International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

2

1

Abstract - Vapor power cycles are used in steam power plants. In a vapour power cycle heat energy (released by the burning of fuel) is converted into work (shaft work), in which a working fluid repeatedly performs a succession of processes. In a vapour power cycle, the working fluid is water, which undergoes a change of phase. Among the various types of vapor power cycles is the Carnot cycle, which is theoretically the most efficient cycle and sets the limit for the efficiency of any vapor cycle. This limit is known as the Carnot limit. The Rankine cycle and its modifications are used widely and are theoretically the cycles best suited to steam power plants. By studying these cycles, we know practically what all must be done to increase the efficiency and cost effectiveness.

Key Words: Vaporpowercycle,Carnotcycle,Rankinecycle, efficiency,Steampowerplant,water,heatenergy

The steam power cycle is a useful method for constantly convertingheatenergyintomechanicalenergy.TheCarnot cyclehasthemaximumthermalefficiencyofallcyclesina certaintemperaturerange,inaccordwiththesecondlawof thermodynamics. WehaveseenthatCarnotcycleisnotthe theoretical/ideal cycle for steam turbine power plant becauseofthedifficultyofpumpingamixtureofwaterand steamanddeliveringitassaturated wateronly.However, this difficulty is eliminated in Rankin cycle by complete condensation of water vapor in the condenser, and then, pumpingthewaterisentropicallytoboilerpressure.Rankine cycle is a theoretical/ideal cycle for comparing the performanceofsteampowerplants.

Therefore, the Rankine cycle has become a basic cycle generally used in modern thermal power plants. Additionally, with the progress of science and technology, basedontheRankinecycle,therearereheatrankinecycle, regenerativerankinecycleandsoon.Atpresent,theactual cyclesofsteampowerplantsareverycomplex,buttheyare all improved based on the primary cycle. What are the economicdifferencesoftheseimprovedsteampowercycles? Letuscomparethemwithspecificexamples.

***

Example: In a power cycle, the initial parameters of fresh steamarep1=87bar,t1=510˚C,Thepressureofcondenseris pb=0.1bar.Whenthefreshsteamexpandstop2=20barin the steam turbine, a part of the steam is extracted for regenerativeheating,andtherestissenttothereheatertobe heatedto500˚C,andthenreturntothesteamturbinetodo work.Assumeturbineefficiency=65%and100TPH

2.1RankineCycle(ηt = 65%) T (510˚C) 87bar 0.1bar S

1 4 3 2

Fromh-sdiagram,thestateparametersofthecorresponding statepointareasfollows:

h1=3414.3kJ/kg=3414.3*0.23884=815.47kcal/kg h2’=2119.99kJ/kg=506.34kcal/kg(S1 =S2) but ηt=65%

ηt = = 0.65= h2=2573.01kJ/kg=614.54kcal/kg h3=191.8kJ/kg=45.809kcal/kg h4=200.57kJ/kg=47.90kcal/kg

Heatsupplied(qi )=h1 –h4 =3213.72kJ/kg=765.565kcal/kg

Turbinework(wt )=h1 –h2

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

=841.27kJ/kg=200.93kcal/kg

PumpWork(wp)=h4 –h3 =8.77kJ/kg=2.096kcal/kg

Electricitygenerated=200.93*0.860*100/1000 =17.34MW=14909716.25kcal/hr

Firingduty= =109652857.1kcal/hr ηthermal= =25.9% ηcycle = =13.59%

Electricitygenerated=239.1*0.860*100/1000 =20.56MW=17678417.88kcal/hr

Firingduty= =121221428.6kcal/hr

ηthermal= =28.12%

ηcycle = =14.58%

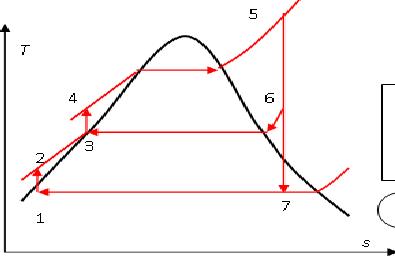

2.3RegenerationCycle

2.2ReheatCycle T 87 bar 0.1 bar S

1 3 2 6 5 4

Fromh-sdiagram,thestateparametersofthecorresponding statepointareasfollows:

h1=3414.3kj/kg=815.47kcal/kg h2 =3147.72kj/kg=751.80kcal/kg(ηHP=60%) h3 =3480kj/kg=831.16kcal/kg h4 =2745.5kj/kg=655.73kcal/kg(ηLP=65%) h5 =191.8kj/kg=45.80kcal/kg h6=193.80kj/kg=46.28kcal/kg

Heatsupplied(qi)=(h1 –h6)+(h3 –h2) =3552.79Kj/kg=848.55kcal/kg

Turbinework(wt)=(h1 –h2)+(h3 –h4) =1001.08Kj/kg=239.1kcal/kg

PumpWork(wp)=h6 –h5 =8.776Kj/kg=2.094kcal/kg

Fig.

