

Widthofchannel=0.57=0.6andDepth=0.833=0.85

Lengthofchannel =dx(Vh /Vs) assumingVhandVs 0.6 m/secand0.45m/sec

Vs=settlingvelocity,Vh=horizontalvelocity =0.85x(0.6/0.45) =1.133m=1.5m

Assumingopening3cmwideand1cmthickness

AreaofscreenAs=Areaofchannel/sinθ = 0.5/sin(50),asθistheinclinationof channelitmostlytaken50degree =0.653m2

Netarea(Anet)=AsXS/(S+tbar) =0.653x(3/(3+1) =0.49m2

Fromcontinuityequation

VaxAc=VbxAnet

Va =approachvelocity

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Vb=peakvelocityorbasinvelocity

Vb=VaxAc/Anet =0.6x0.5/0.49 =0.612m/sec

Check:peakvelocityofscreenshouldbelessthan0.9m/ sec,Here0.612<0.9m/secsoit’sok

Headloss(HL)=Vb2 Va2 /2gC

C=Normalflowthroughascreentakenas0.7

HL=0.6122 0.62 /2x9.81x0.7 =0.001m

Assume55%cloggedonscreen

Netarea=0.55x0.49 =0.269m2

Vb=0.6X0.5/0.269 =1.11m/sec

HL=1.112 0.62/2x9.81x0.7 =0.063m

Thenumberofbarsscreen=ntbar+(n 1)S=w 2 N=14.75=15nos

Dimensionofbarscreen1.5mx0.85mx0.6m=0.765m3 approximately1m3with15barswithopening3cmand1 cmhavingheadloss0.001mwithslope60degree.

Nextunitoperationisgritchambertheyaremainlyusedto removesmallparticleslikegrit.

Flowrate=0.25m3/hrandSOR=2m3/hr/m

Area=0.521m2

Lengthofchannel=d/(VhxVs) =13.26m

Aweirprovidedingritchamberforcontrolwaterflow.

Y=Q/(Vh/W) Y=totalweirlength =0.1/(0.3x0.580) =0.574m

Depthofweir(mm)=y=(2/3.1)xY =0.383mm

TheweirmustbeshapedsothatQ=8.18x10 6xwxy 1.5

Weirwidthw=51.576m

Headloss=36%xdepthofchannel =0.36x0.884 =0.318m=0.3m

Inletallowance30%

Dimensionofgritchamber13.26mx0.589mx0.884mwith free board 0.25 = 7.154 m3 weir width 51.576 m having headloss0.3m

After grit removal the effluent water led to move EC chamber,sodesignofchambergivenbelow, Flowrate=0.25m3/hr

Retentiontime=0.5hrs

VolumeofECunits=0.125m3

AreaofEC =flowrate/SOR =0.25m3/hr/2hrm =0.521m2

Providedepth=1.5mwidth=0.7mlength=0.75m

ECunitdividedinto6chambersdivingbyFRPsheetsof3 mmthickness. 0.7m 1.5m

Alelectrode 0.75m

Aluminumisusedaselectrodeandassumethedimensions are Length =40 cm =0.40 m, breadth = 35 cm = 0.35m thickness=0.1cm=0.01m

AfterECoperationgeneratedsludgeallowsforsettlingfor that they were led to flow in to tube settler. Sutro weir provided inside tube settler to convert sludge particles transitionflowtolaminarflowforeasysettlingofparticles andforboostingsettlingprocessaddedpolymerwith0.035 gm.Designoftubesettlerdescribedbelow,

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2776

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Flowrate=0.25m3/hr

Relativelengthofsettler=l/d

Assumel=1mandd=0.05m

Relativelength=1/0.05 =20m

L’=0.058x(Vo/υ)xd =0.058x(Vox0.05/1.01x10 6) =2.87x103Vom/sec =0.0332Vom/day

Effectivelength=(l/d) L’

Sc =(Vs/Vo)x(sinθ cosθ)

Forrectangularsectioncriticalvalue=11/8andassuming settlingvelocity120m/day.

