International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 08 Issue: 08 | Aug 2021

p-ISSN: 2395-0072

www.irjet.net

Lean Manufacturing Principle & Their Applicability & Benefits in Manufacturing Industries Dr. Syed Imranuddin¹, Dr. U Y Memon² ¹Senior QMS Engineer ²Assistant Professor (Sir Sayyad College Aurangabad) -----------------------------------------------------------------------***----------------------------------------------------------------------

Abstract- Lean manufacturing, spearheaded by Toyota,

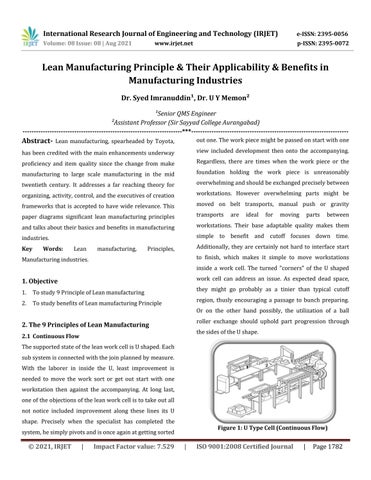

out one. The work piece might be passed on start with one

has been credited with the main enhancements underway

view included development then onto the accompanying.

proficiency and item quality since the change from make

Regardless, there are times when the work piece or the

manufacturing to large scale manufacturing in the mid

foundation holding the work piece is unreasonably

twentieth century. It addresses a far reaching theory for

overwhelming and should be exchanged precisely between

organizing, activity, control, and the executives of creation

workstations. However overwhelming parts might be

frameworks that is accepted to have wide relevance. This

moved on belt transports, manual push or gravity

paper diagrams significant lean manufacturing principles

transports

and talks about their basics and benefits in manufacturing

workstations. Their base adaptable quality makes them

industries.

simple to benefit and cutoff focuses down time.

Key

Words:

Lean

manufacturing,

are

ideal

for

moving

parts

between

Additionally, they are certainly not hard to interface start

Principles,

to finish, which makes it simple to move workstations

Manufacturing industries.

inside a work cell. The turned "corners" of the U shaped work cell can address an issue. As expected dead space,

1. Objective 1.

To study 9 Principle of Lean manufacturing

2.

To study benefits of Lean manufacturing Principle

they might go probably as a tinier than typical cutoff region, thusly encouraging a passage to bunch preparing. Or on the other hand possibly, the utilization of a ball roller exchange should uphold part progression through

2. The 9 Principles of Lean Manufacturing

the sides of the U shape.

2.1 Continuous Flow The supported state of the lean work cell is U shaped. Each sub system is connected with the join planned by measure. With the laborer in inside the U, least improvement is needed to move the work sort or get out start with one workstation then against the accompanying. At long last, one of the objections of the lean work cell is to take out all not notice included improvement along these lines its U shape. Precisely when the specialist has completed the

Figure 1: U Type Cell (Continuous Flow)

system, he simply pivots and is once again at getting sorted

© 2021, IRJET

|

Impact Factor value: 7.529

|

ISO 9001:2008 Certified Journal

|

Page 1782