International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 11 Issue: 05 | May -2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 11 Issue: 05 | May -2024 www.irjet.net p-ISSN: 2395-0072

Mr. Ravat Jigar P.1 , Mr. Patel Rakesh H. 2

1Student, Dept. of Mechanical Engineering, Sankalchand patel university,Gujarat, India

2Professor, Dept. of Mechanical Engineering, Sankalchand patel university,Gujarat, India

Abstract - Componentswithcomplicatedfeatures,which are challenging to obtain using traditional manufacturing procedures, are often made using electrical discharge machining (EDM), a non-traditional machining technique. Thecurrent,pulseontime,andpulseofftimearetheinput parameters in this study, whereas the MRR and surface roughness are the output parameters. The experiment is designed according to Taguchi L9 orthogonal array with three different level of each input parameter. For result interpretation,analysisofvariance(ANOVA)wasconducted andoptimumparametersselectedonthebasisofthesignal tonoiseratio,whichconfirmstheexperimentalresult.Find out most important role of input parameter on output parameter. Experimentwillbeperformedonprofilesuchas Flat,Concave,ConvexofInconel800.Tangibleobservation will be analyzed with parameters like MRR, Surface roughnesstest.Conclusionwillbedisplayedindurabilityof Inconel800withrespecttoElectricDischargeMachine.

Keywords: EDM, Incolen-800, Taguchi method, Minitab.

ElectricitydischargeTheunconventionalmachiningprocess knownasmachininginvolvestheremovalofmaterialbyuse ofthethermalenergyofaspark.Thisisachievedthrougha series of electrical ejections that occur in recurrent sequencesbetween a small gapbetweenanelectrodeand the work piece. For cutting electrically conductive hard metalsandalloys,EDMiswidelyutilisedinthedie-making, automotive, and aerospace sectors. Electrode machining (EDM) is a technique that shapes metal sections by repeatedly ejecting an electrical current between a tool (cathode) and a work piece (anode) in an environment of dielectricliquid,thereforeremovingdebrisandunwanted material.Inthismachiningtechnique,theanodereferstothe work piece connected to the positive terminal and the cathode to the negative terminal. Some examples of dielectricfluidsarekerosene,transformeroil,anddistilled water.

I have selected Inconel 800 sheet material for carried outtheexperiment.

Using a Taguchi method, establish the correlation betweentheinputparameters(Peakcurrent,Pulseontime,

Pulse off time) and the response variable (Surface Roughness).

Examinethevariedeffectsofvariousinputfactorsand analysetheirimpactonoutputprocessparameter,aswellas determinetheirrelativerelevance.Thisisaccomplishedby usinganL9orthogonalarraybasedontheTaguchimethod to investigate their major effects as well as interaction effects.

Optimizationtofindthebestvaluesfortheinputprocess parameters.

3. DESIGN OF EXPERIMENT

3.1 Different Techniques of DOE

1. Factorialdesign

2. ResponseSurfaceMethod

3. MixtureExperiments

4. TaguchiDesign

3.2 Application of DOE

Theproduct'smostidealdesign

Optimalprocessparametercombinations

Long-termanswerstoissueswithproduction

Themostimportantcriteriaforvalidationanddurability tests

Beststrategyforcollectingsurveydata

3.3 Process Parameters

Input Parameter

FactorA:-Current(A)

FactorB:-PulseOnTime (��s)

1. FactorC:-PulseOffTime (��s)

2.

