International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

ADHISHANKAR J 1 , SANJAI P2 , KIRUBHANIDHI D3 , SIVASUBRAMANIYAM C4 , PANDIYAN R5

1,2,3,4Student, Department of Mechanical Engineering, Rajiv Gandhi College of Engineering and Technology,Puducherry, India.

5Assistant Professor, Department of Mechanical Engineering, Rajiv Gandhi College of Engineering and Technology,Puducherry, India. ***

Abstract - Our project motive is to increase the overall properties of by adding inorganic fillers such as copper oxide and PLA three specimen of different matrix were prepared by moulding process and it is subjected to examination to obtain their tensile strength, in addition to that, the microscopic analysis is operated to observe the fracture surface of specimen and the properties of the various specimen was compared and it is recorded

Key Words: PLA and Copper Oxide.

Theoccurrence offracturecommonlyoccursinourdaily lives,forexample,thedishbreaksintoseveralpieceswhen accidentlydroppedonthefloor.Inthepackageindustry,the packageoffoodcanbeopenedbytearing.Incaseoffracture occurs,someoftheseinstancesarespontaneousandothers arecontrolledbypeopleandmostlyduetothemechanismof thedesign.Metalandnon-metalmaterialiswidelyusedin our common lives and especially polymer material has increased significantly in last fifty years. In this research, Polylactic acid (PLA) is mainly focused on. PLA is widely used in packaging industry. The food packaging industry, PLA is widely used and has been applied in Packaging for foodandbeveragesformanyyears.Currently,PLAcoverare installedmorethantheotherplasticcover.Inthelasttwenty years, PLA have also been used as a protection layer for cablesinconstructionstructuretopreventcorrosion.

Polylacticacid(PLA)isatypeofbiodegradablepolymerthat isderivedfromrenewableresourcessuchascornstarchor sugarcane.Itisapopularalternativetotraditionalplastics, which are derived from fossil fuels and have a significant negativeimpactontheenvironment.PLAisconsideredtobe anenvironmentallyfriendlyoptionbecauseitismadefrom renewable resources and can break down into natural components over time. This means that it is less likely to contributetotheaccumulationofplasticwasteinlandfillsor oceans.Inadditiontoitseco-friendliness,PLAalsohasawide range of applications. It can be used to make packaging materials,disposablecutlery,foodcontainers,andeven3D printing filaments. PLA has gained popularity in various

industries due to its versatility and compatibility with existingmanufacturingprocesses.However,it'simportantto notethatPLAisnotwithoutitslimitations.Itcanbemore expensivetoproducecomparedtotraditionalplastics,andit has certain limitations in terms of temperature resistance anddurabilityOverall.

Polylactic acid (PLA) is a type of biodegradable polymer made from renewable resources, such as corn starch or sugarcane.Herearesomekeypropertiesofpolylacticacid:

Biodegradability:PLAisknownforitsbiodegradability, meaningitcanbebrokendownbymicroorganismsin theenvironment,unliketraditionalplastics.

Renewable Resource: PLA is derived from renewable resources,makingitmoresustainablethanpetroleumbasedplastics.

Transparency: PLA has good transparency, making it suitable for transparent or translucent applications. • StrengthandRigidity:PLAhasgoodtensilestrengthand rigidity, which makes it suitable for a wide range of applications

Temperature Sensitivity: PLA has a relatively low meltingpoint,typicallyaround150-160degreesCelsius, which should be considered when choosing PLA for hightemperatureapplications.

Limited Chemical Resistance: PLA is not resistant to most organic solvents and has limited resistance to moisture, so it may not be suitable for certain environmentsorapplications.

Processability: PLA can be processed using various techniques, such as injection molding or 3D printing, making it versatile for different manufacturing processes.

It'simportanttonotethatspecificpropertiesofPLAcan varydependingonthegradeorformulationbeingused

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Polylacticacid(PLA)hasseveraladvantagesthatmakeitan attractivealternativetotraditionalplastics.Herearesome keyadvantagesofpolylacticacid:

Biodegradability: PLAisfullybiodegradableandcanbe brokendownbymicroorganismsintheplasticsthatcan takehundredsofyearstodecompose

Renewable Resource:PLAisderivedfromrenewable resourcessuchascornstarchorsugarcane,makingita moreenvironmentallyfriendlychoice.Ithelpsreduce reliance on fossil fuels and supports the use of sustainableagriculturalpractices

Versatility: PLA can be processed using various techniqueslikeinjectionmolding,blowmolding,and3D printing. This versatility allows for a wide range of applicationsinindustriessuchaspackaging,foodand beverages,textiles,andbiomedical.