Fromh-sdiagram,thestateparametersofthecorresponding statepointareasfollows:

h1=191.8kj/kg=45.80kcal/kg h2 =193.80kj/kg=46.28kcal/kg h3 =908.5kj/kg=216.98kcal/kg h4 =916.38kj/kg=218.86kcal/kg h5 =3414.3kj/kg=815.47kcal/kg h6=3121.41kj/kg=745.51kcal/kg(ηHP=65%) h7=2472.35kj/kg=590.49kcal/kg(ηHP=65%)

Energybalanceoffeedwaterheater mh6 +(1-m)h2 =h3 m=0.2441kg/kgofsteam

Heatsupplied(qi)=h5 –h4 =2497.92kj/kg=596.60kcal/kg

Turbinework(wt)=(h5 –h6)+(1-m)(h6 –h7) =783.50kj/kg=187.132kcal/kg

PumpWork(wp)=(h2 –h1)+(h4 -h3) =9.88kj/kg=2.35kcal/kg

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page962

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Electricitygenerated=187.132*0.860*100/1000 =16.09MW=13834909.72kcal/hr

Firingduty= =85228571.43kcal/hr ηthermal= =30.97% ηcycle = =16.20%

2.4Onestageregenerationandonereheatcycle

Fromh-sdiagram,thestateparametersofthecorresponding statepointareasfollows:

h1=191.8kj/kg=45.80kcal/kg h2 =193.80kj/kg=46.28kcal/kg h3 =908.5kj/kg=216.986kcal/kg h4 =916.38kj/kg=218.86kcal/kg h5 =3414.3kj/kg=815.47kcal/kg h6=3143.94kj/kg=750.89kcal/kg(ηHP=60%) h7 =3467.3kj/kg=828.129kcal/kg h8 =2744.29kj/kg=655.44kcal/kg(ηLP=65%)

Byenergybalanceoffeedwaterheater

mh6+(1-m)h2 =h3 m=0.2422kg/kgofsteam

Heatsupplied(qi)=(h5 –h4)+(1-m)(h7 –h6) =2442.96Kj/kg=655.12kcal/kg

Turbinework(wt)=(h5 –h6)+(1-m)(h7 –h8) =818.256Kj/kg=195.43kcal/kg

PumpWork(wp)=(h2 –h1)+(h3–h4) =9.889Kj/kg=2.36kcal/kg

Electricitygenerated=195.43*0.860*100/1000 =16.80MW=144453399.83kcal/hr

Firingduty= =93588571.43kcal/hr

ηthermal= =29.47%

ηcycle = =15.43%

Underthesameinitialandfinalparameters,wecalculated thethermalefficiencyandcycleefficiency ofRankinecycle, reheat cycle, regenerative cycle, and cycle with one stage regenerative and one reheat, respectively. The results are showninTable1,2and3.

Table 1. Comparisonofcalculationresultsbetweenreheat cycleandRankinecycle.

reheatcycle result Comparisonwith Rankinecycle qi kJ/kg 3213.72 3552.79 ↑339.07 wt kJ/kg 841.29 1001.08 ↑159.79 wp kJ/kg 8.776 8.776 → ηthermal 25.90% 27.93% ↑2.03% ηcycle 13.59% 14.58% ↑0.99%

Rankine cycle

Table 2. Comparisonofcalculationresultsbetween regenerativecycleandRankinecycle.

Rankinecycle

regenerativecycle result Comparisonwith Rankinecycle

qi kJ/kg 3213.72 2497.92 ↓715.8 wt kJ/kg 841.29 783.507 ↓57.783 wp kJ/kg 8.776 9.88 ↑1.11

ηthermal 25.90% 30.97% ↑5.07% ηcycle 13.59% 16.20% ↑2.61%

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Table 3. Comparisonofcalculationresultsbetweenone stageregenerationandonereheatcycleandRankine cycle.

