International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

Prathamesh Jadhav1, Deepa Bagildavar2, Preeti Hiresheddi3, Sunil Huttagannavar4 , Lohit Dalal5, Shridevi Baragi6

1Student, Dept. of Ece engineering, SGBIT Belagavi, Karnataka, India

2Student, Dept. of Ece engineering, SGBIT Belagavi, Karnataka, India

3Student, Dept. of Ece engineering, SGBIT Belagavi, Karnataka, India

4Student, Dept. of Ece engineering, SGBIT Belagavi, Karnataka, India

5Professor, Dept. of Ece engineering, SGBIT Belagavi, Karnataka, India

6Professor, Dept. of Ece engineering, SGBIT Belagavi, Karnataka, India

Abstract- “IOT-basedautomaticbillingandmilkquality management system” is an integrated solution designed toenhancetheefficiencyandaccuracyofmilkprocessing operations. This project focuses on addressing key challenges in the dairy industry by implementing advanced technologies for quality assessment, billing automation, and auto-filling. The system begins with a robust milk quality measurement module, utilizing sensorsanddataanalyticstoassessvariousparameters such as fat content, temperature, and PH. Real-time monitoring ensures that only high-quality milk is processed, contributing to improved product standards andconsumersatisfaction.TheAutoBillingcomponentof the system automates the billing process by integrating with the milk collection data. This eliminates manual errors, streamlines financial transactions, and provides transparent and traceable billing information for both farmers and processors. The system is designed to generate accurate invoices based on the quality and quantity of milk received from individual farmers, promotingfairnessin transactions.In addition, theAutofilling System optimizes the packaging process by employing automated machinery that efficiently measuresanddispenses theappropriatequantityofmilk intopackagingunits.Thisnotonlyreducesthechancesof human errors but also enhances the overall speed and consistencyofthefillingprocess.Theintegration of these threecomponentsintoaseamlesssystemresultinamore streamlined andcost-effectivemilk processing workflow. The project aims to enhance the overall productivity of dairyfarmsandprocessingunits,ensuringthedeliveryof high-quality products toconsumers whilepromotingfair and transparent business practices within the dairy supplychain.

Key words- IoT, Milk quality management, Billing automation,Auto-filling,Dairyindustrychallenges

Thedairyindustryplaysacrucialroleinglobalfood productionandeconomy.Withadvancementsintechnology, therehasbeenaparadigmshifttowardsmodernizingdairy operationsforefficiency,accuracy,andqualityassurance.

OnesuchinnovationistheIoT-basedAutomaticBillingand MilkQualityManagementSystem,aimedatrevolutionizing the traditional milk collection process. The conventional milkcollectionprocessinvolvesmanualsampling,testing, andbilling,whicharelabor-intensive,time-consuming,and prone to errors.Moreover, ensuring milk qualityand fair pricing for both producers and consumers remains a challenge.TheproposedsystemleveragesIoTtechnologyto addressthesechallengesbyautomatingtheentireprocess whileenhancingqualitycontrol.

The advent of the Internet of Things (IoT) has revolutionizedvariousindustries,includingagricultureand dairy farming. One such innovative application is the development of an IoT-based automatic billing and milk quality management system. This system integrates IoT technology with traditional dairy farming practices to streamline operations, enhance. efficiency, and ensure productquality.Atitscore,theIoT-basedautomaticbilling and milk quality management system comprises several interconnectedcomponentsdesignedtomonitor,assess,and managecrucialparametersrelatedtomilkproductionand billing processes. These components include sensors for measuring fat content, pH levels, and temperature of the milk,aswellasmechanismsforauto-fillingcontainersand generatingautomatedbills.

TheIoT-basedsystemconsistsofsensornodesinstalled at milk collection points, processing units, and billing terminals. These nodes are equipped with sensors for measuringkeyparameterssuchasfatcontent,pHlevel,and temperatureofthemilk.Thedatacollectedbythesesensors aretransmittedwirelesslytoacentralprocessingunitwhere theyareanalyzedinreal-time.Thefatcontentmeasurement isparticularlycrucial asitdirectlyimpactsthegradeand market value of the milk. Fat Measurement: Accurate measurement of fat content in milk is essential for determining its quality and value. The system employs specializedsensorsortechniquessuchasultrasonicornearinfraredspectroscopytopreciselymeasurethefatcontent.

