International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

P.C. Prakash1 , B. Nithin Kumar2, N. Tejeswara Rao3, J. Veera Narayana4, P. Venkat Charan5, D. Gowtham6

1 Assistant professor, Department of Mechanical Engineering, Annamacharya Institute of Technology & Sciences, Tirupati

2 3 4 5 6 Student, Department of Mechanical Engineering, Annamacharya Institute of Technology & Sciences, Tirupati

Abstract - This paper aims to develop a structural design for 100 Ton hydraulic press by means of fundamental calculation and FEA techniques for study and optimization in the construction of design. As the budget of the company is limited, they need to select machines which operate at high capacity at low cost. The design of hydraulic press is developed based on the load application and operation performed. To reduce material and money spending by the company, the design is made in an effective manner with less machining operation and less material usage.

Key Words: Manual calculation, Finite Element Method, Hydraulic press, Solid Edge, Analysis, Optimization.

Ahydraulicpressisamachinewhichisdesignedtodevelop acompressiveforce.Itworksonthebasesofpascal’slaw, thepressurethroughoutaclosedsystemisconstant. Crown, gateway,bed,andcylinderarethemaincomponentsofthe press.Inthisworkahydraulicpressisdesignedonthebases offundamentalcalculation,laterit’sanalyzedinSolidEdge software. An integrated approach is chosen to verify the structuralperformanceandstressdistributionareidentified using Solid Edge. According to the structural values the dimensionsofthestructurearemodifiedtoperformbetter.

D.Ravi et.al (2014): Developed a C frame power press design. The model of press was developed in PRO/ENGINEER software. The analysis of the press is carried out using ANSYS package.The weightofthe press wasreducedbyreducingthethicknessoftheframeandbed, press was analyzed in loading condition. The result of the analysisisinacceptablelimit.

N.A. Anjum et.al (2017): Ahydraulicpresswasdeveloped toperformequalchannelangularpressing.Atthebeginning they designed 100 Ton, but the test results satisfied the workingloadof40Ton.

Mohammed Iqbal Khatib et.al (2020): constructed a manualoperatedhydraulicpressof5tonusingMildSteel,I section plate. The advantage of this press is interchangeabilityofmoldanddiewithoutdismantlingthe ramassembly.

Akshay Vaishnav et.al (2016): The development of top plate/ crown was done using FEM analysis method. In 3 differentdesignsaredevelopedandFEManalysisonthisby ANSYSsoftwareandcometoconclusionthatdesign3isthe safestone.

To reachtheaim of this work,various designcalculations and various material selection are done for optimization. VariouspartsofmachinearedesignedandanalyzedinSolid Edge.

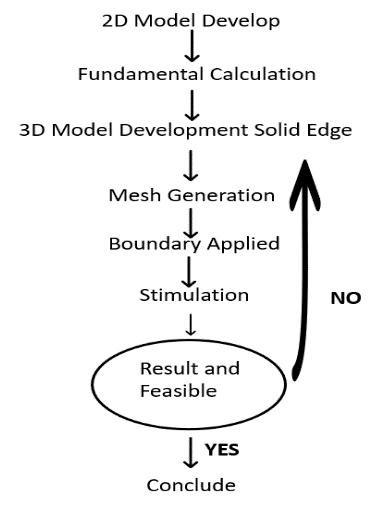

Figure 1: Abouttheprocessflow.

Theflowchartshowstheprocessfromthebeginningtillthe endofcompletedevelopmentofhydraulicpress.

Heprocessesbeginswithdesignof2Dmodel,basedonthe fundamental calculations later a 3D model is developed. Then mesh generation is done in which we select the material used. After that boundaries are applied to model andtheStimulationisdone.Basedontheoutputifitsatisfies the required conditions then we accept it, if not then we redesignthemodel,andthestepswillberepeateduntilthe requiredconditionsaresatisfied.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

4.Problem Identification

Themaincomponentsliketopplate,guidewaysandbedare subjected to continuous load which causes arise the formationstressatthetimeofworkingcondition.So,forthis stressdistributionisobtainedforeachpart.

Requirement:

Cylinderworkingpressure:300Bar

Cylindertestingpressure:450Bar

Forceextractedbythecylinder:100Ton

Strokeofcylinder:400mm

4.1. Design Calculation of Hydraulic Press

Every design begins with fundamental calculation by applyingvariouskidofstressdevelopment.

Designofhydrauliccylinder:

Theworkofhydrauliccylinderistogeneratecompressive force(F),withapressure(P)duringtheforwardstroke. P=

MaxbendingmomentforsimplysupportedbeamM=

Momentofinertiaofcross-sectionalareaI=

Then, b= (Where b < allowable)

Designofbed:

Thebedissubjectedtocompressionforcewhichisproduced duringtheworkingofhydrauliccylinder.

