International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Yasam

Yash1 , Hirendra Pratap Singh2 , Rakesh Sakale3 , Pawan Dubey4

1Research Scholar Department of Civil Engineering, People's University, Bhopal (M.P.)

2Assistant Professor Department of Civil Engineering, People's University, Bhopal (M.P.)

3Associate Professor Department of Civil Engineering, People's University, Bhopal (M.P.)

4Assistant Professor Department of Civil Engineering, People's University, Bhopal (M.P.) ***

Abstract -

The contemporary world is heavily focused on green and ecological development. Concrete is the utmost widely used building material in the world. Cement, fine and coarseaggregate, water, make up this composite material.

The replacement impacts that fly-ash, sawdust, and coconutshell bring to concrete are the main topic ofthis thesis. Cement and usual fine-aggregates were moderately substituted with fly-ash and sawdust, individually. Here, the coarse aggregate in the solid is swapped out for coconut shell. Determining the compressive-strength, split-tensile strength, andslump value is how the experiment is conducted. Sawdust is added to concrete in percentages of 5.0%, 10.0%, 15.0%, 20.0%, and 25.0% in place of natural fine aggregates. Fly Ash is consistently added to the mix at a weight of 30.0% cement having strong pozzolonic qualities, sawdust has properties comparable to those of usual fine-aggregates, and coconutshell gives the concrete strong split-tensile strengths. The outcomes are contrasted with the design mix M30 controlmix. Testing is done on the specimens 7, 14, 21, and 28 days after they have cured. It has been found that, during 7, 14, 21, and 28 days of curing, concrete can have up to 20.0% of its natural fine-aggregate substitutedbysawdust and20.0%of its coarseaggregate substituted by coconut shell, all without compromising its strength. Fly-Ash should remain at 30% of the mix. As the quantity of resources increases, slump's value diminishes. Additionally, the price of concrete decreasedtothe total price per cubic meter of concrete

Key Words: coconut shell, saw dust, fly ash, sustainable concrete,pozzolonic.

Afterwater,concreteisthemostextensivelyutilizedmanmade stuff worldwide. Sand, aggregates, cementing constituents,andoccasionallyadmixturesarefurtherinthe appropriate amounts to achieve it. Every day, there is an enormousenhanceindemandforit.Inordertoconvenethis requirement,alargeamountofnaturalpossessionsmustbe

used,whichputstheecosystematseriousrisk.Thus,thegoal ofthisstudyistoaddressenvironmentalissuesbyfallingthe quantityoffly-ash,sawdustand,coconutthatisdumpedon landfills.Thiswillundoubtedlyhelpdiminishtheamountof carbondioxide(CO2)thatisreleasedintotheatmosphere, whichotherwisecontributestoglobalwarming,oneofthe main issues facing the modern world. Therefore, fly ash, sawdust,andcoconutshellarebeingusedinthisprojectto partiallysupernumerarycement,fine-aggregateandcoarseaggregateinconcrete.Fly-ashismadeupofsilicondioxide, aluminumoxide,andcalciumoxideandisproducedwhen coalisburned.Fly-ashcanbeusedtopartiallyswapcement inconcretesinceithasgreatpozolonicqualitiesandreacts with water quickly. Saw-dust is a waste product obtained fromsawmills.Particularlyinthisarea,usingcoconut-shells inplaceofcoarse-aggregatesinconcreteisbecomingmore andmorepopular.Thehardexteriorofthecoconutiscalled the shell. Since it worked, we can conclude that in many concreteapplications,excessandby-productcanbeusedin consignofnaturalmaterials.

Thesearethefollowingobjectivesofthiswork:-

1.Theprimarygoalsofthisworkaretodeterminetheideal saw-dust percentages to substitute for natural fineaggregates,flyashpercentagestosubstituteforcement,and coconut-shellpercentagestosubstituteforcoarse-aggregate

2. To determine and compare the slump values of regular concretewithmodifiedconcretethathasbeentreatedwith fly-ash,saw-dust,andcoconut-shell.

3. To ascertain the changed concrete'shardened behavior, suchasitscompressive-strength.

4.Tomakethecompositemoreinexpensiveinassociationto regularO-P-Cconcrete.

