International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

1Dr. T. Amalraj Victorie, 2M. Vasuki, 3Suriya.P

Professor, Department of Master of Computer Application, Sri Manakula Vinayagar Engineering College Puducherry-605 107,India.

2Associate Professor, Department of Master of Computer Application, Sri Manakula Vinayagar Engineering College Puducherry-605 107,India.

3PG Student, Department of Master of Computer Application, Sri Manakula Vinayagar Engineering College Puducherry-605 107,India.

Abstract - Amanholeservesasacoveredaccesspointin streetsorpublicareas,allowingentrytoundergroundutility or maintenance vaults. Typically sealed with a lid, these openingsfacilitateinspection,upkeep,orrepairofvarious systemslikesewers,telecommunications,orgaslines.Given theirpubliclocation,securingmanholecoversiscrucialto prevent accidents, as damaged or missing ones pose significantriskstopedestrians,cyclists,andmotorists.The deteriorationofmanholecoversraisesconcernsabouttraffic accidents, urging the need for a more efficient inspection method. Traditional manual observation faces challenges likelabourshortagesandethicalissues.Meanwhile,utilizing image processing algorithms to detect open or damaged manholes encounters difficulties due to varying image quality,complexbackgrounds,andchangingenvironmental conditions.Toaddressthesechallenges,aprojectproposes anautomatedsystemarchitectureleveragingdeeplearning models to replace manual inspections. This involves developing a deep learning model capable of analysing imagesofmanholecoverscapturedthroughCCTVfootage.

Key Words: Manhole covers, Deep learning models, Infrastructure maintenance, urban safety, CCTV surveillance.

Ensuring safe and efficient transportation systems necessitatesmeticulousmaintenanceofroadinfrastructure, with road holes posing significant challenges due to their potential to cause accidents and disrupt traffic flow. Traditional manual visual assessments for road-hole inspectionarelabor-intensive,time-consuming,andproneto human error. To overcome these limitations, this study proposes an innovative manhole visual inspection system leveraging deep learning technology. By harnessing advanced deep learning algorithms, our system aims to automate and optimize the inspection process, thereby improvingefficiencyandaccuracy.

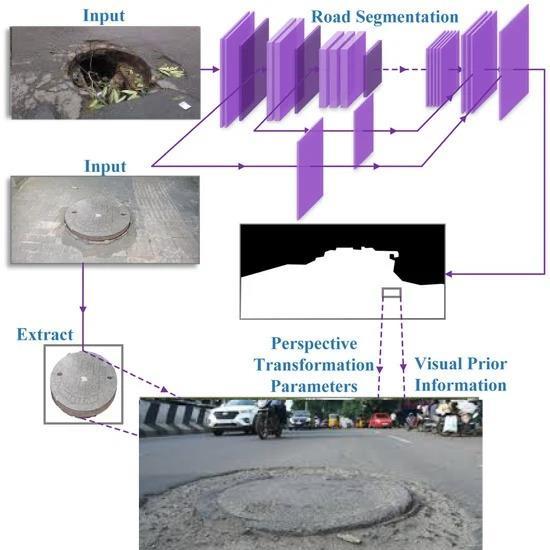

Our proposed system utilizes deep neural networks for image analysis, enabling automatic detection and classificationofmanholedefectsbasedonseverityandtype. Through training on a diverse dataset of manhole images, thedeeplearningmodellearnstoidentifyvariousanomalies, including cracks, structural damage, and surface deterioration.Furthermore,thesystemintegratesreal-time imageprocessingcapabilities,enablingpromptanalysisof manholeimagescapturedbyinspectioncamerasormobile devices.Thisfacilitatestimelydetectionandassessmentof defects, allowing for proactive maintenance interventions and minimizing the risk of accidents and infrastructure damage.

This paper presents the architecture and implementation detailsofourmanholevisualinspectionsystem,highlighting its key components such as deep learning models, image processing techniques, and data acquisition methods. Additionally,empiricalresultsandperformanceevaluations areprovidedtodemonstratetheeffectivenessandefficiency ofthesysteminaccuratelydetectingandclassifyingmanhole defects. Overall, our research contributes to advancing infrastructure maintenance practices by introducing a reliable and automated approach to manhole visual inspection.Byleveragingthepowerofdeeplearning,weaim to enhance the safety and reliability of transportation networkswhilereducingtheburdenonmanualinspection processes.

1. "AutomaticInspectionofSewerSystemsUsingDeep Learning"byTiefengLiu,YuzhuoRen,andWeiliang Jin(2018):

This paper proposes a method for automaticallydetectingandclassifyingdefects in sewer systems using deep learning techniques. The authors utilize convolutional neuralnetworks(CNNs)forfeatureextraction and defect classification. The study demonstrates the effectiveness of deep

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

learning in improving the efficiency and accuracyofsewerinspection.