Stress= i.e., c= (whereA=cross-sectionalareaof bed= )

Designofguideway:

The main reason for the guideway failure is due to the applicationofexcessiveloadsonit.Thiscausesthebuckling effect.Toovercomethis,weuseEuler’sColumnFormula.

F= (WhereLe=effectivelength)

WhereA=crosssectionalareaofpiston= inmm2

Fromthispistondiameterortheboreofthecylindercanbe determined.

Forfindingwallthicknessofcylinder:

Circumferencefailure th=

Longitudinalfailure tl =

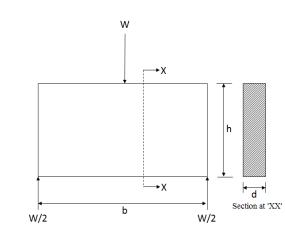

Designofcrown:

The crown is subjected to pure bending stress during the operation.

Considering bending moment M, the bending equation is givenby,

Inthecauseofbothendsarefixedthe Le = =

Slendernessratio= (WhereK=radiusofgyration= )

Note: Whilecalculatingthebendingmovementtheloaddue toself-weightneededtobeneglected.

4.2. Analysis and Testing

The components of hydraulic press are designed in Solid Edgesoftwareforworkingloadof100Tonwiththefactorof safety 1.5 (i.e., designed load of 150 Ton). The following details are material properties used for components in hydraulicpress.

Table 1: Materialsusedandtheirproperties Part

Cylinder Aluminum 7075T6 2712 275 71000

Crown Structural steel 7833 262 210000

Guide ways Structural Steel 7833 262 210000

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Bed Grey cast iron of class60

Piston and piston rod Hard chrome plated steel

6920 275 110000

7833 262 210000

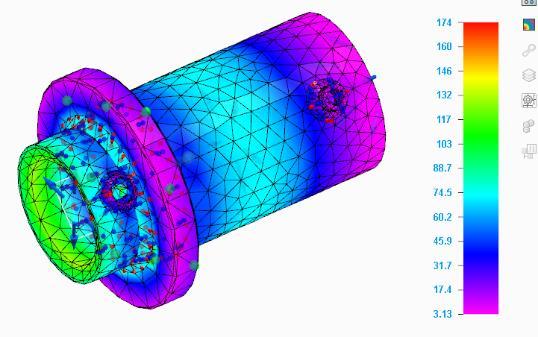

FEAisperformedusingSolidEdgesoftwaretodeterminethe stress acting in it. Below shown images are related to the outputfromtheanalysis.

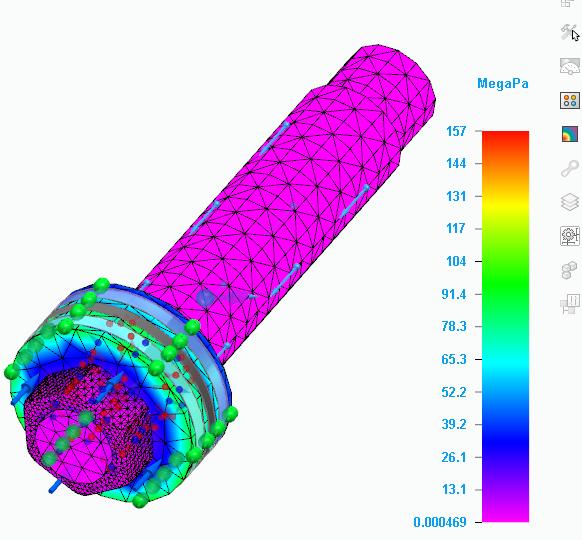

For the analysis of the cylinder, 300 bar of hydraulic pressureisappliedinsidethecylinderandbyconstrainat the holder which is permanently joined by the means of welding.

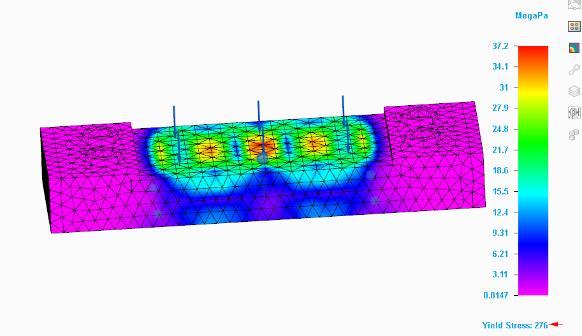

Fortheanalysisof bedconstrainsare provided belowthe bed where there is a direct contact between bed and surfaces.

