International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Mohd Nazim1 , Mridul Anand2 , Parveen Prajapati3

Delhi Technological University, Rohini Delhi 110042

Abstract - This project addresses the growing importance of bulletproof vests in safeguarding individuals within high-risk occupations, particularly law enforcement and military personnel. Bulletproof vests serve a dual purpose as both a barrier and an energy absorber, mitigating the impact of bullets and protecting users. Our study employs the Finite Element Method (FEM) to conduct an impact analysis, focusing on Three primary composite materials used in bulletproofvests:Aramid,Ultra-high-molecularweight polyethylene (UHMWPE) , ceramic .

Key Words: Impactanalysis,Bulletproofvest,Composite materials,Aramid,UHMWPE,Ceramic.

1.INTRODUCTION

1.1 Etymology

Inadynamicallychangingworldwhereprioritizingpersonal safety is paramount, the continuous advancement of effectiveprotectivegearhasemergedasapivotalfocusof research. Within the spectrum of protective equipment, bulletproof vests stand out as indispensable guardians, playingacriticalroleinensuringthesafetyandwell-beingof law enforcement personnel, military operatives, and individualsengagedinhigh-riskprofessions.

Bulletproofvests,alternativelyreferredtoasballisticvests orbodyarmor,aremeticulouslycraftedtoofferdependable protection against ballistic threats, including bullets and projectiles.Theseexceptionalpiecesofequipmentboasta storiedhistory,undergoingcontinuousevolutiontoachieve enhancedcharacteristicssuchasgreaterlightweightdesign, flexibility, and the capacity to withstand the impact of progressivelypowerfulfirearms.

The efficacy of bulletproof vests is intricately tied to the materialsemployedintheirconstruction.Earlyiterationsof thesevestsfeaturedthicklayerscraftedfrommaterialslike silk, leather, and even metal plates. Nevertheless, the landscapeofbodyarmorunderwentatransformativeshift with the advent of composite materials, marking a substantial leap in protective technology. This innovation notonlyelevatedthelevelofsafeguardingbutalsoresulted in a remarkable reduction in both weight and bulkiness, redefiningthestandardsofmodernbodyarmor.

Composite materials represent an innovative class of engineeredmaterialsformedbytheamalgamationoftwoor more constituent materials, each possessing distinct properties.Thisstrategiccombinationistailoredtoharness the strengths of each component, yielding performance characteristics that surpass those of individual materials usedinisolation.Withintherealmofbulletproofvests,the integrationofcompositeshasusheredinatransformative era,fundamentallyalteringthelandscapeofprotectivegear. This advancement has facilitated the development of lightweight,flexible,andexceptionallyeffectivebodyarmor, marking a paradigm shift in the approach to personal protection.

Composite materials, comprising two or more distinct phases, are strategically combined to attain specific propertiessuchasstrength,stiffness,andtoughness.Inthe realmofbulletproofvests,thesematerialsformprotective layerscapableofabsorbinganddistributingtheimpactofa bullet.Aramidfibers,Kevlar,andultra-highmolecularweight polyethylene (UHMWPE) fibers are widely employed in bulletproof vests. Aramid fibers, known for their high strength to-weight ratio, offer exceptional ballistic protection, while UHMWPE fibers, with their lightweight nature, provide excellent ballistic defense. Kevlar is incredibly strong, about five times stronger than steel by weight. these materials have demonstrated superior protectivecapabilitiesinvariousstudies.

Aramid fibers, derived from synthetic polymers containing amide groups, boast high tensile strength, a superior modulus, and exceptional resistance to abrasion, heat,andchemicals.Theirlightweightdesignenhancestheir ballisticprotectionagainsthigh-velocityprojectiles.Onthe other hand, UHMWPE fibers, crafted from extended polyethylenemolecules,exhibitanimpressivestrength-toweight ratio, excelling in strength for their weight. These fibers are highly resistant to abrasion, chemicals, and UV radiation,providingrobustballisticprotectionagainsthighvelocityprojectiles.