Reduced Carbon Footprint: PLA production emits fewergreenhousegasescomparedtotheproductionof conventionalplastics.UsingPLAcanhelpreducecarbon emissionsandmitigateclimatechangeimpact.

Good Printability:PLAiswidelyusedinthe3Dprinting industry due to its ease of printing and good layer adhesion. It has become a popular choice for professionals

Transparency: PLA can be formulated to have good transparency,makingitsuitableforapplicationswhere visual appearance is important, such as packaging or displaycases

Low Toxicity: PLA is considered to have low toxicity andisgenerallysafeforhumancontact.Itisoftenused infoodpackagingandmedicalapplicationswheresafety iscritical

1.1.3

Polylacticacid(PLA)hasawiderangeofapplicationsdueto itsuniqueproperties.Herearesomecommonapplicationsof PLA:

Packaging: PLA is commonly used in packaging materialssuchasclamshells,trays,cups,andfilms.Its transparencyandrigiditymakeitsuitablefordisplaying andprotectingvariousproducts.

Food and Beverage Containers: PLA'slowtoxicityand biodegradabilitymakeitapopularchoiceforfoodand beveragecontainerslikedisposablecutlery,disposable plates,andcups.Itiscommonlyusedinthefoodservice industryandatevents.

Textiles: PLA fibers can be used to make fabrics and textiles.Thesefiberscanbeblendedwithothernatural or synthetic fibers to improve their mechanical properties and make sustainable clothing and accessories

Agriculture: PLAmulchfilmsareusedinagricultureto reduceweedgrowth,retainsoilmoisture,andregulate soiltemperature.Thesefilmscanbeleftinthefieldand will biodegrade over time, eliminating the need for removalanddisposal.

Medical and Pharmaceutical Applications: PLA is utilizedinmedicalandpharmaceuticalapplicationssuch as sutures, drug delivery systems, tissue engineering scaffolds, and implants. Its biocompatibility and biodegradabilitymakeitsuitablefortheseapplications

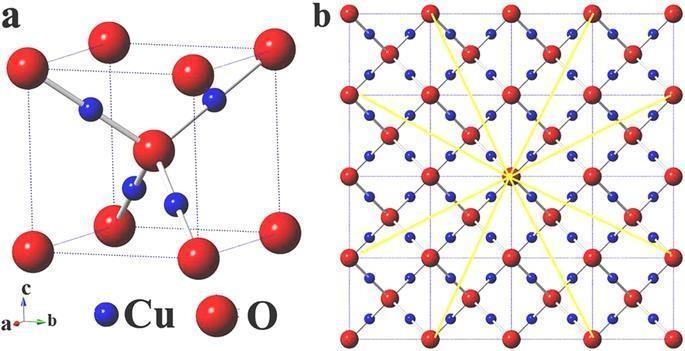

Thisstudyaimstoprovide anupdatedsurveyofthemain synthesismethodsofcopperoxide(CuO)Nanoparticlesin ordertoobtaintailorednanosystemsforvariousbiomedical applications.Thesynthesis approachsignificantlyimpacts thepropertiesofsuchnanoparticlesandtheirpropertiesin turn have a significant impact on their biomedical applications.Althoughnotwidelyinvestigatedasanefficient drug delivery system, CuO nano particles have great biologicalpropertiesincludingeffectiveantimicrobialaction againsta wide rangeofpathogensandalsodrug resistant bacteria.These propertieshaveledtothedevelopment of various approaches with direct applications to the biomedicalfield,Itisalsobelievedthatthesenanosystems couldrepresentefficientalternativesinthedevelopmentof smartsystemsutilizingbothdetectionofpathogensandfor thetreatmentofinfections