Rankine cycle

onestageregenerationandone reheatcycle result

Comparisonwith Rankinecycle

qi kJ/kg 3213.72 2742.96 ↓470.76 wt kJ/kg 841.29 818.25 ↓23.04 wp kJ/kg 8.776 9.889 ↑1.11

ηthermal 25.90% 29.47% ↑3.57% ηcycle 13.59% 15.43% ↑1.84%

Fromtheaboveresultitcanbeseenthatthermalefficiency andcycleefficiencyishigherinregenerativerankinecycle thanreheataswellasonestageregenerationreheatrankine cyclecomparewiththesameparameters.

Heatenergysuppliedtotheboilerishigherinreheatrankine cycle and heat energy supplied to the boiler is lower in regenerativerankinecycle.

Work of turbine is higher in reheat rankine cycle i.e., electricity production is also high as compare to regenerationandasonestageregenerationreheatrankine cycle.

From the above result it can be seen that regeneration involves the utilization of heat within the system while reheatingorsuperheatingrequiresadditionalheataddition fromoutside.Thus,thesuitabledegreeofregenerationmay bebetteroverreheatingorsuperheatingoptions.

[1] YarongWang,andPeirongWang,“Thermalperformance comparison of Rankine cycle, reheat cycle and regenerative cycle with the same initial and final parameters”E3Swebofconferences245,03015(2021)

[2] Gulab Chand Sahu, Manoj Sao, Abhishek Kumar Jain, “Comparison Between Regenerative , Reheat & CogenerationSteamPlantonthebasisofTurbineInlet

Temperature”IJARSETISSN2350–0328,Vol.4,Issue1, February2017

[3] R.K. Naradasu, R.K. Konijeti, and V.R. Alluru, “Thermodynamic analysis of heat recovery steam generatorincombinedcyclepowerplant”,International OrganizationOfScienceResearch,Vol.11,pp.143-156, 2007

[4] R.K.Kapooria, S.Kumar, K.S.Kasana, “An analysis of a thermal power plant working on a Rankine cycle: A theoreticalinvestigation”,JournalofEnergyinSouthern Africa,Vol19,pp.77-83,February2008.

[5] Ivan Sunit Rout, Abhishek Gaikwad, Vinod Kumar Verma,MohammadTariq,“ThermalAnalysisofSteam Turbine Power Plants”, International Organization Of ScienceResearch,Vol.7,pp.28-36,May.-Jun.2013

[6] Charles Mborah, Abeekuh Brew Hammond, Seth P. Agbomadzi, “Thermodynamic Analysis of the Gas and Steam Turbines at Takoradi Thermal Power Station”, European Journal of Technology and Advanced EngineeringResearch,Vol.1,pp.62-72,2010.

[7] Raviprakash kurkiya, Sharad chaudhary, “Energy AnalysisofThermalPowerPlant”,InternationalJournal ofScientific&EngineeringResearch,Vol.3,pp.1-7,July2012.

[8] M. A. Jegadeswaran, V. Sam Daniel, G. Thamaraikkannan,“AnalysisforEfficiencyImprovement and Fuel Savings Opportunities in Thermal Power Plant”, The International Journal Of Science & Technoledge,Vol3,pp.9-15,September,2015.

[9] Adeyinka O. Adeoye, Christian O. Osueke, Anthony O. Onokwai, Chinedu A.K Ezugwu, “Enhancing the Performanceof75mwSteamPowerPlantwithSecond LawEfficiency,CondenserPressureandRankineCycle”, TheInternationalJournalOfEngineeringAndScience, Vol.4,pp.18-29,2015.

[10] P.Srinivasarao, Dr. P. Ravinder Reddy, Dr.K.Vijaya KumarReddy,“AdvancePowerPlantTechnologiesand SteamCycleforSuperCriticalApplication”,International Journal of Scientific and Research, Vol. 2, pp. 1-10, September2012.

[11] Onkar Singh, “Applied Thermodynamics” third editon ISBN(13):978-81-224-2916-9

[12] P K Nag, “Basic and Applied Thermodynamics” eight editonISBN0-07-047338-2

[13] Xu, Y.P., Ke, X.Y. (2012) Thermal Engineering.China ElectricPowerPress,Beijing

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page964

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[14] Cheng, G.T., Wang, Y.Z. (2007) Engineering Thermodynamics(SecondEdition).BeijingUniversityof TechnologyPress,Beijing.

[15] Chen, Z.H. (2009) Basic Thermal Engineering, China ElectricPowerPress,Beijing.

[16] Shen, W.D., Geng, T.J. (2007) Engineering Thermodynamics,HigherEducationPress,Beijing

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page965