ComparisonofsomepropertiesofAramidandUHMWPE fibresandceramic

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Properties

1 Tensile High Tensile strength of3-Gpa Even higher tensile strength of 3.5-4.5 GPa Comparable tensile strength (approx. 3-4 Gpa)

2 Elasticity Low elasticity Young’s modulus: 70140Gpa High elasticity Young’s modulus: 80150Gpa Lowelasticity similar to aramid for durability

3 Abrasion Resistance Excellent abrasion resistance Good abrasion resistance Highabrasion resistancefor prolonged effectiveness

4 Chemical Resistance Good chemical resistance Good chemical resistance Resistant to checmicals, suitable for diverse environments

5 Heat Resistance Good heat resistance, melting point: 500-600 degree Lower melting point: 130-150 degree High heat resistance with a meltingpoint beyond 1600 degree

1.4 ARMOR CLASSIFICATION FOR BALLISTIC RESISTANT ARMOR

IS17051:2018servesastheprincipalstandardinIndiafor assessing the ballistic resistance of personal body armor, particularlybullet-resistantjackets.Specificallydesignedfor use by law enforcement and military personnel, this standard delineates the minimum performance requirementsacrossseventhreatlevels.Itprovidesexplicit testingprotocols,performancecriteria,andacomprehensive certification process for bullet-resistant jackets in accordancewithIndianregulations

Table 2: ThreatLevelsforbulletresistancejacketsasper IS17051:2018

Intheprojectreport,AnsysExplicitDynamicswasemployed for analyzing the impact on composite materials used in bulletproof vests. This numerical method is specifically tailoredfordynamicandtransienteventssuchasimpacts, explosions,andcrashsimulations.Explicitdynamicsexcels atcapturinghighstrainratesandrapidmaterialresponses associated with such dynamic occurrences. When a bullet impactsacompositematerial,itimpartssignificantenergy overashortduration,resultinginlocalizeddeformationand stress concentration. The utilization of explicit dynamics enables accurate simulation of these rapid and transient phenomena, providing precise predictions of material behaviorunderimpactconditions.

Incontrast,Implicitdynamics,orimplicittimeintegration,is a method suited for solving problems involving slow and gradual changes in structural behavior over time. Implicit dynamicstypicallyemployslargertimestepsizescompared totheexplicitdynamicsapproach.

Twonumericalmethodscommonlyusedforsolvingimpact problemsaretheFiniteDifferenceMethod(FDM) and the FiniteElementMethod(FEM).FDM iscapableofhandling complexgeometriesbutrequiresastructuredgridcovering the entire domain, often applied to regular grids like Cartesiangridsoradaptedforirregulargrids.Ontheother hand, FEM is well-suited for intricate geometries and irregular domains, accommodating unstructured meshes whereelementsarenotnecessarilyalignedregularly.This flexibility makes FEM a popular choice for problems involving complex geometries or regions with varying materialproperties,aligningwithourchoiceforanalysis.