Copperoxide(CuO)nanoparticleswerecharacterisedand investigatedfortheirpotentialantimicrobialapplications.It was found that nano scaled CuO, generated by thermal plasma technology, contains traces of pure Cu and Cu2 O nanoparticles. Transmission electron microscopy (TEM) demonstrated particle sizes in the range 25–90 nm. TEM energydispersivespectroscopygavetheratioofcopperto oxygen elements as 54.18% to 45.26%. The mean surface area was determined as 15.69 m2 /g by Brunau–Emmet–Teller (BET) analysis. CuO nano particles in suspension showed activity against a range of bacterial pathogens, includingmeticillin-resistantStaphylococcusaureus(MRSA) and Escherichia coli, with minimum bacteri- cidal concentrations (MBCs) ranging from 100 g/ml to 5000 g/mL.TheabilityofCuOnanoparticlestoreducebacterial populations to zero was enhanced in the presence of subMBC concentrations of silver nano particles. Studies of copperoxideCuOnanoparticlesincorporatedintopolymers suggestreleaseofionsmayberequiredforoptimumkilling

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Table -1: SampleTableformat

Properties of copper oxide

Boilingpoint 2000oC

Meltingpoint 1325oC

Density 6.315g/mL

flammability NonFlammable

Fig -1: COPPEROXIDE-STRUCTURE

1.2.1 ADVANTAGES OF COPPER OXIDE

Havinganarrowbandgapof1.2eV

Energy conversion, Optoelectronic devices and catalyst.

Superthermalconductivity,Photovoltaicproperties, Highstability,andAntimicrobialactivity.

Haveotheruniquemagneticandsuper-hydrophobic properties.

HaveSemiconductingProperty

Usefulinbatteries,catalysis,solarenergyconversion, high-temperaturesuperconductors

Copper oxide nano particles can improve the mechanical properties of the composite, such as stiffness,strength,andtoughness.

Copper oxide nano particles can improve the electricalandthermalconductivityofthecomposite.

Copper oxide nano particles can improve the wear resistanceandcorrosionresistanceofthecomposite.

Copperoxidenanoparticlescanimprovethethermal stabilityofthecomposite.

Injectionmouldingofplasticcreateshigh-qualitythreedimensional objects that can be commercially reproduced. Theinjectionmouldingprocessstartwithmeltingplasticina hopper. The melted, liquid plastic is injected into a tightly closed mould. The plastic quickly takes the shape of the surroundingmould.Onceithascompletelyset,themouldis openedtoreleasetheplasticobject.Themouldcangenerally be used many times beforeneeding to be replaced. Plastic itemssuchasyogurtcups,buttertubs,plastictoysandbottle capsusetheinjectionmouldingprocess

Vertical injection moulding machines functions like traditionalhorizontalmachines,howeverit’sorientationis on the vertical axis. The available type of machine is as follows, hydraulic, electric and hybrid. Vertical injection moulding machines require little floor space due to the orientation of the machine. Vertical injection moulding machines are particularly suited for insert moulding applications.Componentscanbeeasilyloadedintothemould andheldinplacebygravitypriortoovermoulding.Vertical injectionmouldingmachinesoftenincorporateashuttleor rotarytable,allowingloadingandde- mouldingwithinthe machinescycletime

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Diesandmouldsarebothtoolsforshaping.Diesareusedto shape sheet metal and other metal forms. A typical application is the making ofautomobile bodyparts. On the otherhand,mouldsareusedininjectionmouldingsuchas withmeltedresinorcastingmoltenmetal

3 TESTING AND EVALUATION

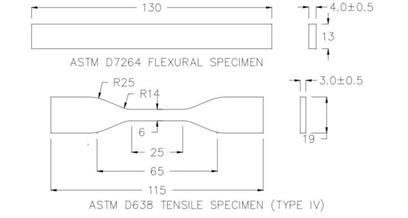

Flexural testing assesses a material's resistancetobending, vital for understanding its flexibility and durabilityacross applicationslikeplasticlockarmsandsupportbeams.ASTM D790 and ISO 178 provide standardized procedures to determineflexuralmodulus,crucialformaterialselectionand performanceevaluation.Challengesinflexuretestinginclude stress concentration at loading points and fretting wear, mitigatedbyfour-pointtestsandinnovativeapproacheslike usingpolypropyleneshims.Flexuraltesting,performedwith two-point or three-point bending fixtures, operates in compression mode to determine the material's behavior understress,fromfixedstrainlimitstocompletefailure.