11/8=(120/Vo)x(sin(60 (20 0.333Vo) cos(60) X (10+0.0165))

SolvingaboveEquationforfindVo

Vo=388.6m/day

Totalentranceareaoftube=Q/Vo =2.893x10 6/4.497x10 6 =0.6433m2

Assumed/w=1.5

D=0.982mandw=0.654m

Volume0.25x4hrs(detentionperiod) =1m 3

Lengthoftubesettler=1.58m

Dimensionoftubesettler=1.58mx0.654mx0.982m

Theybottomprovide60degreegroundinclination

Aftersettlingthewaterledtoflowintopressuresandfilter and activated carbon filter. They are in circular in section andthedimensionsare;

Flowrate=0.25m3/hr

Retentiontime=2hrs

Volume=0.25m3/hrx2hrs

=0.5m3

Area=2πrh

Height(h)=0.976=1m

Radius(r)=0.082m=taken0.4m

Diameter(d)=0.2m

Dimensionoffilters=0.2mdiameterx1mheight

specification Pressure sandfilter Activated carbonfiler

Flowrate 0.25 m /hrs 0.25m/hrs

Filtration rate (assume)

Height of straight provide (standard)

15m3/hr m2 13m3/hrm2

1.65m 1.65m

Volume (standard) 20m 20m

Diameter 4m 4m

Media Sand and gravel Activated carbon with IV>900

Aftercompletetreatmenttreatedwatercollectedinatreated watertankwhichdesignedas;

Flowrate=0.25m3/hrs

Retentiontime=4hrs

volumeV=0.25x4 =1m3

Area=flowrate/SOR =0.512m2

Depth/widthratio=1.5thenwidth= 0.6mdepth=0.85m length=1.95m

Dimensionoftreatedwatertank=2mx0.6mx0.85m

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2777

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Thetreatmentplantismadeupofconcreteandsteel.Final estimateincludefixedcostandrunningcostofthesystem 20bagsofcement,1.5tonesandand0.20tonegravelsare used.Theestimatevaluesshowsbelow;

Table 3: Totalcostofunitoperations

Items Volume cost Totalcost

Barscreen 1m3 15,000 15,000

Grit chamber 7.152m3 15,000 1,07,280

ECunit 0.787 ( 30 units) 20,000 6,00,000

Tube settler 1.5 25,000 37,500

Pressure sandfilter 20 (4mdia &1.65 height)

Activated carbon filter

20 (4m dia & 1.65m height)

2500 50,000

I=current T=timeuses M=molarmassAl F=faradays constant(96485.3329) N=noofelectronsinoxidationprocess V=volume Consumption=60x(24x60x60)x26.89 /(96485.3329x3 x30)

=0.0034kg/m3

Permonth=0.0034x30 =0.102kg/m3

IncaseofAl=0.102x400=40.8/ =41/ Permonth =41x30=1230/ 4electrodeused with14sets total=56

Totalcost=56x1230 =68,880/

Chemicalconsumptioncost

Consumptionofcausticsoda0.03 0.035g/L Assumingthecostofcausticsoda=32/ (day) Formonth=32x30=960/ Chemicalconsumptioncostforanyear=11,520/

Laborchargeforayear=5,56,000/year Sludgedisposalcostforanyear=15,000/ Generator(standby)=85,000/

Totalcostoftreatmentplantis25,5,0940/

4000 80,000

Collection tank 3 15000 45,000

Treated watertank 1m3 15,000 15,000

Filtertank 0.5m3 20,000 10,000

Dosageofpump=10(5standby){0.25hpconsumption with4hrs}

ECunit=0.5Hp(for20hrs=10hp)

Pressuresandfilter=16Hp

TotalHp=27HP

Rateof1unitcurrent=8/ Costofcurrentperday=27x8=216/

Permonth=6480/

Foranyearcurrentconsumptioncost=77,760/ Theelectrodechargesare;