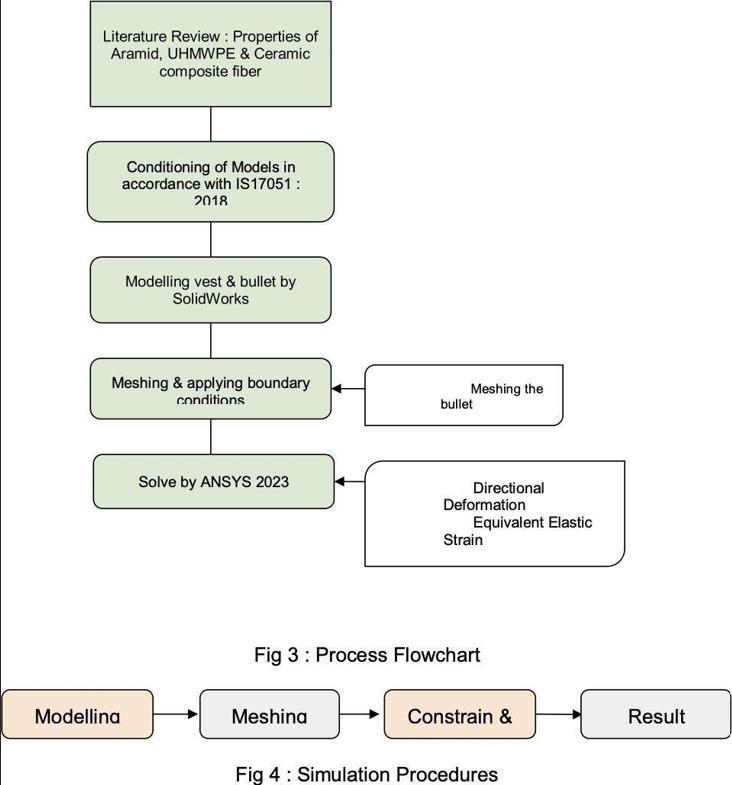

The research stages, as illustrated in the flowchart below, involve a sequential process encompassing various stages andteststoensuretheacquisitionofoptimalresults.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

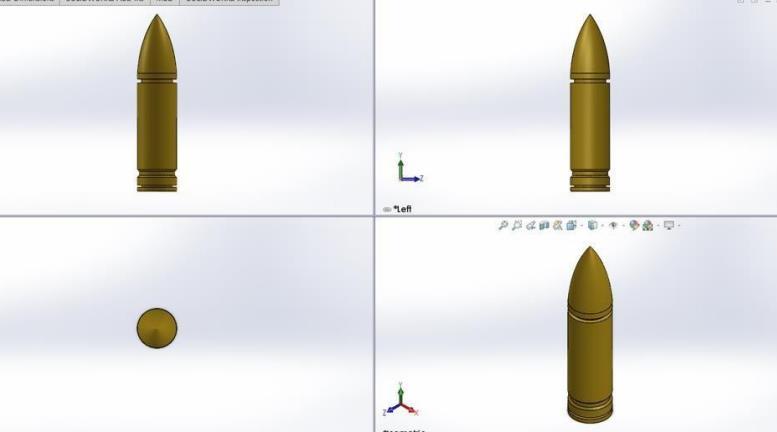

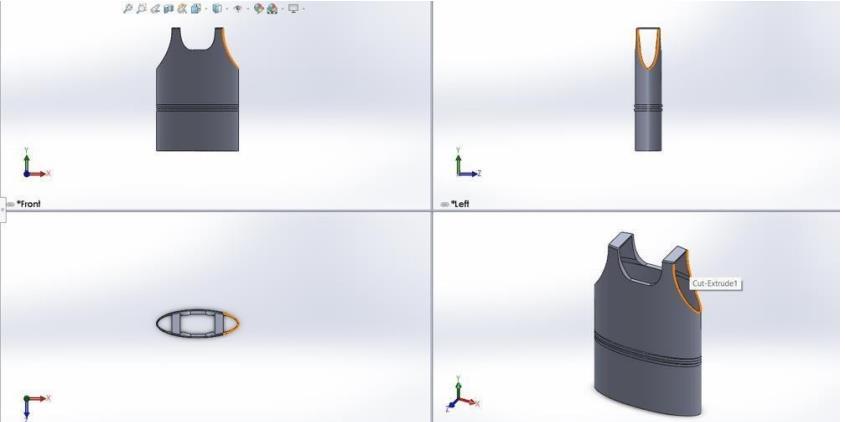

The first step in the analysis is to create models for the Bulletproof vest and the bullet using SolidWorks 3D modelingsoftwarepackage.Sotocreateaballisticsetup,we needtofirstcreatethesketches,partsandthenassembleits partsi.e.vestandbullet

Table 3:DimensionsofBulletsandBulletProof-Vest

Threat Levels Bullet Dimensions Bullet Weight Vest Thickness Distance ofImpact

Threat Level1 9x19mm 7.88gm 10mm 5m

Dimensionsandweightofbulletsareinaccordancewiththe armorclassificationof IS17051:2018 givenbytheBureauof IndianStandards.

Solidwork Model

ToimporttheSolidWorksassemblyintoAnsyssoftwarefor the analysis, we need to first save the SolidWorks assembly(which is currently in .SLDASM format) to .IGS format,sothatitcouldbeeasilyimportedgeometryduring theexplicitdynamicsanalysis.