A Universal testing machine (UTM) is used to test the mechanicalproperties(tension,compressionetc.)ofagiven testspecimenbyexertingtensile,compressiveortransverse stresses.Themachinehasbeennamedsobecauseofthewide rangeoftestsitcanperformoverdifferentkindofmaterial

4. RESULTS AND DISCUSSION

WeboughtthematerialPLAandCopperoxidetomixitNwith thefollowingcompositionasstatedbelow

NeatPLA100gm

100gmPLA+1gmCuO

100gmPLA+3gmCuO

100gmPLA+5gmCuO

RESULT: TYPE:1<<TYPE:2<<TYPE:3<< As per the above compositionthespecenfortensile,compressionandflexural willbepreparedbyinjectionmouldingprocess.Afterthatwe planned to conduct thetensile,compression and flexural testinginthespecimensusinguniversaltestingmachine.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

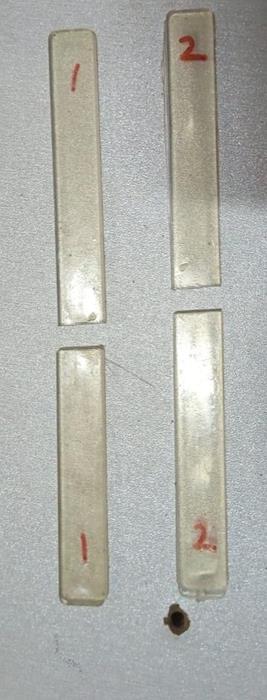

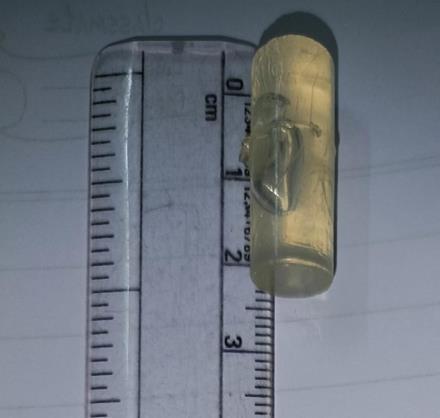

Fig-10:BEFORECOMPRESSIONTEST

Fig-11:AFTERCOMPRESSIONTEST

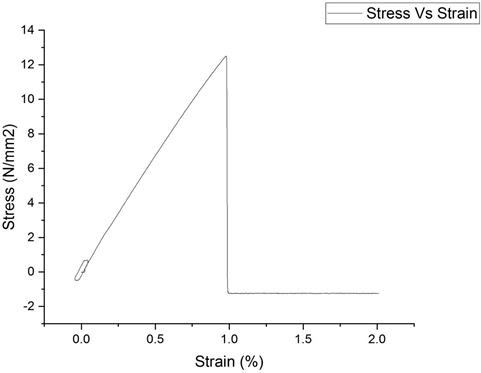

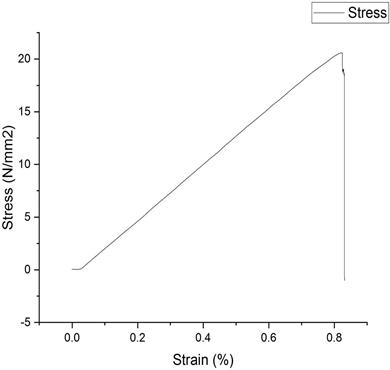

4.1 TENSILE STRESS STRAIN CURVE:

Chart–1:STRESSVSSTRAIN

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072 © 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008