Output Parameter

MRR(mm3/min)

SurfaceRoughness(��m)

Table-1: Levelofprocessparameter

13 17 28

OnTime 150 180 265 PulseOffTime 15 16 20

Table-2: L9OrthogonalArrayLevel

Table-3: ResultsTableForConvexProfile

Table-4: ResultsTableForFlatProfile

Table-5: ResultsTableForConcaveProfile

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 11 Issue: 05 | May -2024 www.irjet.net p-ISSN: 2395-0072

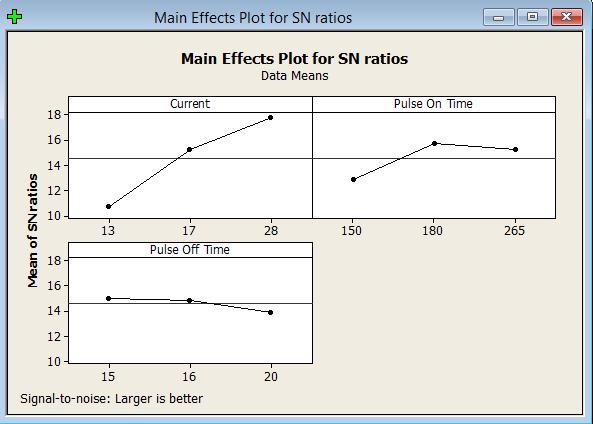

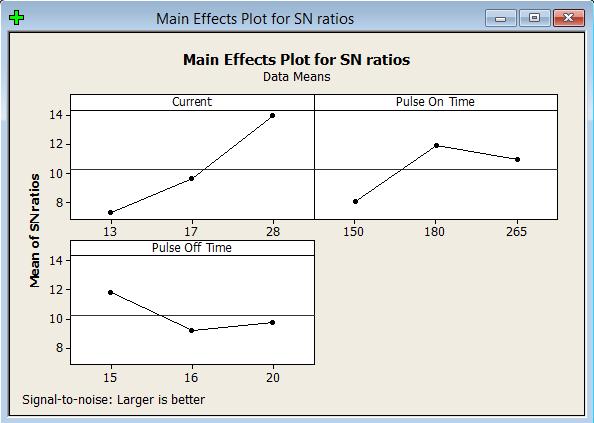

Fig-3: MainSNratioeffectplot(MRR-Convex)

This figure shows the principal plot for MRR at 3 mm thickness for current, pulse on time, and pulse off time. ExperimentaldataindicatesthehighestMRRat28A,180��s pulseontime,and15��spulseofftime.ThelowestMRRwas observedat13A,150��spulseontime,and15��spulseoff time.

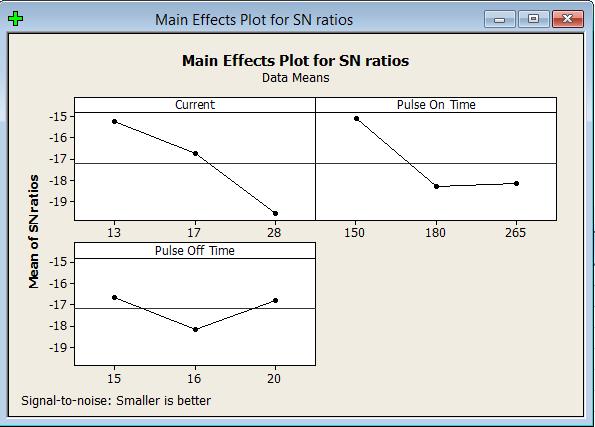

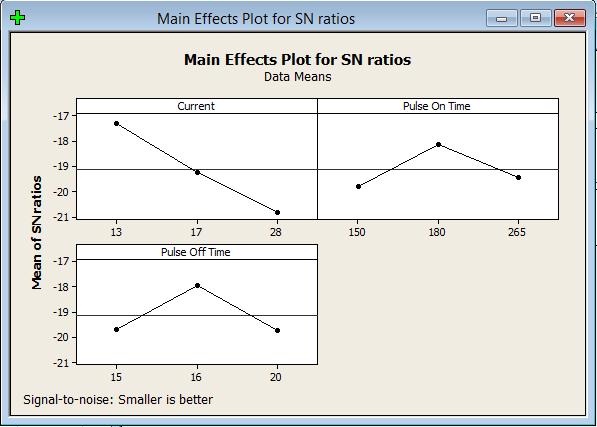

Fig-4: MainSNratioeffectplot(SR-Convex)

Current,pulseontime,andpulseofftimeaffectthemainplot for surface roughness at 3 mm thickness, as seen above. Experimental results indicate that surface roughness was maximumat28Acurrent,265��spulseon,and16��spulse off,andlowestat13Acurrent,150��spulseon,and15��s pulseoff.