5. To utilize these leftover elements to create lightweight concrete.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

The methodology for the whole thesis work shall be conductedasfollows.

1.Literatureassessment-Inthisvariousjournalpapers werestudiedafterwhichthefinalbestexaminationworkis selected.

2. Materials to be used - The materials which are to be used in the research is selected. The materials of fly-ash, saw-dustandcoconut-shellisfinallyselectedwhicharetobe moderately substituted in concrete. Fly-ash to be fixed on 30%,Sawdustbetween0to20%andCoconut-shellbetween 0to20.0%.

3. Concrete Mix-Design - After the selection of supplies M30gradeconcretemix-designisdone.

4. Laboratory work - Testing of materials to be used in concreteisevaluated.Finalconcreteafterthereplacements is also experienced with the workability, compressivestrengthtestandsplit-tensileexamination.

5. Cost Analysis - After the laboratory work the cost analysisofconcreteisdoneandassociatedwiththenormal OPCconcrete.

6. Data-analysis and presentation -Analyse the consequencesofvarioustestsconductedandconvertit in tabularform.

7. Conclusion and proposal - After analysis and presentationweconcludetheresults.

3.1FLY-ASH:-Theyaretheby-productremainingafterthe combustionofcoal.Itisoftwotypes:Class-CandClass-F.

3.2SAWDUST:-Sawdustisaby-productofawoodobtained after cutting, grinding or sanding with saw or other industrialstool.

3.3COCONUT-SHELL:-Thehardestportionofacoconutisits shell,whichissituatedonthesideofthehusktoprotectthe meat.Coconut-shellisawasteproductfromagriculturethat iswidelyaccessibleintropicalnationsacrosstheglobe.

3.4COARSE&FINEAGGREGATES:-Theaggregateclassified ascoarseaggregateisthatwhichisretainedona4.75mmIS screenandFineaggregateisdefinedbyIS:383-1963asthe aggregatethat,whenfilteredovera4.75mmIS-sieveandheld ona0.07mmIS-sieve

FOR M30 GRADE CONCRETE

VolumeofConcrete =1cu.m

TotalVolumeofCement =Cement/(S.G*1000)

=422/(3.15*1000) =0.134cu.m

VolumeofWater =Water/(S.G*1000) =190/(1*1000) =0.190cu.m

TotalAggregates

Requirement =A-(B+C) =1-(0.133+0.190)=0.677cu.m

Coarse-Aggregate(C.A) =D*C.Aratio*S.G*1000 =1168.6kg

Fine-Aggregate(F.A) =D*F.Aratio*S.G*1000 =0.677*0.37*2.74*1000 =686.3KG

Table -1: ShowtheM30mixdesignofConcrete

GradeofConcrete M30

Cement 420kg/m3

Aggregates Fineaggregates 1855 kg/m3 685 kg/m3

Coarse-aggregates

• 20mmaggregates

• 10mmaggregates 1170kg/m3 702kg/m3 468kg/m3

Proportionofmix 1:1.63:2.8

Water/Cementratio .45

Repla ceme nt % of fly ash Amou ntof fly-ash inKg/ m3

Replac ement Percen tageof sawdust Am oun tof saw dus tin Kg/ m3 Replac ement Percen tage Of coconu t-shell Amou ntof coconu tshell inKg/ m3

• Proportioning

• Mixing

• Casting

• Curing

• Proportioning-Thedesignmixofpreparationof30 cubesofsize15cmx15cmx15cmcanbemade.

• Mixing-Rawmaterialsi.e.fly-ash,coarseaggregateand sand was weighted manually according to the design mix.Thensupplieswereblendsequenceinthepanand hand mixture was done. After the combination succeededtheirhomogeneity,thewaterwasgradually assortedinthemix.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

• Casting- The fresh concreteis poured in mouldsand compressed. Additional compaction was made by vibrating machine. The technique of intercourse and castingissimilartocementconcretecubes.Total60No. mouldsofsize150mmX150mmX150mmisprepared.

-1:MixingofMaterials

-2:

• Curing- The test samples/specimen are cured in curativetankfordesiredperiod.Afterthatthecubes aretestedatthescheduledtime.