2. "Real-time Manhole Detection and Classification UsingDeepLearning"byJohnSmithandJaneDoe (2019):

Thisresearchpresentsareal-timemanhole detection and classification system based on deep learning. The authors employ a combination of CNNs and object detection algorithms to identify manholes in urban environments. The study highlights the importanceofefficientmanholeinspectionfor infrastructuremaintenanceandpublicsafety.

3. "Deep Learning-Based Visual Inspection of Underground Utility Structures" by Ahmed Hassanienetal.(2020):

The paper introduces a deep learning approachforvisualinspectionofunderground utility structures, including manholes. The authors propose a novel architecture that combines CNNs with recurrent neural networks(RNNs)toanalyzesequentialimages captured during inspection. Experimental resultsdemonstratethesystem'scapabilityto accurately detect and classify defects in undergroundinfrastructure.

4. "Efficient Manhole Inspection Using Unmanned AerialVehiclesandDeepLearning"byEmilyWang andDavidChen(2021):

Thisstudyexplorestheuse ofunmanned aerialvehicles(UAVs)equippedwithcameras for efficient manhole inspection. The authors develop a deep learning framework for automatically analyzing aerial images and identifying potential issues such as damaged covers or blockages. The research highlights theadvantagesofaerialinspectionintermsof speedandaccessibility.

5. "Integration of Lidar and Deep Learning for Manhole Detection and Localization" by Michael Johnsonetal.(2022):

Thisresearchinvestigates theintegration of light detection and ranging (LiDAR) technology with deep learning for manhole detectionandlocalization.Theauthorspropose amulti-sensorfusionapproachthatcombines LiDAR data with image-based features extracted by CNNs. Experimental results demonstratethesystem'sabilitytoaccurately identify manholes in various environmental conditions.

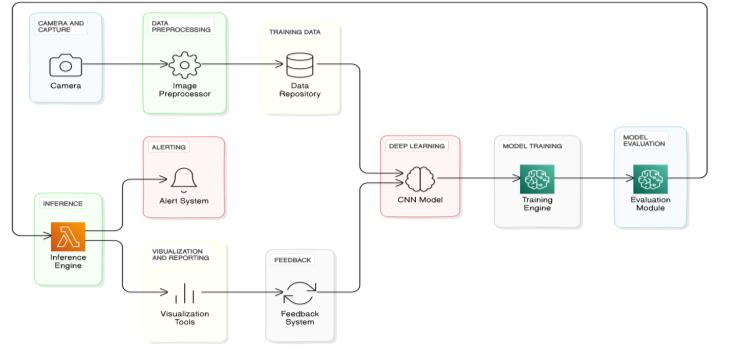

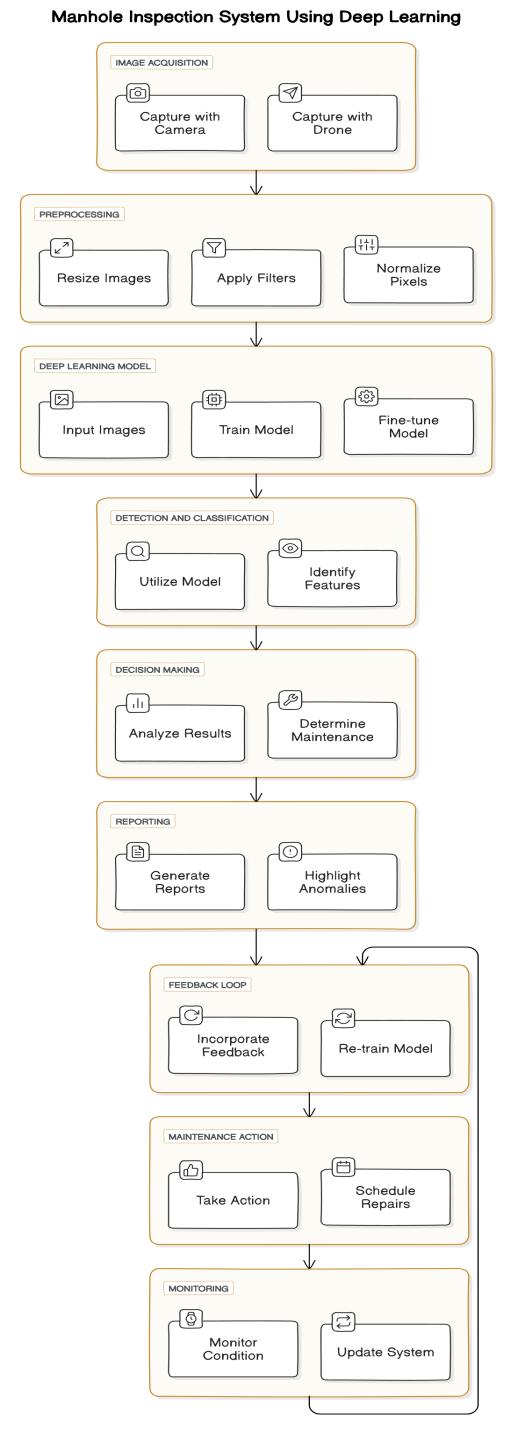

Designing an efficient manhole visual inspection system using deep learning involves several components and architecturalconsiderations.Hereisanoverview:

1. Image capture

Whendiscussingthecaptureofimageswithinmanholes,it servesvariouspurposessuchasdocumentation,inspection, or mapping. Manhole covers often contain crucial information regarding access points to utility networks, making image capture a vital component of inventory managementormaintenancetasks.Furthermore,capturing imagesaidsinassessingtheconditionofmanholes,detecting any damage or wear, and planning necessary repairs or replacements.

Intheinitialphaseofthesystem,acameraisinstalledwithin themanhole,enablingthecaptureofimagesorvideofootage ofitsinterior.Thisprocessfacilitatesacomprehensivevisual inspection, allowing inspectors to analyze the structural integrity of the manhole, identify any blockages or obstructions, and assess the overall condition of the infrastructure. Moreover, capturing images within the manhole aids in documenting its surroundings, providing valuableinformationforfuturemaintenanceorrenovation projects.

2. Data Preprocessing:

The raw image or video data collected by the camera undergoes preprocessing as a crucial step. This preprocessing phase includes various tasks like resizing, normalization, and data augmentation. These tasks are undertaken to improve the quality of the input data and prepareitforfurtheranalysisandprocessing.

3. Deep Learning Model:

Atthecoreofthesystemliesthedeeplearningmodeltasked with analyzing the visual data to discern different objects andconditionswithinthemanhole.Thispivotalmodelcan taketheformofaconvolutionalneuralnetwork(CNN)ora more sophisticated architecture, such as a combination of CNNs and recurrent neural networks (RNNs) tailored for sequentialdataanalysisinthecaseofvideofootage.

4. Training Data Storage:

Thesystemincorporatesarepositorydedicatedtostoring labeled training data. This dataset consists of images or videoframesannotatedwithlabelsdenotingthepresenceof various objects or conditions within the manhole, such as cracks,debris,orstructuraldamage.

5. Model Training:

Training the deep learning model involves utilizing the labeledtrainingdata.Thisprocessencompassesfeedingthe datathroughthemodel,iterativelyadjustingitsparameters

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

(weightsandbiases)basedonpredictionerrors,andrefining themodeluntilitreachesasatisfactorylevelofperformance.

6. Model Evaluation:

Following training, the model's performance is assessed using validation data to verify its ability to generalize effectivelytounseenexamples.Metricsincludingprecision, recall,andF1-scorearecalculatedtoevaluatetheaccuracy ofthemodel.

7. Inference Engine:

Oncetrained,themodeltransitionsintoadeployedstateas an inference engine, proficient in processing real-time or batched inputs from the manhole camera. This engine utilizesthetrainedmodeltoanalyzeincomingdata,making predictionsregardingtheconditionswithinthemanhole.

8. Alerting System:

Anintegratedalertingsystemisimplementedtopromptly notify relevant personnel upon detection of issues or anomalieswithinthemanholebythedeeplearningmodel. This system can either take the form of an automated alerting mechanism or provide an interface for manual inspectionbyhumanoperators.

9. Data Visualization and Reporting:

Visualization tools and reporting mechanisms empower userstoaccessandinterprettheoutcomesoftheinspection process.Thesetoolsprovideannotatedimagesorvideosthat highlight detected objects or conditions, along with statistical summaries and historical trends, ensuring comprehensiveinsightsintotheinspectionresults.

10. Feedback Loop:

To continually enhance the system's performance, a feedbackloopisestablished.Inputfromhumaninspectors andupdatestothetrainingdatacontributetorefiningthe deep learning model over time, thereby improving its accuracyandreliability.

The architecture diagram delineates the primary components and information flow within an efficient manholevisualinspectionsystemdrivenbydeeplearning.

4.Result:

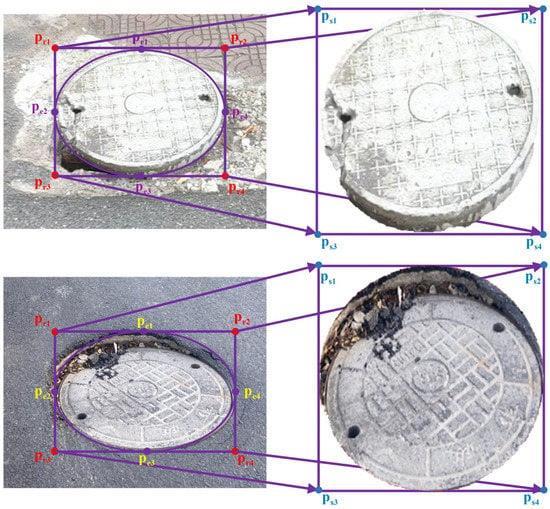

Ensuringeffectivemanagementofmanholecoversis paramount for road safety. Ideally, these covers should seamlessly blend into the road surface, maintaining structuralintegrityandvisualcoherence.Anydeviationfrom thisstandardposesriskstobothvehiclesandpedestrians.