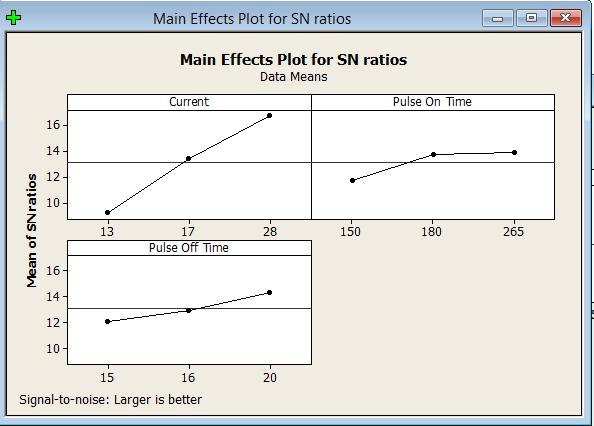

Fig-5: MainSNratioeffectplot(MRR-Flat)

This figure shows the principal plot for MRR at 3 mm thicknessforcurrent,pulseontime,andpulseofftime.The largestMRRwasseenat28Acurrent,150��spulseontime, and 20 ��s pulse off time in experiments. The lowest MRR wasobservedat13A,150��spulseontime,and15��spulse offtime.

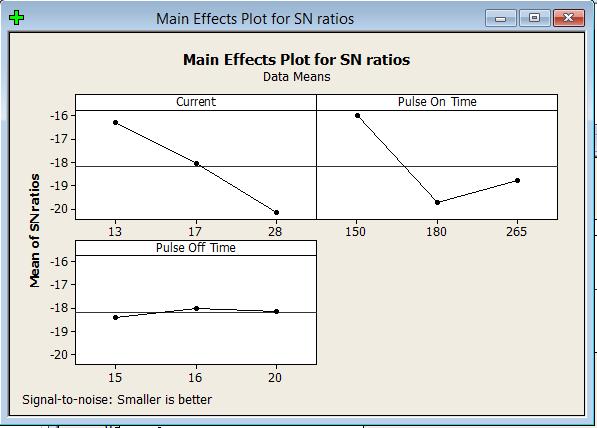

Fig-6: MainSNratioeffectplot(SR-Flat)

Current,pulseontime,andpulseofftimeaffectthemainplot for surface roughness at 3 mm thickness, as seen above. Maximumsurfaceroughnesswasattainedat28Acurrent, 180��spulseontime,and15��spulseofftime,accordingto experimental results. The lowest surface roughness was observedat13A,150��spulseontime,and15��spulseoff time.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 11 Issue: 05 | May -2024 www.irjet.net p-ISSN: 2395-0072

Fig-7: MainSNratioeffectplot(MRR-Concave)

This figure shows the principal plot for MRR at 3 mm thicknessforcurrent,pulseontime,andpulseofftime.The highestmaximumreturnratio(MRR)wasobservedat28A, 180��spulseontime,and15��spulseofftime,accordingto experimentalresults.ThelowestMRRwasobservedat17A, 150��spulseon,and16��spulseoff.

Fig-8: MainSNratioeffectplot(SR-Concave)

Current,pulseontime,andpulseofftimeaffectthemainplot for surface roughness at 3 mm thickness, as seen above. Theexperimentfoundthatthemaximumsurfaceroughness wasachievedat28A,150��spulseontime,and20��spulse offtime.Thelowestsurfaceroughnesswasobservedat13A, 180��spulseonand16��spulseoff.