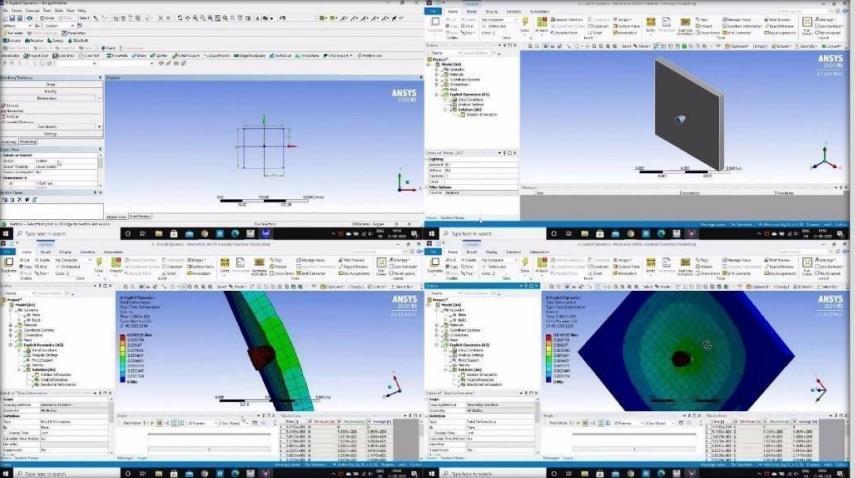

These are the steps to do the setup in Ansys : Step 1: First we need to create a new project in Ansys by openingAnsysWorkbench.

Step2:Nowweneedtoselecttheanalysissystemwewant touse,herewehaveusedExplicitDynamics

Step3:Nowthenextstepistoimportthegeometryintothe AnsyssoftwareforFEAanalysis

Step4:WeneedtogototheAnsysMechanicalsoftwareby right-clickingontheModelOptionandthenbyselectingthe Edit option, this will take us to where we will doing the actualanalysispart.

Table 4: Meshingindifferentthreatlevels

Properties ThreatLevel1 ThreatLevel2 Element

CurvatureMinSize 0.005m 0.015m ElementOrder Linear Linear

Table 5: BoundaryconditionsonModelsatdifferent threatlevels

Properties Threatlevel1 ThreatLevel2

Speed 500m/s 710m/s

Distanceofimpact 5m 10m

Endtime 0.012s 0.014s

ResultNumberofpoints 20 20

FixedSupport

Both sides & bottom of the vestdesign Both sides & bottom of the vestdesign

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

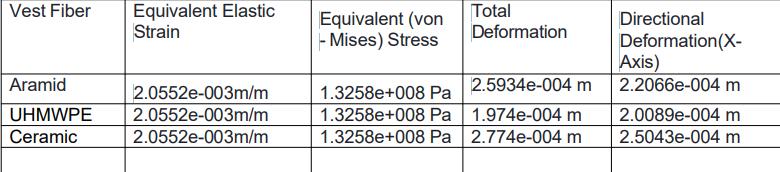

Now,inthefinalphase,wedelineatethespecificoutcomes sought post-simulation. The ensuing values represent the key parameters obtained upon the completion of the simulation.

