International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 07 Issue: 01 | Jan 2020

p-ISSN: 2395-0072

www.irjet.net

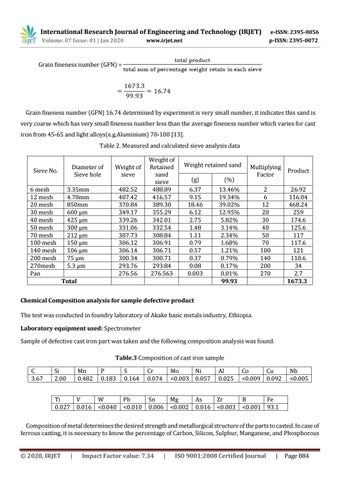

Grain fineness number (GFN) =

Grain fineness number (GFN) 16.74 determined by experiment is very small number, it indicates this sand is very coarse which has very small fineness number less than the average fineness number which varies for cast iron from 45-65 and light alloys(e.g.Aluminium) 70-100 [13]. Table 2. Measured and calculated sieve analysis data Diameter of Sieve hole

Sieve No. 6 mesh 12 mesh 20 mesh 30 mesh 40 mesh 50 mesh 70 mesh 100 mesh 140 mesh 200 mesh 270mesh Pan

Weight of sieve

3.35mm 4.70mm 850mm 600 µm 425 µm 300 µm 212 µm 150 µm 106 µm 75 µm 5.3 µm

482.52 407.42 370.84 349.17 339.26 331.06 307.73 306.12 306.14 300.34 293.76 276.56

Weight of Retained sand sieve 488.89 416.57 389.30 355.29 342.01 332.54 308.84 306.91 306.71 300.71 293.84 276.563

Weight retained sand (g)

(%)

6.37 9.15 18.46 6.12 2.75 1.48 1.11 0.79 0.57 0.37 0.08 0.003

13.46% 19.34% 39.02% 12.95% 5.82% 3.14% 2.34% 1.68% 1.21% 0.79% 0.17% 0.01% 99.93

Total

Multiplying Factor 2 6 12 20 30 40 50 70 100 140 200 270

Product 26.92 116.04 468.24 259 174.6 125.6 117 117.6 121 110.6 34 2.7 1673.3

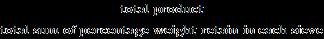

Chemical Composition analysis for sample defective product The test was conducted in foundry laboratory of Akake basic metals industry, Ethiopia. Laboratory equipment used: Spectrometer Sample of defective cast iron part was taken and the following composition analysis was found. Table.3 Composition of cast iron sample C 3.67

Si 2.00

Mn 0.482

P 0.183

Ti 0.027

V W 0.016 <0.040

S 0.164

Cr 0.074

Mo Ni <0.003 0.057

Pb <0.010

Sn Mg 0.006 <0.002

Al 0.025

As Zr 0.016 <0.003

Co Cu <0.009 0.092

Nb <0.005

B Fe <0.001 93.1

Composition of metal determines the desired strength and metallurgical structure of the parts to casted. In case of ferrous casting, it is necessary to know the percentage of Carbon, Silicon, Sulphur, Manganese, and Phosphorous © 2020, IRJET

|

Impact Factor value: 7.34

|

ISO 9001:2008 Certified Journal

|

Page 884