5. CONCLUSION

In present work experiment carried out on EDM machine withinconel-800materialbyusingtaguchidesignConvex, Flat, Concave shape brass electrode can be used in experimentalworkForgettinghighMRRthencurrentmust

behighPulseofftimeisinsignificantforMRRPulseontime up-to certain range impact on MRR The most significant parameteriscurrent for more effect on outputparameter Comparedtoelectrodeswithflatorconcaveprofiles,those withaconvexbottomprofileworkbetter.

Flat profile electrode performs better than the concave profileelectrode.

[1]M.M.Rahman,M.A.R.Khan,K.Kadirgama,M.M.Noor,& R.A. Bakar “Experimental Investigation into Electrical DischargeMachiningofStainlessSteel304”(2011)

[2] SanthoshGotagunaki,VardhamanS.Mudakappanavar, R. Suresh “ Wire electrical discharge machining characteristics of rare earth oxides reinforced AZ91D magnesium alloy hybrid composite using Taguchi-grey relationalanalysisapproach”(2023)

[3] PrashantP.Shingare,SohamMujumdar“ Experimental Investigation of Powder-mixed Dielectrics for Electrical DischargeMachining”(2022)

[4] Huu-PhanNguyen,Van-DongPham“ Singleobjective optimizationofdie-sinkingelectricaldischargemachining with low frequency vibration assigned on workpiece by taguchimethod”(2019)

[5] Ch. Shekar , K. Kishore , P. Laxminarayana “ Material removalrateandsurfaceroughnessonmachiningofInconel 718 by electrical discharge machine using Taguchi technique”(2020)

[6] Nakka Nagaraju, RVNR Surya Prakash, Venkata Ajay Kumar. G and N.G. Ujwala “ Optimization of Electrical Discharge Machining Process parameters for 17-7 PH StainlessSteelbyusingTaguchiTechnique”(2020)

[7] N. Manikandan , J.S. Binoj, P. Thejasree, P. Sasikala,P. Anusha“ ApplicationofTaguchimethodonWireElectrical DischargeMachiningofInconel625”(2020)

[8] S.UjjainiKumar,N.Manikandan,J.S.Binoj P.Thejasree, S. Shajahan , D. Arulkirubakaran “ Multi objective optimization of wire-electrical discharge machining of stelliteusingTaguchi–Greyapproach”(2020)

[9] M. Fakkir Mohamed , K. Lenin “ Experimental investigation on wire electrical discharge machining parameters for aluminium 6082 T6 alloy using Taguchi design”(2020)

[10] S.H.Tomadi,M.A.Hassan,Z.Hamedon, Member, IAENG R.Daud,A.G.Khalid“

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 11 Issue: 05 | May -2024 www.irjet.net p-ISSN: 2395-0072

Analysis of the Influence of EDM Parameters on Surface Quality, Material Removal Rate and Electrode Wear of TungstenCarbide”(2009)

[11] Mao-yongLIN,Chung-chenTSAO,Chun-yaoHSU,Aihuei CHIOU, Peng-cheng HUANG, Yu-cheng LIN “ Optimizationofmicromillingelectricaldischargemachining ofInconel718byGrey-Taguchimethod”(2013)

[12] G. SELVAKUMAR, G. SORNALATHA, S. SARKAR, S. MITRA “ Experimental investigation and multi-objective optimizationofwireelectricaldischargemachining(WEDM) of5083aluminumalloy”(2014)

[13] PoovazhaganLakshmanan,G.Kumanan,L.Arunkumar , S.C. Amith “ Experimental investigations of material removal rate on Mg/SiCp-flyash hybrid metal matrix compositesbyelectricaldischargemachining”(2021)

[14] ChinmayaPMohanty,SibaShankarMahapatra,Manas Ranjan Singh “ An Experimental Investigation of Machinability of Inconel 718 in Electrical Discharge Machining”(2014)