Based on the measured parameters, the system automatically grades the milk quality and calculates the appropriate billing amount. Auto-filling mechanisms are

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

employed to streamline the collection process, ensuring accurate quantity measurement and reducing spillage or wastage. Auto billing functionality enables seamless and transparent transactions between dairy farmers and collectioncenters,eliminatingmanualinvoicingerrorsand disputesOneofthekeyfeaturesofthesystemisitsabilityto generate automated bills based on the grade of the milk calculatedfromthemeasurementsobtainedbythesensors.

Thegradeisdeterminedbyfactorssuchasfatcontent,pH levels,andtemperature,whichareindicativeofthemilk's quality. By automating the billing process, the system eliminatestheneedformanualinvoicing,therebysavingtime and reducing administrative overhead

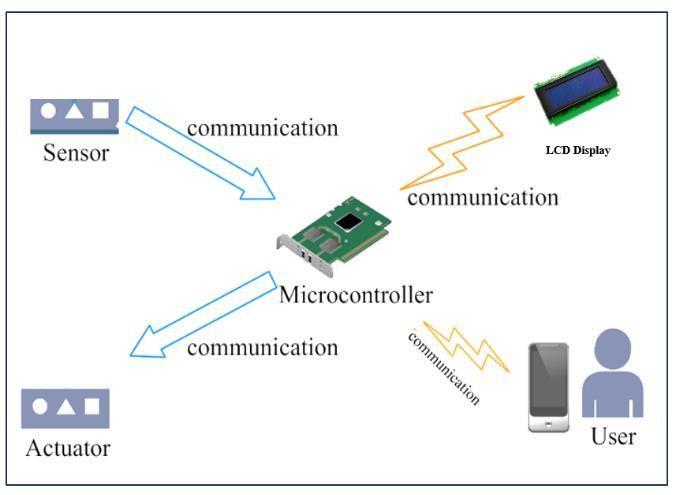

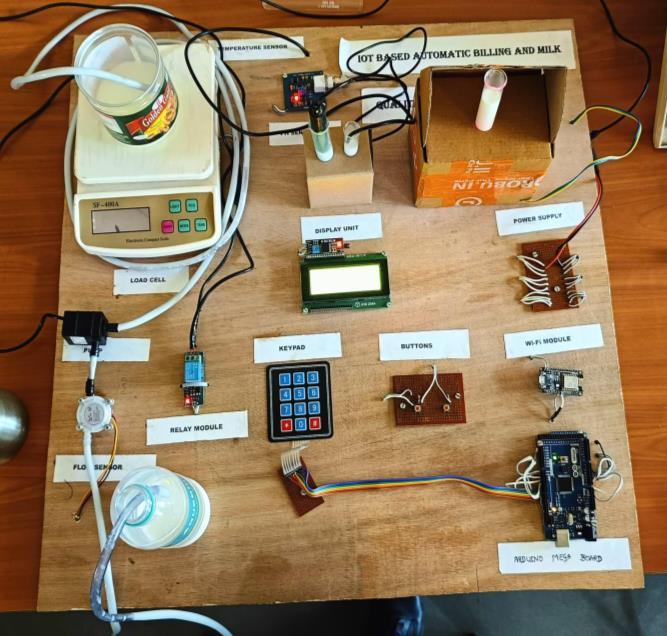

Fig.1.1.1

AnIoTsystemisanetworkofdevicesthatcollectandshare data. The block diagram shows the basic components and how they interact. Sensor: The sensor is used to detect or measureaphysicalcharacteristicoftheenvironment,suchas temperature, light, or motion. Microcontroller: The microcontroller is the brainof the system.It receives data fromthesensor,processesit,andthensendsinstructionsto the actuator. Actuator: The actuator is a device that takes action based on the instructions from the microcontroller. Forexample,itmightturnonanLED,openavalve,orsounda buzzer. LCD Display: The LCD display shows information aboutthesystem,suchassensorreadingsoractuatorstatus Communication: Thecommunicationarrowsshowhowthe different components communicate with each other. The wireless communication system allows the devices to communicatewitheachotherwithoutwires.