1.TotalDeformation

2.EquivalentStress

3.EquivalentElasticStrain

Aramid Bullet Proof Results

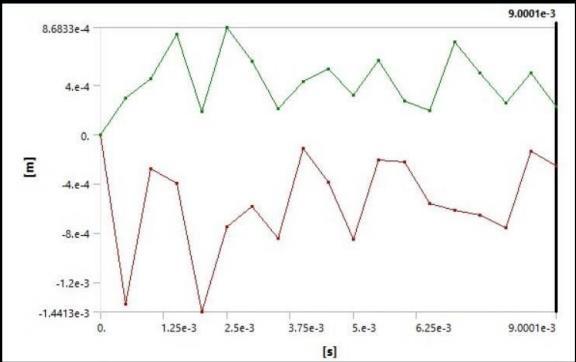

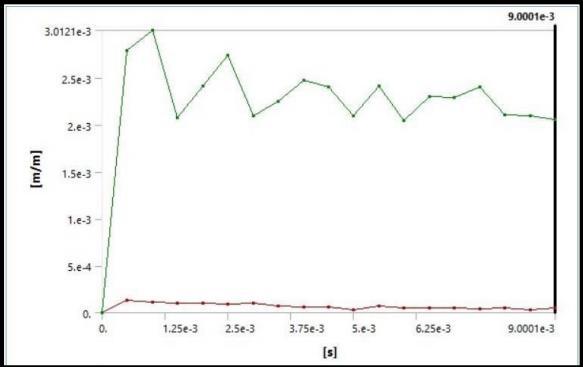

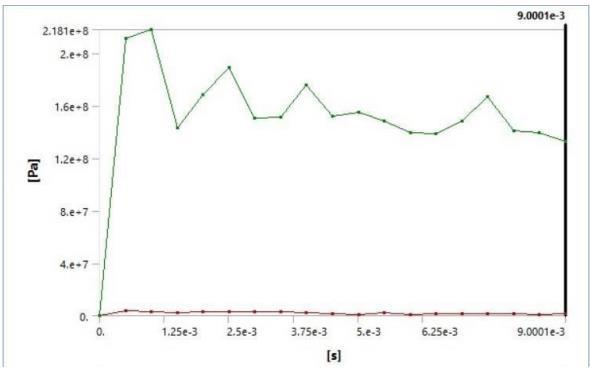

Directional Deformation (X-axis)

Equivalent Elastic Strain

Equivalent Stress

3. CONCLUSIONS

•Conductedimpactanalysisonbulletproofvests'composite materials(Aramid,UHMWPE)usingFEMinSolidWorksand Ansys2023R1software.

• Simlated bullet impact per Bureau of Indian Stanards (IS17051:2018),assessingdeformation,strain,stress,and velocities.

• Identified UHMWPE's better impact distribution while noting Aramid's superior energy absorption and reduced penetrationinhandgunbullettests

[1].M.Grujicic,P.S.Glomski,Material,―MaterialModeling andBallisticResistanceAnalysisofArmor-GradeComposites ReinforcedwithHighPerformanceFibers,ASMInternational, January2009

[2]. Priyawart Lather, ― Analysis of composite materials usedinbulletproofvestsusingfemtechnique,International JournalofScientific&EngineeringResearch,May-2013.

[3].BureauofIndianStandards,IS17051:2018,“TEXTILES BULLET RESISTANT JACKETS PERFORMANCE REQUIREMENTS”

[4].NaveenKumar,“BulletproofVestandItsImprovement–AReview”January2016IJSDR|Volume1,Issue1

[5]. Muruganantham.S1, Sabarimoorthy.S2, Sivamani.D2 “Designandanalysisofbulletproofjacket”IJIAREC,Volume7Issue-2

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

[6]. Jeyasri J1, Ajith.M2, Darshan N C3, ManiBharathi, Sivasankar,“DESIGNANDFABRICATIONOFBULLETPROOF VEST”JETIRMay2019,Volume6,Issue5

[7].SashiKant,TanujJoshi,andRavikantSharma,“Modeling and Analysis of CompositeBullet-Resistant Jacket“, ResearchGate,April2021.

[8]. Muhammad Anhar Pulungan1, Sutikno2, M S M Sani3 “Analysis of Bulletproof Vest Made from Fiber Carbon Composite and Hollow Glass Microsphere (HGM) in AbsorbingEnergyduetoProjectileImpact”,IOPPublishing.

[9].DBürger,ARochadeFaria,SFMdeAlmeida,FCLde Melo,MaurícioV.Donadon2012“Ballisticimpactsimulation of an armor-piercing projectile on hybrid ceramic/fiber reinforcedcompositearmours“,ScienceDirect.

[10].AARamadhan,”The Influence of Impact on Composite ArmourSystemKevlar 29/polyester-Al2O3”,International Conference on Mechanical Engineering Research, 2011.

[11].ThiyagarajanK,MartinL,ElayarajaN,SivaprakasamP (2014) ”Modelling of kevlar-Al alloys and finite element simulationof mechanical properties''.ARPNJEngAppl Sci 9(5):599–607.