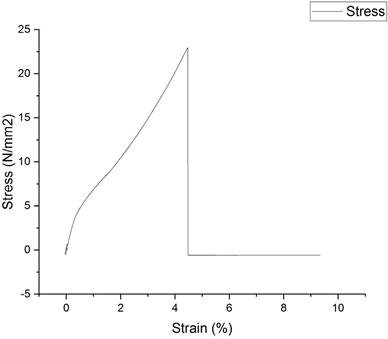

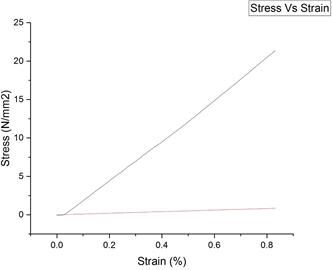

Chart–2:STRESSVSSTRAIN

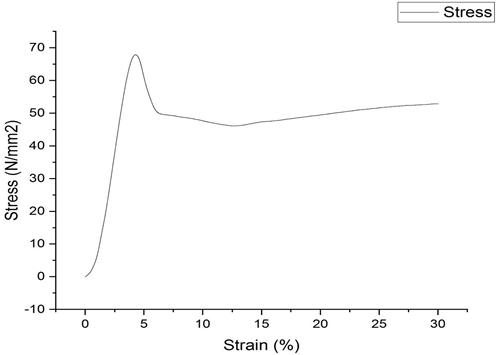

4.2 FLEXURAL TEST GRAPH:

Chart–3:STRESSVSSTRAIN

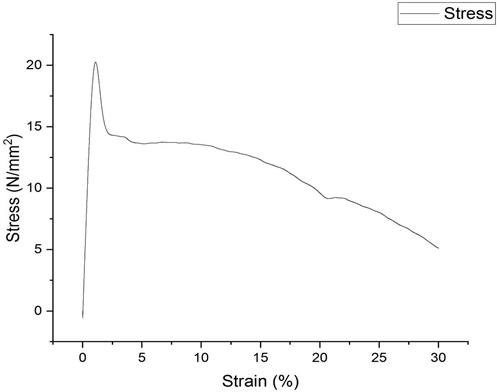

Chart–4:STRESSVSSTRAIN

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

–5:STRESSVSSTRAIN

–6:STRESSVSSTRAIN

5. CNCLUSIONS

Based on the investigation conducted on the tensile and flexural strength of polylactic acid (PLA) based nanocomposites, it can be concluded that incorporating nanoparticles has a significant effect on enhancing the mechanicalpropertiesofPLA.Thenanocompositesexhibited improved tensile and flexural strength compared to pure PLA, indicating their potential for various applications requiring higher mechanical performance. The specific enhancements observed depend on factors such as nanoparticle type, size, and concentration. Further optimization and characterization are necessary to fully exploit the potential of these nanocomposites in practicalapplications.

[1] MarioBragaglia,et.al.,Polylacticacidasbiobasedbinder fortheproductionof3DprintingfilamentsforTi6Al4V

alloymanufacturingviaboundmetaldeposition,Journal ofMaterialResearchandTechnology,27,22023.

[2] Carmen Fonseca, et. al., Poly (lactic acid)/TiO2 nanocompositesasalternativebiocidalandantifungal materials,MaterialscienceandEngineering,57,2015.

[3] Gooya Banaei, et. al., The release of polylactic acid nanoplastics (PLA-NPLs) from commercial teabags. Obtention,characterization,andhazardeffectsoftrueto-life PLA-NPLs, Journal of Hazardous Materials,458,2023

[4] An Xiaoyan, et. al., Application of a new nano- TiO2 compositeantibacterialagentinnursingmanagementof operatingroom:Basedonreal-timeinformationpush assistantsystem,PreventiveMedicine,172,2023

[5] HumaAli,et.al.,Synthesisandcharacterizationofecofriendly TiO2 nanoparticle from combine extract of onionandgarlicpeel,JournalofKingSaudUniversity–Science,35,2023

[6] Alif Daffa Setyoputra, et. al., The Characterisation of MWCNT-rGO-TiO2 Nanocomposite as Potential Electrode Material for Hybrid Supercapacitor, InternationalJournalof

[7] Wen Shen, et. al., Effects on ultrafine fibers with electrospun bead jet method based on 3arm PLA, MaterialsLetters,261,2020

[8] Guilong Wang, et. al., Glass fiber reinforced PLA composite with enhanced mechanical properties, thermal behavior, and foaming ability, Polymer,181,2019

[9] KeZhang,et.al.,Rheologicalanalysisoftitaniumdioxide nano-whiskerbasedelectrorheologicalfluids,Journalof IndustrialandEngineeringChemistry,83,2020

[10] UmairBaig,et.al.,Singlestepproductionofhigh-purity copperoxide-titaniumdioxidenanocompositesandtheir effectiveantibacterialandanti-biofilmactivityagainst drugresistantbacteria,MaterialsScience&Engineering C,113,2022

[11] Diego de Dio Ferreira, et. al., Total Reflection X- ray Fluorescence spectrometry 53 determination of titanium dioxide released from UV-protective textiles duringwash,AppliedRadiationandIsotopes,165,2020

[12] XinLi,et.al.,Materialflowanalysisoftitaniumdioxide and sustainable policy suggestion in China, ResourcesPolicy,67,2020