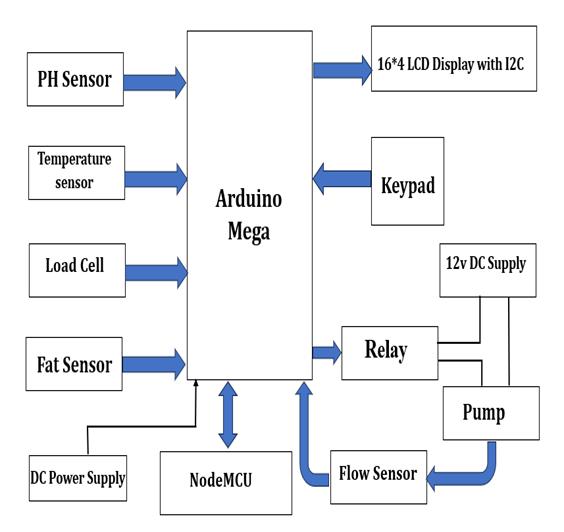

The core of the IoT-based automatic billing and milk quality management system is structured around several key components: sensors PH, temperature, load cell, and fat sensor, a central processing unit Arduino Mega with

ATMEGA328microcontroller,aflowmanagementmodule pumpandflowsensor,andanIoTcommunicationmodule (NodeMCUboard).Eachofthesecomponentsplaysacrucial role in the seamless operation of the system, working in tandemtomeasure,analyze,process,andcommunicatemilk qualityandquantitydata.

MicrocontrollerUnit(MCU)-ArduinoMega

AttheheartofthesystemliestheArduinoMega,whichis equippedwiththeATMEGA328microcontroller.Thisunitis responsiblefor:

Receivingdatafromvarioussensors.

Processing this data to determine milk quality parameterssuchaspH,temperature,fatcontent, andvolume.

Calculatingthegradeandpriceofthemilkbased onpredefinedcriteriaandalgorithms.

Managinguserinputsandoutputsthroughauser interface.

Controlling peripheral devices like pumps and sensorsbasedonuserrequestsandsensordata.

Fig.2.1BlockDiagramofTheProposedMethod

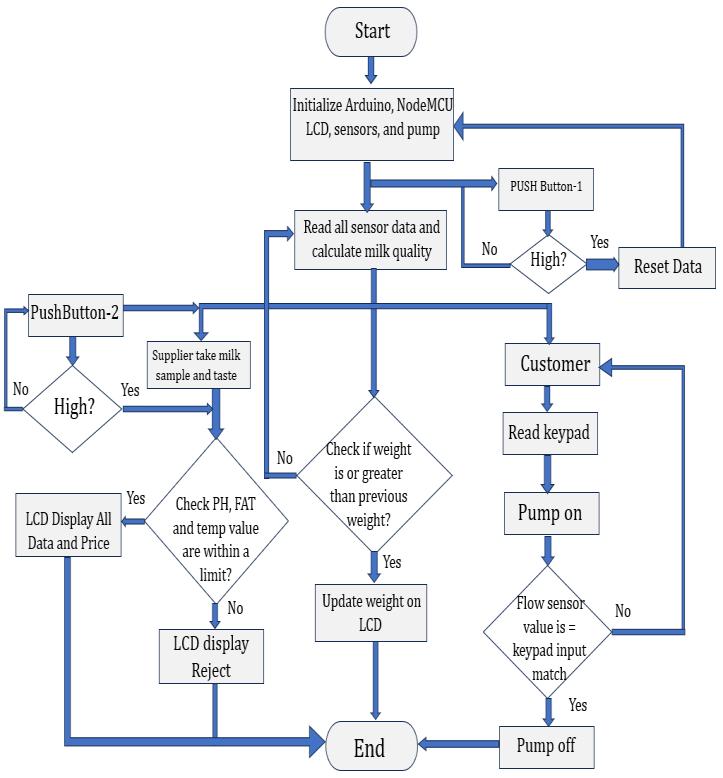

TheFlowchartofthisproposeddepictstheprocessofmilk qualitymanagementthatusesIoT(InternetofThings)to enhanceefficiency

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

2.2FlowchartoftheproposedSystem

Initial Display:Thesystempowersupanddisplays "Milk QualityManagementSystem"ontheLCD.