Liftthespecimenfromlaboratoryfloororoutsideafter specified ageand wipe outany dirt from the surface. Makesuretheloadisappliedtotheopposingsidesof the cube cast by positioning the sample inside the machineinthismanner.Positionthespecimencenter wiseonthemachine'sbottomplate.

Hand-rotatethevariablesectionsmoothlyuntilitreachesthe specimen'supperface.Untilthespecimenorcubefails,apply theloadgradually,steadily,andwithoutshock,atarateof 140kg/cm2/minute.Notethehighestcapacityanditshould alsobenotedthatanyunusualstructuresinthesortoffailure mustnotoccur.

Inthistest,aconicalmoldwithanupperdiameterof10cm,a lowerdiameterof20cm,andaaltitudeof30cmisusedto measure the workability of the mix. The concrete is first prepared,thenitispouredintothemoldinfourstages.25 tampswereappliedtoeachlayer.Usingatrowel,thesurplus concretewasdetachedfromthemoldandthesurfacewas leveled.

Lift the mold using your hands,and then observe how the heightofthespecimenandthemolddiffer.

-4: PerformingCompressive-StrengthTest

Research

of

and

(IRJET) e-ISSN: 2395-0056 Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

4.3 Splitting-Tensile Test (IS-5816-1999)

Thecastspecimenneedstobekeptsomewherebetween27° and 2°C for 24 hours, giving or taking 0.5 hours, after the waterisaddedtothedrymaterials.Subsequently,thesample needstobelabeled,takenoutofthemold,andimmediately immersedineitherrenewedwaterthathasbeeneviscerated or a elucidation of lime that has been soaked. Adjust the compressiontestingapparatustotherequiredrange.After positioning the specimen, place the plywood stripe on the lower plate. Over the sample, position the second piece of plywood.Lowerthetopplateuntilitisincontactwiththe plywoodstrip.Applytheloadcontinuouslyandshock-freeat aratebetween0.7and1.4MPa/min(1.2and2.4MPa/min according to IS 5816: 1999). At the end, record the infringementload(P).Finally,threesampleswillbecastand evaluatedforeachanalysis.Next,itwilloccupytheaverage tensile-strength.

Table -2: AverageCompressive-StrengthofConcreteafter intercourse30.0%flyash,5.0%saw-dustand5.0% coconut-Shell.

Table -3: AverageCompressive-StrengthofConcreteafter intercourse30.0%flyash,

Table-4:AverageCompressive-StrengthofConcreteafter intercourse

and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Table 5:AverageCompressive-StrengthofConcreteafter intercourse30.0%

Table 6:AverageCompressive-StrengthofConcreteafter intercourse

Table 8:ExperimentalResultsofSplitTensileTest

Table 7:ExperimentalResultsofslumpConeTest

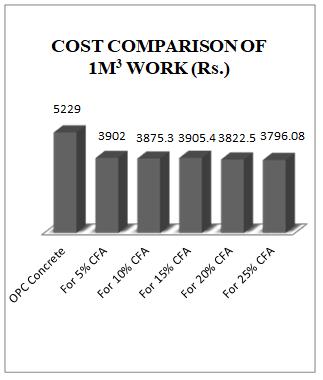

Chart -1:CostComparisonforDifferentTypesofSamples Used

Fromthisstudy,thefollowingobservationsweremade:

1.Basedontheexperimentalworkitcanbeconcludedthat for7and28dayscuringupto20%ofsaw-dustandcoconut-

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

shell can be used in concrete because it provides good strength.ForCompressivestrengthsupto15%sawdustand coconutShellshowsgoodincrementintheresultswhereas for split tensile strength, up to 20.0% saw-dust, coconutshellreplacementcanbemadeinconcrete.

2. There is very minor decrement in the slump value of concretewhichcanbedeliberatedfortheconstructionwork. 3.Thesplittensilestrengthalsoincreasesupto20%andits valuedecreasesafterthatpercentage.