Costofaluminum=400/ kg

Consumptionofelectrode=IXTXM/(FXN)xV

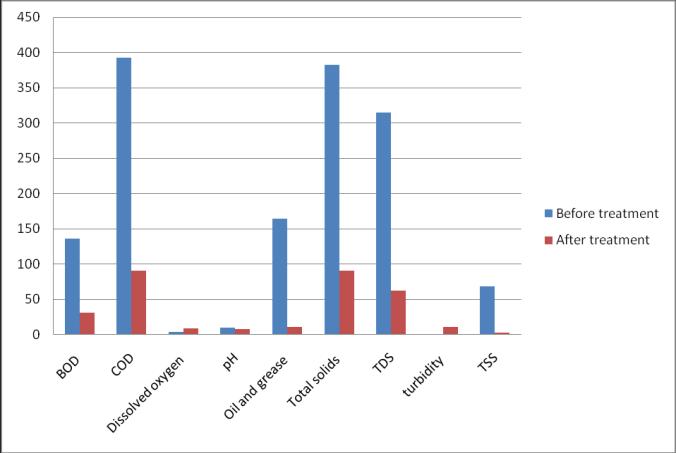

Electro Coagulation (EC) is most efficient method for removalofcontaminantsandoilandgrease.

Firstly car wash effluent water shows alkaline character after treatment that became neutral character.

Car wash water shows high oil and grease after treatmentthatremoved93.54%

COD, turbidity and TSS are highly present in car wash effluent water. later treatment process they removedmorethan70%

ThevariationofeffluentwaterbeforeandafterECprocess showsbelowtableandgraphicalrepresentation;

Table 4: Parametersbeforeandaftertreatment

SLno Parameter Carwash water{m g/l}

After electro coagulation

Percentage of removal efficiency

1 BOD 136 30.23 77.772%

2 COD 392.41 90.12 77.34%

3 Dissolved oxygen 3.17 8.1 60.86%backto water

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2778

4 pH 8.63 7.2 5 Oil and grease 164 10.59 93.54% 6 Totalsolids 382 90 76.439% 7 TDS 314 62 80.25% 8 turbidity 98.5NTU 10 89.84% 9 TSS 68 2 95%

friendly.becausetheycontainlessharmfulsubstancerather thanitsapplicablelimit.

After analysis final result more than 75% of water can be recycle and reuse they reduce water pollution and environmentalpollution.

[1] JamilAhamad(2017)“Designofcarwashwastewater treatment process for local station” Pakistan journal dealsthedesignoftreatmentprocessinalocalstation. The treatment process comprised coagulation, sedimentation and filtration unit (sand & gravel). JournalofPakistaninstituteofchemicalengineers.

[2] Sowmyas,RevathiMC(2021)“Treatmentofcarwash waterusingelectrocoagulation,chemicalandbiological process”Acomparativestudyofcarwashwaterusing biologicalprocessandelectrocoagulationusingcombo ofcuandALelectrode.Internationaljournalofcreative researchthoughts,vol09issue06

[3] SNimal,Abdulakbarshanazfathima(2018)“Recycling automobilestationwashwaterChennai”international journalofcivilengineeringandtechnology,vol9,issue4

Chart -1:Beforeandaftertreatmentofeffluentwater

The table 4 and chart 1 shows effluent water parameter variationbeforeandaftertreatmentprocessandalsoshows thepercentageofremovalefficiencyofEC.Theresultshows that most of the contaminants are removed through EC processandthewaterqualitybecomenormalsoitcanbe used for reuse or back washing. Although EC is removes pathogenssothetreated watercanbeusedforgardening process. ComparativelyECisoneofthemethodeco friendly andlessusageofchemicals.

Water demand increases day by day so the quality and quantity became diminish tidy sum rate. In car washing stationreuseandrecycleofwaterisasustainablesolution forwaterscarcityproblemandurbanwaterdemand.This project reveals that EC contain AL electrode is the most effective method for removes contaminants in car wash water.ECissimpleandeco friendlymethod,costeffective method compared to other recycle method. It need less humanpowerandchemicalsfortreatingeffluentwater.ECis integratedtechnologyprovidecleanandlessspace.

AnalyzeoverallresultECprovidemorethan75%removal efficiency.Sothetreatedwatercanreusewitheco friendly. Thesludgeproducedaftertreatmentcanbedisposedineco

[4] Neerja sree and varsha asokan (2019) “ treatment of automobileusingplantbasedcoagulants”international researchjournalofengineeringandtechnology,vol06, issue06

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2779