Check Stock:Thesystemchecksifthereisstock(milk)on theweightsensor.

Ifstockispresent,itdisplaysthestockvalue.

Ifnostockisdetected,itcontinuestodisplay"Milk QualityManagementSystem".

User Action - Calculate:

Iftheuserpressesthe'Calculate'button,thesystem proceedstogatherinputfromvarioussensors(like temperature,fatcontent,etc.).

Themilkparametersandpricearethencalculated basedontheseinputsanddisplayedontheLCD.If the 'Calculate' button is not pressed, the system continuestodisplaythestockvalue.

User Action - Reset:

Iftheuserpressesthe'Reset'buttonatthisstage,the system returns to the initial display of "Milk Quality ManagementSystem".Ifnot,theprocessmovestothe nextuserdecisionpoint.

User Sale Input:

Theuserinputsthedesiredamountofmilktoselltothe customerviaakeypad.

Ifthe'#'keyispressed,the pumpstartsandthemilk dispensingbegins.

If the '#' key is not pressed, the system prompts for correctinputsuntilitisprovided.

Pumping and Monitoring:

While the pump is active, the flow sensor continuouslymonitorsthemilkflow.

If an out-of-range flow is detected, the pump is stopped.

If the flow is within the acceptable range, the pumpingcontinues.

Final User Action - Reset:

Ifduringorafterthesale,theuser pressesthe'Reset' button, the system returns to the initial display "Milk QualityManagementSystem".

Ifthe'Reset'buttonisnotpressedafterthetransaction is completed, the system ends the current operation cycle,readyforanewone.

This flow chart ensures that the milk quality managementsystemoperatesefficiently,handlingstock checks,userinputs,andsalestransactionssystematically whilecontinuouslymonitoringandadjustingbasedon userinteractionsandsensordata.

1. Data Acquisition: Sensors continuously monitor and gatherdataonmilkparameters.

2.DataProcessing:TheArduinoMegaanalyzessensordatato determinemilkqualityandcalculatepricing

3.UserInteraction:Throughauserinterface,thesellercan inputthedesiredamountofmilktosell,whichtriggersthe systemtodispensemilkusingthepumpandmeasurethe amountusingtheflowsensor.

4.DataCommunication:TheNodeMCUtransmitsallrelevant datatoacloudserverorlocalhost,allowingforreal-time trackingandmanagement.

5. AutomaticBilling:Basedonthequalityandquantityof milkdispensed,thesystemautomaticallycalculatesthecost, whichcanbeinstantlycommunicatedtothecustomerand processedfortransaction.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

TheproposedIoT-basedsystemautomatescriticalaspectsof milk quality management and billing, providing a scalable, efficient,anduser-friendlysolutionfordairybusinesses.By integratingadvancedsensors,robustprocessingcapabilities, andIoTconnectivity,thesystemensureshigh-qualitydairy products reach consumers in an economically efficient manner.Futureenhancementsmayincludeintegrationwith blockchainforsecuretransactionsandexpandedanalyticsfor predictivemaintenanceandsupplychainoptimization.This detailed block diagrammethodologynotonlyillustrates the interconnectivityofthecomponentsbutalsounderscoresthe practicalimpactofIoTinmodernagriculturalpractices.