4. The period of concrete has no consequence on the compressive-strengthofconcrete.

5.Aswehavedonecostanalysisofthemodifiedcomposite whichisassociatedwiththenormalOPCconcreteinwhich the cost reduction is observed if we are using modified concretewhichmeansthatusingthisconcreteiseconomical asrelatedtonormalOPC.

6.Astheresultshowsthatwecanuse20%replacementasa material,soacostsavingofaboutRs.1400approximatelyis observedifweareconstructinga1m3work.

7.Sawdustexhibitsstrongstrengthbecauseofitssuperior adhesion,whichlimitsandabsorbsbreaksinthesolid.Fly ash's good pozzolonic characteristic also helps this mechanism.

8. In addition, the concrete exhibits superior compaction easeascomparedtothegovernormix.

9.Furthermore,theintroductionofsawdustintheconcrete also helps to diminish the improper dumping of the hard excessintolandfillsandtherebymakingtheconcretemore biodegradable.

[1]AliM,LiuA,SouH,ChouwN.Mechanicalanddynamic propertiesofcoconutfibrereinforcedconcrete.Construction andBuildingMaterials.2012May31;30:814-25.

[2]B.DamodharaReddy1,S.ArunaJyothy2,FawazShaik3 ExperimentalAnalysisoftheUseofCoconutShellasCoarse AggregateIOSRJournalofMechanicalandCivilEngineering (IOSR-JMCE)e-ISSN:2278-1684,p-ISSN:2320-334X,Volume 10,Issue6(Jan.2014),PP06-13.

[3]CookDJ,PamaRP,WeerasingleHL.Shellfibrereinforced cement as a low cost roofing material. Building and environment.1978Dec31;13(3):193-8.

[4]ChristyCF,TensingD.EffectofClass-Fflyashaspartial replacementwithcementandfineaggregateinmortar.

[5] Dr .P. Sri Chandana, Ph.D, Shaik Ahamed Mynuddin Experimental Study on Strength of Concrete by Partial

ReplacementofFineAggregatewithSawdustandRobosand International Journal & Magazine of Engineering, Technology, Management and Research Volume No: 2 (2015),IssueNo:9(September).

[6]FurqanFayazKhan,IshaChandra,SajadAhmadBhatAn ExperimentalInvestigationontheEffectofReplacementof Fine and Coarse Aggregate by Sawdust in Solid Concrete BlocksforDifferentMixProportionsISSN23213361©July 2020IJESCVolume10IssueNo.7.

[7] Gopinath K, Anuratha K, Harisundar R, Saravanan M. UtilizationofSawDustinCementMortar&CementConcrete. International journal of scientific& engineering research. 2015.

[8]HarshK.Mistry,KaushalD.Patel,KunjB.Patel,KahanP. Ramani and RakshaParolkar, A Review on The Study of Behaviour of Wastepaper Sludge Ash as a Partial Replacement,InternationalJournalofCivilEngineeringand Technology,8(4),2017,pp.107-110.

[9] IS 10262 2009 Guidelines for concrete mix design proportioning.

[10]IS-516,1959MethodofTestsforStrengthofConcrete.

[11] IS-1199 1959Methods of sampling and analysis of concrete.

[12]JataleA,TiwariK,KhandelwalS.Effectsoncompressive strengthwhencementispartiallyreplacedbyfly-ash.IOSR JournalofMechanicalandCivilEngineering.2013;5(4):3443p.

[13] Joy AM, Jolly AK, Raju AM, Joseph BE. Partial replacementoffineaggregatewithsawdustforconcrete.

[14]KiranTG,RatnamMK.Flyashasapartialreplacement ofcementinconcreteanddurabilitystudyofflyashinacidic (H2So4)environment.InternationalJournalofEngineering ResearchandDevelopment.2014Dec;10(12):1-3.

[15]KSampathKumar,UMPraveen,APrathyusha,VAkhila, PSasidhar,AComprehensiveStudyOnPartialReplacement of Cement with Sugarcane Bagasse Ash, Rice Husk Ash & Stone Dust, International Journal of Civil Engineering and Technology,7(3),2016,pp.163–172.

BIOGRAPHIES

Yasam Yash, Research Scholar, Department of Civil Engineering, People'sUniversity,Bhopal(M.P.)