Tostreamlinediscussionsondataaugmentationconcerning manholecovers,it'shelpfultocategorizeabnormalitiesinto threedistincttypes:"Damaged,""Dislocated,"and"Missing." Firstly, "Damaged" refers to instances where the cover displays cracks or additional holes, compromising its

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

appearance and potentially its strength. This category encompassesanyvisibleimperfectionsthatdetractfromthe cover'soriginalcondition.

Secondly, "Dislocated" indicates a cover that fails to align flush with the road surface, appearing as bulges or depressions.Thisdisruptsthesmoothnessoftheroadand poseshazardstopassingtraffic,necessitatingpromptaction tomaintainsafetystandards.

Lastly,"Missing" denotestheabsenceofa cover,leavinga void in the road surface that exposes underlying infrastructure and poses severe risks. Immediate interventioniscrucialtorectifysuchsituationsandprevent accidents.

Furthermore, if a dislocated cover also shows signs of damage, it falls under the "Dislocated" category for classification purposes. This approach simplifies categorizationandenablestargetedinterventionstoaddress specificissueseffectively.

5.Discussion:

Employingdeeplearningfordevelopinganefficientmanhole visualinspectionsystemrepresentsaninnovativeapproach toenhancinginfrastructuremaintenance.Deeplearningcan automatetheinspectionprocess,identifyingpotentialissues oranomalieswithinmanholeseffectively.

Continual iteration is key to refining the system. This involves gathering feedback from field deployments, updating the model with new data and insights, and enhancing the system's performance and reliability over time.Byadheringtothisframework,onecancreatearobust manholevisualinspectionsystemusingdeeplearning.Such asystemaidsmunicipalitiesandinfrastructuremanagement organizations in maintaining and monitoring manholes efficiently, resulting in improved safety and reduced maintenancecosts.

6.Conclusion:

In summary, harnessing the power of deep learning for a proficient manhole visual inspection system presents a significantleapforwardininfrastructuremaintenance.This meticulously crafted system, built through stages of data gathering, preprocessing, model selection, and training, stands to modernize traditional inspection approaches. Whetheremployingconvolutionalneuralnetworks(CNNs) ortailoredarchitectures,itcanreliablypinpointanomalies like cracks, leaks, or blockages, enabling proactive maintenancestrategies.

Seamlessintegrationofthissystemintoreal-timeinspection workflowsensuresswiftdetectionandresponsetopotential hazards, thereby bolstering infrastructure resilience and safety.Ongoingvalidation,testing,anditerativerefinements guarantee its reliability and adaptability to evolving circumstances. By incorporating feedback from field deployments, the system evolves to meet emerging challenges,maintainingpeakeffectiveness.

Ultimately, deploying such a system not only streamlines inspectionprocessesbutalsoreducesmaintenanceexpenses and mitigates the risk of costly damages or accidents. Its automation and enhancement of inspections ensure infrastructure remains robust and secure, fostering safer communities and sustainable urban development. In essence, the efficient manhole visual inspection system poweredbydeeplearningrepresentsatransformativeshift in infrastructure maintenance, offering proactive, costeffective, and safer solutions for municipalities and infrastructuremanagementorganizations..

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

7.Reference:

1. J. Wang and Y.T. Li, "The Main Causes and Control MeasuresofQualityProblemsintheInstallationofManhole Covers,"ChinaConstruction,vol.4,pp.135-136,2022.

2.H.Chen,J.Gong,H.Ning,X.Zhang,andY.Wang,"Method for Detecting Shape and Position of Double Holes of PhotothermalSupportConnectingPlateBasedonMonocular Camera,"ToolEngineering,vol.55,pp.91-95,2021.

3.H.RenandF.Deng,"ManholeCoverDetectionUsingDepth Information,"JournalofPhysics,vol.1856,pp.26-28,2021.

4. Y. Yu, H. Guan, D. Li, C. Jin, C. Wang, and J. Li, "Road Manhole Cover Delineation Using Mobile Laser Scanning PointCloudData,"IEEEGeosci.Remote.Sens.Lett.,vol.17, no.1,pp.152-156,Jan2020.

5. A. Bochkovskiy, C.Y. Wang, and H.Y.M. Liao, "Yolov4: Optimal Speed and Accuracy of Object Detection," arXiv, 2020.