The "IoT-Based automatic billing and Milk Quality Managementsystem"marksasignificantadvancementinthe dairyindustry,addressingvariouslong-standingchallenges through the application of the Internet of Things. This comprehensive solution integrates state-of-the-art technologiestoenhancethequalitycontrol,billing,andfilling processesinthedairysupplychain,ensuringaseamlessflow from farm to consumer. Enhancing Milk Quality with IoT Sensors:AtthecoreofthisinnovativesystemareIoT-enabled qualitysensorsstrategicallydeployedatcriticalpointsinthe supplychain.Thesesensorsperformreal-timeanalysisofthe milktodetectparameterssuchastemperature,pHlevels,and bacterialcontent.Thisimmediatedatacaptureensuresthat anydeviationfromestablishedqualitystandardsisquickly identified,allowingforpromptactiontorectifyanyissues, therebymaintainingtheintegrityandsafetyofthemilk.AutoBilling Module: The auto-billing module is a critical component of this system. It utilizes the data from IoT sensorstoaccuratelycalculatechargesbasedonthequality and quantity of milk delivered. This automation ensures transparency and fairness in billing, reducing errors associated with manual entry and helping to build trust betweendairyfarmersandprocessors,aswellasbetween processorsandretailers.EnergyandResourceEfficiency:The IoTsystemoptimizestheuseofenergyandresourcesacross the dairy processing chain. By aligning energy usage and resourceallocationwithactualproductionneeds,thesystem reducesexcessconsumptionandminimizeswaste.Thisnot only lowers operational costs but also contributes to the environmentalgoalsofthedairyindustry.Transparencyand Traceability:Everystepofthemilk'sjourneyfromthefarmto the consumer is recorded and monitored through the IoT system.Thisleveloftraceabilityisinvaluableforconsumer confidence and regulatory compliance. Consumers increasinglydemandtransparencyinthefoodsupplychain, andthissystemprovidesitbyofferingdetailedinformation abouttheproduct’sorigin,handling,andquality.

ImpactontheDairySupplyChain:Byintegratingthese technologies,thesystemtransformstheentiredairysupply chain. It enhances efficiency and transparency, reduces waste,andimprovesproductquality.Theseimprovements

can lead to better market competitiveness for dairy businessesandhighersatisfactionforconsumers.

Theresultsanddiscussionsectionsprovideinsightsinto thedatacollectedduringtheexperimentationphaseofthe projectandelaborateontheirimplicationsinthecontextof theIoT-basedautomaticbillingandmilkqualitymanagement system.

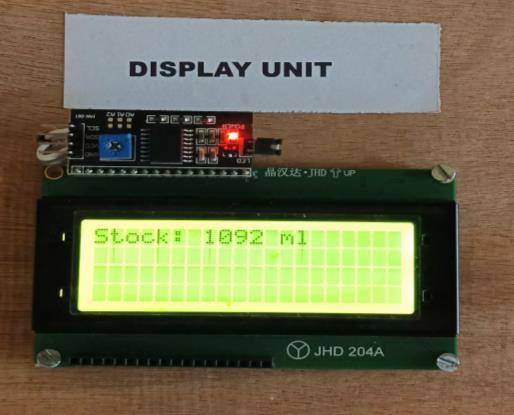

The system accurately measured the weight of the milk usingaloadcell,providingoutputdisplayedontheLCDas stock value. This real-time feedback on the milk's weight allowedforefficientinventorymanagementandensuredthat themilksupplycouldbecloselymonitored.Throughmultiple testsandcalibrationoftheloadcell,thesystemconsistently provided precise readings. This reliability is essential for maintainingasmoothworkflowandavoidingdiscrepanciesin billingorinventorycontrol.

The PH sensor and temperaturesensorprovided essential data onthe quality ofthe milk. The PHvalue indicates the milk'sacidity, which isan importantfactor indetermining freshnessandsuitabilityforconsumption.Thetemperature sensorensured that themilk was storedatanappropriate temperaturetopreserveitsquality.Thesystemeffectively tracked these parameters and displayed them on the LCD, allowing for immediate assessment and decision-making. This comprehensive monitoring of PH and temperature helped in adhering to quality standards and regulatory requirements.

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

Price Calculation

Fig.4.3PriceCalculation

ApricingtablewascreatedbasedonthevaluesofPH,fat content, and temperature. This table was designed to accountforvariationsinmilkqualityandensurefairand dynamic pricing for the consumer.Byusingthesystem's dataonmilkquality,thepricingtablecouldadjustpricesin real-timetoreflectchangesinthemilk'scharacteristics.This dynamicpricingstrategyisbeneficialforboththesellerand thebuyer,asitensuresthesalepricematchesthemilk's quality.

Fig.4.4DispensingofMilk

Thesystemwasequippedwithaflowsensortodispensemilk according to the user's requirements. The flow sensor measuredthequantityofmilkdispensed,ensuringthatthe exact amount requested by the customer was delivered. Whenthedesiredamountwasdispensed,thepumpwould automaticallyturnoff,preventinganyoverfloworwastage. This level of precision in dispensing not only improved customer satisfaction but also helped in accurately billing customersbasedonthevolumeofmilkpurchased.