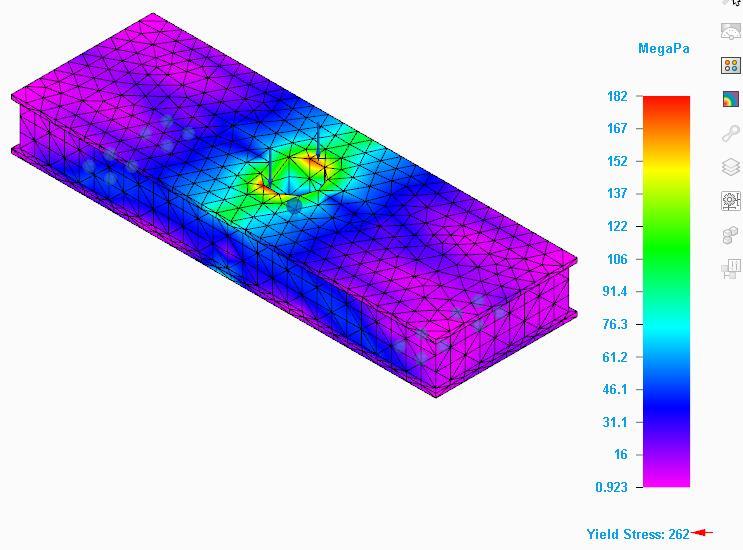

A load of 100 Ton (creaction generated due from the hydrauliccylinder)andweightofhydrauliccylider(i.e,500 kg)isactingonthetopofthecrown.Thecrownconsideof

internalsectionalstructurewhichimproviesthecapacityof withstandingtheload.

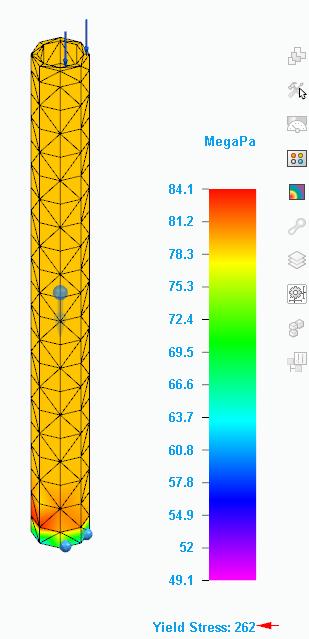

On the top of piston, a hydraulic pressure of 300 bar acts whichcasesthedeformationonpistonandbucklingonthe rod which is directly connected to the piston. For this the constrainsaremadeatthe bottomofthepistonasshown below.

There two main reason why do analysis on guide way is buckling and the reactions. In buckling condition the load and weight of the componets on the top are needed to carriyed by the guide way. This a type of continous load acting condition. In case of reaction when specimen is in testingconditiontheloadactingonthebedistransimmited totheguideways.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Figure 5: Stressanalysisonguideway

5.Result

Table 2: Analysisdataoutput

6. CONCLUSIONS

AsshownintheresultsectionMaxStressareoptionwitha F.O.S of 1.5. The obtained stress is with the limit. So, the structuraldesigndevelopedfor100Tonhydraulicpressis safeandsatisfiestheconditionsofengineering.

REFERENCES

[1] V.B. Bhandari, “Design of Machine Elements”, Tata McGraw-HillPublishingCo.Ltd.,NewDelhi,2008.

[2] D.Ravi,“ComputerAidedDesignandAnalysisofPower Press”, Middle East journal of Scientific Research 20(10):1239-1246,2014.

[3] O.O.Ojo,“Design,FabricationandStructuralAnalysisofa 5TonHydraulicPressand MouldMachineforCrucible Production”, Computational Engineering Vol.3 Issue 3, September2020,Pg:46-58.

[4] N.A.Anjum,“Design,FabricationandManufacturingof 100 Ton Hydraulic Press to Perform Equal Channel Angular Pressing”, Technical Journal, University of EngineeringandTechnology(UET)Taxila,PakistanVol.22 No.11-2017.

[5] Mohammed Iqbal Khatib, “Design and fabrication of 5 TonHydraulicPressMachine”,InternationalJournalof ScientificResearchinScience,Engineering&Technology, Vol.7Issue2,March-April2020Pg:22-30.

[6] Akshay Vaishnav, “Design Optimization of Hydraulic PressPlateUsingFiniteElementAnalysis”,International JournalofEngineeringResearchandApplications,Vol.6 Issue5,May2016,PgNo.58-66.

[7] B.Parthiban,“DesignAndAnalysisOfCTypeHydraulic Press Structure And Cylinder”, International Journal Of ResearchInAeronauticalAndMechanicalEengineering, Vol2,PgNo.47-56.

[8] Deepak Annasaheb More, “Design, Development And Optimization Of Hydraulic Press”, IJRASET Volume 3 IssueVI,June2015.