IoT-BasedAutomaticBillingandMilkQualityManagement System We have developeda comprehensive solution that addresseskeyaspectsofmilkproduction,qualityassessment, anddistribution.Thisprojectintegratesseveralcomponents, includingloadcells,pHsensors,temperaturesensors,anda custom-designedmilkfatsensor,toaccuratelymeasureand monitor various properties of the milk. The data collected fromthese sensors is displayed on anLCDscreen for easy visualization and monitoring. The project also includes an automaticbillinganddispensingsystemthatallowsusersto enter the desired amount of milk they wish to sell to customers.Thesystemthendispensesthespecifiedamount of milk and calculates the price based on the milk's parameters,suchasweight,pHvalue,temperature,andfat content. The integration of IoT technology in this project enhancestheefficiencyandreliabilityofmilkproductionand distributionprocesses.Byautomatingthemeasurementand monitoring of milk properties, the system reduces the likelihoodofhumanerror and ensures that the milk meets qualitystandards.Thiscontributestocustomersatisfaction and builds trust in the milk's quality.The project also

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

highlightstheimportanceofreal-timedatavisualizationand decision-making.Theabilitytoquicklyassessandrespondto changes in milk quality and quantity allows producers to optimize their operations and maintain consistent quality. Furthermore,theprojectdemonstratesthepotentialforIoT technology to revolutionize traditional industries by providing innovative solutions that improve productivity, qualitycontrol,andcustomerservice

In conclusion, IoT Based Automatic Billing and Milk QualityManagementSystemisasignificantachievementthat showcasesthepotentialofintegratingadvancedtechnology intothedairyindustry.Byprovidingaccuratemeasurements, efficientbilling,andqualitycontrol,thesystemcontributesto a more streamlined and effective approach to milk productionanddistribution.Thisprojectpavesthewayfor further innovations in the field and serves as a model for otherindustriesseekingtoadoptIoTsolutions.

[1] Dr G Rajakumar, Dr T Ananth Kumar, Dr TS Arun Samuel,DrEMuthuKumaran,“IoTBasedMilkMonitoring SystemforDetectionofMilkAdulteration”,IJPAM,2018.

[2]SumitraGoswami,AshokDangi,“Arduino-BasedMilk Quality Monitoring System”, International Journal of Agriculture Environment & Biotechnology, Volume 14, Issue2,IJAEB,2021.

[3]MSujatha,PNagarjuna,AHemanthVenkata,“Visible spectroscopy analysis of fat content in milk using LabVIEW”, International Journal of Recent Technology andEngineeringVolume-7,Issue5S4,IJRTE,2019.

[4] Manisa Rathi A. and Raveesh SJ Proposed a “AutomatedMilkQualityAnalyzerwithBillingSystem”inthe International Journal of Environment, Agriculture and Biotechnologyin2022

[5]Prof.DiptiS.Bhade1,ShradhaJ.Dobariya,SanchitaS. Landge, Prachi D. Babhale, Veebha M. Proposed a “ImplementationOfIotBasedMilkQualityAnalyzerUsing AVRMicrocontroller”intheJETIRMay2019.

[6] Sanya Kaunkid, Apinan Aurasopon, and Anut Chantiratiku Proposed a “Automatic Milk Quantity RecordingSystemforSmall-ScaleDairyFarmsBasedon InternetofThings”

[7] V.Hema,, N. Monishkumar, N. Nandhakumar, B. Narmadha Proposed a “Iot Based Milk Monitoring System For Detection Of Milk Quality Using Sensor” in IJCRT2020.

[8] Dhamale Avinash, Game Avinash, Kandekar Kiran, Prof. RG Dabhade, “Milk Analyzing and Billing System”, Vol2,Issue2,IJARIIE,2016.

[9].CristianPiras,OliverJHale,ChristopherKReynolds,AK Jones, Nick Taylor, Michael Morris, Rainer Cramer, “Speciation and milk adulteration analysis by rapid ambientliquidMALDImassspectrometryprofilingusing machine learning”, Biotechnology and Biological Sciences ResearchCouncil,2020.